101E-OM0906-00

OPERATION MANUAL

MINI-CRAWLER CRANE

Serial No. G0121 and up

k WARNING

Unsafe use of this machine may cause serious injury or death. Operators

must read this manual before operating this machine. This manual should

be kept near the machine for reference and periodically reviewed by all

personnel who will come into contact with it.

NOTICE

MAEDA has Operation Manual written in some other languages. If a foreign

language manual is necessary, contact your local distributor for availability.

0-1

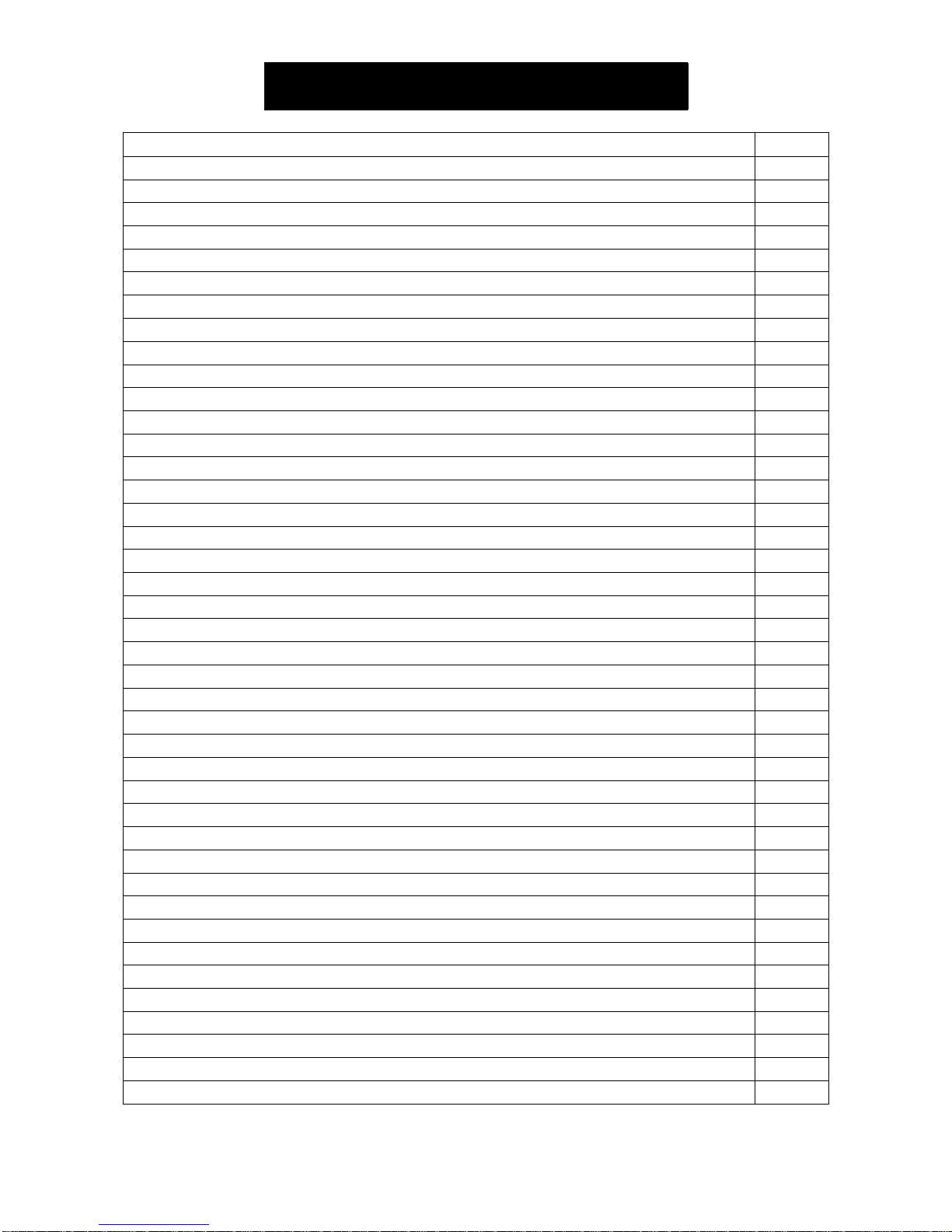

CONTENTS

ITEM

Page

INTRODUCTION

1- 1

1. INTRODUCTION

1- 2

2.FOR SAFE USE OF MACHINE

1- 3

3. MACHINE OVERVIEW

1- 4

3.1 SPECIFIED OPERATIONS

1- 4

3.2 MACHINE CONFIGURATION

1- 4

3.3 MACHINE FUNCTIONS

1- 5

4. QUALIFICATION FOR OPERATION

1- 6

4.1 QUALIFICATION FOR CRANE OPERATION

1- 6

5. TERMINOLOGY

1- 7

5.1 DEFINITION OF TERMS

1- 7

5.2 DIAGRAM OF WORKING RADIUS AND LIFTING HEIGHT

1- 8

5.3 TOTAL RATED LOAD CHART

1- 9

5.4 ANGLE INDICATOR

1-14

SAFETY

2- 1

1. BASIC PRECAUTIONS

2- 2

2. DRIVING RELATED PRECAUTIONS

2- 7

2.1 BEFORE STARTING THE ENGINE

2- 7

2.2 AFTER STARTING THE ENGINE

2- 8

2.3 WORKING WITH THE CRANE

2-12

3. TRANSPORT PRECAUTIONS

2-21

4. BATTERY HANDLING PRECAUTIONS

2-23

5. MAINTENANCE PRECAUTIONS

2-25

5.1 PRECAUTIONS BEFORE MAINTENANCE

2-25

5.2 PRECAUTIONS DURING MAINTENANCE

2-27

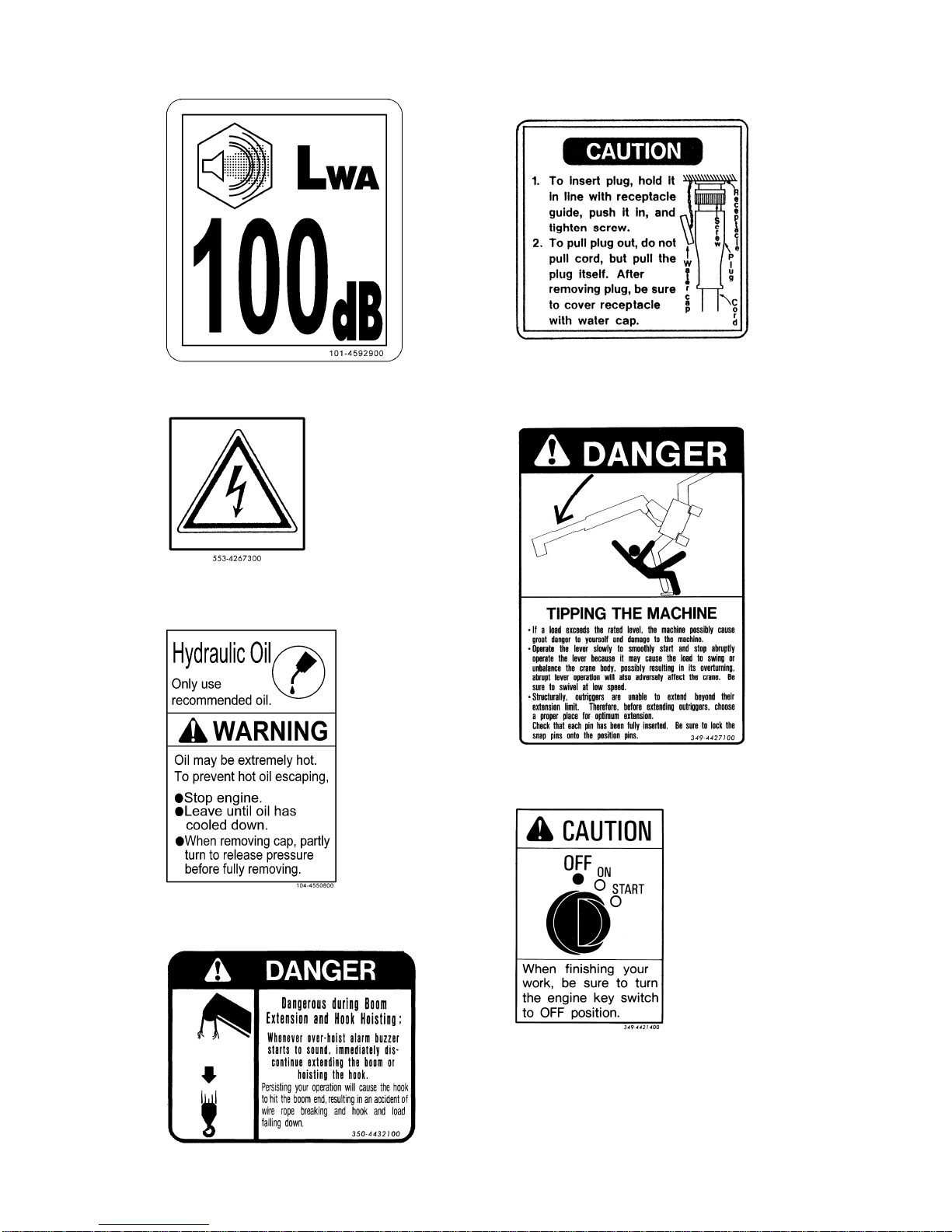

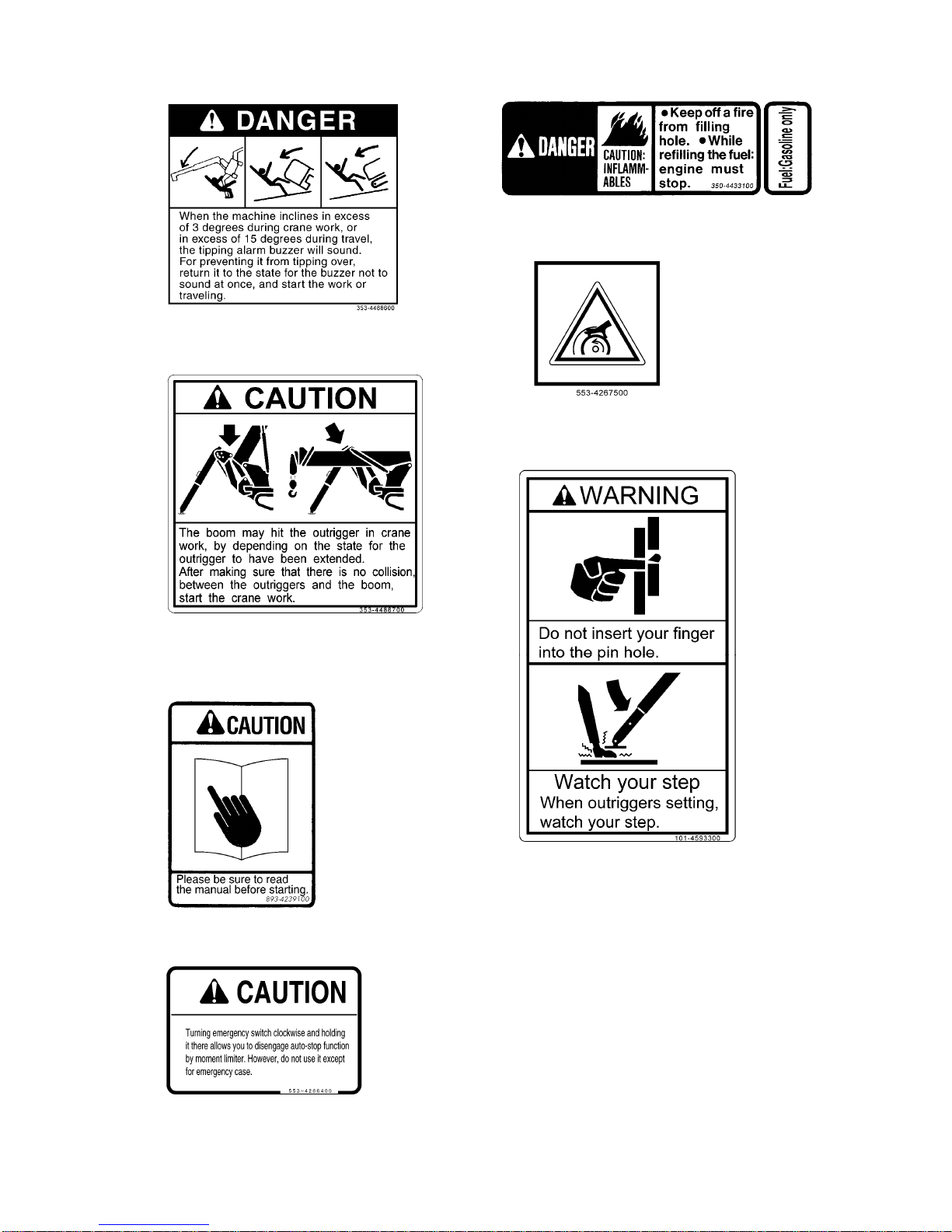

6. SAFETY LABEL LOCATIONS

2-32

7. WEEE DIRECTIVE LABEL LOCATIONS

2-39

OPERATION

3- 1

1. MACHINE BY SECTION

3- 2

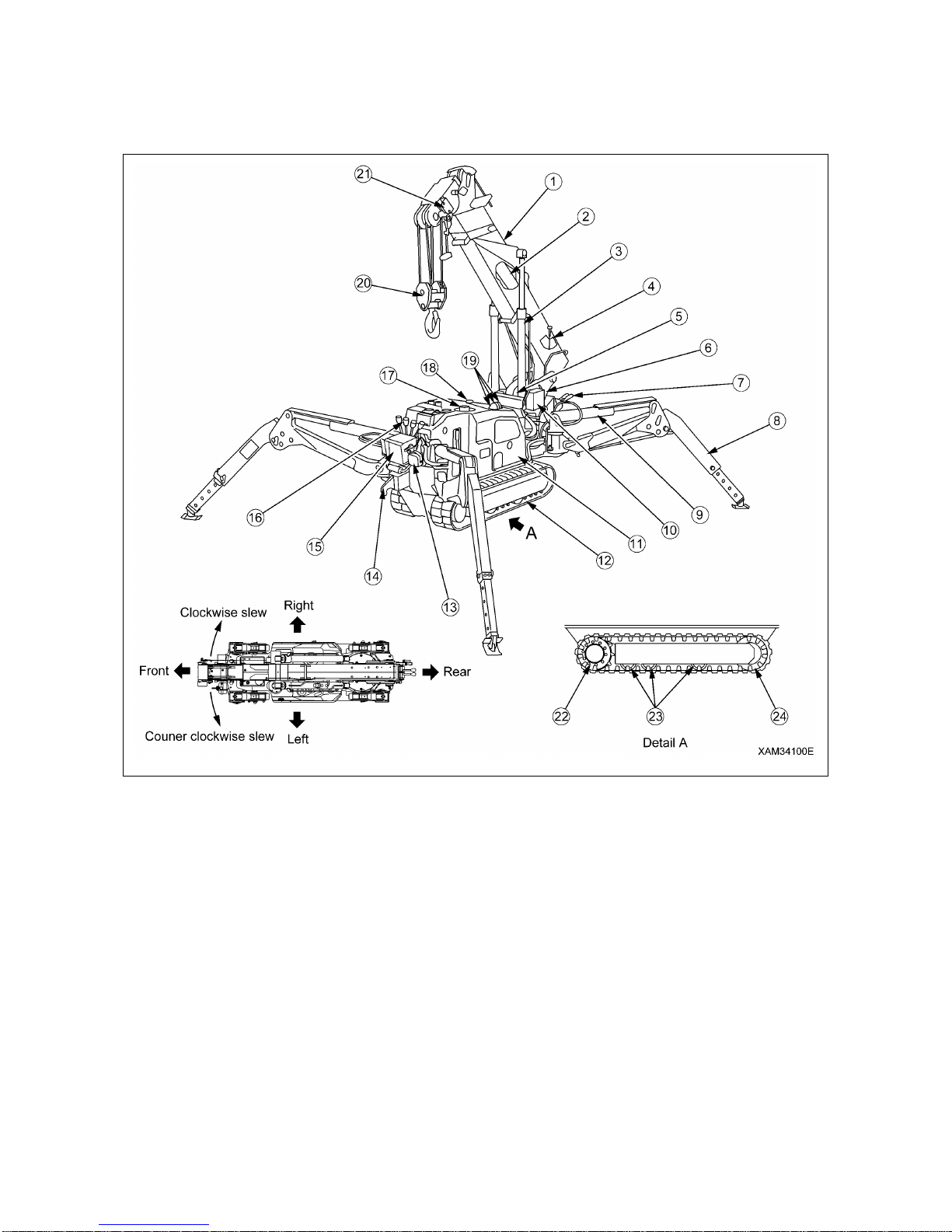

1.1 MACHINE BY UNIT

3- 2

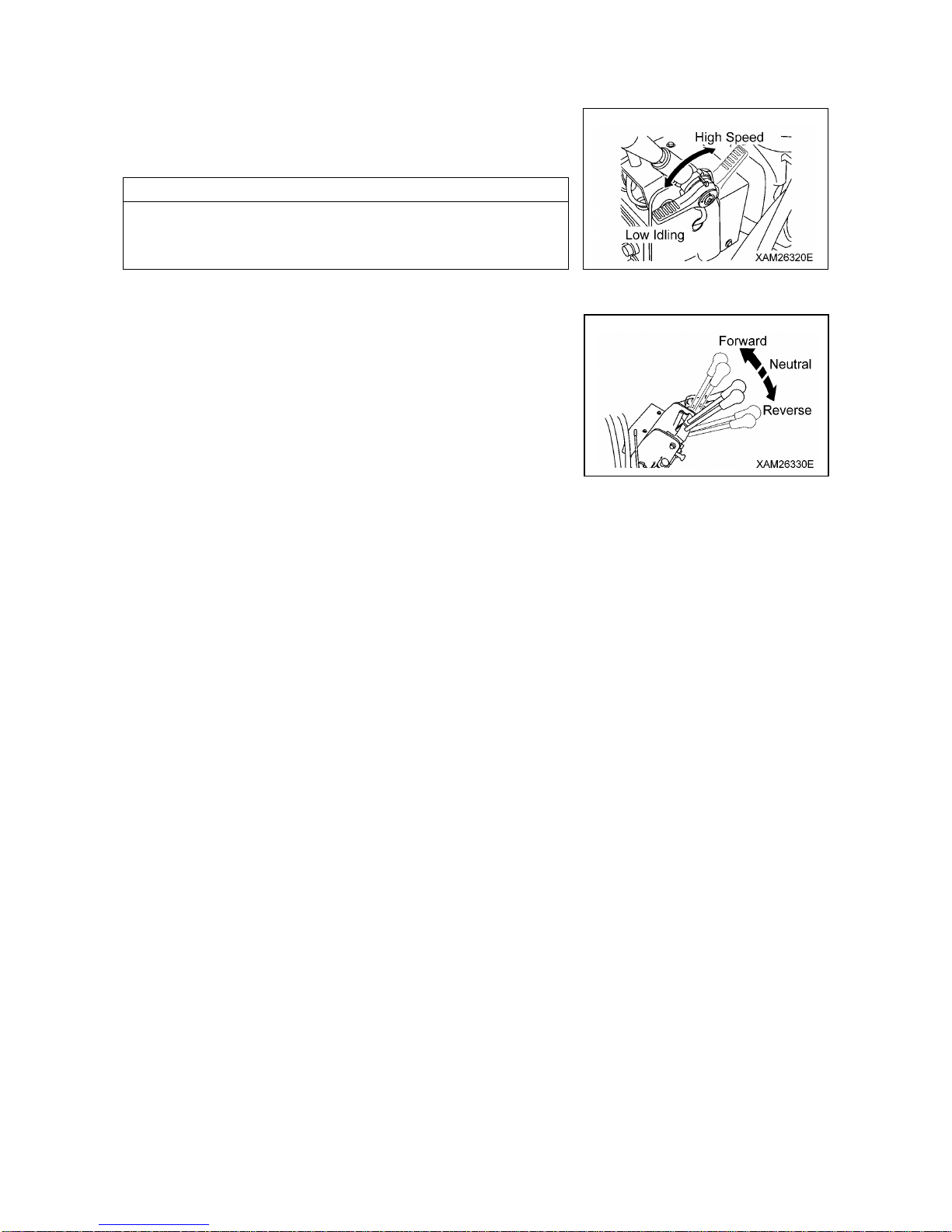

1.2 TRAVELLING OPERATION UNIT

3- 3

1.2.1 DESCRIPTION OF EACH LEVER

3- 4

1.2.2 DESCRIPTION OF EACH SWITCH

3- 6

1.2.3 DESCRIPTION OF EACH METER AND LAMP

3- 8

1.3 CRANE OPERATION UNITS

3- 9

1.3.1 DESCRIPTION OF EACH LEVER

3-10

1.3.2 DESCRIPTION OF EACH SWITCH

3-11

1.4 MOMENT LIMITER (OVERLOAD DETECTOR)

3-16

1.4.1 MOMENT LIMITER CONFIGURATION

3-16

1.4.2 FUNCTION OF MOMENT LIMITER

3-17

1.4.3 MOMENT LIMITER OPERATIONS

3-18

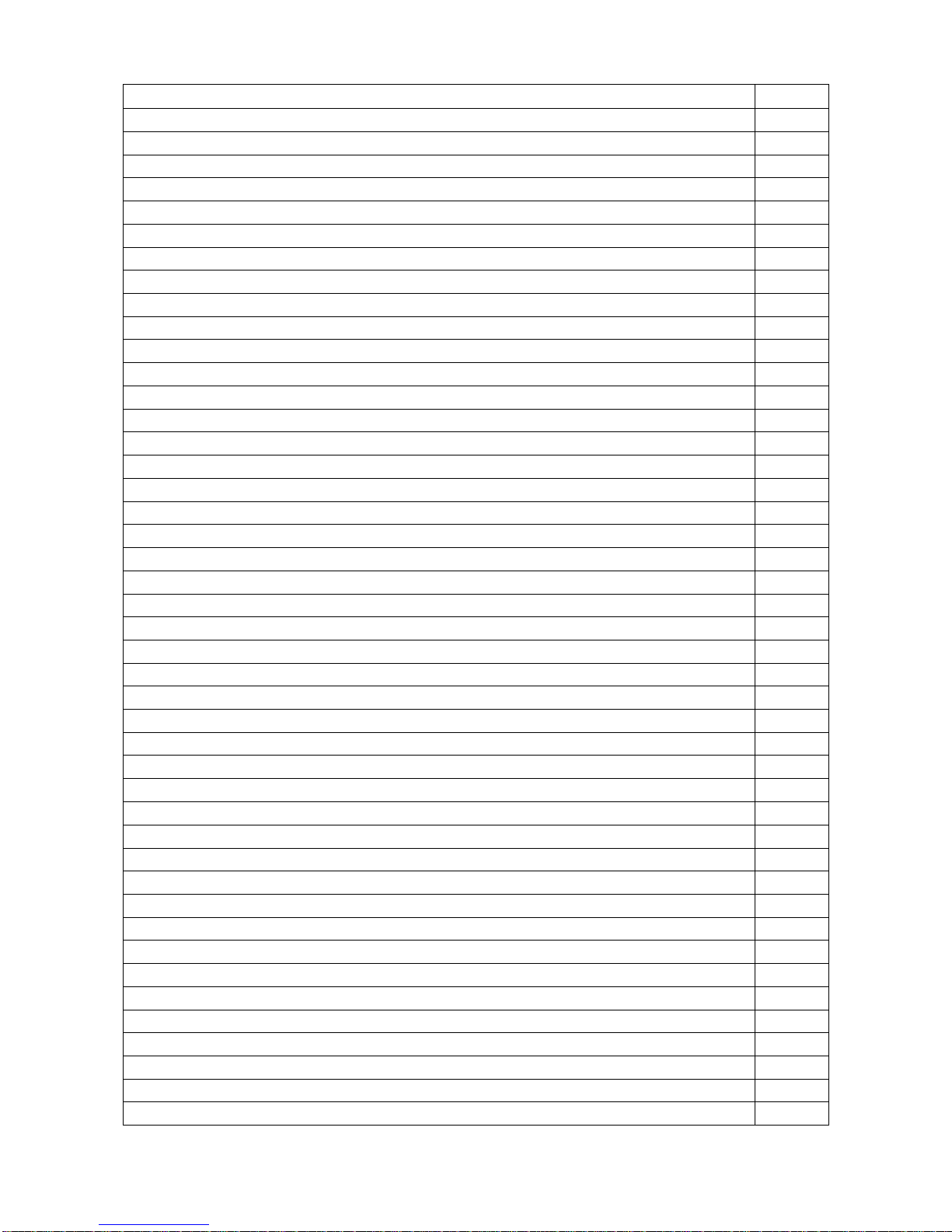

0-2

ITEM

Page

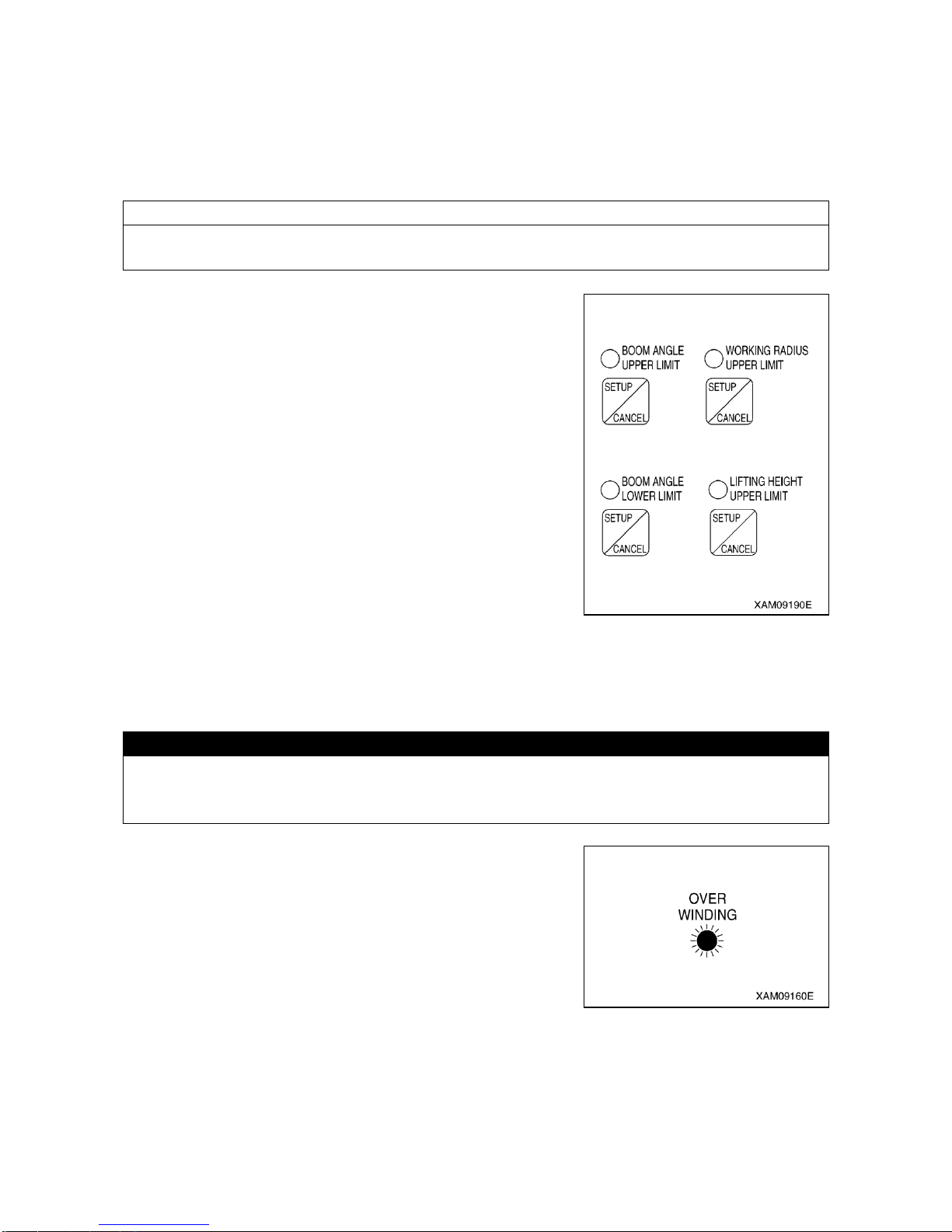

1.4.4 NAMES OF MOMENT LIMITER DISPLAY UNIT

3-20

1.4.5 OTHER MOMENT LIMITER FUNCTIONS

3-29

1.4.6 MOMENT LIMITER STARTING STATUS

3-30

1.4.7 MOMENT LIMITER ERROR CAUSES AND ACTIONS TO BE TAKEN

3-31

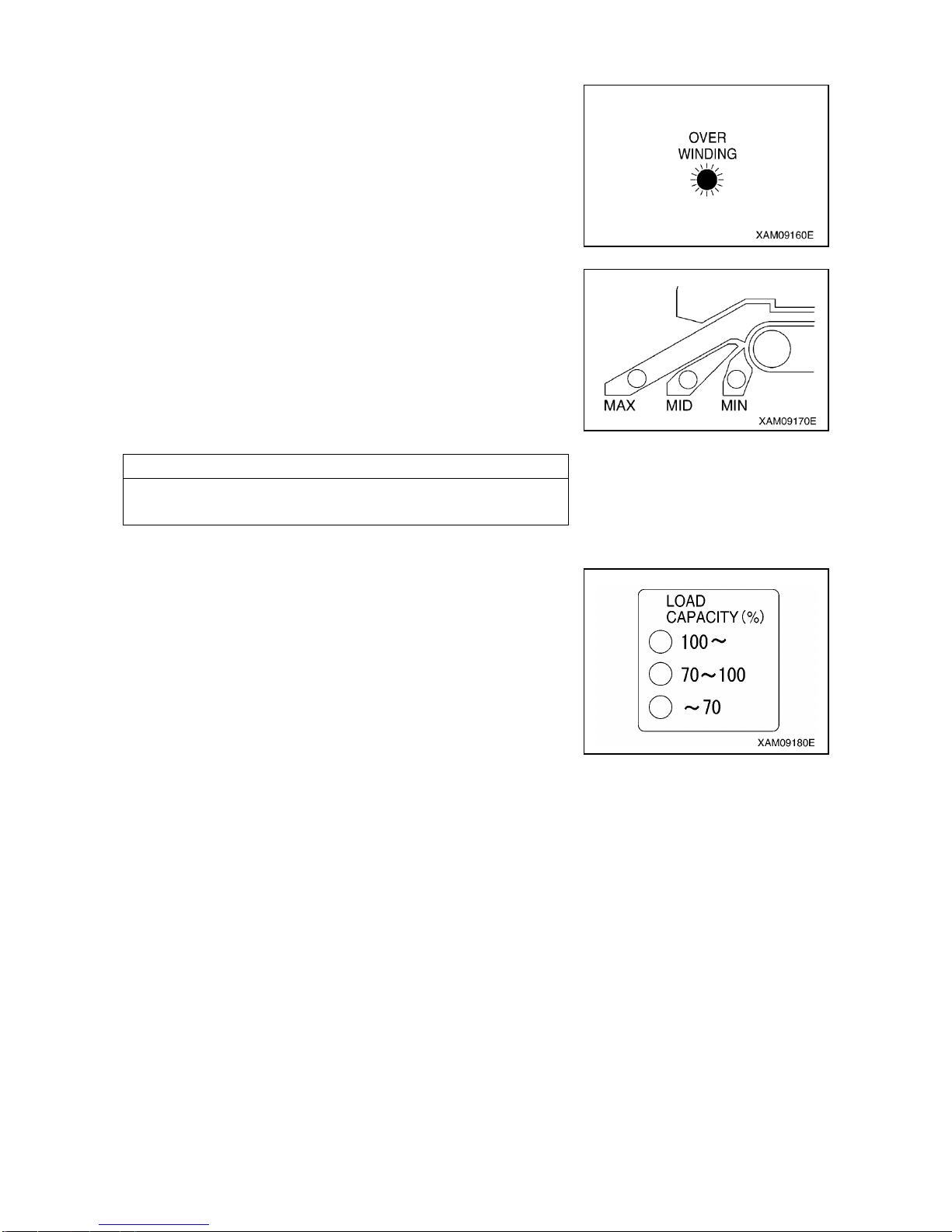

1.5 OVER HOIST DETECTOR

3-32

1.6 MACHINERY COVER

3-33

2. OPERATIONS

3-34

2.1 CHECKS BEFORE OPERATION

3-34

2.1.1 CHECKS BEFORE STARTING THE ENGINE (VISIBLE CHECKS)

3-34

2.1.2 CHECKS BEFORE STARTING THE ENGINE

3-37

2.1.3 CHECKS AFTER STARTING THE ENGINE

3-46

2.2 STARTING THE ENGINE

3-54

2.2.1 NORMAL ENGINE START

3-54

2.2.2 STARTING THE ENGINE WITH AUXILIARY STARTER SWITCH

3-56

2.2.3 STARTING THE ENGINE WITH RECOIL STARTER

3-58

2.3 OPERATIONS AND CHECKS AFTER STARTING THE ENGINE

3-59

2.4 BREAKING-IN MACHINE

3-61

2.5 MACHINE TRAVELLING POSITION

3-61

2.6 STARTING MOVING THE MACHINE

3-62

2.7 CHANGING MACHINE TRAVELLING MODE

3-63

2.8 CHANGING DIRECTION OF THE MACHINE

3-63

2.9 STOPPING/PARKING THE MACHINE

3-64

2.10 STOPPING THE ENGINE

3-65

2.11 INSPECTION AFTER STOPPING THE ENGINE

3-65

2.12 CAUTIONS WHILE DRIVING

3-66

2.13 OUTRIGGER SET UP OPERATION

3-68

2.13.1 NAME OF OUTRIGGER COMPONENTS

3-70

2.13.2 OUTRIGGER SET UP OPERATION

3-70

2.14 CAUTIONS BEFORE CRANE OPERATION

3-75

2.15 OPERATIONS BEFORE CRANE OPERATIONS

3-76

2.16 CRANE OPERATION POSITION

3-77

2.17 HOOK RAISING/LOWERING OPERATION

3-78

2.18 BOOM DERRICKING OPERATION

3-79

2.19 BOOM TELESCOPING OPERATION

3-80

2.20 SLEWING OPERATION

3-81

2.21 ACCELERATION OPERATION

3-82

2.22 CRANE STOWING OPERATION

3-83

2.23 OUTRIGGER STOWING OPERATION

3-85

2.24 DO’S AND DON’TS DURING CRANE OPERATIONS

3-91

3. HANDLING RUBBER TRACKS

3-93

3.1 GOOD USE

3-93

3.2 WARRANTY

3-93

3.3 PROHIBITIONS AND CAUTIONS WHEN USING RUBBER TRACKS

