OPERATION MANUAL

CRAWLER CRANE

542E-OM1803-00

CC423S

- 1

Serial No. 21001 and up

Unsafe use of this machine may cause serious injury or death. Operators

must read this manual before operating this machine. This manual should be

kept near the machine for reference and periodically reviewed by all

personnel who will come into contact with it.

MAEDA has Operation Manual written in some other languages. If a foreign

language manual is necessary, contact your local distributor for availability.

NOTICE

CONTENTS

Item

INTRODUCTION

1. INTRODUCTION 2

2. FOR SAFE USE OF THE MACHINE 3

3. MACHINE OVERVIEW 4

3.1 SPECIFIED OPERATIONS 4

3.2 MACHINE STRUCTURE 4

3.3 MACHINE FUNCTIONS 5

4. QUALIFICATIONS FOR OPERATION 6

4.1 QUALIFICATIONS FOR CRANE OPERATION 6

5. TERMINOLOGY 7

5.1 TERMS AND DEFINITIONS 7

5.2 DIAGRAM OF WORKING RADIUS AND LIFTING HEIGHT 8

5.3 RATED TOTAL LOAD CHART 9

6. NECESSARY INFORMATION FOR SERVICING 12

SAFETY

1. BASIC PRECAUTIONS 16

1.1 PRECAUTIONS BEFORE STARTING WORK 16

1.2 PREPARING FOR SAFE OPERATION 17

1.3 PRECAUTIONS FOR FIRE PREVENTION 19

1.4 CAUTIONS IN GETTING ON AND OFF THE MACHINE 20

1.5 OTHER PRECAUTIONS 21

2. OPERATION RELATED PRECAUTIONS 22

2.1 PRECAUTIONS ON WORK SITE 22

2.2 CAUTIONS WHEN STARTING ENGINE 25

2.3 PRECAUTIONS FOR STARTING CARRIER AND OPERATING CRANE 27

2.4 CAUTIONS DURING CRANE OPERATION 30

3. TRANSPORT PRECAUTIONS 38

4. TOWING PRECAUTIONS 39

5. MAINTENANCE PRECAUTIONS 40

5.1 PRECAUTIONS BEFORE MAINTENANCE 40

5.2 PRECAUTIONS DURING MAINTENANCE 43

6. SAFETY LABEL LOCATIONS 47

Page

1

15

i

Item

OPERATION

1. NAME OF EACH SECTION 56

1.1 MACHINE UNITS 56

1.2 CRANE OPERATION UNITS 57

2. EXPLANATION OF EACH EQUIPMENT 58

2.1 MACHINE MONITOR 58

2.1.1 MONITOR BASIC ACTION AND DISPLAY 60

2.1.2 WARNING DISPLAY 66

2.2 SWITCHES 67

2.3 MOMENT LIMITER (OVERLOAD DETECTOR) 71

2.3.1 CONFIGURATION OF MOMENT LIMITER 71

2.3.2 FUNCTIONS OF MOMENT LIMITER 72

2.3.3 MOMENT LIMITER OPERATION AND CANCELLING (RECOVERY) 74

2.3.4 MOMENT LIMITER FUNCTIONS 77

2.3.5 MAINTENANCE SWITCH 85

2.4 OVER-HOISTING PREVENTION DEVICE 86

2.5 OPERATION LEVERS AND PEDALS 87

2.6 LOCKING COVER 90

2.7 ENGINE BONNET 91

2.8 FUSE 93

2.9 FUSIBLE LINK 94

2.10 HOLDER FOR OPERATION MANUAL 94

2.11 GREASE GUN HOLDER 94

3. OPERATION 95

3.1 INSPECTING AND ADJUSTING BEFORE STARTING ENGINE 95

3.1.1 VISIBLE CHECKS 95

3.1.2 PRE-OPERATION INSPECTION 98

3.1.3 OPERATIONS AND CHECKS BEFORE STARTING ENGINE 108

3.1.4 INSPECTION AFTER STARTING ENGINE 109

3.2 STARTING ENGINE 112

3.2.1 NORMAL STARTING OF ENGINE 112

3.2.2 STARTING ENGINE IN COLD ENVIRONMENT 113

3.3 OPERATIONS AND CHECKS AFTER STARTING ENGINE 114

3.3.1 WARM-UP 114

3.4 STOPPING ENGINE 116

3.5 BREAK-IN OPERATION 117

3.6 MACHINE TRAVELLING POSTURE 118

3.7 STARTING (FORWARD AND BACKWARD)/STOPPING THE MACHINE 119

3.8 CHANGING DIRECTION OF THE MACHINE 123

3.9 SLEWING THE MACHINE 125

3.10 CAUTIONS BEFORE CRANE OPERATION 126

3.11 OPERATION BEFORE CRANE WORK 128

3.12 CRANE OPERATION POSTURE 130

Page

55

ii

Item

3.13 HOISTING AND LOWERING 131

3.13.1 NORMAL HOISTING AND LOWERING 131

3.13.2 HOISTING OPERATION WITH HOOK STOWAGE SWITCH 132

3.14 BOOM DERRICKING OPERATION 133

3.15 BOOM TELESCOPING OPERATION 134

3.16 SLEWING OPERATION 135

3.17 CRANE STOWAGE OPERATION 136

3.17.1 CRANE STOWAGE OPERATION AT THE TIME OF SIMPLE STOWAGE OF

HOOK BLOCK

3.17.2 CRANE STOWAGE OPERATION AT THE TIME OF NORMAL STOWAGE OF

HOOK BLOCK

3.18 PROHIBITED OPERATIONS DURING CRANE WORK 141

3.19 PERFORM TRAVELLING WITH HOISTED LOAD 143

3.19.1 PRECAUTIONS FOR TRAVELLING WITH HOISTED LOAD 143

3.19.2 OPERATION POSTURE DURING TRAVELLING HOIST 144

3.19.3 OPERATION OF TRAVELLING HOIST WORK 145

3.19.4 CANCEL OPERATION OF TRAVELLING HOIST OPERATION POSTURE 145

3.20 BLADE OPERATION 146

3.20.1 PRECAUTIONS WHEN USING THE BLADE 146

3.20.2 BLADE OPERATION 147

3.20.3 WORK THAT CAN BE DONE WITH THE BLADE 147

3.21 PARKING THE MACHINE 148

3.22 INSPECTION AND CHECK AFTER COMPLETING WORK 149

3.22.1 AFTER STOPPING ENGINE 149

3.22.2 LOCKING 149

3.23 CAUTIONS IN DRIVING 150

4. HANDLING WIRE ROPE 153

4.1 CRITERIA FOR WIRE ROPE REPLACEMENT 153

4.2 WINCH WIRE ROPE REEVING SYSTEM AND GROSS RATED LOAD 155

4.3 CORRECTIVE ACTIONS AGAINST TWISTED WIRE ROPE 156

5. TRANSPORTATION 159

5.1 LOADING/UNLOADING 160

5.1.1 LOADING 161

5.1.2 FIXING THE MACHINE 163

5.1.3 UNLOADING 164

5.2 HOISTING MACHINE 165

5.2.1 HOISTING MACHINE WITH BOOM LOWERED 165

5.2.2 HOISTING MACHINE WITH BOOM RAISED 167

6. HANDLING MACHINE IN COLD ENVIRONMENT 169

6.1 PREPARING FOR LOW TEMPERATURE 169

7. LONG-TERM STORAGE 172

7.1 BEFORE STORING MACHINE 172

7.2 DURING STORAGE 172

7.3 AFTER STORAGE 172

Page

136

139

iii

Item

8. TROUBLESHOOTING 173

8.1 WHEN FUEL RUNS OUT 173

8.2 PHENOMENON WHICH IS NOT A FAULT 173

8.3 WHEN BATTERY HAS DISCHARGED 174

8.3.1 BATTERY HANDLING PRECAUTIONS 174

8.3.2 REMOVING/INSTALLING BATTERY 175

8.3.3 CAUTIONS IN CHARGING BATTERY 176

8.3.4 STARTING ENGINE WITH BOOSTER CABLE 177

8.3.5 STARTING ENGINE 178

8.4 WHEN THESE PHENOMENA HAPPEN 179

8.4.1 ELECTRICAL COMPONENTS 179

8.4.2 MACHINE BODY 179

8.4.3 ENGINE 180

8.4.4 MOMENT LIMITER COMPONENTS 182

8.4.5 OVER-HOISTING PREVENTION DEVICE 182

8.5 LIST OF ERROR CODES 184

INSPECTION AND MAINTENANCE

1. PRECAUTIONS FOR MAINTENANCE 188

2. BASIC MAINTENANCE 191

3. LEGAL INSPECTION 194

4. PERIODIC REPLACEMENT OF IMPORTANT COMPONENTS 195

5. CONSUMABLES 196

6. OTHER REPLACEMENT PARTS 197

7. USE OF FUEL AND LUBRICATING OIL 198

7.1 USE OF FUEL AND LUBRICATING OIL ACCORDING TO TEMPERATURES 198

8. STANDARD TIGHTENING TORQUE 200

8.1 STANDARD TIGHTENING TORQUE LIST 200

9. INSPECTION AND MAINTENANCE LIST 201

10. MAINTENANCE PROCEDURE 203

10.1 FIRST MAINTENANCE OF NEW MACHINE 203

10.1.1 INITIAL 50 HOURS MAINTENANCE 203

10.1.2 INITIAL 500 HOURS MAINTENANCE 203

10.2 PRE-OPERATION INSPECTION 203

10.3 IRREGULAR MAINTENANCE 204

10.4 MAINTENANCE EVERY 50 HOURS 223

10.5 MAINTENANCE EVERY 100 HOURS 225

10.6 MAINTENANCE EVERY 250 HOURS 226

10.7 MAINTENANCE EVERY 500 HOURS 230

10.8 MAINTENANCE EVERY 1000 HOURS 233

10.9 MAINTENANCE EVERY 1500 HOURS 235

10.10 MAINTENANCE EVERY 2000 HOURS 236

10.11 MAINTENANCE EVERY 3000 HOURS 239

Page

187

iv

Item

SPECIFICATIONS

1. PRINCIPAL SPECIFICATIONS LIST 242

2. SPECIFICATION DIMENSIONAL DRAWING 243

3. RATED TOTAL LOAD CHART 244

4. WORKING RADIUS/LIFTING HEIGHT 247

SEARCHER HOOK (OPTION)

