Page 1

Product User Guide

AVS140-1

Autoclave Validation Data Logging System

To view the full MadgeTech product line, visit our website at www.madgetech.com.

Page 2

2

Page 3

Table of Contents

Autoclave Validation Data Logging System ..........3

Hardware ............................................................ 4-5

Software .............................................................. 6-7

IQ/OQ/PQ Validation Protocol ............................. 8

System Installation ................................................ 9

Maintenance ....................................................10-11

Autoclave Validation System

The AVS140-1 is a complete system used to perform autoclave validations. The AVS140-1 consists of a

NIST traceable high temperature data logger, an IFC400 Interface and the MadgeTech 4 Secure Software

providing tools to users to assist with FDA 21 CFR Part 11 compliance.

Data Logger

Software

IQ/OQ/PQ

Validation Protocol

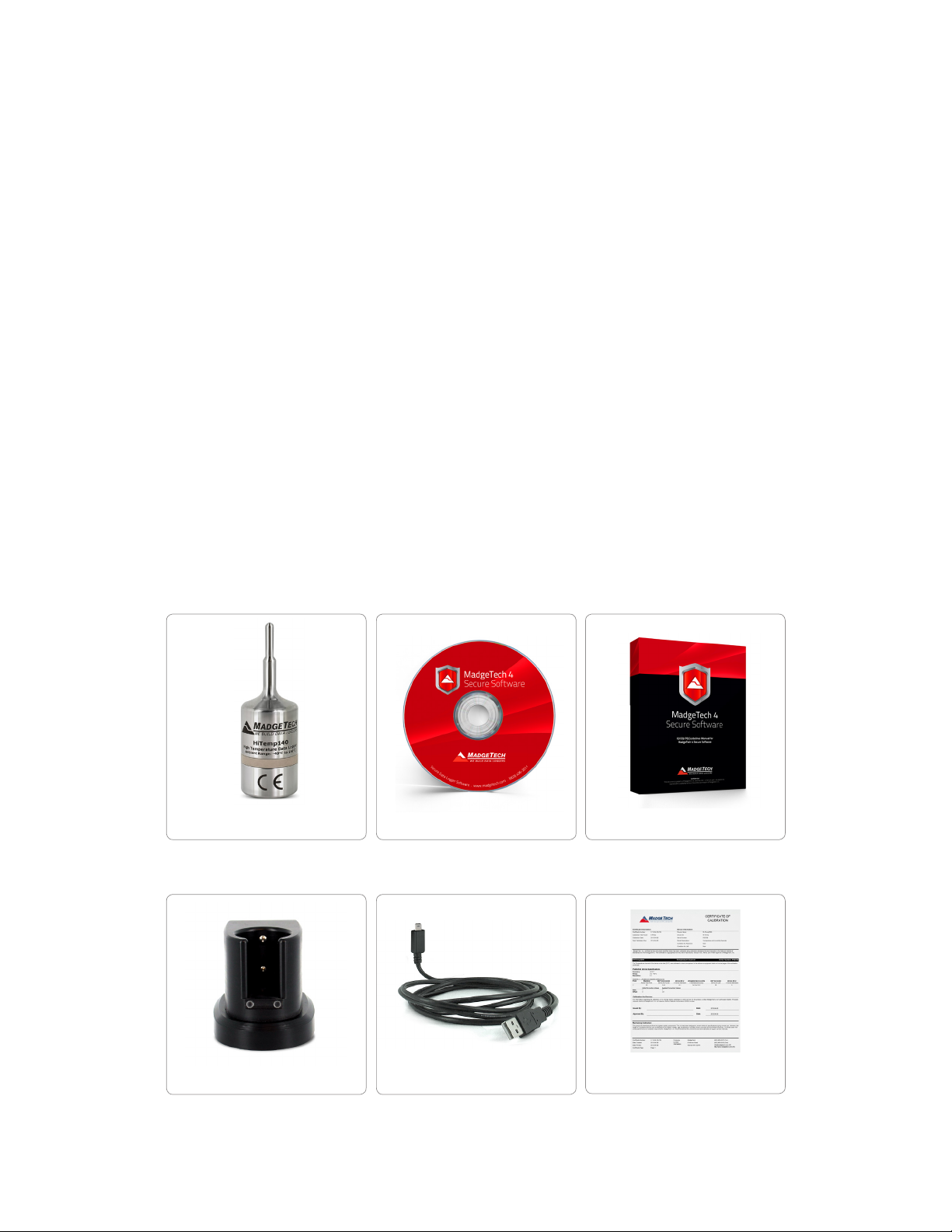

HiTemp140 MadgeTech 4 Secure Software

Data Logger Interface & USB Cable Certificate of Calibration

USB Cable NIST Calibration CertificatesIFC400

IQ/OQ/PQ Validation

Protocol Workbook

AVS140-6 Product User Guide | 3

Page 4

Hardware

HiTemp140 Product Overview

High Temperature Data Logger

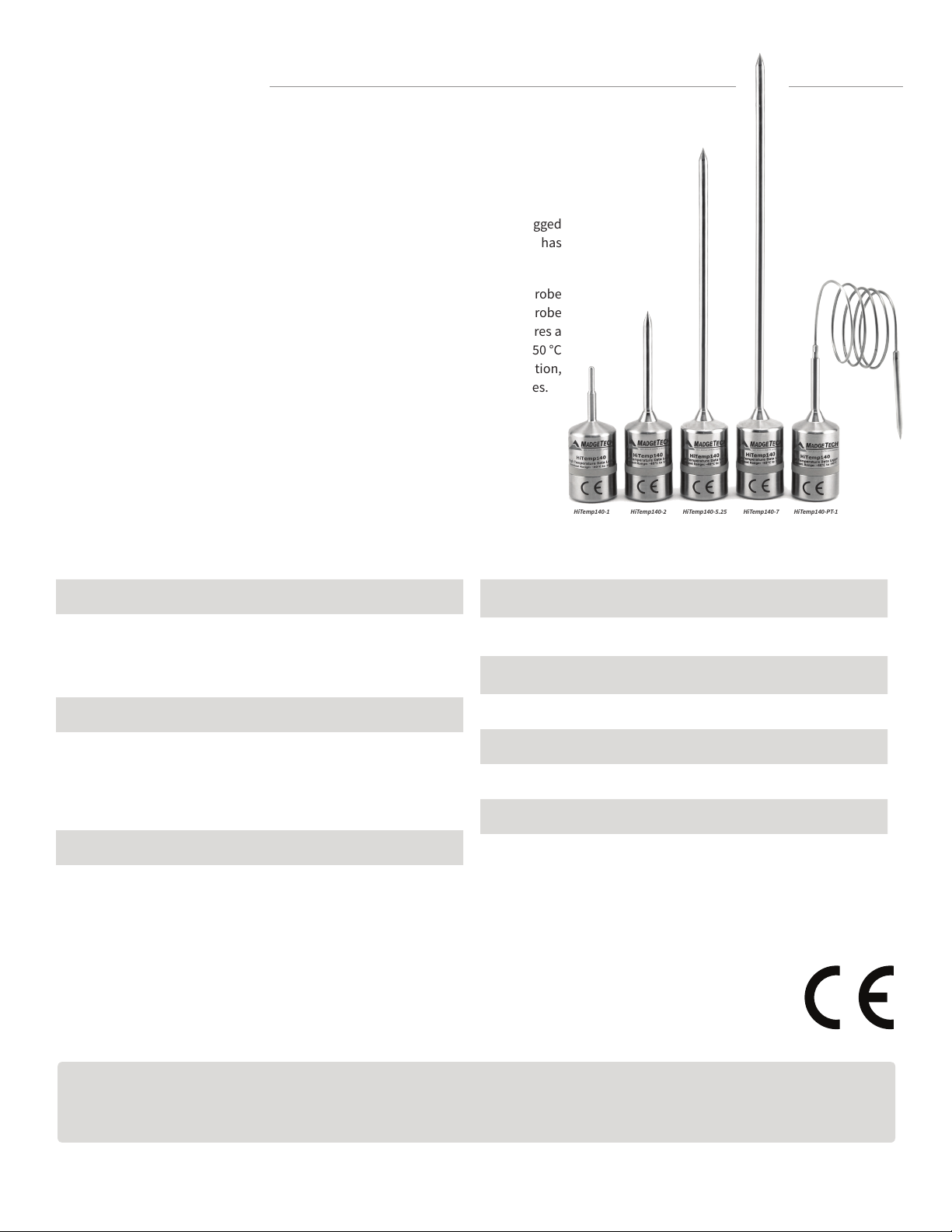

The HiTemp140 data logger is MadgeTech’s solution for high precision, rugged

