Page 1

Red 485

Dark Blue Pantone 289

Light Blue 58% of Pantone 289

Red 485

Dark Blue Pantone 289

Light Blue 58% of Pantone 289

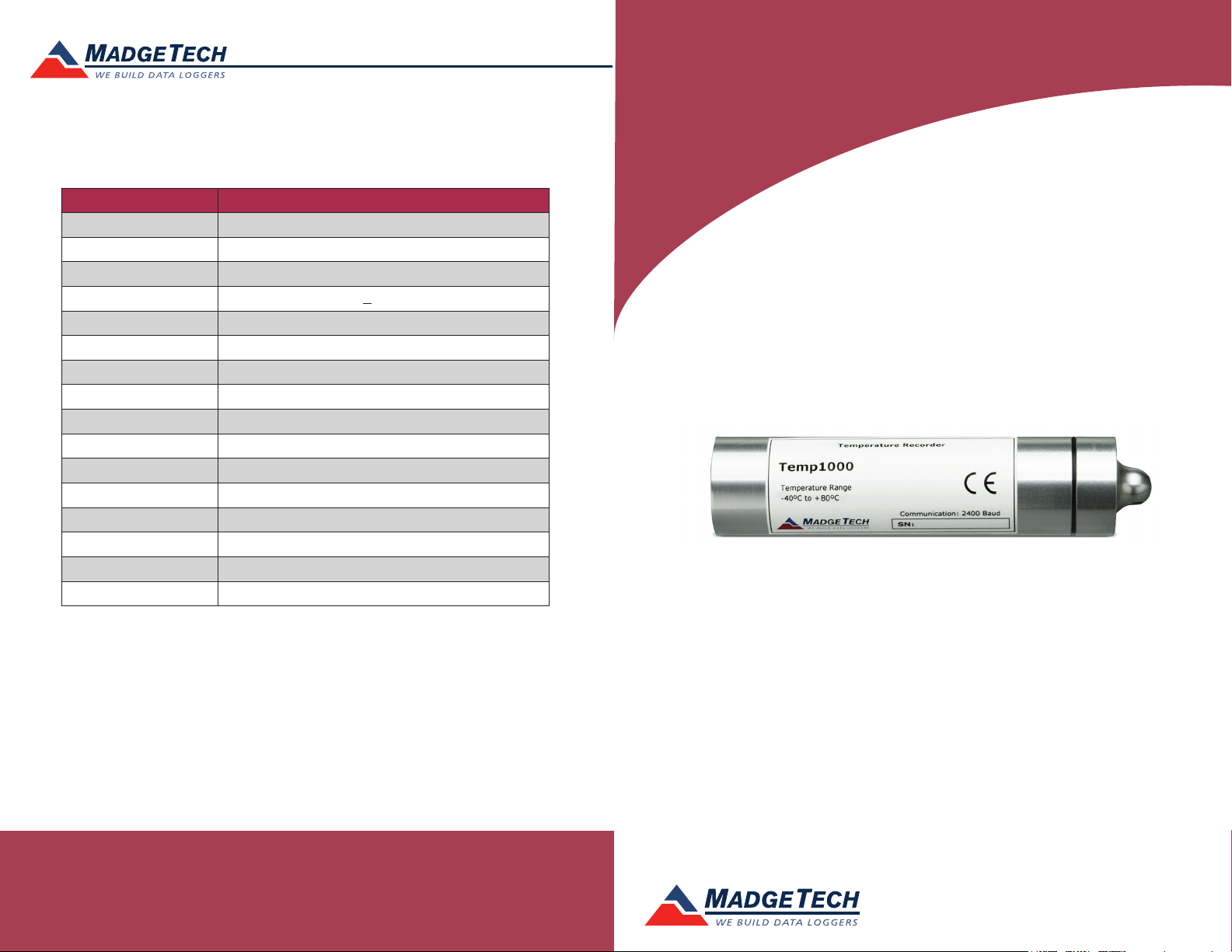

Description Temp1000

Temperature Sensor Internal semiconductor

Temperature Range –40 °C to +80 °C

Temperature Resolution 0.1 °C

Calibrated Accuracy +0.5 °C

Memory 32,767

Sample Rate 2 seconds up to 12 hours

Required Interface Package IFC110 or IFC200

Baud Rate 2,400

Typical Battery Life 1 year

Operating Environment -40 °C to +80 °C, 0 to 100 %RH

Material Available in anodized aluminum or 303 stainless steel

Dimensions 4.3 in x 1.0 in dia. (110mm x 26mm dia.)

