Page 1

Owner's Guide

READ AND KEEP THESE INSTRUCTIONS FOR FUTURE REFERENCE.

Gas Range Featuring

• Conventional Surface Burners

• Pilot Ignition

or

• Pilotless Ignition

• Time-of Day Clock, if equipped

CONTENTS

IMPORTANT SAFETY INSTRUCTIONS ......... 1-3 MAINTENANCE ............................ 13-15

Cooktop .................................... 13

CLOCK AND TIMER .......................... 4-5 Burner grates ................................ 13

Analog clock and timer ........................ 4 Surface burners ............................. 13

Digital clock and timer ......................... 4 Oven door .................................. 14

Electronic clock and timer ...................... 5 Oven racks .................................. 14

Oven bottom ................................ 14

SURFACE COOKING ........................ 6-7

Broiler drawer ............................... 14

Ignition system ............................... 6 Oven light ................................... 15

• Pilot ignition

• Pilotless ignition Leveling legs ................................ 15

How to remove range for cleaning. 15

To light surface burner ......................... 6 .............

About the surface burner flame ............... 6 Proportional valve adjustment ................. 15

Additional information ........................ 6 GENERAL INFORMATION 16

Factors that determine flame size .............. 7 Electrical connection

Selecting flame size .......................... 7 Use of aluminum foil

Canning ..................................... 7

CARE AND CLEANING ..................... 17-19

USING YOUR OVEN ................ •......... 8-12 Cleaning chart ............................ 17-18

Oven characteristics ........................... 8 Continuous cleaning oven ................. 19

Ignition system ............................... 8 ....

• Pilot ignition SERVICE ................................. 20-21

• Pilotless gnitior Before calling service chart .................... 20

Oven veto .................................... 8 How to obtain service ......................... 21

Oven burner ................................. 8

Oven Ihermostat ............................ 8 WARRANTY ................................. 22

To set oven .................................. 9

Preheating ................................... 9

Rack positions ................................ 9

General baking tips .......................... 10

Common baking problems .................... 11

How to broil ................................. 12

8113P042-60

(1/93)

Page 2

FORFUTUREREFERENCE

Forfuturereferencewe suggestyoure-

tain this manual after recording the WARNING: If the informa-

modelnumberandserialnumberofthistion in this manual is not

gas appliance in the spaces provided.

Thisinformationcanbefoundontherat-followed exactly, a fire or

ing platelocatedonthesidesofthelow- explosion may result caus-

er range front frame. Pull out lower ing property damage, per-

drawertosee ratingplate, sonal injury or death.

- Do notstore or usegaso- _._ ___

line or other flammable

L%)

MODELNUMBER vapors and liquids in the

vicinity ofthis orany oth-

SERIAL NUMBER er appliance.

-WHAT TO DO IF YOU

SMELL GAS: _k WARNING

DATEOF PURCHASE

• Do not try to light any • ALL RANGES

appliance. CAN TIP

These numbers identifyyour range.

Pleaseusethemin anycorrespon- • DOnottouch any elec- • INJURY TO PERSONS

dence or servicecallsconcerningyour trical switch; do not COULD RESULT

appliance, use any phone in your

Please retaintheproofof purchasedoc- building. • INSTALL ANTI-TIP

DEVICES PACKED

umentsforwarrantyservice. • Immediately call your WITH RANGE

gas supplier from a

• SEE INSTALLATION

neighbor's phone. ,

Follow the gas suppli- INSTRUCTIONS

er's instructions.

To reduce the risk of tipping of the

• If you cannot reach appliance from unusual usage or by

your gas supplier, call excessive loading of the oven door,

the fire department, the appliance must be secured by a

properly installed anti-tip device. To

- Installation and service checkifdevice isinstalledproperly:Use

must be performed by a aflashlightandlookunderneathrange

to see thatone of the rearlevelinglegs

qualified installer, ser- is engagedinthe bracketslot.

vice agency or the gas

supplier.

Page 3

Page 4

Page 5

Page 6

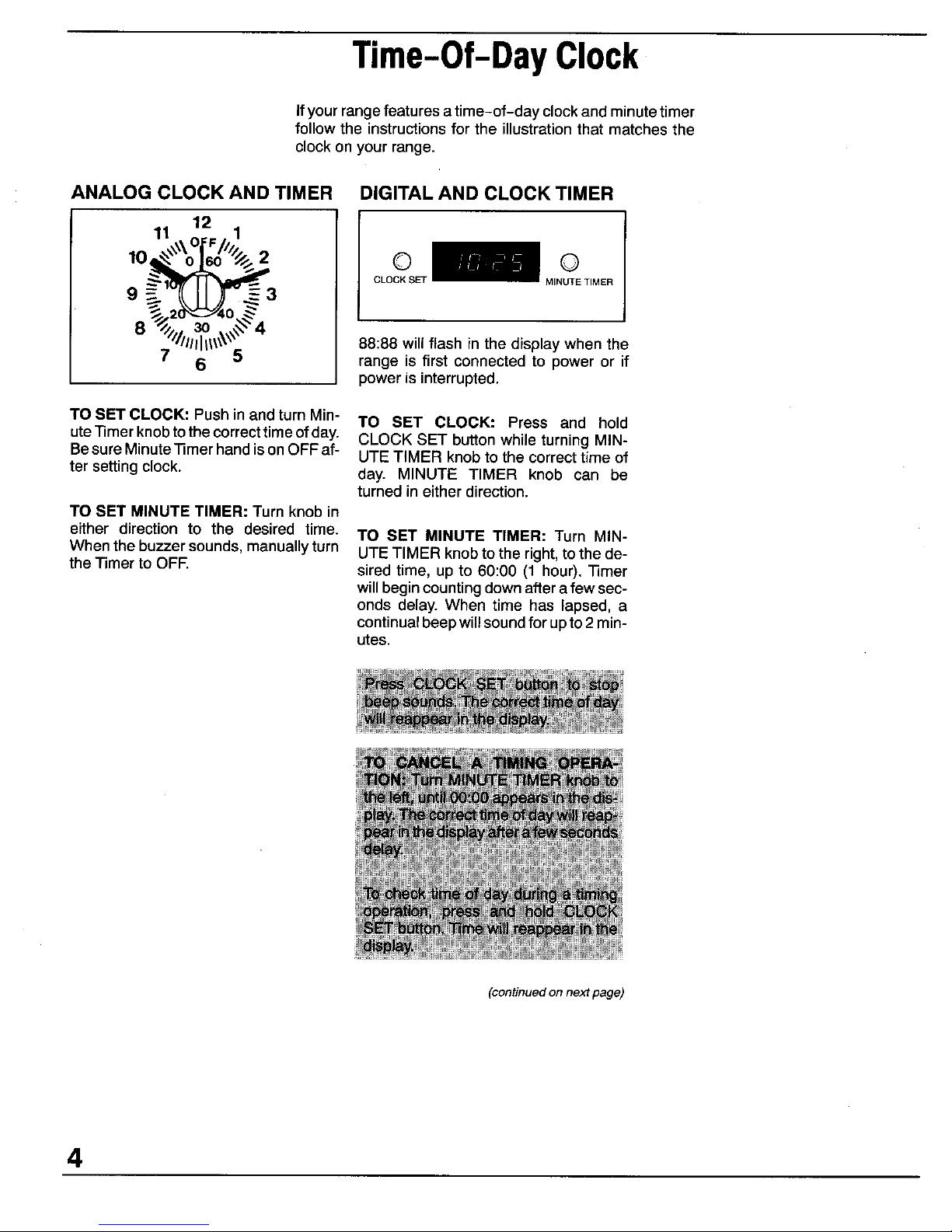

Time-Of-DayClock

Ifyour rangefeatures atime-of-day clockand minutetimer

follow the instructions for the illustration that matches the

clock on your range.

