Page 1

Application Note

Complete Environmental Monitoring

•

UltraShock

What Does the UltraShock Do?

The UltraShock is a portable data logger designed to record the following environmental

variables: shock (g-force; impact/acceleration), temperature, humidity, and pressure. Recording

shock using the Shock101* data recorder is often adequate in many cases such as shipment

monitoring, or laboratory/drop testing. However, recording temperature, humidity, and

pressure, gives the UltraShock added versatility. In addition, these data loggers record the

vector sum, giving the user the overall acceleration data of the goods being monitored.

Using a built-in semiconductor (MEMS) accelerometer, various models of the UltraShock and

Shock data recorders can sense accelerations with ranges of ±5g, ±50g, and ±100g. This type

of sensor is commonly used for a variety of industries, including consumer, industrial,

aerospace, military, automotive, and safety-critical processes. They are often used in the

following applications:

•

Complete Environmental Shipment Monitoring

• Live Cargo Shipments

• Museum Monitoring

• Highly Expensive Fragile Equipment Transportation and Monitoring

• Aircraft Turbulence / Flight Data Recording

• Aircraft Takeoff and Landing Recording

• Endurance Testing

• Fragility Testing

• Crash/Impact Testing

• Assembly Line Monitoring

• Brake Testing

• Laboratory Drop Testing

• Machinery Monitoring

• Railcar Coupling Impacts

• Container Testing

• Insurance Claims

Examples of Use

Below are some examples that illustrate shock recorder concepts:

E

XAMPLE 1

A person standing on earth is experiencing a g-force of approximately 9.8 m/s2 due to the

earth’s gravity. The magnitude of a shock is the multiple of g due to acceleration. At earth’s

gravity (9.8 m/s2) the person is experiencing 1g. If for example, the mass of this person is 85

kg. Then the force upon this person is 837 Newton’s (kg X m/s2) (85kg X 9.8m/s2). The same

person in a racecar accelerating at 3g’s is effectively experiencing a force of 2,511 Newton’s

(837 Newton’s x 3g).

*

for more details see http://www.madgetech.com/dynamic_site/view_product.php?itemnumber=SHOCK101

UltraShock & UltraShock –EB

(EB = 10 year Extended Battery)

MadgeTech Inc.

(603) 456-2011 Phone

(603) 456-2012 Fax

www.madgetech.com

support@madgetech.com

201 Route 103 West

Po Box 50

Warner NH 03278

Complete Environmental Monitoring: UltraShock DOC-AN00001-00 REV B 2007.07.11 page 1 of 9

Page 2

Application Note

EXAMPLE 2

A rocket engine is being transported a long distance with a new shipping company. After the

engine has arrived at site B, the user downloads the data from the shock logger and discovers

that the engine has experienced a shock of “2g”. If the shock value was being examined for

this rocket engine, which has a mass of 7,000 kg, experiences an acceleration of 2g, the net

force applied to the object is 137,200 Newton’s (kg X m/s2). In this case, the rocket engine has

a maximum force specification of 100,000 Newton’s. With the shock data in hand, the user

knows that the rocket engine’s transit exceeded specification and the new shipping company is

disqualified.

How to Use the UltraShock in the Real World

E

XAMPLE 1 (MECHANICAL STRESS)

A sensitive microscope with a lever arm is determined to support a maximum mass of 250

Newton’s on the microscope end (opposite the base). The user knows the microscope has a

mass of 15 kilograms. While this microscope was being shipped, the microscope end was

subjected to 3.4 g’s. The user wants to determine the amount of force that was applied to this

microscope to determine if it had been damaged. In this case, the user is solving for force. So,

F= mg = (15kg) (3.4g X 9.8 m/s2=33.2) =499.8 Newton’s (kg X m/s2). Upon downloading the

data for this application, the user would be able to determine the exact time and data value of

which this microscope was subjected to 3.4 g’s.