1. SAFETY PRECAUTIONS 250

1.1 MOMENT LIMITER SETTINGS 250

1.2 SAFETY LABEL LOCATIONS 251

2. NAMES OF SEARCHER HOOK PARTS 253

3. MONITOR INDICATION 254

4. MOMENT LIMITER OPERATION AND CANCELLING (RECOVERY) 256

5. OPERATION 258

6. INSPECTION AND MAINTENANCE 261

6.1 CONSUMABLES 261

6.2 INSPECTION AND MAINTENANCE LIST 262

6.3 PRE-OPERATION INSPECTION 263

6.3.1 CHECKING BEFORE STARTING ENGINE 263

6.3.2 INSPECTION AFTER STARTING ENGINE 264

7. WORKING RADIUS AND RATED TOTAL LOAD 265

7.1 WORKING RADIUS AND LIFTING HEIGHT CHART FOR SEARCHER HOOK 265

7.2 RATED TOTAL LOAD CHART FOR SEARCHER HOOK 266

Page

241

249

v

This Page Intentionally Left Blank.

vi

INTRODUCTION

1. INTRODUCTION 2

2. FOR SAFE USE OF THE MACHINE 3

3. MACHINE OVERVIEW 4

4. QUALIFICATIONS FOR OPERATION 6

5. TERMINOLOGY 7

6. NECESSARY INFORMATION FOR SERVICING 12

1

1. INTRODUCTION

Thank you for purchasing Maeda Crawler Crane CC423S-1.

This manual is a guidebook for safe and effective use of this machine.

This manual describes the procedures and precautions to follow for proper operation and

maintenance of the machine.

Many accidents are caused due to failure to observe safety precautions for operation,

inspection, and maintenance.

Be sure to read this manual and understand the procedures for machine operation,

inspection, and maintenance thoroughly before using this machine.

Failure to observe the basic precautions described in this manual may lead to serious

accidents.

Improper operation of this machine can lead to serious injuries or death.

Operators and maintenance personnel must always read this manual prior to

operation or maintenance of this machine.

Keep this manual in a designated place so that all personnel that work on this

machine will read it for reference periodically.

• Avoid operating this machine before understanding this manual thoroughly.

• Keep this manual at hand so that you can read it when necessary.

• If you lose or damage this manual, contact Maeda or our sales service agency

immediately to order a new one.

• This manual should always accompany this machine upon transfer of the

machine to the next owner.

If the machine is resold to a third party without informing us in advance, no

warranty whatsoever shall be applicable.

• This manual is based on the data that was available at the time of the creation of

the manual.

The information of this manual, including maintenance specifications, tightening

torque, pressure, measuring method, adjustment value, and illustrations, are

subject to change without prior notice due to continuous machine improvement.

These changes may affect the machine maintenance procedure. Always obtain

the latest information from Maeda or our sales service agency before performing

maintenance of this machine.

For safety instructions, refer to “2. For Safe Use of the Machine” on page 3 and

“Safety” on page 15 and later.

Storage place of the operation manual

Pocket behind the operator seat

2

2. FOR SAFE USE OF THE MACHINE

This manual classifies the risks into the following three categories for easy understanding of the safety

information.

This denotes that there is an imminent hazard which will cause serious

This manual also uses the following indications to provide other precautions for handling the

machine and helpful information.

CAUTION

NOTES

The operations, inspections, maintenance and safety precautions for this machine that are

outlined in this manual are relevant to specified tasks.

It is impossible to anticipate all situations where the machine is used.

Thus, the precautions given in this manual and on this machine do not necessarily cover every

safety issue.

When performing the machine operation, inspection or maintenance in a situation that is not

covered by this manual, be sure to take necessary measures and actions for safety on your own.

Even in the above case, never attempt work or operations that this manual prohibits you to do.

injury or death.

It also provides information on how to avoid such hazard.

This denotes that there is a hazard which can cause serious injury or

death.

It also provides information on how to avoid such hazard.

This denotes that there is a potential hazard which may cause minor or

moderate injury or serious damage to the machine.

It also provides information on how to avoid such hazard.

This denotes that failure to properly handle the machine may damage it

or shorten its life.

This denotes helpful information.

3

3. MACHINE OVERVIEW

3.1 SPECIFIED OPERATIONS

This machine is to be used for the following operation(s):

• Crane operation

• Travelling hoist operation

This machine is a mobile crane consisting of the upper swiveling body equipped with a boom

type crane and the lower crawler type carrier.

This self-propelled crane is capable of moving (travelling) in the work site and craning an object

weighing up to the rated total load.

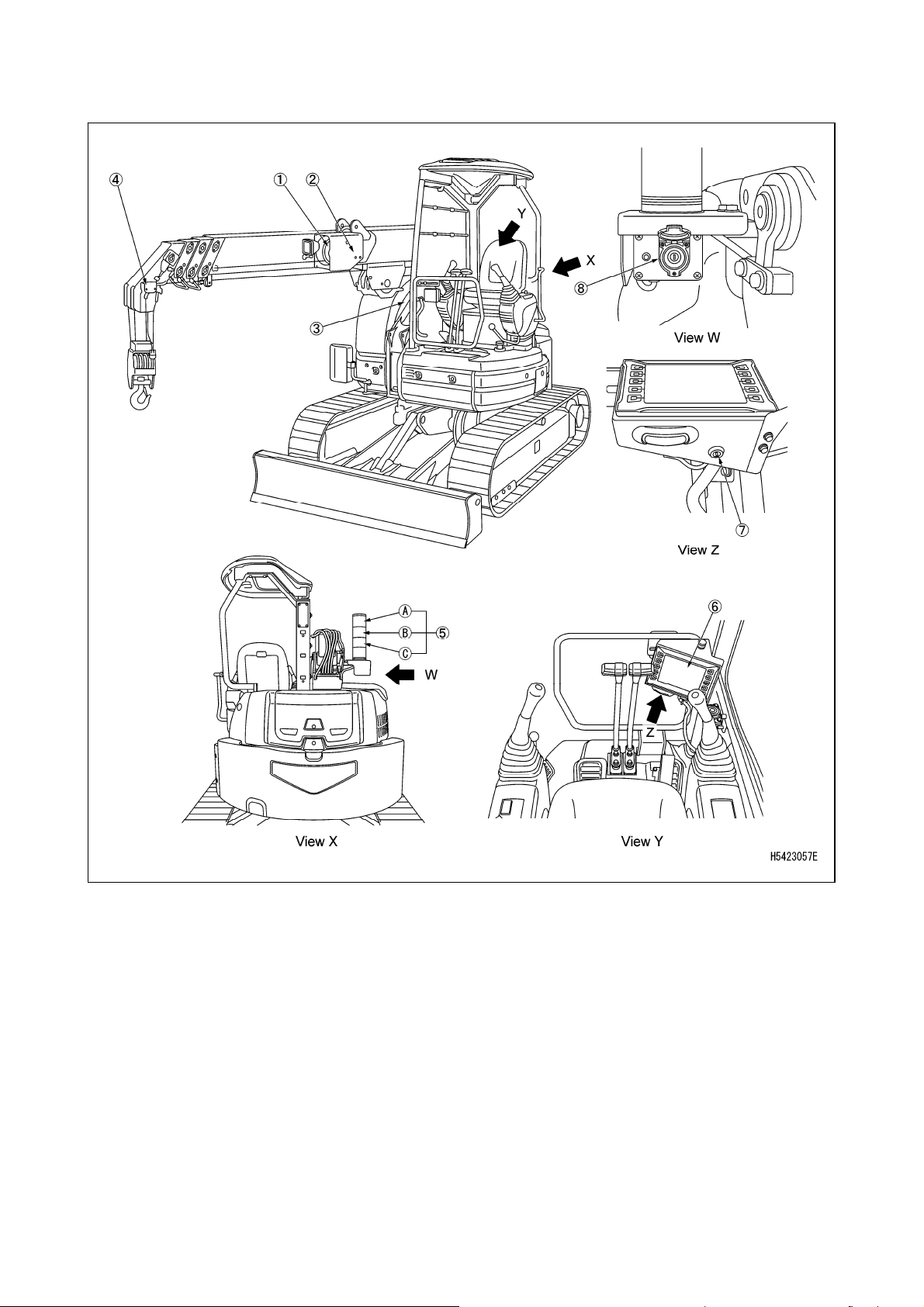

3.2 MACHINE STRUCTURE

EXTERNAL VIEW

(1) Carrier

(2) Upper slewing body

(3) Safety device

In this manual, the front, rear, left and right directions are defined with the

basic reference direction that the operator sits on the operator’s seat with

the carrier’s sprocket (A) in the rear and viewing the machine’s travelling

direction (forward). For the slewing of boom (upper slewing body), the

boom slewing directions (clockwise for right and counterclockwise for left)

are determined as viewed from above the machine.

4

This machine is composed of the following units and systems:

CARRIER

Consists of the travelling system.

UPPER SLEWING BODY (CRANE)

Consists of the engine, travelling operation unit, crane operation unit, boom telescoping unit,

boom derricking unit, slewing unit, hook block and winch system.

