Page 1

Macurco™ CD-6H / CD-6MC

Carbon Dioxide Detector, Controller and Transducer

User Instructions

IMPORTANT: Keep these User Instructions for reference.

Page 2

2

Page 3

Table of Contents

1 GENERAL SAFETY INFORMATION ........................................................................................................................................... 5

1.1 Intended Use ........................................................................................................................................................................ 5

1.2 List of Warnings and Cautions within these User Instructions .............................................................................................. 5

2 USER INSTRUCTIONS AND LIMITATIONS ............................................................................................................................... 6

2.1 Use For ................................................................................................................................................................................. 6

2.2 Do Not Use For ..................................................................................................................................................................... 6

2.3 General Description .............................................................................................................................................................. 6

2.4 Features ............................................................................................................................................................................... 7

2.5 Specifications........................................................................................................................................................................ 7

3 INSTALLATION AND OPERATING INSTRUCTIONS ................................................................................................................. 8

3.1 Location ................................................................................................................................................................................ 8

3.2 Installation............................................................................................................................................................................. 8

3.3 Power Up ............................................................................................................................................................................ 12

3.4 Operation ............................................................................................................................................................................ 12

3.5 Default Configuration – Factory Settings ............................................................................................................................ 13

3.5.1 Selecting Default Configuration – “dEF” .................................................................................................... 13

3.5.2 Selecting Power Up Test Option – “PUt” ................................................................................................... 14

3.5.3 Selecting Display Option – “dSP” .............................................................................................................. 14

3.5.4 Selecting Buzzer Option – “bUZ” .............................................................................................................. 14

3.5.5 Selecting Alarm Relay Setting – “ArS” ...................................................................................................... 14

3.5.6 Selecting Alarm Relay Configuration – “Arc” ............................................................................................. 14

3.5.7 Selecting Fan Relay Settings – “FrS” ........................................................................................................ 14

3.5.8 Selecting Fan Relay Delay – “Frd” ............................................................................................................ 14

3.5.9 Selecting Fan Relay Minimum Runtime – “Frr” ......................................................................................... 15

3.5.10 Selecting Fan Relay Latching Option – “FrL” ............................................................................................ 15

3.5.11 Selecting Trouble Fan Setting Option – “tFS” ........................................................................................... 15

3.5.12 Selecting 4-20mA Output Option – “420” .................................................................................................. 15

3.6 Onboard Diagnostics .......................................................................................................................................................... 15

4 Maintenance .............................................................................................................................................................................. 16

4.1 End-of-life Signal ................................................................................................................................................................ 16

4.2 Cleaning ............................................................................................................................................................................. 16

4.3 Testing ................................................................................................................................................................................ 17

4.3.1 Operation Test .......................................................................................................................................... 17

4.3.2 Manual Operation Test ............................................................................................................................. 17

4.3.3 Carbon Dioxide Gas Test .......................................................................................................................... 18

4.3.4 Field Calibration Kit – CD6-FCK ............................................................................................................... 18

4.3.5 FCK Information ........................................................................................................................................ 18

4.4 Gas Testing ........................................................................................................................................................................ 18

4.4.1 Testing the Fan Relay ............................................................................................................................... 18

4.4.2 Testing the Alarm Relay ............................................................................................................................ 19

4.4.3 Testing the 4-20mA current loop ............................................................................................................... 20

4.4.4 Manual Calibration – CD-6MC ONLY ....................................................................................................... 20