E

XAMPLE 2 (SHIPPING)

Qualifying a new shipping company is a perfect application for an UltraShock. An UltraShock

recorder is being used to record the shipment of military ordinance that is sensitive to

temperature, pressure, humidity, and shock. The ordinance has the following maximum

specifications: temperature 55°C; pressure 25 PSIA; relative humidity 90%, shock 10 g’s. The

ordinance appears to have arrived safely at its destination, and the personnel at the site remove

the UltraShock to download the data. Upon downloading the data, the personnel find that the

shock, humidity, and pressure are all within specification. However, the ordinance was exposed

to a temperature of 57°C. The user can now conclude, based on the UltraShock data, that this

shipping company is not adequate for shipping military ordinance.

E

XAMPLE 3 (INSURANCE CLAIM)

The UltraShock data logger is frequently used to ensure the supply chain and shipping process

protects the value of the goods under transportation. Often a user will want to attach a device

that records shock to a shipment to ensure it reaches its destination unharmed. In this

example, the user receives a large shipment (500) of work benches. Seeing some damage to

the shipping crate, the receiver decides to not accept the shipment until the data from the

UltraShock is analyzed. After downloading the data from the UltraShock, the user is able to

determine that at 2:33 p.m. three days ago, the shipment container the desks were in was

exposed to 45 g’s. Without even opening the goods, the shipment was rejected. If the goods

had been accepted, a claim could have been filed with the shipping company using the

UltraShock data as evidence.

Sample Rate vs. Reading Rate

When the UltraShock is recording data, the shock data is constantly sampling at 512 times a

second (every 1.953 milliseconds or 512 Hz). However, it is impractical, and largely

unnecessary, to record each shock sample. Instead, the Ultrashock records the peak value (the

MadgeTech Inc.

(603) 456-2011 Phone

(603) 456-2012 Fax

www.madgetech.com

support@madgetech.com

201 Route 103 West

Po Box 50

Warner NH 03278

Complete Environmental Monitoring: UltraShock DOC-AN00001-00 REV B 2007.07.11 page 2 of 9

Page 3

Application Note

furthest from 0g whether high or low) seen over the reading rate (set by the user). As an

example, if the reading rate is set to 2 seconds, the UltraShock will sample the X, Y, and Z axis

accelerometers 1,024 times and then write the peak value of each axis sampled to non-volatile

memory.

In regard to temperature, pressure and humidity samples: If the sample rate is faster than 2

seconds, temperature, humidity, and pressure will sample at 2 seconds. If the sample rate is

slower than 2 seconds, temperature, humidity, and pressure is sampled within 2 seconds

before the sample is written.

One artifact of this sampling technique is that the data timestamp reflects the data preceding

the time stamp. To illustrate, if there was data with a sample rate of 1 minute and a shock spike

time stamped at 12:01:00 then the actual spike could have occurred anytime between

12:00:00 and 12:01:00. The temperature, pressure and humidity samples would have been

taken approximately between 12:00:58 and 12:01:00.

The vector sum (the forth shock channel) is calculated in the MadgeTech software and is the

vector sum of the x, y, and z axes.

222

Vector sum =

where X = X axis reading, Y = Y axis reading, Z= Z axis reading.

Vector Sum, X, Y, Z are all in gravity units.

This is automatically displayed, along with all readings, to provide the user with the overall

acceleration of the equipment or shipment being monitored.

How to Change the Reading Rate

The reading rate on the device can be set through the MadgeTech software. The reading rate

is the period at which the UltraShock records a peak value from previous data and then records

it to non-volatile memory. Before the device is started the user can specify the reading rate to

fit the application. The reading interval records from 64 readings/second to 1 every 5 minutes.

As previously stated, the sampling rate is a continuous 512Hz regardless of the reading interval.

The UltraShock records the peak value (farthest from 0g) per every sampling rate.

Choosing the Right Reading Rate for Your Application

The reading rate will vary depending on your application. For applications requiring a high

reading interval, such as a cargo shipment, a reading rate of 5 seconds may be suitable. With a

5 second reading rate, the Ultrashock can record approximately 240 hours, or ten days worth

of data. For applications requiring a medium reading interval such as vehicle monitoring, a

reading rate of 30 seconds may be adequate. Applications such as impact testing may use a

reading rate of 64Hz, which would yield excellent shock resolution.