Weight (Aluminum) 4 oz (110 g)

Weight (Stainless) 8 oz (230 g)

Approvals CE

Submergible Fully Submergible (IP68)

Product Information Card

Temp1000

Temp1000

Rugged Temperature Data Logger with Aluminum Enclosure

Temp1000-SS

Rugged Temperature Data Logger with Stainless Steel Enclosure

Battery Warning

WARNING: FIRE, EXPLOSION, AND SEVERE BURN HAZARD. DO NOT SHORT CIRCUIT, CHARGE,

FORCE OVER DISCHARGE, DISASSEMBLE, CRUSH, PENETRATE OR INCINERATE. BATTERY MAY

LEAK OR EXPLODE IF HEATED ABOVE 80 °C (176 °F).

See MadgeTech’s terms and conditions at www.madgetech.com

Specifications subject to change.

MadgeTech, Inc.

6 Warner Road

Phone 603.456.2011

www.madgetech.com

l

Warner, NH 03278

l

Fax 603.456.2012

l

info@madgetech.com

DOC-1012035-00 REV 10 2014.04.24

To view the full MadgeTech product line,

visit our website at www.madgetech.com.

Page 2

Temp1000

Product Notes

Getting Started

To access the COM Port for the interface cable, unscrew the key-ring end cap. Screw the

end cap onto the data logger until the o-ring cannot be seen, before deploying it.

Submergibility

The Temp1000 is fully submergible and is rated IP68. It can be placed in environments

with up to 150 feet (45 m) of water.

O-Rings

O-ring maintenance is a key factor when properly caring for the Temp1000. The o-rings

ensure a tight seal and prevent liquid from entering the inside of the device.

Please refer to the application note “O-Rings 101: Protecting Your Data”, found on the

MadgeTech website, for information on how to prevent O-ring failure.

Installation Guide

Installing the Interface cable

- IFC200

Insert the device into a USB port. The drivers will install automatically.

- IFC110

Plug the serial cable into the port and verify it is secure.

Installing the software

Insert the Software USB Stick in an open USB port. If the autorun does not appear, locate

the drive on the computer and double click on Autorun.exe. Follow the instructions

provided in the Wizard.

Device Operation

Connecting and Starting the data logger

- Once the software is installed and running, plug the interface cable into the data logger.

- Connect the USB end of the interface cable into an open USB port on the computer.

- The device will appear in the Connected Devices list, highlight the desired data logger.

- For most applications, select “Custom Start” from the menu bar and choose the desired

start method, reading rate and other parameters appropriate for the data logging

application and click “Start”. (“Quick Start” applies the most recent custom start options,

“Batch Start” is used for managing multiple loggers at once, “Real Time Start” stores the

dataset as it records while connected to the logger.)

- The status of the device will change to “Running”, “Waiting to Start” or “Waiting to

Manual Start”, depending upon your start method.

- Disconnect the data logger from the interface cable and place it in the environment to

measure.

Note: The device will stop recording data when the end of memory is reached or the device is stopped. At this point the

device cannot be restarted until it has been re-armed by the computer.

Product Information Card

Downloading data from a data logger

- Highlight the data logger in the Connected Devices list. Click “Stop” on the menu bar.

- Once the data logger is stopped, with the logger highlighted, click “Download”. You will

be prompted to name your report.

- Downloading will offload and save all the recorded data to the PC.

Device Maintenance

Battery Replacement

Materials:

Small Needle Nose Pliers

Replacement Battery (TLH-5902)

- Carefully unscrew the communications end cap.

- Using a small pair of needle nose pliers, remove the snap-ring by carefully pinching the

gold retaining ring together.

- Press gently on the white disk to force one end up and pull the electronics out.

- The battery is the purple cylinder on the circuit board. Gently remove the old battery.

- Insert the new battery one lead at a time, using pliers to fully push the leads into the

sockets. Note: The battery should be flat against the circuit board, and the positive lead

should be closest to the communications jack.

- Ensure the circuit board is inserted into the white plastic bushing. The sensor cable

should not be twisted, or kinked. From the connection to the circuit board, it should run

up towards the battery, then down to the sensor.

- Insert the electronics back into the tube, gently push the board back into the tube and

push the white disk back around the communication jack. and screw the cap back on.

Recalibration

The Temp1000 standard calibration is one point at 25 °C.

Pricing:

Recalibration traceable to NIST $70.00

Recalibration $40.00

Additional Services:

Verification Point $15.00 per point

Prices and specifications subject to change. See MadgeTech’s terms and conditions at www.madgetech.com.

To send the devices back, visit www.madgetech.com, select Services then RMA Process.

Loading...

Loading...