3-94

4. WHAT TO DO WITH TWISTED WINCH WIRE ROPE

3-97

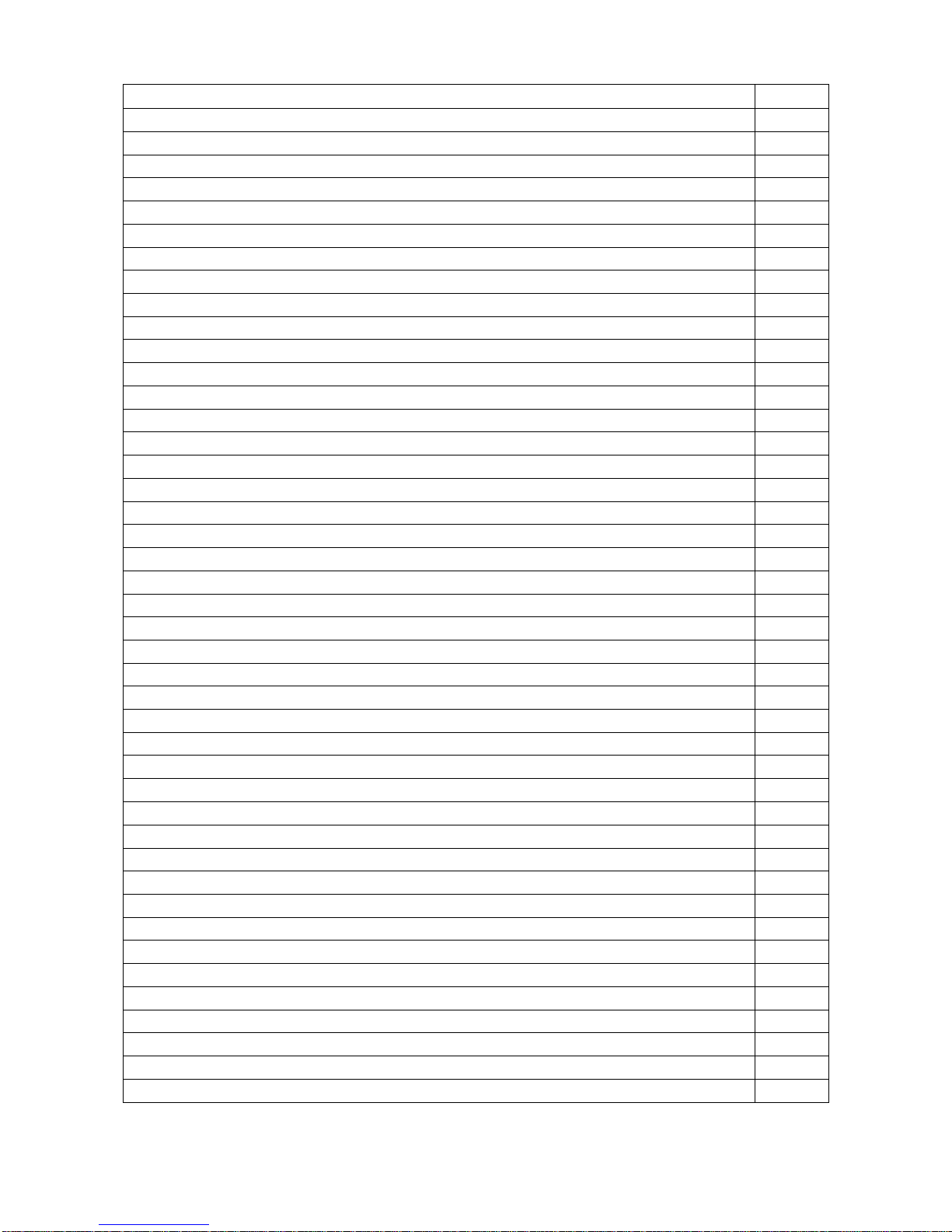

0-3

ITEM

Page

5. TRANSPORTATION

3-98

5.1 LOADING/UNLOADING

3-98

5.2 HOISTING MACHINE

3-99

5.3 CAUTIONS IN LOADING MACHINE

3-100

5.4 CAUTIONS DURING TRANSPORTATION

3-100

6. HANDLING IN COLD WEATHER

3-101

6.1 PREPARING FOR LOW TEMPERATURE

3-101

7. LONG-TERM STORAGE

3-103

7.1 BEFORE STORING THE MACHINE

3-103

7.2 DURING STORAGE

3-103

7.3 AFTER STORAGE

3-103

8. HANDLING THE BATTERY

3-104

8.1 CAUTIONS IN HANDLING BATTERY

3-104

8.2 REMOVING/INSTALLING THE BATTERY

3-105

8.3 CAUTIONS WHEN CHARGING THE BATTERY

3-106

8.4 STARTING THE ENGINE WITH BOOSTER CABLE

3-107

9. TROUBLESHOOTING

3-109

9.1 ELECTRICAL COMPONENTS

3-109

9.2 MACHINE BODY

3-109

9.3 ENGINE

3-110

INSPECTION AND MAINTENANCE

4- 1

1. PRECAUTIONS FOR MAINTENANCE

4- 2

2. BASIC MAINTENANCE

4- 4

3. LEGAL INSPECTION

4- 6

4. CONSUMABLES

4- 6

5. LUBRICATING OIL

4- 7

5.1 USE OF LUBRICATING OIL ACCORDING TO TEMPERATURES

4- 7

6. ACCESSORY TOOLS AND STANDARD TIGHTENING TORQUE

4- 8

6.1 ACCESSORY TOOLS

4- 8

6.2 STANDARD TIGHTENING TORQUE LIST

4- 8

7. INSPECTION AND MAINTENANCE LIST

4-10

8. MAINTENANCE PROCEDURES

4-12

8.1 INITIAL 10 HOUR MAINTENANCE

4-12

8.2 INITIAL 25 HOUR MAINTENANCE

4-12

8.3 INITIAL 50 HOUR MAINTENANCE

4-12

8.4 INITIAL 200 HOUR MAINTENANCE

4-12

8.5 CHECKS BEFORE OPERATION

4-12

8.6 IRREGULAR MAINTENANCE

4-13

8.7 MAINTENANCE EVERY 50 HOURS

4-24

8.8 MAINTENANCE EVERY 100 HOURS

4-30

8.9 MAINTENANCE EVERY 250 HOURS

4-30

8.10 MAINTENANCE EVERY 500 HOURS

4-31

8.11 MAINTENANCE EVERY 1000 HOURS

4-33

0-4

ITEM

Page

SPECIFICATIONS

5- 1

1. SPECIFICATIONS

5- 2

2. OVERALL DIMENSIONS

5- 4

3. OUTRIGGER SPREAD DIMENSIONS

5- 5

4. RATED TOTAL LOAD CHART

5- 6

5. WORKING RANGE

5- 9

REMOTE CONTROL

6- 1

1. OUTLINE OF REMOTE CONTROLLER

6- 2

1.1 FEATURE

6- 2

1.2 CONFIGURATION

6- 2

1.3 FUNCTIONS OF REMOTE CONTROL SYSTEM

6- 3

2. SAFETY PRECAUTIONS

6- 4

2.1 FOR SAFETY OPERATIONS

6- 4

2.2 PRECAUTIONS FOR CRANE OPERATION

6- 6

2.2.1 PRIOR TO STARTING ENGINE

6- 6

2.2.2 SUBSEQUENT TO STARTING ENGINE

6- 7

2.2.3 TERMINATING THE OPERATION

6- 7

3. LOCATIONS OF SAFETY LABELS

6- 8

4. COMPONENTS OF THE TRANSMITTER

6-10

5. COMPONENTS OF THE RECEIVER

6-15

5.1 COMPONENTS OF THE RECEIVER

6-15

5.2 FUSE IN THE RECEIVER

6-17

6. MODE SETTING OF THE TRANSMITTER

6-18

6.1 A MODE

6-18

6.1.1 OPENING A MODE SCREEN

6-18

6.1.2 MESSAGES IN THE A MODE SCREEN

6-18

6.1.3 AN EXAMPLE FOR SETTING IN THE A MODE

6-22

6.2 PROCEDURE IN THE OPERATION MODE

6-23

6.2.1 CALL OUT CRANE MODE

6-23

6.2.2 CALL OUT OUTRIGGER MODE

6-24

7. CHECKING BEFORE OPERATION

6-26

7.1 CHECKING BEFORE STARTING ENGINE

6-26

7.1.1 CHECKING BEFORE TURNING ON THE TRANSMITTER

6-26

7.1.2 CHECKING AFTER TURNING ON THE TRANSMITTER

6-27

7.1.3 CHECKING RECEIVER

6-31

7.2 CHECKING AFTER STARTING ENGINE

6-32

7.2.1 VERIFICATION FOR THE ENGINE START AND STOP

6-32

7.2.2 CHECKING “OUTRIGGER MODE” OPERATION

6-33

7.2.3 CHECKING “CRANE MODE” OPERATION

6-35

8. OPERATION

6-38

8.1 CAUTIONS BEFORE OPERATION

6-38

8.2 OPERATION IN OUTRIGGER MODE

6-39

8.2.1 OUTRIGGER SETTING

6-41

8.2.2 OUTRIGGER STOWING

6-43

0-5

ITEM

Page

8.3 OPERATION IN CRANE MODE

6-44

8.3.1 SLEWING OPERATION

6-46

8.3.2 BOOM TELESCOPING

6-46

8.3.3 HOOK RAISING AND LOWERING

6-47

8.3.4 BOOM DERRICKING

6-47

8.3.5 SET-UP AND CANCEL MICRO SPEED

6-48

8.3.6 ENGINE STOP AND EMERGENCY STOP PROCEDURE

6-50

8.3.7 ENGINE START AND RESET PROCEDURE

6-50

8.4 CHECKING AFTER CRANE OPERATION

6-51

9. TROUBLE SHOOTING

6-52

9.1 BEFORE TROUBLE SHOOTING

6-52

9.2 ERRORS IN THE REMOTE CONTROL DEVICES

6-53

10. SYSTEM SPECIFICATIONS

6-55

0-6

1-1

INTRODUCTION

1. INTRODUCTION

1- 2

2.FOR SAFE USE OF MACHINE

1- 3

3. MACHINE OVERVIEW

1- 4

4. QUALIFICATION FOR OPERATION

1- 6

5. TERMINOLOGY

1- 7

1-2

1. INTRODUCTION

Thank you for purchasing our Mini Crawler Crane “MC-174CRM”.