ANALOG CLOCK AND TIMER DIGITAL AND CLOCK TIMER

12

11.x\ OFF/z1

+o,_"'o Id"%2 0 0

9 _ 1 ___ MINUTETIMER

8 _/,., 3o .,_4

"'//ll/h_x_x\" 88:88 willflash inthe display when the

7 6 5 range is first connected to power or if

poweris interrupted.

TO SETCLOCK: Push in andturn Min- TO SET CLOCK: Press and hold

uteTimerknobtothecorrecttimeofday. CLOCK SET button while turning MIN-

Besure MinuteTimer hand is on OFFaf- UTE TIMER knob to the correct time of

tersetting clock, day. MINUTE TIMER knob can be

turned in eitherdirection.

TO SET MINUTE TIMER: Turn knob in

either direction to the desired time. TO SET MINUTE TIMER: Turn MIN-

When the buzzersounds, manuallyturn UTETIMER knobto the right,to the de-

the Timer to OFF. sired time, up to 60:00 (1 hour). Timer

will begin counting downafter afew sec-

onds delay. When time has lapsed, a

continualbeep will soundfor upto 2 min-

utes.

(continued on next page)

4

Page 7

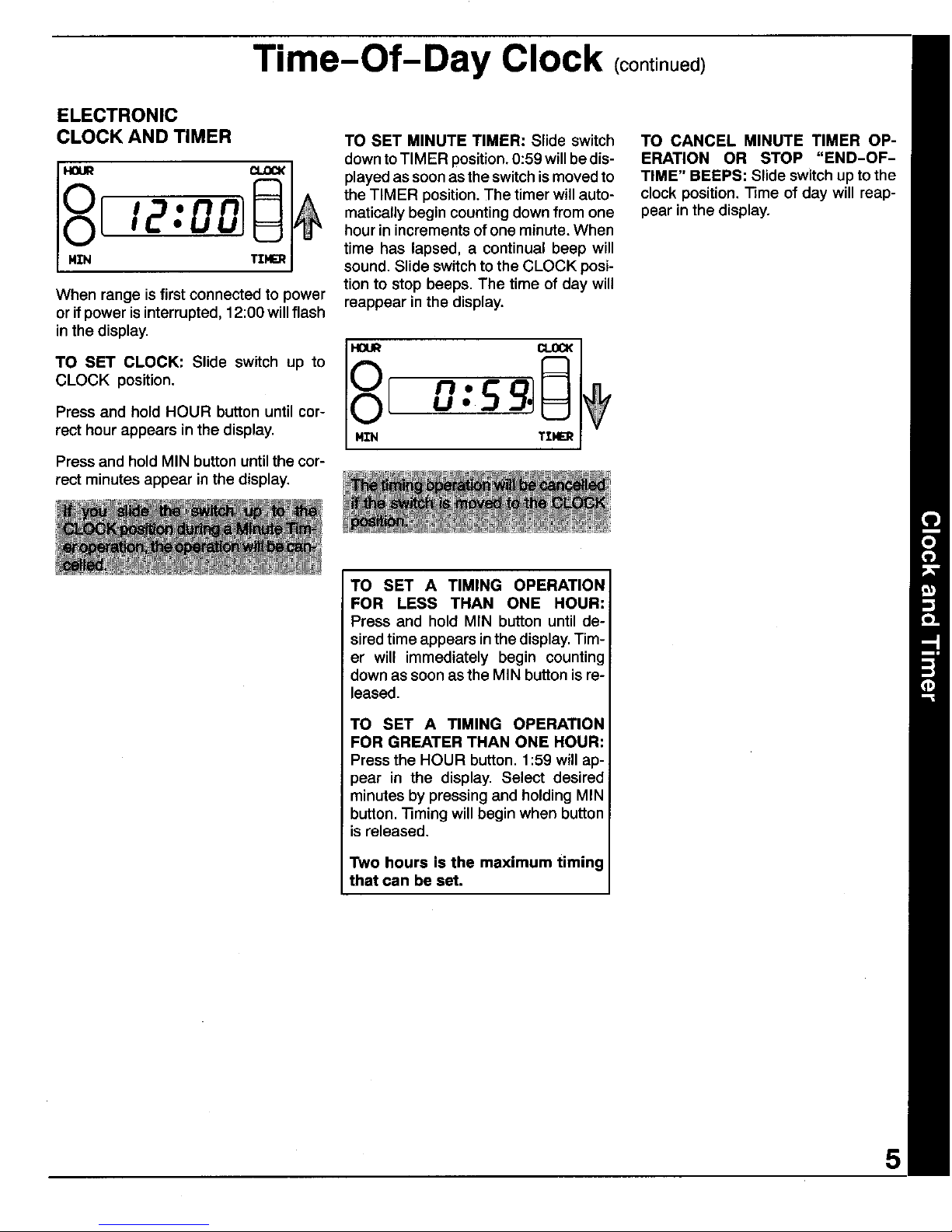

Time-Of-Day Clock (continued)

ELECTRONIC

CLOCK AND TIMER TO SET MINUTE TIMER: Slide switch TO CANCEL MINUTE TIMER OP-

downtoTIMERposition.0:59willbedis- ERATION OR STOP "END-OF-

HOUR CLOCK playedassoonastheswitchismovedto TIME" BEEPS: Slideswitchupto the

8[ 12 00] I_ $ the TIMER position.The timerwillauto-clock position."l'imeof day will reap-

maticallybegincountingdownfrom one pear in the display.

hour in incrementsof one minute.When

time has lapsed, a continual beep will

NZN TIMER sound. Slideswitchto the CLOCKposi-

tionto stopbeeps.The time of day will

When rangeisfirstconnectedtopower reappearinthedisplay.

orifpowerisinterrupted,12:00willflash

inthedisplay.

