Page 1

AimSafety PM

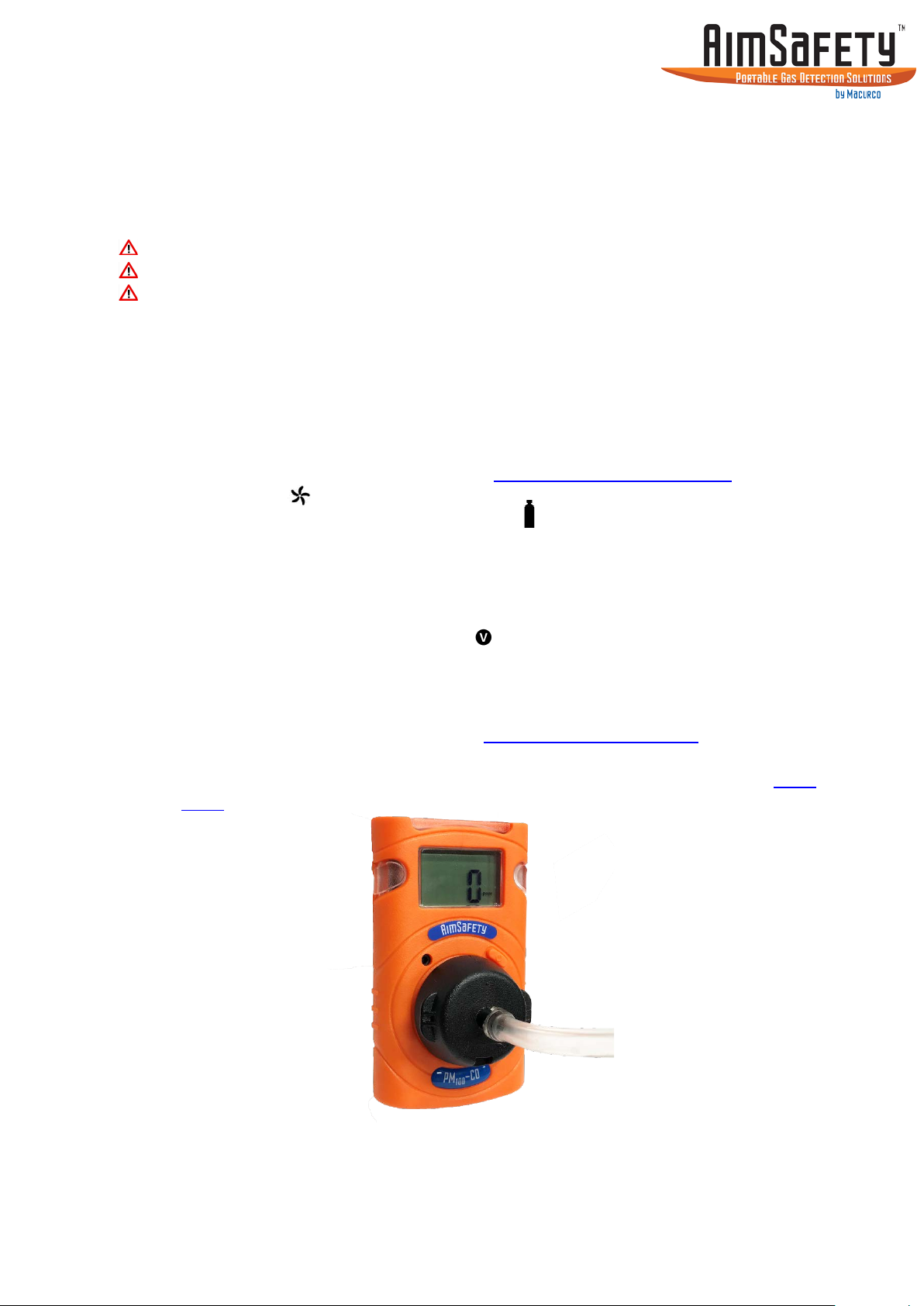

Personal Single Gas Monitor

User’s Manual

100

P/N 34-2900-0206-2 Rev. A

July 2018

Page 2

PM

Page 2

User’s Manual

100

Table of Contents

1. General Information ............................................................................................... 4

2. Specifications .......................................................................................................... 5

3. Product Overview ................................................................................................... 6

4. Activation................................................................................................................ 7

5. User Interface ......................................................................................................... 8

6. Bump Test ............................................................................................................. 14

7. Calibration ............................................................................................................ 16

8. Event Log .............................................................................................................. 19

9. Maintenance and Cleaning ................................................................................... 20

10. Disposal ................................................................................................................ 21

11. Certificates ............................................................................................................ 21

12. Limited Warranty .................................................................................................. 22

13. Contact Information ............................................................................................. 22

Page 3

PM

Page 3

User’s Manual

100

WARNING

Any unauthorized attempt to repair or modify the product, or any other cause of

damage beyond the range of the intended use, including damage by fire, lightning,

or other hazard, voids liability of the manufacturer.

Activate this product only if sensor, visual, detection, and audible cover are clear from

contaminants such as dirt and debris that could block the area where gas is to be

detected.

Do not clean and rub the LCD screen of the products with a dry cloth or hands in

hazardous environment to prevent static electricity.

Perform cleaning and maintenance of the products in fresh air that is free of

hazardous gases.

Test the response of the sensor regularly with a gas concentration exceeding the

alarm set point.

Test LED, audio, and vibration manually.

