Page 1

Medical and Pharmaceutical

Data Logging Solutions

Sterilization & Facilities Monitoring

Page 2

Simplifying How the World Measures & Records Data

MadgeTech, Inc. is a global company, based in New England

and founded on old-fashioned principles, customer

service, quality, and trust. MadgeTech’s President, Norman

Carlson, started the company in 1996 and charted the

growth of the product lines and services while maintaining

those solid core principles.

Our Can Do team of engineers and technical sta

consistently incorporate new and innovative ideas into

our data loggers. In short, we push the envelope, raising

the bar in innovation and quality. Our competitors have

praised us by adopting many of our ideas as their own.

Over time, MadgeTech has become the industry standard

in the data logger market.

MadgeTech continuously develops new, cutting-edge

products, creating solutions for our customers around

the world in industries across the board. Our growing

network of distributors has expanded our presence to

Norman E. Carlson,

markets far beyond our home-headquarters in New

Hampshire, our products are now sold in over 100

countries around the world.

Our employees are committed to quality and customer

satisfaction. Behind the full range of MadgeTech’s products

and services is the cumulative expertise of experienced

engineers, manufacturing and electronic professionals

and technicians. Our knowledgeable sales team can oer

technical advice to assist in selecting the right product for

each application, as well as providing aer-sales support.

MadgeTech is dedicated to providing customers with

reliable, aordable products, hassle-free ordering, and

excellent service, saving customers time and money.

It is our goal to earn your trust in meeting your needs

and providing innovative solutions. The products and

services that bear the MadgeTech name come with quality

assurance and the best support in the industry today.

Founder & President

Page 3

Data Logging Solutions

Steam Sterilization

Lyophilization

Dry Heat Sterilization &

Depyrogenation

Vaccine Temperature Monitoring

Ethylene Oxide Sterilization

Dry Ice Shipping

Cold Chain

Real Time Continuous

Environmental Monitoring

Service & Calibration

Page 4

Steam Sterilization

MadgeTech has designed a series of data loggers specifically for validating temperature and pressure within

autoclaves. These rugged, stand-alone, fully-submersible devices can be placed directly inside the autoclave with

the product(s), providing an overall temperature and pressure profile to validate the entire sterilization cycle.

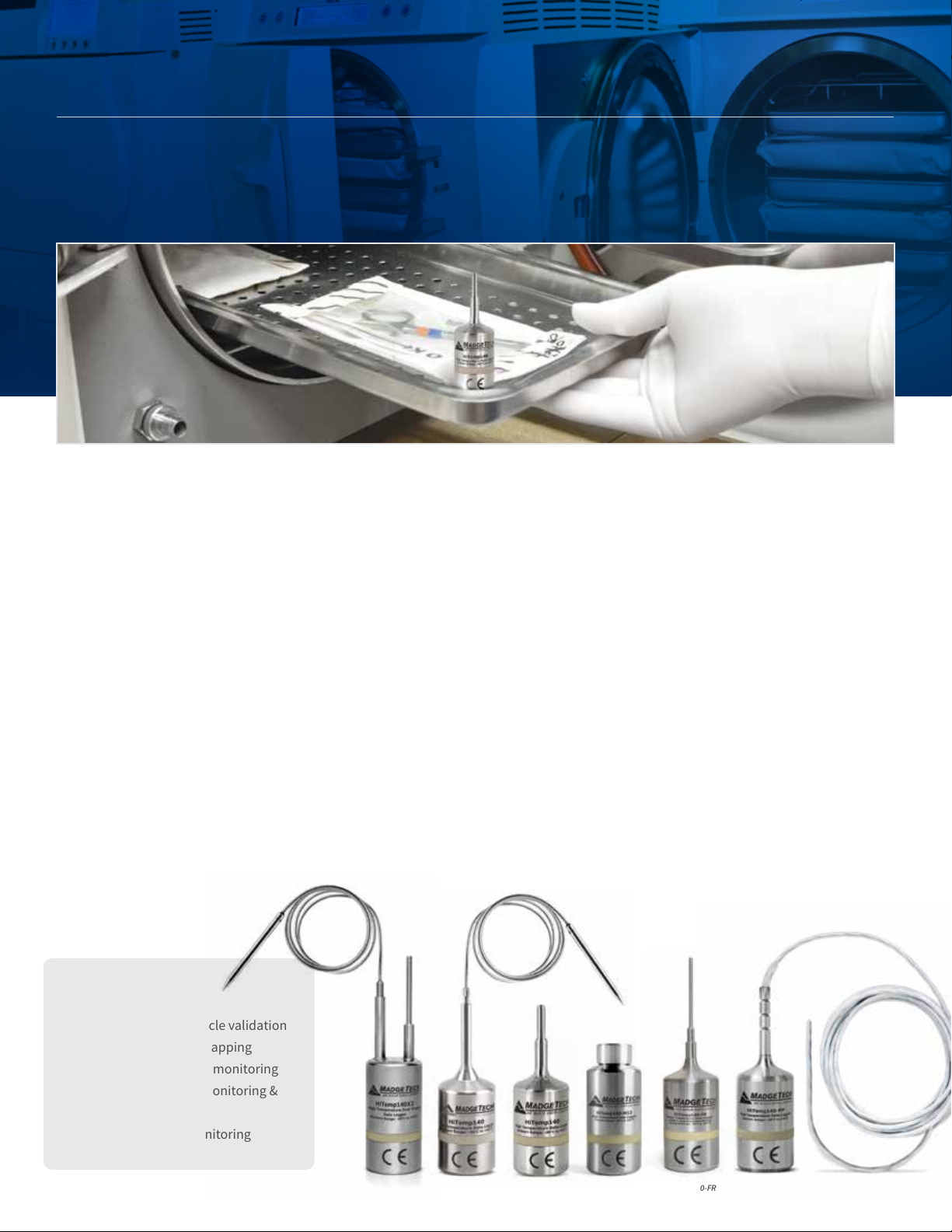

HiTemp140

Data Logger for High Temperatures

The HiTemp140 and HiTemp140-PT series data loggers are MadgeTech’s solution for precise high temperature monitoring. These data