This manual is a guidebook for the safe and effective use of this machine.

This manual describes the procedures for proper operation and maintenance of the machine.

Warnings and precautions defined in this manual must be observed for safety.

Accidents are caused when operation, inspection, or maintenance is not followed according

to these guidelines.

Be sure to read this manual and understand the procedures for machine operation,

inspection, and maintenance thoroughly before operating this machine.

Failure to observe the basic precautions defined in this manual may lead to hazardous

accidents.

Failure to use this machine properly can lead to serious personal injury or death.

Operators and maintenance personnel must always read this manual prior to

operation or maintenance of this machine.

Save this manual at a designated place for reference when necessary. All personnel

who work on this machine are to carry out periodic reference.

• Only those who have a thorough understanding of the fundamental procedures

provided in this manual are qualified to perform machine operation.

• Keep this manual handy for reference when necessary.

• Should you lose or damage this manual, contact Maeda or our sales service

agency immediately for ordering a new manual.

• This manual should always accompany this machine upon transfer of the machine

to the next owner.

• This manual has adopted data that was available at the time of the creation of the

manual.

The contents of this manual, including maintenance specifications, tightening

torque, pressure, measuring method, adjustment value, and illustrations, are

subject to change upon unremitting refinement of the machine, without notice.

Machine maintenance may be susceptible to revisions. Always obtain the latest

information from Maeda or our sales service agency before performing

maintenance of this machine.

For safety instructions, see “2. For Safe Use of Machine” on page 1-3 and “Safety”

on page 2-1.

1-3

2. FOR SAFE USE OF MACHINE

This manual classifies the risks into the following three categories to present the details of the safety

labels in easy-to-understand manner.

This denotes that there is an imminent hazard which will cause serious

personal injury or death.

Follow instructions to avoid danger.

This denotes that there is a hazard which can cause serious personal injury

or death.

Follow instructions to avoid danger.

This denotes that there is a potential hazard which may cause minor or

moderate personal injury or serious damage to this machine.

Follow instructions to avoid danger.

This manual also provides the following to indicate what must be observed for the sake of the machine

and what will be of help.

This denotes that failure to handle the machine properly may damage the

machine or shorten its life.

This denotes helpful information.

This manual covers not only procedures for operation, inspection, and maintenance of this machine, but

also safety precautions where this machine is only used for specified tasks.

Not every event is foreseeable and therefore, cautions given in this manual and on this machine do not

necessarily cover every safety-related issue.

The result of operation, inspection, and maintenance carried out in a way that is not described in this

manual are your responsibility.

Even in the above case, never attempt any work or operation that this manual prohibits you to do.

CAUTION

NOTES

1-4

3. MACHINE OVERVIEW

3.1 SPECIFIED OPERATIONS

This machine is to be used for operation listed below.

• Crane operation

This machine is a mobile crane with a rubber track travelling dolly (carrier) mounted with a boom crane.

This self-propelled crane is capable of moving (travelling) in the worksite and craning an object weighing

within the rated total load.

This is also a remote-controlled crane.

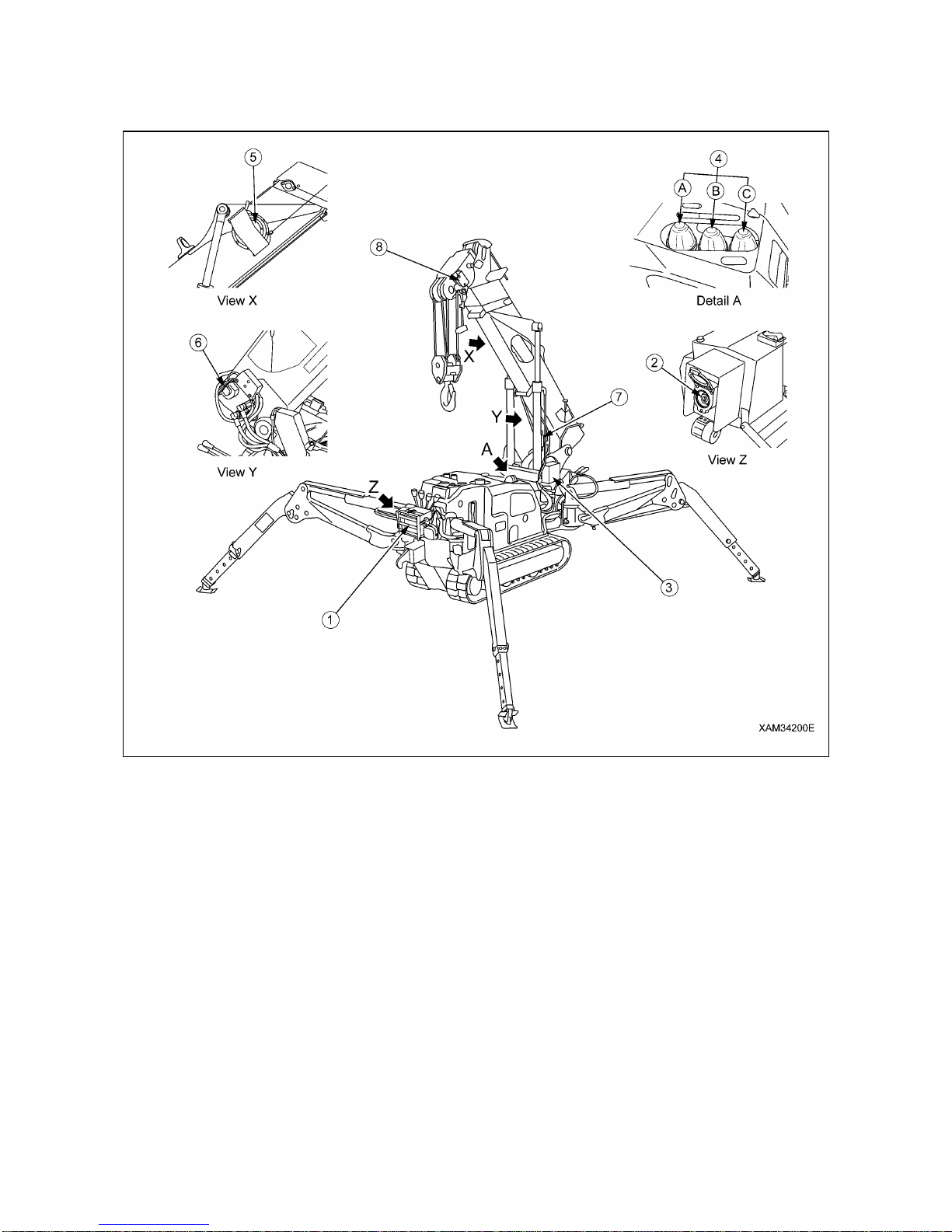

3.2 MACHINE CONFIGURATION

(1) Travelling dolly

(2) Crane

(3) Safety device

Viewed from the operator’s seat, the front, back, left, and right of the

machine are determined in this manual, viewing in the travelling

direction (front) of the machine.

Boom slewing motion is determined with the machine viewed from

immediately above; slew clockwise denotes right-handed motion and

slew counterclockwise denotes left-handed motion.

EXTERNAL VIEW

1-5

This machine is composed of the units listed below.

[1] TRAVELLING DOLLY

This is composed of a travelling gear, engine, travelling operation unit, and crane operation unit.

[2] CRANE

This is composed of a telescoping system, derrick system, hook block, winch system, and outrigger

system.

[3] SAFETY DEVICE

This is composed of the following parts and devices: Over hoist detector/automatic stop device, angle

indicator, hydraulic safety valve, hydraulic automatic locking device, slinging rope detachment protector,

alarm buzzer, audio alarm, level, crane tip-over alarm (an alarm issued in the event of the crane operation

at 3-degree inclination and travelling at 15-degree inclination), travelling lever lock, travelling/crane

selector switch (designed to prevent the machine from craning at travelling), moment limiter (working

envelope limited), working status lamp.

3.3 MACHINE FUNCTIONS

[1] TRAVELLING DOLLY

• This is a compact machine designed to keep the overall width between the crane and outrigger

minimized with them housed (in travelling position).

This compact design is ideal for work in confined areas.

• Two-travelling lever operation enables not only direction changes among forward, backward, and

right/left but pivot turn and spin turn.

[2] CRANE

• An automatic slide outrigger is included in the crane to permit outrigger extension and grounding from

the operator’s station.

• Through the combined use of telescoping, derricking, slewing, and winch system operation, the crane is

capable of raising or lowering the hook block and moving an object weighing within the rated total load

to a designated position within the confines of the working envelope.

• Remote-control units allow remote outrigger setting and remote crane operation.

1-6

4. QUALIFICATION FOR OPERATION

• A high incidence of occupational accidents in crane operation has been reported.

Be aware that experienced engineers are also no exception.

• Warnings and precautions defined in this manual shall be observed for safety assurance

during operation of the machine.

4.1 QUALIFICATION FOR CRANE OPERATION

Only personnel that have obtained the correct training or license stipulated by laws and regulations

applicable to the place of use are qualified to operate this machine.

Contact the relevant government office or our sales service agency for further information.

1-7

5. TERMINOLOGY

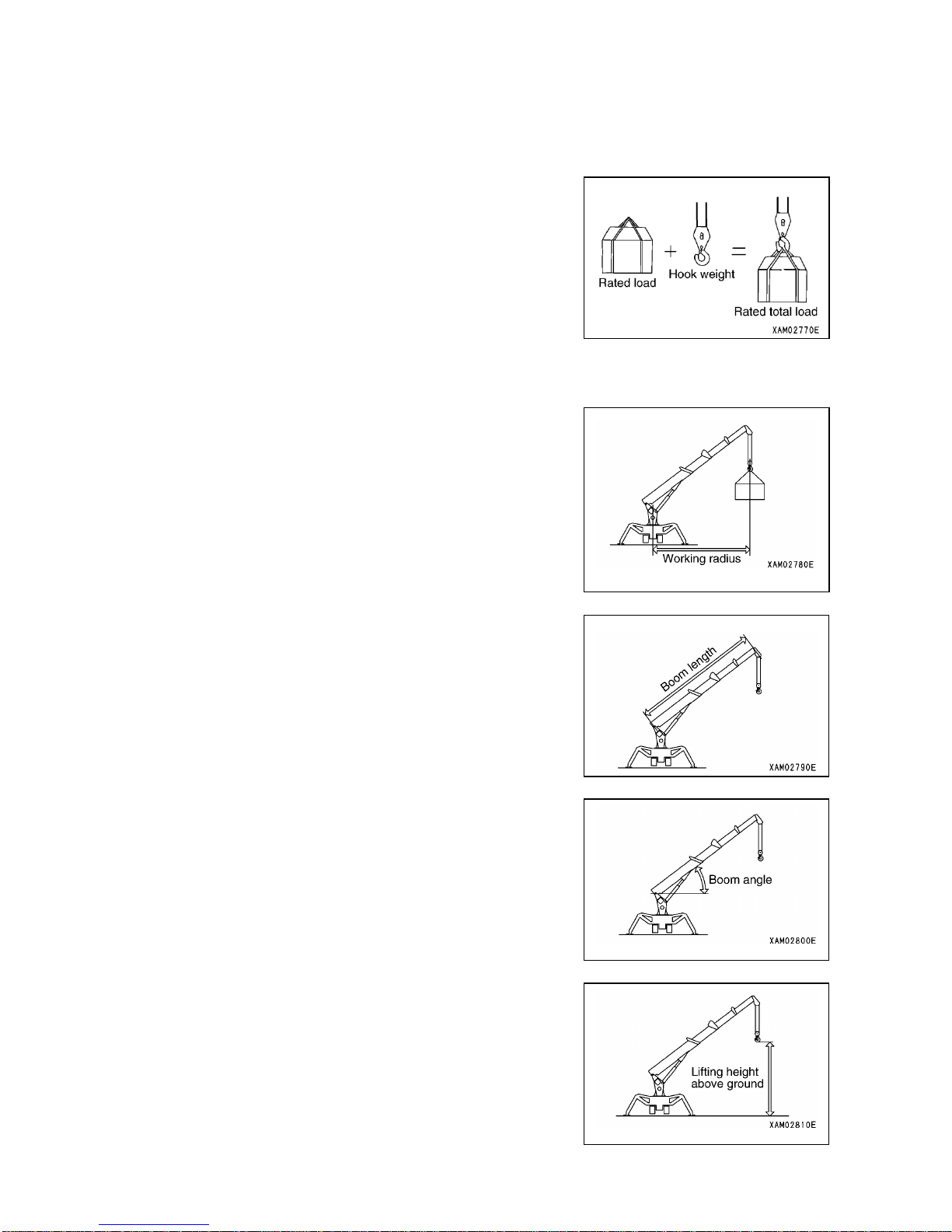

5.1 DEFINITION OF TERMS

[1] RATED TOTAL LOAD

This is the maximum load that can be applied according to a boom

length and angle. The load includes the mass (weight) of hoisting

accessories (hooks) and slinging ropes.

[2] RATED LOAD

This is a load derived by subtracting the mass (weight) of hoisting

accessories (hooks) and slinging ropes from the rated total load,

which is a withstand load for hoisting.

[3] WORKING RADIUS

This is a horizontal distance between the axis of slewing and the

hook center.

[4] BOOM LENGTH

This is a distance between the boom primary pin and the sheave

pin of the end boom.

[5] BOOM ANGLE

This is an angle which the boom forms with the horizontal plain.

[6] LIFTING HEIGHT ABOVE GROUND

This is a vertical distance between the hook bottom and the ground

with the hook raised to the upper limit.

1-8

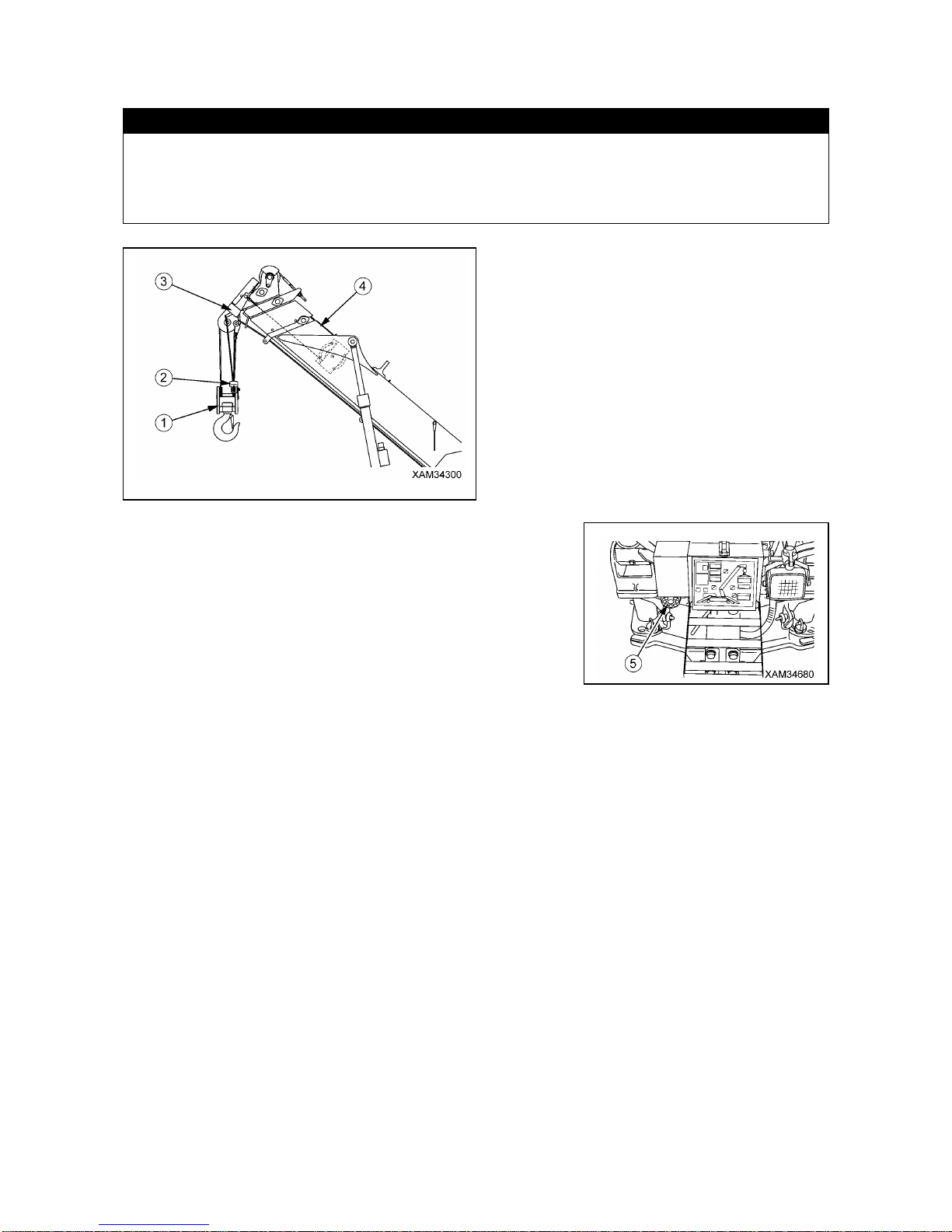

5.2 DIAGRAM OF WORKING RADIUS AND LIFTING HEIGHT

• The diagram of working radius and lifting height shows the relationships between the working

radius of this machine, boom angle, and lifting height above the ground with no object

hoisted. The diagram has been made allowing for no deflection in the boom.

• The boom (4) in the diagram of working radius and lifting height represents a state that half of

the “ mark” passes boom (3).

1. Point A denotes a boom angle and point B denotes a lifting

height above ground in the figure at right.

The same working radius is applied to points A and B.

2. The “diagram of working radius and lifting height” shows the

relationships the working radius, boom angle, and lifting

height at no load, allowing for no deflection in the boom.

A deflection occurs in the boom when an object is hoisted,

which causes the working radius to widen slightly.

The rated total load decreases with increase in the working

radius. Actual crane operation requires the planning of work,

allowing for sufficient clearance more than that provided in

the diagram.