Gas concentration measurements by the sensor can vary based on the environment

(temperature, pressure and humidity). Therefore, calibration of PM

performed in the same (or similar) environment of the device’s actual use.

If the temperature changes sharply during use of the device (e.g., indoors vs

outdoors), the value of the measured gas concentration can suddenly change. Please

use the PM

after the gas concentration value has stabilized.

100

Severe vibration or shock to the device may cause a sudden reading change. Please

use PM

after the value of gas concentration has stabilized. Excessive shock to PM

100

can cause the device and/or sensor to malfunction.

All alarm values are set based on the alarm standard that is required by international

standards. Therefore, alarm values should be changed only under the responsibility

and approval of the administration of the work site where the instrument is used.

Use IR communications in the safety zone which is free of hazardous gases.

Do not attempt to replace the battery and sensor as PM

is designed to be

100

disposable. Changing the battery and sensor may impair intrinsic safety and the

attempt will void warranty.

should be

100

100

CAUTIONS

Before operating this device, please read the manual carefully.

This device is not a measurement device, but a gas detector.

If calibration and self-test fails continuously, please do not use the device.

For the O

detector, perform calibration every 30 days in the fresh air environment.

2

Before use, please check the activation date, and if the activation date has past,

please do not use the device.

Clean detectors with a soft cloth and do not use chemical substances for cleaning.

To maintain a 24-month lifetime, avoid the below activities except in necessary cases

to check events(Max/Min), lifetime/concentration, and alarm set points. Otherwise,

the frequent use of the button will deplete the battery lifetime less than 24 months.

1. Push the button frequently without valid reasons.

2. Frequent alarm operation or alarms are remained for a long time.

*Normal Alarm Use: 1 time and 2 minutes per d ay.

3. Connect with the PM Link frequently except the bump testing.

View a serial number on the label at the back side of the device. (ex, 20170101)

1. The serial number indicates below.

ex: SG 01 01 001 2017(Year) 01(Months) 01(Day) 001(Manufacture Order)

Page 4

PM

Page 4

User’s Manual

100

1. General Information

The PM

protects workers by providing exposure detection for specific gases in hazardous

environments. The PM

provides real-time gas concentrations on an easy to read LCD display. A three-tier

alarm system warns the user of the presence of unsafe gas levels with audible,

visual, and vibrating alarms. The PM

(CO), Hydrogen Sulfide (H2S) and Oxygen (O2).

Key Features

Lightweight and Compact

3.3 oz (93 g) toxic sensors, 3.7 oz (104 g) oxygen sensor

User Friendly

Menu-driven, intuitive end-user operation

Programmable Alarm Thresholds

Audio, buzzer, and flashing display alarm

Programmable Calibration and Bump Test Due Notifications

On/Off, and timing based on end-user’s needs

• Sensor options: CO, H2S, O2

• Large, easy-to-read display

• Single button operation

• Event logging

• Visual alarm with bright flashing LEDs

• Distinct audible alarm

• Vibrating alarm

• Durable weather resistant case

• Rugged clip

Programmable options (PM Link)