loggers can indefinitely withstand temperatures of up to 140 °C (284 °F) and have an accuracy of ±0.1 °C. The HiTemp140 features a rigid

external RTD probe capable of measuring extended temperatures, up to 260 °C (500 °F). Varied probe lengths are available up to 7 inches.

The HiTemp140-PT features a 24 inch flexible steel RTD probe capable of measuring extended temperatures, up to 350 °C (662 °F).

The HiTemp140X2 series of dual probe high temperature data loggers oer extreme flexibility for high temperature monitoring

applications. This product is ideal for applications such as autoclave validation, sterilization processes and much more.

The HiTemp140-FR is a high temperature data logger with an ultra-fast response time, to record temperature during rapidly changing

thermal processes. This high temperature data logger is capable of recording as fast as 4 Hz.

The HiTemp140-FP probe design is narrow and lightweight making it ideal for placement within small vials, test tubes and other small

diameter or delicate applications. The flexible lightweight probe minimizes the risks of breakage (both vial and probe) and makes

placement of the probe is easy to manipulate.

The HiTemp140-M12 is a high temperature data logger designed with a built in M12 probe connecter. This logger is compatible with

dozens of M12 RTD probes and capable of measuring up to 850 °C (probe dependent).

Applications

• Steam sterilization cycle validation

• Autoclave chamber mapping

• Blood plasma sample monitoring

• Refrigerator/freezer monitoring &

mapping

• Continuous oven monitoring

4

HiTemp140X2

HiTemp140-PT-1

HiTemp140-1

HiTemp140-M12

HiTemp140-FR

HiTemp140-FP

Page 5

PRTemp140

High Temperature and Pressure Data Logger

The PRTemp140 is a data logger designed to validate if appropriate temperature and

pressure levels have been achieved during the steam sterilization cycle. It is built with

a precision stainless steel pressure gauge. The data logger has an accuracy of ±0.1

°C and ±0.03 Bar (±0.435 PSI), which can be achieved over a wide temperature range,

from +20 °C to +140 °C (+68 °F to +284 °F). The PRTemp140 is available in either a Flush

Top or NPT Pressure Port Top design, with an optional female luer fitting accessory.

NPT Pressure Port Top Luer FittingFlush Top

AVS

Autoclave Validation Data Logging System

MadgeTech oers the AVS Autoclave Validation System to satisfy demanding autoclave needs. This system comes with five HiTemp140,

High Temperature Data Loggers and one PRTemp140 Temperature and Pressure Data Logger, all loggers with NIST certified calibration.

The IFC406 Multiplexer Interface and one MadgeTech Secure Soware License with IQ/OQ/PQ validation workbook are also included

with this system. The AVS comes with all components securely packaged in a sleek and protective aluminum briefcase, ideal for storage

or transporting the system to multiple facilities or locations.

The AVS kit can be custom configured with any combination of HiTemp140 data loggers oering a wide variety of probe lengths to

choose from.

The AVS kit includes (Standard Package):

• (5) HiTemp140 High Temperature Data

Loggers with 1 inch probe, all with NIST

Calibration Certificates

• (1) PRTemp140 High Temperature and

Pressure Data Logger with an NPT port,

with NIST Calibration Certificate

• IFC406 Multiplexer interface

• MadgeTech Secure Data Logger Soware,

with IQ/OQ/PQ validation protocols and

workbook

• Aluminum Storage Briefcase

Order today at www.madgetech.com

|

5

Page 6

Dry Heat Sterilization, Depyrogenation

& Extreme Temperature Validation

For applications that require extended exposure to high heat, MadgeTech has developed a line of thermal enclosures for use with the

HiTemp140 series data loggers. These thermal shields and barriers expand the capabilities of the HiTemp140 series, making an ideal

solution for monitoring the extreme temperatures and exposure time required for eective Depyrogenation or Dry Heat Sterilization.

