Page 1

Multi-Level Switch Kits

Assembly Instructions

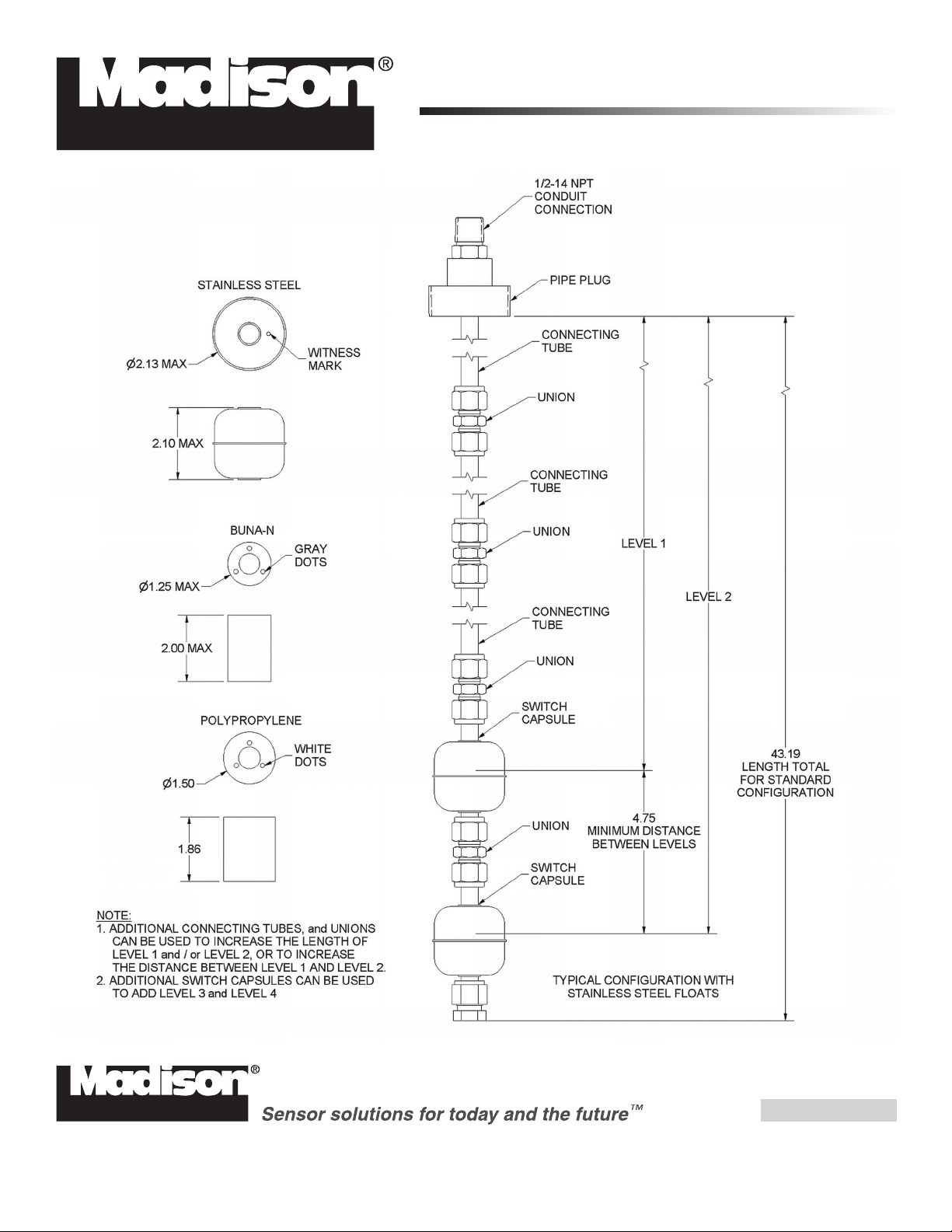

1. Lay out the supplied components in the configuration that your application requires. A typical configuration is

shown in the drawing on reverse. Determine the lengths of the Connecting Tubes required for your application.

