MAG SL100DC Series Installation Manual

App

e

g

y

g

A

(

SL100DCx series – Sliding gate system

Gate Automatic System

MAG SL100ACx series is a complete sliding gate automation system.

Components in MAG SL100DCx series

1 PVC box

2 Control board

3 Motor

4 Limit switch

5 Mountin

6 Base plate

7 Limit switch stopper

8 Gear rack

bracket

Preliminary check

To ensure trouble-free operation, make sure that the gate (whether existing or yet to be installed) has the following

specification:

• Max gate weight 600kg

• Strong and rigid leaf frame

• Flat leaf face, with no protruding parts and no vertical members

• Straight, smooth and even movement of the least over its entire travel

• No sideway oscillation of the leaf

• Upper and lower sliding system in perfect condition

• The use of floor tracking with a rounded channel is preferred because it reduces friction in the sliding

movement

• Only two slide wheel

If any welding or brazing is required on the gate, it should be done before installing the automation system. The

condition of the gate structure will have direct affect on the reliability and safety of the automation system. We are

ready to install SL100P after making sure all the above items are checked.

Installation guide

9Ke

10 Pinion

11

12 Spacer

13 Bolt

14 Remote control transmitter

15 Remote control receiver

to unlock clutch

lan key to release clutch

lication not

ear

with screw tread)

© Install_CelmerSL100P - All specification and suggested dimension is for reference only- subject to change without further notice.

1

Door

Door

frame

g

Suggested installation steps include the following:

1. Doing the wiring groundwork at installation site

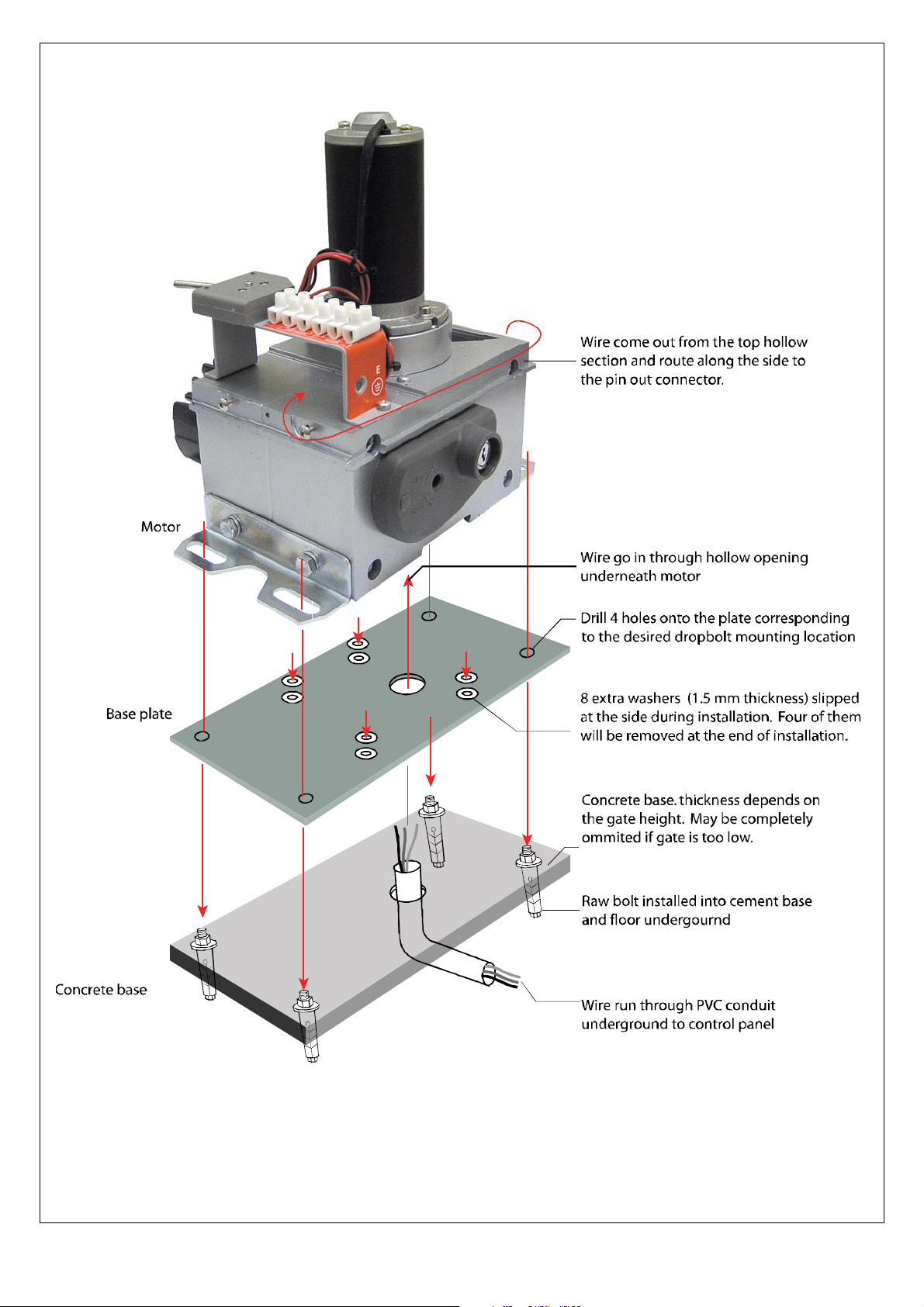

2. Installation of the operator motor

3. Installing control panel to the pillar wall

4. Installation of gear rack to gate

5. Mounting the limit switch stopper to the gear rack

6. Remove 4 extra washers from the motor operator

7. Testing and verifying wiring

** Step 2 and 3 might be interchanged while waiting for the cement base to dry. Special chemical can be added to the

cement base to shorten the dry time.

