Made BIKCWN001BLA-UK, BIKCWN003BLA-UK, BIKCWN004BLA-UK, BIKCWN002BLA-UK, BIKMLW001COP-UK User Manual

...

Colwyn Single Speed City Bike

BIKCWN001BLA-UK

BIKCWN003BLA-UK

BIKCWN004BLA-UK

BIKCWN002BLA-UK

Mallow Single Speed City Bike

BIKMLW001COP-UK

BIKMLW002COP-UK

BIKMLW003COP-UK

BIKMLW004COP-UK

Made in China

Recommendations for the continual

safe use of this product are stated

throughout this manual. Please retain

for future reference.

GB

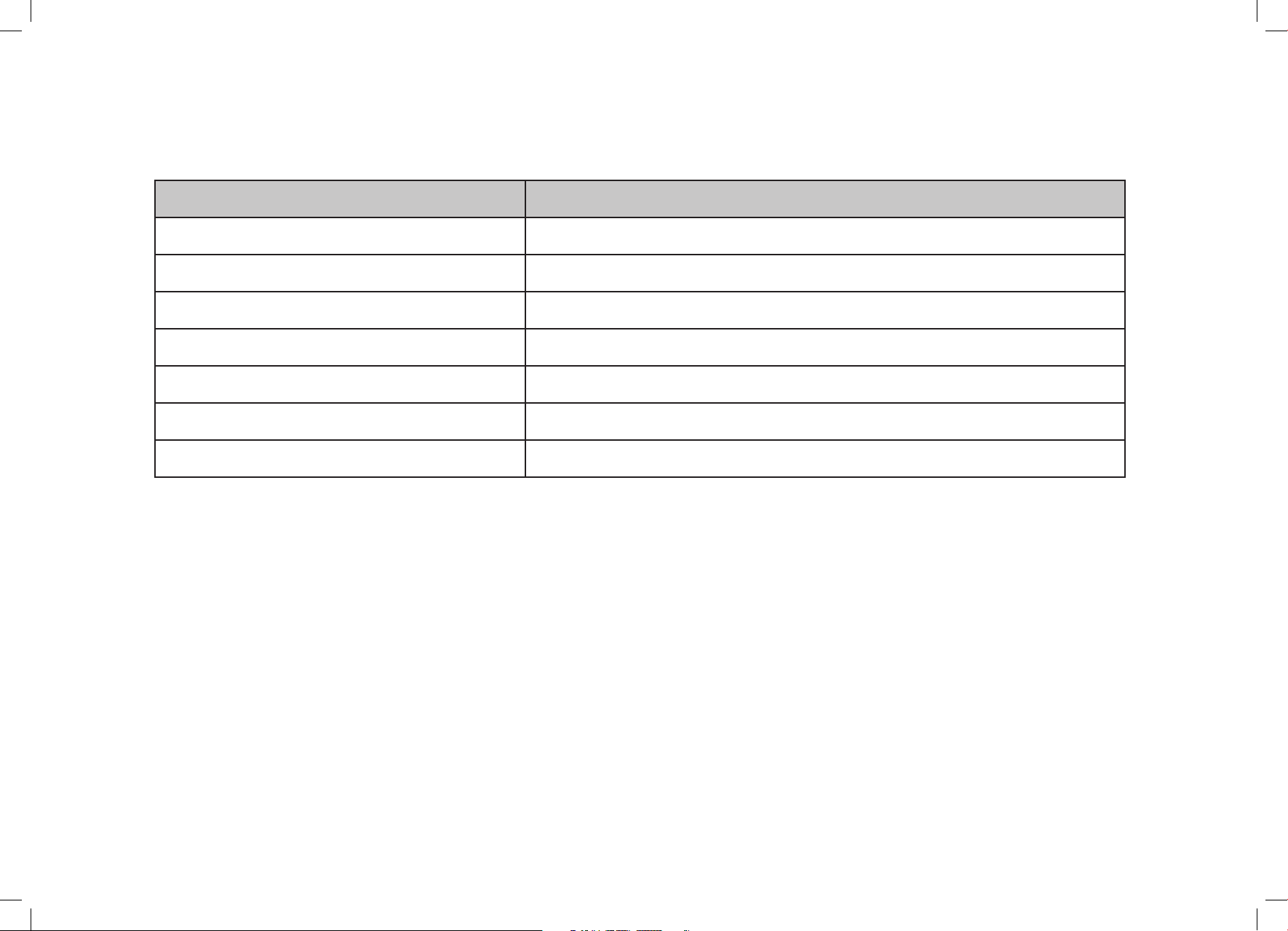

Model number Product description, color, size

BIKCWN001BLA-UK Colwyn Single Speed City Bike, Matt Black and Copper, S/M

BIKCWN003BLA-UK Colwyn Single Speed City Bike, Matt Black and Copper, M/L

BIKCWN002BLA-UK Colwyn Single Speed City Bike, Matt Black and Gold, S/M

BIKMLW001COP-UK Mallow Single Speed City Bike, Copper and White, S/M

BIKMLW002COP-UK Mallow Single Speed City Bike, Copper and White, M/L

BIKMLW003COP-UK Mallow Single Speed City Bike, Copper and Black, S/M

BIKMLW004COP-UK Mallow Single Speed City Bike, Copper and Black, M/L

1

Congratulations on the purchase of your new bicycle!

With proper assembly and maintenance, this bicycle will offer you years of enjoyable riding.

IMPORTANT:

Carefully read this manual and follow all instructions. Your bicycle may come with additional instruction sheets.

Please ensure that you read and become familiar with their contents. Keep this manual for future use. If this

bicycle was purchased for a child, it is the responsibility of the purchaser to verify the bicycle has been properly

assembled, and that the user has been properly trained and instructed on the use of this bicycle.

This manual is provided to assist you and is not intended to be a comprehensive manual covering all aspects

of maintaining and repairing a bicycle. The bicycle purchased is a complex piece of equipment that must

be properly assembled and maintained in order to be ridden safely. If there are any doubts about the proper

assembly and maintenance of the bicycle, have it assembled and maintained by a professional bicycle

mechanic.

RECORD YOUR SERIAL NUMBER

Your bicycle has a unique serial number stamped into

the bottom of the frame shown in the figure. Record this

number HERE for future reference. This number is helpful

in reclaiming your bicycle if ever lost or stolen.

THIS INFORMATION IS ONLY AVAILABLE ON

THE BICYCLE ITSELF.

There is no record of your serial number where purchased

or with our company. It is your responsibility as owner to

record this information.

Serial number: _______________________________________

2

Safety warnings

In the interest of safe cycling, make sure you read and

understand this bicycle owner’s manual.

The above safety alert symbol is important, along

with words such as DANGER, WARNING, CAUTION,

IMPORTANT, and NOTE or NOTICE. Pay close attention

to the information following these words and/or symbol

because it involves rider safety.

• DANGER and WARNING: Pay special attention to

these. Failure to do so could result in serious injury or

death to the rider or others.

• CAUTION: If not followed these instructions could

result in injury or mechanical failure or damage to the

bicycle.

• NOTE or IMPORTANT: These specify something that

is of special interest.

Owner’s responsibility

IMPORTANT: Reading and following the information

and instructions in this manual are essential to the

rider’s ability to ride safely.

1. It is the responsibility of the owner—or in the case

of a younger rider—the parents or guardian of the

rider to ensure all assembly instructions have been

followed. Even if the bicycle has been assembled by

the seller or a professional assembly company.

2. Brakes are essential to safety. Check and make

sure that the brakes are working properly before

riding the bicycle. Remember any mechanical

system changes condition during use and must be

maintained and checked before every use.

3. Bicycle laws may vary depending on location. Know

and understand the rules and laws that apply in the

riding area.

4. Know how to operate the bicycle and all related

equipment before the first ride. Ensure that other

individuals allowed to use the bicycle know how to

properly and safely use the bicycle.

3

5. There are many different types of bicycles and often

these types are designed for different uses. Know

the type of bicycle, including proper bicycle sizing

for the rider, which ensures good control during

use.

6. Any major service or adjustments on the bicycle

should be carried out by a competent adult or

a professional bicycle mechanic. If you wish to

make adjustments yourself, this manual contains

important tips on how.

CAUTION: Any adjustments made are entirely at the

owner’s risk. If in doubt, have adjustments and/or

repairs done by a qualified bicycle mechanic.

7. Check the bicycle regularly and do any required

maintenance.

WARNING:

• As with all mechanical components, the bicycle is

subject to wear and high stresses. Different materials

and components might react to wear or stress fatigue

in different ways. If the design life of a component has

been exceeded, it may suddenly fail, possibly causing

injuries to the rider. Any form of crack, scratches, or

change of colouring in highly stressed areas indicate

that the life of the component has been reached and

it should be replaced.

NOTE: Only use original parts for replacement. Original

replacement parts can be obtained from authorised

retailers. Only authorised retailers will be able to supply

you with a tested part appropriate for your bicycle’s

purpose.

Intended use

• This bicycle is classified under Condition 1 of the industry use conditions. Condition 1 bicycles are for

riding on a paved surface where the tires do not lose

ground contact. These bicycles are intended for use

only on public roads, paths, and tracks that are in

good condition. These bicycles are NOT intended for

off road use.

• This bicycle is not compatible with luggage holders or

child seats.

• The maximum weight limit of this bicycle is 125 kg

(max weight of rider + bicycle). DO NOT OVERLOAD.

4

WARNING: Do NOT use your bicycle for freestyle and stunt riding, jumping or competitive

events. Even if you are riding a mountain bicycle, you should know that off-road use or any

similar activities can be dangerous, and you are warned that you assume the risk for personal

injury, damages or losses incurred from such use. Do not ride your bicycle when any part is

damaged or not working properly. If you are unsure how to carry out repairs or maintenance on

your bicycle, consult a local bicycle mechanic for professional assistance and support.

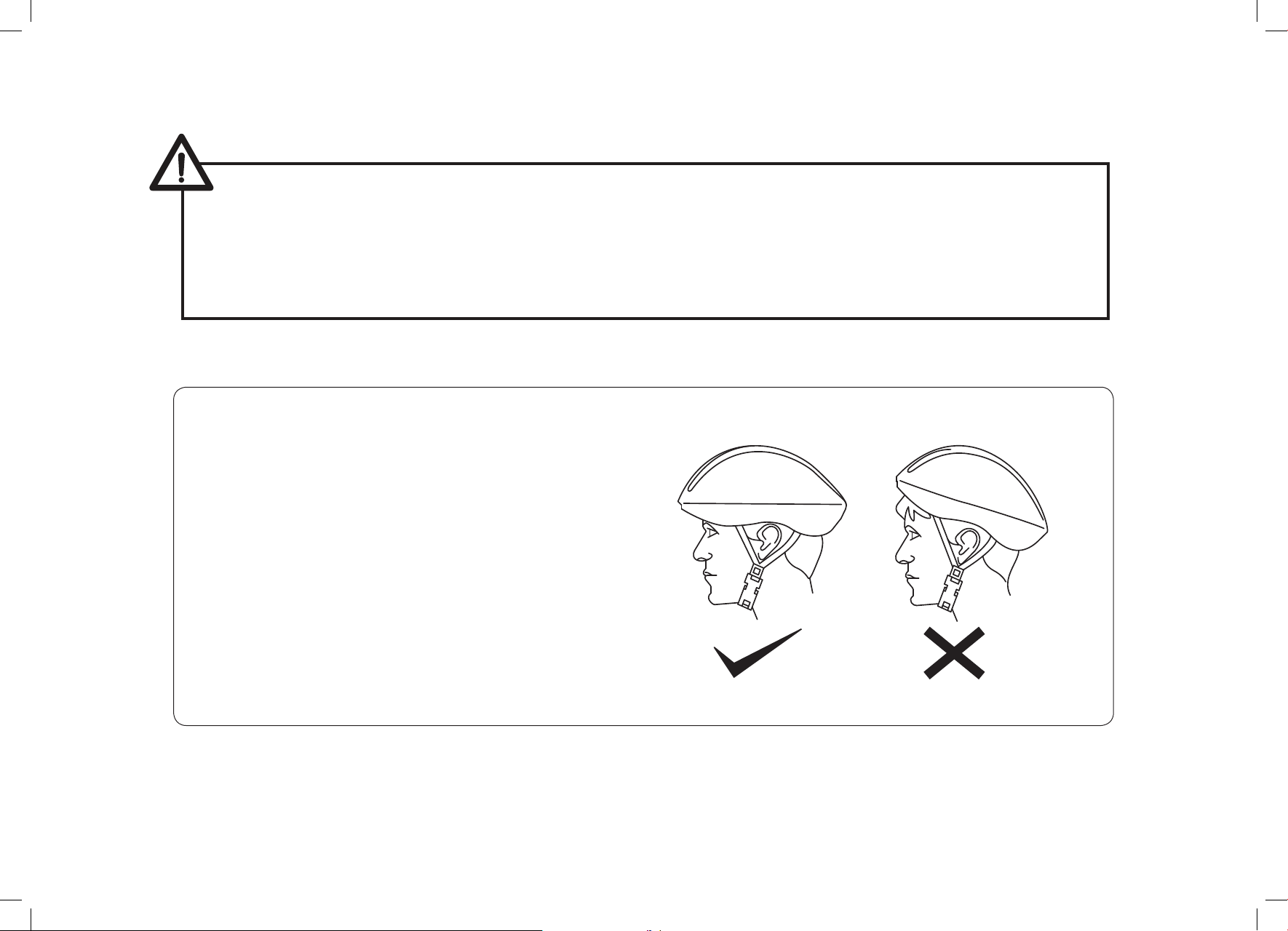

ALWAYS WEAR A HELMET — IT COULD

SAVE YOUR LIFE!

A properly fitting bicycle helmet fully compliant with

EN 1078 should be worn at all times when riding your

bicycle.