Other important factors to consider are battery life and memory capacity. For example, an

UltraShock set to a 5 second reading interval will yield roughly 10 days of data before the

memory capacity is reached. Furthermore, a Shock101 at a 5 second reading interval will yield

roughly 20 days of data. It is important to determine the proper reading rate for your

application for if the logger is set to an excessively fast reading rate the battery may run out of

zyx ++

MadgeTech Inc.

(603) 456-2011 Phone

(603) 456-2012 Fax

www.madgetech.com

support@madgetech.com

201 Route 103 West

Po Box 50

Warner NH 03278

Complete Environmental Monitoring: UltraShock DOC-AN00001-00 REV B 2007.07.11 page 3 of 9

Page 4

power. For example, an UltraShock sampling at 64Hz will yield roughly 45 minutes of data.

Additionally, a Shock101 sampling at 64Hz will yield roughly 1 hour and 30 minutes of data.

For recording sessions longer than seven days, an UltraShock-EB or an external power source

Application Note

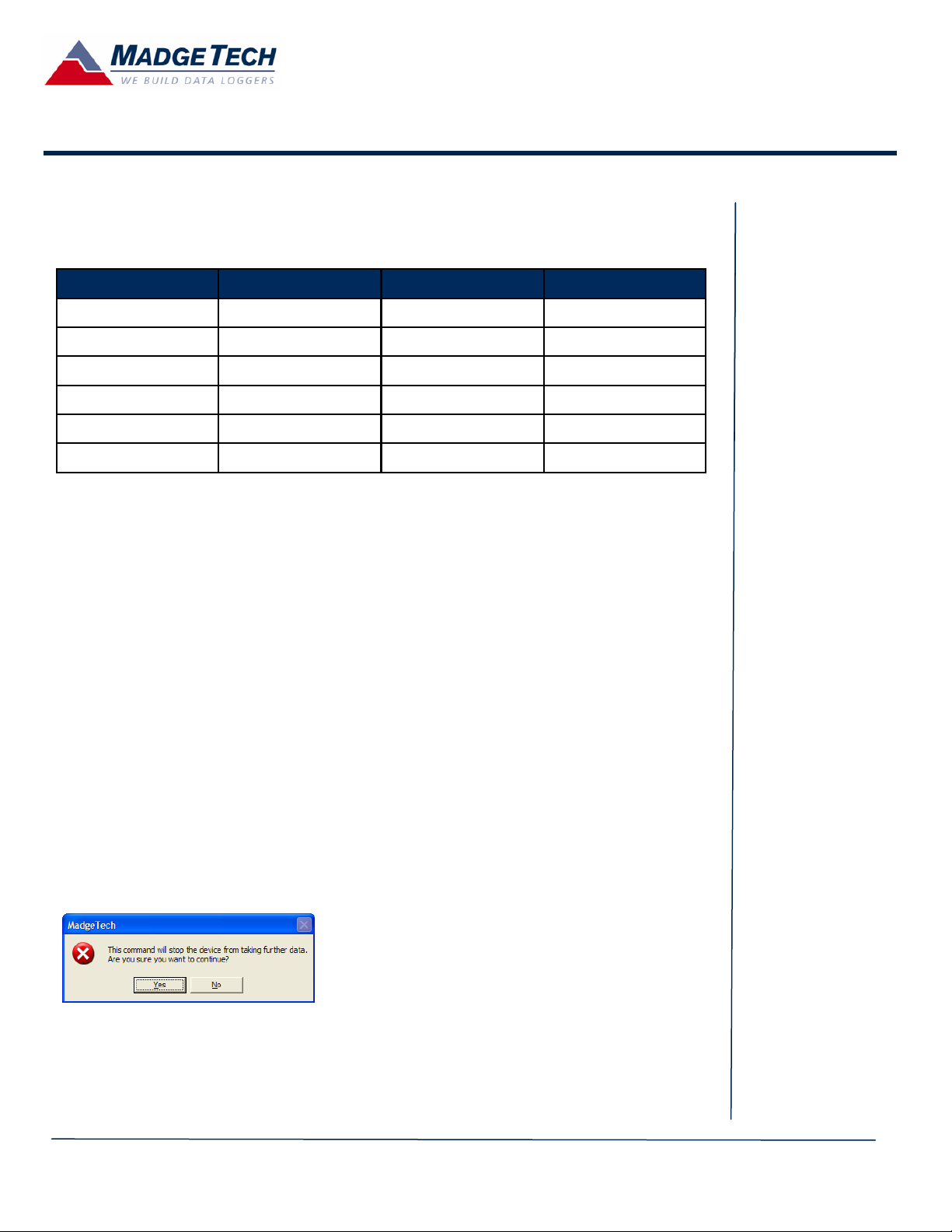

Product Name Number of Channels Reading Rate Memory Capacity

UltraShock 6 @ 5 seconds Approx. 10 days

Shock101 3 @ 5 seconds Approx. 20 days

UltraShock 6 @ 64Hz Approx. 45 minutes

Shock101 3 @ 64Hz Approx. 1.5 hours

UltraShock-EB 6 @ 10 seconds Approx. 40 days

Shock101-EB 3 @ 15 seconds Approx. 60 days

must be used.

Non-Volatile Memory

Since the UltraShock and Shock (EB and non-EB) feature non-volatile memory, any data that is

recorded will not be lost, even when not powered. This is unlike typical volatile memory used