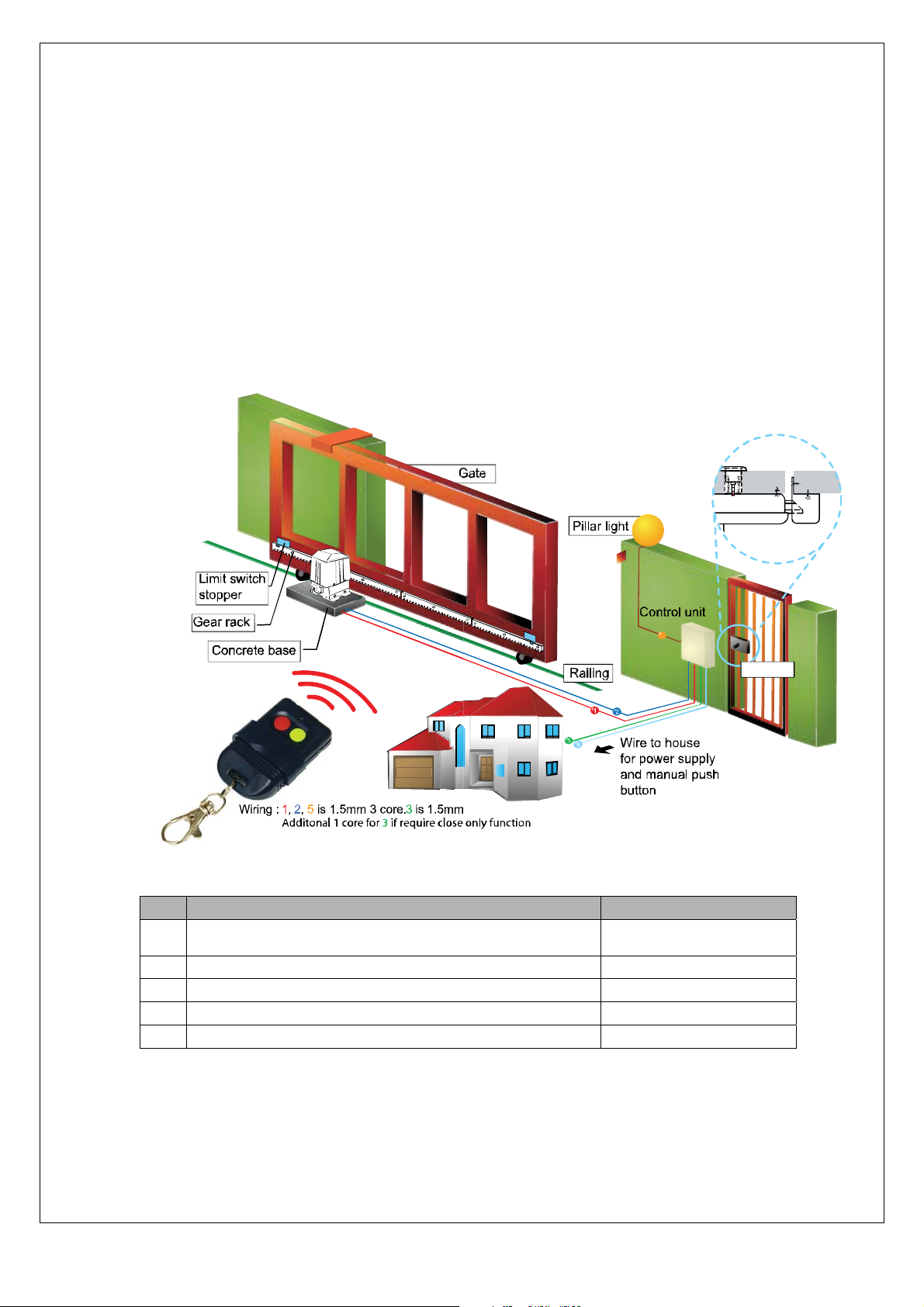

Standard installation layout

The below typical layout can be used to plan wiring groundwork at actual installation site. Use suitable rigid and/or

flexible pipes for laying power cables. Always keep low voltage accessory cables separated from 230V power cables.

To avoid interference, use separate sheaths. It is suggested to use the following recommended cable specification.

Lock remain secured

during power failure

- weatherproof

5

Wiring :1,2,5is 1.5mm 3 core.3is1.5mm 2core.4 is 2.5mm3 core.

Description Wire specification

1

Connectin

(Close, common and open)

limit switch signal from motor to control unit.

3 core, 1.5 mm diameter

2 AC230V power supply from control unit to the motor 3 core, 1.5 mm diameter

3 In door push button for manual control of the gate. 2 core, 1.5 mm diameter

4 AC230V power supply to the control unit 3 core, 2.5 mm diameter

5 Pillar light power supply 3 core, 1.5 mm diameter

© Install_CelmerSL100P - All specification and suggested dimension is for reference only- subject to change without further notice.

Rimlock

2

Installing the motor operator

© Install_CelmerSL100P - All specification and suggested dimension is for reference only- subject to change without further notice.

3

Loading...

Loading...