The correct helmet should:

• be comfortable

• be lightweight

• have good ventilation

• fit correctly

• cover the forehead

• be securely fastened on the rider.

5

Rules of the road

CAUTION: Before riding your bicycle, check the brakes

and other parts of the bicycle. Make sure all parts are

tightened, assembled correctly, and working properly.

The first ride should be taken in a large, open, level

area. If you have a problem, check the assembly

instructions and follow the maintenance procedures in

this book.

1. CAUTION: WET AND ICY WEATHER WARNING:

Check your brakes frequently. The ability to stop is

critical. Roads are slippery in wet weather so avoid

sharp turns and allow more distance for stopping.

Brakes may become less efficient when wet.

Leaves, loose gravel, and other debris on the road

can also affect stopping distance. If at all possible,

do not ride in wet weather—vision and control may

be impaired, creating a greater risk of accidents

and injury.

2. WARNING: NIGHT TIME OPERATION: It is NOT

recommended to ride your bicycle at night. If you

have an emergency that requires you to ride at

night you must have proper lights and reflectors.

NEVER ride at night without a helmet, taillight,

white front reflector, red rear reflector, pedal

reflectors, and white wheel reflectors. You must be

able to clearly see the surface where you are riding

and be seen by others.

3. Always wear shoes when riding a bicycle. Avoid

loose fitting clothes. Wear a cuff band or a trouser

clip to keep trousers from getting caught in the

chain wheel. Long sleeves, long trousers, gloves, eye

protection, a good helmet, elbow and knee pads

are recommended. Wearing a helmet is required by

law in many countries and is always a good idea.

4. Obey all traffic regulations. Most traffic regulations

apply to bicycle riders as well as automobile

operators. Observe all county and local traffic

regulations, signs, and signals. Check with your

local police station on bicycle licensing and

inspection, and where it is legal to ride your bicycle.

5. NOTE: Some countries and local laws may require

that your bicycle be equipped with a warning

device such as a horn or a bell.

6. Cover the bicycle’s stem, handlebar, and top tube

with safety pads for additional protection.

7. Do not ride your bicycle if the chain cover is not

attached, or if any of the bicycle’s mechanical

systems are not functioning properly. Doing so

could result in personal injury or damage to the

bicycle.

8. If any components becomes loose while riding,

STOP immediately and re-tighten or contact a

mechanic for repair.

6

Before riding

A minute spent checking your bicycle before each ride

significantly improves your safety and the enjoyment

of your ride. Each time before you ride make a habit of

performing the following safety checks:

1. Stand in front of the bicycle facing rearward and

hold the front wheel securely between your legs.

Try to twist the handlebar and verify that they do

not move. Then pull the handlebars up, trying to lift

the bicycle. There should be no movement.

2. Try and push the front wheel from side to side and

confirm that it feels tight and will not wobble. Lift

the front wheel up by the handlebars and strike

the wheel downwards with the heel of your hand.

Confirm that it is securely attached to the fork.

Spin the front wheel and confirm that it does not

wobble or contact the fork or brake pads.

3. Try to lift, push down, and twist the seat to confirm

that it’s tight.

4. Check the connection of the pedals to the crank

arms. You should see no pedal screw threads and

the pedal should feel firm and positioned parallel to

the ground.

6. Check and make sure that the fenders and accessories are firmly attached and will not contact any

moving parts. Make sure all reflectors are in position and not broken.

7. Lastly, put on your bicycle safety helmet and mount

your bicycle. Your safety is well worth just a minute.

Be sure to read and follow the warnings and instructions in the Assembly, Maintenance and other

sections of this manual.

WARNING: This bicycle must be properly

assembled before use. It is strongly recommended that you review the complete

Assembly guide and perform checks specified in this manual before riding. Failure to

properly assemble and maintain your bicycle could result in serious injury or death.

5. Apply your brake(s) and make sure they feel firm to

the touch. Spin the wheel(s) and apply the brakes.

The brakes should effectively stop the wheel(s).

7

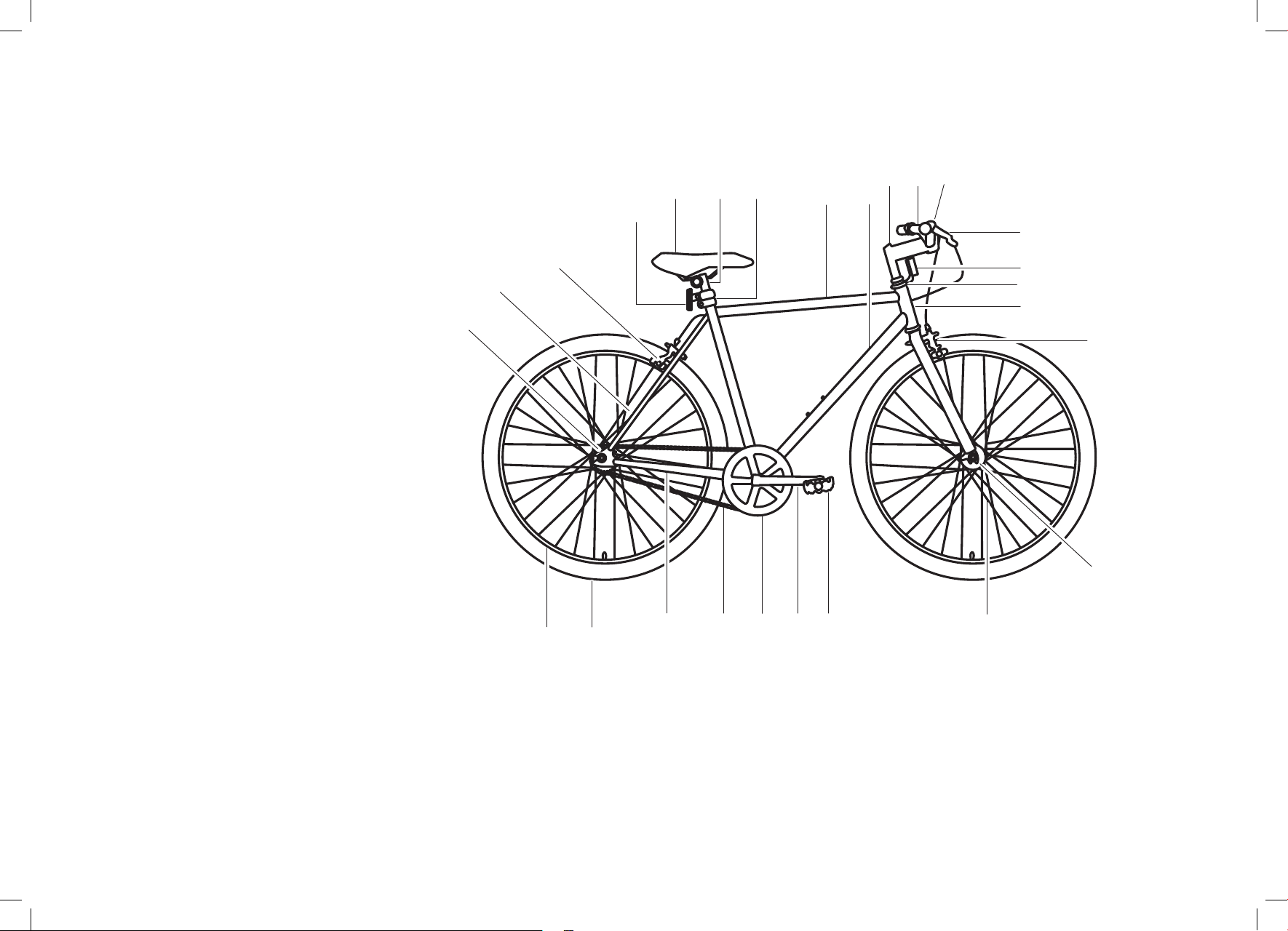

Configuration of a bicycle

NOTE: This is a typical bicycle. Your bicycle

may have other or different parts, and in some

cases, may not have all parts shown here.

20

21

22

23

24

25

26

3

1

2

4

5

6

7

8

9

10

11

8

1. Top tube

2. Down tube

3. Stem

4. Handlebar

5. Grips

6. Brake lever

7. Front reflector

8. Headset

1819

9. Headtube

10. Front brake

11. Front hub

12. Spokes

13. Pedal

14. Crank arm

15. Chain wheel

16. Chain

17. Chain stay

18. Tyre

19. Rim

20. Rear hub

21. Seat stay

121314151617

22. Rear brake

23. Rear reflector

24. Seat

25. Seat post

26. Seat post

clamp

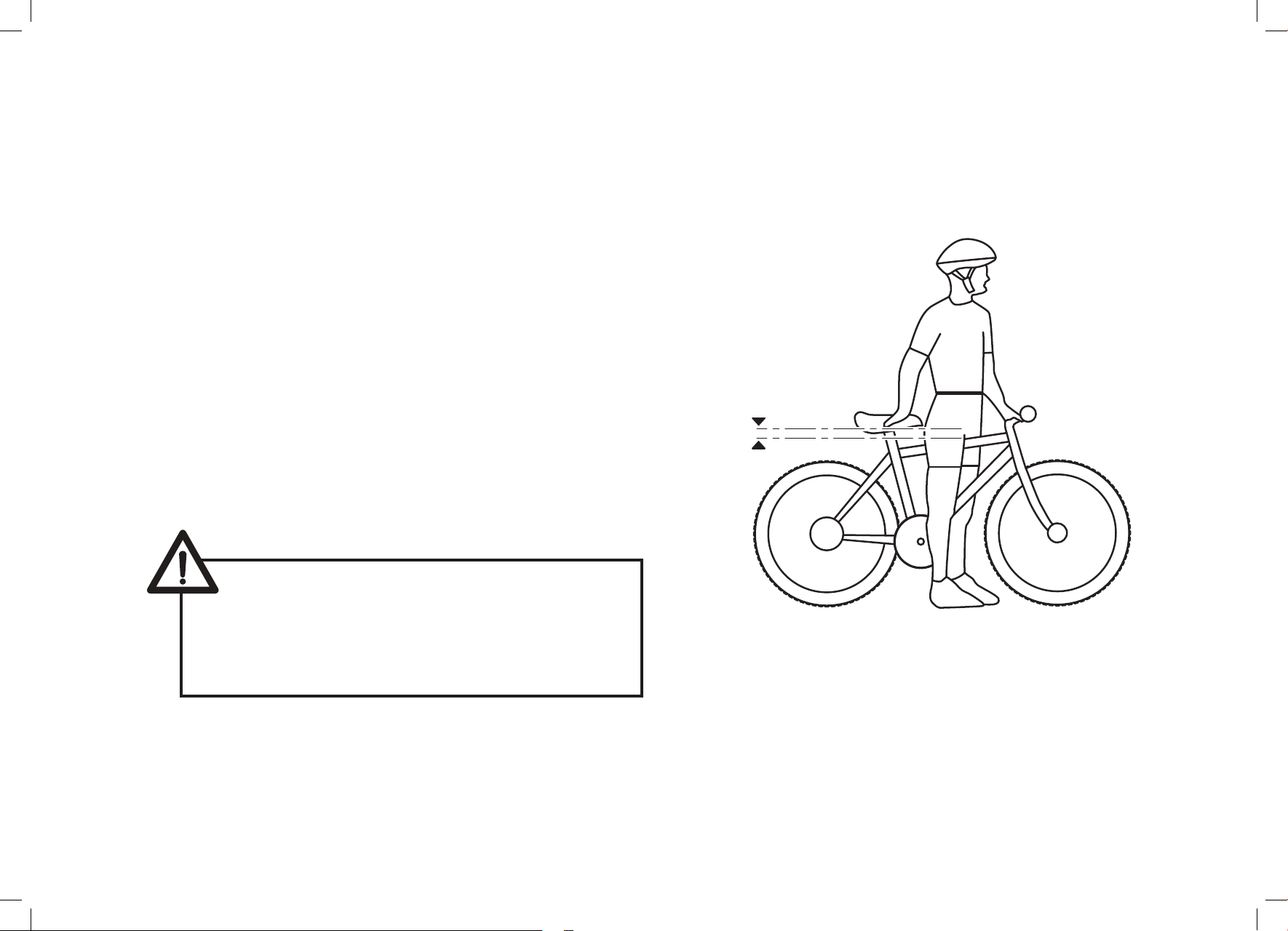

Bicycle size and fit

Correct frame size

When selecting a new bicycle, the correct choice of

frame size is a very important safety consideration. The

ideal clearance will vary between types of bicycles and

rider preference. Correct frame size makes straddling

the frame, when off the seat, easier and safer in

situations such as sudden traffic stops.

3–5 cm

WARNING: There should be a clearance of

no less than 3–5 cm between the groin area

of the rider and the top tube of the bicycle

while the rider straddles the bicycle with

both feet flat on the ground.