for computer memory (RAM), which loses data when the power is removed. With the use of

non-volatile memory, the UltraShock and Shock series of recorders will not lose data even when

there is no power source present (e.g., battery becomes discharged).

Recording Data Example

To start the device, connect one end of a MadgeTech interface cable (either an IFC110 or

IFC200) to the UltraShock/Shock via the stereo plug. Next, connect the other end of the

MadgeTech interface cable to the target PC via a serial or USB connection. To communicate

with the data logger, start the MadgeTech software and setup communications. To do this,

click “Communication” from the menu bar and either configure the communications

automatically (select “Autoconfigure Comm Port”) or manually (click “Select Comm Port” and

“Select Baud Rate”). Once the correct communication port and baud rate (115,200 baud) are

selected, click “Device” then “Identify Device and Read Status”. If a “Device Status” window

appears, the UltraShock has communicated with the software.

Upon establishing communications, start the device by clicking “Device” then “Start

Device” (Ctrl + A) from the menu bar. If a window appears asking the user to choose “Yes” or

“No” to reset the data, it is generally best to click “Yes” to continue. However, if the data

MadgeTech Inc.

(603) 456-2011 Phone

(603) 456-2012 Fax

www.madgetech.com

support@madgetech.com

201 Route 103 West

Po Box 50

Warner NH 03278

logger contains important data, click “No.”

Complete Environmental Monitoring: UltraShock DOC-AN00001-00 REV B 2007.07.11 page 4 of 9

Page 5

Application Note

MadgeTech Inc.

