Page 1

Red 485

Dark Blue Pantone 289

Light Blue 58% of Pantone 289

Red 485

Dark Blue Pantone 289

Light Blue 58% of Pantone 289

Description QuadProcess OctProcess

Current Range

Current Resolution

Calibrated Accuracy

Input Impedance

Channels 4 8

Memory 32,767/channel 16,383/channel

Reading Rate 1 reading every second up to 1 reading every 12 hours

LED Indicator None

Required Interface Package IFC200

Baud Rate 2,400

Typical Battery Life 1 year

Operating Environment -20 °C to +60 °C, 0 %RH to 95 %RH (non–condensing)

Material Anodized aluminum

Dimensions

Weight 13 oz (370 g) 17 oz (480 g)

Approvals -

3.5 in x 4.4 in x 1.0 in

(89 mm x 112 mm x 26

mm)

*See Table Below

3.5 in x 4.4 in x 1.5 in

(89 mm x 112 mm x 39

mm)

Product User Guide

OctProcess and QuadProcess

*Current Series Range, Resolution and Calibrated Accuracy

Nominal Range +1 mA +25 mA +100 mA

Measurement Range

Common Mode Input Range 0 to 2.5 V 0 to 2.5 V 0 to 2.5 V

Resolution 0.05 µA 1 µA 5 µA

Calibrated Accuracy @ 25 °C 50 Ω 10 Ω 2 Ω

+1.5 mA +30 mA +120 mA

Battery Warning

WARNING: FIRE, EXPLOSION, AND SEVERE BURN HAZARD. DO NOT SHORT CIRCUIT, CHARGE,

FORCE OVER DISCHARGE, DISASSEMBLE, CRUSH, PENETRATE OR INCINERATE. BATTERY MAY

LEAK OR EXPLODE IF HEATED ABOVE 60 °C (140 °F).