• Stealth Mode

• Go/No Go display

• Bump Test due

• Calibration due

is a maintenance-free, disposable portable single-gas monitor that

100

continuously monitors ambient air conditions and

100

has sensor options for Carbon Monoxide

100

Page 5

Page 5

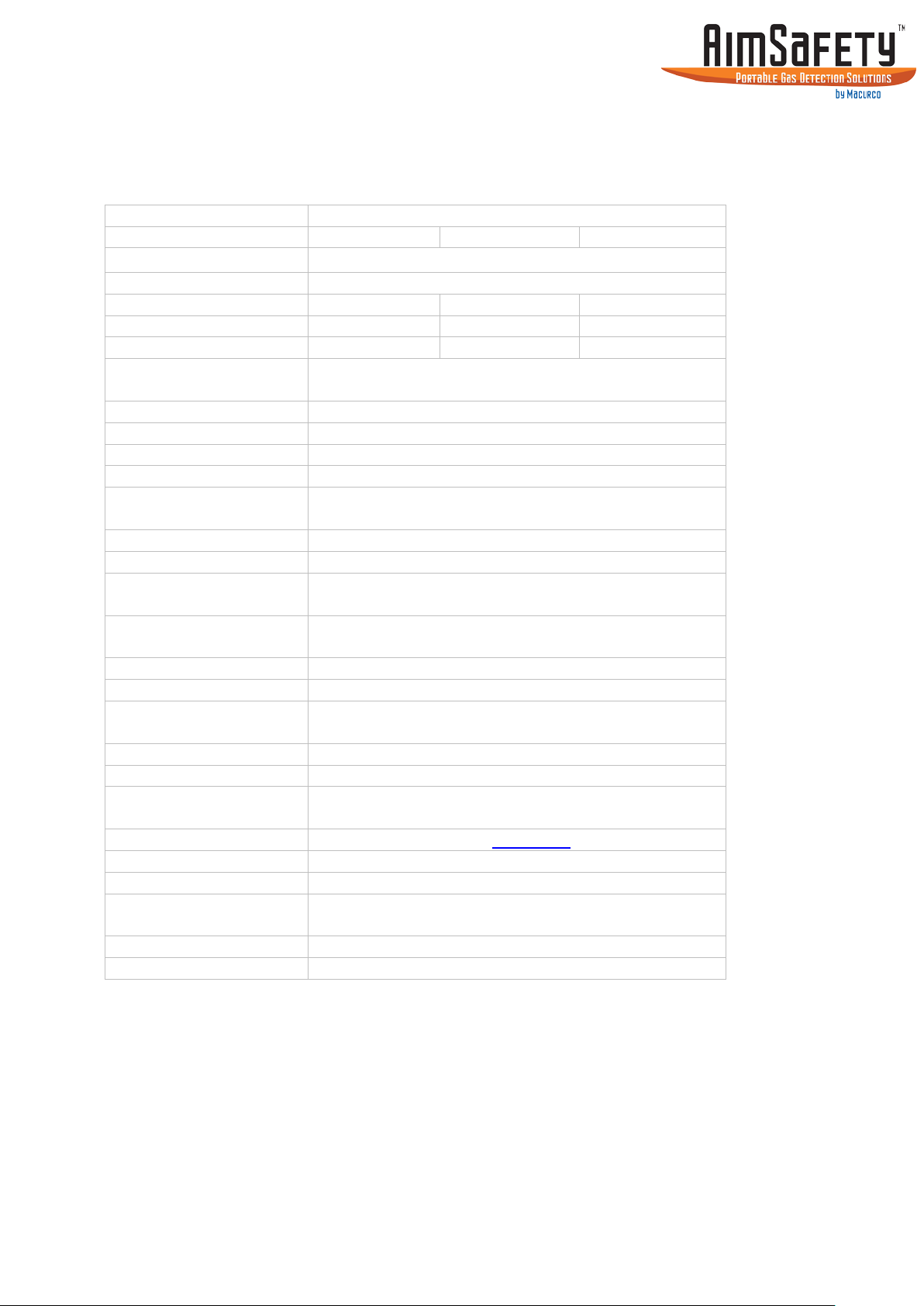

2. Specifications

Model

PM

100

Gas Type

O2

CO

H2S

Detecting Method

Diffusion

Measure type

Electrochemical Cell

Range

0 – 30% Vol

0 – 500 ppm

0 – 100 ppm

Sensor life

2 years

> 2 years

> 2 years

Resolution

0.1% Vol

1 ppm

0.1 ppm

User Settings

User Selectable via PM Link and PC Software or Bump

Test-Calibration Station

Display

LCD Display

Alarm display

RED, Flashing LEDs (Light-Emitting Diode)

Audible alarm

90 dB at 4 inches (10 cm)

Vibrating alarm

Vibration Alarm

Alarm level set

User Selectable via PM Link and PC Software or Bump

Test-Calibration Station

Event Logging

30 events

Mounting type

Clip

Program set mode

User Selectable via PM Link and PC Software or Bump

Test-Calibration Station

Operating temperature

-40°F to +122°F (-40°C to +50°C)

-31°F to +122°F (-35°C to +50°C) (for O2)

Operating humidity

5% to 95% RH (Non-condensing)

Battery

3.6V 1.2Ah

Operating Life

24 months, based on 2 minutes of alarm per day

(with limited IR communication usage)

Material

Polycarbonate and rubber

Dimensions

3.6”(L) x 2.2”(W) x 1.3”(H) (91 mm x 54 mm x 32 mm)

Weight

3.3 oz (93 g) Toxic, 3.7 oz (104g) O2 (Battery, clip

included)

