Page 1

Temperature Data Logging Solutions for

USDA Regulation Compliance and HACCP Programs in the

Meat Industry

Page 2

Simplifying How the World Measures & Records Data

MadgeTech, Inc. is a global company, based in

New England and founded on old-fashioned

principles, customer service, quality, and

trust. MadgeTech’s President, Norman Carlson,

started the company in 1996 and charted the

growth of the product lines and services while

maintaining those solid core principles.

Our ‘Can Do’ team of engineers and technical

sta consistently incorporate new and

innovative ideas into our data loggers. In

short, we push the envelope, raising the bar in

innovation and quality. Our competitors have

praised us by adopting many of our ideas as

their own. Over time, MadgeTech has become

the industry standard in the data logger market.

MadgeTech continuously develops new,

cutting-edge products, creating solutions for

our customers around the world in industries

across the board. Our growing network of

distributors has expanded our presence to

markets far beyond our home-headquarters in

New Hampshire, our products are now sold in

over 100 countries around the world.

Our employees are committed to quality and

customer satisfaction. Behind the full range

of MadgeTech’s products and services is the

cumulative expertise of experienced engineers,

manufacturing and electronic professionals and

technicians. Our knowledgeable sales team can

oer technical advice to assist in selecting the

right product for each application, as well as

providing aer-sales support.

MadgeTech is dedicated to providing customers

with reliable, aordable products, hasslefree ordering, and excellent service, saving

customers time and money. It is our goal to earn

your trust in meeting your needs and providing

innovative solutions. The products and services

that bear the MadgeTech name come with

quality assurance and the best support in the

industry today.