SAFETY DEVICE

Comprises the over-hoisting prevention device, over-lowering prevention device, overload

preventive device, slinging rope detachment protector, hydraulic safety valve, telescoping

cylinder hydraulic automatic locking device, derricking cylinder hydraulic automatic locking

device, alarm buzzer, machine body inclination alarm, levelling instrument (monitor display),

tri-colour revolving working status lamp, travelling crane stop, travelling automatic stop, working

radius limiter function, irregular winding prevention roller, crane operation recording function.

3.3 MACHINE FUNCTIONS

CARRIER

• The carrier is of a crawler type, which facilitates running in rough terrain and soft ground.

• Operating the two travelling levers enables not only travelling direction changes (forward,

backward, right and left) but also pivot turns and spin turns.

UPPER SLEWING BODY

• The upper slewing body is allowed to perform a 360 degrees slewing by slewing operation.

• Through the combined use of the telescopic boom, derrick and slewing systems besides the

winch system, the crane can raise and lower the hook block to move the lifted object to the

desired position within the rated total load and the specified working envelope.

5

4. QUALIFICATION FOR OPERATION

• A high incidence of occupational accidents in crane operation has been reported.

Be aware that experienced engineers are also no exception.

• Warnings and precautions defined in this manual shall be observed for safety assurance

during operation of the machine.

4.1 QUALIFICATION FOR CRANE OPERATION

Only personnel that have obtained the required license or training stipulated by laws and

regulations applicable to the place of use are qualified to operate this machine.

Contact the relevant government office or our sales service agency for further information.

6

5. TERMINOLOGY

5.1 TERMS AND DEFINITIONS

RATED TOTAL LOAD

The maximum load that can be applied according to the

boom length and angle. The load includes the mass

(weight) of hoisting accessories (hooks) and slinging

ropes.

RATED LOAD

A load derived by subtracting the mass (weight) of hoisting

accessories (hooks) and slinging ropes from the rated total

load, and can be hoisted.

WORKING RADIUS

A horizontal distance between the axis of slewing and the hook

centre.

BOOM LENGTH

A distance between the boom primary pin and the sheave pin

at the tip of the boom.

DERRICKING ANGLE

An angle which the boom forms with the horizon.

LIFTING HEIGHT ABOVE GROUND

A vertical distance between the hook bottom end and the

ground with the hook raised to the upper limit.

7

5.2 DIAGRAM OF WORKING RADIUS AND LIFTING HEIGHT

• The working radius/lifting height shows relationship between working radius, boom angle

and lifting height above ground of this machine with no load hoisted, and deflection of the

boom is not included.

• Stage “3” in the diagram of working radius and lifting height indicates that one half

portion of the “

1. In the figure on the right, point A denotes a boom angle

and point B denotes a lifting height above ground.

The same working radius applies to point A and point B.

2. The “diagram of working radius and lifting height” shows

the relationships between the working radius, boom

angle and lifting height at no load, allowing for no

deflection in the boom.

A deflection occurs in the boom when an object is hoisted,

which causes the working radius to widen slightly.

The rated total load decreases with increase in the

working radius. Actual crane operation requires the

planning of work, allowing for sufficient clearance more

than that provided in the diagram.

mark” is extruding from the 2nd stage boom.

8

5.3 RATED TOTAL LOAD CHART

• Rated total load chart is based on level, hard ground.

• The rated total load in the chart is based on actual working radius with deflection which

occurs in the boom under load.

• When boom (2) is extended even for a minimal extent, perform the work within the

capacity indicated in the column of “boom (2)”.

• When boom (3) is extended even for a minimal extent, perform the work within the

capacity indicated in the column of “boom (3)”.

• When more than one-half of the “

mark” of boom (3) is exposed from boom (2), perform

the work within the capacity indicated in the column of “boom (4)”.

• If working radius exceeds the value of Working Radius column in the chart by any extent,

work should be performed within the rated total load in the next column of Working

Radius.

• The rated total load chart indicates the load including the mass of hoisting accessories

(hook mass: 30 kg).

CC423S-1 RATED TOTAL LOAD CHART

Working

radius

(m)

(1) 3.18 m boom (2) 5.03 m boom

Stationary

hoist

Travelling

hoist

Stationary

hoist

Travelling

hoist

(3) 6.87 m

boom

Stationary

hoist

(4) 8.71 m

boom

Stationary

hoist

1.50 2930 1465 2930 1465 1870 1190

2.00 1730 865 1710 855 1710 1190

2.50 1200 600 1190 595 1190 1190

2.85 980 490 980 490 980 980

3.00 900 450 900 900

3.50 720 360 720 720

4.00 600 300 600 600

4.50 500 250 500 500

4.70 460 230 460 460

5.00 430 430

5.50 370 370

6.00 330 330

6.54 290 290

7.00 260

7.50 235

8.00 215

8.38 200

Boom angle

range (degrees)

0 – 42.9 0 – 64.2 0 – 72.3 0 – 76.5

9

The rated total load chart provides the maximum loads that the crane is capable of hoisting

depending on boom length, for each working radius.

Boom length

The headings in the rated total load chart, “3.18 m boom (1)”, “5.03 m boom (2)”, “6.87 m boom

(3)” and “8.71 m boom (4)” denote the states displayed in the following figures:

1. “3.18 m boom (1)”: All the booms are retracted.

2. “5.03 m boom (2)”: Booms (3) and (4) are retracted, with boom (2) fully extended.

If boom (2) is extended even to a small extent, work should be performed in accordance with

the values of this column.

3. “6.87 m boom (3)”: With boom (2) fully extended, booms (3) and (4) are in a state of

intermediate extension, where half of the “

mark” is exposed from boom (2).

If booms (3) and (4) are extended even to a small extent, work should be performed in

accordance with the values of this column.

10

4. “8.71 m boom (4)”: All the booms are fully extended.

If more than half of the “

mark” of boom (3) is exposed from boom (2), work should be

performed in accordance with the values of this column.

11

6. NECESSARY INFORMATION FOR SERVICING

When arranging servicing of the machine, or when ordering parts, please contact the Company

or our sales service agency with the following information.

Machine ID plate

This is located on the lower right part of the canopy.

Engine No. ID plate location

This is located on the upper surface of the engine.

12

EPA ID plate and location

This is located on the upper surface of the engine.

EPA: Environmental Protection Agency

(US Environmental Protection Agency)

Hour meter location

This is displayed on the machine monitor.

13

This Page Intentionally Left Blank.

14

SAFETY

1. BASIC PRECAUTIONS 16

2. OPERATION RELATED PRECAUTIONS 22

3. TRANSPORT PRECAUTIONS 38

4. TOWING PRECAUTIONS 39

5. MAINTENANCE PRECAUTIONS 40

6. SAFETY LABEL LOCATIONS 47

All the safety precautions defined in this manual should always

be read and observed.

Failure to follow the safety precautions can cause serious

personal injury or death.

15

1. BASIC PRECAUTIONS

Incorrect operation and servicing may result in serious bodily accidents. Before starting operation and

servicing, read this manual and safety labels to observe their warnings and precautions.

1.1 PRECAUTIONS BEFORE STARTING WORK

OBSERVE THE MANUAL AND SAFETY LABELS

• Read well and understand this manual as well as the safety labels

attached to various parts of this machine. Attempt to

drive/operate without understanding fully may result in wrong

operation that may cause personal or equipment accidents.

• Fully understand the proper use and inspection/maintenance

procedures, and perform the work safely.

• Make sure this manual and the safety labels attached to various

parts of this machine are legible all the time.

Whenever illegibility or loss occurs, order us or our sales service

agency and put the safety label back to the original location.

QUALIFICATION FOR OPERATION

• The operators of this machine are required to have adequate qualification.

Be sure to acquire the qualification before engage in the operation.

See “Introduction 4. Qualifications for Operation” for details of the operational qualification.

• When performing operations using this machine, be sure to carry the “mobile crane operator’s license”

or the “completion certificate of skill training course for the operation of light duty mobile cranes all the

time. Also, when performing a slinging operation, always carry the “completion certificate of skill

training course for slinging operation”.

• The operators are requested to receive education and training of the handling methods and other

subjects at the office, and obtain sufficient operation skills before work.

COMMIT TO SAFE OPERATION

• Follow the instructions and signs given by the manager and work supervisor, and observe safety first

during work.

• Follow the crane work basics during work.

• Always make sure to carry out inspections before using this machine.

• Do not work under bad weather for instance strong wind, thunder or mist.

• Do not drive under any condition when you are overtired, under the influence of alcohol or after taking

soporific drugs.

• Follow all of the workplace rules, safety regulations and operation method sequences during

operations and inspection/maintenance.

• Pay attention to surrounding conditions and pedestrians all the time during operation.

Whenever pedestrian approaches unwarily, abort the operation once, and take a measure such as

issuing a warning.

• When operating, be mentally prepared for unexpected situation so that you can take measures

immediately.

• Never attempt any use out of the capabilities and purposes described in this manual under any

circumstances.

• Observe the designated rated total load and work range when operating.

• Never attempt inattentive driving, harsh driving or awkward operation under any circumstances.

• Pull out the key when leaving the operator’s seat.

16

1.2 PREPARING FOR SAFE OPERATION

PROVIDE SAFETY DEVICES FOR SURE

• Check that all guards, covers and mirrors are attached properly. Repair immediately if damaged.

• Understand how to use the safety devices well and use properly.

• Do not detach the safety devices under any circumstances. Keep control to achieve proper function all

the time.

• Improper use of the safety devices may lead to serious accidents.

• Do not rely too much on the safety devices whilst operating.

PREPARE FOR ABNORMALITY

• Make sure to carry out inspections and maintenances, and make

an effort to prevent accidents before happening.

• Whenever you feel an abnormality in the machine, abort the

operation immediately, ensure safety and report to the manager.

• Assign in advance who takes which solution to prevent secondary

accident.