HOUR CLOCK

TO SET CLOCK: Slide switch uptOcLoCKposition. O[ 0 _ 5 _----'_I_ _ f

PressandholdHOUR buttonuntilcor-

rect hourappears in the display. MZN TXNER

PressandholdMINbutton untilthecor-

rectminutesappear inthe display,

TO SET A TIMING OPERATION

FOR LESS THAN ONE HOUR:

Pressand holdMIN buttonuntilde-

siredtimeappearsinthedisplay.Tim-

er will immediatelybegin counting

downassoonasthe MINbuttonisre-

leased.

TO SET A TIMING OPERATION

FORGREATER THAN ONE HOUR:

PresstheHOUR button.1:59willap-

pear in the display. Select desired

minutesbypressingandholdingMIN

button."_mingwillbeginwhen button

isreleased.

Two hours is the maximum timing

that can be set.

5

Page 8

SurfaceCooking

IGNITION SYSTEM TO LIGHT SURFACE BURNER ADDITIONAL INFORMATION

Yourrange will feature either pilot igni- 1. Place utensil on burnergrate. * When the range isfirst installed,the

tion(a standing pilotlightsthe burner) or pilotsmay be difficultto lightdue toair

pilotless ignition (a spark from the igni- 2. Push in and turn knob to the LITE inthegasline.Tobleedoffairfromthe

tor lights the burner), position. After the burner lights, turn line, hold a lighted match next to the

the knob to the desired flame size. burner and turn knob on. When the

PILOT IGNITION burner lights, turn the knob off and

To light pilot: Raise cooktop and hold - proceedas directed.

a lighted match near the pilot ports. I • Be sure all surface controls are set

There are two pilot ports. _ in the OFF position prior to supplying

I_ 1 _ gas to the appliance.

• CAUTION: If flame should go out

during a cooking operation, turn the

burner off. If gas has accurnulated

and a stronggas odor is detected,

NOTE: The knobon your appliance wait 5 minutes for the gasto dissi-

may not look like the knob in this il- pate before relighting burner.

lustration, but it will operate as de- • You may heara"popping" sound on

scribed in this booklet. LP gas when the surface burner is

turned off. This is a normal operating

PILOTLESS IGNITION sound of the burner.

Tooperatesurfaceburnerduringa pow- • Ifa knobisturnedveryquicklyfrom

erfailure: HI toLOsetting,theflamemaygoout,

1. Hold a lighted matchto the desired particularlyifthe burneriscold.

surface burnerhead.

2. Push in and turn knob to the LITE ._ _[_ J-

position.The burner willthen light.

3. Adjust knob to obtain the desired ABOUT THE SURFACE

flame size. BURNER FLAME

• A properlyadjustedburnerwithclean

portswilllightwithina few seconds.

• On naturalgas,the flamewillbe blue

witha deeperbluecore;thereshouldbe

notraceofyellowinthe flame.

Ifthisoccurs,turntheknobtothe OFF

A yellowflame indicatesan improper position.Wait several seconds,then

mixtureof air/gas.This wastes fuel, so lightthe burneragain.

havea servicemanadjustthe mixture if

a yellowflameoccurs.

• On LPgas, someyellowtippingis ac-

ceptable.Thisisnormalandadjustment

isnot necessary. (continuednext page)

6

Page 9

SurfaceCooking(continued)

FACTORS THAT DETERMINE SELECTING FLAME SIZE CANNING

FLAME SIZE • Use a HIGH flame settingto quickly Acceptablewater-bathorpressurecan-

UTENSIL SIZE: Adjustthe flame size bringliquidstoa boilorto begina cook- netsshouldnotbeoversizedandshould

soitdoesnotextendbeyondtheedgeof ing operation.Then reduce to a lower haveaflat bottom.Thefollowingare not

the cookingutensil.Thisisfor personal settingtocontinuecooking.Neverleave recommended:Oversizedcannersora

safetyand to preventpossibledamage food unattended when using a HIGH verylargecannerthat restsontwo sur-

to the appliance, utensil or cabinets flame setting, face burnergrates.

above the appliance. When canning, use the HIGH setting

/._ just until the water comes to a boil or

-- pressureis reached inthe pressurecan-

_'_ __ ner,then reduceto the lowestflame set-

ting that maintains the boil or pressure.

__ • An intermediate flame size is usedto

" continue a cookingoperation. Food will

not cook any faster when a higher

flame setting is used than that need-

. Utensils which extend more than two ed to maintain a gentle boil. Remem-

inches beyond the grate or touch the ber,water boilsatthe sametemperature

cooktopmay cause heatto build up,re- whether boiling gently or vigorously.

suiting in damage to the burner grate,

burneror cooktop. •Use alow flamesize tosimmer orkeep

foods at serving temperatures.

• Utensils,such as woks with a support

ring,which restrictaircirculation around

theburnerwill cause heatto build upand I

may result in damage to the burner __ -t_._x;_ \\\

grate, burneror cooktop.

UTENSIL MATERIALS: Optimum

cooking performance can be achieved

when heavygauge,flat, smooth bottom,

metal utensils with straight sides and

tightfitting lids are used.

• Aluminum or aluminum-clad stain-

less steel pans heat more evenly so a

slightlylargerflamecan be used.

• Stainless steel, porcelain andheat-

proof ceramic or glass heat unevenly;

cast aluminum and iron heat slowly;

and,Teflon-coated utensilsaresensi-

tive to heat. Thesematerials require a

lowerflameto producemore even cook-

ing results. Adjust flame so it extends

halfway to the edge of the utensil bot-

tom.

COVERED UTENSILS: Foods cook

faster when the utensil is covered be-

cause more heat is retained. Lower the

flame size when covering utensils.

7

Page 10

UsingYourOven

OVEN VENT OVEN THERMOSTAT

The oven vent is located at the base of The oven thermostat knob is used to se-

the backguard. When the oven is in use, lect and maintain the oven temperature.

this area may feel warm or hot to the Always turn this knob just to the desired

touch. To prevent problems do not: temperature - not to a higher tempera-

Block the vent opening, touch the area ture and then back. This provides more

near the opening or place utensils near accurate oven temperatures. Turn this

the vent opening, knob to OFF whenever the oven is not in

use.

OVEN BURNER

IGNITION SYSTEM The size and appearance of a properly _,_ t

adjusted oven burnerflame should beas

Your appliance will feature either pilot shown:

ignition (a standing pilot lights the oven 1

burner) or pilotless ignition (a glo bar _ cr_

lights the oven burner). _ / '_

,9

Be sure oven control is set in the OFF

position prior to supplying gas to the ap-

pliance. Coneincenterissmaller THERMOSTAT

PILOT IGNITION On some models, there is an indent at

the 350°F setting.