Norman E. Carlson,

Founder & President

Page 3

Data Logging Solutions for Temperature Critical

Applications in the Meat Industry

Wireless Continuous Process Monitoring

Post-Slaughter Pasteurization Cycles

Meat Cooking & Cooling

Smokehouses

Oven Temperature Profiling

Meat Storage

Page 4

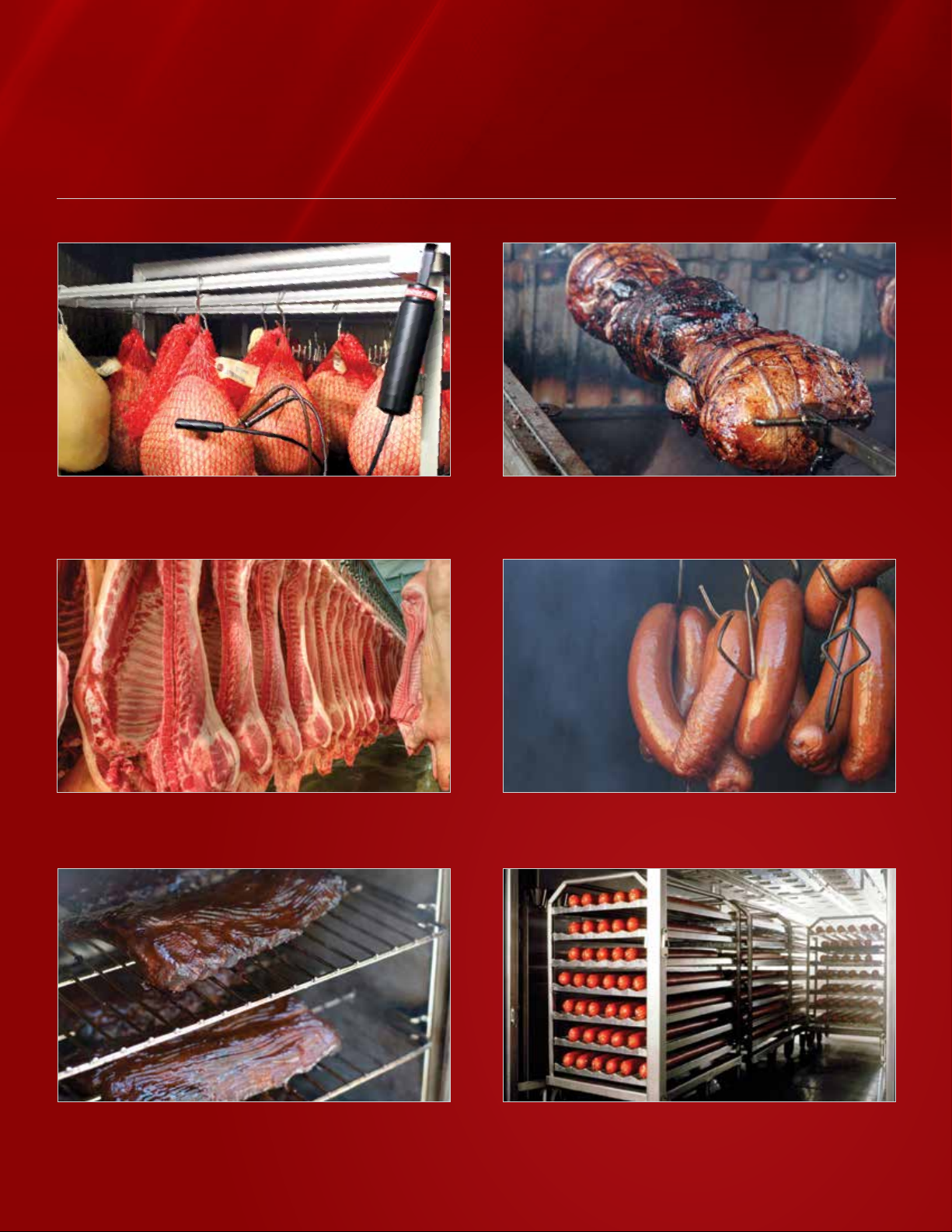

Wireless Continuous Process Monitoring

Cooking, Cooling and Storage Data Loggers

MadgeTech’s wireless, continuous monitoring data logging system provides a streamlined solution for measuring and

recording the cooking, cooling and storage of meat and food products. Wireless data loggers are placed throughout

a facility to measure processes such as cooking and cooling cycles or environmental monitoring in coolers, freezers

or warehouses. The RFC1000 transceivers are placed throughout the site and communicate with the wireless data

loggers. Full communication is performed wirelessly and real-time data is sent back to a central PC. If the data

received is out of a safe range, the system can be configured to send an email, text message or on-screen alarm. Data

can be transmitted up to 2000 maximum outdoors (line of sight, unobstructed) and 500 maximum indoors. To

transmit over longer distances, additional RFC1000s are added.

Wireless Meat Temperature Monitoring

RFOT

The RFOT is designed for use in monitoring and recording the temperature of meat

products during cooking, cooling and storage. It can be used in smokers and other

cooking processes up to 212 °F (100 °C) as well as coolers and freezers down to -4 °F

(-20 °C). It is completely splash proof and can withstand wash down cycles.

Once the loggers are deployed, they can be stopped and started, and data can be

downloaded, from a central PC.

New! Rugged T-Handle

Tested to withstand thousands

of cycles.

4

Probe attachment designed for use

with hot dogs, sausages and other

RFOT-HDA

small linked meat products.

Page 5

Wireless Data Loggers

RFRHTemp2000A & RFTCTemp2000A

MadgeTech has designed the 2000A Wireless Series for customers that require employees to check

temperatures of coolers, freezers, warehouses, etc. This series includes a digital display to see the

current reading, as well as minimum, maximum and average statistics based on the data recorded to

memory. Data is also sent wirelessly back to a central PC through the RFC1000 mesh network.

This series also includes an audible alarm to alert users in close proximity. If the temperature or

humidity exceeds the safe range, the audible alarm enables the user to take immediate action. Email,

text message or on-screen alerts can also be configured.

The RFRHTemp2000A is a wireless temperature and humidity data logger. It is ideal for monitoring warehouses and other temperature

and humidity sensitive environments. The RFTCTemp2000A is a wireless thermocouple based temperature data logger. This device

can measure both ambient temperature as well as thermocouple temperature and can be used for ovens, coolers, freezers, and more.

RFRHTemp2000A

Features

• LCD Screen

Wireless Temperature and

Humidity Data Logger with

LCD display on table mount.