1-9

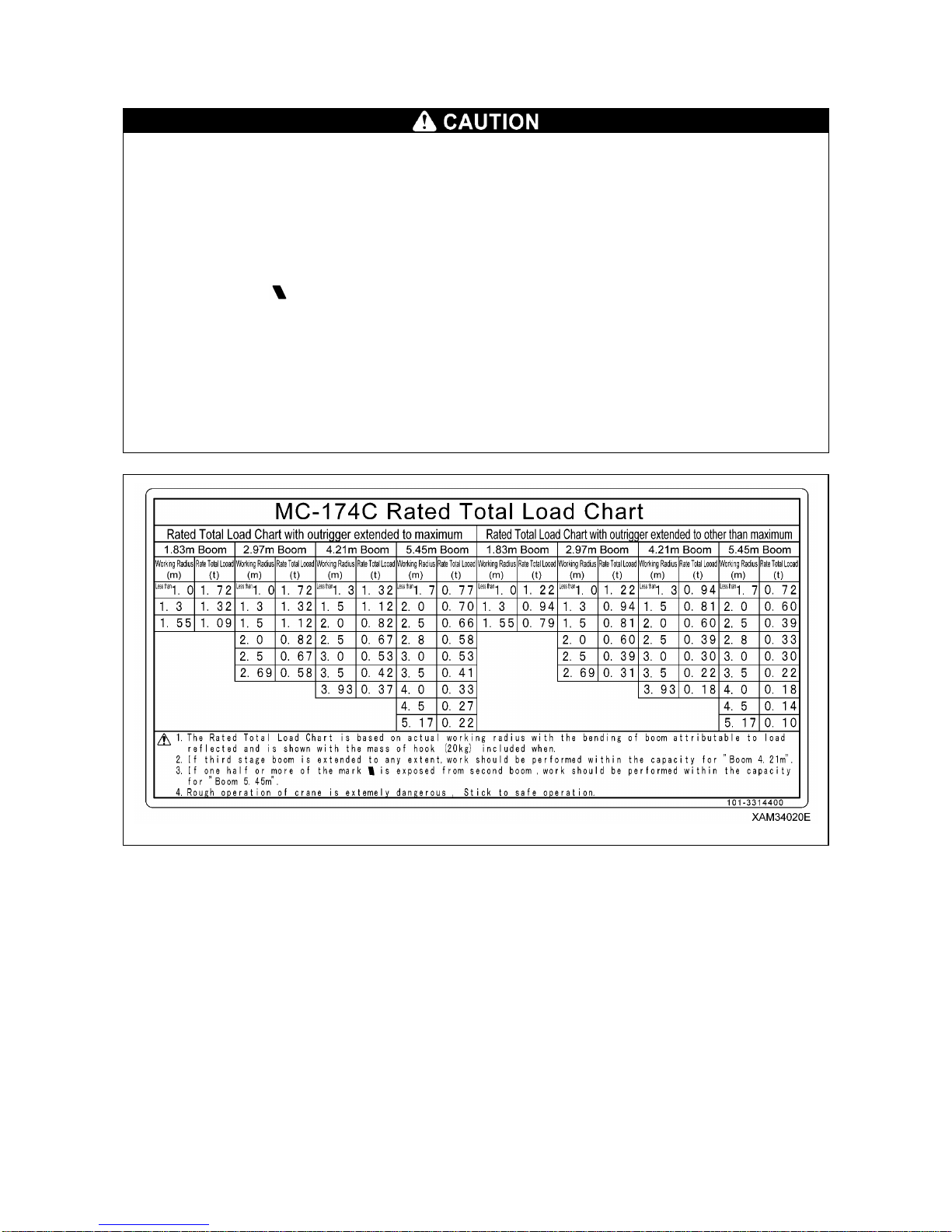

5.3 TOTAL RATED LOAD CHART

• All the values provided in the total rated load chart are based on the assumption that the

machine is placed on a level and firm surface.

The machine may topple over if proper outrigger setting or ground condition fails to be

assured. Exercise due caution when performing crane operation.

• The values in the total rated load chart are determined based on the working radius allowing

for deflection that is developed when load is applied to the boom.

• When extending 3rd boom even if only slightly, crane operation should proceed to the extent

of performance of “4.21m Boom”.

• When half of the “ mark” passes 2nd boom, crane operation should proceed to the extent of

performance of “5.45m Boom”.

• If the working radius exceeds that stated in the table even if only slightly, crane operation

should proceed with respect to the rated total load corresponding to the working radius in the

following table.

• The rated total load is a load including the mass of a hoisting accessory (hook: 20kg).

• When the crane is used with the outriggers extended other than at the maximum, crane

operation should proceed with respect to the values specified in the total rated load chart

corresponding to Rated Total Load Chart with outrigger extended to other than Maximum.

1-10

The total rated load chart provides the maximum loads that the crane is capable of hoisting objects in

parallel with the length of the boom. The loads are specified by working radius.

[1] BOOM LENGTH

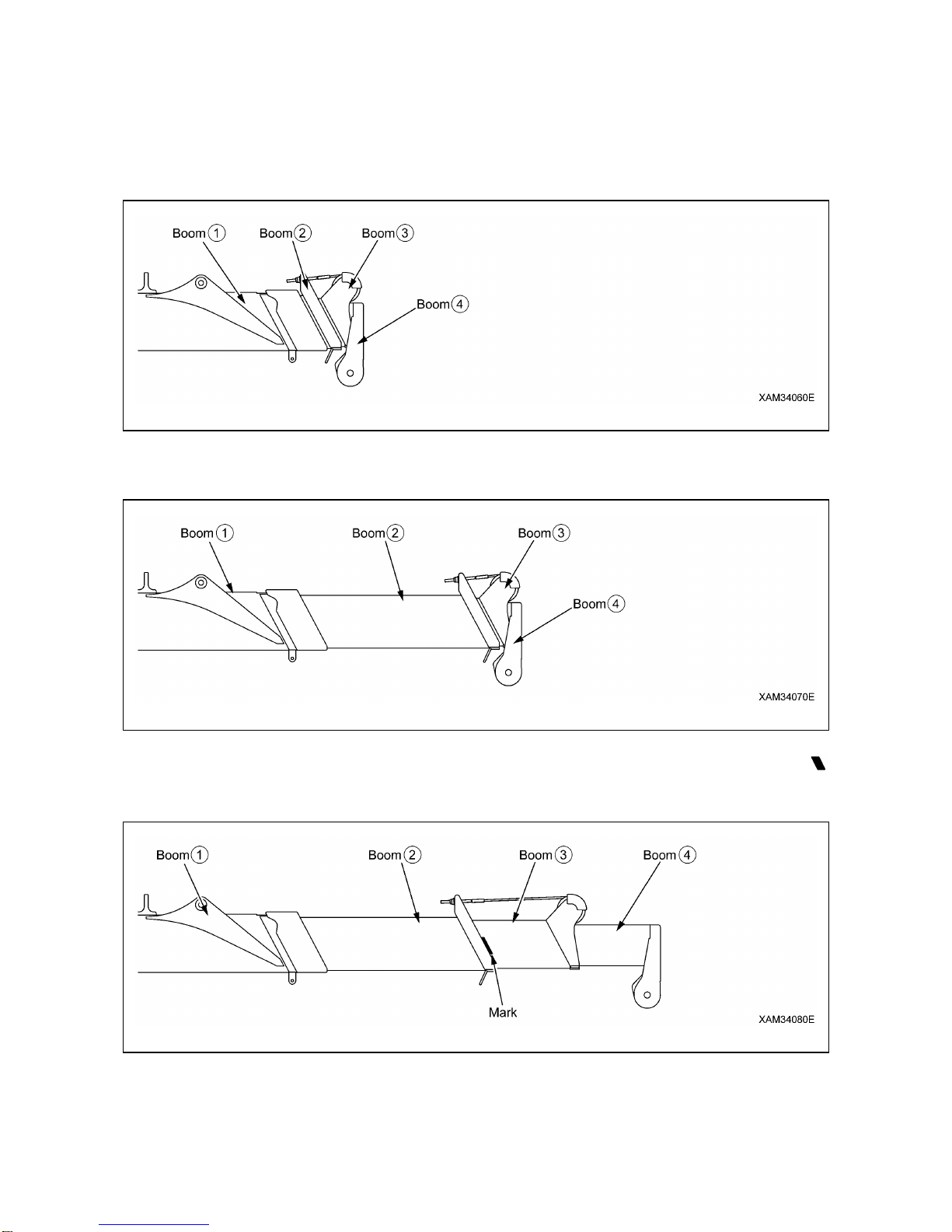

The following figures illustrate the condition of the booms, “1.83m Boom”, “2.97m Boom”, “4.21m Boom”

and “5.45m Boom” in the preceding boxes in the total rated load chart.

1. “1.83m Boom”: All the booms are retracted.

2. “2.97m Boom”: With booms (3) and (4) retracted, boom (2) is fully extended.

“2.97m Boom” is to apply to crane operation with boom (2) extended even if only slightly.

3. “4.21m Boom”: With booms (2) fully extended, booms (3) and (4) are extended midway (half of the “

mark” passes boom (2)).

“4.21m Boom” is to apply to crane operation with booms (3) and (4) extended even if only slightly.

1-11

4. “5.45m Boom”: All the booms are fully extended.

“5.45m Boom” is to apply to crane operation with half of the “ mark” on boom (3) passes boom (2).

1-12

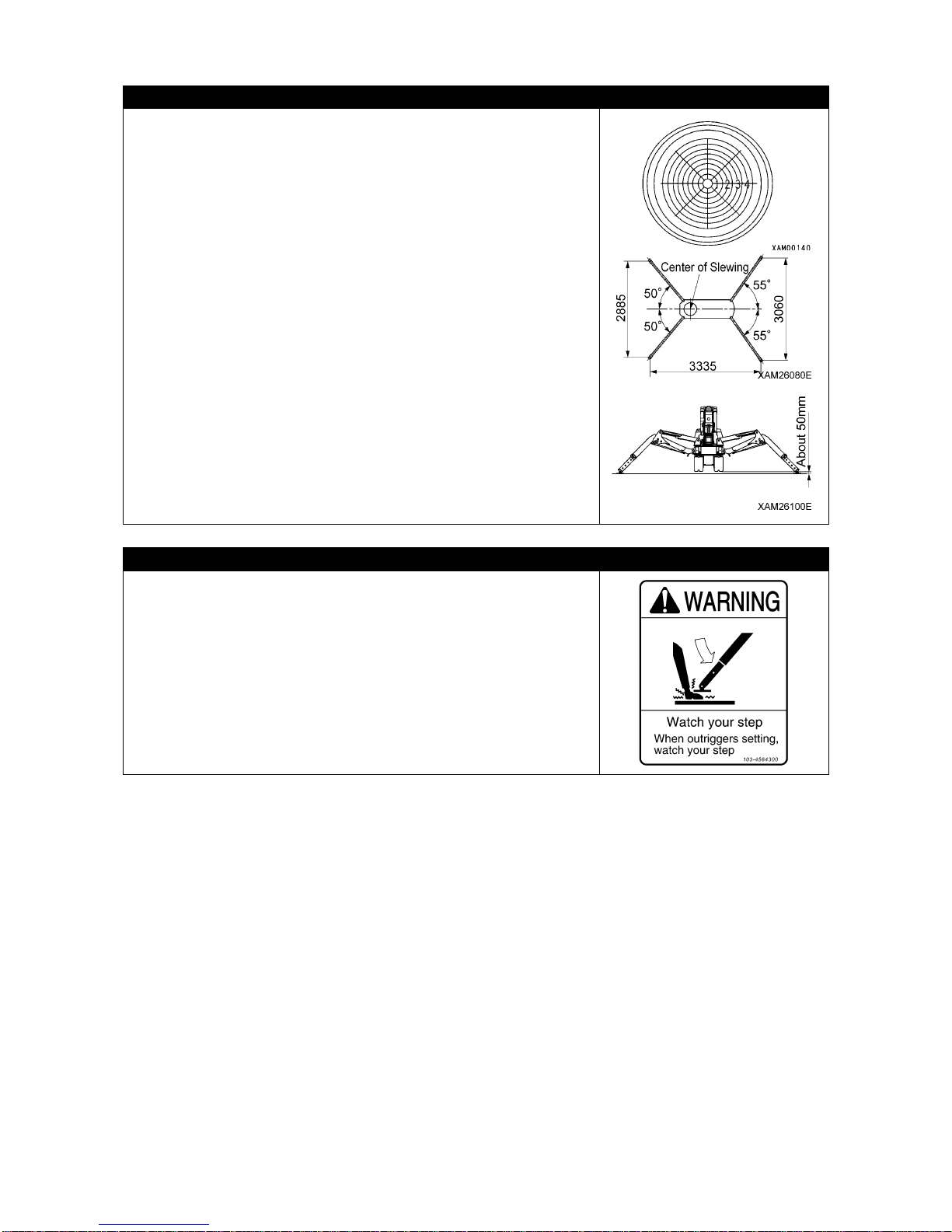

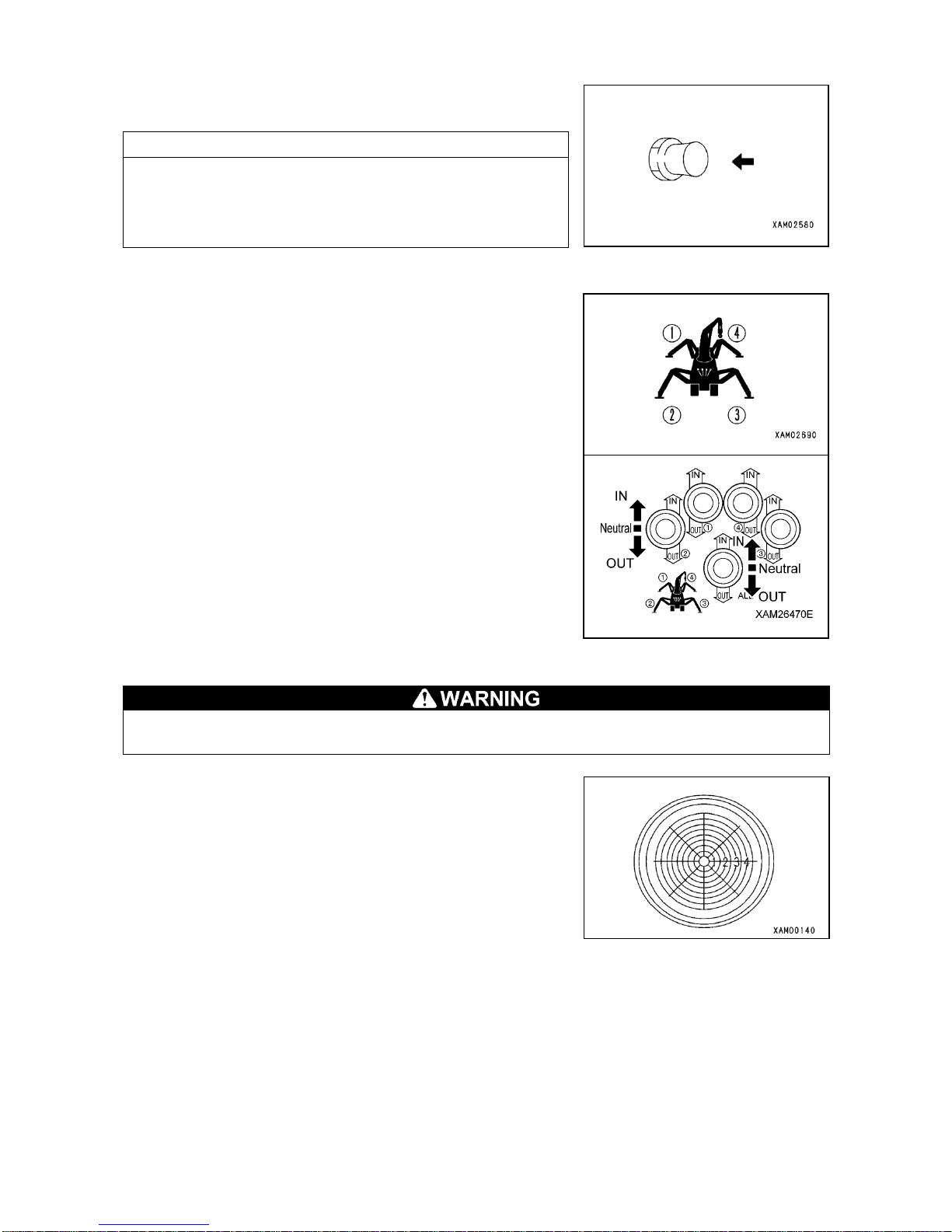

[2] OUTRIGGER MAXIMUM EXTENSION

• Make sure all the outriggers are placed in the correct position before performing crane

operation.

It is strictly forbidden to perform any crane operation before you place outriggers.

• Always place the machine in a horizontal position with the use of the level when extending the

outriggers. A warning buzzer sounds when the machine is inclined 3° or more and stops when

the machine is placed in a horizontal position.

• Where a crane operation in a condition that outriggers are not fully extended is required, see "

Rated Total Load Chart with outrigger extended to other than Maximum" of the Rated Total

Load Chart. Failure to perform crane operation with proper values may cause the machine to

topple over. Exercise caution when performing operation.

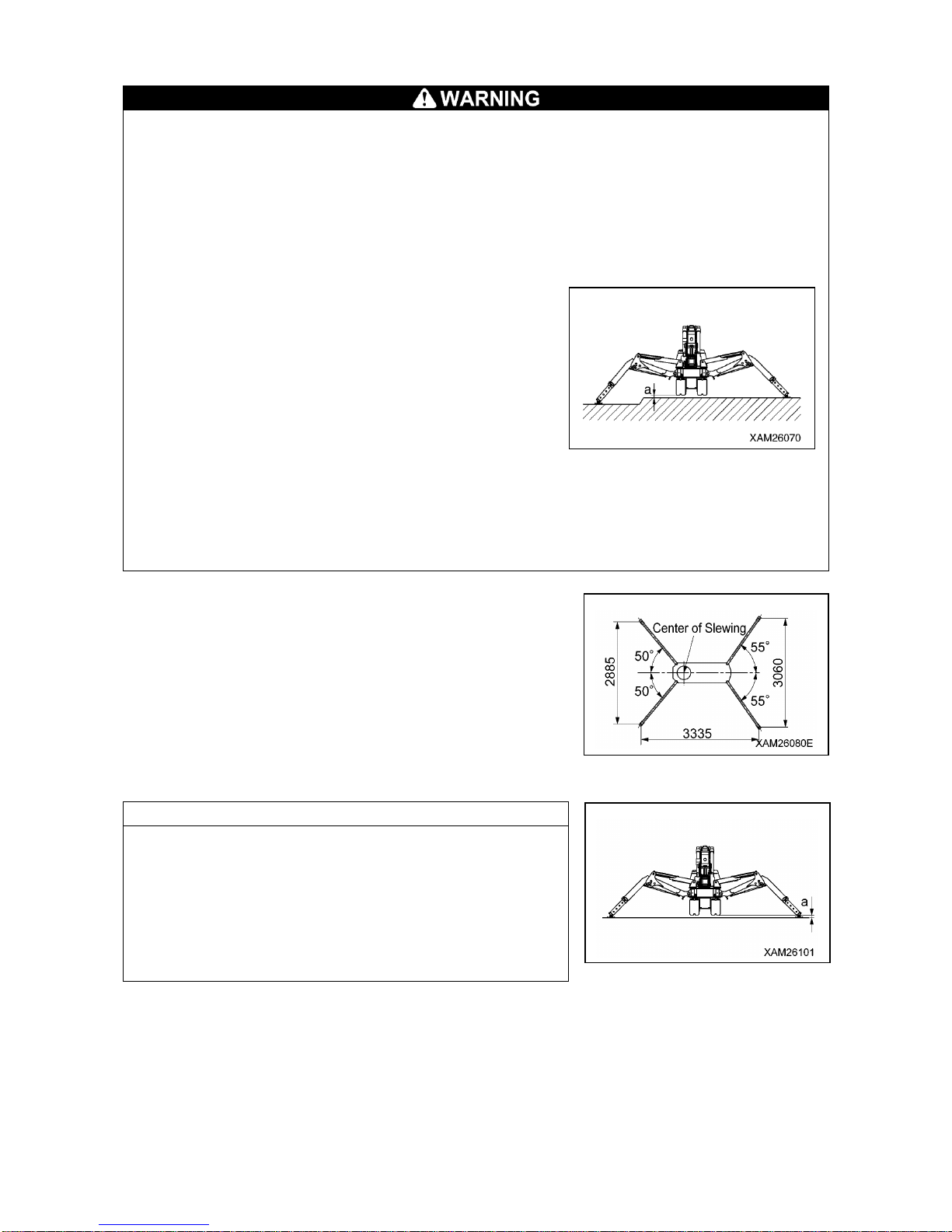

• Despite the maximum extension of all the outriggers, the

width of extended outriggers decreases due to an

ungraded ground even when clearance "a" in the right

figure is 50 mm. Crane operation should proceed with

respect to the values specified in “When the crane is

used with the outriggers extended midway” in the total

rated load chart.

• Where any of the outrigger inner box is retracted into the

outer box, only " Rated Total Load Chart with outrigger

extended to other than Maximum " of the Rated Total

Load Chart is applicable for that crane operation, even

when it is retracted for the length of 1 position pin span.

• The machine becomes unsteady at some point if it undergoes a 360-degree slewing with an

object hoisted. Irrespective of the rated total load, ensure operation is in a short working

radius and at low speed.

The diagram shown on the right represents the condition “When

the crane is used with the outriggers extended at the maximum” in

the total rated load chart.

If the inner box is retracted even if only slightly, crane operation

should proceed with respect to the values specified in the total

rated load chart corresponding to “Rated Total Load Chart with

outrigger extended to other than Maximum”.

See "OPERATION 2.13 OUTRIGGER SET UP OPERATION” for

proper setting of the outriggers.

NOTES

Outrigger maximum extension is defined as that:

1. The outrigger is set at the positioning pin position (55 degrees

front, 50 degrees back).

2. The inner box of all the outriggers is extended fully.

3. All the outriggers are placed on a level surface.

4. Approx. 50mm is assured for clearance "a” (between the

outrigger bottom and crawler bottom) as shown in the figure to

the right.