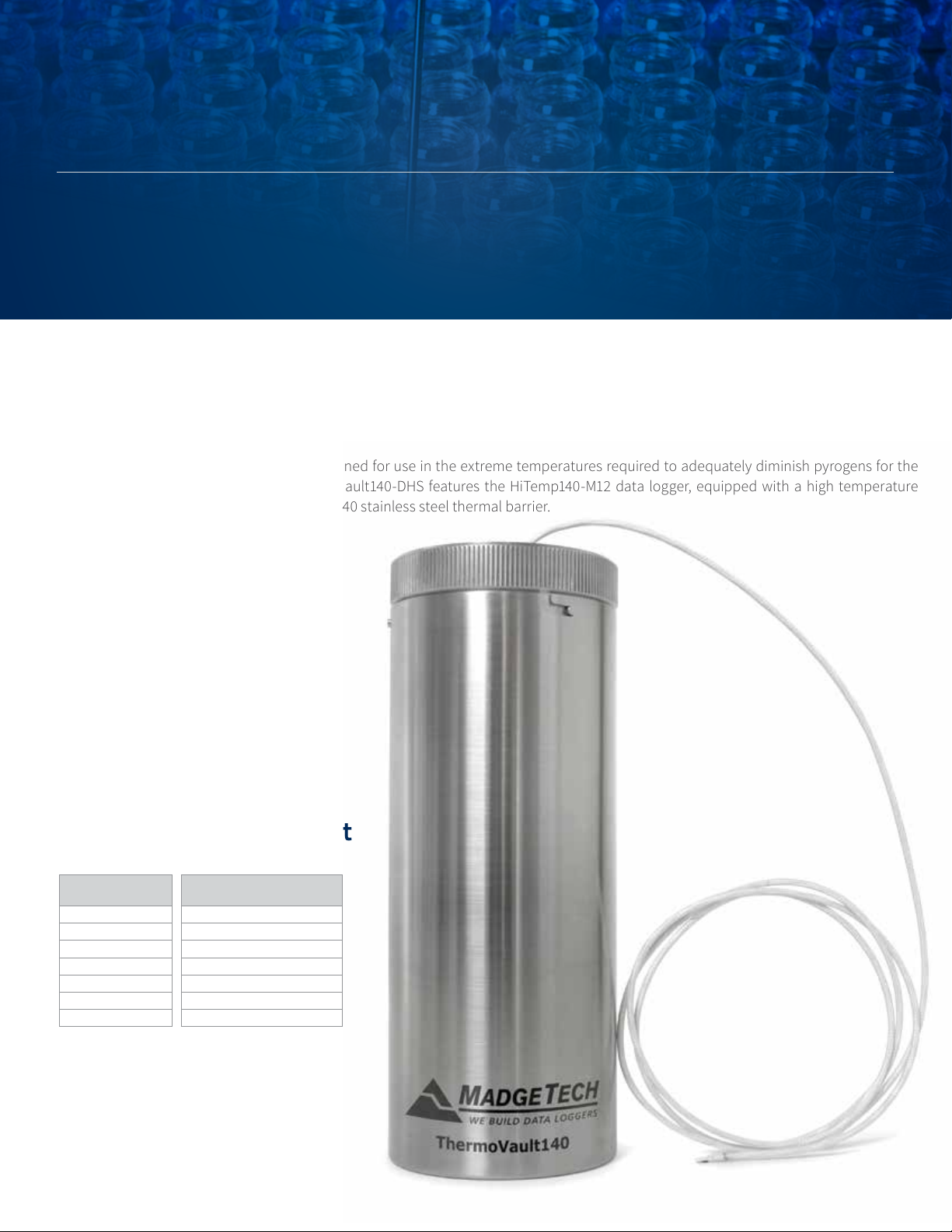

ThermoVault140-DHS

Dry Heat Sterilization Data Logging System

The ThermoVault140-DHS is a Dry Heat Sterilization Data Logging System, designed to be used in environments up to 400 °C for dry heat

applications. This system is specifically designed for use in the extreme temperatures required to adequately diminish pyrogens for the

eective sterilization of goods. The ThermoVault140-DHS features the HiTemp140-M12 data logger, equipped with a high temperature

detachable RTD probe and the ThermoVault140 stainless steel thermal barrier.

The ThermoVault140-DHS System includes:

• HiTemp140-M12 High Temperature Data Logger

• 36 inch Glass Braided RTD probe

with a ceramic tip

• ThermoVault140 Thermal Barrier

Time vs Temperature Chart

Expos ure Time in Air (minutes)Temperature

Ambient

-40 °C to +140 °C

150 °C

200 °C

250 °C

300 °C

350 °C

400 °C

*Please consult the measurement range of your data logger for

temperatures over 250 °C. (The thermal barrier extends the operating temperature of the data logger up to, but not exceeding the

measurement range)

ThermoVault140-DHS

Indefinitely

525

285

205

165*

140*

50*

6

Page 7

HiTemp140-M12

High Temperature Data Logger with an M12 Probe Connector

The HiTemp140-M12 is a high temperature data logger featuring and M12 probe connector.

Compatible with a wide variety of M12 RTD probe styles, this logger is capable of measuring up to

850 °C. (probe dependant)

All MadgeTech HiTemp140 series of data loggers are designed out of food grade stainless steel

and can be placed in environments as high as 140 °C (284 ° F).

The device records and stores up to 43,690 time stamped readings and is equipped with non-

volatile solid state memory which retains data even if the battery becomes discharged.

Time vs Temperature Chart

Expo sure Time in Air (minutes)Temperature

Ambient

-40 °C to +140 °C

150 °C

200 °C

250 °C

300 °C

350 °C

*Please consult the measurement range of your data logger

for temperatures over 250 °C. (The thermal barrier extends

the operating temperature of the data logger up to, but not

exceeding the measurement range)

Thermal Shield

Indefinitely

88

45

32

n/a

n/a

Thermal Shield

For Extended High Temperature Monitoring

For applications above 140 °C, a thermal shield is available for most models of the HiTemp140 and HiTemp140-PT series data loggers.

The thermal shield extends the operating temperature of the data logger, allowing it to be exposed to higher temperatures for a longer

amount of time. Flush and vented models are available to help provide probe protection.