Approval

See Certificates

Ingress Rating

IP67

Compliance

Electromagnetic Compatibility Directive 2014/30/EU

Manufacturing Approval

The detector manufacturer is certified compliant with ISO

9001:2000 provisions

Options

PM LINK, PM

100

Bump Test-Calibration Station

Warranty

2 years

PM

User’s Manual

100

2.1. PM

Specifications

100

Page 6

Page 6

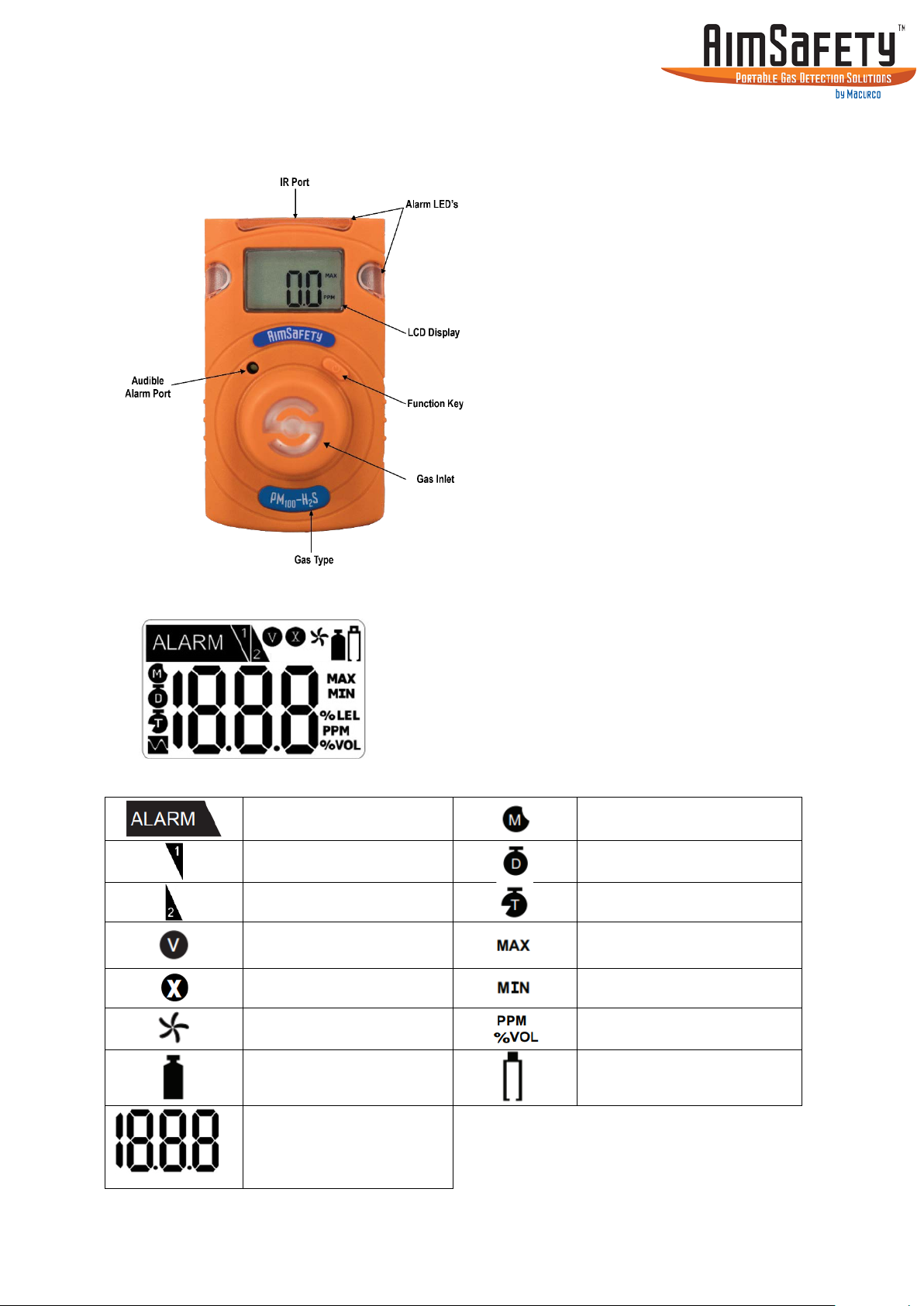

3. Product Overview

Stabilization Success

Or Firmware Version

3.1. Monitor Overview

PM

User’s Manual

100

3.2. Display Overview

LCD display symbols

Alarm condition

Low Alarm

High Alarm

Stabilization Failure

Remaining Month(s)

Remaining Day

Remaining Hour(s)