1-13

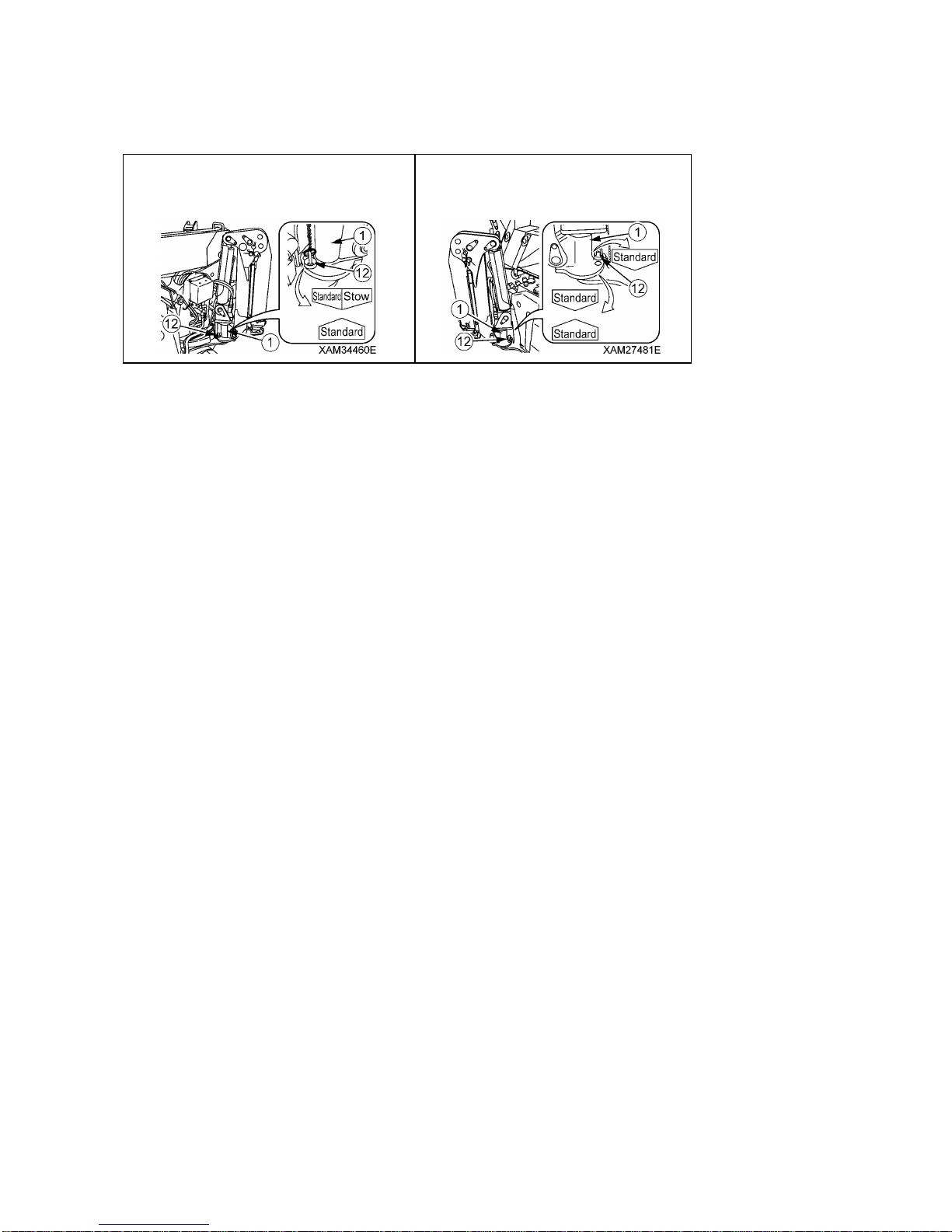

[Placement of outrigger position pins when "outriggers are extended to maximum".]

Figures below shows the placement of outrigger position pins (12) in a condition that "outriggers are

extended to maximum"

The left rear outrigger.

(The right rear outrigger is symmetrical.)

The left front outrigger.

(The right front outrigger is symmetrical.)

1-14

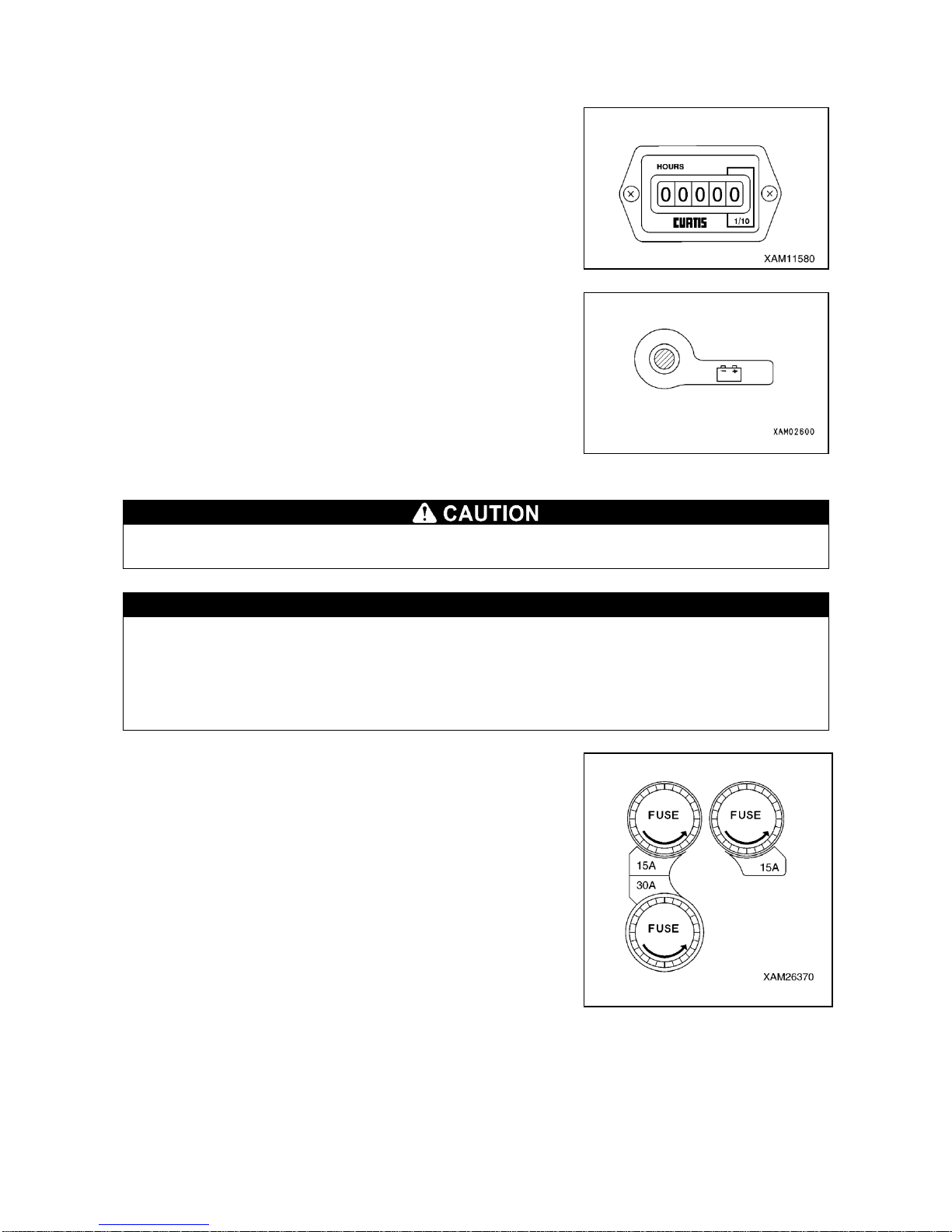

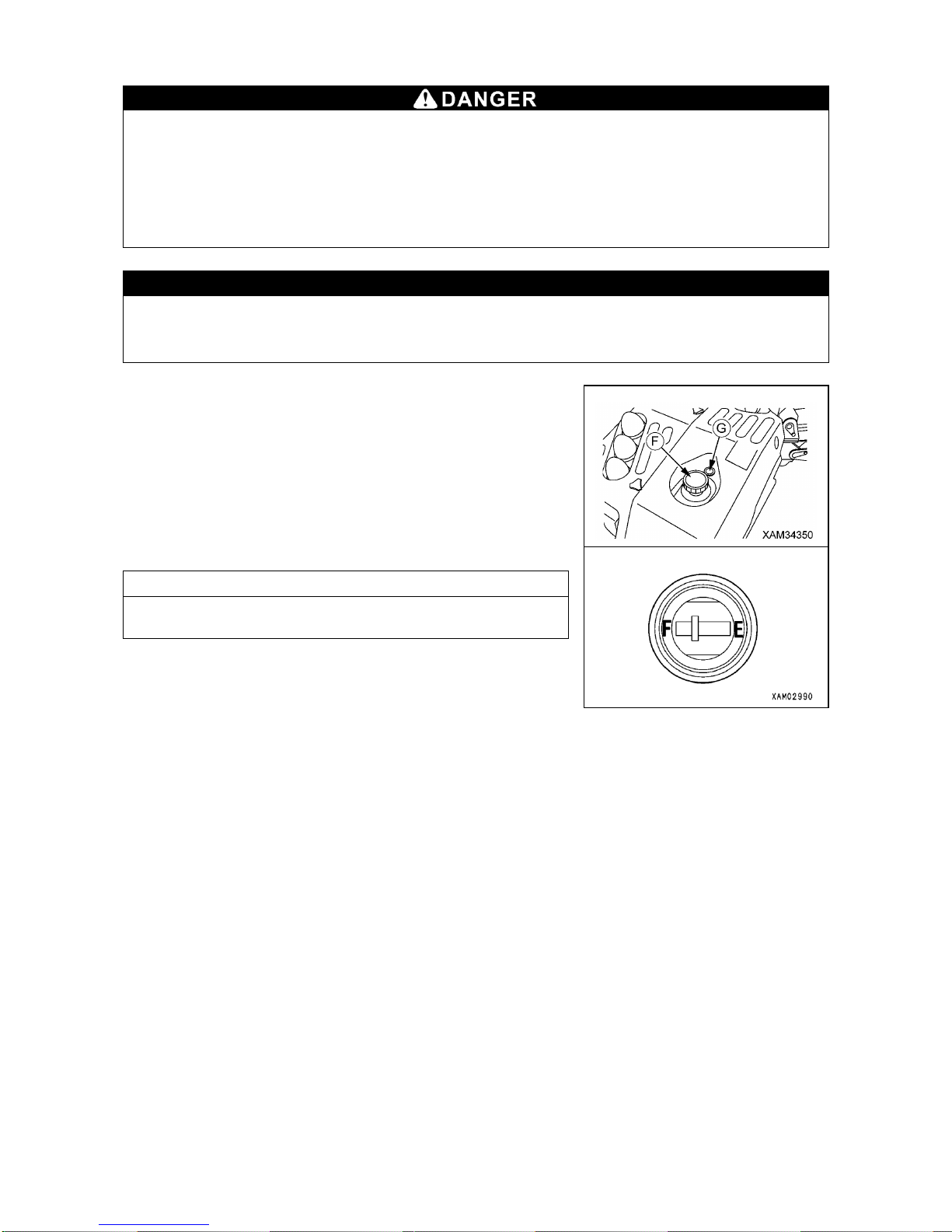

5.4 ANGLE INDICATOR

• Use the Boom angle indicator to check the angle of the boom in operation when the crane is

operated from a distance; using a remote-controller, for instance.

• Before hoisting a load, always see the Rated Total Load Chart to determine the correct boom

length (i.e. number of boom boxes used) and angle, then check the actual weight of the load

with the applicable rated total load and ensure that weight of both of the load itself and sling

utensils never exceeds the rated total load. The Boom angle indicator is helpful to confirm the

boom angle, then,

The Boom angle indicators are attached to both

left and right sides of the No.1 Boom. The

indicator consists of a scale plate and a pointer

as shown in the figure on the right.

Use boom angle indicators as follows:

• Read the figure which the pointer indicates.

The figure shows the "Boom angle" of the

moment.

2-1

SAFETY

1. BASIC PRECAUTIONS 2- 2

2. DRIVING RELATED PRECAUTIONS 2- 7

3. TRANSPORT PRECAUTIONS 2-21

4. BATTERY HANDLING PRECAUTIONS 2-23

5. MAINTENANCE PRECAUTIONS 2-25

6. SAFETY LABEL LOCATIONS 2-32

7. WEEE DIRECTIVE LABEL LOCATIONS 2-39

All the safety precautions defined in this manual should

always be read and observed.

Failure to follow the safety precautions can cause serious

personal injury or death.

2-2

1. BASIC PRECAUTIONS

OBSERVE THE MANUAL AND SAFETY LABELS

• Read thoroughly and understand this manual as well as the safety

labels on various part of this Machine. Attempting to drive/operate

without understanding fully may result in wrong operation that may

cause personal or equipment accidents.

• Fully understand the proper use and inspection/maintenance

procedures, and exercise safe working.

• Make sure this manual and the safety labels labeled on various part

of this Machine are legible all the time.

Whenever illegibility or loss occurs, contact us or our sales service

agency to put the safety label back to the original loca tion.

DRIVING LICENSE

• Full training or a License are necessary to drive this Machine.

Always obtain training or a license before driving.

See “Introduction 4. Qualification for Operation” for details

• Drivers are reques ted to receive educat ion and training of the handling methods and other subjects

from the applicable office, and obtain sufficient driving operation skill before work.

WEAR PROTECTIVE EQUIPMENT AND CLOTHES SUITABLE FOR WORK

• Always put on a helmet, safety shoes and safety belt.

• Select and make sure to put on necessary protective equipment

suitable for the relevant working condition.

• Do not wear loose garments or accessories that may catch

operation levers or protrusions and cause unexpected movement of

the Machine.

COMMIT TO SAFE OPERATION

•Obey the instructions and signs given by the manager and work supervisor, and observe safety first

during the work.

• Obey the crane work basics during work.

• Before starting driving or work, always carry out the inspections.

• Do not work in bad weather for instance strong wind, thunder or mist.

• Do not drive under any circumstances when you are overtired, under the influence of alcohol or after

taking a somnific drug.

• Obey all of the workplace rules, safety regulations and operation method sequences during driving

operations and inspection/maintenance.

• Pay attention to the surrounding conditions and pedestrians all the time when driving or working.

Whenever a pedestrian approaches without taking due care, stop working straight away, and take a

measure such as issuing a warning.

• When driving, be mentally prepared for any unexpected situation and so that you can take measures

immediately.

• Do not attempt any use out of the capabilities and purposes described in this manual under any

circumstance.

• Observe the designated rated total load and work range when driving.

• Do not attempt inattentive driving, harsh driving or awkward operation under any circumstances.

• Remove the key when leaving the machine.

2-3

USE OF MACHINE THAT WAS RENTED OR PREVIOUSLY USED BY SOMEONE ELSE

Check the following subjects in writing before using any Machine th at wa s rented or previo usly u sed by

someone else.

In addition, check the inspection record table for the maintenance conditions such as the periodic

inspections.

(1) Crane capacity

(2) Crane maintenance condition

(3) Behavior and disadvantage unique to the crane

(4) Other subjects that require attention when driving

(a) Operating conditi on of the brakes, crutches etc.

(b) Presence/absence and lighting condition. Checkup of lighting and rotating lamps

(c) Operation condition of hook, winches, boom, outriggers and related items

CHECK SAFETY DEVICES

• Check that all guards and covers are attached properly. Repair immediately if damaged.

• Understand how to use the safety devices well and use properly.

• Do not detach any safety device under any circumstan ces. Keep control to achieve pr oper function all

the time.

• Improper use of safety device may lead to serious bodily accidents.

• Do not trust safety device too much during operation.

FOLLOW INSTRUCTIONS AND SIGNS WHEN WORKING

• When working with the crane, appoint a work supervisor and agree

mutual signs beforehand, and follow the work supervisor and signs

during work.

• When working at a location where many areas are out of view from

the driver, be especially careful to follow the instructions and signs

of the work supervisor and pay attention when driving.

• When working with the crane, the clearance between the boo m and

the travelling dolly and also the gaps between the movable parts of

the derrick cylinder may catch body parts such as an arm or finger.

The driver is requested to make sure no one is within the working

radius of the crane before operating the crane.

PREPARE FOR ABNORMALITY

• Carry out secure inspections and services to prevent accidents.

• Whenever you feel abnormality of the Machine, abort working

immediately, ensure safety and report to the manager.

• Assign in advance who takes which solution to prevent a secondary

accident.

• Do not drive the Machine when fuel or hydraulic oil is leaking from

the Machine. Report to the manager the abnormality, and fully repair

the fuel/hydraulic oil problem before use.

This machine uses gasoline/LPG as its fuel. Pay particular attention

to any fuel leakage.

• Before leaving the Machine, lower the hoisted load to the ground,

stop the engine and remove the engine key.

2-4

TEMPORARY STORAGE WHEN ABNORMALITY IS FOUND WITH MACHINE

In case the Machine is found with an abnormality and is therefore

stored temporarily waiting for service, apply following measures to

notify all people in the office that its use is prohibited due to failure.

• Indicate warning tags on the crane operation lever and other

applicable parts.

Write clearly the information such as abnormality contents, name

and contact of the storage manager, and the term of storage.

• Keep immobile when parked by putting blocks on the rubber tracks

as pawls.

• Remove the engine key and take it with you.

PROVISION OF FIRE EXTINGUISHER AND FIRST AID BOX

Always observe followings to prepare for injuries and fires.

• To prepare for fires, decide the fire extinguisher storage location

and install one, fully read the attached label for the usage and be

prepared for fighting emergencies.

• Decide the location to store the first aid box. In addition, inspect the

first aid box periodically and replenish the contents as necessary.

• Decide the measures to take upon an injury or fire accident.

• Decide how to contact the emergency address (for instance the

emergency physician, ambulance or fire depa rtment), and show the

contact address at designated position so any person ca n make th e

contact.

DO NOT RUSH AND BE CAREFUL WHEN WORKING

• Do not attempt sudden lever operation or harsh driving.

• When two or more cranes work close to each other, drive carefully

while paying attention to accidents such as trips caused by

contacting each other. Also, appoint a guide if necessary for

increased prevention of contact accidents.

• When abnormality or danger occurs during work, abort working

immediately to avoid hazard.

• Stop work under in bad w eather conditions (heavy rain, strong wind,

thunder, thick fog).

Decide when to abort working by seeing the "work abort decision

standard" in the work schedule and by discretion of the work

supervisor of the site.

DO NOT MODIFY

Do not modify the Machine without our written consent under any circumstance.

The modification raises a safety issue, so consult us or our sales service agency beforehand.

We cannot be held responsible for any bodily accident or failure caused by modification that was

performed without consulting us.

2-5

SAFETY WHEN REFILLING FUEL

• This machine operates using gasoline/LPG.

Do not refill with the wrong kind of fuel.

Refilling with the wrong fuel may damage the engine.

• Always stop the engine before refilling fuel.

Refilling the fuel when engine is driving may ca use leaked fuel to

catch fire from hot muffler or other related parts.

• Oversupply of fuel results in spilling and is dan gerous. Refill slightly

lower than the specified level.

Always wipe away cleanly whenever the fuel spills.

• Securely close the tank cap after replenishing fuel.

KEEP FIRE AWAY FROM OIL

Attempt to let a fire approach the fuel, hydraulic oil or engine oil may

result in catching fire. Strictly observe the followings.

• Do not let any fire such as a cigarettes or matches near the

combustibles.

• Securely close all of the fuel and oil container caps.

• Keep the fuel and oils in well-ventilated location.

• Store the fuel and oils in a fixed location and keep unauthorized

persons away.

• Do not leave the site when replenishing the fuel or oil.

Be especially careful to observe "Safety when refilling fuel"

described earlier when replenishing fuel.

• Cleanly wipe away any fuel or oil spilled during replenishment.

HANDLING IN HIGH TEMPERATURE

For a short time after ceasing operation of the Machine, the engine

itself and engine oil, cooling water and hydraulic oil will have a high

temperature, and in addition the pressure is accumulated inside the

hydraulic oil tank.

Any attempt to inspect the engine, remove the radiator cap, drain oil,

drain water or replace the filter under such condition may result in

burns.

Wait until the temperature cools, then carry out the following

procedure.

1. To prevent emission of the high temperature oil, stop the engine

and wait until the oil temperature drops.

2. Loosen the bolts so that the cap is raised a little to allow the

release of inner pressure.

3. Remove bolts and then remove cap.

(To find how much the oil temperature dropped, hold your hand near

the surface of the hydraulic oil tank or similar location without actually

contacting and find out from the ambient temperature.)

2-6

BEWARE OF ASBESTOS DUST

Inhalation of air containing asbestos may result in lung cancer. This

Machine does not use any asbestos, but asbe stos may be contained

in the wall, ceiling or other part of construction within the work area o f

this Machine. In addition, be careful of the followings when working

with a material that may be using asbestos.

• Put on designated dust free mask and/or other equipment as

necessary.

• Do not use compressed air for cleaning.

• Spray water when cleaning to prevent asbestos dusts from flying

into air.

• Always work downwind when driving the Machine at a site that may

contain asbestos dusts.

• Strictly observe the assigned rules related to the working site and

environmental standard.

CRANE INJURY PREVENTION

Do not let whole or part of your body enter any of the following

clearances, since such act may cause serious bodily accidents.

• Between the boom and the travelling dolly.

• Between the outrigger support and the ground contact surface.

• Between the boom/post and the derrick cylinder.

• Between the winch drum and the wire ropes.

• Between sheaves and wire rope.

• Between the crawlers and the ground.

BEWARE OF EXHAUST GAS

When starting the engine or handling fuel/cleaning oil/paint indoors or

at a location with bad ventilation con dition, prevent gas-poisoning risk

by improving the ventilation by opening the windows and exits.

If the ventilation is insufficient even after opening the windows and

exits, set up a ventilation fan.