Thermal Shields shown with HiTemp140 series data loggers.

Order today at www.madgetech.com

|

7

Page 8

Ethylene Oxide Sterilization (EtO/EO)

In accordance with ANSI/AAMI/ISO 11135, it is required for temperature and humidity levels be monitored during

an EtO/EO sterilization process. MadgeTech data loggers can be used to validate these parameters to ensure an

environment in which suicient sterility levels are achieved.

MadgeTech has developed data loggers designed specifically to validate temperature and humidity requirements for EtO sterilization

cycles. The Temp1000IS data logger measures temperature and the RHTemp1000IS measures both temperature and humidity.

Both devices are designed to withstand harsh environments and record data at user selected time intervals, providing a complete

temperature and humidity profile of each EtO cycle. The stand alone operation and compact size of these data loggers allows them to

fit easily into the sterilization chamber with the product load.

As federal regulations mandate that facilities produce records for each EtO sterilization cycle, all recorded readings are automatically

saved upon download and can then be included with validation documents and reports to verify a successful sterilization cycle. The

MadgeTech 1000IS Series has become the data logger of choice for the EtO sterilization industry.

The Temp1000IS and RHTemp1000IS are designed to be placed direc tly inside the sterilization chamber and meet the required regulation

equipment standards. These devices have been certified by FM Approvals as intrinsically safe for Class I, Division 1, groups A, B, C, D, and

non-incendive for Class I, Division 2, groups A, B, C, D, hazardous environments.

RHTemp1000IS

Intrinsically Safe Humidity & Temperature Data Logger

The new RHTemp1000IS is MadgeTech’s most robust temperature and humidity data logging solution.

FM Approved to be Intrinsically Safe for Class 1, Division 1, groups A, B, C, and D and non-incendive

for Class 1, Division 2, groups A, B, C, and D, the RHTemp1000IS is certified as safe for use in many

hazardous locations where explosive gas atmospheres are present.

The RHTemp1000IS features a cutting-edge thermoset-polymer capacitive sensor, that provides

the longest operating life in an ethylene oxide-based (EtO) sterilization process. With the ability to

maintain resistance against various chemical liquids and vapors like isopropyl, benzene, toluene,

formaldehydes, oils and common cleaning agents, this sensor is ideal for EtO processes, as well as

continuous, long term use.

The RHTemp1000IS enclosure is made of 316 Stainless Steel. It’s small size and sleek design allows it

to be placed precisely in critical locations for temperature and humidity mapping.

Its ultra-fast communication speed allows for programming and data download in just seconds. Using

the IFC400 docking station, communications are established automatically through metal contacts

and up to 18 units can be programmed simultaneously using the IFC406 multiplexer.

8

Page 9

Temp1000IS

Intrinsically Safe Temperature Data Logger

The Temp1000IS provides an Intrinsically Safe solution for temperature monitoring in hazardous

locations. It is FM Approved to be Intrinsically Safe for Class 1, Division 1, groups A, B, C, and D and nonincendive for Class 1, Division 2, groups A, B, C, and D, certifying it safe to use in explosive acetylene,

hydrogen, ethylene, and propane gas atmospheres.

The Temp1000IS features a highly accurate precision 100 Ω platinum

RTD sensing element. The external 1 inch RTD probe provides a faster

response time in comparison to most standard internal sensors.

The Temp1000IS comes housed in a 316 Stainless Steel enclosure. An

optional key ring attachment is available for additional installation

configurations.

Key Ring End Cap available

for the RHTemp1000IS and

Temp1000IS

IFC406

Multiplexer Data Logger Interface

The IFC406 Multiplexer Data Logger Interface allows for multiple data

loggers to be connected and download data simultaneously. Each IFC406

accomodates up to 6 data loggers, up to 3 IFC406 units may be daisy-chained

together to communicate with a total of 18 devices through 1 USB port.

To connect multiple IFC406 Interfaces together, simply join the units side by side, making sure the spring pin contacts are connected and

magnetically joined.

MadgeTech EtO Servicing

To successfully utilize data loggers for monitoring EtO processes, it is

imperative to routinely verify accuracy through periodic calibration

checks and servicing.

MadgeTech oers professional calibration services for all MadgeTech

data loggers. Traceable to NIST for temperature, humidity, pressure,

voltage, and current.

Standard servicing plans for EtO processing include:

• Free device evaluation

• As Found data collection

• RH sensor replacement

• O-Ring replacement

• Battery replacement

• Calibration and adjustment at standard or custom points

Test Equipment

• (2) PGC Temperature and Humidity Stability Chambers

• Various Circulating Baths

• Pressure Calibrator

Reference Equipment

• Rotronic hygrometers

• Accuracy of:

±1 %RH, 0 %RH-90 %RH

±0.3 °C, 0 °C-80 °C (special temperature

accuracy of 0.05 °C @ 25.0 °C)

• Fluke Calibration 1502A Thermometer Readouts

• Accuracy of: ±0.030 °C, -80 °C to +300 °C

• Mensor CPC 6000 Pressure Calibrator

• Accuracy of: ± 0.05 psi

Test and Reference Equipment Subject to:

• Annual Calibration

• Annual Validation

• Annual Mapping

Order today at www.madgetech.com

|

9

Page 10

Lyophilization

LyoTemp

Lyophilization Data Logger

The LyoTemp is designed to be a rugged, reliable, cost-eective solution for temperature monitoring inside lyophilizers. The ease of use

and simple setup provide a significant time and cost savings over traditional thermocouple based systems.