• Never operate the machine when fuel or hydraulic oil is leaking

from the machine. Report the manager about the abnormality,

and repair the leaking point of the fuel/hydraulic oil completely

before use.

The fuel for this machine is diesel fuel. Be especially careful for

the presence of fuel leak.

• Before leaving the machine, lower the hoisted load to the ground,

stop the engine and pull out the starter switch key.

TEMPORARY STORAGE WHEN ABNORMALITY IS FOUND WITHIN MACHINE

In case the machine is found with an abnormality and is therefore

stored temporarily waiting for service, apply following measures to

notify all persons in the office that “the use is prohibited due to

failure.”

• Put on warning tags on the operation lever and other applicable

parts.

Write clearly the information such as abnormality contents, name

and contact of the storage manager, and the term of storage.

• Keep it immovable when parking by, for instance, putting the

blocks on the rubber tracks as pawls.

• Pull out the engine key and keep it with you.

WEAR PROTECTIVE EQUIPMENT AND CLOTHES SUITABLE FOR WORK

• Always put on a helmet and safety shoes. Be sure to wear

protective equipment appropriate to the work such as goggles,

masks, gloves, ear protection and safety harnesses.

• Long hair that protrudes from the helmet is in danger of getting

caught in the machine, so take precautions so that it will not

become entangled.

• Do not wear loose garments or accessories as these may get

caught on operation levers, the start switch, the emergency stop

switch or other protruding parts, leading to unexpected movement

of the machine.

• Check the functioning of all protective equipment before use.

17

USE OF MACHINE THAT WAS RENTED OR PREVIOUSLY USED BY SOMEONE ELSE

Check the following subjects in writing before using any machine that was rented or previously used by

someone else.

In addition, check the inspection record table for the maintenance conditions such as the periodic

inspections.

(1) Crane capacity

(2) Crane maintenance conditions

(3) Behaviors and disadvantages unique to the crane

(4) Other subjects that require attention while operating

(a) Operating condition of brakes, clutch and others

(b) Presence/absence and lighting condition check-up of lighting and rotating lamps

(c) Operating condition of hook, winch, boom and others

ALWAYS KEEP THE MACHINE CLEAN

• If the machine remains contaminated with soil, sand, oil and

grease, it may cause slipping, tripping or tumbling when getting

on the machine or maintenance servicing. Thus, wipe off the soil,

sand, oil and grease sticking to the machine to keep it clean all

the time.

• When washing the machine with water or cleaning it with steam,

prevent its electrical devices from being directly splashed with

water. Water entering the electrical system is dangerous and will

cause electrical devices to malfunction resulting in faulty or

improper operations. If the machine malfunctions, it may behave

unexpectedly, resulting in serious injury.

CLEAN AND TIDY UP THE OPERATOR’S CABIN.

• Before getting in the cabin, wipe off shoe soles to remove dirt, oil and grease. Stepping on the pedals

with shoes that are contaminated with dirt, oil and grease may cause slipping, resulting in an accident.

• Do not leave parts or tools in the operator’s cabin. The parts and tools left in the cabin may cause

unexpected actions, resulting in serious injury.

• Do not attach suction cups to the window glass. It may work as a lens to cause fire.

• Do not bring any dangerous substances (such as combustibles and explosives) in the cabin.

• Do not use a mobile phone during running or operating. It may disturb operations, resulting in serious

injury.

PROVISION OF FIRE EXTINGUISHER AND FIRST AID BOX

Always observe the following to prepare for injuries and fires.

• To prepare in case of fire, decide on a location and install a fire

extinguisher, and make sure to read the label for terms of usage.

• Decide the location to store the first aid box. In addition, inspect

the first aid box periodically and replenish the contents as

necessary.

• Decide the measures to take upon an injury or fire accident.

• Decide how to contact the emergency address (for instance the

emergency physician, ambulance or fire department), and put up

the contact address at designated position so that anyone can

make the contact.

18

1.3 PRECAUTIONS FOR FIRE PREVENTION

WHAT TO DO IF A FIRE OCCURS

• Turn the starter switch OFF to stop the engine.

• Get out of the machine by using a handrail and steps.

• Do not jump off the machine. You may fall and get hurt.

PREVENTING FIRE

• Fire caused by fuel, oil, anti-freezing fluid, or wind-washer

liquid

Attempt to let a fire approach the fuel, oil, anti-freezing fluid, or

wind-washer liquid may result in catching fire. Strictly observe the

following.

• Do not smoke or use fire near the machine.

• Before refueling, be sure to stop the engine.

• Do not leave the site when replenishing the fuel or oil.

• Close and securely tighten the cap of fuel tank and hydraulic oil

tank.

• Do not spill fuel on an overheated surface and parts of electric

system.

• After refueling, cleanly wipe off spilt fuel and oil.

• Put rags and other combustibles smeared with oil in a safe

container and store it in a safe place.

• Use incombustible cleaning oil for the objects such as the

components, and do not use diesel fuel, petrol or anything else

that may catch fire.

• Do not weld or gas flame-cut piping and tubing containing

flammable solutions.

• Store the fuel and oil in a specified well-ventilated location and

prohibit public access.

• Before performing grinding or welding of the machine, move

inflammables to a safe place.

• Fire due to deposition or adherence of combustibles.

• If any of such combustibles as dead leaves, chips, paper litters,

and charcoal dust is deposited on or sticking to the peripheral

area of engine exhaust manifold, muffler, battery or under-cover,

remove it.

• To prevent fire caused by bonfire sparks or other types of fire that

can be caught, remove such combustibles as dead leaves, chips,

paper litters, and charcoal dust that may be deposited on or

sticking to the peripheral area of cooling units (radiator and oil

cooler).

• Fire originating from electric wiring

Fire may be incurred by a short-circuit of electric system. Strictly

observe the following.

• Keep every connection of electric wiring clean and fix it securely.

• Check for any loosening or damage of electric wiring on a daily

basis, and if any loosened connector or wiring clamp is found,

re-tighten it and repair or replace any damaged electric wiring.

• Fire originating from piping

Check the clamps and cushions of each hose and tubing to ensure

that they are securely fixed. Any loosening may give rise to vibration

during operation, rubbing with other parts to damage hose, or

spouting of high pressure oil, resulting in fire or physical injury.

• Explosion triggered by lighting fixture

• When inspecting fuel, oil, battery electrolyte and coolant water,

use a lighting apparatus of explosion-proof specifications.

• When disconnecting power source from the machine, follow the

instructions described in this manual.

19

1.4 CAUTIONS IN GETTING ON AND OFF THE MACHINE

USE A HANDRAIL AND STEPS WHEN GETTING ON AN OFF THE MACHINE

When getting on and off the machine, be sure to observe the

following precautions in order to prevent physical accidents such as

slipping and falling or tumbling.

• Use the arrow-marked handrails and steps shown in the figure at

the right when getting on and off the machine.

• When getting on and off the machine, always face the machine,

allow the three parts of limbs (both feet and a hand, or a foot and

both hands) to come into contact with the hand rails and steps to

hold your body.

• Before getting on and off the machine, check the handrails and

steps for any damage or loosening, and for any oil or dirt sticking to

the machine surface. When oil or dirt is deposited, do not fail to

thoroughly clean it so that the surface is not slippery. Repair any

damage and re-tighten any loosened bolts.

• Do not grasp operating levers and locking levers when getting on

and off the machine.

• Never step on the engine bonnet and cover that are not treated with

anti-skidding coating.

• Do not get on or off the machine while holding a tool in hand.

• Do not jump on or off the machine. Also, do not get on or off the

moving machine.

• Even if the machine unexpectedly begins to move unmanned, never

jump on it to stop it.