(603) 456-2011 Phone

(603) 456-2012 Fax

www.madgetech.com

support@madgetech.com

201 Route 103 West

Po Box 50

Warner NH 03278

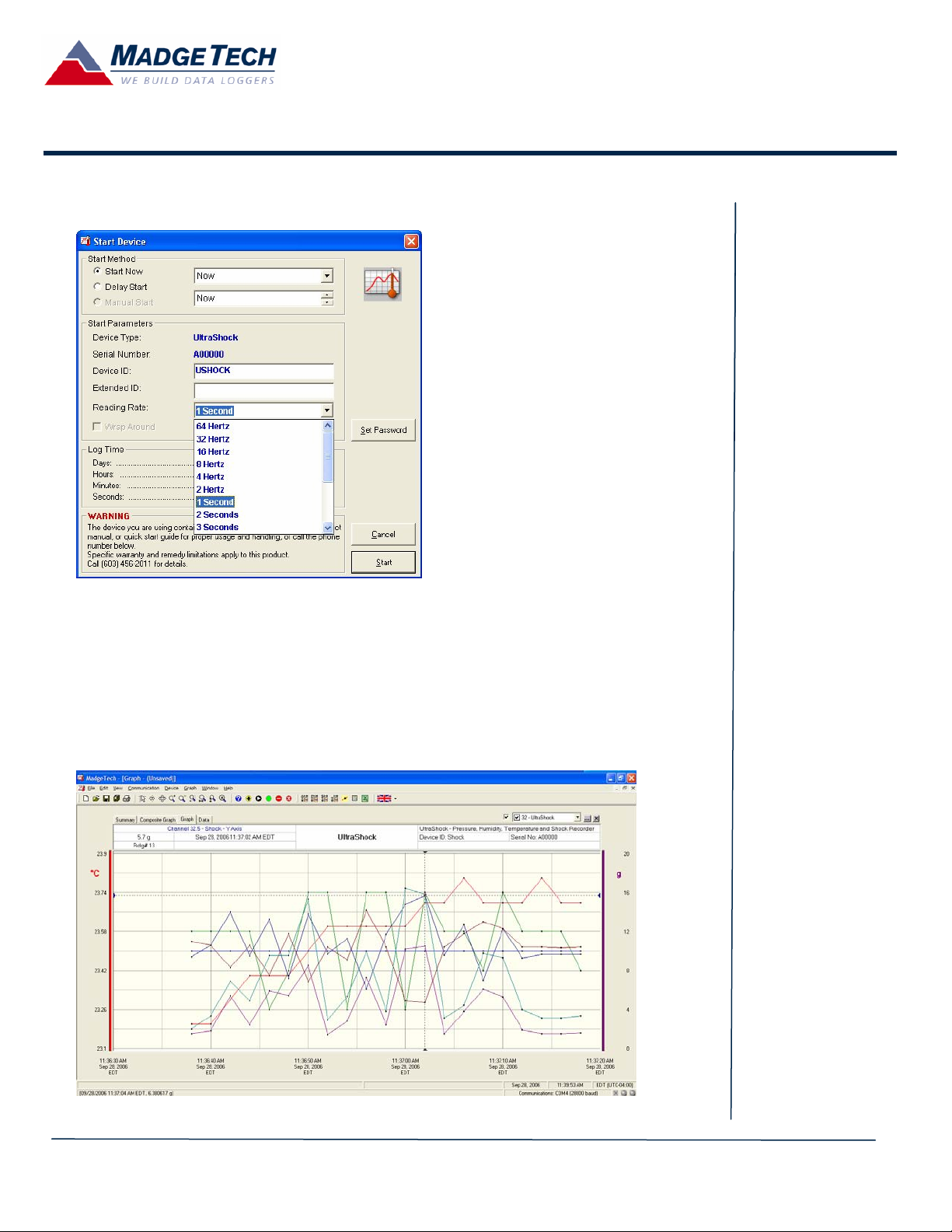

After clicking “Yes”, the following window will appear:

Change the “Reading Rate” to “1 Second” by clicking the combo box and selecting “1

Second”. When the device has started, a window will appear telling the user the device has

been started. Click “OK”. Shake the data logger from side to side. After 20-30 seconds, stop

the device by clicking “Device” then “Stop Device” (Ctrl + Z). A window will appear telling the

user the device has been stopped. Click “OK”.