The LyoTemp data logger is designed for use in ultra-low operating temperatures for processes such as lyophilization. The LyoTemp has

an operating range of -60 °C to +75 °C, enabling the entire device to be placed inside the lyophilizer chamber. It features a hermetically

sealed thermistor, oered in a 48 inch length, to allow for temperature monitoring inside vials and ampoules. The MicroDisc accessory

can be fitted to the end of the thermistor, providing a solution for surface temperature monitoring for chamber mapping.

The compact size and simple operation make the LyoTemp user friendly and reliable. The LyoTemp has three LED indicators to alert or

inform the user of the logging status and manual start and stop options available at the device. Other features of the LyoTemp include

delayed start configuration, user configurable alarms and password protection.

MicroDisc, surface temperature

probe attachment also available

10

Page 11

Vaccine Monitoring

MadgeTech’s Vaccine Temperature Monitoring System (VTMS) is ideal for the continuous measurement and data

logging of temperature sensitive vaccines or pharmaceuticals in refrigerators, freezers, coolers and incubators.

VTMS

Vaccine Temperature Monitoring System

With the ability to view and reset statistics manually, the VTMS data logging system provides the tools needed to comply with specific

storage and handling instructions for medical observations and control mandated by the CDC.

The system includes a NIST traceable RFTCTemp2000A data logger with thermocouple probe, Glycol bottle and a power supply.

Additionally, the RFTCTemp2000A data logger in the VTMS system has a convenient LCD to display the current reading, minimum,

maximum and average statistics. The RFTCTemp2000A is wall mountable and capable of transmitting data wirelessly in real time to

a central PC.

The Thermocouple probe is detachable from the data logger

The VTMS mounted outside of the

enclosure to be monitored

Order today at www.madgetech.com

|

11

Page 12

Shipping & Storage Data Loggers

MadgeTech’s shipping and storage data loggers monitor and record the temperature of items in storage or during

transit. They eiciently collect data to aid in maintaining product quality and compliance.

TransiTemp-EC

Cold Chain

The TransiTemp-EC temperature recorder is designed for high volume, low cost in-transit

recording. It has a custom molded case with a handle for convenient attachment and comes

in single and multi use versions. This compact, portable, easy to use device will measure and

record up to 8,191 readings. The storage medium is non-volatile solid state memory, providing

maximum data security even if the battery becomes discharged or when the device stops

taking data.

TransiTempII

2-8 °C Refrigerators

The TransiTempII is a low cost, splash proof temperature data logger featuring a highly

precise semiconductor temperature sensor and an ABS plastic enclosure. This aordable,

NIST traceable device is ideal for monitoring and recording the temperature of all types of

perishable products, including food items and medical/pharmaceutical goods, both in

storage and in transit.

12

Page 13

Cr yo-Temp

Dry Ice Shippers & Freezers

The Cryo-Temp is a stand alone, ultra low temperature logger that can measure as low as

-86 °C without the need for external probes. The enclosure is designed with a handle for

easy attachment and is IP64 (splash proof). It is equipped with three LED’s to signify logging,

indicate when user-set warning limits have been breached and when temperature alarm limits

have been exceeded. The features of this device make it ideal for monitoring pharmaceutical

shipments, blood-bank storage, stem-cell samples and any other substance that requires dryice shipments or storage.

LNDS

Liquid Nitrogen, -196 °C Dryshipper Tanks

MadgeTech’s LNDS, Liquid Nitrogen Data Logging System, is an ultra-low temperature measurement system created specifically for the

monitoring of temperature sensitive substances that need to be preserved at cryogenic temperatures.

The LNDS can be mounted to the top or outside of a cryo-shipping container or freezer, and the probe sheath can be inserted into the

tank. The user can then directly view the internal temperature through the LCD on the logger, in addition to minimum, maximum, and

average statistics.

The LNDS system includes the TCTemp2000 data

logger, type E thermocouple probe, and NIST

traceable calibration at -196 °C, -80 °C and 0 °C.

Order today at www.madgetech.com

|

13

Page 14

Wireless Continuous Process Monitoring

For real time continuous monitoring, MadgeTech’s wireless (RF) series is a time-saving and cost eective solution

for validating temperature, humidity, pressure levels and more. A selection of models are available for use in a

multitude of applications.

2000A Series

MadgeTech’s 2000A two-way wireless series of data loggers is designed for users who want an automated, reliable monitoring solution.

Ideal for monitoring environments such as laboratories, warehouses, refrigerators, and freezers, a selection of models are available to

meet the needs of a variety of applications. The device takes readings at user-specified intervals, with data being transmitted back to

a central PC for a real time update of temperature and/or humidity readings. A local LCD display also provides instant readout of min,

max, average, and current readings.

The 2000A series also includes an audible and visual alarms for users close by. If the temperature, humidity, pressure or CO2 levels

exceed the user defined safe range, the alarm will sound enabling the user to take immediate action. Email and text message alarms

can be programmed in addition to the audible alarm, ensuring real time notifications regardless of location.