9

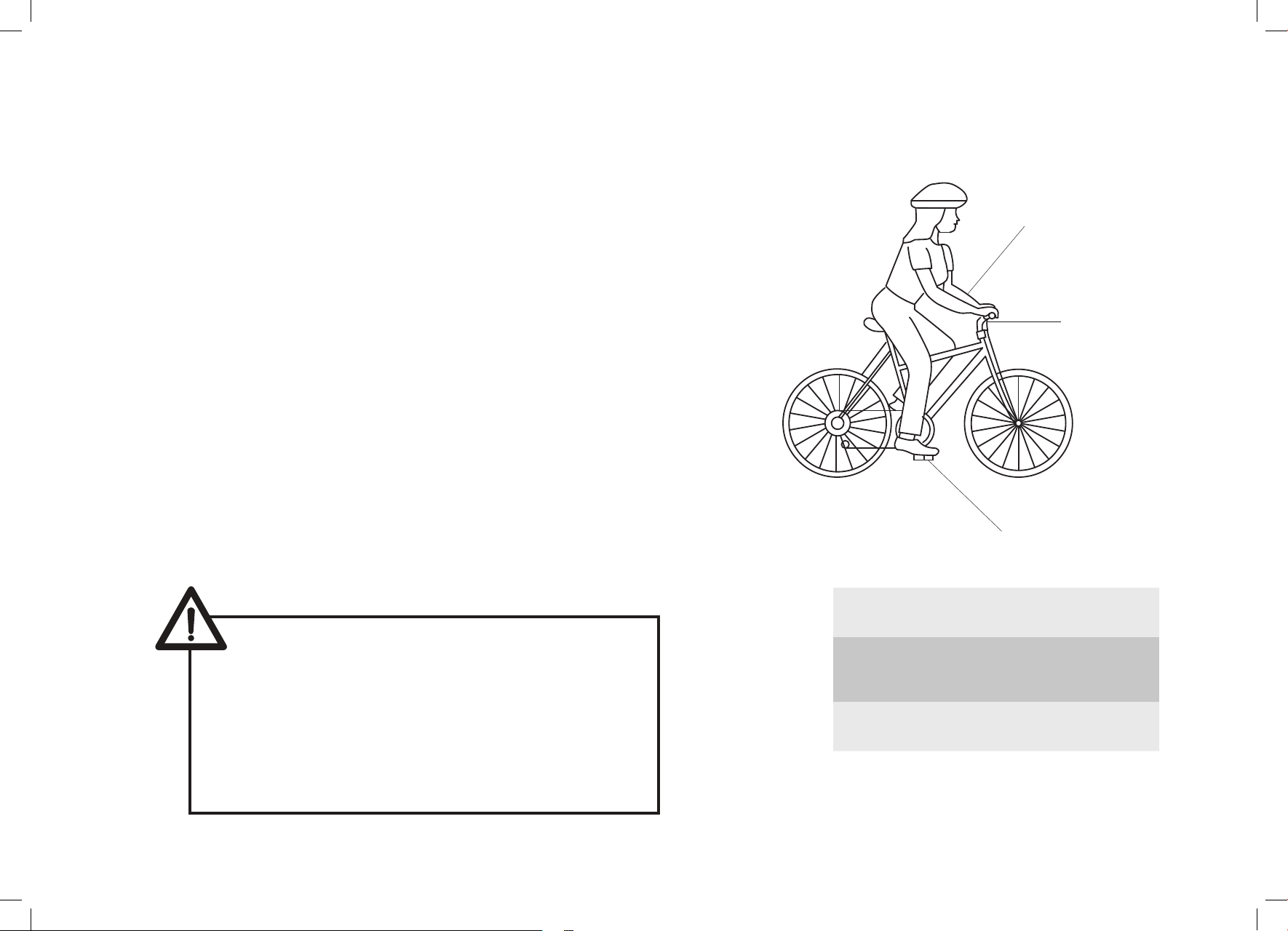

Seat height

In order to obtain the most comfortable riding position

and offer the best possible pedalling efficiency, the seat

height should be set correctly in relation to the rider’s

leg length. The correct seat height should not allow

leg strain from over-extension, and the hips should not

rock from side to side when pedalling.

1

While sitting on the bicycle with one pedal at its lowest

point, place the ball of your foot on the pedal. The

correct seat height will allow the knee to be slightly

bent in this position.

Arm reach

To obtain maximum comfort, the rider should not over

extend his or her reach when riding. There should be a

slight bend in the rider’s elbows. Refer to the Assembly

section to learn how to adjust the seat height and arm

reach.

WARNING: The seat’s “minimum insertion”

mark should not be visible when the seat is

inserted into the seat mast of the bicycle. Do

not raise the seat beyond this mark. The seat

post or frame may break causing you to lose

control and fall. Always check and make sure

that the seat post clamp is tightened securely

before riding.

2

3

1. Arms not over-extended

2. Handlebar and stem about the

same height as the seat

3. Pedal in bottom position

10

Assembly

Your new bicycle was assembled and tuned in at the factory and then partially disassembled for shipping. The

following assembly instructions will enable you to prepare your bicycle for your first ride. For more details on

inspection, lubrication, maintenance, and adjustment of any area please refer to the relevant sections in this

manual. Consult a professional bicycle mechanic if you have ANY doubts or concerns about properly as-

sembling, repairing, or maintaining your bicycle.

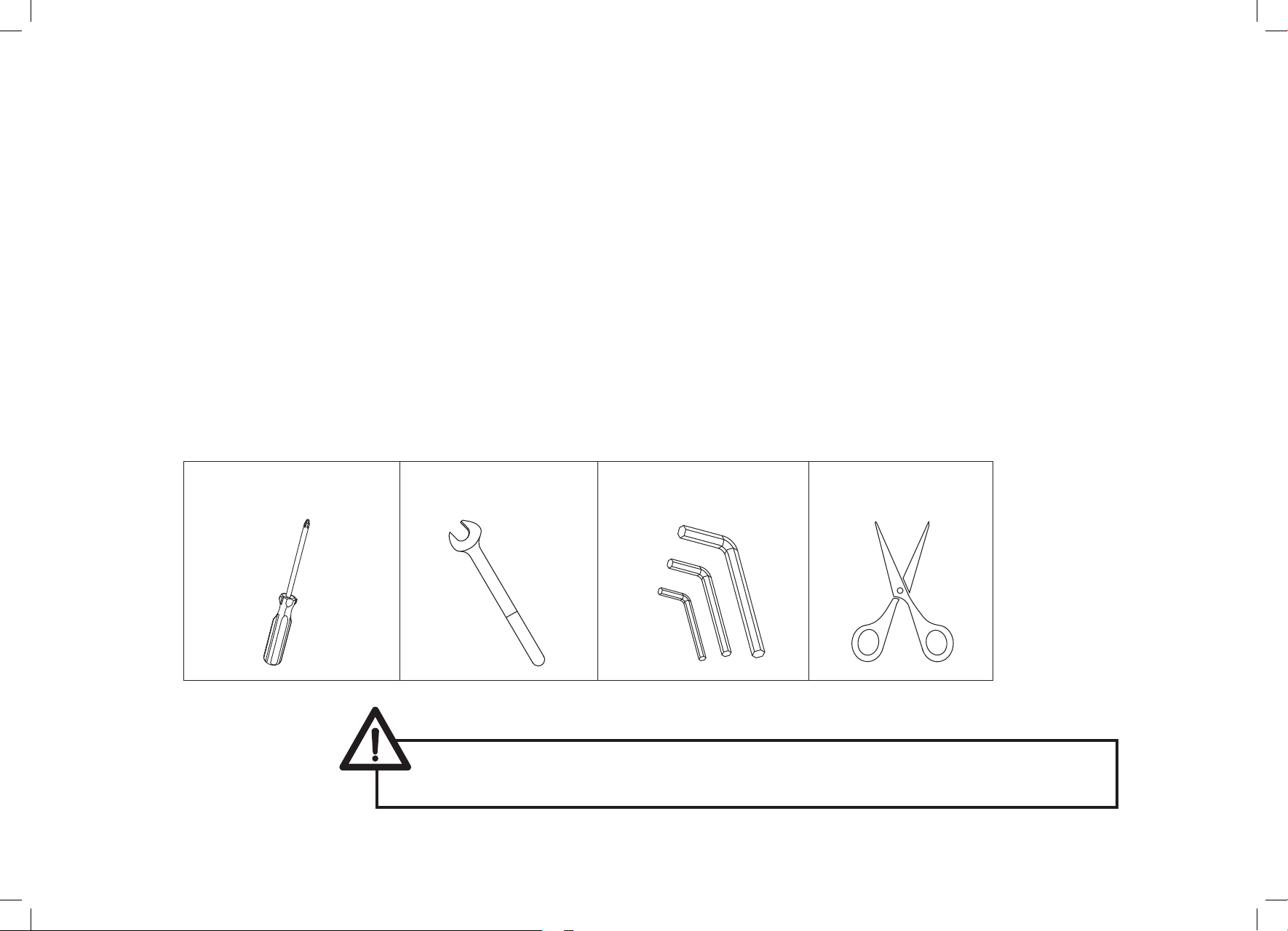

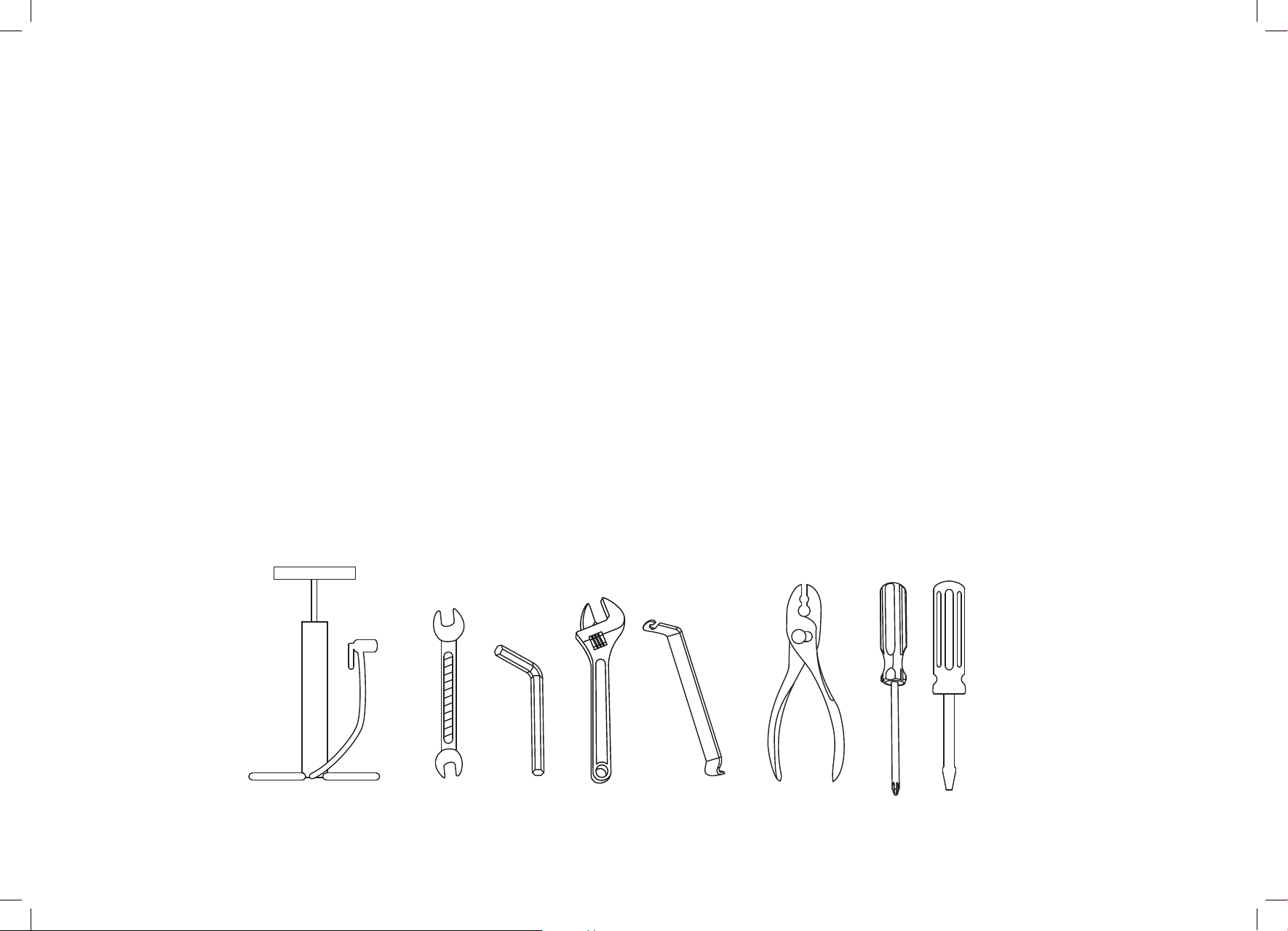

Tools needed

The following tools are needed to assemble your purchased bicycle.

Cross screwdriver Spanner

#5

DANGER! Failure to properly assemble and maintain your bicycle could

result in serious injury or death.