temperature monitoring. It can withstand temperatures from -40 °C to 140 °C and has

an accuracy of ±0.1 °C.

The HiTemp140 can store up to 32,700 readings, and features a rigid external probe

capable of measuring extended temperatures, up to 260 °C (500 °F). Custom probe

lengths up to 7 inches are available. Also available, is the HiTemp140-PT that features a

24 inch flexible stainless steel probe for measuring extended temperatures up to 350 °C

(662 °F). The probe is durable and can be spiraled, bent or angled in any direction,

making it easy to log temperatures within bottles, vials or other hard to reach places.

HiTemp140-1 HiTemp140-2 HiTemp140-5.25 HiTemp140-7 HiTemp140-PT-1

HiTemp140 Specifications

Temperature Sensor: 100 Ω Platinum RTD

HiTemp140:

Probe Measurement

Range:

Temperature Resolution: 0.01 °C (0.02 °F)

Calibrated Accuracy:

Reading Rate: 1 second up to once every 24 hours

Memory: 32,700 readings

-200 °C to +260 °C (-328 °F to +500 °F)

HiTemp140-PT:

-200 °C to +350 °C (-328 °F to + 662 °F)

±0.1 °C/±0.18 °F

(20 °C to +140 °C/68 °F to +284 °F)

±0.3 °C/±0.54 °F

(-20 °C to +19.99 °C/-4 °F to +67.98 °F)

±0.4 °C/±0.72 °F

(-40 °C to -20.01 °C/-40 °F to -4.02 °F)

Battery Life:

Time Accuracy:

Operating Environment:

Dimensions (Body): 1.6 in x 0.970 in dia. (40 mm x 24.6 mm dia.)

Submersible: Yes (IP68)

Weight: 4.2 oz (120 g)

Material: 316 Stainless Steel

Approvals: CE

1 year typical

(1 minute reading rate at 25 °C/77 °F)