CAUTIONS IN STANDING UP FROM THE OPERATOR’S SEAT OR LEAVING THE MACHINE

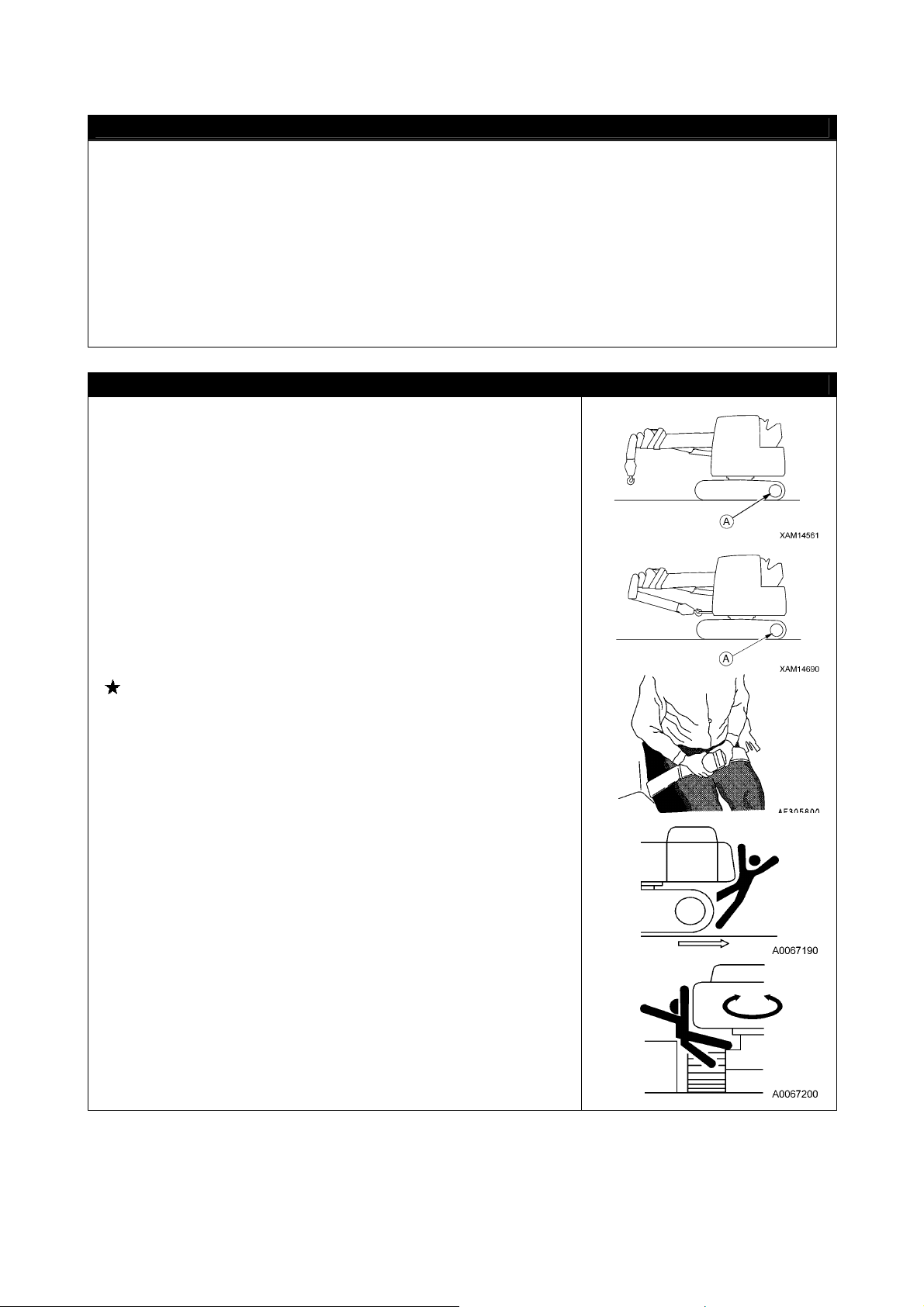

• Before standing up from the operator’s seat, such as to make

adjustments to the operator’s seat, be sure to retract the crane, set

the lock lever (1) to “LOCK” position (L) and to stop the engine.

Inadvertently touching operating levers may cause the machine to

suddenly move and invite serious injury.

• When leaving the machine, be sure to retract the crane, set the lock

lever (1) to “LOCK” position (L), and stop the engine. Also apply

every lock, be sure to bring the key back, and store it in a specified

place.

20

1.5 OTHER PRECAUTIONS

CAUTION AGAINST BEING CAUGHT

In the periphery of the upper slewing body and crane unit, the

clearance varies with the motion of derricking cylinder and winch. If

being caught in it, serious injury may occur.

Keep persons away from all rotating and telescoping sections.

Never allow your body or part of it to get in the following gaps:

• Between the boom and the upper slewing body.

• Between the boom and the derricking cylinder.

• Between winch drum and wire rope.

• Between each sheave and wire rope.

REMODELING THE MACHINE IS PROHIBITED

Do not modify the machine without our written consent under any circumstances. Particularly, partial

welding of the machine may damage the safety device.

The modification raises a safety issue, so consult us or our sales service agency beforehand.

We cannot be held responsible for any personal injury or failure caused by remodeling of the machine

that was performed without consulting us.

CAUTIONS ON ATTACHMENTS AND OPTIONAL UNITS

• We cannot be held responsible for any personal injury, failures or property damage of attachments

and optional units that are not recognized by us.

• Installing an attachment or optional units may give rise to safety and legal issues, and thus the

customer is kindly requested to consult with us or our sales service agency beforehand.

• Depending on the combination of attachments and optional units they may cause interference with

operating cabin and machine parts. Interference with the machine during operation may cause serious

injury. Check to ensure that the attachments and optional units to be used would interfere with the

machine, and use them within the interference-free range.

• Never fail to read the descriptions on the attachments and optional units given in the instruction

manual of the installed attachment as well as this manual.

CAUTIONS ON THE CANOPY WINDOW

Due to their resin construction, when the ceiling window or right side window is scarred, visibility is

impaired and the probability of breakage rises. Replace the scarred ceiling window glass at an early

stage. Leaving the scars increases the risk of breakage by any object falling onto the ceiling window,

resulting in injury.

CAUTIONS ON RUNNING THE ENGINE INDOORS

To prevent the risk of petrol poisoning from starting the

engine/handling fuel and cleaning oil/painting indoors or at a

location with bad ventilation, open the windows and exit doors.

If the ventilation is insufficient even after opening the windows and

exit doors, set up a ventilation fan.

21

2. OPERATION RELATED PRECAUTIONS

2.1 PRECAUTIONS ON WORK SITE

SURVEY AND SAFETY ASSURANCE OF WORK SITE

A number of risks that may cause serious injury are imbedded in a work site. Before starting work, check

the following matters beforehand to ensure that no danger is present at the work site:

• When working near straw-thatched roofs, dead leaves or dead grass, beware of those fire-catching

object.

• Investigate the ground and road surface condition of the work site and decide the best working

method. Do not operate the machine at a site where risk of landslide or rock fall exists.

• Flatten the inclination of the work site before starting work.

• When working over the roadway, enforce “keep out” by, for instance, assigning guides or surrounding

the site by barriers, and ensure the safety of the traffic vehicles and pedestrians.

• Enforce “keep out” to prevent people from entering the work site and apply measures to prevent

people from approaching. Attempt to approach the moving machine may result in pinching or hard

collision by contact, and may result in serious accidents and deaths.

• When running on a shallow bottom stream or weak ground, examine the water depth, water flow

velocity as well as ground condition and land features in advance in order to avoid hazardous place for

travelling and operation.

• The ground of a zone adjacent to a cliff, road shoulder, and deep ditch is likely to be loosened, and

thus it should be avoided for running and performing operation. The ground in such a zone may be

collapsed by the mass and/or vibration of the machine, which may trip or fall. Be especially careful

after rain, use of dynamite, or earthquakes, as the ground will be unstable.

• The ground of an area near an earth fill or in the vicinity of a dug gutter may be collapsed by the mass

and/or vibration of the machine, resulting in the trip or fall of the machine. Before starting operation,

take necessary measures to make the ground intact and safe.

SECURING VISION

Running and operating in places with poor visibility prevent the operator from detecting hazards around

the machine and recognizing work site status, and thus may cause serious injury.

When running and operating the machine in place with poor visibility, strictly observe the following:

• If adequate view cannot be secured, deploy personnel as a marshaller as required. In that case, limit

the number of signaling marshaller to one person.

• In a dark place, turn on the working light and head lamps equipped with the machine, and use

additional lighting devices as required to light up the work site.

• When visibility is spoiled by fog, snow, rain or sand dust, stop the operation.

• If the mirrors mounted on the machine are contaminated, clean them and adjust the field of view to

secure visibility.

RECOGNISING THE SIGNAL OF MARSHALLERS AND STREET SIGNS

• To ensure the identification of weak road shoulder and ground, install sign boards. Further, for a place

with poor visibility, appoint marshaller as required. In that case, limit the number of signaling

marshaller to one person.

The operator should pay attention to sign boards and follow the marshaller’s instructions.

• All the personnel involved should understand the meaning of every signal, sign and sign board.

22

BEWARE OF ELECTRICAL CABLE ABOVE

• Do not let the machine touch the electrical cables above.

High voltage cables may also inflict electrical shock by close

proximity.

• Slinging operators are likely to suffer electrical shocks.

Always observe the following to prevent accidents.

• If the boom or the wire ropes may contact an electrical cable in

the workplace, consult the electricity company and make sure

that the measures (for instance placement of a guard personnel

or application of wrap tubes and warning tags to the electrical

cable) stipulated by the related regulations are taken before

starting work.

• Put on rubber soled shoes and rubber gloves, and be careful

that the body parts unprotected by rubber or other insulation do

not contact the wire rope or the machine frame.

• Place a guide and let them watch so that the boom, wire rope or

machine frame does not go near the electrical cable too much.

Before doing so, decide the emergency signs and other

necessities.

• Ask the electricity company for the voltage in the electrical

cables at the work site.

• Keep a safe distance shown in the following table between the

boom/machine frame and electrical cables.

(Distribution cable)

Low voltage

Special voltage

(Power cable)

Voltage of

Electrical Cable

100/200 V 2 m

6,600 V 2 m

22,000 V 3 m

66,000 V 4 m

154,000 V 5 m

187,000 V 6 m

275,000 V 7 m

500,000 V 11 m

Minimum Safe

Distance

MEASURES WHEN ELECTRIC CHARGE ACCIDENT OCCURS

If an electric charge accident occurs, react calmly and take measures in the following procedure.

1. Report

Immediately report to the electricity company or related management company, and receive

instructions for the power transmission stop, emergency procedures and related matters.

2. Evacuation of related personnel from vicinity of machine

Evacuate all personnel, including workers, from the vicinity of the machine to prevent secondary

disasters.

Personnel who suffered electrical shock by holding a sling rope, guide rope or other conductor when

the machine was charged should evacuate by their own effort.

Do not try to help personnel affected by electric shock. Otherwise, secondary electrical shock

accident will occur.

3. Emergency procedure

In the case of personnel receiving an electric shock due to the machine being electrically charged, do

the following:

(1) If the machine is operational, immediately move it to a safe location away from the cause of the

electrical charge. Take care not to break or disrupt the distribution power cable.

(2) Move the machine to a safe location, and after making sure the machine is not electrically

charged, take the affected personnel to the hospital.

4. Measure after accident

After the accident, do not reuse as is. Such attempt may cause unexpected accidents and enhances

failures.

Ask us or our sales service agency for repair.

23

CAUTIONS WHEN OPERATING CRANE IN LOCATION WITH HIGH OUTPUT MICROWA VE

EMISSION

Operating the crane near high output microwave emission equipment such as a radar or TV/radio

broadcast antenna causes the crane construction to be exposed to the microwave and generates

induced current, therefore is very dangerous. In addition, the mechatronics may become haywire.