To light oven pilot: When cool, remove

oven racks and oven bottom. With the _ I_ Coneapprox.1/2-inch /

oven thermostat knob in the OFF posi-

J

tion, hold a lighted match to the pilot Io-

cated at the backend ofthe oven burner. The oven temperature is maintained by

Once pilot lights, replace oven bottom

and racks, cycling the burner on and off. After the

oven temperature has been set, there

will be about a 45 second delay before

_.zJ the burner ignites. This is normal and no

.,_ _ gas escapes during this delay.

\

PILOTLESS IGNITION

With this type of ignition system, the

oven will not operate during a power fail-

ure or if oven is disconnected from the

wall outlet, No attempt should be

made to operate oven during a power

fail ure. (continuednextpage)

8

Page 11

UsingYourOven(continued)

TO SET THE OVEN PREHEATING

1.When cool, place the racks inthe de- Preheatingis necessary for proper bak-

sired rack positions, ing results. Allow the oven to heat until

thedesiredoventemperature is reached

2. Push in and turn the oven thermostat (approximately 10 to 15 minutes). Se-

knob to the desired oven tempera- lectingatemperaturehigherthanthede-

ture. Allow the ovento preheat for 10 sired temperature will not preheat the

to 15 minutes when baking, oven anyfaster. Infact, this may have a

3. Place the food in the center of the negative effect on baking results.

oven, allowing a minimum of two in- Itis notnecessary to preheatfor broiling

ches between the utensil(s) and the unless darker browning is desired or if

oven walls, cooking thin (3/4-inch) steaks. Allow

4. Check the food for doneness at the burnerto preheat 2to 3 minutes.

minimum time given in the recipe. Preheating isnot necessaryfor roasting

Cook longer if necessary. Opening operations.

theoven door frequently causes heat

loss which may affect cooking results

and increasecooking time.

5. Turn the oven thermostat knob to

OFF and removefoodfrom the oven.

(continuednext page)

9

Page 12

UsingYourOven(continued)

_on#nuednextpage)

10

Page 13

CommonBakingProblemsAndWhyTheyHappen

Pans touching each other or Cakesdon't brown on top. Incorrect rack position.

oven walls. Temperature too low.

Batter uneven in pans. Overmixing.

Oven temperature too low or Too much liquid.

baking time too short. Pan size too large ortoo little

Oven not level, batter in pan.

Undermixing. Oven door opened too often.

Toomuch liquid.

Excessive shrinkage. Toolittle leavening.

Cake high inmiddle. Temperature too high, Overmixing.

Baking time too long. Pan too large.

Overmixing. Temperaturetoo high.

Toomuchflour. Bakingtimetoolong.

Pans touchingeach otheror Panstoocloseto each other

ovenwalls, oroven walls.

Incorrectrackposition.

Cake fails. Toomuchshorteningorsugar. Uneven texture. Toomuchliquid.

Toomuchortoo littleliquid. Undermixing.

Temperaturetoolow. Temperaturetoolow.

Old ortoolittlebakingpowder. Bakingtimetooshort.

Pantoo small.

Ovendooropenedfrequently. Cakeshave tunnels, Notenoughshortening.

Addedincorrecttypeof oilto Toomuch bakingpowder.

cake mix. Overmixingorat too higha

Addedadditionalingredients speed.

tocake mixor recipe. Temperaturetoohigh.

Cakes, cookies, biscuits Incorrectrackposition.

don't brown evenly. Oven door not closed properly. Cakescrack on top. Batterovermixed.

Door gasket not sealing Temperature too high.

properly. Toomuch leavening.

Incorrect use ofaluminum foil. Incorrect rack position.

Oven not preheated.

Pansdarkened, dented or

warped. Cake not done inmiddle. Temperature too high.

Pan too small.

Baking time too short.

Cakes, cookies, biscuits too Oven not preheated.

brown on bottom, Panstouching each otheror

oven walls. Pie crust edges too brown. Temperaturetoo high.

Incorrect rack position. Pans touching each other or

Incorrect use of aluminum foil. oven walls.

Placed 2 cookie sheets on one Edges of crust too thin.

rack. Incorrect rack position.

Used glass, darkened, stained,

warped or dull finish metal Pies or cakes don't brown Used shiny metal pans.

pans. (Use a shiny cookie on bottom. Temperaturetoo low.

sheet.)

Pies have soaked crust. Temperaturetoo low at start of

baking.

Fillingtoo juicy.

Used shiny metalpans.

11

Page 14

UsingYourOven(continued)

HOW TO BROIL

Broilingis a method of cooking used for tender steaks, rare interior,the meatshould be closeto the burner.Place

chops,hamburgers,chicken,fish,andsomefruitsandvege- thepanfurtherdownifyouwishthemeatwelldoneorifspat-

tables.The food is placed directly under the oven burner, taring and smoking occurs.

Thecookingtime isdetermined bythe distancebetween the The distance from the burner depends on the thickness of

meat and the burner,the desired degree of doneness, and the meat and desired degree of doneness. Thin cuts should

the thickness ofthe meat. beplacedon rack#1 (top)or #2 (middle);thicker cuts should

beplaced onrack #2 or #3 (bottom). Broil untilthe top ofthe

GENERALTIPS meat isbrowned. Itshould beapproximately half cooked by

Broilingrequiresthe useofthe broiler panandinsert supplied the timethe top is browned.

with your appliance. It is designedto drain excess liquid and

fat away from the cooking surface to prevent spatters, Trimexcessfatto preventexcessive spattering or smoking.

smoke and flare ups. Cut slashesinthe outer edges of the meatto preventcurling

during cooking.

Foreasierclean-up, linethe broilerpan (bottom piece)with

aluminumfoiland spraythe insertwitha non-stick vegetable If you planto season the meat, itis better to do so afterthe

coating.Donot coverthe broilerpan insertwith aluminum foil surface has browned. Salt tends to delay browning which

as this prevents fat from draining into the pan below.The can result inovercooking. Salting before cooking also draws

broiler can be preheatedfor a few minutes.However,do not the juices out of the meat, causing dryness.

preheatthe broiler pan and insert.

Ifthe food isplacedtoo closeto the burner,overbrowning

and smoking may occur.Generallyfor a brown exteriorand

BROILING CHART TO BROIL:

1. TurntheovenTHERMOSTATknobto

Quantity&/or Approx. Minutes/Side BROIL.

Food Thickness Position Doneness I st Side 2nd Side

It is possibleto broil longer cooking

Bacon thickslice middle well 4- 5 1- 2 foods such as pork chopsat a lower

BeefPatties 3/4"thick middle rare 3-4 2-3 temperature to prevent overbrown-

middle medium 5-6 3-4 ing. Turn the knob to 450°F, rather

middle well 5-6 4-5 than BROIL, for low temperature

Steaks 1" thick bottom rare 3 - 4 3- 4 broiling.

bottom medium 5- 7 4 B 2. Preheatfor 2 to 3 minutes ifdesired.

bottom well 7 8 6 - 7

NOTE: Cooking times in the Broil

11/2"thick bottom rare 7- 8 5- 6 Chart are based on a 2 to 3 minute

bottom medium 8 10 6- 8

bottom well 10 - 11 8- 9 preheat.

