Page 1

Macurco™ Duct Mount Kit

DMK-1

For monitoring gas concentrations in ventilation ducts

Duct Mounted Gas Detection

The Macurco DMK-1 is an air tight enclosure that provides a means to mount any Macurco gas detector to an air

duct. By duct mounting a Macurco gas detector it is able to monitor the air inside of the duct and provide early

detection of carbon monoxide or other gases moving through the HVAC system. The DMK-1 used with Macurco

gas detectors can provide automatic control to prevent recirculation of these gases into additional areas by the

air handling systems, fans and blowers in commercial and residential applications.

Features

• Provides detection and monitoring of gas concentrations in ventilation ducts

• Clear cover allows view of detector, dispays and status lights

• Air tight enclosure

Included with the DMK-1

• Enclosure with cover, gasket and screws

• Strain relief, nut and seal for wiring exit hole

• Exhaust tube

• Foam compression seals

• A full size drill hole position template

Not included with the DMK-1

• Macurco Gas Detector

• Input sampling tube: available in various lengths from HVAC and Security distributors

• Single gang type detectors, CM-E1 and GD-2B, will need a 4” single gang mud-ring not included

Manufactured by Aerionics, Inc. Round Rock, TX – Phone: 1-877-367-7891 – Email: info@aerionicsinc.com – www.macurco.com

Page 2

DMK-1 Specifications

• Size: 6 1/4 x 6 1/4 x 3 1/2 inches (15.9 x 15.9 x 8.9 cm)

• Exhaust Tube: EMT, 1/2” (1.3 cm) diameter 6 1/2” length (16.5 cm)

• Setscrew Adapters: EMT, 1/2” (1.3 cm)

• Shipping Weight: 1.5 pounds (0.68 kg)

Installation

• Install the exhaust tube into the “downstream” setscrew adapter

with the open end of the 45 degree cut facing downstream

• Install the appropriately sized sampling tube (not provided) into

the “upstream” setscrew adapter with the ports facing upstream

• The end of the sampling tube that is in the duct must be closed or

capped to ensure good air flow through the DMK-1 and to the detector

• The sampling tube MUST extend at least 2/3 into the width of the

ventilation duct to ensure that it can properly sample the airstream

within the duct and tube support is required in all instances where

the tube length is greater than three feet

• Be sure that there is a good seal between the DMK-1 and the duct

surface around the sampling and exhaust tubes to ensure good

air flow through the DMK-1 and to the detector

• Never use silicone sealants when installing the DMK-1 as gas

sensors can be poisoned by silicone vapors

Location

The DMK-1 and gas detector should be mounted on air ducts downstream from any duct openings, deflection plates,

sharp bends or branch connections. If it is not physically possible to locate the detector accordingly, it is best positioned as

far from the opening, bend or deflection plates as possible. Supply duct gas detector installation should be downstream of

fans, filters, chillers, heaters and humidifiers. Return duct gas detectors should be located at return air opening within the

compartment, where the air exits each compartment or in the duct system before air enters the return air system common

to more than one compartment.

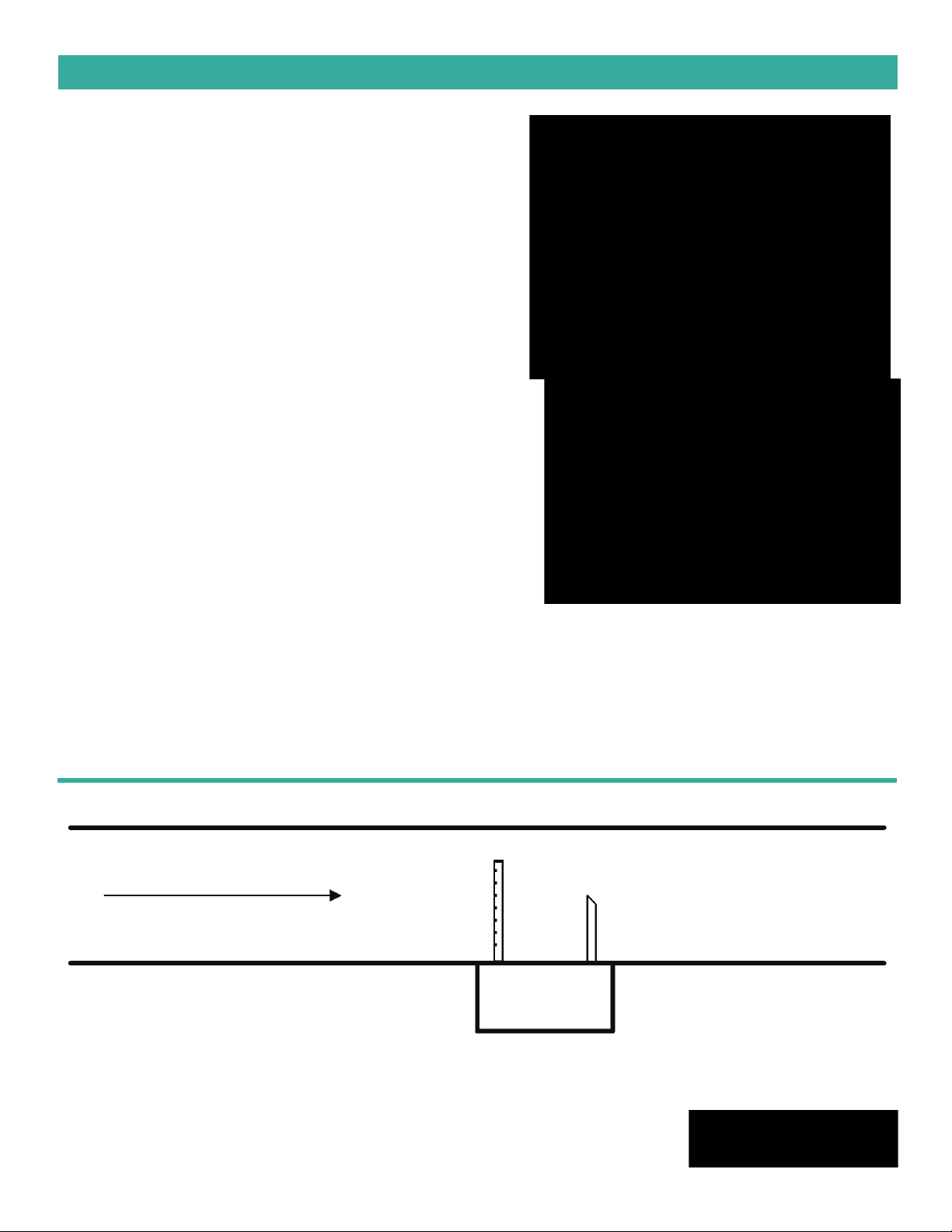

TYPICAL INSTALLATION OF A DMK-1

THE SAMPLING TUBE MUST EXTEND AT LEAST 2/3 INTO THE WIDTH OF THE DUCT

Duct (Cutaway View)

Direction of Air Flow

Upstream Downstream

Sampling

Tube

DMK

Exhaust

Tube

Enclosure

Sampling and exhaust tubes must be installed in the proper orientation to ensure good air flow through the DMK-1 and to the gas detector

Made in the U.S.A. with US and imported materials

© Aerionics 2013. All rights reserved.

Macurco is a trademark of Aerionics, Inc.

Gas Detection Experts

Loading...

Loading...