Establish grounding between the machine frame and the ground when working in such location. In

addition, slinging operators are requested to wear rubber boots and rubber gloves since risk of

electrical shock by contacting parts such as the hook or wire exists.

BEWARE OF ASBESTOS DUST

Inhalation of asbestos dust may result in lung cancer. This machine

does not contain asbestos, but asbestos may be found in the wall,

ceiling or other construction locations within the work site of this

machine. In addition, be careful of the following when working with

a material that may contain asbestos.

• Put on designated dust free mask and/or other protection

equipment where necessary.

• Do not use compressed air for cleaning.

• Spray water when cleaning to prevent airborne asbestos dust.

• Always work at windward location when operating the machine at

a site that may contain asbestos dust.

• Do not allow unauthorized personnel to approach the work site.

• Strictly observe the assigned rules related to the work site and

environmental standards.

24

2.2 CAUTIONS WHEN STARTING ENGINE

PAY ATTENTION TO WARNING SIGNS

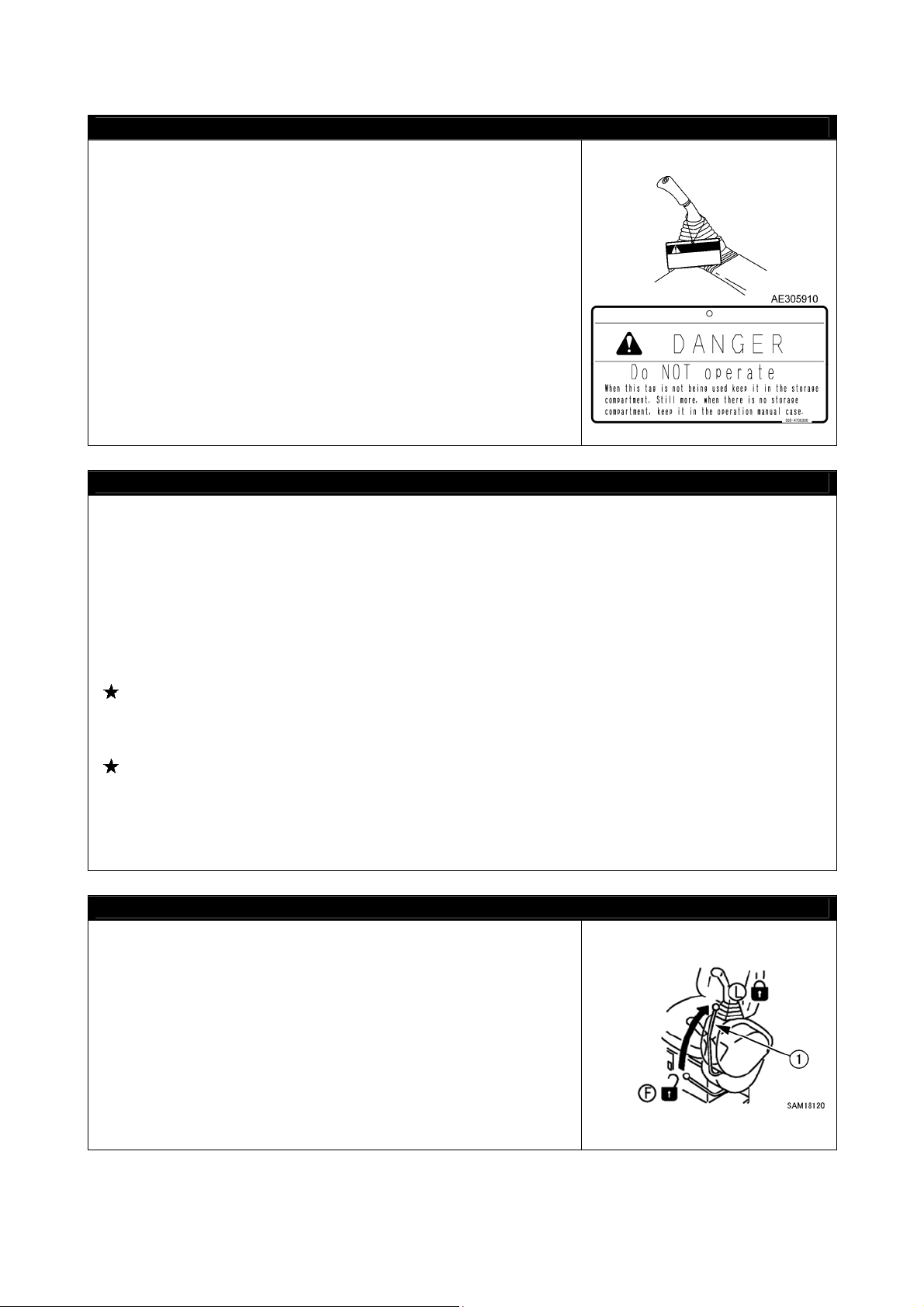

When warning sign “DANGER. Do NOT operate” is put up, the

machine is being inspected and under maintenance. Do not start

the engine and refrain from touching operating levers. Disregarding

the warning sign to operate the machine may give rise to the

danger of involving the maintenance personnel into the rotating

parts or movable parts of the machine, resulting in serious injury.

INSPECTING AND ADJUSTING BEFORE STARTING ENGINE

Prior to starting the engine at the beginning of the day, perform items under “Operation 3.1 Inspections

and Adjustments Before Starting the Engine” and conduct the following inspections. Omitting these

inspections may cause serious bodily accidents.

• Never fail to execute the inspection before starting work.

• Remove the contamination on the window glass surface to secure good view.

• Clean the lens surface of head lamps and working lights and ensure that they are properly lit.

• Check the coolant water level, fuel level, engine oil pan level, air cleaner for any clogging and electric

wiring for any damage.

• Adjust the operator’s seat to the operator’s posture for easy work. Also, check seat belts and their

mounting fixtures for any damage or abrasion.

Refer to the descriptions under “Operation 3.1.2 Pre-operation Inspection (Adjusting the Operator’s

Seat)”.

• Adjust the mirrors to the best position for commanding a good view of rear scene from the operator’s

seat.

Refer to the descriptions under “Operation 3.1.2 Pre-operation Inspection (Adjustment of Mirrors)”.

• Check pedals for any dirt or foreign matter deposited on their movable parts and ensure that they can

function satisfactorily.

• Check instruments to ensure that they function properly and each of the operating levers is in its

neutral position.

Always repair if any result of the above is faulty.

CAUTIONS BEFORE STARTING ENGINE

• Make sure nobody is on or under the machine and in its vicinity

and nobody or no hazard is found within the boom slewing range.

• Do not allow anyone other than the operator to get on the

machine.

• Start the engine only when the operator is sitting on the operator’s

seat.

• Check to ensure that each of the operating levers is in its neutral

position.

• Check to ensure that lock lever (1) is in the “LOCK” position (L).

• Honk the horn for warning before starting the engine.

• Do not start the engine by short-circuiting the starter circuit. This

may cause a fire.

25

CAUTIONS UNDER COLD WEATHER

• Defrost and remove snow from the slewing gear, boom and winch.

Check their movements before starting work.

• Operating the machine without sufficient engine warm-up causes

slow response of the machine to the operation of levers and

pedals, and thus unexpected motion may occur against the

operator’s will. Do not fail to execute the engine warm-up. The

engine requires an adequate warm-up time especially in cold

climates.

• When the battery electrolyte is frozen, do not recharge the battery

or start the engine with another power source. Such act may

cause the battery to catch fire or explode. De-freeze the battery

electrolyte and check for fluid leak before re-charging or starting

the engine by using another power supply.

• After end of the work, wipe off and put on a cover if substances

such as condensation, snow or mud are stuck to the wire harness,

connector (1), switches, sensors or similar part. If the infiltrated

condensation and/or similar substance freeze, the machine may

operate improperly upon the next use and cause unexpected

accidents.

CAUTIONS WHEN STARTING UP USING BOOSTER CABLE

Wrong booster cable connection method may result in fire, so always

observe the following.

• When using a booster cable for engine start, perform the 2-person

operation by one person on the operator’s seat and another on the

battery side.

• When starting the engine using other machine, be careful to

prevent contact between the normal machine and broken

machine.

• Keep the starter switch key of both the normal machine and the

broken machine in “OFF” position when the booster cable is

connected.

• Do not connect to wrong side [connecting (+) to (−), (−) to (+)]

when connecting the booster cable.

• Start connecting from (+) terminal first, but start disconnecting

from (−) terminal (ground) first.

• For the final earth connection, connect to the negative (−) terminal

of the battery of the failed machine.

Refer to the description under “Operation 8.3.4 Starting Engine

with Booster Cable”.

• Avoid contact between clips of the booster cable, and contact

between a clip and the machine when disconnecting the booster

cable.

26

2.3 PRECAUTIONS FOR STARTING CARRIER AND OPERATING CRANE

INSPECTION BEFORE STARTING OPERATION

Omitting the inspections after starting the engine results in delay to discover the machine abnormalities,

and may result in accidents and machine damages.

Inspection should be carried out in a clear area. No unauthorized persons should be able to approach

the machine.

• Ensure that movements of the machine correspond to the symbols on the controller.

• Check the operation status of devices, running status of the machine, winch wind up/down, boom

derricking, and crane operating status such as telescoping and slewing.

• Inspect the sound, vibration, heat and odour of the machine, and check for instrument errors, air leaks,

oil leaks, fuel leaks, water leaks and other bad factors. Be especially careful for the fuel leak.

• Always repair broken parts whenever an abnormality is found.

Attempt to use without servicing may result in unexpected accidents and/or machine failures.

CAUTIONS ON MACHINE FORWARDING/REVERSING AND SLEWING

Always observe the following to prevent serious injuries and

accidental death when moving the machine.

• Set the machine to the travelling posture in the right figure.

Before travelling, be sure to stow the hook block completely.