• Audible and LED Alarm

Indicators

• Battery Life Indicator

RFTCTemp2000A

Wireless Thermocouple Based

Temperature Data Logger with

LCD display on wall mount.

Applications

• Coolers

• Freezers

• Warehouses

• Thermal Mapping

Therm-A-lert Series

The Therm-A-lert Series is designed for wireless environmental monitoring throughout a facility. The

Therm-A-lert-P is designed to measure temperatures within coolers and freezers. The built in external

RTD probe comes with a rigid 4.0 in (102 mm) probe sheath with 9 of lead wire to thread into the cooler

or freezer, while the body of the data logger can remain at ambient conditions.

The Therm-A-lert and Therm-A-lert-RH measure ambient temperature and humidity, respectively.

They are ideal for monitoring warehouses and other temperature and humidity sensitive environments.

Therm-A-lert-P

Wireless Temperature

Data Logger with

External RTD Probe

Therm-A-lert-RH

Wireless Humidity

and Temperature

Data Logger

Features

• Greater Internal Memory

Storage

• Great Value

Therm-A-lert

Wireless Temperature

Data Logger

Order today at www.madgetech.com

|

5

Page 6

Cooler/Freezer

•

Smoker

•

RFC1000

•

RFOT

•

RFRHTemp2000A

•

Therm-A-lert-P

•

RFTCTemp2000A

•

RFOT

Wireless Meat

Temperature Data Logger

RFRHTemp2000A

Wireless Temperature and Humidity

Data Logger with LCD Display

RFTCTemp2000A

Wireless Thermocouple Based Temperature

Data Logger with LCD Display

WIRELESS DIAGRAM for the RFOT,

RFC1000

Connected to a USB Port

It’s Easy! Start Logging in 3 Steps...

1

Deploy the Data Loggers

2

Wirelessly Start the Data Loggers

RFRHTemp2000A, RFTCTemp2000A, and

Therm-A-lert Series Data Loggers

6

Data is instantly transmitted to a computer for

3

real-time monitoring. If user selectable alarm

ranges have been exceeded, an email, text

message or on-screen alarm will be received.

Page 7

RFC1000

Connected to a Power Outlet

Therm-A-lert-P

Wireless Temperature

Data Logger with

External RTD Probe

RFC1000

Wireless Transceiver

The RFC1000 is a wireless transceiver for the RFOT, Therm-A-lert and RF2000A

Series of Data Loggers. The RFC1000 features a 7.0 in (178 mm) pivoting external

antenna, which increases the transmission distance and provides greater

signal strength, and also allows more flexibility with mounting orientation.

RFC1000-IP69K

Splash Proof Wireless Transceiver

For environments that require high pressure, high temperature wash

down, MadgeTech has designed the RFC1000-IP69K. This new splash proof

transceiver can be installed directly in the wash down location, ensuring

100% communication throughout the entire process.

Order today at www.madgetech.com

|

7

Page 8

Standalone

Cooking, Cooling and Storage Data Loggers

High Temperature Wet or Dry Processing Applications

HiTemp140 Series

The MadgeTech HiTemp140 and HiTemp140-PT Series data loggers are designed to be used in a wide range of food and meat applications

to help comply with HACCP requirements and USDA regulations. These data loggers can indefinitely withstand temperatures of up to 284

°F (140 °C) and are completely submersible. The RTD probe and food-grade stainless steel enclosure, is available in both rigid and flexible

probe models. This series allows customers to create a custom validation kit for smokehouse monitoring, oven mapping, pasteurization

and more.

The HiTemp140 features a needle point RTD probe for easy insertion into a product.

Various probe lengths and diameters are available for dierent types of products.

Product Name Applications

HiTemp140-2

HiTemp140-2-TD

HiTemp140-5.25

HiTemp140-5.25-TD

HiTemp140-7

The HiTemp140-PT features a 24.0 in (610 mm) stainless steel

flexible wire with rigid probe sheath that is available in a 1.0 in

(25 mm) or 5.0 in (127 mm) length.