±1 minute/month at 20 °C to 30 °C

(68 °F to 86 °F) (Stand alone mode)

-40 °C to +140 °C (-40 °F to +284 °F),

0 %RH to 100 %RH

BATTERY WARNING: FIRE, EXPLOSION, AND SEVERE BURN HAZARD. DO NOT SHORT CIRCUIT, CHARGE, FORCE OVER DISCHARGE,

CRUSH, PENETRATE, OR INCINERATE. BATTERY MAY LEAK OR EXPLODE IF HEATED ABOVE 150 °C (302 °F).

4

Page 5

Hardware

IFC400 Product Overview

Interface Cable Package

The IFC400 is an Interface Cable Package for the HiTemp140 Data Logger. Included with the

package is a USB Connection Cable and Docking Station Cradle. The IFC400 Data Logger Interface

allows for a device to be connected to a PC.

IFC400 Specifications

Operating Environment:

Connection Type: USB (to PC)

Weight: 0.3 lb (140 g)

Material: Acetal Copolymer

Dimensions: 1.95 in x 2.39 in x 1.5 in (49.3 mm x 60.7 mm x 38.1 mm)

Approval: CE

Battery: This device does not use a battery

-20 °C to +50 °C (-4 °F to +122 °F)

0 %RH to 95 %RH non-condensing

AVS140-6 Product User Guide | 5

Page 6

Software

P

MadgeTech 4 Secure Software

The MadgeTech 4 Secure Soware aids customers in compliance with 21 CFR Part 11 requirements.

The soware ensures standards in which electronic files are considered equivalent to paper

records, saving time and eort. MadgeTech 4 Secure Soware contains criteria such as electronic

signatures, access codes, secure data files, and an audit trail which meet the requirements of 21

CFR Part 11 and help provide data integrity.