Max Peak Value

Min Peak Value

Fresh Air Calibration Icon

Span Calibration Icon

Real-Time Gas Readings

Or Numerical Values

Or Abbreviated Text

Measurement Unit

Lifetime less than 30 days

Or Low Battery

Page 7

PM

Page 7

CAUTION: Before use, check the activate by date on the box. Do not use the

User’s Manual

100

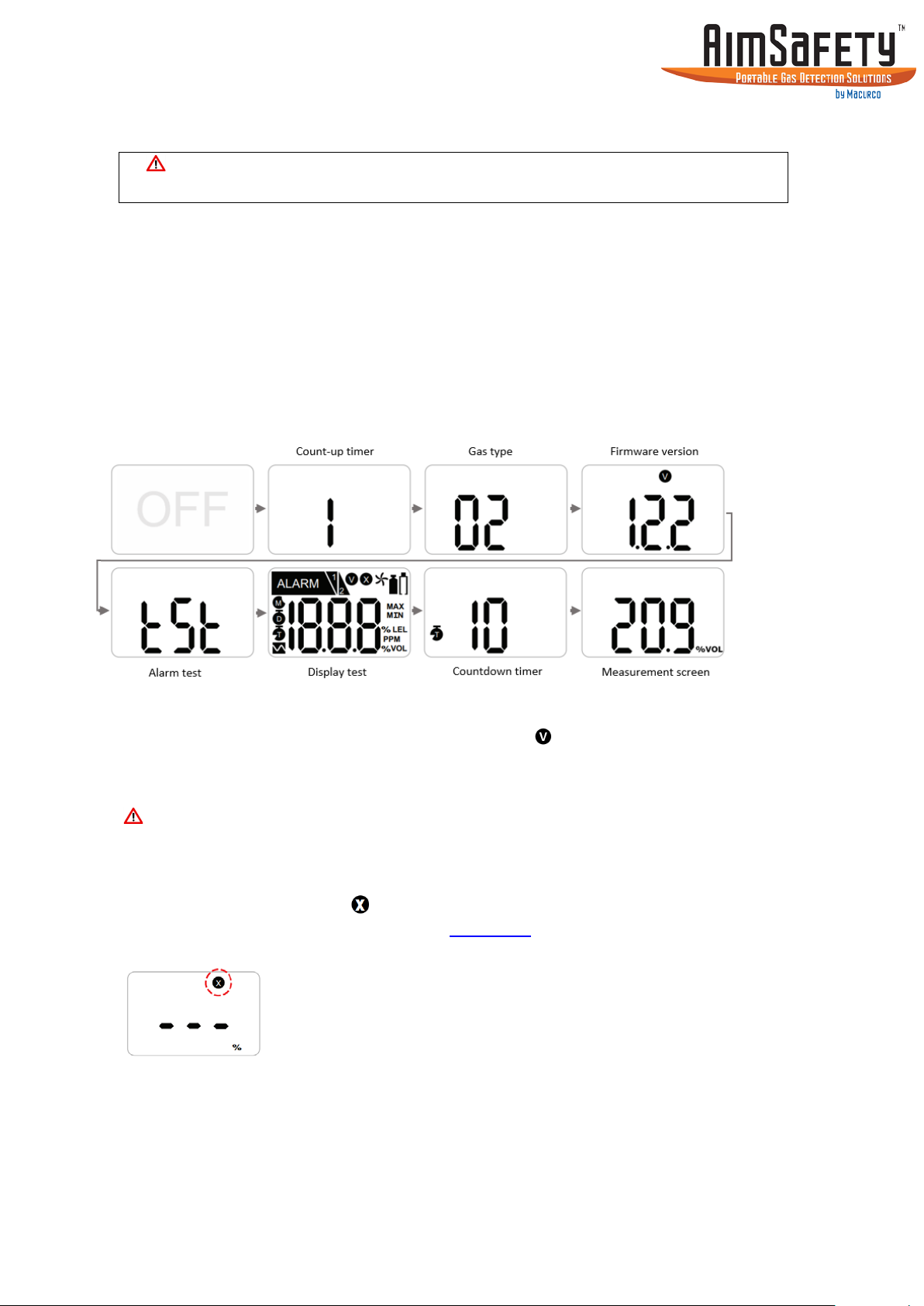

4. Activation

monitor if the activate by date has passed.

Note: The PM

monitor is designed to operate continuously for the life of the instrument

100

and cannot be turned off once activated.

4.1. Activating the Monitor

To activate the monitor, press and hold the [Function key] for 3 seconds. While the key is

depressed, a 3-second count-up timer will be displayed. Once the counter reaches three

(3), release the [Function key].

The monitor will perform the following startup sequence.

The unit will display the gas type, firmware version, display/alarm test, followed by a 10-

is complete, the monitor defaults second stabilization countdown. Once the countdown

to Measurement mode, displaying the current gas readings and the icon.

Sensor readings may drift during shipping. All newly purchased monitors should be

bump tested to a known concentration of gas before use.

If sensor stabilization fails, the icon will appear on the display and no gas concentrations

will be displayed. Perform a calibration (see Calibration) or contact AimSafety for more

information.

Page 8

PM

Page 8

Month

Day

Hour

O2

H2S

CO

User’s Manual

100

5. User Interface

The PM

• Measuring Mode – Standard display operation with real-time gas readings always

displayed

• Basic Mode – Remaining sensor life will be displayed unless an alarm condition is

detected

Gas concentrations are displayed with gas specific units of measure based on the type of

gas to be detect. Oxygen concentrations are displayed in percent by volume (%Vol) and

toxic concentrations are displayed in parts per million. (PPM)

5.1. Display Modes

Measuring Mode is the default mode. Once the monitor is activated the meter will

has two operational modes:

100

continually display measure gas concentrations in real-time.

Basic Mode is an optional mode where the remaining sensor life will be displayed if the

detected gas levels are below the alarm threshold. The monitor will display the active gas

reading only after an alarm threshold has been exceeded. Basic mode can only be enabled

using the PM Link and software, or the Bump Test-Calibration Station.

Page 9

PM

Page 9

User’s Manual

100

5.2. Menu Screens

From the Measurement screen, pressing the [Function key] will step to the next screen.

Note: If you do not press the [Function key] within 10 seconds, the display reverts to

the main screen.

Stealth Mode Press the [Function key] to advance to Stealth Mode (if enabled). Stealth is an

optional setting that disables all audible, vibrating alarms and alarm LEDs.

When Stealth is enabled, an “StL” screen is added to the menu to indicate that

the audible and vibrating alarms are disabled. The display alarm flags are the

only indication of an alarm condition.

Peak MIN Press the [Function key] to advance to Peak MIN indicated by the MIN icon on

the display (O2 only), with the numerical value displayed. The Peak MIN is the

lowest concentration of oxygen that the sensor has detected since the peaks

were last cleared.

Peak MAX Press the [Function key] to advance to Peak MAX indicated by the MAX icon on

the display, with the peak max concentration displayed. The Peak MAX is the

highest concentration of gas that the sensor has detected since the peaks were

last cleared.

Clear Peaks Press the [Function key] to advance to Clear Peaks indicated by “CLr” on the

display. To clear the peaks, press and hold the [Function key] for three seconds.

The unit will beep once, and the MIN/MAX icon will turn off.

Remaining Life Press the [Function key] to advance to Remaining Life indicated by one of three

icons on the display. Remaining life is the amount of time left on the monitor

before End-of-Life. The remaining life is displayed in months, days, or hours as

indicated by the display icons.

Alarm 1 Press the [Function key] to advance to Alarm Set Point 1 indicated by the 1 flag

on the display. This is the first (low for O2) set point that activates the monitors

alarms. The unit will store this alarm data in event logging.

Alarm 2 Press the [Function key] to advance to Alarm Set Point 2 indicated by the 2 flag

on the display. This is the second (high for O2) set point that activates the

monitors alarms. The unit will store this alarm data in event logging.

Firmware Press the [Function key] to advance to Firmware Version indicated by the V icon

on the display. This is the current firmware version that is loaded into the

monitor.

Calibration Press the [Function key] to advance to Calibration indicated by the calibration

cylinder bottle icon on the display. The calibration gas concentration will be

displayed. See Calibration for more information on monitor calibration.

Page 10

Page 10

Menu Flow Chart

Measurement screen

Stealth (Optional)

Peaks MIN (O2 only)

Peaks MAX

Clear Peaks

Remaining Life

Alarm Set Point 1

Alarm Set Point 2

Firmware Version

Calibration

PM

User’s Manual

100

5.3. Alarm and Alerts

When the gas concentration exceeds the monitor’s alarm set points the alarms will

activate: The display will show the Alarm icon, the Alarm 1 or Alarm 2 icon, and the gas

level. The monitor will vibrate, the buzzer will sound, and the LEDs will flash.