RFTemp2000A & RFRHTemp2000A

For Ambient Environmental Monitoring

Applications

• Laboratory Monitoring

• Warehouse Monitoring

• Incubators

• Stability Chambers

• Clean Rooms

• Environmental Mapping

• Refrigerators and Freezers

RFTemp2000A

Wireless Temperature Data Logger

14

RFRHTemp2000A

Wireless Temperature & Humidity Data Logger

Parameters

• Temperature

• Humidity

• Pressure

• Current

• Voltage

• Pulse

• Carbon Dioxide

Page 15

RFCO2RHTemp2000A

For CO2, Humidity & Temperature Monitoring

Applications

• Incubator Monitoring

• Building Monitoring

• HVAC Testing

• Agricultural Monitoring

Benefits

• Immediate notification of parameter breaches with the use of audible, email,

on-screen or text message alarms

• Data is automatically saved as it is transmitted

• Automatic update of graph, grid, and statistics reports within the soware

• Customizable alarm capabilities

• Up to a 3 year battery life, user-replaceable

• Visual verification of min, max, average and current readings via local LCD

• Wall or surface mount options

RFC1000

Wireless Transceiver

MadgeTech’s RFC1000 is a high powered transceiver that has a

substantially long transmission range, providing enhanced performance

in occluded environments (ovens, refrigerators, etc.). The RFC1000 also

features an external antenna, allowing more flexibility with mounting

positions in both orientation and proximity to metal walls. The device

may be used as a repeater, or directly plugged into the Windows PC.

All MadgeTech Wireless Data

Loggers are compatible with

MadgeTech Cloud Services.

See page 18 for details.

Order today at www.madgetech.com

|

15

Page 16

Wireless Continuous Monitoring System

Vaccine Temperature

Monitoring System

16

VTMS

Data Loggers to Transceiver

RFTemp2000A

Wireless Temperature

Data Logger

RFRHTemp2000A

Wireless Temperature &

Humidity Data Logger

RFC1000

Wireless Transceiver

Transceiver to Base Station PC

RFCO2RHTemp2000A

Wireless CO2, Humidity and

Temperature Data Logger

Connect any Data Logger directly to Base Station

Base Station PC

With Plugged in Transceiver

Page 17

Wireless Temperature & Humidity Alarming System Overview

Setup and installation of MadgeTech wireless data loggers is quick and easy. Little to no manual programming is necessary, as

loggers and repeaters are designed to communicate with each other as soon as they are turned on.

Alarm Notifications:

• Email

• Text Message

• On-screen

• LED Visual on Logger

1. Deploy the data loggers

2. Wirelessly start the

loggers at the main PC

3. Data is instantly

transmitted to the main PC

for real time monitoring

Order today at www.madgetech.com

|

17

Page 18

MadgeTech Cloud Services provides instant access to temperature,

humidity, pressure data and more from any internet enabled device!

The MadgeTech Cloud Hosted data logging platform provides continuous logging and monitoring of temperature, pressure, and

humidity data while giving users instant access from any location. With MadgeTech Cloud Services, data loggers can securely transmit

data in real time to be viewed on any internet or data enabled device such as a computer, tablet, or cell phone.

Benefits

• Scalable Solution with Limitless Applications

• Quick and Easy Setup

• Monitoring and Logging Continuously

• Access Data Instantly from Anywhere in the World

• Email & Text Message Alarm Notifications

• Powerful, Customizable User Interface

• Data Dashboard Overview

• World Class Support

18

Page 19

Features

Access Data Instantly and Securely from Anywhere in the World

Because data is sent to the cloud, data can be made available for viewing from any internet enabled location around the world.

Scalable Solution with Limitless Applications

With MadgeTech Cloud Services, this system is dynamically

designed to perfectly fit applications requiring anywhere from

a single data logger, to networks of hundreds of loggers in

multiple locations. The MadgeTech Cloud platform provides

facilities on-demand data supervision oering peace of mind

and flexibility like never before.

Email & Text Message Alarm Notifications

The MadgeTech Cloud platform allows users to configure alarms to custom fit their needs. Notifications can be sent via email or text

message the moment a threshold is exceeded. Notifications are also available on screen as well as audible and visual alerts directly on

the device. When an alarm is triggered, users get immediate notifications via text message or email and have instant access to review

the situation within seconds.

Monitoring and Logging Continuously

As a monitoring system, the MadgeTech Cloud allows for instant

access to real time data in the palm of your hand. As a logging

solution, recorded data is buered and saved to the device’s

internal memory. This provides uninterrupted continuous

monitoring even in the event of a power loss or network failure.

Quick &

Easy Setup

View Data From

Anywhere

Access Data

Instantly

Secure

Solution

Email & Text

Notifications

Order today at www.madgetech.com

|

19

Page 20

MadgeTech Data Logger Software

P

This simple, easy-to-use, Windows-based soware enables the user to eortlessly collect, display, and analyze data. A variety

of powerful tools can be used to examine, export, and print professional quality reports with just a click of the mouse. This

soware can be downloaded for free from the MadgeTech website.

Simple, Easy-to-use, Windows-based Software

Cooling Flags Copy to ExcelDigital CalibrationAutomatic Statistics

Software Features

• Multiple Graph Overlay

• Statistics

• Digital Calibration

• Zoom In / Zoom Out

20

• Timeslice

• Lethality Equations (F0, PU,Fh, Fd)

• Mean Kinetic Temperature

• Full Time Zone Support

Tabular Data ViewCustomizable Graphs

Calculation

• Data Annotation

• User Friendly File Management

• Min. / Max. / Average Lines

• Cooling Flags

• Data Table View

• Automatic Report Generation

• Summary View

Page 21

MadgeTech 4 Secure Software

MadgeTech 4 Secure Soware aids customers in compliance with 21 CFR

Part 11 requirements. The soware ensures standards in which electronic

files are considered equivalent to paper records, saving time and eort.