ChickenBreastHalves bottom well 8- 9 7- 8 3. Place the broiler pan on the recom-

mended rack position shown in the

Fish Fillets 1"thick middle 5 - 6 3 - 5

1/2" thick middle 4- 5 3- 5 broiling chart.

HamSlices 12"thick middle 5-6 4-5 4. Follow the suggested times in the

(precooked) broilingchart. Meat should be turned

once about halfway through its cook-

PorkChops (450°) 1" thick bottom well 12- 14 8 - 9 ing time.

Weiners/Sausage middle 2 - 4 2 - 3 5. Check the doneness by cutting a slit

(precooked) in the meat near the center to check

the color.

12

Page 15

Maintenance

COOKTOP BURNER GRATES SURFACE BURNERS

¥ourrangewillfeatureeitheranupswept Surface burnersare secured in place

cooktopor a fiat cooktop.Bothtopscan duringtransportationwith springclips.

beliftedupforconvenientaccesstothe Once the range isinstalled,these may

burnerboxarea.Theflatcooktopcanbe be removedtoallowquickand easyre-

removed.Theupswepttopishingedand movalofthe burner.

canbe raisedbutnot removed.

TO REMOVE BURNER:

To raise upswept cooktop: When

cool, graspfront edge of cooktopand When reinstallingsquaregrates, place Allowburnertocool.Liftcooktop.Tore-

gentlyliftupuntilthetwosupportrodsat indentedsidestogethersostraightsides movebumer,liftupslightlyandpullout.

the frontofthe cooktopsnapintoplace, are atfrontandrear.

Tolower top: Holdfrontedgeofcook-

top and carefully push back on each

supportrodtoreleasethenotchedsup-

port,Then gentlylowertop intoplace.

Thesupportrodswillslideintotherange Burnergratesaredurablebutmay lose

frame, theirshinedueto usageand hightem-

peratures.

To remove flat cooktop: When cool,

first remove grates and drip bowls,if

equipped.Grasptwofrontburnerwells

and liftup.

I

The top can be completely removed or, if

equipped with a metal suppport rod, can

rest on the rod. Support rod is located

acrossthe front ofthe burner box. (continued next page)

13

Page 16

Maintenance(continued)

OVEN DOOR OVEN RACKS BROILER DRAWER

The two oven racksare designedwith a Store clean broilerpan and insert in the'

lock-stop edge to keep the racks from broiler drawer.

coming completely out of the oven.

To remove: Pull drawer out to the first

Toremove: Besurethe rackiscool.Pull stop position.Lift up front of drawer and

the rack straightout untilitstops. Tiltthe pull to the second stop position. Grasp

front of the rack up and continuepulling sides and lift up and out to remove

When opening oven door, allow steam the rack out of the oven. drawer. Gently move drawer side-to-

and hot airto escape before reaching in side as you pull the drawer out.

oven to check, add or removefood. To replace: Tilt the front end ofthe rack

upandplacetherackbetweenthe rack

To remove door: Open door to the supports.Slideitbackuntilitclearsthe "k / '_

"stop"position(openedabout4 inches) lock-stopposition.Lowerthe frontand

andgraspdoorwithbothhandsateach slidetherackstraightin.Pulltherackout

side.Do notuse doorhandle to lift door. to the lock-stop positionto be sure itis _

Lift upevenly until door clearsthe hinge positionedcorrectly and then return itto

arms. its normal positon.

OVEN BOTTOM To replace: Fit ends of drawer glides

ontorails. Liftup drawerfront and gently

push in to first stop position. Gently

move drawer side-to-side as you push

in the drawer. Lift up drawer again and

continue to slide drawer to the closed

To remove: When cool, remove the position.

oven racks. Slide the two catches, lo-

cated at each rear corner of the oven

bottom,toward the front ofthe oven.

To replace door: Grasp door at each

side,alignslotsinthedoor withthe hinge

armsandslidedoordownontothehinge

armsuntilcompletelyseatedonhinges.

Lift the rear edge of the oven bottom

slightly,then slide it back until the front

edgeoftheoven bottom clearsthe oven

front frame. Remove oven bottom from

oven.

To replace: Fit front edge of oven bot-

tom intofrontframe. Lower rear of oven

bottom and slide the catches back to

lock ovenbottom into place. (continuednext page)

14

Page 17

Maintenance(continued)

OVEN LIGHT HOW TO REMOVE PROPORTIONAL VALVE

RANGE FOR CLEANING ADJUSTMENT (if equipped)

AND SERVICING The LOW setting should produce a

Follow these procedures to remove ap- stable flame when turning the knobfrom

Before replacing oven light bulb, DIS- pliancefor cleaning or servicing: HI toLO. The flame should be 1/8 inch or

lower and must be stable on all ports on

CONNECT POWER TO RANGE. Be LOW setting.

sure bulb and range parts are cool. Do 1. Shut-off gas supply to appliance.

nottouchahotbulbwithadampclothas To adjust: Operate burner on HI for

the bulb may break. 2. Disconnect electrical supply to ap- about 5 minutes to preheat burner cap.

pliance, if equipped. Turn knob backto LO; remove knob, and

To replace oven light: Use a dry pot insert a small screwdriver intothe center

holder, to prevent possible harm to 3. Disconnect gas supply tubing to ap- of the valve stem. Adjust flame size by

hands;very carefully remove bulb. Re- pliance, turning adjustment screw in either direc-

place with a 40 watt APPLIANCE bulb. tion.

Reconnect power tothe range. 4. Slide range forward to disengage

range from the anti-tip bracket. (See

Installation Instructions for location of

LEVELING LEGS bracket.)

5. Reverse procedure to reinstall. If gas i_

line has been disconnected, check for

y

Leveling legs are located on each corner gas leaks after reconnection. (See

of the base of the range. Installation Instructions for gas leak

test method.)

NOTE: A qualified servicer should dis-

connect and reconnect the gas supply.

% _,,_ To prevent range from accidently tip-

ping, range must be secured to the floor

by sliding rear leveling leg into an anti-

tip bracket supplied with the range.

_,_ WARNING: Possible risks may result NOTE: All gas adjustments should be

from abnormal usage, including exces- done by a qualified servicer only.

sive loading of the oven door and of the

Place a level horizontally on an oven risk of tip over, should the appliance not

rack and check front-to-back and side- be reinstalled according to the installa-

to-side. Level by turning the legs. tion instructions.

15

Page 18

GeneralInformation

ELECTRICAL CONNECTION USE OF ALUMINUM FOIL

Appliances which require electrical Use aluminum foil ONLY as

power are equipped with a three- instructed in this book. Improperuse

prong grounding plug whichmust be of aluminumfoil may cause damageto

plugged directly into a properly theoven,affectcookingresults,andcan

groundedthree-hole 120 voltelectrical also resultinshockand/orfire hazards.

outlet.