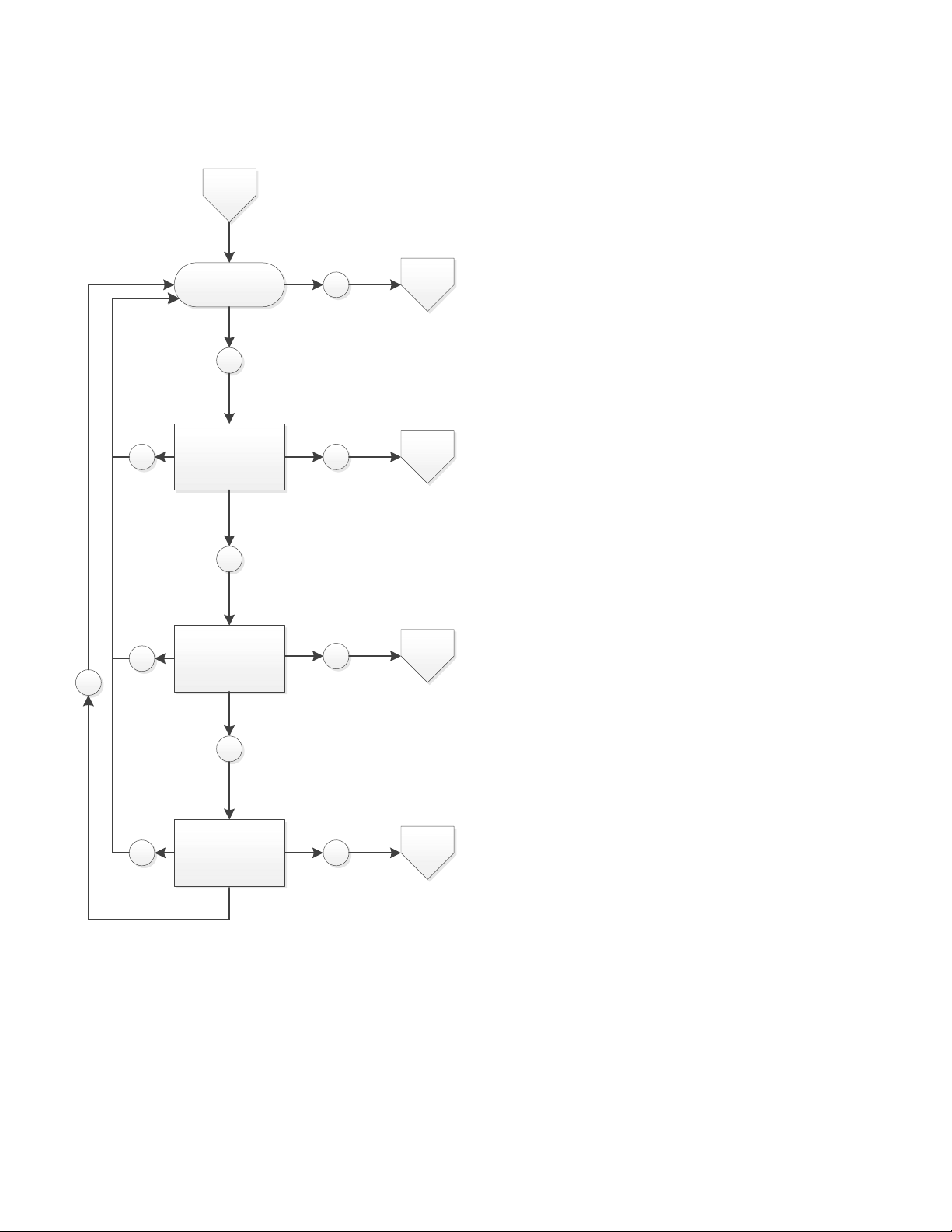