Features & Benefits

Aids in complaints with FDA 21 CFR Part 11/820 and GxP

guidelines. Features additional security benefits such as:

• Audit Trails

• Secure data file

• Sophisticated user management

• Electronic signatures

• Time and cost saving validation package, stands up to

interrogation from auditors

• Automatic data security and audit trail

• Sophisticated user management

• Traceability with customizable electronic signatures

Meeting compliance with regulations for the FDAs Good Manufacturing Practices, or those set forth in Quality Plans, has become increasingly

complex. MadgeTech has simplified this process by including IQ/OQ/PQ protocols with its MadgeTech 4 Secure Soware package.

This enormous time and money saving feature eliminates the need to develop in-house soware validation procedures. The MadgeTech

IQ/OQ/PQ protocol is in support of FDA and cGMP guidelines. In addition, MadgeTech oers a Soware Validation Workbook to help the

user verify the functionality of the soware.

Areas Evaluated

Installation Qualification (IQ)

• A description of the MadgeTech system

• Verification that all MadgeTech system

equipment, soware and accessories are

received in good condition

• A check for complete documentation

• Verification that the installation of

MadgeTech equipment is completed

properly

• Verification that MadgeTech soware

is installed properly on the target

workstation

• Verification of basic communication

between MadgeTech data logger(s) and

the target workstation(s)

Operational Qualification (OQ)

• Functional verification of MadgeTech

data loggers

• Handling and maintenance information

for the use of MadgeTech equipment

• MadgeTech operating procedures for

primary functions

• Verification of proper communication

between the MadgeTech data logger(s)

and the workstation(s)

• Verification that the data logger

hardware is operational

Performance Qualification (PQ)

Recommendation

• Additional handling precautions

for maintaining the accuracy of

MadgeTech equipment

• Periodic maintenance information

for the use of MadgeTech equipment

• Periodic calibration verification in

the field

• Comparison of the reported values

to a known good standard

• Verification of acceptable

performance in the target system

Order today at www.madgetech.com

|

21

Page 22

Matrix

Product RFTemp2000A RFRHTemp2000A

Measurement

Range

Resolution

Calibrated

Accuracy

Operating

Range

Memory

IP Rating

Material

Required

Interface Cable

Probe

-20 °C to +60 °C

0.01 °C

±0.5 °C

(0 °C to +55 °C)

-20 °C to +60 °C

0 %RH to 95 %RH

32,256 Reading s 16,128 Readings 10,752 Readings 16,128 Readings 32,700 Readings 43,69 0 Readings 32,767 Readings 32,700 Readings 32,767 Readings 43,690 Readings 32,767 Readings 16,3 50 Readings 32,767 Readings 8,191 Readings 32,767 Readings 32,767 Readingsz 131,071 Readings

IP22 IP22 IP22 IP22 IP68 IP68 IP68 IP68 IP68

ABS Plastic ABS Plastic ABS Plastic ABS Plastic 316 Stainless Steel 316 Stainless Steel 316 Stainless Steel

RFC1000 RFC1000 RFC1000 RFC1000 IFC400 or IFC406 IFC400 or IFC406 IFC400 or IFC406 IFC400 or IFC406 IFC400 or IFC406 IFC400 or IFC406 IFC300 IFC400 or IFC406 IFC400 or IFC406 IFC103 IFC300 IFC300 IFC200

Internal Senso r Internal Sensor External Sensor

-20 °C to +60 °C

0 %RH to 95 %RH

0.01 °C

0.1 %RH

±0.5 °C

(0 °C to +55 °C)

±3.0 %RH, ±2.0 %RH

typical @ +25 °C

(10 %RH to 90 %RH;

+5 °C to +55 °C)

-20 °C to +60 °C

0 %RH to 95 %RH

RFCO2RHTemp2000A

0 ppm to 200 ,000 ppm

0 °C to +55 °C

0 %RH to 95 %RH

10 ppm

0.08 °C

0.08 %RH

±70 ppm

±1.0 °C

±3.0 %RH from

25 %RH to 75 %RH

@ 25 °C, 7 %RH

otherwise

0 °C to +55 °C

0 %RH to 95 %RH

VTMS

-20 °C to +60 °C

0.1 °C 0.01 °C 0.001 °C 0.01 °C 0.01 °C

±0.1 °C

-20 °C to +60 °C

0 %RH to 95 %RH

External Thermocouple

Probe, Typ e K

Thermocouple Included

HiTemp14 0/

HiTemp140-PT

-200 °C to +260 °C

PT: -200 °C to +350 °C

±0.1 °C

(+20 °C to +140 °C)

±0.3 ° C

(-20 °C to +19.99 °C)

±0.4 °C

(-40 °C t o -20.01 °C)

-40 °C to +140 °C

0 %RH to 100 %RH

Exte rnal RTD Probe

HiTemp140 -M12 HiTemp14 0-FR Thermal Shield PRTemp140

-200 °C to +85 0 °C -20 0 °C to +260 °C -200 °C to +260 °C

±0.5 ° C from +160 °C

±1.0 °C fro m 0 °C to

-40 °C to +140 °C

0 %RH to 100 %RH

Detachable External

(M12 Compatible)

to +400 ° C

+16 0 °C

RTD Probe

±0.1 °C

(+20 °C to +140 °C)