Allen wrenches

#4, #5, #6

Scissors

11

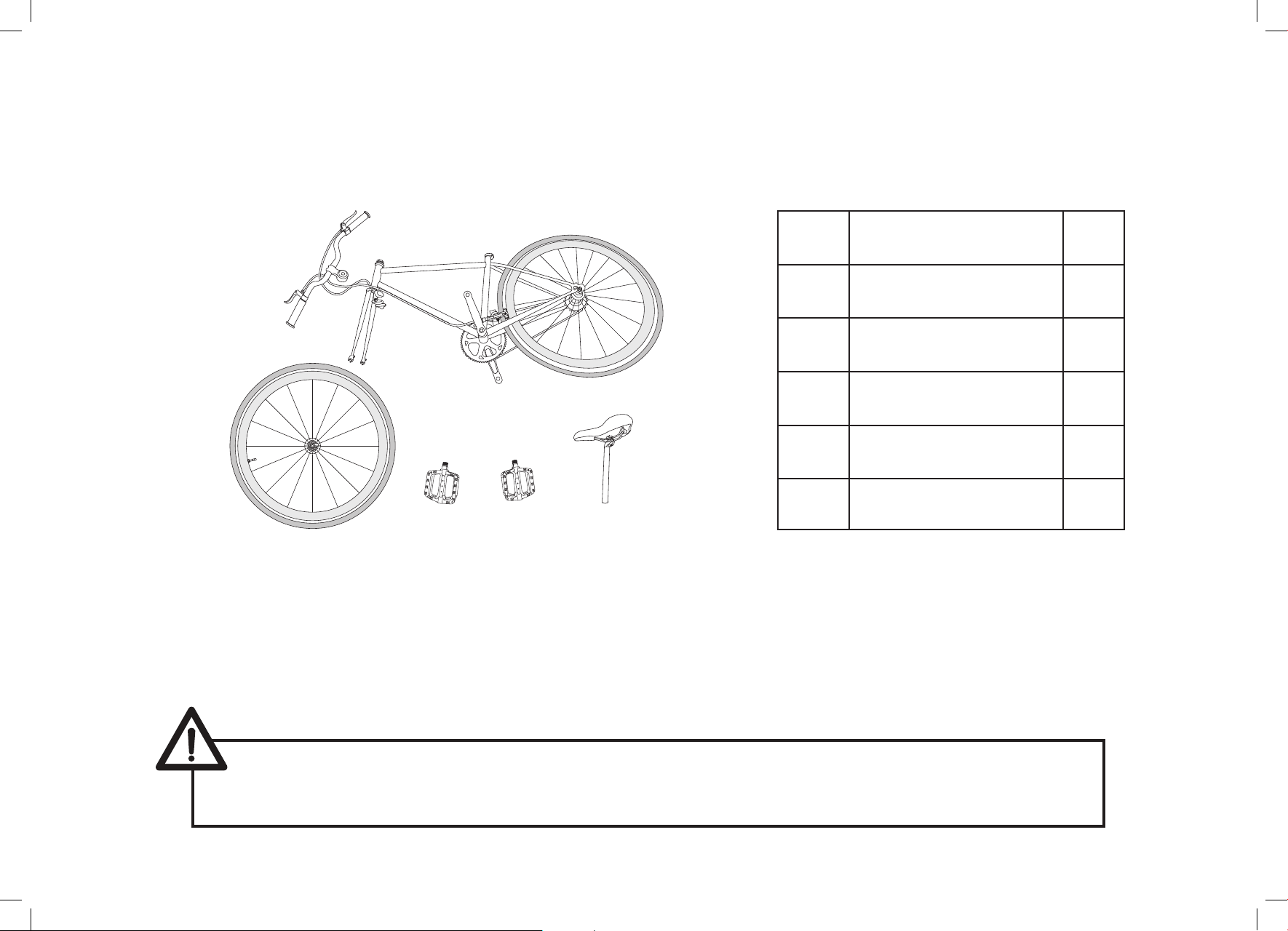

Unpacking

Code Component Qty

A

A Pre-assembled bicycle 1

B Front wheel 1

C Left pedal 1

B C D E

R

1. Remove all bicycle components inside the box.

2. Check and make sure no parts are loose or damaged.

3. Carefully remove the front wheel which is attached to the side of the bicycle for shipping.

4. Carefully remove all other packaging material from the bicycle. This includes zip ties, axle caps, and

materials protecting the frame.

R

D Right pedal 1

E Seat 1

12

CAUTION: The pre-assembled bicycle comes with the brakes already installed. Carefully

position the handlebar and the brake cables to avoid damaging the cables during assembly.

Do not disassemble the brakes or remove the brake cables.

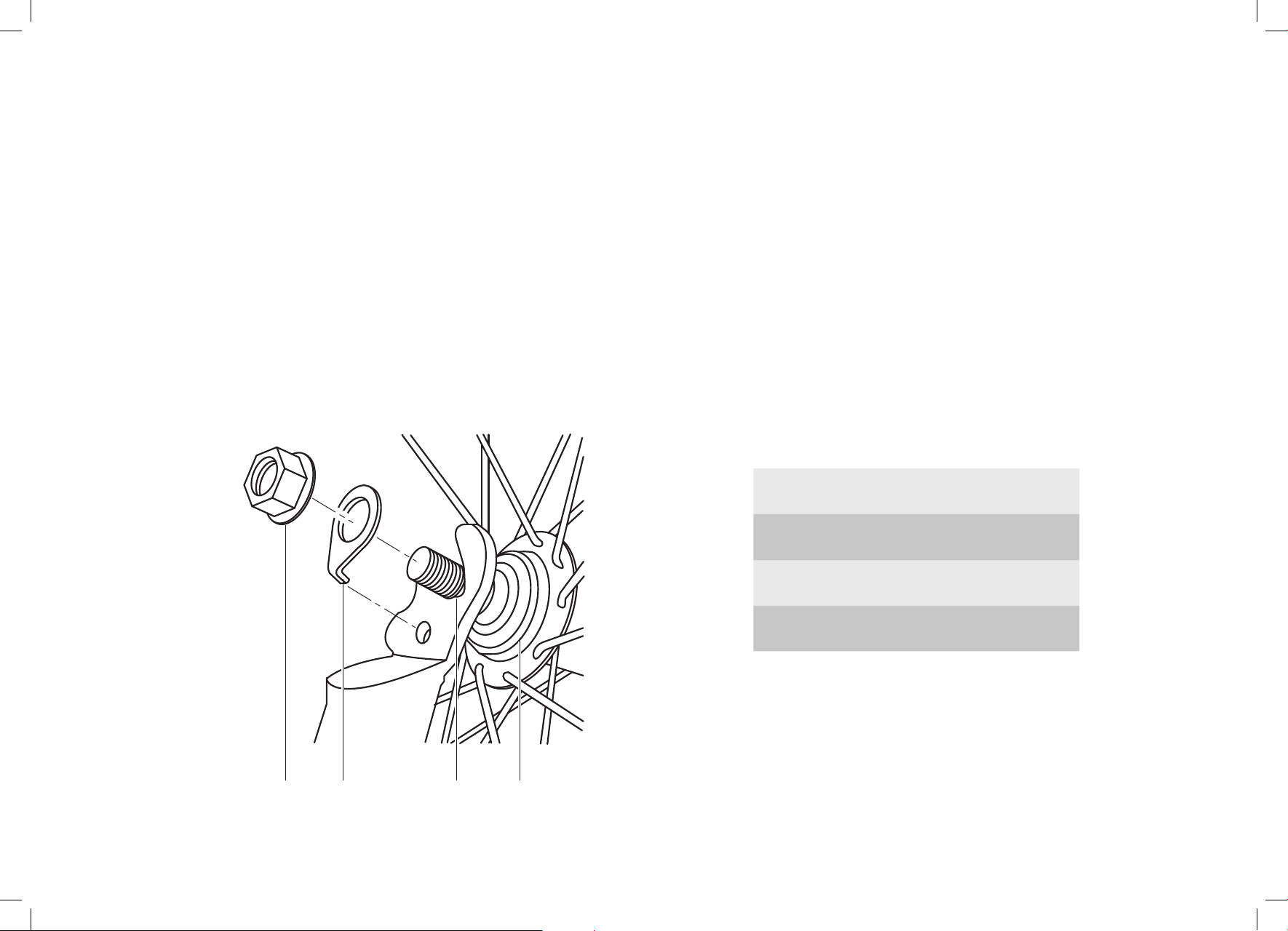

I. Installing the front wheel

1. Loosen the front wheel head nut / axle nut (1).

2. Place the bicycle in a position where the front fork

is facing upwards. Place the front wheel between

the fork allowing both wheel axles (3) to rest on the

fork.

3. Slide the L-shaped washer retainer (2) onto the

wheel axle and into the hold on the fork as shown

in the figure.

4. Centre the wheel (4) in the fork. Alternating between

sides, securely tighten the head nut / axle nut with a

spanner.

5. Spin the wheel (4) to check if the wheel is properly

centred and does not wobble. If the wheel is not

properly centred or if it wobbles, loosen the nuts and

realign.

Torque for the head nut / axle nut: 24–28 Nm

1. Head nut / axle nut

2. Washer retainer

3. Wheel axle

1 2

3

4. Front wheel

4

13

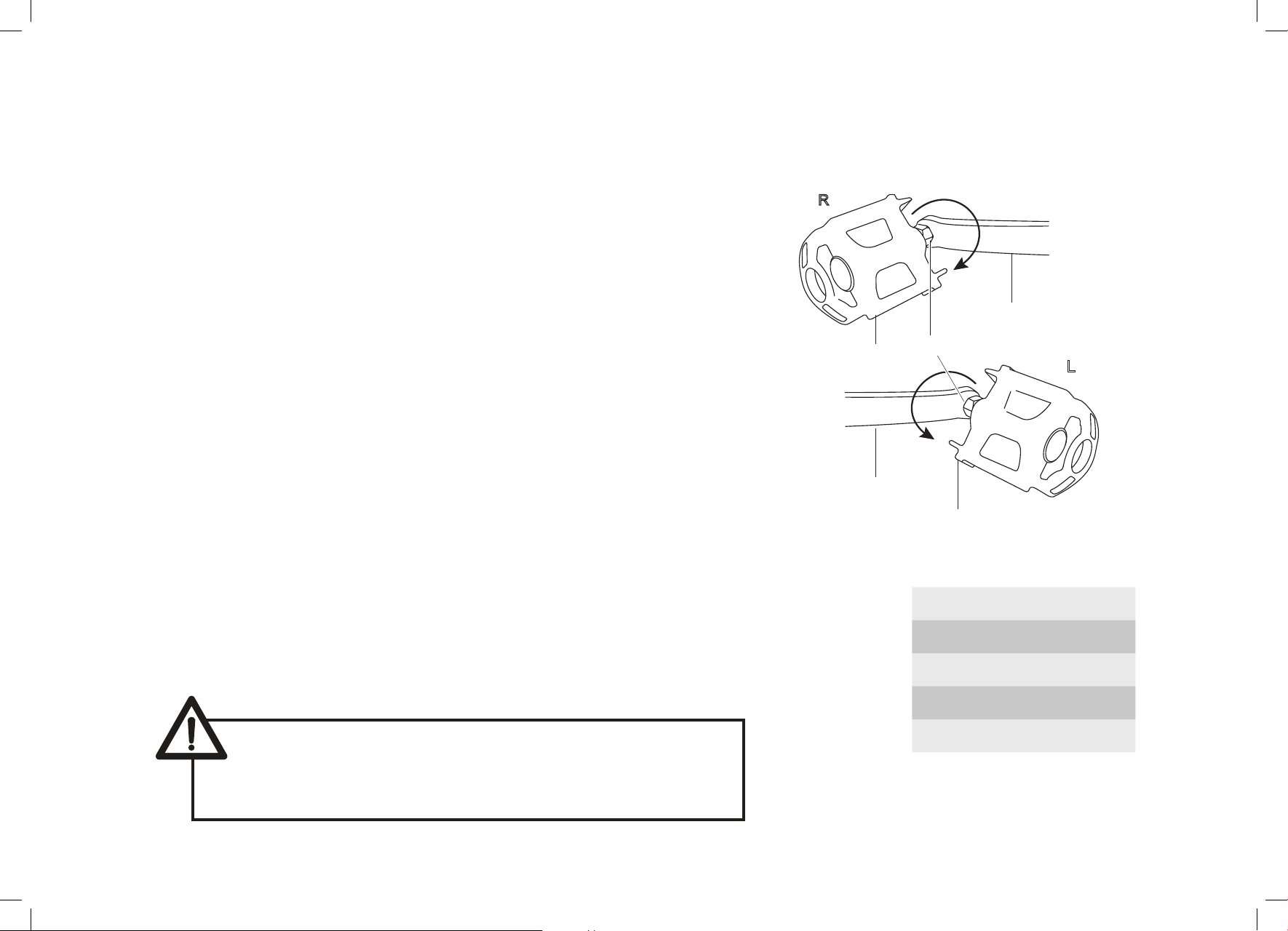

II. Installing the pedals

1. Take the pedal (1) marked “R” and position its axle into the

right crank arm. NOTE: The mark is found on the front face

of the axle.

2. Thread the pedal (1) onto the right crank arm (3) by turning

the pedal clockwise.

3. Once the axle is threaded all the way in, use a spanner to

securely tighten the nut (2) locking the pedal into place.

4. Take the pedal (4) marked “L” and position its axle into the

left crank arm (5).

5. Thread the pedal (4) into the left crank arm (5) by turning

the pedal counterclockwise.

6. Once the axle is threaded all the way in, use a spanner to

securely tighten the nut (2) locking the pedal into place.

NOTE: Pedals cannot be assembled into the wrong crank.

Ensure that each pedal goes into the correct crank by checking

the letter markings thoroughly before assembling. DO NOT

force a pedal into the wrong crank arm.

Torque for the pedal lock nut: 30 Nm

R

3

1

2

L

5

4

1. Right pedal

2. Nut

14

CAUTION: Make sure that you do not cross-thread the

pedals. Cross-threading will damage the threads in

the crank arm. If the pedal does not turn easily, do not

force it. Back the spindle out and start over.