MadgeTech provides on-site IQ/OQ/PQ services to help the user validate the data logging system.

Our trained sta are extremely knowledgeable with the standard IQ/OQ/PQ protocols of the

MadgeTech data logging system. This service is a cost-eective means to save time and ensure

proper implementation of IQ/OQ/PQ of the MadgeTech data logging system with a minimal

disruption to sta and operations. Get more information on our IQ/OQ/PQ On-Site Service.

Cooling Flags Copy to ExcelAutomatic Statistics

6

Tabular Data ViewCustomizable Graphs

Calculation

Page 7

Great New Features

The MadgeTech 4 Secure Soware is a powerful, intuitive tool containing features that are designed to save on both time

and headaches. Both management and users will find MadgeTech’s new soware exciting: users will love the familiar

interface and numerous shortcuts, while management will appreciate the increased data security and time-saving

elements. Some of the most highly-anticipated new features include:

Workflows

Configure routine data logging tasks to run

while you are free to do other things. The

Workflows feature enables the automation of

tasks such as creating reports, downloading

data, starting and stopping devices or even

sending email notifications!

Administrator & User Settings

Users can be given two levels of access,

either administrator or user. Administrators

have access to all the security settings, while

users only have access to communicate with

the data loggers and analyze data.

Time Markers

Easily mark a desired point in time on any

report using Time Markers. Time Markers

appear as a vertical line in a graph or a colored

row in a data table, Time Markers can help

to organize dierent stages or cycles within

your process or any reference points critical to

interpreting your data as desired.

Groups

Users and Administrators can be assigned to

Groups and can be easily maintained using a

variety of permissions.

Advanced Statistics

MadgeTech 4 Secure Soware has expanded

to oer more options and statistics available

for data analysis.

• Time until threshold statistics

• Sterilization Data (F0 and A0)

• Default statistic settings

Electronic Signature

By clicking the Electronic Signature button,

users and administrators can add electronic

signatures. The electronic signature contains

the printed name of the signer, date and

time of the signing and the meaning of the

signing.

Login

Login attempts and lockout duration can

be assigned within the Login tab. There are

numerous password and account settings

for the administrator to set such as the

complexity of the password and status of

each user account. The user management

tab is only available to administrative users.

Audit Trail

An Audit Trail is kept automatically with

information such as who has logged in and

out, what files were downloaded, save, printed

etc. Each record is date and time stamped and

includes the user information.

AVS140-6 Product User Guide | 7

Page 8

IQ/OQ/PQ

IQ/OQ/PQ Validation Protocol

Meeting compliance with regulations for the FDAs Good Manufacturing Practices, or those set forth in Quality Plans, has become increasingly

complex. MadgeTech has simplified this process by including IQ/OQ/PQ protocols with its MadgeTech 4 Secure Soware package.

This enormous time and money saving feature eliminates the need to develop in-house soware validation procedures. The MadgeTech IQ/OQ/

PQ protocol is in support of FDA and cGMP guidelines. In addition, MadgeTech oers a Soware Validation Workbook to help the user verify the

functionality of the soware.

Installation Qualification (IQ)

• A description of the MadgeTech system

• Verification that all MadgeTech system equipment, soware and accessories are

received in good condition

• A check for complete documentation

• Verification that the installation of MadgeTech equipment is completed properly

• Verification that MadgeTech 4 Secure Soware is installed properly on the target

workstation

• Verification of basic communication between MadgeTech data logger(s) and the

target workstation(s)

Operational Qualification (OQ)

• Functional verification of MadgeTech data loggers

• Handling and maintenance information for the use of MadgeTech equipment

• MadgeTech operating procedures for primary functions

• Verification of proper communication between the MadgeTech data logger(s) and

the workstation(s)

• Verification that the data logger hardware is operational

Performance Qualification (PQ) Recommendation

• Additional handling precautions for maintaining the accuracy of MadgeTech equipment

• Periodic maintenance information for the use of MadgeTech equipment

• Periodic calibration verification in the field

• Comparison of the reported values to a known good standard

• Verification of acceptable performance in the target system

8

Page 9

System Installation

Installing the Software

A

1. Inserting the MadgeTech 4 Secure Soware CD into the CD drive on the Windows PC.

An autorun window should appear. If the autorun does not appear, locate the drive on the

computer by selecting the Start menu and choosing Computer or My Computer. Browse to the

CD drive and select the autorun.exe file. For Windows 7 and Windows 8 users, a dialog box may

appear with a list of options. Select Open Folder to View Files and select the autorun.exe file.