Product Name Applications

Canning, Internal Temperature Product

Canning, Internal Temperature Product

Internal Temperature Product Monitoring:

Canning

Canning

Monitoring: Sausage

Monitoring: Sausage

Hams, Briskets and other

Large Meat Products

HiTemp140-PT-1

HiTemp140-PT-5

8

Internal Temperature Product Monitoring:

Bacon, Small Sausage Links, Jerky,

Patties, Nuggets

Internal Temperature Product Monitoring:

Bacon, Small Sausage Links,

Jerky, Patties, Nuggets

HiTemp140-1 HiTemp140-2 HiTemp140-5.25 HiTemp140-7 HiTemp140-PT-1

Page 9

Extended Temperature Monitoring

Thermal Shield

For applications above 284 °F (140 °C), a thermal shield is available for the

HiTemp140 and HiTemp140-PT Series data loggers. Made of food-grade PTFE, the

Thermal Shield extends the operating temperature of the data logger for extreme

temperature monitoring.

Time vs Temperature Chart

Ambient

Temperature

-328 °F (-200 °C) 18 minutes n/a

-292 °F (-180 °C) 19 minutes n/a

-256 °F (-160 °C) 21 minutes n/a

-220 °F (-140 °C) 24 minutes n/a

-184 °F (-120 °C) 27 minutes n/a

-148 °F (-100 °C) 32 minutes n/a

-112 °F (-80 °C) 40 minutes n/a

-76 °F (-60 °C) 55 minutes 25 minutes

-40 °F (-40 °C) 70 minutes 32 minutes

-4 °F to +284 ºF

(-20 °C to +140 ºC)

302 °F (150 °C) 88 minutes 40 minutes

320 °F (160 °C) 75 minutes 34 minutes

338 °F (170 °C) 63 minutes 29 minutes

356 °F (180 °C) 55 minutes 26 minutes

374 °F (190 °C) 50 minutes 23 minutes

392 °F (200 °C) 45 minutes 21 minutes

410 °F (210 °C) 42 minutes 19 minutes

428 °F (220 °C) 39 minutes 18 minutes

446 °F (230 °C) 36 minutes 17 minutes

Exposure Time

in Air

Indefinitely Indefinitely

Exposure Time

in Liquid

HiTemp140 Series shown in Thermal Shields.

Vented model and flush-top shown.

Vented Model

Protects Probe

Flush Model

Allows for Probe Piercing

HiTemp140 Series Applications

• HACCP Programs

• Compliance with USDA Regulations

• Food and Meat Process Monitoring

• Oven Monitoring and Mapping

• Cooling and Storage Monitoring

• Pasteurization

• Conveyor Cooking and Cooling Cycles

464 °F (240 °C) 34 minutes 16 minutes

482 °F (250 °C) 32 minutes 15 minutes

Order today at www.madgetech.com

|

9

Page 10

Standalone

Cooking, Cooling and Storage Data Loggers

Validate Post-Slaughter

Pasteurization Cycles

CTL2000

The CTL2000 Carcass Temperature Data Logger measures and records data utilizing up to eight

thermocou ple channels, allowing the user to verify and validate post-slaughter pasteurization cycles.

The CTL2000 aids in reducing pathogens, and helps to ensure that post-slaughter pasteurization

process parameters are met.

The CTL2000 has a black anodized aluminum enclosure with a stainless steel hook allowing the

device to be hung directly from a carcass. This durable data logger is splash proof and can be used

throughout the entire pasteurization process. The CTL2000 can measure and record data utilizing

up to eight thermocouples which can be inserted into dierent sections of the carcass to provide an

overall temperature profile.

Marinating and Tenderizing

MicroTemp

The MicroTemp is a miniature, submersible temperature data logger. Only 2.6 in (66 mm) tall and 0.7 in (18 mm) in

diameter and completely housed in a food-grade 316 stainless steel enclosure, this recorder can easily withstand

acidic ingredients and monitor and record temperature throughout the entire marinating and tenderizing process.

10

Page 11

4 Channel Oven

Temperature Profiler

QuadThermoVault

The QuadThermoVault is a four channel thermally insulated oven temperature

profiler. The QuadThermoVault features a stainless steel enclosure with PTFE

insulation and can withstand oven temperatures of up to 662 °F for up to

25 minutes. The device sits at 2.45 in (62 mm), allowing it to fit inside most

conveyer ovens, and comes equipped with four thermocouples to monitor

multiple locations. An eight channel model is also available.