DOC-1057035-00 REV 12 2014.11.25

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

OctProcess-1mA

8-Channel Low Level DC Current

Data Logger

OctProcess-25mA

8-Channel Low Level DC Current

Data Logger

OctProcess-100mA

8-Channel Low Level DC Current

Data Logger

QuadProcess-1mA

4-Channel Low Level DC Current

Data Logger

QuadProcess-25mA

4-Channel Low Level DC Current

Data Logger

QuadProcess-100mA

4-Channel Low Level DC Current

Data Logger

Page 2

QuadProcess and OctProcess

Wiring the Data Logger

Wiring Options

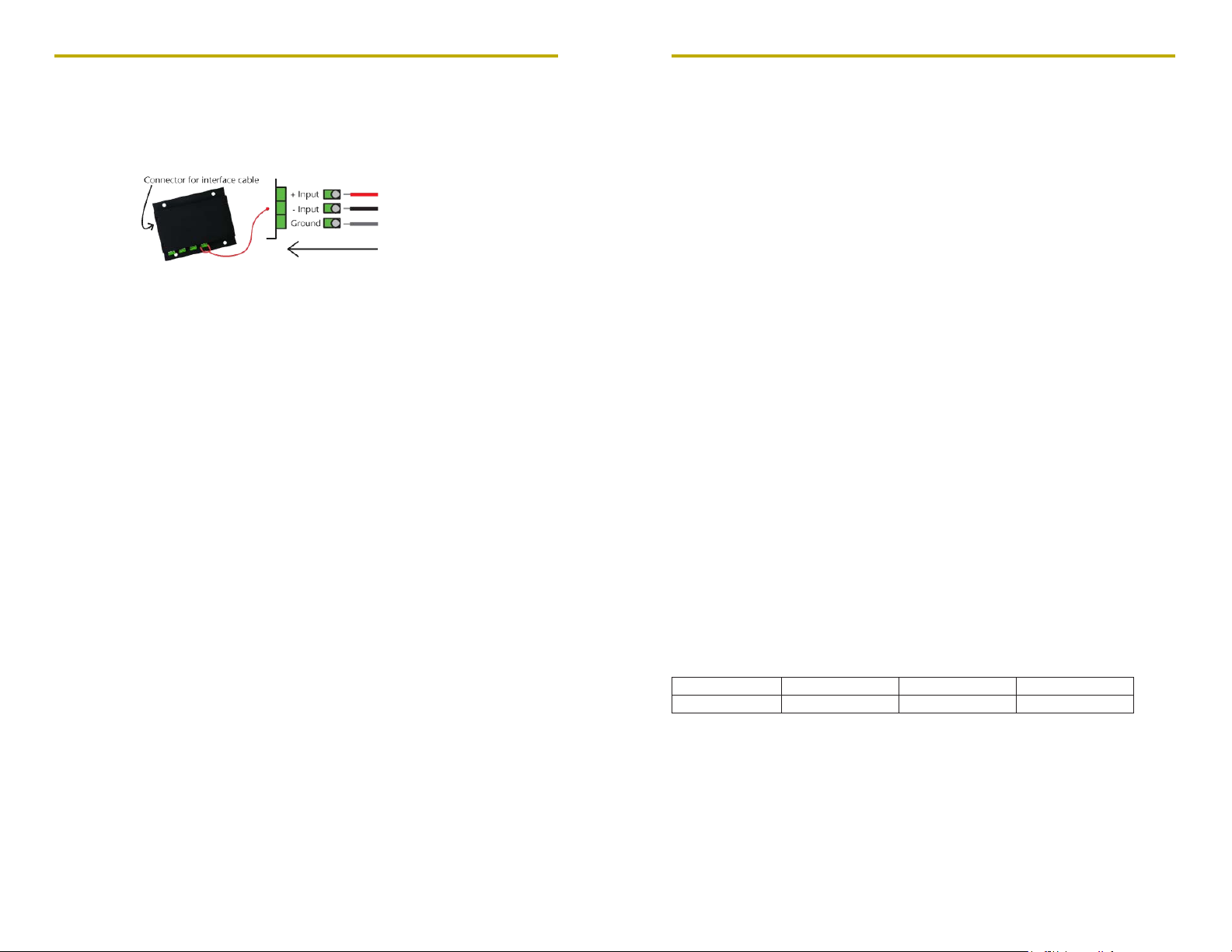

The QuadProcess and OctProcess both have two-position removable screw terminal

connections. The QuadProcess has 4 connections, the OctProcess has 8 connections. They

accept 3-wire configurations.

Warning: Note the polarity instructions. Do not attach wires to the wrong terminals.

Product Notes

Engineering Units

Engineering units are used to convert one measurement reading to another. The

MadgeTech software allows for software level Engineering Units (conversion applied to

data after download). Certain devices have device level Engineering Units, which upon

download automatically appear in the chosen unit of measure.

Please refer to the application note “Engineering Units”, found on the MadgeTech website,

for information on how to manage Engineering Units. Also view the Engineering Units

Video for step-by-step setup instructions.

Installation Guide

Installing the Interface cable

- IFC200

Insert the device into a USB port. The drivers will install automatically.

- IFC110

Plug the serial cable into the port and verify it is secure.

Installing the software

The Software can be downloaded from the MadgeTech website at the following link: www.

madgetech.com/software-download. Follow the instructions provided in the Installation

Wizard.

Device Operation

Connecting and Starting the data logger

- Once the software is installed and running, plug the interface cable into the data logger.

- Connect the USB end of the interface cable into an open USB port on the computer.

- The device will appear in the Connected Devices list, highlight the desired data logger.

- For most applications, select “Custom Start” from the menu bar and choose the desired

start method, reading rate and other parameters appropriate for the data logging

application and click “Start”. (“Quick Start” applies the most recent custom start options,

Product User Guide

“Batch Start” is used for managing multiple loggers at once, “Real Time Start” stores the

dataset as it records while connected to the logger.)

- The status of the device will change to “Running”, “Waiting to Start” or “Waiting to

Manual Start”, depending upon your start method.

- Disconnect the data logger from the interface cable and place it in the environment to

measure.

Note: The device will stop recording data when the end of memory is reached or the device is stopped. At this point the device

cannot be restarted until it has been re-armed by the computer.

Downloading data from a data logger

- Highlight the data logger in the Connected Devices list. Click “Stop” on the menu bar.

- Once the data logger is stopped, with the logger highlighted, click “Download”. You will

be prompted to name your report.

- Downloading will offload and save all the recorded data to the PC.

Device Maintenance

Battery Replacement

Materials:

- Remove the cover from the device by unscrewing the four screws.

- Remove the battery from its compartment and unsnap it from the connector.

- Snap the new battery into the terminals and verify it is secure.

- Replace the cover taking care not to pinch the wires. Screw the enclosure back together

securely. Note: Be sure not to over tighten the screws or strip the threads.

Recalibration

The QuadProcess or OctProcess standard calibration is at two points. The points are

dependent on the range of the data logger.

Additional Services:

Custom calibration and verification point options available, please call for pricing.

Calibration Points 0 mA and .9-1 mA 0 mA and 22.5-25 mA 0 mA and 90-100 mA

3/32” HEX Driver (Allen Key) and a Replacement Battery (U9VL-J)

Range 1 mA 25 mA 100 mA

Find Quality Products Online at: sales@GlobalTestSupply.com

www.GlobalTestSupply.com

Loading...

Loading...