3. Right crank arm

4. Left pedal

5. Left crank arm

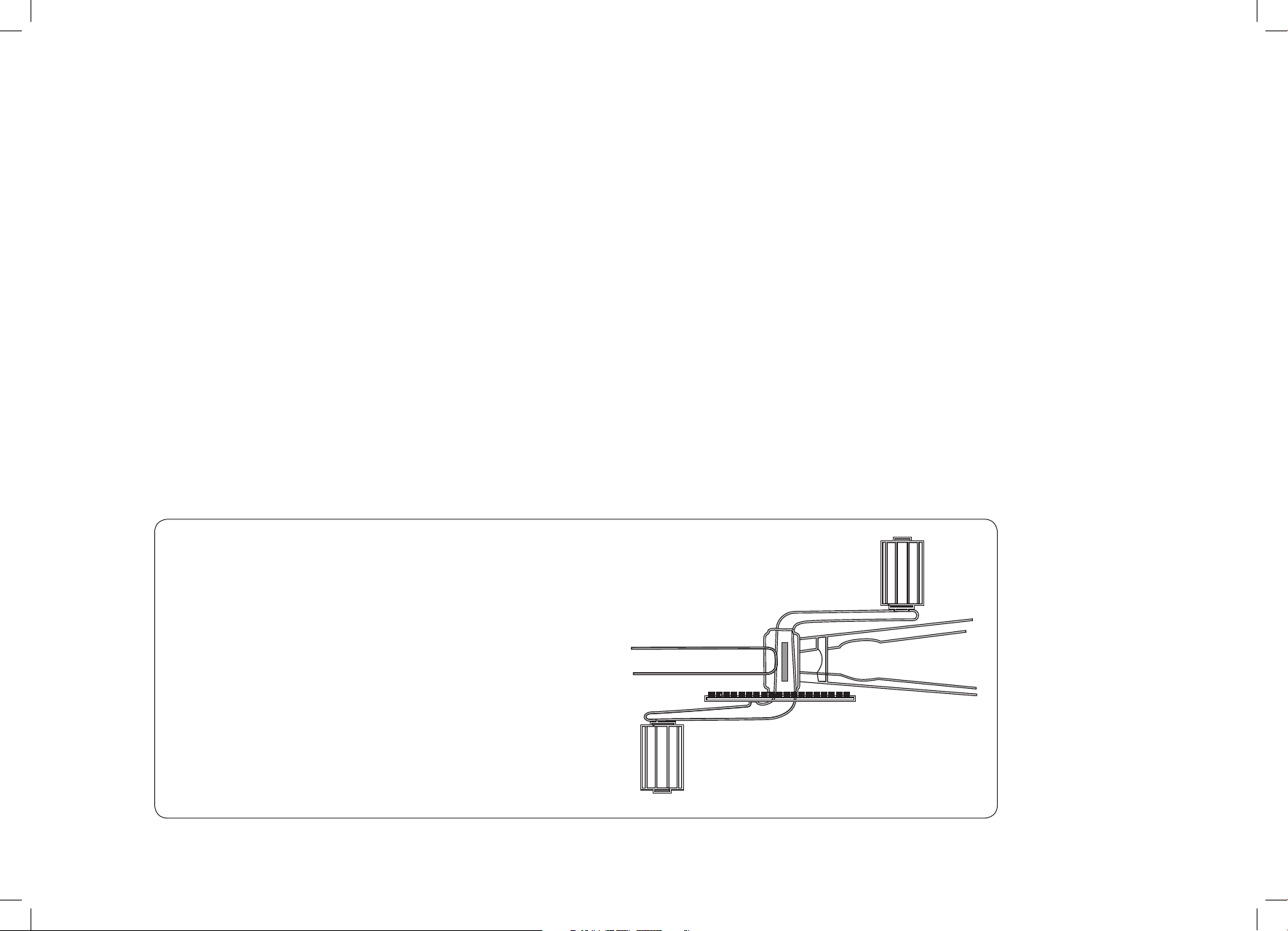

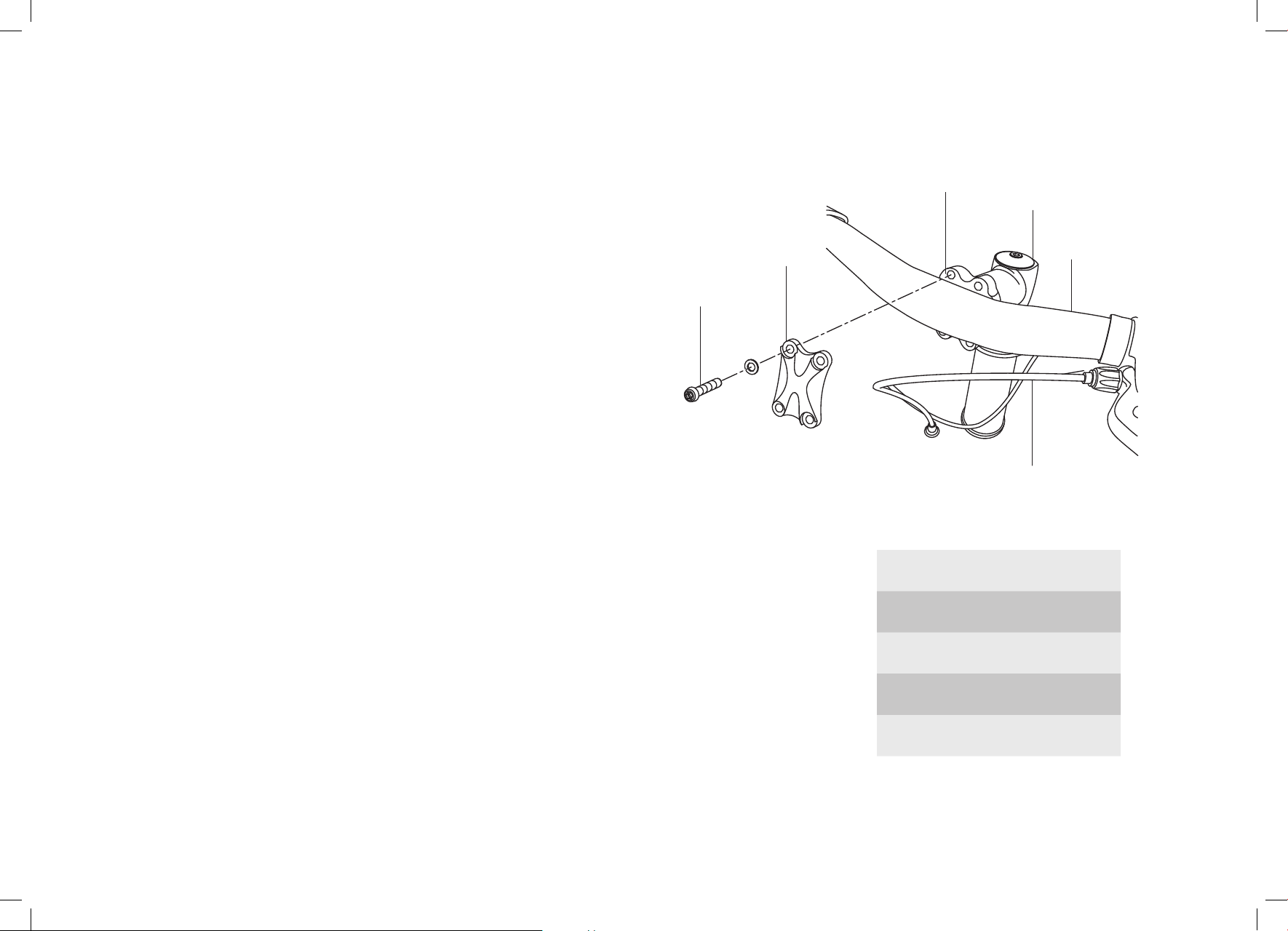

III. Installing the handlebar

1. Stand the bicycle upright with two wheels on the

ground. The front forks should be facing forward.

2. Use an allen wrench to loosen the 4 bolts (1) from

the handlebar clamp (2) on the stem (3).

3. Remove the bolts and washers (1) and the front half

of the clamp (2). Set them aside for later use.

4. Place the handlebar (4) onto the holder (2).

5. Rotate the handlebar (4) up or down so that the

brake levers are in line with your hand and arm for

easy use. Arrange the brake cables (5) in a way as to

not to interfere with the installation or steering of

the bicycle.

2

3

2

4

1

6. Reinstall the front half of the handlebar clamp (2)

and reinsert the bolts and washers (1).

7. Tighten the bolts (1) securely using an allen wrench.

Torque for the handlebar clamp bolts: 8 Nm

NOTE: Your bicycle comes with the front and rear brakes

already pre-assembled. Be familiar with the use of hand

brakes:

• Left lever for rear brake, right lever for front brake (UK)

• Right lever for rear brake, left lever for front brake (Europe)

A greater force is required to activate the rear brake due to

longer cable length.

5

1. Bolt and washer

2. Handlebar clamp

3. Stem

4. Handlebar

5. Brake cable

15

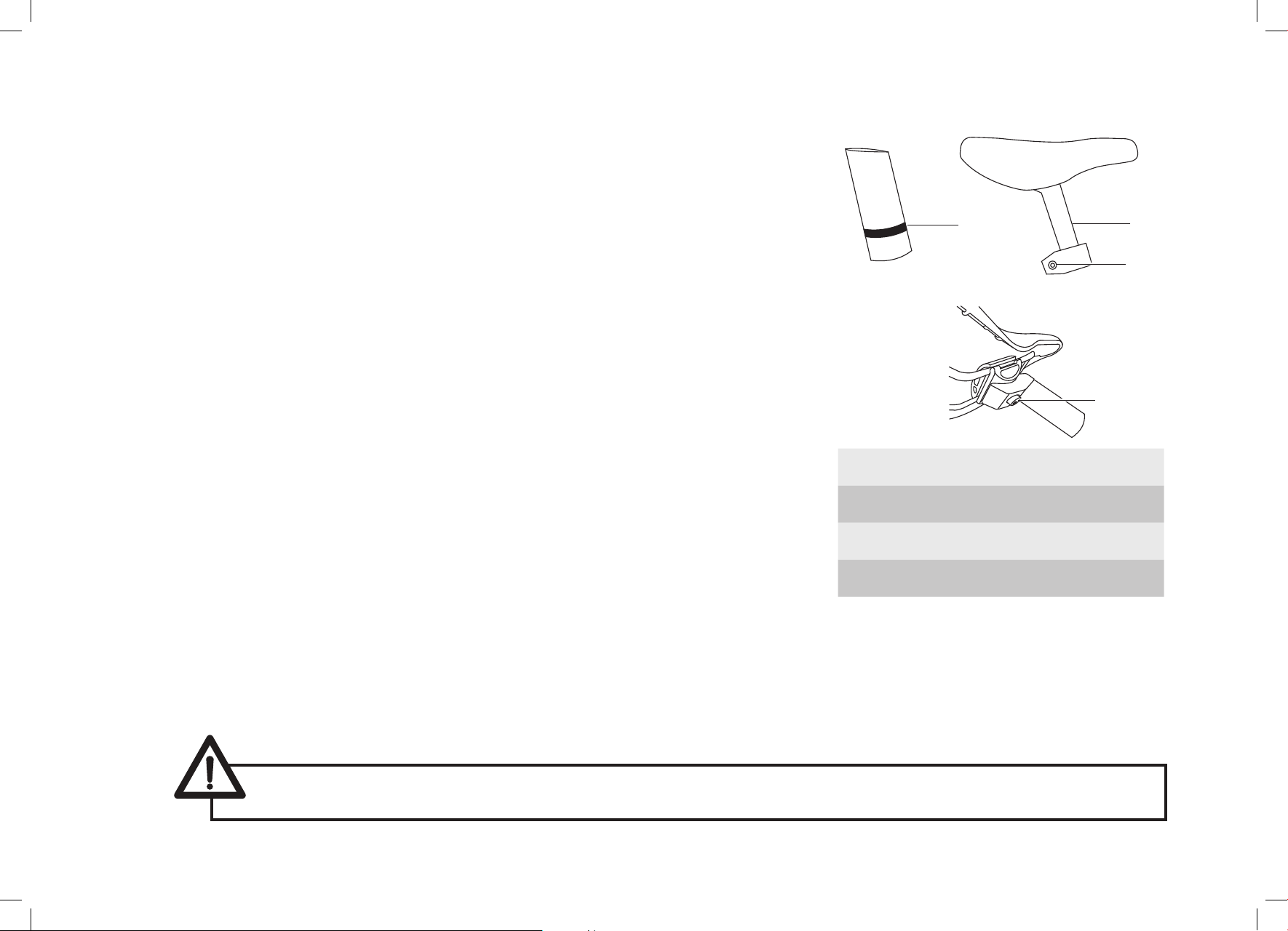

IV. Installing the seat

1. Insert the seat post (1) into the bicycle tube past the

minimum insertion line (4) indicated on the seat post. Loosen

the seat post clamp (2) using an allen wrench if necessary.

2. Tighten the seat post clamp (2) just enough to hold the seat

and follow the instructions for adjusting the seat height. See

“Bicycle size and fit” section for recommendations.

Adjusting the seat height

4

1

2

1. Pull the seat up or push the seat down to adjust the seat

height to your preference.

2. Using an allen wrench, tighten the seat post clamp securely

after adjustments are made.

Adjusting the arm reach

1. Loosen the adjusting bolt (3) underneath the seat.

2. Tilt the seat upward or downward to adjust the angle of the

seat to your preference. Push the seat forward or backward

to adjust the distance of the seat from the handlebar. Refer

to the calibrated line found on the seat’s bottom rails to fine

tune the angle and position of the seat.

3. After adjustments are made, tighten the adjusting bolt

securely with an allen wrench.

WARNING: Ensure that the seat is inserted past the minimum insertion line indicated in the seat

post. Failure to do so may cause the seat post or frame to break causing you to lose control and fall.