Time vs Temperature Chart

Ambient

Temperature

212 °F (100 °C) 110 minutes

302 °F (150 °C) 62 minutes

392 °F (200 °C) 45 minutes

482 °F (250 °C) 35 minutes

500 °F (260 °C) 33 minutes

572 °F (300 °C) 30 minutes

662 °F (350 °C) 25 minutes

Maximum

Duration

Extreme Temperature Monitoring

ThermoVault140-PT-1

The ThermoVault140-PT-1 is an extreme, high temperature thermal barrier designed for use with the

HiTemp140-PT-1 data loggers. The thermal barrier is a stainless steel enclosure containing a Dewar

flask and PTFE insulation. This durable system can withstand temperatures up to 482 °F (250 °C) when

completely submerged and 662 °F (350 °C) in dry heat applications. The ThermoVault140-PT-1 is built for

use in harsh applications that require extreme temperature monitoring and is ideal for ovens of all kinds.

Time vs Temperature Chart

Ambient

Temperature

302 °F (150 °C) 525 minutes 285 minutes

392 °F (200 °C) 285 minutes 120 minutes

482 °F (250 °C) 205 minutes 80 minutes

572 °F (300 °C) 165 minutes* n/a

662 °F (350 °C) 140 minutes* n/a

*Please consult the measurement range of your data logger for temperatures over

250°C. (The thermal barrier extends the operating temperature of the data logger up

to, but not exceeding the measurement range)

Time In Air To

Max Internal

Temperature

Time In Liquid

To Max Internal

Temperature

Order today at www.madgetech.com

|

11

Page 12

MadgeTech Data Logger Software

P

This simple, easy-to-use, Windows-based soware enables the user to eortlessly collect, display, and analyze data. A variety

of powerful tools can be used to examine, export, and print professional quality reports with just a click of the mouse. This

soware can be downloaded for free from the MadgeTech website.

Simple, Easy-to-use, Windows-based Software

Cooling Flags Copy to ExcelDigital CalibrationStatisticsTabular Data ViewGraph View

Software Features

• Multiple Graph Overlay

• Statistics

• Digital Calibration

• Zoom In / Zoom Out

12

• Timeslice

• Lethality Equations (F0, PU)

• Mean Kinetic Temperature

• Full Time Zone Support

• Data Annotation

• User Friendly File Management

• Min. / Max. / Average Lines

• Cooling Flags

• Data Table View

• Automatic Report Generation

• Summary View

Page 13

MadgeTech Data Logger Software

MadgeTech 4.0 Soware can communicate with multiple loggers through multiple interface cables. Capable of simultaneous start, stop

and download of over 100 devices, this soware serves as your virtual command center for large scale facilities and small. Display your

data in graphs, with tabbed views and multi-monitor support. Utilize the infinite graphing flexibility by combining channels and datasets

as desired. All graphing makes use of accelerated graphics hardware for real-time updating and high performance visuals.

The MadgeTech 4.0 Soware is designed with a built-in database for automatic storage of downloaded data. The look and feel is organized

much like standard email programs to aid in user friendliness and ease of use. The MadgeTech 4.0 soware also oers extensive alarming

options across multiple devices, wireless and non-wireless. Alarm output options include email, on-screen, text message and run-aprogram alerts.

To round out the list of improvements, MadgeTech 4.0 has a powerful and comprehensive statistics system that allows the user to

customize and view statistics as desired. Another feature is customizable engineering units. This enables users to support and program

devices with many dierent unit types as well as the ability to display them as an alternate unit if desired.

The MadgeTech 4.0 Software is available to download for

free from our website, www.madgetech.com.