Immediately exit the area to clean air. The alarms will clear once the gas concentrations go

below the alarm set points.

Page 11

Page 11

Alarm and Alert indication chart

Alarm

Alarm Standard

LCD Display

Alarm and Vibration Display

concentration

concentration

Life

remaining

End-Of-Life in less than 30

days

Sensor test

failure

PM

User’s Manual

100

Low Alarm

High Alarm

Exceeds 1st

Alarm set point

Exceeds 2nd

Alarm set point

Below 30 days

End-Of-Life Past 24 months

Test failure

Battery Low

Or calibration

Low battery

power

Icons & gas

Icons & gas

Icon & buzzer

Icon

Monitor has reached End-OfLife. (Replace the unit with a

new PM

100

)

Perform a successful

calibration to clear

Replace the unit with a new

PM

100

Bump test Bump test due

Calibration Calibration due

Calibration

Failed

Failed calibration

Perform a successful bump

test to clear

Perform a successful

calibration to clear

Perform a successful

calibration to clear

Page 12

PM

Page 12

Gas Type

CO

H2S

O2

Low Alarm

35 ppm

10 ppm

19.5%

High Alarm

100 ppm

15 ppm

23.5%

End

LCD

Test

Buzzer

LED

Buzzer

Display

Alarm 1

Alarm 2

User’s Manual

100

5.4. Default Alarm Set Points

Note: Alarm levels can only be changed using the PM Link and software, or the Bump Test-

Calibration Station.

5.5. Self-Test Reminder

The Self-Test reminder option can be enabled using the PM Link and software or the Bump

Test-Calibration Station. The Self-Test reminder can be configured to n/a (Off) or between 8

hours to 20 hours. The default configuration is set to “Off”, no Self-Test reminder will be

displayed.

When enabled, the monitor will prompt the user to perform the test by displaying “StS” on

the display when the test is due.

• To activate the test, press the [Function key].

The unit will then perform the following:

• Buzzer test

• LED test

• Vibration

• LCD test

• Display Alarm set point 1

• Display Alarm set point 2

• End

The user is required to ensure that all the tests pass successfully and that the alarm values

are set to the proper levels.

Do not use the monitor if any of the tests fail or if the alarm values are incorrect

Page 13

PM

Page 13

Bump Test Due

Apply Gas

Gas Detected

Test Passed

Remove Gas

Main Screen

User’s Manual

100

5.6. Bump Test Reminder

The Bump Test due reminder option can be enabled using the PM Link and software or the

Bump Test-Calibration Station. The Bump Test reminder can be configured from n/a (Off) to

365 days. The default configuration is set to “Off”, no Bump Test reminder will be displayed.

When enabled, the monitor will prompt the user to perform the test by displaying “btS” on

the display when the test is due.

• Ensure that the sensor is reading zero (or 20.9% for Oxygen)

• Attach the calibration (cal) cap on top of the sensor inlet

• Connect the hose from the gas regulator of the calibration gas cylinder to the cal

cap. Ensure the calibration gas and gas concentrations match the sensor installed in

the instrument

• To activate the test, press and hold the [Function key] for 3 seconds and “tSt” will be

displayed

• Turn on the gas regulator

• Once gas is detected, “GAS” will be displayed

• After the test is passed, “SUC” and the icon will appear on the display followed by

the alarm notification

• Once the test has passed, remove the calibration cap and turn off the calibration

gas

• Allow a few minutes for the gas to dissipate

• After the gas has dissipated from the sensor, clear the sensor Peak values

Check the calibration gas concentrations, cylinder expiration date, and the monitor gas

settings and re-test the unit. Or perform a full calibration as defined in the calibration

section.

Clear Alarm Flags

If the sensor fails the bump test, an “FA” message with the icon will briefly display, then

the “bts” message will resume.

If the Bump Test fails, do not use the monitor until a successful Bump Test or

Calibration is performed.

Page 14

PM

Page 14

User’s Manual

100

6. Bump Test

A bump test is used to test that the monitor is working properly. During a bump test, a

known concentration of gas is applied to the sensor to verify that the sensor responds to

the gas, and the alarms activate. This is the only way to effectively confirm that all

characteristics of the monitor and the sensor are working correctly.

A bump test should be conducted before each day’s use.

Ensure that you are in a clean environment before performing a Bump Test.

The monitor must be calibrated if it fails a Bump Test.

To perform a manual Bump Test: (without the Bump Test Reminder active)

• Ensure that the sensor is reading zero (or 20.9% for Oxygen)

• Attach the calibration (cal) cap on top of the sensor inlet

• Connect the hose from the gas regulator of the calibration gas bottle to the cal cap.

Ensure the calibration gas and gas concentrations matches the sensor installed in

the instrument.

• Access the Calibration menu (see section Accessing the Calibration Menu)

• “CAL” and the icon are displayed.

• Press the [Function key] once and “CAL” and the icon will appear.

• Press the [Function key] again “btS” will be displayed.