-40 °C to +140 °C

0 %RH to 100 %RH

Exte rnal RTD Probe Exte rnal RTD Probe Internal Senso r

±0.1 °C

(+20 °C to +140 °C)

±0.3 ° C

(-20 °C to +19.99 °C)

±0.4 °C

(-40 °C t o -20.01 °C)

-200 °C to +250 °C

0 %RH to 100 %RH

316 Stainless Steel

Enclosure: PTFE

More Details

Refer to page 14 Refer to page 14 Refer to page 15 Refer to page 11 Refer to page 4 Refer to page 7 Refer to page 4 Refer to page 7 Refer to page 5 Refer to page 6 Refer to page 10 Refer to page 8 Refer to page 9 Refer to page 12 Refer to page 12 Refer to page 13 Refer to page 13

Data Logger Calibration

Why Calibrate?

All physical sensors become less accurate due to the environment, usage, stress, and even time. The degree to which these changes

occur varies from device to device. For example, a voltage device will dri very little over the years whereas a humidity sensor can dri

significantly in several weeks if subjected to a corrosive environment.

Calibration Certificates

The calibration certificates are generated at the end of the manufacturing process. Each certificate indicates the date and conditions

of calibration. These certificates provide the documentation needed to satisfy most requirements, certifying that a product has been

properly calibrated. The calibration certificate also provides traceability back to National Institute of Standards and Technology (NIST)

standards on select models, non-NIST available for all other models.

Calibration Services

MadgeTech’s calibration laboratory oers a variety of standard and customized calibration services. The scope of MadgeTech’s services

covers the following parameters temperature, humidity, pressure, voltage, current, shock and more.

Standard calibration values and pricing can be found on the Product Information Card for each data logger. The Product Information

Card can be found on the website page for that product. The standard calibration is normally a one or two point correction of the

reported values, depending on the type of device being calibrated. Additional or nonstandard points incur an additional fee.

22

Page 23

0 Bar to 5 Bar

(0 PSIA to 72. 5 PSIA)

-20 °C to +140 °C

0.0001 Bar

0.01 °C

ThermoVault140-DHS

-200 °C to +85 0 °C -60 °C to +75 °C

0.001 °C 0 .1 °C

LyoTemp RHTemp1000IS Temp1000IS TransiTemp-EC TransiTempII CryoTemp LNDS

-40 °C t o +80 °C

0 %RH to 100 %RH

non-condensing

0.01 °C

0.1 %RH

-40 °C t o +80 °C -20 °C to +70 °C -40 °C t o +80 °C -86 °C t o +35 °C -200 ° C to +260 °C

0.01 °C 0.1 °C 0.1 °C 0 .1 °C 0.1 °C

±0.03 Bar

±0.1 °C

-20 °C to +140 °C

0 %RH to 100 %RH

316 Stainless Steel

±0.5 ° C from +160 °C

±1.0 °C fro m 0 °C to

Time Dependant

See Char t on Page 6

IP50 (no O- Ring)

IP68 (wit h O-Ring)

Enclosur e: 300 Ser ies

Seals: PT FE & Silicone Ru bber

Insulatio n: Dewar Fla sk & PTFE

Detachable External

(M12 Compatible)

to +400 ° C

+16 0 °C

Stainless Steel

RTD Probe

±0.5 ° C

±0.5 ° C

-60 °C t o +75 ° C

0 %RH to 100 %RH

IP50 Not IP Rated Not IP Rate d IP20 IP64 IP64 IP20

ABS Plastic 316 Stainless Steel 316 Stainless Steel ABS Plastic ABS Plastic ABS Plastic

External Sensor Internal Senso r E xternal RTD Pro be Internal Sens or Internal Se nsor Interna l Sens or

±3 %RH max imum;

±2.0 %RH t ypical at

+25 °C

-40 °C t o +80 °C

0 %RH to 100 %RH

non-condensing

±0.5 ° C

-40 °C to +80 °C

0 %RH to 95 %RH

±0.5 ° C

(-10 °C to +40 °C)

±1.0 °C

(-20 °C to +70 °C)

-20 °C to +70 °C

0 %RH to 90 %RH

±0.5 °C

(-10 °C to +40 °C)

-40 °C to +80 °C

0 %RH to 100 %RH

±1.0 °C ±0.5 ° C

-86 °C to +35 °C

0 %RH to 100 %RH

-20 °C to +60 °C

0 %RH to 95 %RH

Black Anodized

Aluminum

Exte rnal Sens or, Type E

Thermocouple Included

NIST Calibration Certificates

MadgeTech’s calibration laboratory oers a variety of standard and customized calibration services.

The scope of MadgeTech’s NIST Calibration Services include the following parameters:

• Temperature

• Humidity

• Pressure

• Voltage

• Current

A certificate of conformance is of oered for the Pulse, Event and State data loggers which do not require calibration.

For details on MadgeTech’s calibration services, please contact the services department.

ISO 17025/A2LA Accredited Calibration Certification

MadgeTech can supply A2LA accredited calibrations to ISO 17025 standards. Please contact a sales representative for details on

calibration abilities and pricing. Note: This certification must be requested prior to sending the device in for recalibration.

Order today at www.madgetech.com

|

23

Page 24

MadgeTech, Inc

6 Warner Road, Warner, NH 03278

T: (603) 456-2011 F: (603) 456-2012

info@madgetech.com

www.madgetech.com

Loading...

Loading...