Order today at www.madgetech.com

|

13

Page 14

Matrix

Product RFOT RFRHTemp2000A RFTCTemp2000A Therm-A-lert-P Therm-A-lert Therm-A-lert-RH HiTemp140 HiTemp140-PT HiTemp140-TSK CTL2000 MicroTemp ThermoVault140-PT-1 QuadThermoVault

Range

Resolution

Calibrated Accuracy

Memory

IP Rating

Material

Required Interface

Cable

Probe

More Details

Body: -4 °F to +212 °F

(-20 °C to +100 °C)

Probe: -58 °F to +392 °F

(-50 °C to +200 °C)

0.018 °F (0.01 °C)

±0.18 °F / ±0.1 °C

(14 °F to 302 °F / -10 °C to +150 °C)

±0.9 °F / ±0.5 °C

(outside of that range)

20,000 Readings 16,128 Readings 16,128 Readings 30,000 Readings 30,000 Readings 15,000 Readings 32,700 Readings 32,700 Readings 32,700 Readings

IP67, Splash Proof IP31 IP31 IP31 IP31 IP31 IP68 IP68 IP68 IP65, Splash Proof IP68

TECAFORM® ABS Plastic ABS Plastic ABS Plastic ABS Plastic ABS Plastic 316 Stainless Steel 316 Stainless Steel

RFC1000 RFC1000 RFC1000 RFC1000 RFC1000 RFC1000 IFC400 or IFC406 IFC400 or IFC406 IFC400 or IFC406 IFC200 IFC202 IFC400 or IFC406 IFC200

4.0 in (102 mm)

External RTD Probe

Refer to page 4 Refer to page 5 Refer to page 5 Refer to page 5 Refer to page 5 Refer to page 5 Refer to page 8 Refer to page 8 Refer to page 9 Refer to page 10 Refer to page 10 Refer to page 11 Refer to page 11

-4 °F to +140 °F

(20 °C to +60 °C)

0 to 95 %RH

0.018 °F (0.01 °C)

0.1 %RH

±0.9 °F / ±0.5 °C

(32 °F to 131 °F / 0 °C to +55 °C)

±3.0 %RH, ±2.0 %RH

typical @ 25 °C

(10 %RH to 90 %RH; 5 °C to 55 °C)

Internal Sensor

-4 °F to +140 °F

(-20 °C to +60 °C)

0.018 °F (0.01 °C) 0.018 °F (0.01 °C) 0.018 °F (0.01 °C)

±0.9 °F (±0.50 °C)

External Thermocouple Probe

Not Included

Body: -4 °F to +176 °F

(-20 °C to +80 °C)

Probe: -328 °F to +500 °F

(-200 °C to +260 °C)

±0.18 °F / ±0.1 °C

(-4 °F to +176 °F /

-20 °C to +80 °C)

4.5 in (114 mm)

External RTD Probe

Body: -4 °F to +176 °F

-4 °F to +176 °F

(-20 °C to +80 °C)

±0.9 °F / ±0.5 °C

(32 ºF to 122 °F /

0 °C to +50 °C)

Internal Sensor Internal Sensor External RTD Probe External RTD Probe External RTD Probe

(-20 °C to +80 °C)

0 to 95 %RH

noncondensing

0.018 °F (0.01 °C)

0.1 %RH

±0.9 °F / ±0.5 °C

(32 °F to 122 °F /

0 °C to +50 °C)

±3.0 %RH (±2 %RH typi-

cal at 77 °F / 25 °C)

HACCP (Hazard Analysis and Critical Control Points): Seven Principal Steps

1. Conduct a hazard analysis

Identify the potential hazard(s) associated with food production at all stages, from primary production, processing, manufacture and distribution until the

point of consumption. Assess the likelihood of occurrence of the hazard(s) and identify measures for their control.

2. Identify the critical control points (CCPs)

Determine the points, procedures, or operational steps that can be controlled to eliminate the hazard(s) or minimize its (their) likelihood of occurrence.

A “step” means any stage in food production and/or manufacture including the receipt and/or production of raw materials, harvesting, transport,

formulation, processing, storage, etc.

3. Establish critical limit(s)

Establish critical limit(s) which must be met to ensure the CCP is under control.

MadgeTech oers data loggers that enable the user to monitor and record temperature, humidity and other parameters to establish critical limits.