Foilcan be usediftheseguidelinesare

followed:

_)_ • Do not use aluminum foil directly

_ under the cool(ware. Foil will reflect

heatawayfromtheutensilcausinginad-

equatebrowning.Placinga piedirectly

onfoilmayresultinasoggybottomcrust

and inadequatebrowning.

A/ways disconnect power to app/i- • Do not place aluminum foil directly

ance before servicing, onthe oven bottomas this may dam-

age the oven bottom. A piece of foil

The three-pronggroundingplug offers that is slightlylargerthan the cooking

protectionagainstshock hazards. DO utensilcanbeplacedontherackdirectly

NOT CUT OR REMOVE THE THIRD belowthe rackcontainingthe utensil.

GROUNDING PRONG FROM THE

POWER CORD PLUG. • Do not completely cover an oven

rackwith foil. Thisblocksairflowinthe

oven, constitutesa safety hazard, and

will adversely affect cooking results.

• Never cover the broiler insert with

aluminum foil as this prevents fat

from draining to the pan below. The

broiler pan can be lined withfoil.

16

Page 19

CareandCleaning

CLEANING CHART

PARTS CLEANING AGENTS DIRECTIONS

Baked Enamel • Soap andwater UseadrytowelorclothtowipeupspilFs,especiallyacid(milk,lemonjuice,fruit,mustarc

or Porcelain Enamel • Pasteof bakingsodaandwater tomatosauce)orsugaryspills.Surfacemaydiscolorordullifsoilisnotimmediatelyre-

. Cooktop • Mildliquidcleaner moved.Thisis especiallyimportantforwhitesurfaces.

• Ovendoor • Glass cleaner

• Broilerdrawer Whensurfaceiscool,washwith warm soapywater, rinseanddry. Forstubbornsoil,use

• Side panels mildlyabrasivecleaningagents suchas bakingsoda paste or BonAmi. If desired,athin

• Backguard coatof mildappliance wax canbeusedto protectthe sidepanels.A glasscleanercanbe

usedto add "shine"to the surface.

NOTE:Donot useabrasive, causticor harshcleaningagents suchassteel wool pads or

oven cleaners. These productswill scratch or permanently damage the surface.

NOTE: Neverwipe a warm orhot surfacewith adampcloth asthis maydamagethe sur-

face and may cause a steam burn.

Broiler pan and • Soapand water Removefromovenafteruse.Coolthen pouroffgrease.Placesoapyclothoverinsertand

insert =Plasticscouringpad pan;letsoaktoloosensoil.Washinwarmsoapywater.Usesoap-filledscouringpadto

• Soap-filledscouringpad removestubbornsoil.Cleanin dishwasherifdesired.

• Dishwasher

NOTE:Foreasiercleanup,sprayinsertwithanon-stickvegetablecoatingandlinebroiler

panwithaluminumfoil.

NOTE:Alwaysstorecleanbroilerpanandinsertin thebroilercompartment.If panand

insertarenotcleanedaftereachuse,thesoilmightbecomehotenoughtoignitathenext

timethe ovenis used.

Burner box • Soapandwater Burnerbox,locatedunderlift-up cooktop,shouldbecleanedfrequentlytoremovespil-

• Pasteof bakingsodaand water lovers.Ifsoilisnotremovedand isallowedto accumulate,itmay damagethefinish.To

• Non-abrasiveplasticpador sponge cleanremovegratesandsurfaceburnersand cleanwithsoapandwater,rinseanddry.

• Liquidcleaner

• Glasscleaner

Chrome drip bowls, • Soap and water Cleanbowlsaftereach use withsoapand water.Removestubbornstainswith baking

if equipped • Pasteofbakingsodaandwatar sodapasteandplasticscouringpad.Topreventscratchingthefinish,donotuseabrasive

• Plasticscouringpad cleaningagents.Rinse,dryand replace.

NOTE;Bowlscanpermanentlydiscolorifexposedtoexcessiveheatorifsoilisallowedto

bakeon.

Control knobs * Soapandwater Toremoveknobsforcleaning,gentlypullforward.Washinmilddetergentandwater.Do

notsoakknobsinwater.Donotuseabrasivecleaningagents.Theywillscratchfinishand

removemarkings.Rinsedryand replace.Turn ON each burner to see ifknobs have

beenreplaced correctly.

(continuedon next page)

17

Page 20

CareandCleaning(continued)

PARTS CLEANING AGENTS DIRECTIONS

Glass • Soapand water Washwithsoapandwater.Useawindowcleaneranda softclothaftercleaning.Remove

• Backguard • Paste of bakingsoda andwater stubbornsoil with paste ofbakingsoda and water. Rinsewith acloth wrungout indear

• Oven window • Glasscleaner water. Dry.Donot useabrasive materialssuch asscouringpads,steelwool or powdered

cleaningagents.

NOTE: To avoid inside staining of oven door glass, do notoversaturate cloth.

Grates • Detergentandwater Gratesare madeofporcelain-coated steel.Theycan becleaned atthe sinkwith deter-

• Non-abrasiveplasticpad gentandwateror inthedishwasher.Toclean bakedon soil,placea dampsoapypaper

toweloverthegrateandletstandfor30minutes.Useanon-abrasiveplasticpadtoscour

stubbornsoil.

NOTE:Neveroperateburnerwithoutagrate inplace.Toprotecttheporcelainfinishonthe

gratefrom excessiveheat,neveroperatesurfaceburnerwithout acookingutensilonthe

grate. It isnormal for grates to losetheir shine over a period of time.

Metalfinishes • Soapand water Washwith soap and water.Removestubborn soilwith paste of bakingsoda and water.

• Backguard • Paste of bakingsodaandwater Usea windowcleanerand a softclothto removefingermarksorsmudges.

• Trimparts • Glass cleaner

• Manifoldpanel NOTE:Donotuseovencleaners,abrasiveorcausticagents.Theywilldamagethefinish.

Oven bottom • Soapandwater Continuousclean ovenbottom:See page 19.

• Porcelainenamel • Pasteof bakingsodaandwater

• Non-abrasiveplasticpad Porcelainovenbottom:Clean,whencool,withsoapandwater,non-abrasiveplasticpad

• Oven cleaner orovencleaner.Rinsewithclearwater.Tomakecleaningeasier,protecttheovenbottom

by(1)usinglargeenoughcookwaretopreventboilovers;(2) placea pieceofaluminum

foil,thatisslightlylargerthanthecookware,onthe lowerrack.NEVER placefoildirectly

onthe ovenbottom.

Protectoven bottomagainstacidspills(milk,cheese,tomato,lemonjuice,etc.) orsugary

spills(piefilling)astheymay pit ordiscolorthe oven bottom.