2-7

2. DRIVING RELATED PRECAUTIONS

2.1 BEFORE STARTING THE ENGINE

ESTABLISH SAFETY OF THE WORKING SITE

• Confirm that no danger is present at the working site before starting

work.

• Investigate the ground and road surface condition of the working

site and decide the best working method.

• Flatten the inclination of the working site as much as possible before

starting work. Also, if sand and gravel are excessive, hose down

before work.

• When working over the roadway, place guides or surrounding

barriers, to ensure the safety of traffic, vehicles and pedestrians.

• Prevent people from entering the working site and apply measures

to prevent people from approaching.

Attempting to approach a moving Machine may result in hard

collision by contact or pinching, and may result in serious bodily

accidents and deaths.

• When travelling in the water or crossing over shallow water, check

the ground condition, depth and water velocity beforehand and

make sure not to exceed the allowable water depth (no higher than

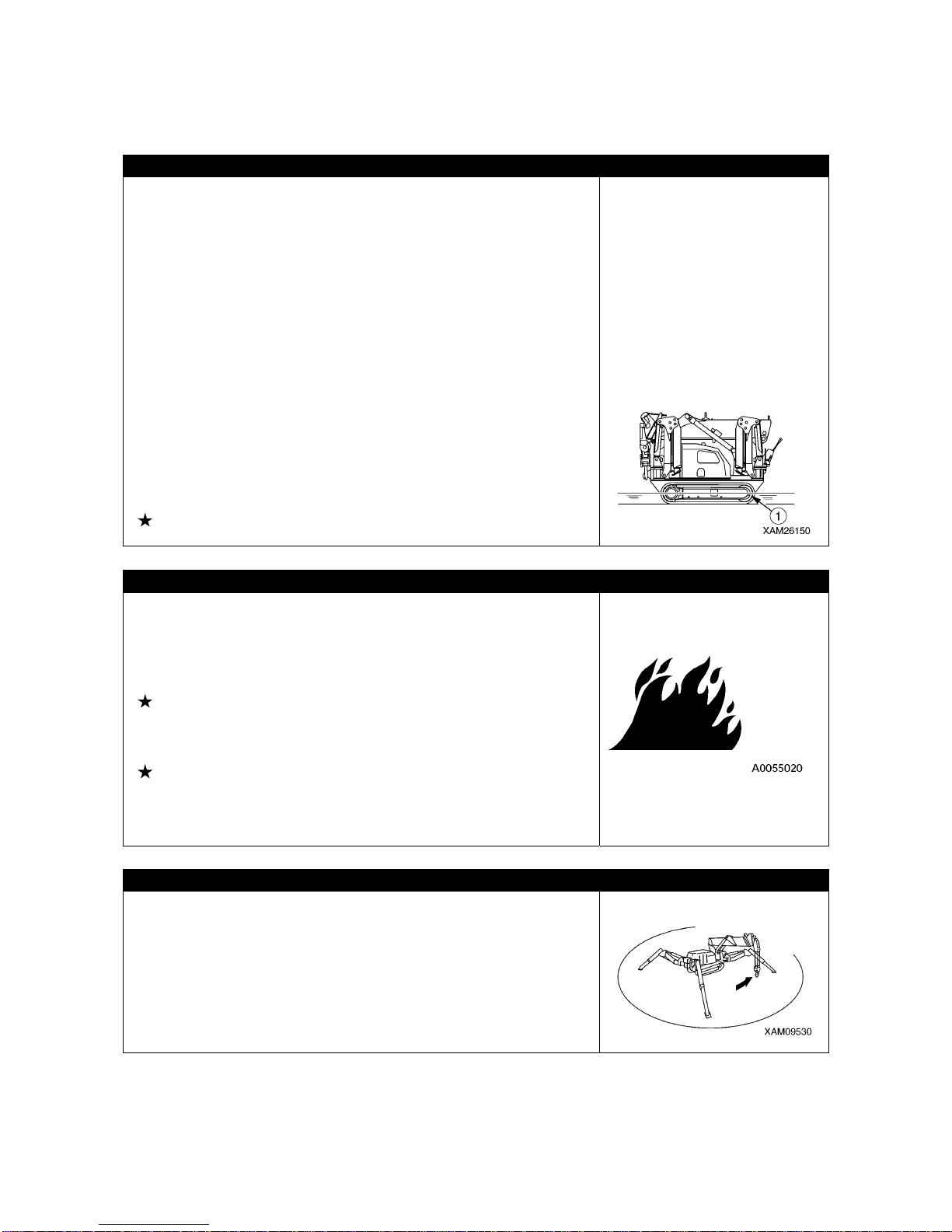

center of idler (1)).

See “Operation 2.12 [2] Allowable Water Depth” for details

INSPECTION BEFORE STARTING ENGINE

Execute following inspections before the first engine startup of the

day.

Omitting these inspections m ay result in serious bodily accidents.

• Inspect for fuel/oil leak, accumulation of combustibles around the

engine and battery systems, and similar phenomenon.

See “Operation 2.1 Checks Before Operation” for details.

• Inspect the fuel quantity, cooling water quantity, hydraulic oil tank

quantity, air cleaner blockage, electrical wiring damage, and check

operations of safety devices and instruments.

See “Operation 2.1 Checks Before Operation” for details.

• Make sure the operation levers are at neutral position.

Check that the operation linkages operate adequately.

Always repair if any result of the above is faulty.

CAUTIONS WHEN STARTING ENGINE

• Make sure no person or object is within the boo m swing radius area

before starting engine.

• Blow the horn for warning before starting the engine.

• Do not start the engine by short-circuiting the starter circuit. Such

actions may cause a fire.

2-8

2.2 AFTER STARTING THE ENGINE

INSPECTION AFTER STARTING THE ENGINE

Omitting the inspections after starting the engine results in delay to notice any machine abnormalities,

and may result in bodily accidents and Machine damage.

Inspect a wide area to ensure no obstacles, also ensure people are prevented from approaching the

Machine.

• Inspect the equipment operation conditions, Machine travelling conditions, outrigger operation

conditions, winch winding up and down, boom derricking, and crane operation conditions such as

extension, retraction and swinging.

• Inspect the sound, vibration, heat and odor o f the Machine , an d che ck for instrument er rors, a ir lea ks,

oil leaks, fuel leaks and other bad factors. Be extra careful with fuel leaks.

• Always repair broken part whenever an abnormality is found.

Attempt to use without servicing may result in unexpected bodily accidents and/or Machine failures.

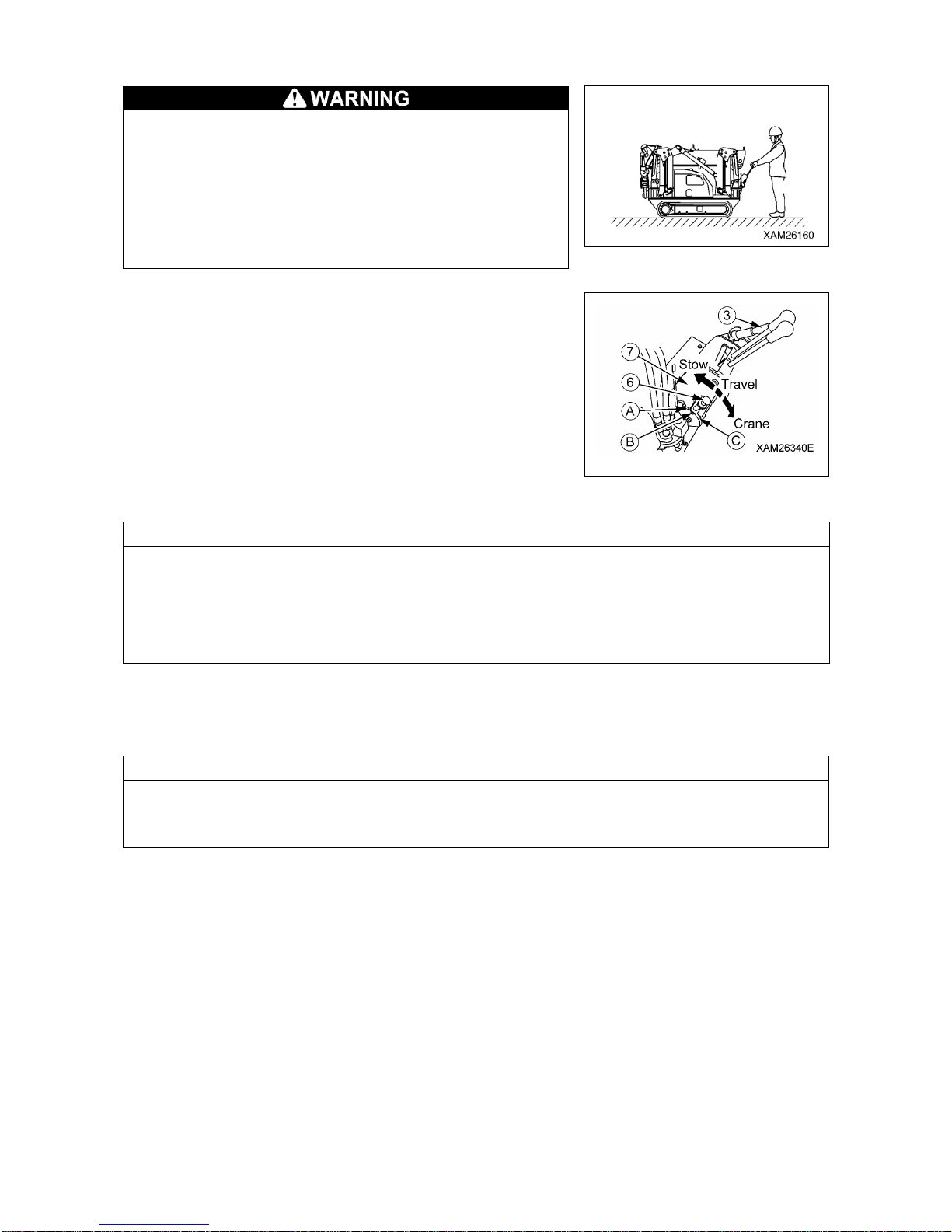

CAUTIONS WHEN STARTING TO MOVE THE MACHINE

To prevent serious injuries and death accidents, always execute the

followings before moving the Machine.

• Set the Machine to the travelling position in the right diagram.

Do not travel when the hook block is not contained.

• Ensure the boom is fully lowered and retracted.

• Fix the hook block into the containment position.

• Ensure the outrigger is contained.

See “Operation 2.5 Machine Travel Position” for details.

• Make sure again that no one or object is in the vicinity before

starting to move.

• Blow the horn for warning before starting to move .

• When travelling, be sure to stand in front of the travel lever located

on the travel control panel side. When the machine starts moving,

walk and keep your pace with the machine speed.

• The Machine is prohibited to travel when a person or load is on the

travelling dolly or the boom.

• When travelling, stow hook and outrigger, and make sure of the

surrounding safety.

• When stowing outriggers, insert each position pins completely to

lock.

CAUTIONS WHEN MOVING FORWARD/BACKWARD OR CHANGING DIRECTION

Always observe followings to prevent serious injuries and death

when moving the Machine.

• Drop the speed early and wait until the Machine stops before

changing from forward to backward, or backward to forward.

• Blow the horn and alert the people nearby before changing

between forward/backward movements or changing direction.

• Check that no one is around the Machine.

The front of the Machine frame requires special attention because

certain areas of vision are blocked, so stop the Machine as

necessary and make sure no one is at front or around.

• Place a guide if the location is hazardous or with a bad view.

• Make sure to prevent people from crossing the moving direction or

in the direction to be changed.

2-9

CAUTIONS WHEN TRAVELLING

Always observe the following to prevent serious injuries, fatal

accidents when the Machine is travelling.

• Do not attempt looking sideways or other dangerous acts when

driving.

• Do not over speed, start moving suddenly, stop suddenly, swing

suddenly or meander since such acts are dangerous.

• When travelling backward, the operator should be extre mely careful

of uneven ground. Lower the speed and drive the machine care fully

and take care not to get trapped by bumps or other obstacles.

• Whenever you find a machine abnormality (sound, vibration, odor,

instrument error, fuel le ak, water le ak or oil leak), imm ediatel y park

the Machine in a safe location and inspect the cause.

• Do not suddenly change the direction. Doing so may cause the

Machine to lose balance or damage the machine or nearby objects.

• When travelling over uneven terrain, change travel speed mode to

"low speed" to travel as slow as possible to prevent tripping, and

avoid acute operation when changing the direction.

• Avoid moving over obstacles as much as possible.

Change travel speed mode to "low speed" and travel as slowly as

possible when moving over an obstacle for unavoidable reason.

Also, do not move diagonally over obstacles th at cause the Machine

to tilt excessively (10 degrees or more).

• When travelling, ensure extra clearance to prevent accidental

contact with other machinery or objects.

• When travelling in water or crossing over shallow water, check the

ground condition, depth and water velocity (never attempt to enter

into flowing water) beforehand and make sure not to exceed the

allowable water depth (no higher than center of idler (1)).

See “Operation 2.12 [2] Allowable Water Depth” for details.

• Check weight limits against the Machine mass before crossing over

a bridge or construction that is private property. In case of public

road, ask the applicable road management administration and

follow the given advice.

• Do Not travel with load hoisted.

BE CAREFUL WHEN TRAVELLING OVER SLOPES

ALWAYS observe followings to prevent serious injuries, death or

accidents when travelling over a slope for unavoidable reason.

• Be careful of tripping and skids when travelling over slope.

• Do not change orientation on or horizontally when travelling over

slope. Practice safe travelling by for instance lowering to the flat

land and divert.

See “Operation 2.12 [3] Cautions on Upward/downward slope”

for details.

• Skids happen more than you think on grass, fallen leaves, and on

wet steel plates.

Avoid the Machine from being horizontal over the slope as much as

possible, and decrease the speed sufficiently.

• Travel slowly in low speed when travelling downhill, after changing

travel speed mode to "low speed". In addition, apply brake (by

setting the travel lever to neutral) as necessary.

2-10

BE CAREFUL OF TRIPPING ON UNSTABLE GROUND

Always observe the following to prevent serious injuries and fatal

accidents when travelling over unstable ground for unavoidable

reason.

• Do not enter soft grou nd area. T he Machi ne is diffi cult to e vacuate

from such area.

• The ground near cliff, roadside and deep gully is unstable, so avoid

going near such ground as much as possible.

The Machine may trip or fall when the ground loosens due to mass

and/or vibration of the Machine. Be especially careful that the

ground is likely to loosen after rain, use of dynamite or earthquake.

• Avoid going near the earth fills or dug gutters that are unstable.

Crumbles caused by mass and/or vibration of the Machine may

cause the Machine to tilt.

CAUTIONS WHEN THE GROUND IS COVERED IN SNOW OR FROZEN

Always observe the following to prevent serious injuries and fatal

accidents when travelling over a snow covered ground or frozen road

for unavoidable reason.

• The snow covered ground and frozen roads cause slips even when

the inclination is small, so decrease the speed when travelling and

avoid starting suddenly, stopping suddenly and swinging suddenly.

Uphill and downhill are especially likely to cause slips and thus

dangerous.

• Ground of the frozen road becomes soft when the air temperature

rises and causes the machine travel and other operations to be

unstable. Be very careful.

• Under cold weather, check that the lo ad to be hoisted is not frozen,

stuck to the ground or any other surface. Attempting to hoist without

knowing the load is frozen, stuck to the ground or any other surface

is dangerous.

• Do not directly contact metal surface with your body part such as a

finger or hand under cold weather.

Attempt to contact the metal surface of the Machine under harsh

cold weather may cause the skin to stick to the frozen surface.

• Remove snow and/or ice laid on the Machine that causes the safety

nameplates to be hard to read. Be especially careful to securely

remove those that are on the boom and thus may fall.

CAUTIONS WHEN PARKING

• Park at a location where the ground is level, ro ck falls and landslides

do not occur, if it is a lowland check that flooding does not occur.

• If you must park on a slope for an unavoidable reason, use blocks

as pawls to immobilize the Machine.

• When parking on the street, place flags, protection barr iers, lightin g

and caution notices that do not interfere with the traffic, so that other

vehicles are aware.

• Stop the engine before leaving the Machine.

Always remove the starter key and store in a fixed location.

• When parking, the lock lever must be placed to “Lock”.

2-11

PRECAUTIONS IN COLD WEATHER

• Remove snow from and defreeze the swing gear, boom and winch

related parts, and check the movements before work.

• Warm up thoroughly.

Attempting to operate the operation levers and switches without

enough warm-up will cause the Machine to be slow in reaction, and

may result in unexpected accidents.

• Avoid acutely accelerating the engine shortly after starting the

engine.

• Increase the oil temperature of the hydraulic circuit by relieving the

oil pressure (let the pneumatic oil escape to the hydraulic oil tan k by

raising it above the hydraulic circuit set pressure) by using operation

lever. Doing so improves the Machine reactions and prevents

improper operations.

• If the battery fluid is fro zen, do not charge battery or start the engine

using other power source.

Such acts may cause the battery to catch fire.

Before charging or starting up using other power source, defreeze

the battery fluid and check that failur e s such as battery fluid leak do

not exist.

• After end of the work, wipe off and apply wraps if substances such

as condensation, snow or mud are stuck to the wire harness,

connector (1), switches, sensors or similar part.

If the infiltrated condensation and/or similar substance freezes, the

Machine may not operate properly upon the next use and cause

unexpected accidents.

2-12

2.3 WORKING WITH THE CRANE

INSPECTION BEFORE STARTING WORK

Check that the safety devices and crane operate properly.

• Operate each of the operation levers and switches under no load, and check operations are perfor med

normally.

Repair immediately if any abnormality exists.

• Check that the safety devices such as the moment limiter, and over hoist detector device activate

properly.

CAUTIONS WHEN HANDLING MOMENT LIMITER

• Use/store the moment limiter under the following ranges of ambient temperature.

Temperature of use: 10 to 50 °C Storage temperature: -20 to 60 °C

• Avoid direct sunlight so that the temperature of the moment limiter body does not exceed the range.

• Avoid locations with strong acid or alkaline atmosphere as much as possible. Otherwise, unexpected

failures may occur.

• Do not apply impact to the moment limiter body for instance by colliding with an object.

Such attempt may damage the case and may result in failures and improper operations.

• Do not push the panel sheet of the moment limiter body by a force more than necessary or push with

sharp object such as a tip of a screwdriver. Such action may damage the panel sheet and may result in

failures and improper operations.

• Do not remove the case cover or panel sheet from, or disassemble the moment limiter body. Such

action may damage the case and/or panel sheet and may result in failures and improper operations.

CAUTIONS WHEN SETTING UP MOMENT LIMITER

• The moment limiter calculates the moments assuming the Machine is level.

If you work with the crane when the Mac hine is not level, warnings and alarms a re not issued even

when the rated total load is near.

Always set the outrigger horizontally to the ground while looking at the level gauge.

• Before using the crane, check that the boom angle di splay, boom length display and real load display

of the moment limiter are displayed correctly following the crane movements. At tempting to use wi thout

the correct display res ults in failure to obtain correct measurement result and may result in serious

bodily accidents caused by improper operation and/or breakage of nearby equipment.

• Always make sure the wire strand sett ing of the mome nt limiter matches wit h the wire strand of the

crane. If the wire strands do not match, always let the wire strands match by changing the wire strand

setting of the moment limiter or by changing the wire strand of the crane. Attempting to use with

unmatched wire strands results in failure to obtain correct measurement result and may result in

serious bodily accidents caused by improper operation and/or breakage of nearby equipment.

• Do not carelessly change the setting when measuring with the moment limiter. Such action results in

failure to obtain correct measurement result and may result in serious bodily accidents caused by

improper operation and/or breakage of nearby equipment.