4. Establish Procedures to Monitor control of the CCP

a. What will be monitored b. How will it be monitored c. How oen will it be monitored d. Who will perform the monitoring

MadgeTech Data Loggers help to ensure critical control limits are being met. They can be used to validate ovens, freezers, coolers or be used to monitor

the internal temperature of product in process.

14

Page 15

Internal:

-4 °F to +140 °F

-328 °F to +482 °F

(-200 °C to +250 °C)

-328 °F to +482 °F

(-200 °C to +250 °C)

-328 °F to +482 °F

(-200 °C to +250 °C)

(-20 °C to +60 °C)

Remote:

-40 °F to +176 °F

(-40 °C to +80 °C)

-328 °F to +662 °F

(-200 °C to +350 °C)

-40 °F to +662 °F

(-40 °C to +350 °C)

-436 °F to +2498 °F (-260

°C to +1370 °C)

0.018 °F (0.01 °C) 0.018 °F (0.01 °C) 0.018 °F (0.01 °C) 0.09 °F (0.05 °C) 0.018 °F (0.01 °C) 0.018 °F (0.01 °C) 0.09 °F (0.05 °C)

±0.18 °F / ±0.1 °C

(68 °F to +284 °F / 20 °C to +140 °C)

±0.54 °F / ±0.3 °C

(-4 °F to +67.98 °F / -20 °C to +19.99 °C)

±0.72 °F / ±0.4 °C

(-40 °F to -4.02 °F / -40 °C to -20.01 °C)

±0.18 °F / ±0.1 °C

(68 °F to +284 °F / 20 °C to +140 °C)

±0.54 °F / ±0.3 °C

(-4 °F to +67.98 °F / -20 °C to +19.99 °C)

±0.72 °F / ±0.4 °C

(-40 °F to -4.02 °F / -40 °C to -20.01 °C)

±0.18 °F / ±0.1 °C

(68 °F to +284 °F / 20 °C to +140 °C)

±0.54 °F / ±0.3 °C

(-4 °F to +67.98 °F / -20 °C to +19.99 °C)

±0.72 °F / ±0.4 °C

(-40 °F to -4.02 °F / -40 °C to -20.01 °C)

316 Stainless Steel

Enclosure: PTFE

±0.9 °F (±0.5 °C) ±0.9 °F (±0.5 °C)

500,000 Readings per

Channel

32,767 Readings 32,700 Readings

Anodized Aluminum 316 Stainless Steel

External Thermocouple Probe

Not Included

Internal Sensor External RTD Probe

±0.18 °F / ±0.1 °C

(68 °F to +284 °F / 20 °C to +140 °C)

±0.54 °F / ±0.3 °C

(-4 °F to +67.98 °F / -20 °C to +19.99 °C)

±0.72 °F / ±0.4 °C

(-40 °F to -4.02 °F / -40 °C to -20.01 °C)

IP50 (no O-Ring)

IP68 (with O-Ring)

Enclosure: 300 Series

Stainless Steel

Insulation: Dewar Flask & PTFE

±0.9 °F (±0.5 °C)

1,000,000 Readings

per Channel

Not Rated

304 Stainless Steel with

PTFE insulation

External Thermocouple

Probe, Type K

Thermocouple Included

5. Establish Corrective Action Procedures

Establish the corrective action to be taken when monitoring indicates that a particular CCP is not under control.

6. Establish a Record Keeping System

Establish documentation concerning all procedures and records appropriate to these principles and their application.

The MadgeTech Soware makes record keeping a simple task. Easily tailor graphs and create custom reports for the product being processed to help

comply with federal guidelines and regulations.

7. Establish Verification Procedures

Establish procedures for verification to confirm that the HACCP system is working eectively.

MadgeTech data loggers play a key role in the HACCP plan. MadgeTech oers SOP’s (Standard Operating Procedure’s) to aid the user to ensure the data

loggers are installed correctly, operating properly and performing as they should.

Order today at www.madgetech.com

|

15

Page 16

Rev 1 2014.06

MadgeTech, Inc

6 Warner Road, Warner, NH 03278

T: (603) 456-2011 F: (603) 456-2012

info@madgetech.com

www.madgetech.com

Loading...

Loading...