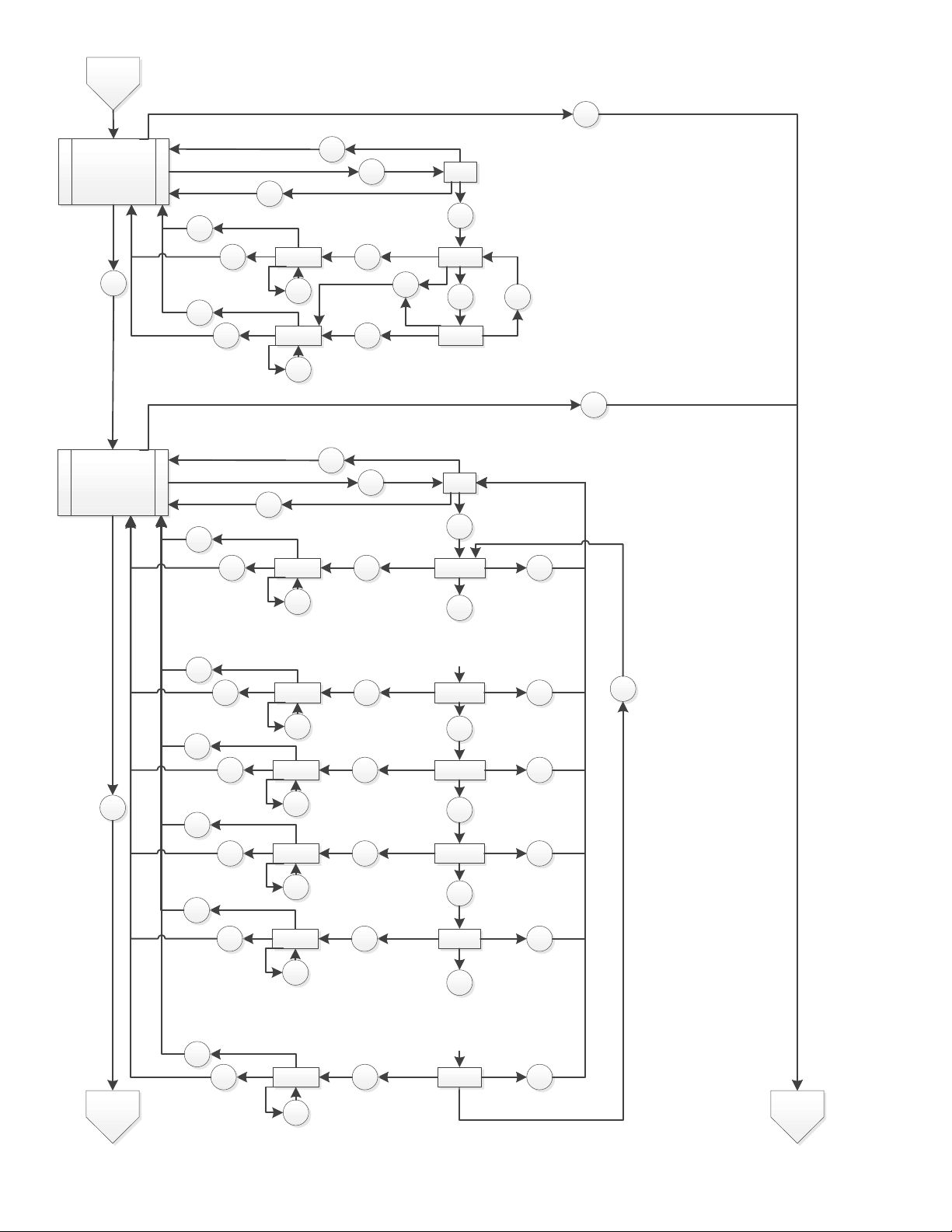

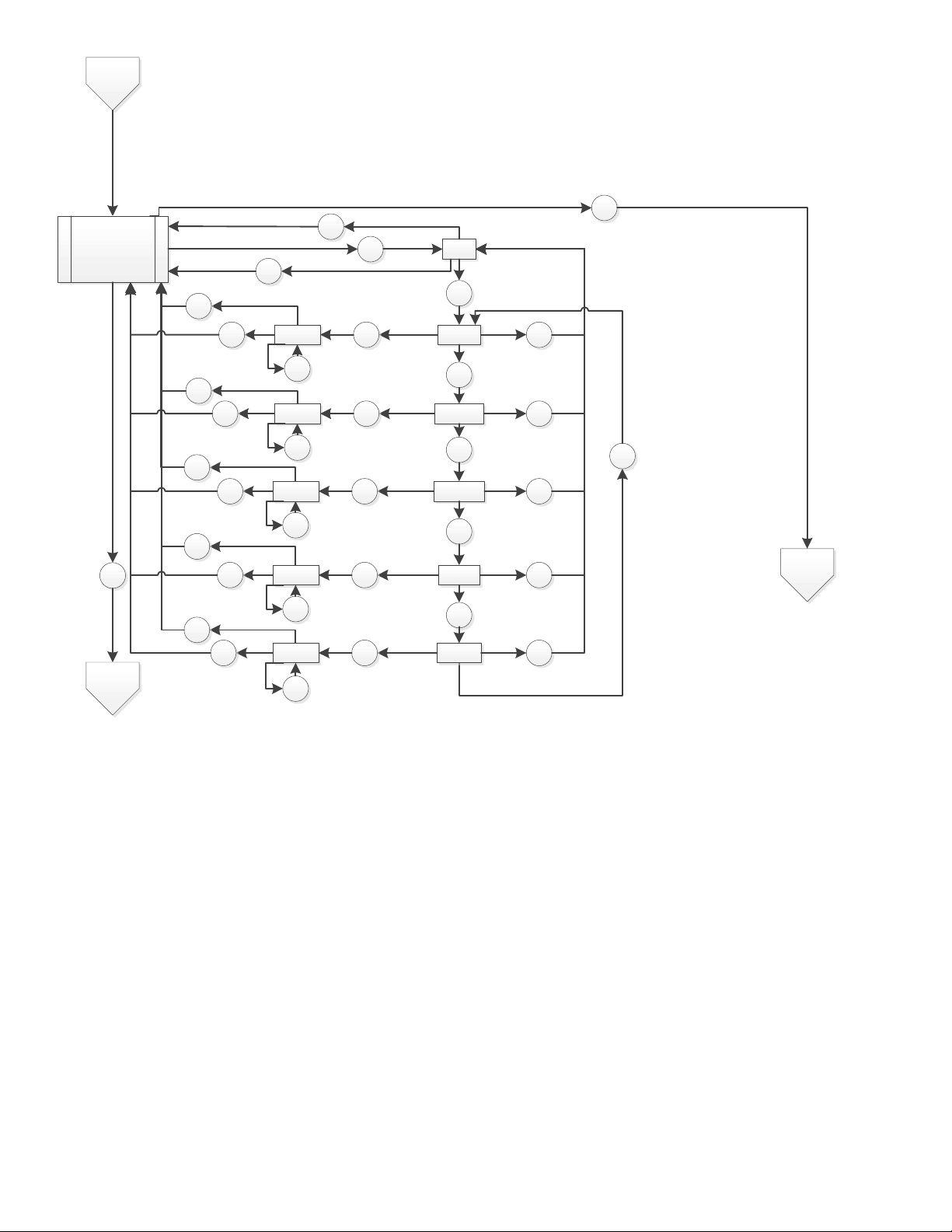