Foreasiercleaning,ovenbottomcanberemovedandcleanedatthesink.Donotsoakor

immerseoven bottominwateror placeunderrunningwater.

Ovencavity Cleaning action beginswheneverthe Brushoffheavy soilwitha nylonor plasticpad. Do notuse paper towels,cloths,or

• Continuousclean ovenis on.The oven mustbe usedfor spongesbecausetheovenwallsareporousandparticlesofthesematerialswiIIruboffon

oven cleaningtotakeplace.Higheroventem- thewalis.Rinseareawitheleanwateronly.Donotuseanytypeofovencleaner,cleanser

Seepage19 )eratures and longer baking times or detergentonthissurfaee.

speedthe cleaningaction.

Oven cavity • Soapandwater Cleanoveninteriorwithsoapandwater;rinse.Usecleansingpowdersoraplasticscour-

. Porcelainoven • Mildabrasivecleaners ingpadtoremovestubbornsoil.Wipeacidorsugarstainsassoonastheoveniscoolas

• Plasticpad thesestainsmaydiscolororetchtheporcelain.Do notusemetallicscouringpadsasthey

• Ovencleaner willsoratehtheporcelain.Tomakecleaningeasier,place1/2cuphouseholdardmoniaina

shallowglassandleaveinacoldovenovernight.Theammoniafumeswillhelploosenthe

burnedon greaseandfood.Ovencleanerscan beusedontheporcelainovenbutfollow

manufacturer'sdirections.Ifovencleanerwas used, thoroughlyrinseovencavityand

capillarytubewhichislocatedatthetopoftheoven.Ovencleanerscannotbeusedonthe

continuouscleaningovenfinish.

Oven racks • Soap and water Cleanwithsoapywater.Removestubbornsoilwithcleansingpowderorsoapfilledscour-

• Cleansing powders ing pad. Rinseand dry.

• Plastic pad

Soapfilled scouring pad NOTE:Ifracksbecomedifficulttoslide, athin coatofvegetableoilonthe undersideofthe

rack will make sliding easier.

Plasticfinishes • Soap and water Whensurface iscool, cleanwith soap and water; rinse,and dry. Use a windowcleaner

• Doorhandles • Pasteof baking soda and water and a soft cloth.

• Backguardtrim • Non-abrasive plastic pador sponge

• Overlays NOTE:Neveruseovencleaners,abrasiveorcausticliquidor powderedcleaningagents

• Knobs onplastic finishes. These cleaning agents will scratch or marr finish.

• Endcaps NOTE:To preventstaining or discoloration,wipe upfat, grease or acid (tomato, lemon,

vinegar, milk,fruitjuice, marinade) immediately with a dry papertowel or cloth.

Silicone rubber • Soapand water Wash withsoapandwater,rinseanddry. Donot removedoorgasket.

• Doorgasket

Surface burners • Soap and water Clean as necessarywith warm soapy water. Removestubborn soilby scouring with a

• Pasteof bakingsodaand water non-abrasiveplasticscouringpadandapasteofbakingsodaandwater.Cleanportswith

• Plasticscouringspongeorpad a straightpin.Donotenlargeordistorttheports.Donotusea woodentoothpick.Itmay

breakoffandclogport.DO NOT CLEANBURNERSWITH THE FOLLOWING caustic

cleaners:ovencleaners,steelwoolorabrasivecleaningagents.Thesemaydamagefin-

ish.Burnerscanbe driedinthe oven setat 140°F.CAUTION: Burnerand burnertube

mustbe drybeforeuse.

18

Page 21

CareandCleaning(continue.)

CONTINUOUS CLEANING OVEN (if equipped)

WHAT IS THE CONTINUOUS MANUALLYCLEANING HINTS

CLEANINGOVEN? HEAVYSPILLOVERS Brittlecrustsor stainscan be loosened

The finish of the ContinuousCleaning The specialfinishwillclean mostspat- byGENTLYtappingstainwithawooden

Ovenisidentifiedbyitsdarkgraycolor, tere during normal oven use unless or plasticutensil.Brushawayany loose

and rough,poroustexture.The rough there is a heavybuildupofsoil. Heavy soil that flakesoff. Varnishtype stains

texturepreventsgrease spattersfrom spilloverssuch as pie or casserole usuallyneedtobesoftenedwithasmall

formingbeadswhichrundownthewalls boiloverswill notclean effectivelywith- amountofwaterordampcloth.Remain-

leaving unsightlystreaks. Rather,the out some manual help. The crustyor ingsoilwillgraduallyreducewithcontin-

roughtexture absorbsspattersand al- varnish-likestainsthatformfromthese uedovenuseat normalbakingtempera-

lowsthem to spread,thus exposinga spilloversclogtheporesandpreventthe tures.

largerareatothe hotovenair.Thecata- specialfinishfrombeingexposedtothe

lyst,when exposedto heat,speedsthe hot oven air. This greatlyreducesthe

oxidationof soil. cleaningeffectivenessofthe finish. DO NOT USE ANY TYPE OF OVEN

CLEANER, POWDERED CLEANS-

ERS, SOAP,DETERGENT OR PASTE

Cleaning action automaticallybegins Thesecrustyorvamish-likestainsmust ON ANY CONTINUOUS CLEANING

whenevertheovenisturnedonforbak- either be removedor brokenupbefore SURFACE. ALSO, DO NOT USE ANY

ingor roasting.The oven MUST be "on" cleaningcaneffectivelytakeplace. ABRASIVE MATERIALS, STEEL

for cleaningto take place. No cleaning WOOL, SHARP INSTRUMENTS OR

willoccurwhentheovenisoff.The spe- SCRAPERS FOR THEY WILL DAM-

cialcatalyticfinish mustbe exposedto TO MANUALLY CLEAN AGETHE FINISH.

hot oven air before soil will begin to HEAVYSPILLOVERS

graduallyreduceinsize. Brushoffheavysoilwitha nylonbrushor

plasticpad.DONOT USE papertowels, Avoidspilloversby usingutensilsthat

FACTORSAFFECTING LENGTH OF clothsorspongesfortheovenwallsare arelargeenoughtoholdfood.A cookie

porousand particlesofthese materials sheetorpieceofaluminumfoil,justa lit-

CLEANING TIME willruboffonthewalls.Rinsearea with tie largerthanthepan,canbeplacedon

The higherthe oven temperature,the

fasterthecleaningaction.The lengthof clearwater only. the rackdirectlybelowthe rackholding

cleaningtimewilldependon thesefac- the utensiltocatchspills.

tors:Typeof soil,amountorsize ofsoil,

oven temperature and length of time

ovenisinuse.Timemayvaryfromafew Overa periodof time, wear marksmay

minutestoseveralhours.Soildeposited appearonthe embossedracksupports.

at theendof a cyclemaystillbevisible. This isnormaland resultsfromsliding

This will usuallyfade with continued the racksinand outofthe oven. Wear

ovenuse untilthesoilgraduallydisap- markswillnot affectthecleaningaction

pearsorcan bewipedupmanually.The oftheoven.

oven will appear presentablyclean,

eventhough some spatters may be pre-

sent.