• Before travelling, move the sprocket to the rear of the machine.

Leaving the sprocket in front of the machine causes the

direction of actual running to be in reverse of the running lever,

and thus the machine may move toward undesired direction,

resulting in serious bodily accidents.

• Make sure the boom is fully lowered and retracted.

• When moving the machine for a short distance, fix the hook

block in the retracting position at the tip of the boom. When

moving it for a long distance, fix the hook block to the hook

holder at the front end of the upper slewing body.

Refer to the descriptions under “Operation 3.6 Machine

Travelling Posture”.

• If any person is staying around the machine, they may come into

contact of the machine or may be caught by it, resulting in a

serious bodily accident.

Before starting to move, strictly observe the following:

• Operate the machine only when the operator is sitting on the

operator’s seat.

• Do not fail to wear the seat belt. Otherwise, the operator may be

forced to jump out of the cabin because of an emergency

braking, resulting in injury.

• Make sure to check around again so that no one or no object is

in the vicinity before starting to move.

• Before starting to move, be sure to honk the horn to warn

people around the machine.

• When running, check to ensure that the travelling alarm sounds

normally.

• When there is a view-obstructing range in the rear of the

machine, appoint a marshaller to ensure that no contact

accident will occur and slew the machine by paying adequate

attention.

Even if the machine is equipped with mirrors and the rear

observation camera, be sure to appoint a marshaller.

27

CAUTIONS WHEN TRAVELLING

Always observe the following to prevent serious injuries and

accidental death when moving the machine.

• Set the machine to the travelling posture in the right figure.

Refer to the preceding subsection “CAUTIONS ON MACHINE

FORWARDING/REVERSING AND SLEWING”.

• Do not attempt looking sideways or other dangerous act when driving.

• Do not over speed, start moving/stopping/slewing suddenly, or

meander since such acts are dangerous.

• During travelling, keep an adequate distance from persons,

structures and other machines to prevent any contact accident.

• Avoid moving over any obstacle. Travel as slowly as possible

when moving over an obstacle for unavoidable reason. Since the

machine tends to tumble more easily in the lateral direction rather

than in the longitudinal direction, never attempt to move over an

obstacle that will cause the machine to inclined to leftward or

rightward.

• When travelling on a rough terrain, keep the vehicle speed at low

level to avoid tumbling and also avoid any abrupt change of

travelling direction. Such may cause the machine to lose balance

or damage the machine or nearby object.

• When running on a bridge or crossing over a structure, check the

withstand strength of the bridge or viaduct against the machine

mass beforehand. Further, when running on a public road, check

with the competent authorities and follow their instructions.

• When operating the machine in a place where machine height is

restricted such as in a tunnel, in a building, under an overpass or

cables, pay close attention to prevent the machine and crane from

coming into contact of those objects and operate the machine

slowly.

BE CAREFUL WHEN TRAVELLING OVER SLOPE

ALWAYS observe the following to prevent serious injuries and death

accidents when travelling over a slope for unavoidable reason.

• When running on a slope, be sure to store the hook block in the

hook holder at the front end of the upper slewing body to form a

running posture. Any simplified fixation of the hook at the tip of

boom gives rise to the risk of loosening during running.

Refer to the descriptions under “Operation 3.6 Machine Travelling

Posture” for the travelling posture of the machine.

• When running on a slope having an inclination of 10 degrees or

more, climb the slope in the reverse direction and run downhill in

the forward direction. Thus, always allow the machine front to face

the valley when running on a slope. Climbing the slope in the

forward direction and going downhill in the reverse direction cause

the machine to be unstable, giving rise to the risk of tumbling or

lateral skidding.

• When travelling on a slope, face the machine perpendicular to the

slant face and never change the direction or travel transversely.

Practice safe travelling by for instance lowering to the plain land

and divert.

• Always keep such condition during running that the machine can

stop any time when it slips or becomes unstable.

• When running downhill, lower the engine revolution and set the

running lever close to the neutral position and run in a low speed.

• When running on a ground covered with grass and leaves or on a

wet steel plate, keep the speed to minimal. If the ground in such

condition is inclined only slightly, it is extremely slippery.

• If the engine comes to a sudden stop, immediately return each

operating lever to its neutral position, and then restart it.

28

BE CAREFUL OF TRIPPING ON UNSTABLE GROUND

Always observe the following to prevent serious injuries and death accidents when travelling over an

unstable ground for unavoidable reasons.

• Do not enter soft ground area. The machine may get stuck.

• The ground near cliff, roadside and deep gully is unstable, so avoid going near such ground as much

as possible.

The machine may trip or fall when the ground loosens due to mass and/or vibration of the machine. Be

especially careful after rain, use of dynamite, or earthquakes, as the ground will be unstable.

• Avoid going near the earth fills or vicinity of dug gutter that are instable.

Crumbles caused by mass and/or vibration of the machine may cause the machine to tilt.

CAUTIONS WHEN TRAVELLING SNOW COVERED OR FROZEN GROUND

ALWAYS observe the following to prevent serious injuries and death accidents when travelling over

snow covered ground or frozen road for unavoidable reason.

• The snow covered grounds and frozen roads cause slips even when the inclination is small, so

decrease the speed when travelling and avoid sudden starting/stopping/slewing. Uphill and downhill

are especially likely to cause slips and thus dangerous.

• Frozen ground tends to be weak with the increase of atmospheric temperature, and may cause the

machine to tumble or obstruct the operator to get off. Be very careful.

• Moving into an area covered with deep snow may cause the machine to tumble or dive into the snow.

Be cautious of erroneously deviating outward from the road shoulder or driving into a snow drift.

• Running on a snowbound site may encounter the risk of tumbling or collision because of an invisible

road shoulder or snow-covered installations. Be very careful.

• Refrain from directly touching metal surface with your hands or fingers in cold and harsh weather

conditions.

Touching metal surface may result in skin freezing to the metal surface.

• Remove snow and/or ice laid on the machine that causes the safety nameplates to be hard to read. Be

especially careful to securely remove those that are on the boom and thus may fall.

CAUTIONS WHEN PARKING

• For parking, select an area with flat and solid ground.

• For parking, select an area without the risk of landslide, rock fall

and water submersion.

• When parking, set the machine to the “travelling posture” as

shown in the figure at the right.

• Make sure the boom is fully lowered and retracted.

• When parking the machine for a short period of time, fix the

hook block in the retracting position at the tip of the boom.

When parking for a long time, fix the hook block in the hook

holder at the front end of the upper slewing body.

• When inevitably stopping the machine on an inclined area, strictly

observe the following:

• Make sure the boom is fully lowered and retracted.

• When parking the machine for a short period of time, fix the

hook block in the retracting position at the tip of the boom.

When parking for a long time, fix the hook block in the hook

holder at the front end of the upper slewing body.

• Direct the boom toward the valley.

• To keep the machine immobile, apply a block as a chock.

• When leaving the machine, strictly observe the following:

• Set the lock lever (1) to “LOCK” position (L), and stop the

engine.

• Apply all locks. Do not fail to remove the starter key to prevent

the machine from operated by other personnel without

approval, and keep it in a specified place.

29

2.4 CAUTIONS DURING CRANE OPERATION

INSPECTION BEFORE STARTING WORK

Check that the safety devices and crane operate properly.

• Operate each of the operation levers, pedals and switches under no load, and check that operations

take place without any abnormality.

Repair immediately if any abnormality exists.

• Check such safety devices as the moment limiter (overload prevention device), over-hoisting

prevention device and over-lowering prevention device to ensure that they function normally.

CAUTIONS WHEN HANDLING THE MACHINE MONITOR

• Use / store the machine monitor under the following ranges of ambient temperature.

Operating temperature: -30 to 60 °C Storage temperature: -30 to 80 °C

• Avoid direct sunlight so that the ambient temperature in the region of the machine monitor does not

exceed the above range.

• Avoid locations with strong acid or alkaline atmosphere as much as possible. Otherwise, unexpected

failures may occur.

• Do not allow external objects etc. to impact the machine monitor body.

Such attempt may damage the case and may result in failures and improper operations.

• Do not press the screen of the machine monitor with excessive force or press with sharp objects such

as the tip of a screwdriver. This may damage the screen and result in failure or incorrect operation.

• Do not disassemble the machine monitor. Such attempt may result in failures and improper

operations.

CAUTIONS WHEN SETTING MOMENT LIMITER

• In the moment limiter, the moment is calculated on the assumption that the machine is placed

horizontally.

If crane work is performed without the machine being placed horizontally, no forecast or warning is

issued even when the rated total load is approached.

Never fail to check the inclination of the machine by using the level.

• When using the moment limiter, check to ensure that the indicators of boom angle, boom length and

actual load are interlocked with the crane motion to give correct values. If the crane is used with no

correct indication given, correct measurement results cannot be obtained, causing serious physical

injury due to tumbling or damage of the machine.

• When using the moment limiter, be sure to check that the setting of wire falls of the moment limiter

matches the wire falls of the crane. If the number of falls of wire does not match, be sure to change

either the setting of number of falls of wire of the moment limiter or the number of falls of wire of the

crane, to make both match with each other. If used without matching the number of wire falls, correct

measurement results cannot be acquired, possibly leading to breakage of the wire rope and serious

bodily injury.

• Do not change the setting carelessly during measurement with the moment limiter. Otherwise, correct

measurement results cannot be obtained, causing serious physical injury due to tumbling or damage

of the machine.

CAUTIONS FOR SELECTING A PLACE TO INSTALL

Always place the machine on a level, stable and solid ground.

It is dangerous to install on any of the following places:

• Simple asphalt pavement

• Thin concrete pavement

• Flagstone pavement

• Areas where under the pavement surface is hollow due to water erosion and the top soil appears to be

hard but soft in the ground

• Soft ground near a road shoulder or dug hole

• Slope

30

CAUTIONS WHEN WORKING ON A SLOPE

When inevitably perform operation on a slope, provide an earth fill

(B) to create a horizontal, solid and strong footing for installing the

machine in order to prevent it from tumbling.