To download the data from the device, click “Device” then “Read Device Data”. After a few

seconds, the data on the UltraShock will download into the software. The data may look similar

Complete Environmental Monitoring: UltraShock DOC-AN00001-00 REV B 2007.07.11 page 5 of 9

Page 6

Application Note

to the screenshot below:

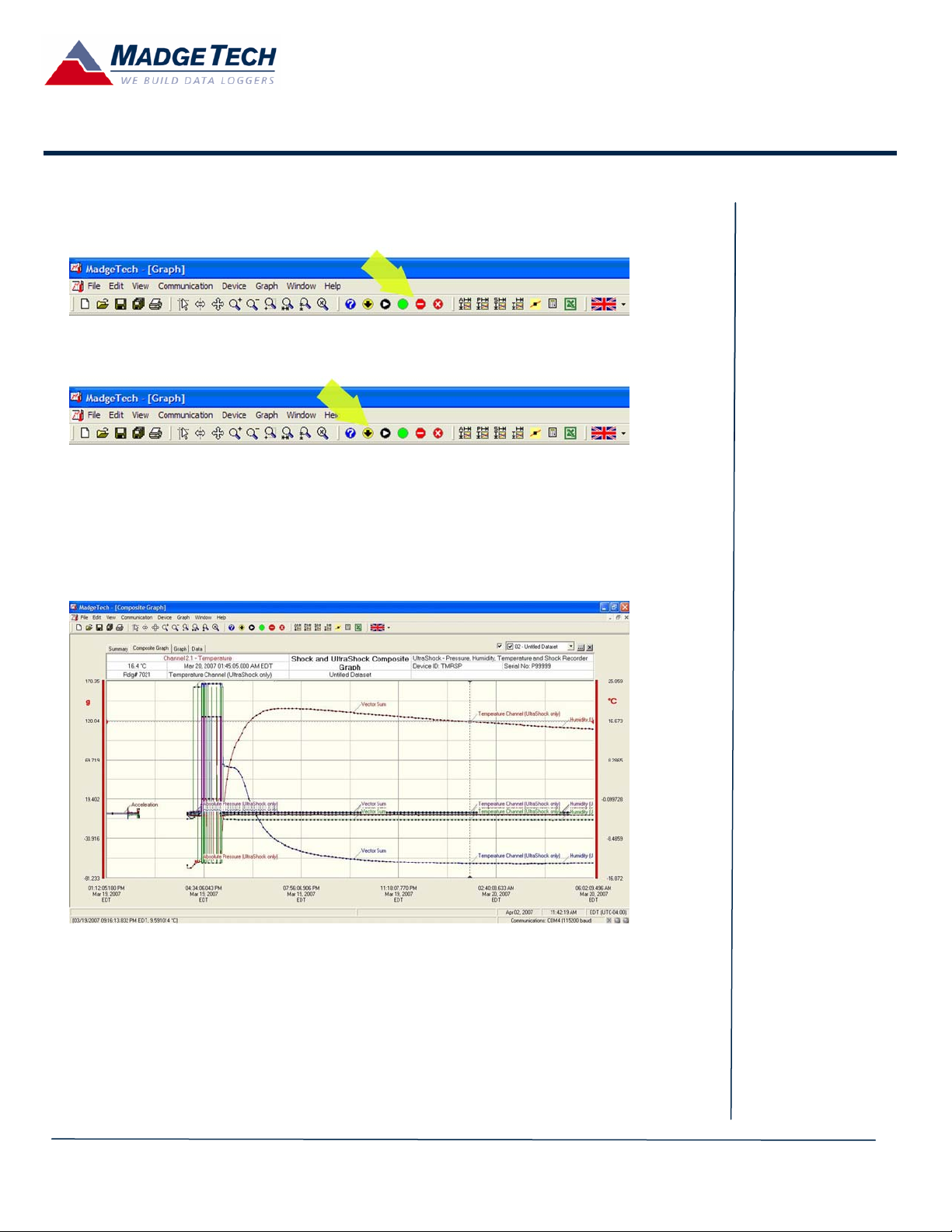

When offloading (i.e., reading, downloading) data from the UltraShock or Shock, it is necessary

to first stop the device by clicking on the red circle with the minus sign (located on the

toolbar).