2. The MadgeTech 4 Secure Soware Setup Screen will display with options as shown to the le.

3. Installing the Windows Driver

To install the drivers for the IFC406, click on the Install USB Interface Drivers link on the MadgeTech

Installer Options window panel. A window will appear prompting for a directory and to start the

installation. The default directory is C:\Program Files\MTI-USB\Datalogger Interface. If you choose

to change the location of the install directory, select the Change Install Location button. Once you

have the install location set click the Install button to start the installation.

4. Installing the .NET 4.0 Framework

If the Windows PC doesn’t already have .NET 4.0 Framework, installation may be required. If you are running Windows 8, these components are

already installed. To see if the .NET 4.0 Framework is already installed on the Windows PC, go to the Windows Control Panel and select Programs.

“Microso .NET Framework 4.0” would be listed as a Windows program. If the Windows PC doesn’t already have .NET 4.0 Framework, click on

MadgeTech Secure Soware and then select Install .Net 4.0 Framework to install.

5. Installing the MadgeTech 4 Secure Soware

Click on MadgeTech Secure Soware and then select Install MadgeTech Secure Soware. Follow the MadgeTech 4 Secure Setup Wizard on-screen

prompts to complete the installation. The installation of MadgeTech 4 Secure Soware is complete!

Connecting the Data Logger Interface

B

1. Remove the Warning Label on the IFC406 to expose the USB connector.

2. Connect one end of the USB cable to the USB port of the IFC400.

3. Connect the other end to a USB port on your PC. When the IFC400 is plugged in, a New Hardware Found message will appear in the lower right

corner of your screen. The new drivers will automatically configure themselves for use with the interface cable. A message will then appear that

the new hardware is installed and ready to use.

4. The installation of the USB data logger interface is complete!

C

Test the Data Logger Interface Operation

To verify that the USB Interface drivers are installed properly, check to ensure the Data Logger Soware can recognize a device.

1. When the interface cable is connected to the PC the blue LED power indicator light should be on.

If the indicator light is not on, unplug the interface cable, wait 5 seconds and plug it back into the PC.

2. Start the MadgeTech 4 Secure Soware.

3. Your device(s) should be listed in the Connected Devices Panel.

AVS140-6 Product User Guide | 9

Page 10

Data Logger Maintenance

Battery Replacement

Materials needed: ER1425S-HT Lithium Battery

Battery Replacement Procedure:

1. Unscrew the end cap of the data logger to expose the battery.

2. Remove the battery.

3. Place the new battery into the data logger. Note the polarity of the battery.

4. Tightly screw the data logger back together until the O-Rings are no longer visible.

BATTERY WARNING: DISCARD USED BATTERY PROMPTLY. KEEP OUT OF REACH OF CHILDREN. DO NOT DISPOSE OF IN FIRE, RECHARGE, PUT IN

BACKWARDS, DISASSEMBLE, OR MIX WITH OTHER BATTERY TYPES. MAY EXPLODE, FLAME, OR LEAK AND CAUSE PERSONAL INJURY.

Recalibration

Recalibration is recommended annually for all MadgeTech data loggers. The Properties window in the MadgeTech 4 Secure Soware displays the

date of the last calibration and the date that the device is next due for calibration. The MadgeTech 4 Secure Soware can also be configured to

send an on screen notification prior to the calibration due date for each device. By default this is set to seven days prior to calibration due date

and can be changed by the user by going to the File tab in the MadgeTech 4 Secure Soware and clicking on Options. Select Device and check

“Display popup notification when a device nears its next calibration date”. The user can then select the number of days before calibration due

date to notify.