3

1. Seat post

2. Seat post clamp

3. Adjusting bolt

4. Minimum insertion line

Torque for the seat post clamp: 10 Nm

Torque for the saddle adjusting bolt: 17 Nm

16

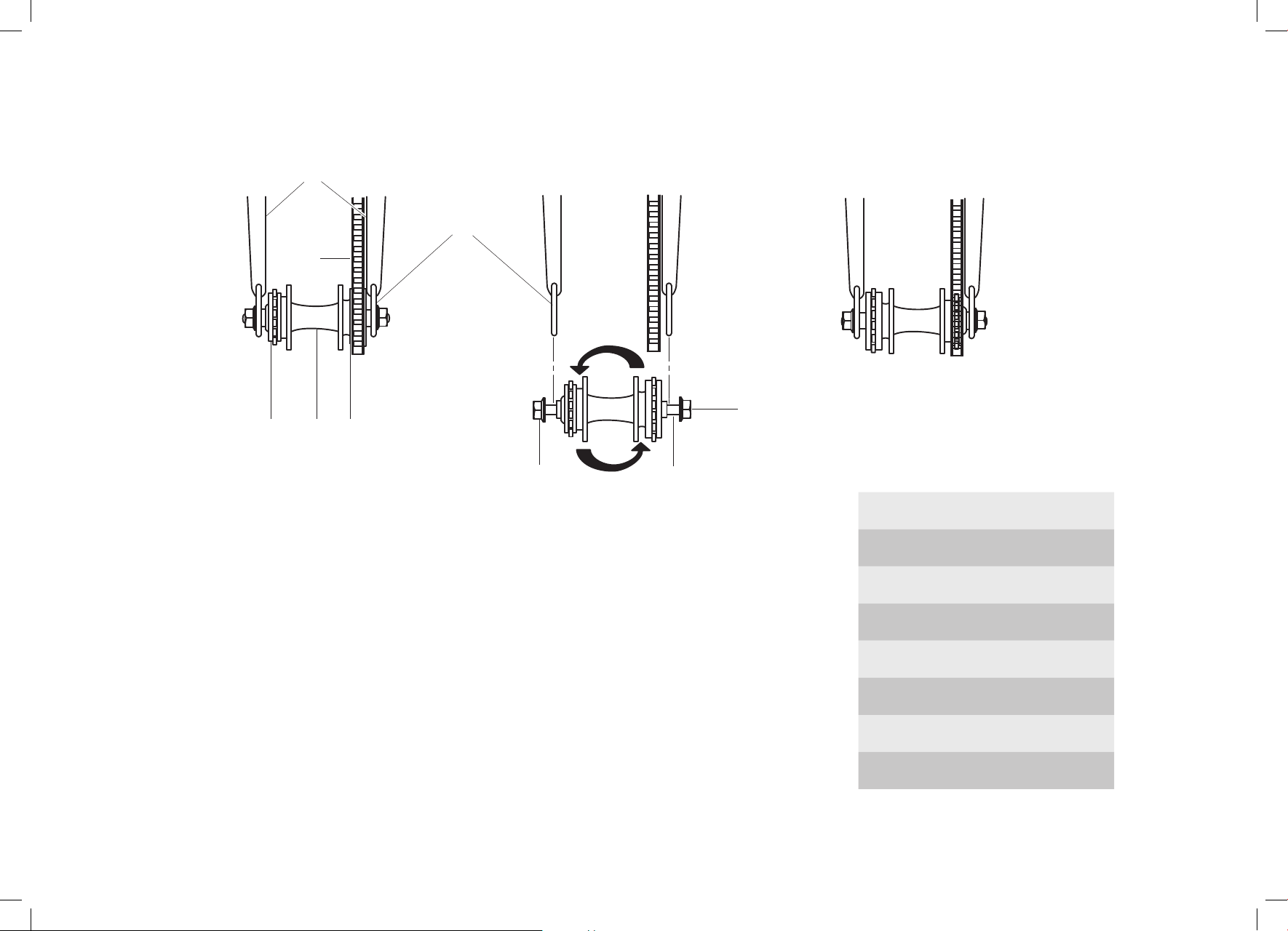

(Optional) Flipping the rear wheel

This bicycle is equipped with a “flip-flop” or doublesided rear hub. A flip flop has sprockets or chain rings

on either side of the hub: a fixed gear on one side, and

a single freewheel on the other side.

By default, your bicycle uses the freewheel instead

of the fixed gear in order to make it easier to climb

hills and let you coast on descents. Should your needs

require you to use the fixed gear, perform the following

procedures to flip the wheel.

How to flip the rear wheel:

See figure on next page.

1. Loosen and remove the axle nuts (7) on both sides

of the rear hub (5).

2. Remove the rear wheel. Slide the wheel forward in

order to dislodge its axles (8) from the frame dropouts (2).

3. Slip the chain (3) off the freewheel (4).

6. Reinstall the rear wheel by sliding its axles into the

frame drop-outs (6). Ensure that the chain (2) is

tight.

7. Reinstall the axle nuts (7) and tighten securely.

WARNING: Be sure to use the front and rear

brakes of the bicycle when the freewheel

is being used.

See the “Chain and chain wheel” section under “Maintenance” for information on proper adjustment of the

chain after installment.

4. Flip the rear wheel 180° degrees relative to the rear

hub so that the fixed gear ring (6) is now on the

right (chain) side.

5. Slip the chain (3) on the fixed gear ring (6).

17

3

1

2

7

4

56

18

7

8

1. Seat stays

2. Drop-outs

3. Chain

4. Freewheel

5. Rear hub

6. Fixed gear ring

7. Axle nut

8. Axle

Reflectors

Your bicycle may be supplied with one front (white), one rear (red), two wheel (white) reflectors,

and four pedal (orange) reflectors.

Reflectors are an important safety and legal requirement and should be securely attached and in

good condition at all times. Periodically inspect all reflectors, brackets, and mounting hardware

for signs of wear or damage. Immediately replace anything damaged.

Some bicycles will require you to install reflectors onto the bicycle. Refer to the following sections

for instructions on installing bicycle reflectors.

WARNING: Reflectors are important safety devices which are designed as an integral

part of your bicycle. Regulations require every bicycle to be equipped with front, rear,

wheel, and pedal reflectors. These reflectors are designed to pick up and reflect street

lights and car lights in a way that helps you to be seen and recognized as a moving

bicyclist. Check reflectors and their mounting brackets regularly to make sure they are

clean, straight, unbroken, and securely mounted. Have your dealer replace damaged

reflectors and straighten or tighten any that are bent or loose.

19

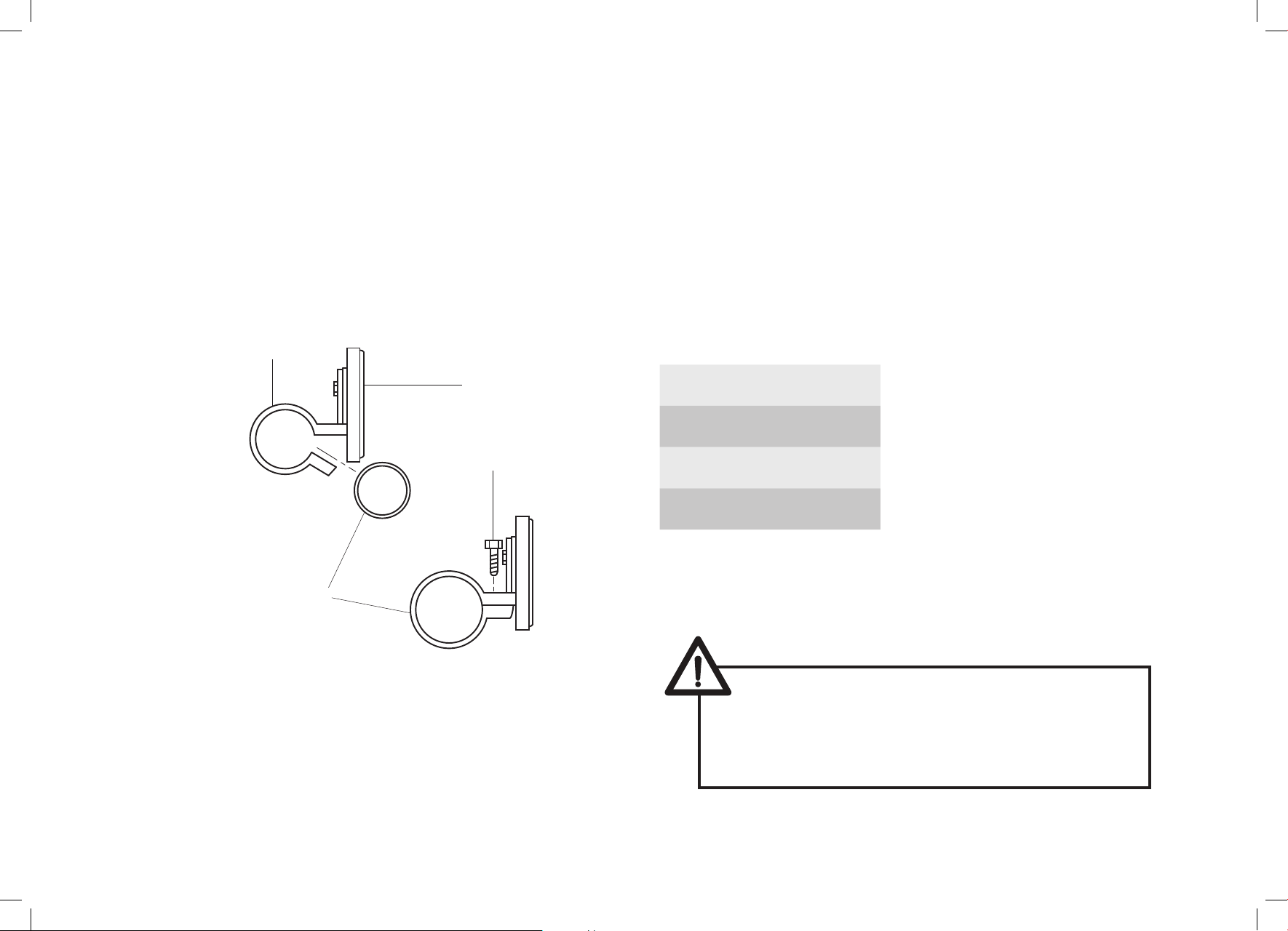

Installing a front mount reflector on the handlebar

1. Loosen and remove the bracket screw (2) from the plastic bracket (4).

2. Install the plastic bracket loop (4) onto the handlebar tube.

3. Position the plastic bracket (4) on the handlebar (3) between the grip and the crossbar, about 12.7 cm

from the end of the handlebar.

4. Tighten the bracket screw (2) securely. If the bracket is still loose, insert a shim inside to make it tight.

4

3

1

2

1. Reflector

2. Bracket screw

3. Handlebar

4. Plastic bracket

CAUTION: Ensure that the reflector is

vertical to the ground and facing straight

forward. If the reflector is aimed up or

down, incoming headlights may not

reflect properly on the reflector.

20

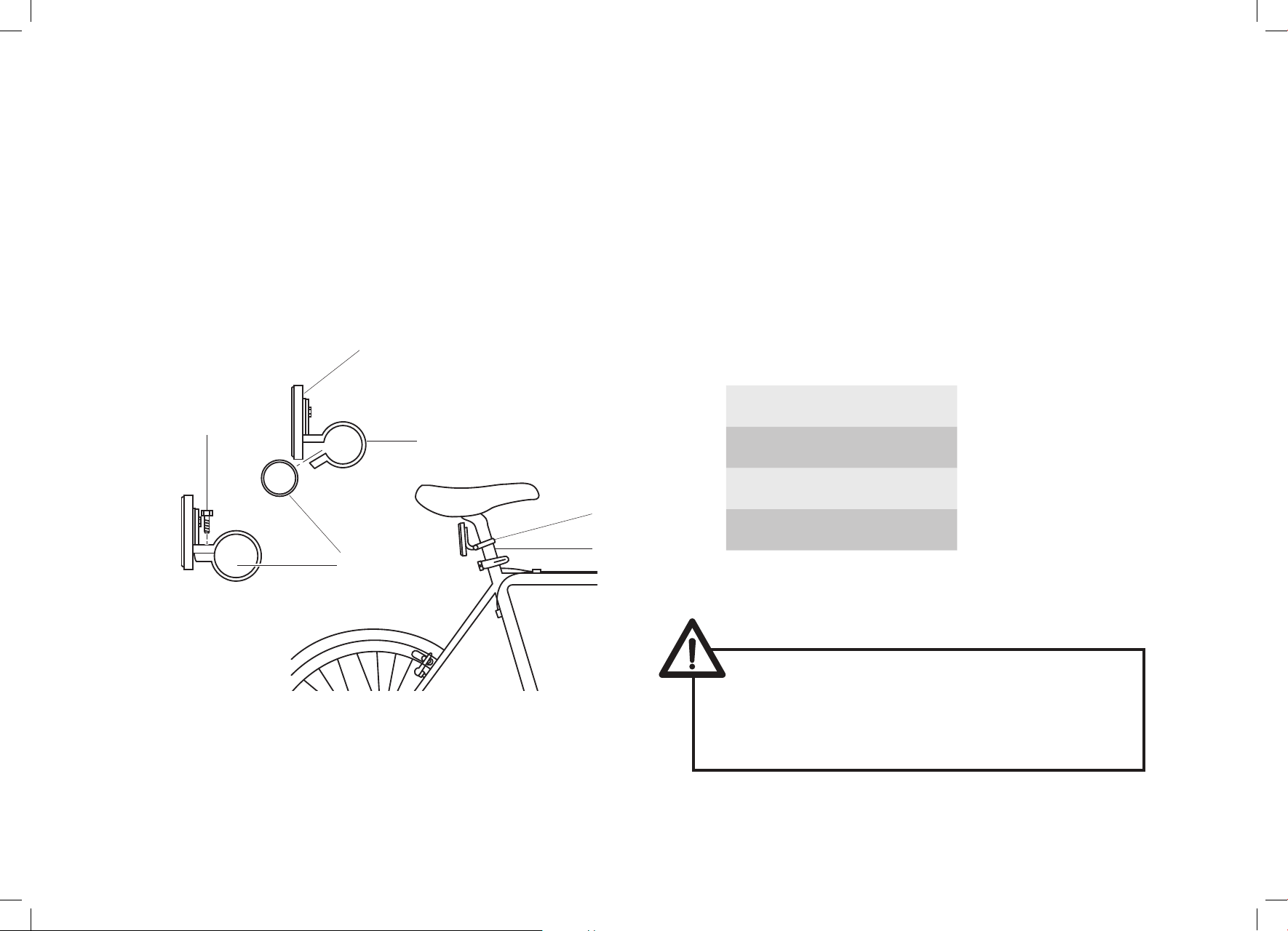

Installing a rear reflector on the seat post

1. Loosen and remove the bracket screw (1) from the plastic bracket (3).

2. Loop the plastic bracket (3) around the seat post (4).

3. Begin to tighten the bracket screw (1) just enough to hold the reflector (2) in place. Adjust the reflector so that it

is in an upright position. Make sure the reflector is facing away from the bicycle.