To download the data from the UltraShock or Shock, the user must click “Device” then “Read

Device Data”, or click the yellow circle with the down arrow (located on the toolbar):

After download, the user can view the data in four different ways: summary, composite graph,

graph, and data. The graph tab is selected by default and it handles one dataset. In the graph

tab the user can perform many tasks, including viewing the data, annotating the data,

changing graph units, and changing the graph scale.

In the composite graph tab, the user can view the data from multiple datasets or devices. In

MadgeTech Inc.

(603) 456-2011 Phone

(603) 456-2012 Fax

www.madgetech.com

support@madgetech.com

201 Route 103 West

Po Box 50

Warner NH 03278

the screenshot below, there are three datasets in the composite graph.

Complete Environmental Monitoring: UltraShock DOC-AN00001-00 REV B 2007.07.11 page 6 of 9

Page 7

Application Note

In the summary tab, the user can analyze the data and gather information such as minimum

and maximum values, averages, standard deviation, mean kinetic temperature, number of

readings, start and end time, duration, and information for each channel (shock, temperature,

humidity, pressure). On the UltraShock the user can scroll down to view statistical data for all

MadgeTech Inc.

(603) 456-2011 Phone

(603) 456-2012 Fax

www.madgetech.com

support@madgetech.com

201 Route 103 West

Po Box 50

Warner NH 03278

channels (see screenshot, below).

In the data tab the user can see the data in a row and column spreadsheet format. This is useful

for quickly checking several data values (see screenshot, below).

For additional interpretation, the user can also change graph units, set the graph scale, format

the graph, and copy data to Excel®.

Complete Environmental Monitoring: UltraShock DOC-AN00001-00 REV B 2007.07.11 page 7 of 9

Page 8

Application Note

To help illustrate how to interpret data, the following example is used. An UltraShock data

logger was sitting on a table for 5 minutes. Then, at 5 minutes and 25 seconds, the UltraShock

was dropped from the table. Five minutes later (duration=10 minutes and 25 seconds), the

UltraShock is connected to a computer and the data is downloaded. Upon downloading, the

user notes that at 5 minutes and 25 seconds, a large spike occurred on one of the shock axes.

MadgeTech Inc.

(603) 456-2011 Phone

(603) 456-2012 Fax

www.madgetech.com

support@madgetech.com

201 Route 103 West

Po Box 50

Warner NH 03278

This graphical information shows when an event occurred (see screenshot, below).

How to Attach the UltraShock

The UltraShock/Shock101 has four mounting screws, one at each corner of the device, while

the Ultrashock-EB/Shock101-EB has six screws, one at each corner and two along the sides. For

information on exact mounting hole spacing, see the figure, below. It is important to note that

the g’s (impact/acceleration) measured by the logger may not be representative of the g’s

experienced by the contents inside of a container, but rather the g’s experienced by the object

to which the logger is mounted. To monitor the goods inside of the container, a data recorder

needs to be attached to the goods, themselves.

Complete Environmental Monitoring: UltraShock DOC-AN00001-00 REV B 2007.07.11 page 8 of 9

Page 9

Application Note

Figure A: UltraShock/ Shcok101 physical characteristics

Figure B: UltraShock-EB/ Shock101-EB physical characteristics

Conclusion

The UltraShock series of data loggers among the finest shock recording instruments available.

Not only are they versatile and easy to use, they also have a large memory capacity, user

adjustable reading rate, fast sampling rate, and the ability to record temperature, humidity,

and pressure. Additionally, these loggers have conveniently placed mounting holes, use nonvolatile memory, and come with MadgeTech’s free, powerful data logging software, which

enables users to quickly generate reports and analyze data in a variety of ways. These accurate

and reliable loggers are perfect for use in any application where involving the recording of

environmental parameters.

MadgeTech Inc.

(603) 456-2011 Phone

(603) 456-2012 Fax

www.madgetech.com

support@madgetech.com

201 Route 103 West

Po Box 50

Warner NH 03278

Complete Environmental Monitoring: UltraShock DOC-AN00001-00 REV B 2007.07.11 page 9 of 9

Loading...

Loading...