• Press and hold the [Function key] for 5 seconds and “tSt” will be displayed

• Turn on the gas regulator

• Once gas is detected, “GAS” will be displayed

• After the test is passed, “SUC” and the icon will appear on the display followed by

the alarm notification and “btS”

• Once the test has passed, remove the calibration cap and turn off the calibration

gas. The monitor will default to the main screen after 20 seconds or you can

manually exit the calibration menu (see Exiting the Calibration Menu)

• Allow a few minutes for the gas to dissipate

• After the gas has dissipated from the sensor, clear the sensor Peak values (See Clear

Peaks)

Page 15

PM

Page 15

Test Failed

Bump Test

Apply Gas

Gas Detected

Test Passed

Remove Gas

Main Screen

User’s Manual

100

Clear Alarm Flags

The unit is now ready for use. Otherwise do not use the monitor until the reason for the

discrepancy for the test has been determined and corrected.

If the sensor fails the bump test, an “FA” message with the icon will briefly display

Check the calibration gas concentrations, cylinder expiration date, and the monitor gas

settings and re-test the unit. Or perform a full calibration as defined in the calibration

section.

If the Bump Test fails, do not use the monitor until a successful Bump Test or

Calibration is performed.

Page 16

PM

Page 16

Fresh Air Calibration

Span Calibration

Bump Test

Exit

User’s Manual

100

7. Calibration

Calibration is the process of adjusting the sensor’s response by using a specific

concentration of calibration gas. Sensors will drift for a variety of reasons, so it is important

to perform a full calibration periodically to ensure that the sensors response to the target

gas are accurate. A full calibration consists of two points, a Fresh Air Calibration and a Span

Calibration.

Fresh Air Calibration adjusts the zero offset of the toxic sensor or sets the oxygen sensor to

20.9% Vol.

Span Calibration adjusts the sensors response to gas to account for sensor drift. It is

recommended to perform a Fresh Air Calibration prior to a Span Calibration.

CAUTION: For O

shipment. Once received, calibration should be performed monthly (or quarterly)

depending on frequency of use.

All alarms are muted during calibration.

units: Initial calibration is performed on all devices prior to

2

7.1. Accessing the Calibration Menu

To access the calibration menu:

• Press the [Function key] to navigate to the Calibration screen.

• While the Calibration screen is displayed, press and hold down the [Function key]

for 5 seconds to access the Calibration mode.

Once the Calibration menu is accessed, “CAL” and the icon will be displayed. Calibration

menu has four options:

• Fresh Air Calibration

• Span Calibration

• Bump Te st

• ESC – Exit Calibration Mode

7.2. Exiting the Calibration Menu

Press the [Function key] until “ESC” is displayed on the screen. Press and hold the [Function

key] for 5 seconds, the monitor will return to the Calibration screen. Press the [Function

key] again and the unit will return to the Measurement screen.

Note: If you do not press the [Function key] within 20 seconds, the display reverts to the

main screen.

Page 17

Page 17

7.3. Fresh Air Calibration

Fresh Air Calibration must be performed in a clean environment that is free from

other gases (calibration is assumed to be performed in an environment with an

Oxygen concentration of 20.9% Vol.). Fresh Air Calibration should not be performed in

a confined space.

To perform a Fresh Air Calibration:

• Access the Calibration menu.

• “CAL” and the

• Press and hold the [Function key] for 5 seconds to start the Fresh Air Calibration.

• When the calibration starts, a countdown (starting at 10) will appear on the screen.

Note: Press the [Function key] during the 10 second countdown to abort.

• Once the countdown is complete “CAL”, the and icons will be displayed

indicating a successful Fresh Air Calibration.

Note: If you do not press the [Function key] within 20 seconds, the display reverts to

the main screen.

icon will be displayed.

PM

User’s Manual

100

icon will appear on the display. If this continues, please contact If calibration fails, the

the sales representative or AimSafety Technical Support.

Page 18

Page 18

7.4. Span Calibration

Gas Type

O2

CO

H2S

Concentration

18.0% Vol

100 ppm

25 ppm

When performing a Span Calibration only use certified calibration gas at the required

concentration level. Do not use expired calibration gas.

To perform a Span Calibration:

• Access the Calibration menu.

• “CAL” and the

• Press the [Function key] once and “CAL” and the icon will appear.

• Attach the calibration (cal) cap on top of the sensor inlet.

• Connect the hose from the gas regulator of the calibration gas bottle to the cal cap

• Press and hold the [Function key] for 5 seconds to start the Span Calibration.

• When the calibration starts, a 90-second countdown displays.

Note: The countdown is only 60 seconds for O2

• Turn on the calibration gas.

• Once completed, the icon and the current gas measurement readings will appear

on the display.

• The device will return to Measuring mode.

• Turn off the calibration gas and remove the calibration cap.

• Clear the Peak values for the sensor. (See Clear Peaks)

All alarms are muted for approximately 10 minutes after a successful span calibration.

PM

User’s Manual

100

icon are displayed.

If the calibration fails, the and icons and CAL will cycle on the display until a

successful calibration is performed. Contact the sales representatives or AimSafety

Technical Support if a successful calibration cannot be performed.

Default Calibration gas concentrations.

Default calibration gas concentrations can be changed using the PM Link and PC software

or with the Bump Test – Calibration Station.

Page 19

PM

Page 19

User’s Manual

100

8. Event Log

Event logging occurs anytime that an alarm condition is met. Once an alarm condition is

met the monitor will automatically save that event in the memory. The monitor can store

up to 30 events, once more than 30 events are stored, any new events overwrite the oldest

ones. The stored log events can be downloaded using the PM Link and PC software or or

with the Bump Test – Calibration Station.