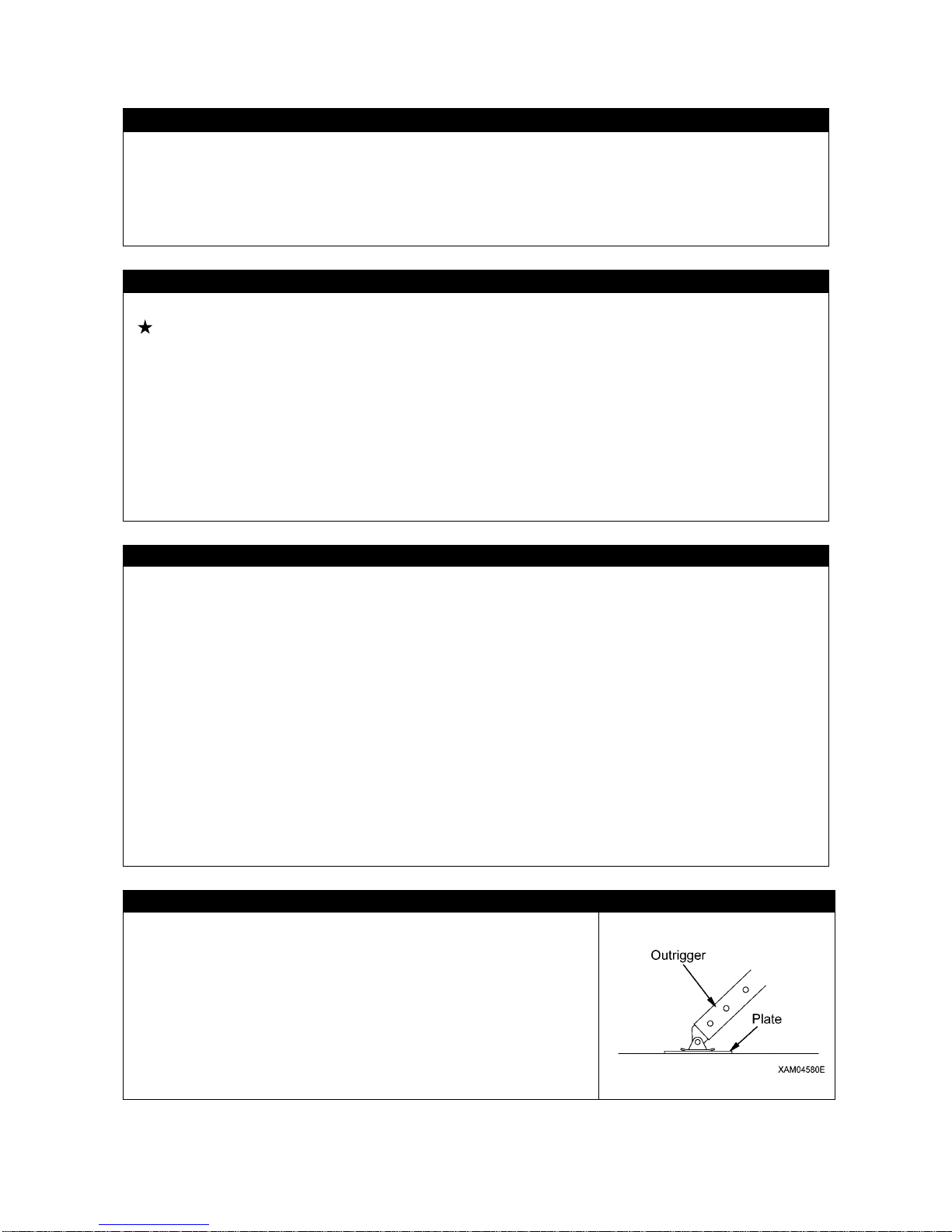

PLACE CRANE ON LEVEL AND HARD GROUND

• Always place the outriggers on a level, stable and solid ground.

Attempt to work with crane without outriggers firmly contacting the

ground may cause the Machine to trip.

• Always place all outriggers before working with crane.

• Do not set any outrigger near the location that may collapse, for

instance, soft ground, roadside or drilled hole.

In case the outriggers need to be placed on soft ground for an

unavoidable reason, always reinforce the ground by laying a

sufficiently large and strong base plate below each of the outrigger

supports.

2-13

CHECK OUTRIGGER PLACEMENT CONDITION

Always observe followings to prevent serious injuries and fatal

accidents when placing the outriggers.

• When placing the outriggers, always keep the Machine level while

looking at the level gauge. Occasionally view the level gauge and

make sure to keep the Machine level during the crane works as well.

• Place the outriggers at a maximum extension condition as the basic

rule.

In case of placing in a non-maximum extension condition for

unavoidable reason, always find the values outrigger extended to

other than maximum value in the total rated load chart before work.

• Place the outriggers so that the rubber tracks are approximately 50

mm above the ground.

• Make sure all of the outrigger position pins are securely fixed.

CAUTIONS WHEN PLACING THE OUTRIGGERS

Do not let people approach nearby when placing the outriggers.

Otherwise serious accidents, for instance the outrigger support

catching a foot, may occur.

2-14

BEWARE OF ELECTRICAL CABLE ABOVE

• Do not let the Machine come into contact with overhead electrical

cables.

High voltage cables may inflict electrical shock just by being nea r to

them.

• People who throw objects are likely to suffer electrical shocks.

Always observe following to prevent accidents.

• If the boom or the wire ropes may come into contact with an

electrical cable in the workplace, consult the electricity company

and make sure that the measures (for instance security personnel

or the application of w rap tubes and warning ta gs to the elect rical

cable) stipulated by the related regulations are taken before

starting work.

• Wear rubber soled shoes and rubber gloves, and be careful that

the body parts unprotected by rubber or other insulation do not

come into contact with the wire rope or the Machine frame.

• Place a guide and let him/her watch so that the boom, wire rope or

Machine frame does not ge t too near to the electrical cable.

Before beginning work, decide on the emergency signs and other

necessities.

• Ask t he e lect ricit y c ompan y f or t he vo lt age i n t he el ect ric al c ables

in the working site.

• Ensure the offset distances (safe distance) shown in the following

table between the boom/Machine frame and electrical cables.

Voltage of

Electrical Cable

Minimum Safe

Distance

Low voltage

(Distribution line)

100・200V

2m

6,600V 2m

Special

(Transmission

line)

22,000V 3m

66,000V 4m

154,000V 5m

187,000V 6m

275,000V 7m

500,000V 11m

2-15

MEASURES WHEN CHARGE ACCIDENT OCCURS

When an electrical charge accident occurs do not panic and follow the steps below:

1. Report

Immediately report to the electricity company or related management company, and receive

instructions on how to stop the power transmission, emergency procedures and any other steps.

2. Evacuation of related personnel from vicinity of Machine

Remove related personnel from around the Machine to prevent secondary disasters.

Personnel who suffered electrical shock by holding a sling rope, guide rope or other conductor when

the Machine was charged should evacuate by his/her own effort.

Do not try to help such person. Otherwise, secondary electrical shock accident occurs.

3. Emergency procedure

Take the solution by following sequence in case of urgency where personnel received electrical shock

because the Machine was charged.

(1) If the Machine can be operated, immediately operate the Machine to move the Machine

constructions away fr om the cont act and out of th e range of t he cause of t he charge. B e careful

not to touch the distribution power cable.

(2) Evacuate th e M ac hi n e com pl et el y away from the cause of the charge, make sure the Machine is

not charged, rescue the electrically shocked personnel and immediately transport them to the

hospital.

4. Measure after accident

After accident, do not reuse as is. Such attempt may cause unexpected accidents and enhances

failures.

Ask us or our sales service agency for repair.

CAUTIONS WHEN WORKING WITH CRANE IN LOCATION WITH HIGH OUTPUT

MICROWAVE EMISSION

Working with the crane near a high output microwave emission equipment such as a radar or TV/radio

broadcast antenna causes the crane construction to be exposed to the microwave and generates

induced current, therefore is very dangerous. In addition, the mechatronics may become haywire.

Establish grounding between the Machine frame and the ground when working in such location. In

addition, slingers are requested to wear rubber boots and rubb er gloves since risk of electrica l shock by

contacting parts such as the hook or wire exists.

2-16

PAY ATTENTION TO WEATHER INFORMATION

• In case of thunderstorm, there is a risk o f lightnin g, so abort w orking with crane, immediately lowe r the

load and contain the boom.

• Exposing the hoisted load to wind causes the load to move and causes the Machine to be unstable,

thus is dangerous. Immediately lower the load and contain the boom when the wind is causing the load

to move.

• If the maximum instantaneous wind speed is 10 m/s or grea ter, abort wor king with crane, immed iately

lower the load and contain the boom.

• Even when the maximum instantaneous wind speed is below 10 m/s, the bigger the hoisted load,

higher the hoisted load position, and longer the boom, the wind effect increases accordingly. Be fully

careful during work.

• When a load such as a steel plate that has a large area exposed to wind is being hoisted, the wind

arriving from front/rear/side of the boom may cause the Machine to trip or damage the boom. Be fully

careful when working.

• When an earthquake occurs, abort working and wait until the earthquake is over.

The following table indicates approximate rela tion between the wind speed and wind effe ct. The wind

speed mentioned in the weathercast is mean wind velocity (m/s) during 10 m at 10 m above the

ground.

Force Wind Speed (m/s) Effect On Land

0 Less than 0.3 Smoke rises vertically.

1 0.3 - below 1.6 Wind motion visible in smoke.

2 1.6 - below 3.4 Wind felt on exposed skin.

3 3.4 - below 5.5 Leaves and smaller twigs in constant motion.

4 5.5 - below 8.0 Dust and loose paper raised. Small branches begin to move.

5 8.0 - below 10.8 Smaller trees sway. Some foam and spray.

6 10.8 - below 13.9

Large branches in motion. Whistling heard in overhead wires.

Umbrella use becomes difficult.

7 13.9 - below 17.2 Whole trees in motion. Effort needed to walk against the wind.

8 17.2 - below 20.8 Twigs broken from trees. Progress impeded.

9 20.8 - below 24.5 Light structure damage. Slates blown off.

10 24.5 - below 28.5 Trees uprooted. Considerable structural damage.

11 28.5 - below 32.7 Widespread structural damage.

2-17

CAUTIONS WHEN SLINGING

• Check the following before hoisting a load.

Attempt to hoist the load without checking may result in serious bodily accidents by a drop of the load

or tripping.

• Observe the values in the total rated load chart.

• Hoist from the center of gravity of the load.

• Check that the wire ropes of the hook block are perpendicular to the ground.

• When the load leaves the ground, stop winding up the load once and check whether the load is

stable.

• Before hoisting a slung load, always check whether the sling wire rope "retainer device" of the hook

block is hung securely. If the "retainer device" is no t hung, the w ire rope may leave the hook blo ck and

cause the load to fall and results in a serious accident.

• Larger wire rope angle when hoisting the load increases for ce that applies to the wire ro pe even when

the load weight is unchanged, thus may cause the wire rope to snap. Pay consideration when slinging

to prevent excessive force being applied to the wire rope.

• Do not hoist more than one load at once.

Such attempt may cause the hoist bra cket to h it and damage th e other hoisted loa d, the loa ds to move

and loose balance and fall or cause other serious accidents.

Do not hoist more than one load even if the total is within the rated total load.

• Hoisting of lengthy load causes the load to lose balance and is dangerous.

In case such load, hoist vertically by using a clamp, or achieve balance o f the hoisted load by applying

a rope to both ends of the load.

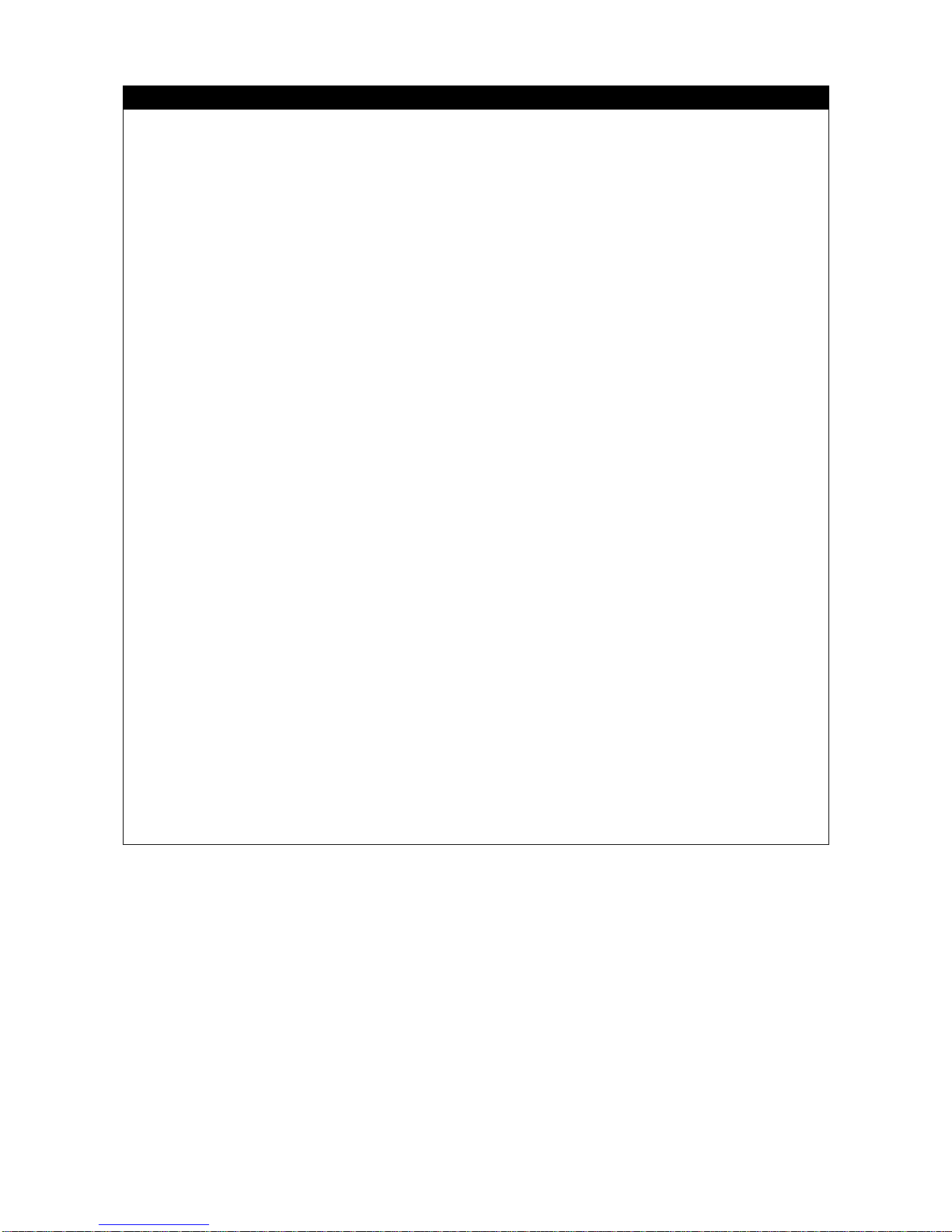

CAUTIONS WHEN HANDLING WIRE ROPE

• The wire rope wears out ov e r time, so inspect before each job, and

replace immediately if at or beyond the replacement standard.

At the same time, inspect the sheave at the tip of the boom and the

sheave of the hook block. Damaged sheaves accelerate the

damage of the wire ropes.

• Use the wire ropes specified by us.

• Always put on leather gloves when handling the wire rope.

• Handing worn and damaged wire may cause injury by wire splinter.

• Do not use any wire rope of which any of the followings apply.

• 10% or more of the wires (except the filler wires) in one twist of the

wire rope are snipped.

• The wire rope diameter abrasion is beyond 7% of the nominal

diameter.

• Is kinked.

• Is excessively deformed or corroded.

• Affected by heat or sparks.

2-18

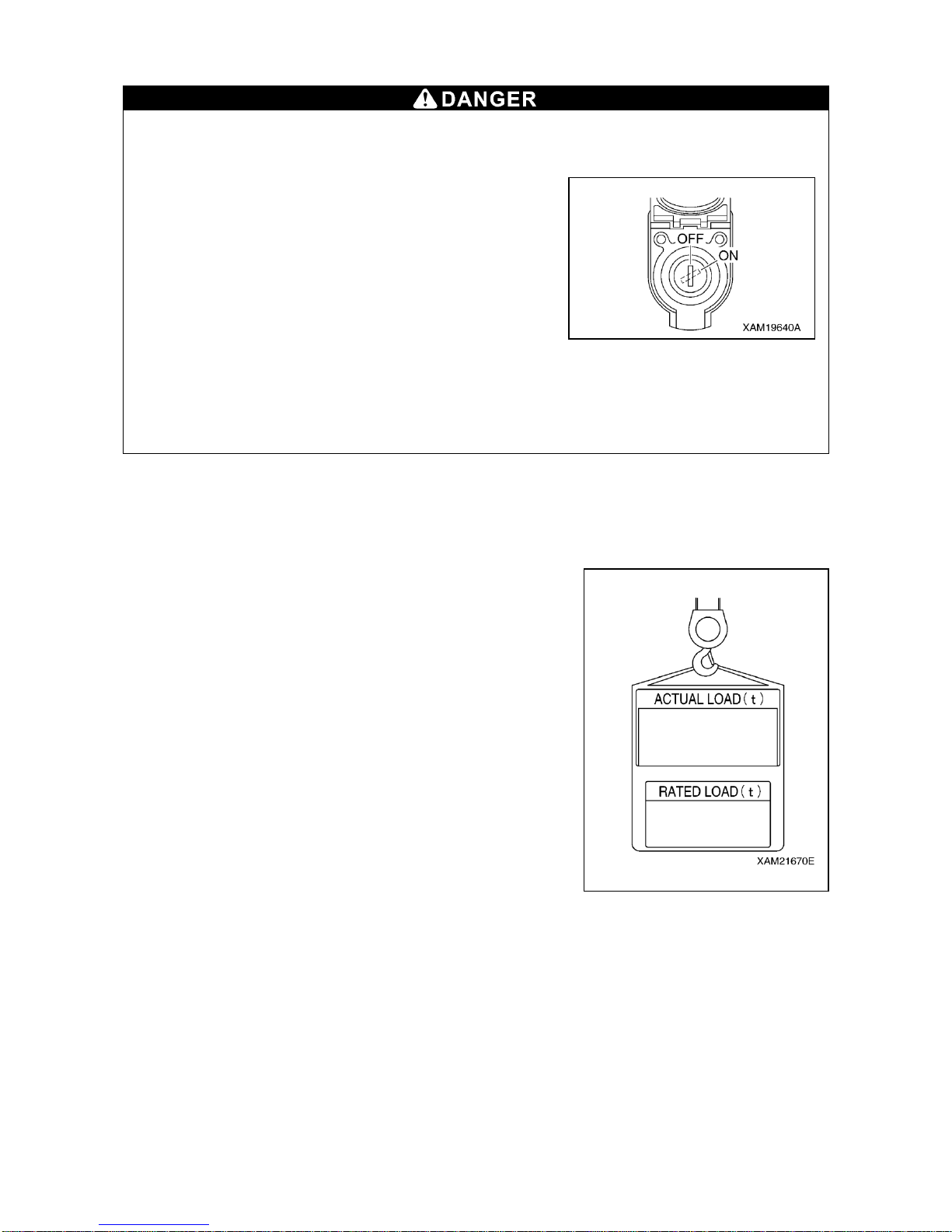

CAUTIONS WHEN WORKING WITH THE CRANE

• Be sure to verify that the emergency stop cancel switch is at OFF (auto) position be fore operating the

crane.

Do not attempt the crane operation when the emergency stop cance l switch is at ON (cancel) position.

The emergency stop cancel switch is permitted to be at ON (cancel) position only during the inspection

or maintenance works.

• Attempting to work beyond the capacity of the Machine may cause serious accidents and failures

caused by for instance tripping or flu ctuation. Obse rve the total rated load ch art when working with the

crane.

• Do not travel with a load being hoisted under any circumstance.

Such attempt may cause the crane to tip and may re sult in serious bodily accidents.

• Be slow when operating the crane.

Sudden lever or accelerator operations may cause risks such as the load moving, falling or colliding

with nearby objects. Be especially careful to be slow during the swing operations.

• Do not let people approach the work radius or below the load, since risks such as fall of the load and

contact with the load exist. Such attempt may result in serious bodily accidents. Also, during the work,

consider the fact that the working radius increases when the load is hoisted and the boom is deflected.

• Attempting to work with the cra ne eve n wh en the vi ew is bad due to loca tion or weather is dangerous.

Ensure brightness by posting a work lamp or other illumination facility in dark places.

When the view is bad because of bad weather (rain, fog, snow), abort working and wait until the

weather recovers.

• Do not use for any other purpose than indicated, for instance raising a person using a crane.

• If the overwinding detector alarm buzzer is heard, immed iately remove your hand fro m the winch lever .

The hook block winding stops. Then, operate the winch lever to Down (push forward) to wind down the

hook block. In addition, the hook block is wound up when the boom is extended, so be sure to ensure

extra clearance between the boom and the hook block during work.

• When the boom extends, the hook block is wound up.

Operate the winch lever to Down (push forward) to wind down the hook block while you extend the

boom.

• Whenever an overload occurs during work, lower the load by winding down the winch by setting the

winch lever to Down (push forward).

Do not raise or lower the boom suddenly. Such an attempt may cause serious accidents by tripping.

• The volume of the hydraulic oil in each of the cylinders changes depending on the temperature.

By leaving idle with a load being hoisted, as the time passes by the oi l temperature drops and the

hydraulic oil volume decreases, and changes may occur such as the boom derrick angle decreasing

and the boom length decreasing.

In this case, stop boom derricking operations and boom extension operations in order to correct.

• Do not leave the driving operation position when a load is hoisted.

Lower the load before leaving the Machine.

• Keep the hook block wound up when not in use.

Otherwise, anyone near the load may collide with the hook block.

• Operator must not leave operators seat during operation.

2-19

CAUTIONS WHEN OPERATING WINCH

• Do not allow anyone below the hoisted load.

• When hoisting a load, always stop at the "takeoff" position where

the hoisted load leaves the ground. Check subjects such as load

stability and load force, then hoist up the load.

• Do not pull laterally, pull toward you or hoist diagonally. Such

attempt may cause the crane to trip or suffer damage.

• Overwinding of the hook block may re sult in collision with the boom,

snipping the wire ropes and causes the hook block and load to fall

and cause serious accidents. Be extra careful to prevent

overwinding of the hook block.

• Be careful to prevent the wire rope and/or hoisted load from

contacting an obstacle such as a tree or steel structure when

hoisting a load.

If caught by an obstacle, do not forcibly wind up the hoist load, but

untangle the caught part before winding up.

• Do not operate the winch system if the rope is badly wound on the

winch drum (tangled). If tangled the rope may be damaged,

shortening its life span, and there is a possibility that it may break

and cause a serious accident. Observe the followin g precautions to

avoid the rope becoming tangled:

• Do not let the hook block hit the ground.

• Before leaving the hook block lowered for a long time for instance

when working with underground, leave at least three loops of wire

rope in the winch drum.

• If the wire rope is twisted and causes the hook block to turn, fully

eliminate the twist before work.

See “ Operation 4. What to do with Twisted Winch Wire Rope” for

details.