19

Page 22

Service

BEFORE CALLING A SERVICETECHNICIAN, CHECK THE FOLLOWING:

PROBLEM CAUSE CORRECTION

1. Surface burnerfailsto light a. pilots are notlit (pilotignition) a. see page 6 to light pilots

b. power supply not connected b. connect power,check circuit breakeror

(pilotless ignition) fuse box

c. clogged burner port(s) c. clean ports with straight pin

d. burners not placed correctly onto gas d. remove and reinstall burner properly

valve

e. surface control not completelyturned to e. turn controlto the LITE position untilthe

the LITE position or turned too quickly burner ignites, then turn control to de-

fromthe LITE position (pilotlessignition) sired flame size

f. power failure (pilotlessignition) f. seepage6tolightburnerduringapower

failure

2. Burnerflame uneven a. clogged burner port(s) a. clean ports with straight pin

b. burner not properly positioned b. seepage 13to correctly replace burner

3. Surface burner flame a. air/gas mixture not proper a. callserviceman to adjust burner

• liftsoff port NOTE: Some yellowtipping with LP gas is

• yellow incolor normal and acceptable.

4. Oven burnerfails to light a. power supply not connected a. connect power, check circuit breaker or

(pilotless ignition) fuse box

b. pilot isout (pilot ignition) b. see page6 to lightpilots

c. power failure (pilotlessignition) c. an ovenequipped with pilotless ignition

will not operate during a powerfailure

or if disconnected from power. See

page 8

5. Popping sound heard when burner This is a normal sound that occurs with some types of gas when a hot burner is turned off.

extinguishes The popping sound is nota safetyhazard andwill not damage the appliance.

6. Clockand/or ovenlight doesnotwork a. power supply not connected a, connect power supply, check circuit

breaker or fuse box

b. bulb may be loose or burned out b. tighten or replace light bulb

c. malfunctioning switch,starter or ballast c. callserviceman to check

d+malfunctioning clock or loose wiring d. callserviceman to check

7. Moisturecondensation on oven a. it is normal for the window tofog during a. leavedoorajarforoneortwominutesto

window, if equipped thefirst few minutes the oven ison allow moistureto escape

b. cloth saturated with water is used to b. Use a damp cloth to clean window to

cleanthe window prevent excesswater from seeping

between the panelsof glass

8. Oven temperature inaccurate a. oven not preheated a. preheat oven 10to 15 minutes

• food takes too long or cooks too b. incorrect rack position b. see page 9

fast c. incorrect use of aluminum foil c. see page 16

• pale browning d. oven bottom incorrectly replaced d. replace oven bottom correctly

• food over-done on outside and e. oven thermostat sensing device out of e. reinstall sensing device securely into

under-done in center holdingclip(s) clip(s)

• over browning See Problem Chart on page 11

See baking Upson page 10

9. Oven smokes excessively during a a. food too close to burner a. movebroiler pandownone rack position

broil operation b. meat has too much fat b. trim fat

c. sauce applied too early or marinade not c. apply sauce during last few minutes of

completely drained cooking. If meat has been marinated,

drain thoroughly before cooking

d. soiled broiler pan d. always clean broiler pan and insertafter

each use

e. broilerinsert coveredwith aluminum foil e. never cover insert with foil as this pre-

vents fat from draining to pan below

10.Poor baking results See pages 9 to 11for information on

baking

2O

Page 23

Service (continued)

SERVICING HOW TO OBTAINSERVICE

When your appliance requires service or

replacement parts, contact your Dealer

or Authorized Servicer. Use only genu-

ine factory or Maycor parts if replace-

ment parts are necessary. Consult the

Yellow Pages in your telephone direc-

tory under appliance for the service cen-

ter nearest you. Be sure to include your

name, address, and phone number,

along with the model and serial numbers

of the appliance. (See inside front cover

for location of your model and serial

numbers.)

If you are unable to obtain service, write

to us. Our address is found on the rating

plate. See inside front cover for location

of rating plate.

If you are not satisfied with the local re-

sponse to your service requirements,

call or write MAYCOR Appliance Parts

and Service Company, 240 Edwards

Street, S.E., Cleveland, TN 37311, (615)

472-3500. Include or have available the

complete model and serial numbers of

the appliance, the name and address of

the dealer from whom you purchased

the appliance, the date of purchase and

details concerning your problem.

If you did not receive satisfactory service

through your servicer or Maycor you

may contact the Major Appliance Con-

sumer Action Panel by letter including

your name, address, and telephone

number, as well as the model and serial

numbers of the appliance.

Major Appliance Consumer Action Panel

20 North Wacker Drive

Chicago, IL 60606

MACAP (Major Appliance Consumer

Action Panel) is an independent agency

sponsored by three trade associations

as a court of appeals on consumer com-

plaints which have not been resolved

satisfactorily within a reasonable period

of time.

21

Page 24

WHAT IS NOTCOVERED BYTHESE TWO WARRANTIES:

1, Conditionsanddamagesresultingfromany of the fol- 4, Productspurchasedforcommercialor industrialuse,

lowing: 5. The cost of service orservice call to:

a. Improper installation, delivery,or maintenance.

a. Correct installation errors.

b. Any repair,modification, alteration oradjustment not

authorizedby Maycor,ora Maycorauthorizedservic- b. Instruct the consumer onthe properuse of the prod-

uct.

er.

c. Misuse,abuse, accidents or unreasonable use. c. Transpor_the appliance to a servicer.

d. Incorrect electrical current,voltage or supply. 6. CONSEQUENTIAL OR INCIDENTALDAMAGES SUS-

e. Improper setting of any control. TAINED BY ANY PERSON AS A RESULT OF ANY

BREACH OF THESE WARRANTIES. Some states do

2. Warranties are void if the original serial numbers have not allow the exclusion or limitation of consequential or

beenremoved,altered,orcannot be readilydetermined, incidentaldamages,so the aboveexclusion maynot ap-

3. Light bulbs, ply to you.

HOW TO RECEIVE WARRANTY SERVICE

1. Contactthe dealerfromwhomyoupurchasedtheapplianceorany authorizedMaycorservicerto

receivewarranty service under these warranties.

2. Should you not receivesatisfactory warranty service from your local servicer, contact:

Customer Assistance

Maycor Appliance Parts and Service Company

240 EdwardsStreet, S.E.

Cleveland, TN 37311

(615)472-3500

3. Have the following informationavailable when requestingwarranty service:

- Yourname and address.

- The model and serial numbers of your appliance.

- The name and address of your dealer or servicer.

- The purchase date of your appliance.

- A clear description of the problem.

(1/93)

Loading...

Loading...