Attempting a diagonal hoisting without ensuring the horizontal

installation of the machine not only disturbs the normal functioning

of the moment limiter (overload prevention device), but also affect

the machine with an unexpected force, resulting in tumbling or

damage of the machine.

FOLLOW INSTRUCTIONS AND SIGNS WHEN WORKING

• When operating the crane, appoint a work supervisor and mutual

signs beforehand, and follow the work supervisor and signs during

operation.

• When operating at a operator’s blind spot, especially follow the

instructions and signs of the work supervisor and operate with

caution.

• When operating the crane, there is a danger of colliding with

slewing boom and upper slewing body and of the gaps between

movable parts of the derrick cylinder that may catch body parts

such as your arm or finger.

The operator is requested to make sure no one is within the

working radius of the crane before operating.

CAUTIONS UNDER COLD WEATHER

• Defrost and remove snow from the slewing gear, boom and winch. Check their movements before

starting work.

• Check the winch brake to ensure that it works properly.

• Operating the machine without sufficient engine warm-up causes slow response of the machine to the

operation of levers and pedals, and thus unexpected motion may occur against the operator’s will. Do

not fail to execute the engine warm-up. The engine requires an adequate warm-up time especially in

cold climates.

For details concerning warm-up, refer to “Operation 3.3.1 Warm-up”.

• Avoid revving up the engine immediately after starting it.

• Deposited snow within the crane operation range may cause tumbling of unloaded objects or catching

feet of operators around the machine. First remove snow before starting a crane operation.

• In cold weather conditions, check that the load before being hoisted is not frozen to the ground or other

substance. Attempt to hoist without knowing the load is frozen and stuck to the ground or other

substance is dangerous.

• At the end of the work, if substances such as condensation, snow or mud are stuck to the wire

harnesses, connectors, switches, sensors or similar parts, wipe them off and put covers on them. If the

infiltrated condensation and/or similar substance freeze, the machine may operate improperly upon

the next use and cause unexpected accidents.

31

PAY ATTENTION TO WEATHER INFORMATION

• A risk of lightning exists in case of a thunderstorm, so abort operating the crane, immediately lower the

load and retract the boom.

• Wind can cause the hoisted load to move back and forth, which could cause the machine to become

unstable. If the hoisted load is affected, immediately lower the load and retract the boom.

• If the maximum instantaneous wind speed is 10 m/s or greater, abort operating the crane, immediately

lower the load and retract the boom.

• Even when the maximum instantaneous wind speed is below 10 m/s, the bigger the hoist load, the

higher the hoist load position, or the longer the boom can increase the effect from the wind. Be very

careful during the work.

• When operating the extended boom, the winch wire rope and electric signal cables are prone to be

blown up by winds, and thus be cautious of the operation. Similarly, the peripheral area of a high-rise

building, winds blow its sides and may gather their velocity much higher, which deserve attention.

• When a load such as a steel plate that has a large area exposed to wind is being hoisted, the wind

arriving from front/rear/side of the boom may cause the machine to trip or damage the boom. Be very

careful during the work.

• The higher the boom is derricked, the higher the probability of tumbling backward is raised by wind

blowing from ahead. Thus, adequate attention is required in the operation.

• When an earthquake occurs, abort the operation and wait until it is over.

The following table indicates approximate relation between the wind speed and wind effect. The wind

speed mentioned in the weathercast is mean wind velocity (m/s) during 10 minutes at 10 m above

the ground.

Force Wind Speed (m/s) Effect On Land

0 Less than 0.3

1 0.3 or more and less than 1.6

2 1.6 or more and less than 3.4

3 3.4 or more and less than 5.5

4 5.5 or more and less than 8.0

5 8.0 or more and less than 10.8

6 10.8 or more and less than 13.9

7 13.9 or more and less than 17.2

8 17.2 or more and less than 20.8

9 20.8 or more and less than 24.5

10 24.5 or more and less than 28.5

11 28.5 or more and less than 32.7 Widespread structural damage.

Smoke rises vertically.

Wind motion visible in smoke.

Wind felt on exposed skin.

Leaves and small twigs move in constant motion.

Dust and loose paper blow up. Small branches begin to

move.

Bushes with leaves start to sway. Waves form on the face of

pond/swamp.

Large branches begin to move. Whistling heard in electrical

wires. Use of umbrella becomes difficult.

Whole trees start to shake. Effort needed to walk against the

wind.

Twigs broke from trees. Progress impeded.

Light structure damage. Slates blown off.

Trees uprooted. Considerable structural damage.

32

CAUTIONS WHEN SLINGING

• Check the following before hoisting a load.

Attempt to hoist the load without checking may result in serious accidents by dropping the load or

tripping.

• Observe the values in the rated total load chart.

• Hoist from the centre of gravity of the load.

• Check that the wire rope of the hook block is vertical.

• When the load leaves the ground, stop winding up the load once and check whether the load is

stable.

• Before hoisting a slung load, always check whether the sling wire rope “retainer device” of the hook

block is hung correctly. If the “retainer device” is not hung, the wire rope may leave the hook block and

cause the load to fall resulting in a serious accident.

• Larger wire rope angle when hoisting the load increases force that applies to the wire rope even when

the load weight is unchanged, thus may cause the wire rope to snip. Give due consideration to slinging

operation so that excessive force is not applied to the wire rope.

• Hoist only 1 load at a time.

Attempts to hoist more than one load may cause the hoist bracket to hit and damage the other hoisted

load, or the loads move and lose balance, causing serious accidents such as tripping.

Do not hoist more than 1 load at a time even if the total combined weight is within the rated total load.

• Hoisting of lengthy load causes the load to lose balance and is dangerous.

In the case of such load, hoist vertically by using a cramp, or achieve balance of the hoisted load by

applying a rope to both ends of the load.

CAUTIONS WHEN HANDLING WIRE ROPE

• Wire ropes can wear out from constant use or old age, so be sure

to inspect every time before work, and replace immediately if at or

beyond the replacement standard.

At the same time, inspect the sheave at the tip of the boom and

the sheave of the hook block. Damaged sheaves accelerate the

damage of the wire ropes.

• Use wire ropes specified by us.

• The operator may be injured by breaking wire strands.

• Always wear leather gloves when handling the wire rope.

• Do not use a wire rope of which any of the following applies:

• 10% or more of strands (except a filler wire) in 1 twist of a wire

rope are snipped.

• The wire rope diameter abrasion is beyond 7% of the nominal

diameter.

• Kinked wire rope.

• Excessively deformed or corroded wire rope.

• Affected by heat or sparks.

33

CAUTIONS WHEN OPERATING CRANE

• Stability of a crane is decisively critical in the transverse direction of the carrier. In the diagonal

direction, although stability is increased, exceeding the rated load may result in damage of the boom

or machine body. Do not turn the moment limiter (overload prevention device) off, even if operating in

the diagonal direction.

• Be sure to check that the override switch is at the “OFF” (auto) position before operating the crane.

Do not attempt to operate the crane with the override switch kept set to the “ON” (cancel) position.

The override switch should be at the “ON” (cancel) position only when the moment limiter is faulty or

during inspection or maintenance works.

• Perform work while paying attention to the display and warning of the monitor of moment limiter

(overload prevention device).

• Attempt to work beyond the capacity of the machine may cause serious accidents and failures caused

by for instance tripping or fluctuation. Observe the rated total load chart when operating the crane.

• Perform the crane operation slowly.

Sudden use of lever or accelerator may cause risks such as shaking, dropping of the load or collision

with the surroundings. Be especially careful to be slow during the slewing operations.

• When operating the crane, appoint a work supervisor and perform the work under the supervisor’s

instructions.

Follow the supervisor’s instructions on the method and procedure for the work. Determine the method

for details of mutual signs and follow the signs.

• Hoisting of lengthy load causes the load to lose balance and is dangerous. In the case of such load,

apply a rope to both ends of to stabilize the hoisted load.

• Do not allow unauthorized personnel to approach the working radius or under the load because of

risks of falling load and contact with load. This could cause a serious bodily accident. Also consider

that the working radius increases when the load is hoisted and the boom is deflected.

• Operations requiring more than the machine performance can cause accidents or failure. Crane

operations must always be carried out according to the rated total load chart.

• Be careful to prevent the wire rope and/or hoisted load from contacting an obstacle such as a tree or

steel when hoisting a load.

If caught by an obstacle, do not forcibly wind up the hoist load, but untangle the caught part before

winding up.

• Do not pull laterally, pull toward you or hoist diagonally. Such attempt may cause the crane to trip or

get damaged.

• It is dangerous to operate the crane under bad weather or at places where the view is not clear.

Work lamps or other lighting devices should be used in dark places.

When the view is bad because of bad weather (rain, fog, snow, etc.), stop the operation and wait until

the weather recovers.

• Do not use for purpose, for instance raising a person using a crane, other than the true purpose.

• If the alarm buzzer of the over-hoist detector sounds, immediately take your hand off the winch lever.

Winding-up of the hook block stops. Then, operate the winch lever “downward” (push it forward) to

wind down the hook block. The hook block also rises when you attempt to extend the boom. Provide

sufficient clearance between the boom and hook block when performing crane operation.

• When the boom is extended, the hook block is wound up. Operate the winch lever “downward” and

extend the boom while lowering the hook block.

• If an overload is caused during work, operate the winch lever “downward” and wind down the winch to

unload.

Do not raise or lower the boom suddenly. Such attempt may cause serious accidents by tumbling.

• The volume of the hydraulic oil in each of the cylinders changes depending on the temperature.

By leaving idle with a load being hoisted, as the time passes by the oil temperature drops and the