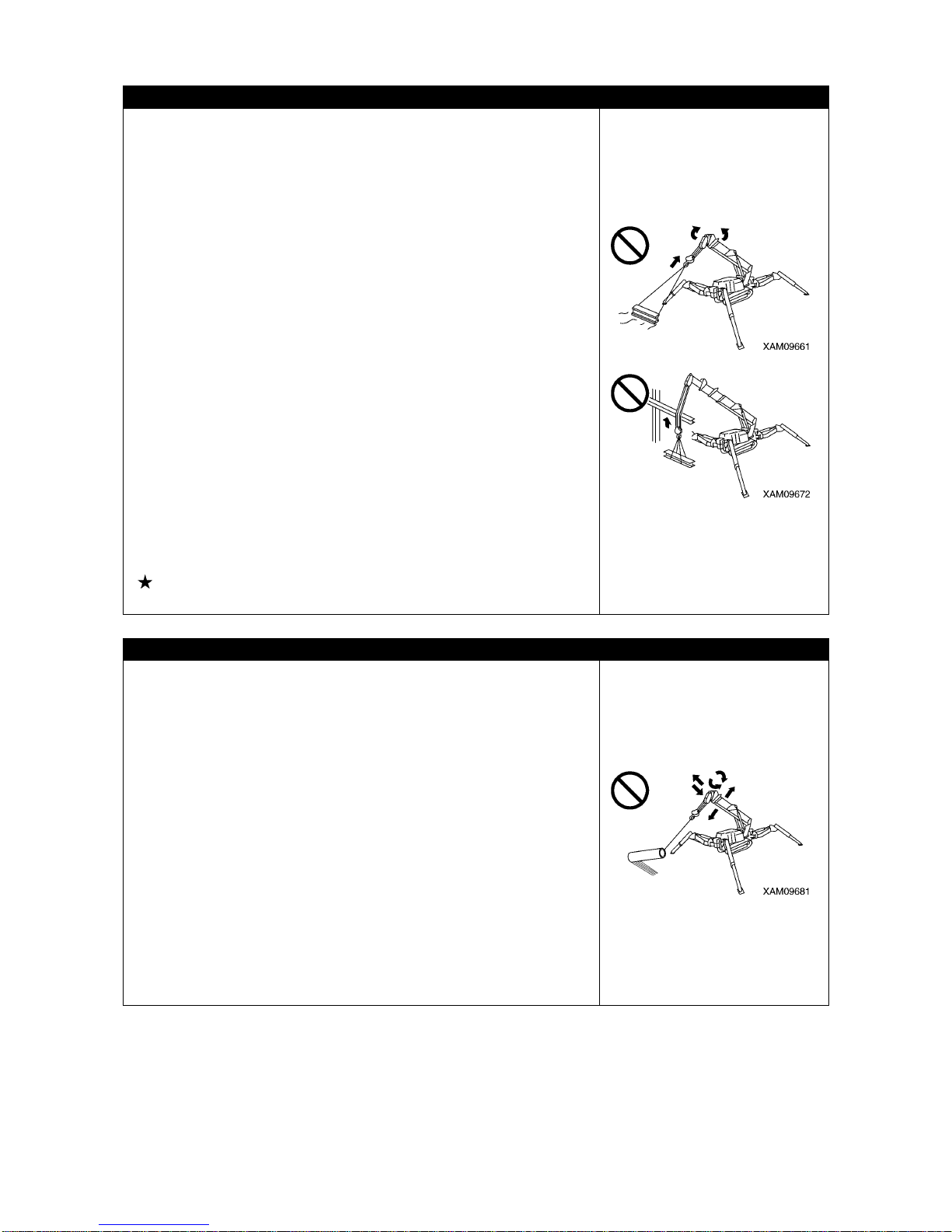

CAUTIONS WHEN OPERATING THE BOOM

• Operate the boom operation lever as slowly as possible .

Especially avoid sudden lever operations when the load is hoisted,

which may cause the load to move and give large impact to the

Machine, and thus may damage the crane or trip the Machine.

• When the boom is lowered, the working radius increases, and the

rated total load that can be hoisted decreases. When working while

raising/lowering the boom, pay extra attention to ensure that the

mass (weight) of the load at the time the boo m is most lowered does

not cause overloading.

• Attempts to pull the load laterally or pull to bring forth the load by

raising/lowering and/or extracting/retracting operation of the boom

are prohibited. Do not attempt under any circumstance.

• Be aware of the hook block windup condition and exercise caution

when extending or retracting the boom.

• When the boom is extended, the working radius increases, and the

rated total load that can be hoisted decreases. When working with

extending/retracting the boom, pay extra attention to en sure that the

mass (weight) of the load at the time the boo m is most lowered does

not cause overloading.

2-20

CAUTIONS DURING SWING OPERATION

• Check the safety in the vicinity and blow the horn before swing ing.

• If the boom derrick angle is small, be careful to prevent the boom

from hitting the driver or the Machine.

•Operate the swing lever as slowly as possible. Make sure to start

smoothly, swing slowly, and stop quietly.

Especially avoid sudden lever operations when the load is hoisted,

which may cause the load to move and cause the Machine to lose

balance, and thus may damage the crane or trip the Machine.

• Attempts to pull to bring forth the load or let the load stand up by

swinging operation are prohibited. Do not attempt under any

circumstances.

• Be careful to prevent the wire rope and/or hoisted load from

contacting an obstacle such as a tree or steel structure when

hoisting a load or when swinging.

If caught by an obstacle, do not forcibly wind up the hoist load, but

untangle the caught part before winding up.

• Certain outrigger extension condition may cause the boom to hit an

outrigger and cause the crane to be damaged or the Machine to trip.

Be careful to prevent the boom from hitting outriggers during swing

operation.

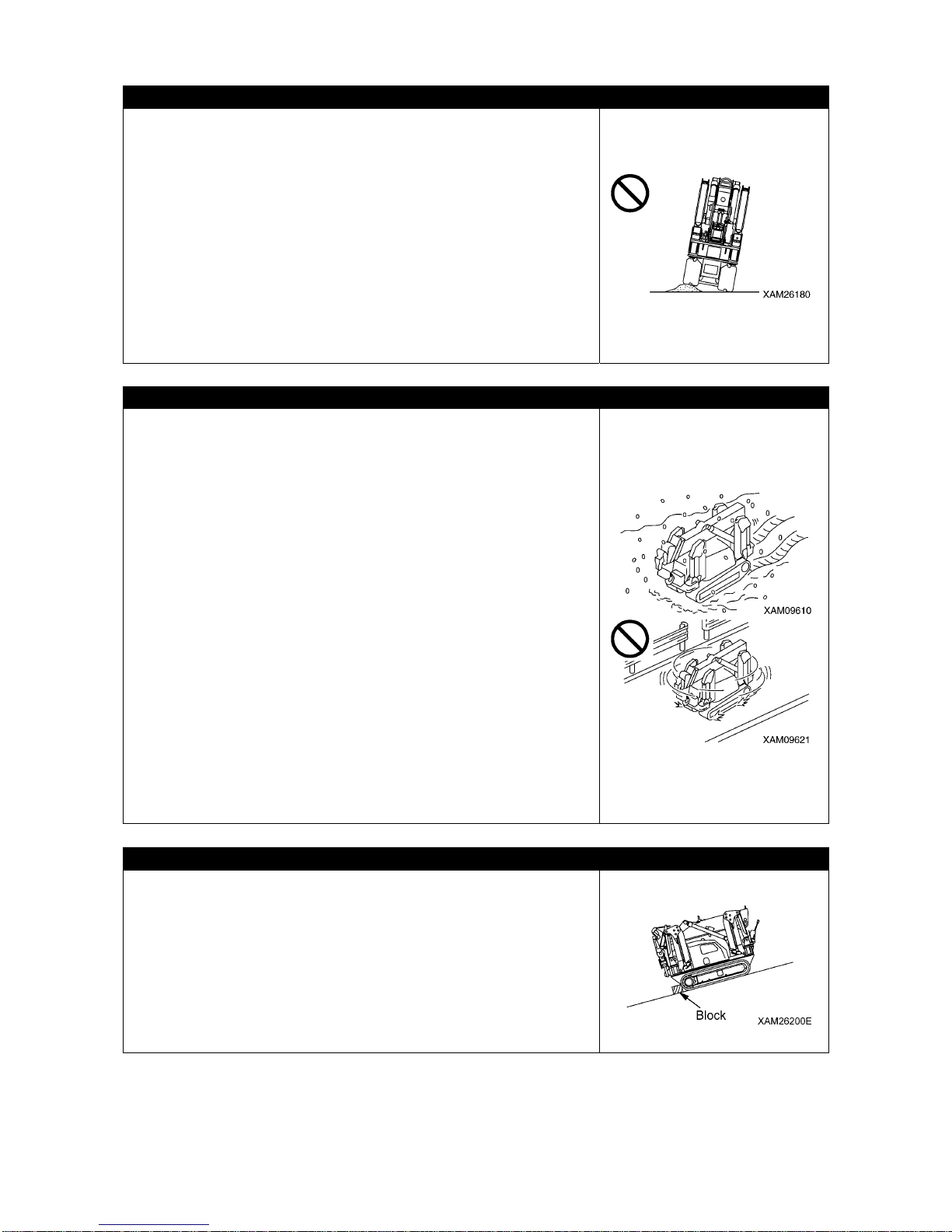

COOPERATION HOISTING IS PROHIBITED AS THE RULE

Cooperation hoisting, that is to use more than one crane to hoist a load, is prohibited.

The cooperation hoisting work is a highly hazardous work that may cause for instance a trip of the

Machine due to uneven center of gravity, fall of the hoisted load or boom damage.

If the need for such work in unavoidab le, e stablish a wor k scheme by re spo nsibility o f the user , discu ss

fully, let the worker fully acknowledge the work method and procedures, then work carefully under the

direct leadership of the work supervisor.

Also observe the following cautions:

• Use cranes of same model.

• Choose a Machine model that can handle sufficiently larger loads than the load to be hoisted.

• Make sure only one person gives signs.

• Limit the crane operations to single operations as the rule, and do not attempt any swing operation.

• Appoint one responsible slinger who is most experienced.

WORKING AT A SITE WITH UNDERGROUND LIFTING

• Leave at least three loops of wire rope in the winch drum when winding down the wire rope in case of

underground work or similar occasion. This Machine is equipped with three-winding stop alarm /

automatic stop device as the safety device, but even then be care ful to prevent this safe ty device from

activating.

• Make sure signs are communicated ful ly.

• Be especially careful with the crane operations.

2-21

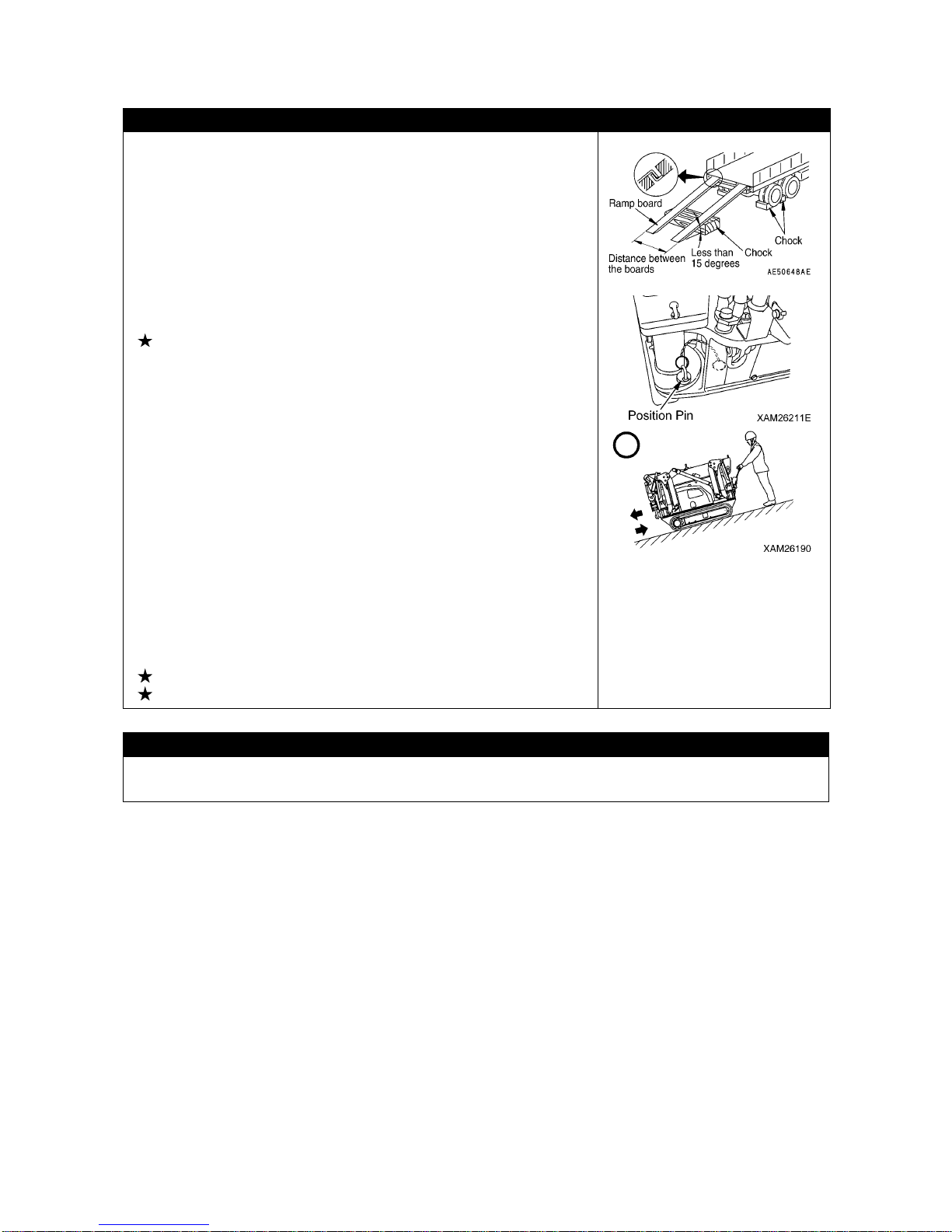

3. TRANSPORT PRECAUTIONS

CAUTIONS WHEN LOADING OR UNLOADING

• Be especially careful when loading or unloading the Machine

because of the risks.

• Select a location that is level and has firm road surface when

loading or unloading the Machine. In addition, keep enough

distance from the roadside.

• Use ramps underneath with an angle less than 15 degrees. In

addition, decide the clearance between ramps to meet the center of

the rubber tracks.

• Always set the Machine in the "travelling position" and securely

insert the position pins (4 pieces) to the outrigger ro tary parts before

loading or unloading the Machine.

See “Operation 2.5 Machine Travel Position” for details.

• Always move backward when loading the Machine. Moving forward

may cause a trip.

• When loading or unloading, set the e ngine rotation to low idlin g (low

speed rotation) and operate slowly by low speed travels.

• Use ramps that have fully strong width, length and thickness, and

that enable safe loading/unloading.

Reinforce with blocks or other substances if the ramps move at all.

• Remove mud and other substances from the footing to prevent the

Machine from skidding over the ramps. Remove anyth ing stuck to

the ramps such as grease, oil or ice, and keep clean.

Be especially careful in the rain when slips can easily occur.

• Do not change direction over a ramp. Temporarily leave the ramp

before correcting the direction.

• Be slow when operating to change the direction on the truck

platform where the footing is unstable.

• After loading the Machine, apply the wood blocks so that the

Machine does not move, and securely fix with wire ropes or other

means.

See “Operation 5.1 Loading/unloading” for details.

See “Operation 5.3 Cautions in Loading Machine” for details.

CAUTIONS DURING TRANSPORT

Observe the related regulations and exercise safety during transport.

2-22

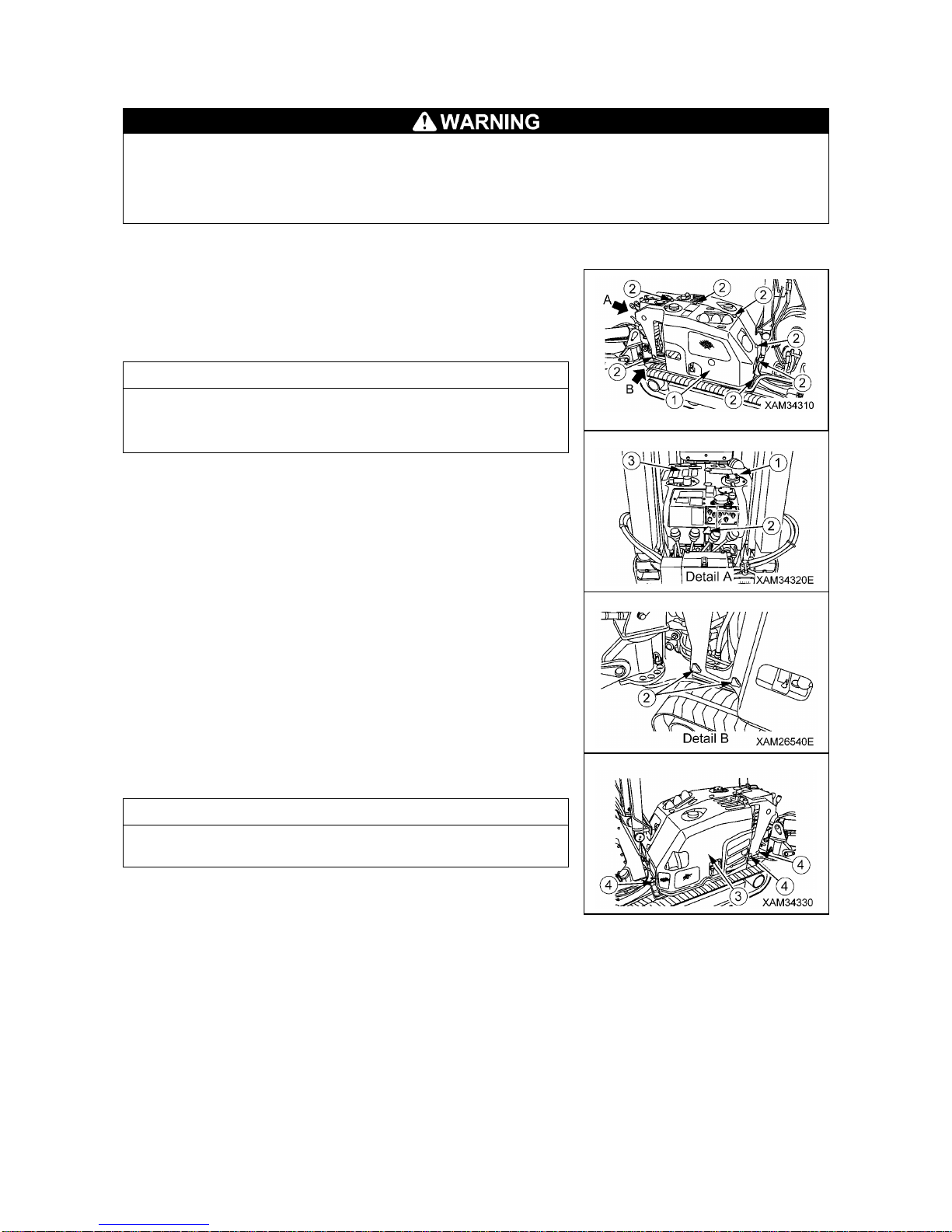

CAUTIONS WHEN LOADING/UNLOADING WITH A CRANE

Be careful of the following when loading or unloading the Ma chine by

hoisting with a crane.

• When lifting up the Machine, always set it to the stowage position

first, and lift from the lifting bracket (A) on the top of the boom.

Always use only this bracket and only one sling wire. Any other

manner than this, i.e. from other lifting brackets or multiple sling

wires, may cause droppage of the machine and result in serious

injury or death.

Where there is no choice but the machine has to be hoisted in a

different manner, please contact us or service agencies.

• Only use sling utensils (e.g. wire ropes and shackles) which are

proved to be capable to the mass (weight) of the machine.

• The crane’s stowed posture when it is hoisted means its "travelling

position" where 4 of outrigger position pins are securely inserted in

the outrigger rotary.

The center of the balance of the machine is specified subject to that

the machine is in its travelling position. In addition, to set it into that

position correctly, secure the hook block (4) to its stowing position,

as well as stretch the wire rope tight which aid to prevent the boom

derricking cylinder form extending.

See “Operation 2.5 Machine Travel Position” for details.

• When the machine is hoisted in such manner for an extensive time ,

the boom derricking cylinder may extend which causes the center of

the balance of the machine to change and put it out of balance.

Thus, hoisting should be limited to within 10 minutes.

• Where it is required to hoist the machine for a longer time

(exceeding10 minutes), or when it is carried by a helicopter, use a

proper carriage deck as shown in the diagram on the right, for safe

transportation.

Recommended hoisting equipment

• Shackle: BC or SC, nominal 14

2-23

4. BATTERY HANDLING PRECAUTIONS

BATTERY HANDLING PRECAUTIONS

The battery fluid includes diluted sulfuric acid, and generates

hydrogen gas, and causes bodily accidents and fires if handle

improperly, so always observe the followings.

• Do not let a cigarette or any fire source approach the battery.

• Always put on protective glasse s and rubber gloves before han dling

the battery.

• If the battery fluid has contacted clothing or skin, immediately wash

away with a large quantity of water.

• If the battery fluid entered an eye, wa sh immediat ely with wa ter and

see the doctor as soon as possible.

• If you have swallowed the battery fluid by mistake, immediately

drink a large quantity of water, milk, raw egg or vegetable oil, and