(NOTE: The tube end extends into the Union Fitting and End Cap .90")

2. Cut the Connecting (empty) Tube(s) to the lengths that your application requires. DO NOT CUT THE SWITCH CAPSULES

(the short tubes with wires)! We suggest the use of a tubing cutter to get clean, square cuts.

3. De-burr the inside and outside of the cut ends of the tubes with a fine file, sandpaper, etc.

Be sure to remove ALL sharp edges from the inside of the tubes to prevent damage to the insulation on the switch wires.

4. Trial assemble all of the tubes, floats and switch capsules using the supplied union fittings and end cap. The Upper Switch Capsule is

the one with the Red wires and an inner tube. The wires from the Lower Switch Capsule must pass through the inner tube. Be sure that

the Switch Capsules and Connecting Tubes bottom out in the union fittings and end cap. ONLY TIGHTEN THE UNIONS HAND TIGHT!!

Using a continuity indicator (light, buzzer, ohm meter, etc.), verify that the switch actuation levels (L1 and L2) are at the required levels

and the switch action (normally open or normally closed) is correct for your application.

BE CERTAIN THAT YOU HAVE THE SWITCH SET-UP THE WAY YOU REQUIRE BEFORE TIGHTENING ANY FITTINGS!

5. Setting switch operation:

Stainless Steel Floats:

NC - (dry position - switch will open on rising fluid level) round witness mark on end of the float AWAY from the large pipe fitting.

NO - (dry position - switch will close on rising fluid level) round witness mark on end of the float TOWARD the large pipe fitting.

Buna-N Floats:

NC - (dry position - switch will open on rising fluid level) the 3 gray dots on the end of the float TOWARD from the large pipe fitting.

NO - (dry position - switch will close on rising fluid level) the 3 gray dots on the end of the float AWAY the large pipe fitting.

Polypropylene Floats:

NC - (dry position - switch will open on rising fluid level) the 3 white dots on the end of the float TOWARD from the large pipe fitting.

NO - (dry position - switch will close on rising fluid level) the 3 white dots on the end of the float AWAY the large pipe fitting.

6. Re-test the electrical operation of both switches using a continuity indicator.

7. When the switch is completely set-up as you require, tighten the Union Fittings and End Cap, using 13/16" and 7/8" wrenches.

Use the 13/16" to hold the body of the fitting and the 7/8" to tighten the nut. Tighten the nuts 1-1/4 turns past finger tight - no more!

8. Be sure to apply a suitable thread sealant to the pipe threads on the top fitting before installing the switch into your tank.

WARNINGS:

• DO NOT cut or modify the switch capsules (the short tubes with the wires)

in ANY way, except to cut the wires to the required length at installation.

• DO NOT exceed the Maximum Pressure and Temperature ratings*, listed below:

Model

ML-5555

ML-4444

ML-8888

Max. Pr

essure

200 PSIG

150 PSIG

100 PSIG

emperature

Max. T

200˚C / 392˚F

105˚C / 221˚F

105˚C / 221˚F

• DO NOT exceed Current and Voltage ratings*, listed below:

W

atts

60

60

60

60

* NOTE: These ratings are for resistive loads ONLY. For inductive loads, maximum life will be

obtained with the use of appropriate transient suppression. Maximum voltage rating = 240 VAC

• Be sure that ALL fittings are assembled and tightened correctly.

V

oltage

240 VAC

120 VAC

120 VDC

24 VDC

Cur

rent (AMPS) Resistive

0.4

0.5

0.2

0.5

Madison Company 800-466-5383

27 Business Park Drive, Branford, CT 06405 • 203-488-4477 • Fax: 203-481-5036

www.madisonco.com • E-mail: info@madisonco.com

© Copyright Madison Company • ECN # • Effective Date • MF-005, Rev. '

ISO 9001 Certified

Page 2

Multi-Level Switch Kits

Typical Switch Configuration

Madison Company 800-466-5383

27 Business Park Drive, Branford, CT 06405 • 203-488-4477 • Fax: 203-481-5036

www.madisonco.com • E-mail: info@madisonco.com

© Copyright Madison Company • ECN # • Effective Date • MF-005, Rev. '

ISO 9001 Certified

Loading...

Loading...