Event log captures the following monitor information:

• Product Name

• Serial number

• Log Type

• Firmware version

• Alarm setpoints

• Life remaining

• Total Number of Events

• Duration of Events

• Zero Calibration date

• Span Calibration date

Each alarm event records the followings event details:

• Date

• Time

• Duration

• Sensor Readings

• Alarm Type

See the PM Link PC software and Bump Test-Calibration Station manual for more

information on Event Log.

Page 20

PM

Page 20

User’s Manual

100

9. Maintenance and Cleaning

The PM

turned off once activated. It is important to avoid the following activities as they will

deplete the battery lifetime to less than 24 months.

1. Frequent or prolonged alarm activation. (Normal Alarm use: 2 minutes per day)

2. Unnecessary [Function key] operation

3. Connecting the PM Link frequently (except for regular bump testing/calibration)

9.1. Maintenance

Do not disassemble unit or attempt to repair or modify any component of this instrument.

This instrument contains no user serviceable parts, and substitution of components may

impair intrinsic safety which may adversely affect product performance.

9.2. Cleaning

CAUTION: Do not attempt to clean the instrument in a hazardous environment. Cleaning

with a dry cloth may generate a static charge and result in an explosion if located in a

hazardous environment.

Occasionally clean the monitor with a soft cloth. Do not use detergents or chemicals. If

necessary, use a damp cloth (water only). It is recommended to install the Calibration Cap

before cleaning the monitor housing, to keep dirt, dust, or moisture away from the sensor

openings and to help keep the sensor filter clean.

Visually inspect the monitor and the IR port window on the top of the monitor. Wipe it with

a soft cloth as needed.

monitor is designed to operate continuously for the life of the unit and cannot be

100

Page 21

PM

Page 21

IECEx:

Ex ia IIC T4 Ga

1: Explosion protected

5: Equipment protection level

Class I, Zone 0, AEx ia IIC T4 Ga

Ed. 3; UL 913, Ed. 8; UL 60079-0, Ed. 6; UL 60079-11, Ed. 6

ATEX:

2198 II 1 G Ex ia IIC T4 Ga IP67

Directive 2014/34/EU

KCS:

Ex ia IIC T4

KTL 16-KA2BO-0457

INMETRO

Ex ia IIC T4 Ga

Standards:

The electrical apparatus and any acceptable variations to it specified in the

EN 60079-11: 2012

Compliance:

Electromagnetic Compatibility Directive 2014/30/EU

Manufacturing

Approval:

The monitor manufacturer is certified compliant with ISO 9001:2000

provisions

User’s Manual

100

10. Disposal

The PM

instrument, follow local solid waste disposal regulations.

is designed to be discarded 2 years after activation. To properly dispose of the

100

11. Certificates

The PM

meets or exceeds the following certification standards.

100

Class I, Division 1, Groups A, B, C, D, T4

C22.2 No. 60079-0:2015; C22.2 No. 60079-11:2014;

C22.2 No. 61010-1-12:2010; UL 61010-1,

KRH 17 ATEX 0013

BVC16.5919

schedule of this certificate and the identified documents, was found to comply

with the following standards:

IEC 60079-0: 2011 Ed. 6

IEC 60079-11: 2011 Ed 6

UL 61010-1, Ed. 3

UL 913, Ed. 8

UL 60079-0, Ed. 6

UL 60079-11, Ed. 6

C22.2 No. 60079-0:2015

C22.2 No. 60079-11:2014

C22.2 No. 61010-1-12:2012

EN 60079-0: 2012+A11:2013

2: Protection Concept

3: Gas Group

4: Temperature Classification

Page 22

Page 22

12. Limited Warranty

AimSafety warrants this product will be free from defective materials and

workmanship for a period of two (2) years from date of manufacture, provided it is

maintained and used in accordance with AimSafety instructions and/or

recommendations. If any component becomes defective during the warranty

period, it will be replaced or repaired free of charge, if the unit is returned in

accordance with the instructions below. This warranty does not apply to units that

have been altered or had repair attempted, or that have been subjected to abuse,

accidental or otherwise. The above warranty is in lieu of all other express

warranties, obligations or liabilities. THE IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR PARTICULAR PURPOSE ARE LIMITED TO A

PERIOD OF TWO (2) YEARS FROM THE PURCHASE DATE. AimSafety shall not be

liable for any incidental or consequential damages for breach of this or any other

warranty, express or implied, arising out of or related to the use of said gas monitor.

Manufacturer or its agent’s liability shall be limited to replacement or repair as set

forth above. Buyer’s sole and exclusive remedies are return of the goods and

repayment of the price, or repair and replacement of non-conforming goods or

parts.

Warranty Procedure

Contact the local AimSafety authorized reseller or AimSafety Technical Support to

obtain a Return Materials Authorization (RMA). An RMA requires the following

information:

• Company name, contact name, phone number, and email address

• Description and quantity of items to be returned

• Equipment serial number(s)

• Reason for return

No returns shall be accepted without an AimSafety RMA. Any returns received

without an RMA will be rejected and returned to the sender.

PM

User’s Manual

100

13. Contact Information

Technical Support

Monday through Friday, 8:00AM to 5:00PM Central (US) Time

Email: support@aimsafety.com

Phone (toll-free): 1-844-325-3050

World Headquarters

3601 North St. Paul Avenue

Sioux Falls, SD 57104 USA

Phone: 1-877-367-7891

Fax: 1-605-951-9616

E-mail: info@aimsafety.com

Web Site: www.aimsafety.com

Loading...

Loading...