4. Tighten the bracket screw (1) securely. If the bracket (3) is still loose, insert a shim inside to make it tight.

2

1

1. Bracket screw

3

2. Reflector

3. Plastic bracket

3

4. Seat post

4

4

CAUTION: Ensure that the reflector is

vertical to the ground and facing straight

forward. If the reflector is aimed up or

down, incoming headlights may not

reflect properly on the reflector.

21

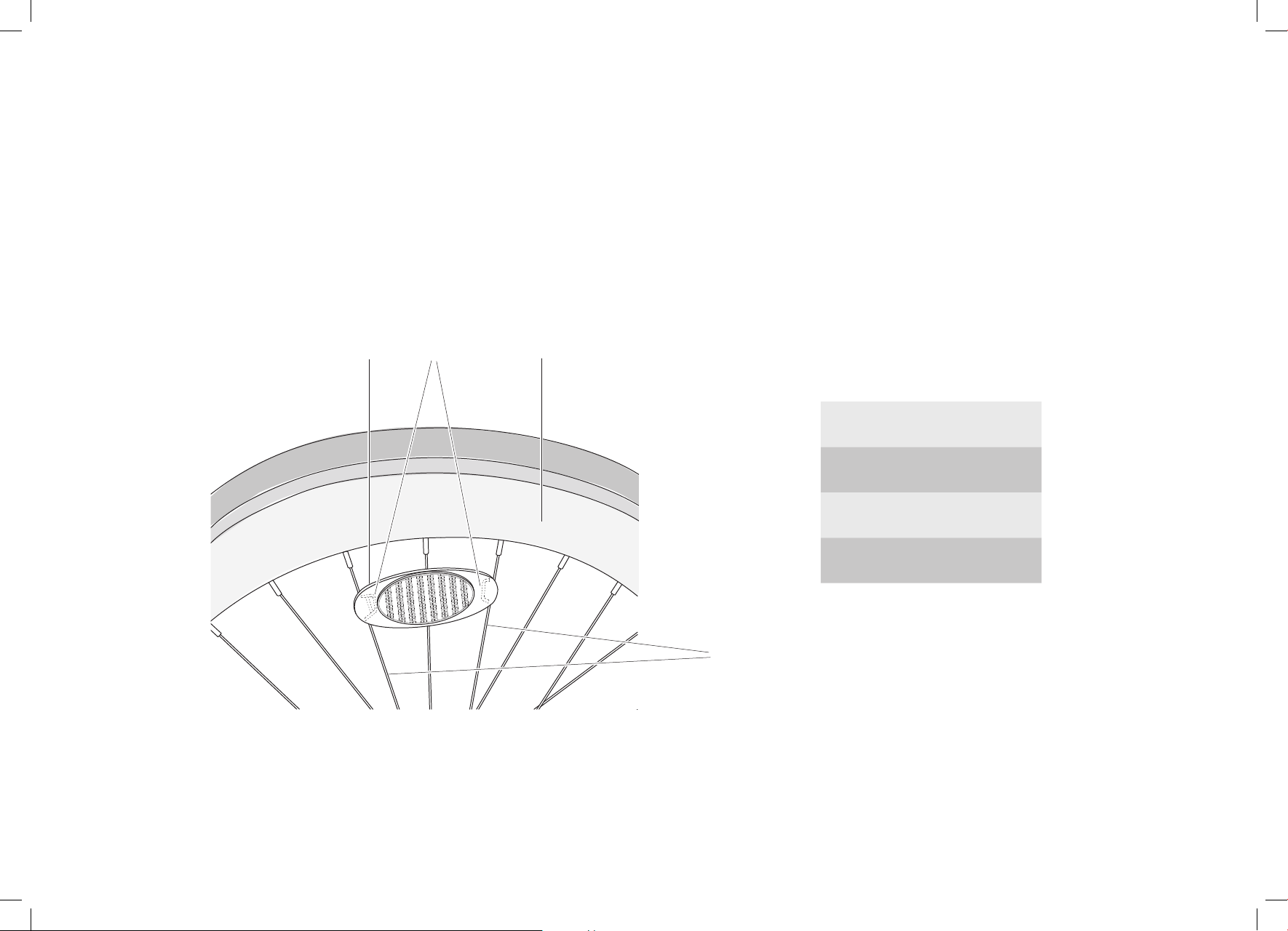

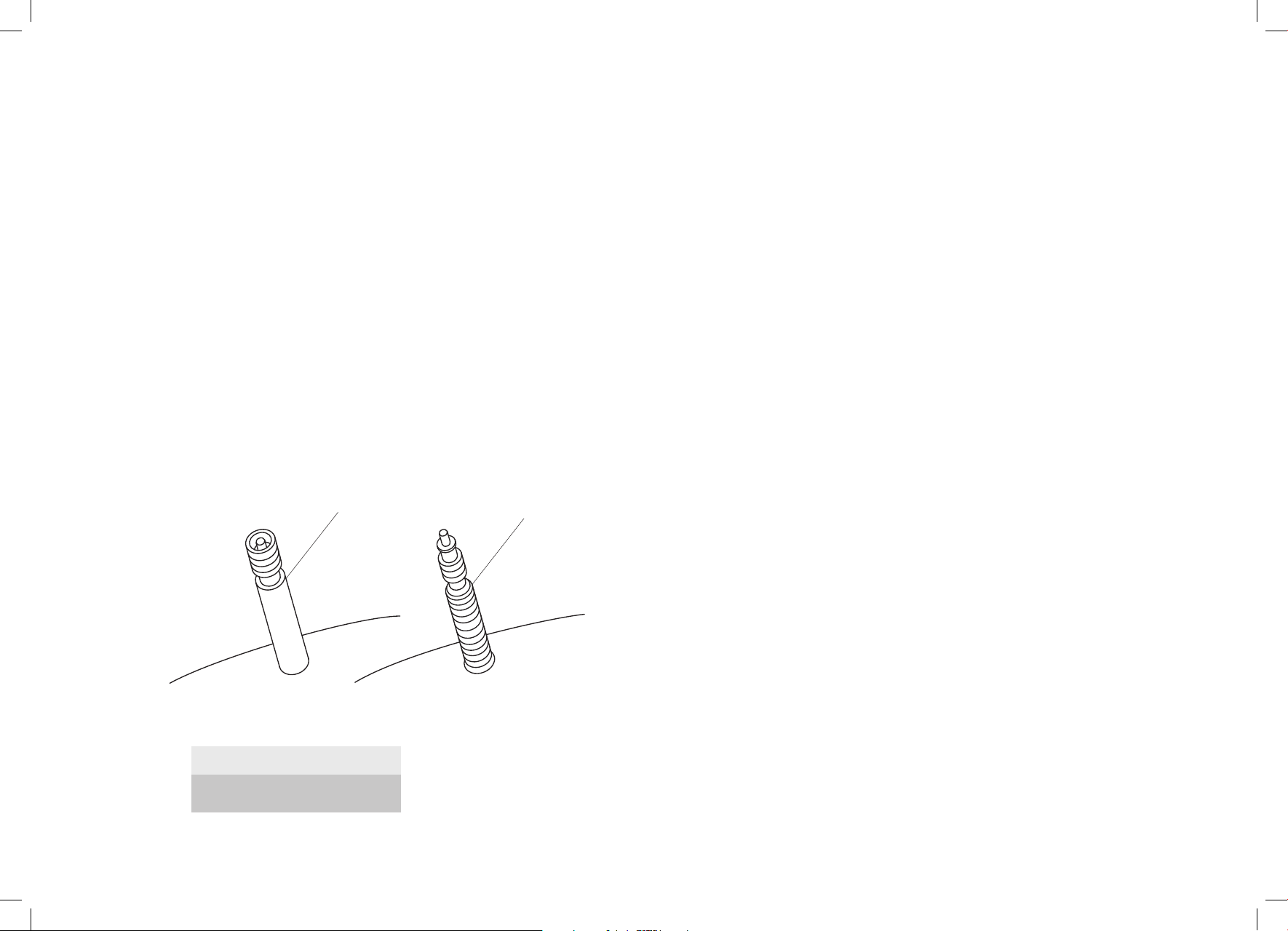

Installing spoke mount wheel reflectors

1. Position the reflector (1) near the hub of the wheel and align both ends of the reflector to the

spokes (4). Make sure that the spokes clip into the brackets (2) located on both ends of the reflector.

2. Gradually push the reflector (1) towards the rim (3) until the reflector is firmly held in place by the

tension from the spokes (4) at either side of the reflector.

3. Repeat steps 1 and 2 when installing a spoke mount wheel reflector on the other wheel.

1

32

1. Reflector

2. Brackets

3. Rim

4. Spokes

4

22

Maintenance

General care

• For painted frames, dust the surface and remove any

loose dirt with a dry cloth. To clean, wipe the bicycle

with a damp cloth soaked in water and mild detergent.

Dry with a cloth and polish using car or furniture wax.

• Use an anti-rust fluid to wipe chrome plated bicycles

and/or parts.

• Use soap and water to clean plastic parts and rubber

tyres.

• Wash your bicycle frequently and wipe or spray all

unpainted parts with anti-rust fluid. Make sure that the

wheels dry completely so that braking performance is

not affected.

• If exposed to rain, dry your bicycle completely and

apply anti-rust treatment to prevent accelerated

deterioration of the bearings.

• Use touch up paint or clear nail polish on scratched or

chipped paint to prevent rust.

• Regularly clean and lubricate all moving parts, tighten

components and make adjustments as required.

• To minimize rust, use BED, SATIN, or TITANIUM surface

treatments.

• Components will wear out eventually and will need

replacing. This is normal and is not covered by any

guarantee or warranty.

substitute presents a great risk to your safety and can

shorten the life of the bicycle.

Storage

• Keep your bicycle in a dry location away from inclement

weather and direct sun exposure. Ultraviolet rays may

cause the paint to fade, and rubber and plastic parts to

crack.

• Before storing your bicycle for a long period of time,

clean and lubricate all components and wax the frame.

Deflate the tyres to half pressure and hang the bicycle

off the ground.

• Do not store the bicycle near electric motors. Ozone

emissions may affect the rubber and paint.

• Do not cover the bicycle with plastic and other material.

Moisture can accumulate and cause rusting.

Security

• Keep a record of the bicycle’s serial number located

on the frame underneath the bottom bracket. See the

beginning of this manual for more information.

• Register the bicycle with the local police.

• Invest in a high quality bicycle lock that can resist

hacksaws and bolt cutters. Always lock your bicycle to

an immovable object when it is left unattended.

• When replacing components, use only original

components for the bicycle. The use of any other

23

Component maintenance

Tools needed for maintenance:

1. Spanner or ring spanner set: 8 mm, 9 mm, 10 mm,

12 mm, 13 mm, 14 mm, 15 mm

2. Pedal spanner 15 mm

3. Allen key wrenches: 4 mm, 5 mm, 6 mm, 8 mm

4. Adjustable spanner

5. Standard flat head screwdriver

6. Standard Phillips head screwdriver

7. Standard slip joint pliers

8. Tyre pump

9. Tube repair kit

10. Tyre levers

Suggested travel tools

The following items should be useful when going on a

long bicycle ride:

1. Spare tube

2. Patch kit

3. Pump

4. Tyre levers

5. Multi-tool

6. Cell phone or change for a pay phone

24

Hand brakes

Maintenance for brakes:

• Keep the wheel rims and the brake pads clean and

free of wax, lubricant, and dirt at all times.

• Keep brakes properly adjusted and in good working

condition at all times.

4. If one pad is closer to the rim than the other, loosen

the lock nut (3) at the back of the brake. Squeeze

the brake lever to hold it centred, and then re-tighten the lock nut (3).

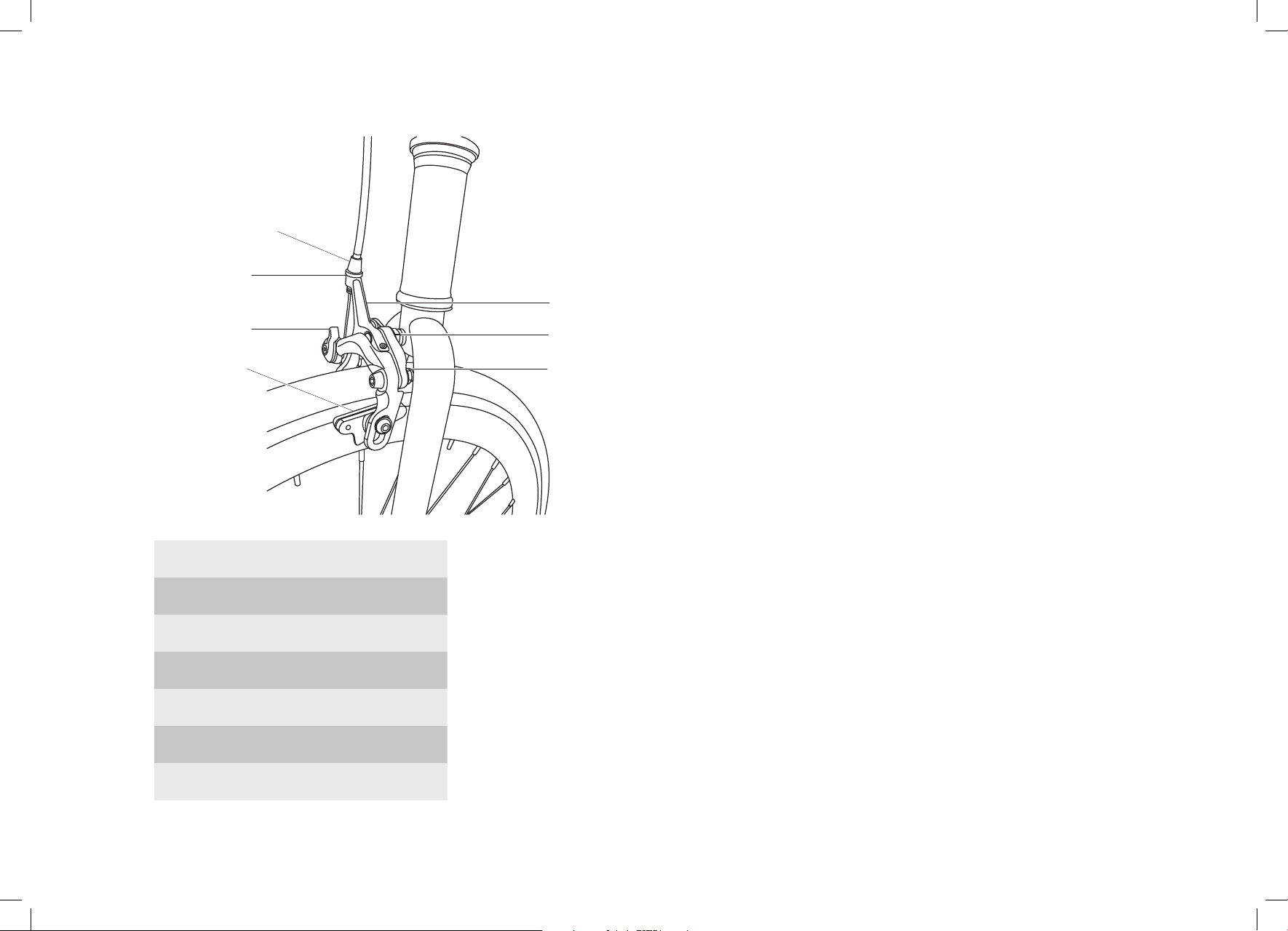

Caliper brakes

You can do some minor brake adjustments using the

cable adjusting barrel. To adjust the front and rear

brake calipers, follow these steps:

1. Squeeze the brake pads (5) against the rim.

2. Loosen the lock nut (7) and then turn the cable adjusting barrel (1) shown in the figure.

3. Check the brake pad (5) clearance. It should be

maximum of 2 mm from the rim.