HiTemp140 Standard Calibrations Points: 2 points at 30 °C and 140 °C.

Use the MadgeTech RMA System to submit the device for recalibration.

Recalibration Pricing:

Recalibration traceable to NIST ............. $70.00

Recalibration .......................................... $40.00

RMA Instructions

To send a device back in to MadgeTech, follow the instructions below to create an RMA (Return Merchandise Authorization) on the MadgeTech website:

1. Visit www.madgetech.com, click on the Services tab, and select RMA Process.

2. When the web page opens, please sign in. If this is the first time, select Create an Account and create one. Once signed in, click on the Make New

RMA button.

3. Complete the applicable fields on the form including customer Billing and Shipping information, even if they are the same. Please see the field

explanation below for a more detailed description about questions asked in the Device Information section.

4. When all of the fields are complete, click Generate RMA.

5. Print out the confirmation page that follows containing the RMA number and MadgeTech’s address for shipping. A Return Merchandise

Authorization must be accompanied by a copy of the RMA paperwork and shipping is prepaid by the customer. The RMA number should be

clearly marked on the outside of the package.

6. Please ship the package via UPS, FedEx, TNT, or DHL to the address listed on the confirmation page. USPS will not ship MadgeTech data loggers.

7. A notification email will be automatically sent when MadgeTech has received the RMA.

10

Prices and specifications subject to change. See MadgeTech’s terms and conditions at www.madgetech.com.

To send the devices back, visit www.madgetech.com, select Services then RMA Process.

Page 11

Data Logger Maintenance

O-Rings

O-Ring maintenance is a key factor when properly caring for the HiTemp140 and PR140. The O-Rings ensure a tight seal and prevent liquid from

entering the inside of the device.

Materials needed for the HiTemp140: HiTemp140-O-Ring

O-Ring Replacement Procedure:

1. Unscrew the end cap from the data logger to expose the O-Ring.

2. Use a small pointed tool (knife or pick) to pry the old O-Ring out of its groove.

3. Make sure that the O-Ring groove is free of any dirt or debris.

4. Partially screw the mating parts back together leaving the O-Ring groove exposed.

5. Apply a thin coat of silicone based lubricant to the O-Ring.

6. Stretch the O-Ring over the cap and into its groove. WARNING: Avoid stretching the O-Ring over the threads! Sharp threads can cut the new O-Ring.

7. Tightly screw the data logger back together until the O-Rings are no longer visible.

Maintenance:

MadgeTech data loggers come directly from the factory with high quality O-Rings that have been properly installed. As a user, there are only a

few things that need to be remembered to maintain a functional O-Ring seal.

DO:

• Clean them frequently (use compressed air or a so brush to avoid abrasion).

• Lubricate regularly (if it doesn’t feel slippery, it needs to be lubricated). We recommend Parker® Super-O-Lube, but any silicone based O-Ring

lubricant will work. This is most important on the seals that are frequently opened and closed for communication with the logger.

• Inspect the O-Ring regularly for signs of failure.

DON’T:

• Poke, jab, pry at the O-Ring with sharp or pointed objects.

• Expose the O-Rings to harsh chemicals.

• Expose the seals to high pressure (the HiTemp140 and PR140 data loggers are rated to 60 PSIG).

• Expose the seal to high temperatures (see specification for operating temperature range).

Support

For more assistance with our products, please contant us using the information below

Phone & Fax

Sales & General Inquiries: (603) 456-2011

Fax: (603) 456-2012

E-mail

General Information: info@madgetech.com

Sales: sales@madgetech.com

Customer Support: support@madgetech.com

Mailing Address

MadgeTech, Inc

6 Warner Road

Warner, NH 03278

Hours of Operation

Monday - Friday,

8:00am - 5:00pm EST

Website

Visit our Online Knowledge Base

at www.madgetech.com/kbase

AVS140-6 Product User Guide | 11

Page 12

MadgeTech, Inc. . 6 Warner Road . Warner, NH 03278

Tel: (603) 456-2011 . Fax: (603) 456-2012 . info@madgetech.com . www.madgetech.com

DOC-1293-036-00 Rev2 2014.10.30

Loading...

Loading...