4. Re-tighten the lock nut (7).

If it is not possible to set the brake pads close enough

to the rim, you may have to adjust the cable length. Do

the following procedure.

1. Screw the cable adjusting barrel 3/4 of the way in.

2. Squeeze the pads against the rim, open the quick

release lever (6) and then pull the brake cable

through using pliers.

WARNING: Ensure the brake fixing nut is

properly tightened. Failure to do this may

cause the brake assembly to dislodge from

the fork.

Most side-pull calipers also have a centring adjustment

bolt (4) that enables you to properly centre the caliper

over the rim. Make sure that there is an equal distance

between the brake pad and the rim on both sides of

the wheel. Also make sure that the brake pads themselves are properly adjusted. The pads should contact

the rim so that it is centred from top to bottom on the

rim surface. The distance between the top of the pad

and the top of rim should be no less than 1 mm to ensure that the brake pad does not contact the tyre in

any way.

3. Close the quick release lever (6) and the squeeze

the corresponding brake lever on the handlebar to

test. Fine tune using the cable adjusting barrel (1).

WARNING: Do not ride a bicycle that is not

operating properly.

25

Wheels

Wheel inspection:

1

7

6

1. Cable adjusting barrel

2. Brake arm

The wheels of the bicycle should be kept in top

condition. Properly maintaining your bicycle’s wheels

ensures good braking performance and stability when

riding. Be aware of the following potential issues:

2

3

45

• Dirty or greasy rims

CAUTION: Dirt and/or grease can render your brakes

ineffective. Do not clean rims with oily or greasy materials. When cleaning, use a clean rag or wash with soapy

water, and then rinse and air dry. Avoid riding when the

rims are wet. When lubricating your bicycle, don’t get

oil on the rim surfaces.

• Cracked or thinning rims

Traditional rim brake systems work by creating friction

between the rim and the brake pad when the rider

applies the brakes. This friction, plus the introduction of

dirt, grease, sand and other contaminants between the

rim and brake pad, will eventually cause the outer wall

of the rim (braking surface) to wear thin.

26

3. Brake assembly lock nut

4. Centring adjustment bolt

5. Brake pad

6. Quick release lever

7. Lock nut

WARNING: In extreme conditions, the thin outer wall

can crack and fail, resulting in possible injury to the rider. Inspect the outer walls of the rims regularly. Contact

a professional bicycle mechanic if cracks or other damages are found.

• Wheels not straight

Lift each wheel off the ground and spin them to see if

they are crooked or out of alignment. If the wheels are

not straight, contact a professional bicycle mechanic

for repair and/or adjustment.

• Broken or loose spokes

Check for missing or damaged spokes. Make sure that

all the spokes are tight.

CAUTION: Damaged or missing spokes render the

bicycle unstable and can result to an accident if not

corrected. Contact a professional bicycle mechanic for

repair immediately.

• Loose hub bearings

Inflating the tyre to near maximum recommended

pressure gives the lowest rolling resistance; but produces the harshest ride. High pressures work best on

smooth, dry pavement. Low pressures, the minimum of

the recommended pressure range, give the best performance on smooth, slick terrain such as hard-packed

clay, and on deep, loose surfaces such as deep, dry

sand.

Tyre pressure that is too low for your weight and the

riding conditions can cause tube puncture by allowing

the tyre to deform sufficiently so that the inner tube is

pinched between the rim and the riding surface.

Lift each wheel off the ground and move the wheel

from side to side. CAUTION: If there is movement be-

tween the axle and the hub, do not ride the bicycle.

Adjustment is required.

Tyres and tubes

Tyre pressure

Bicycle tyres loose pressure over time. For this reason it

is important to check your tyre pressure before riding

your bicycle. It is recommended to inflate the tyres

using a manual bicycle pump.

CAUTION: Pencil type automotive tyre gauges can

be inaccurate and should not be relied upon for

consistent, accurate pressure readings. Use a high

quality dial gauge instead.

Tyre pressure is given either as a maximum pressure or

as a pressure range. How a tyre performs under different terrain or weather conditions depends largely on

the tyre pressure.

Recommended PSI rating for tyres:

See side wall of tyre

WARNING: Never inflate a tyre beyond its

recommended maximum pressure. Exceeding the recommended maximum pressure

may blow the tyre off the rim which could

cause damage to the bicycle and injury to

the rider and others. The best way to inflate

a bicycle tyre to the correct pressure is with

a bicycle pump. Never use a service station

air hose to inflate a bicycle tyre. Service station air hoses are designed for larger tyres

and therefore can easily exceed the recommended maximum pressure of a bicycle

causing the tyre to blow off the rim.

27

Tyre treads

Some special high-performance tyres have unidirectional treads: their tread pattern is designed to work

better in one direction than in the other. The sidewall

marking of a unidirectional tyre will have an arrow

showing the correct rotation direction. If your bicycle

has unidirectional tyres, be sure that they are mounted

to rotate in the correct direction.

Tyre valves

The tyre valve allows air to enter the tyre’s inner tube

under pressure, but doesn’t let it back out unless you

want it to.

There are primarily two kinds of bicycle tube valves:

The Schrader Valve and the Presta Valve (see figure).

1

2

The Schrader valve is similar to the valve on a car tyre.

This is the type of valve stem you should have on your

bicycle. To inflate a tyre with a Schrader valve, remove

the valve cap and push the air hose or pump onto the

end of the valve stem. To let air out of a Schrader valve,

depress the pin in the end of the valve stem using a key

or other appropriate object.

Your bicycle pump should match the tyre valve on your

bicycle.

Fixing a flat tyre:

In an event of a flat tyre and you need to repair the tyre,

follow the steps below.

1. Remove the wheel.

2. Deflate the tyre completely via the valve. Loosen

the tyre bead by pushing it inward all around.

3. Press one side of the tyre bead up over the edge

of the rim to unset the bead. CAUTION: In order to

avoid damaging the rim, use tyre levers and not a

screwdriver.

28

1. Schrader valve

2. Presta Valve

4. Remove the tube, leave the tyre on the rim.

5. Locate and patch the leaks using a tube repair kit

or replace the tube entirely. NOTE: Use a replacement tube with a size and valve that is the correct

type for your bicycle.

6. Locate the possible cause of the leak by matching

the position of the leak in the tube with the tyre.

7. Remove the tyre completely and inspect for a nail,

glass, thorn, etc., and remove them. Also inspect

the inside of the rim to ensure there are no protruding spokes, rust or other potential causes. If needed,

replace the rim tape which covers the spoke ends.

8. Remount one side of the tyre into the rim.

9. Using a hand pump, slightly inflate the tube to give it

some shape.

10. Insert the valve stem through the hole in the rim,

and work the tube into the tyre. NOTE: Make sure

that the valve stem is not twisted or deformed.

11. Remount the other side of the tyre by pushing the

edge toward the centre of the rim using only your

hands. Start on either side of the valve and work your

way around the rim.

12. Before the tyre is completely mounted, push the

valve up the rim to make sure that the tyre can sit

squarely in position.

13. Remount the rest of the tyre, rolling the last, most

difficult part using your thumbs. CAUTION: Avoid using tyre leavers as these can easily puncture the tube

or damage the tyre.

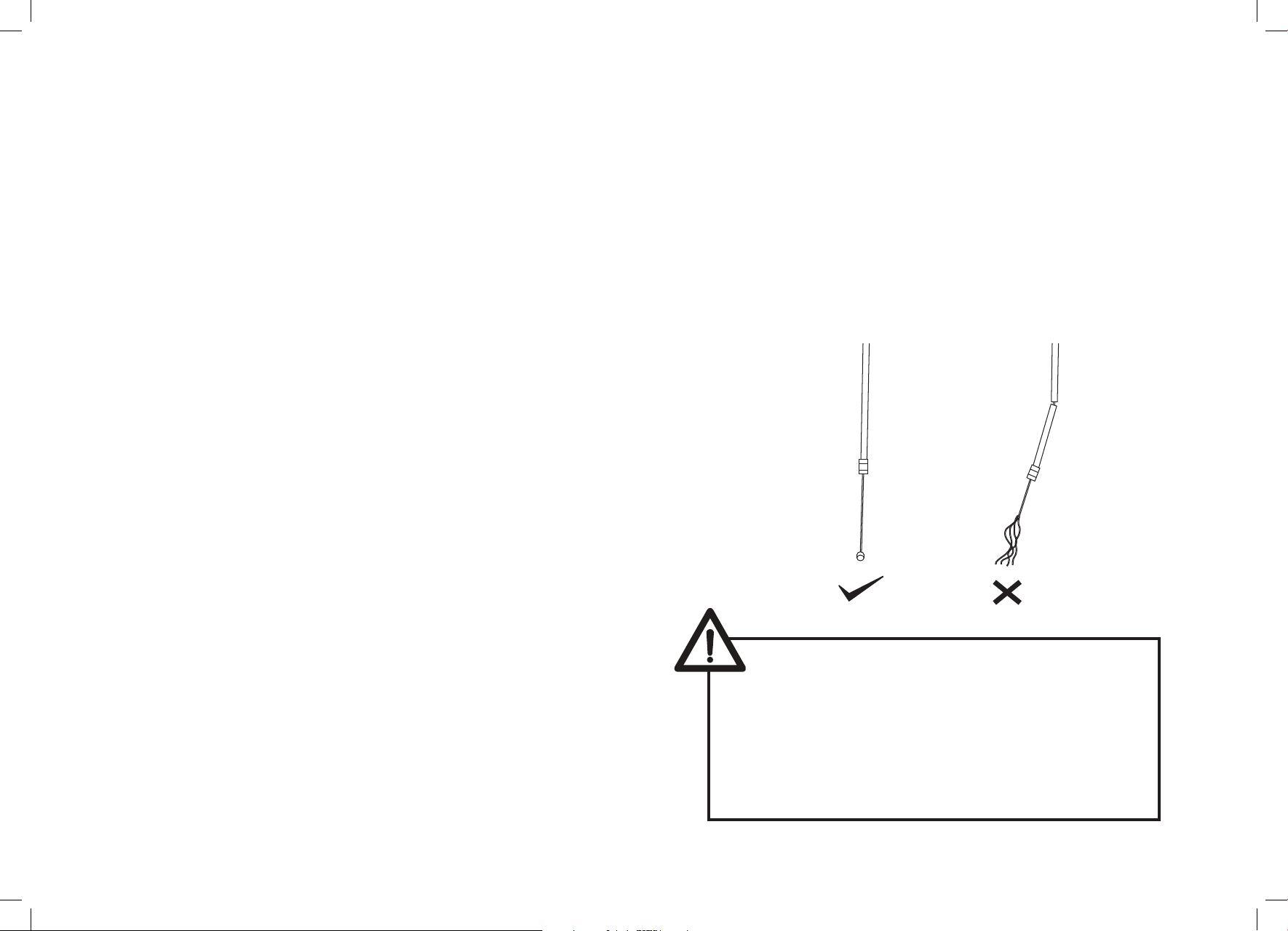

Cables and cable housing

Cables and their housing are one of the most overlooked parts on the bicycle. The first indication that

your cables and housing need to be replaced is an

increased amount of pressure needed to operate the

brakes.

Before every ride, check that there are no kinks or frays

in the cables and housing (see figure).

14. Check that the tube is not caught between the rim

and the tyre bead at any point.

15. Using a hand pump, inflate the tube until the tyre

begins to take shape. Check that the tyre bead is

evenly seated all the way around the rim. When

properly seated, fully inflate the tyre to the recommended pressure.

16. Replace the wheel into the frame checking that all

brakes and quick release levers are properly adjusted.

WARNING: Always check the brake

cable routing to ensure smooth and free

application of the brakes. Cables that are

kinked, frayed or otherwise damaged, or

cables that are wrapped around the stem

or frame may affect braking power or

cause unintended sudden stops and loss of

control.

29

Loading...

Loading...