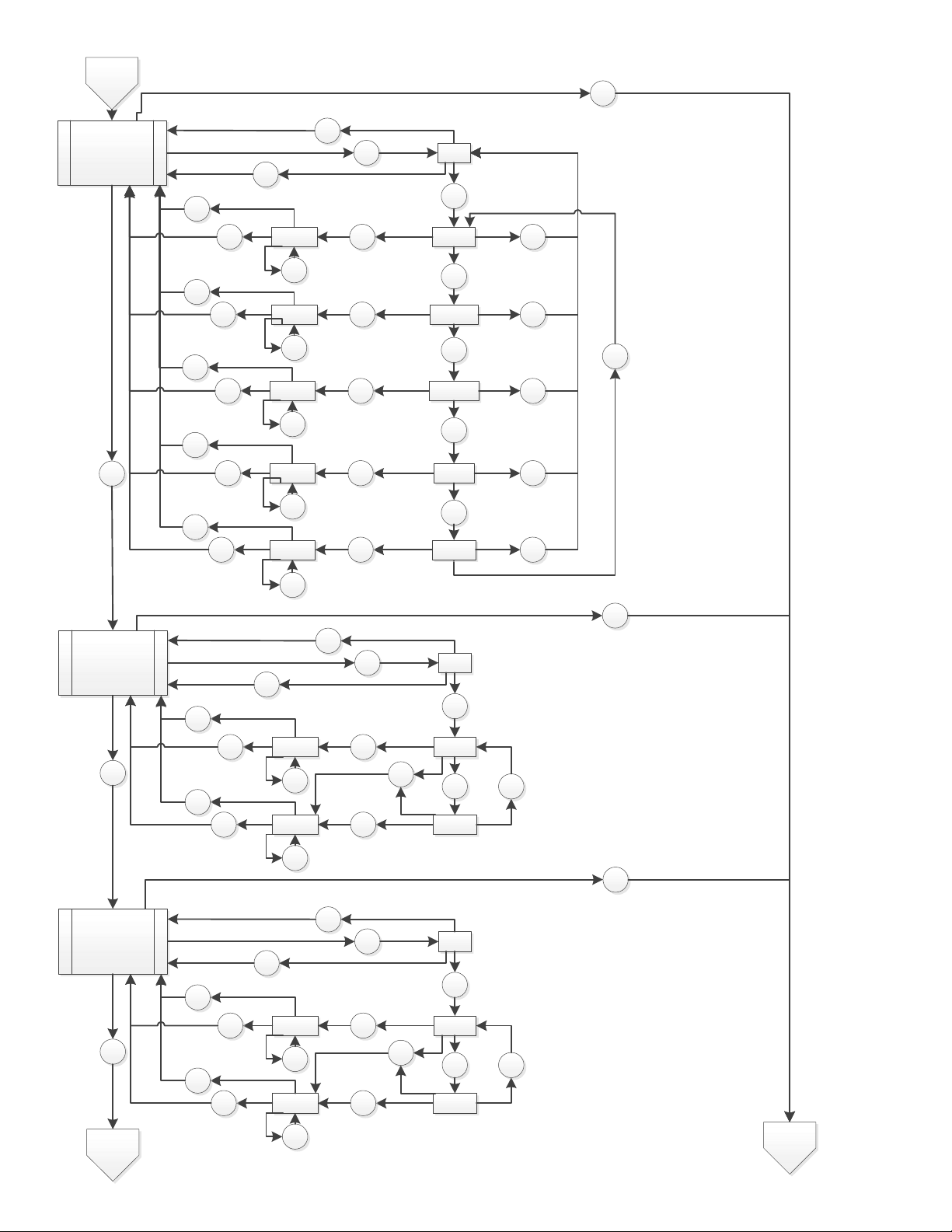

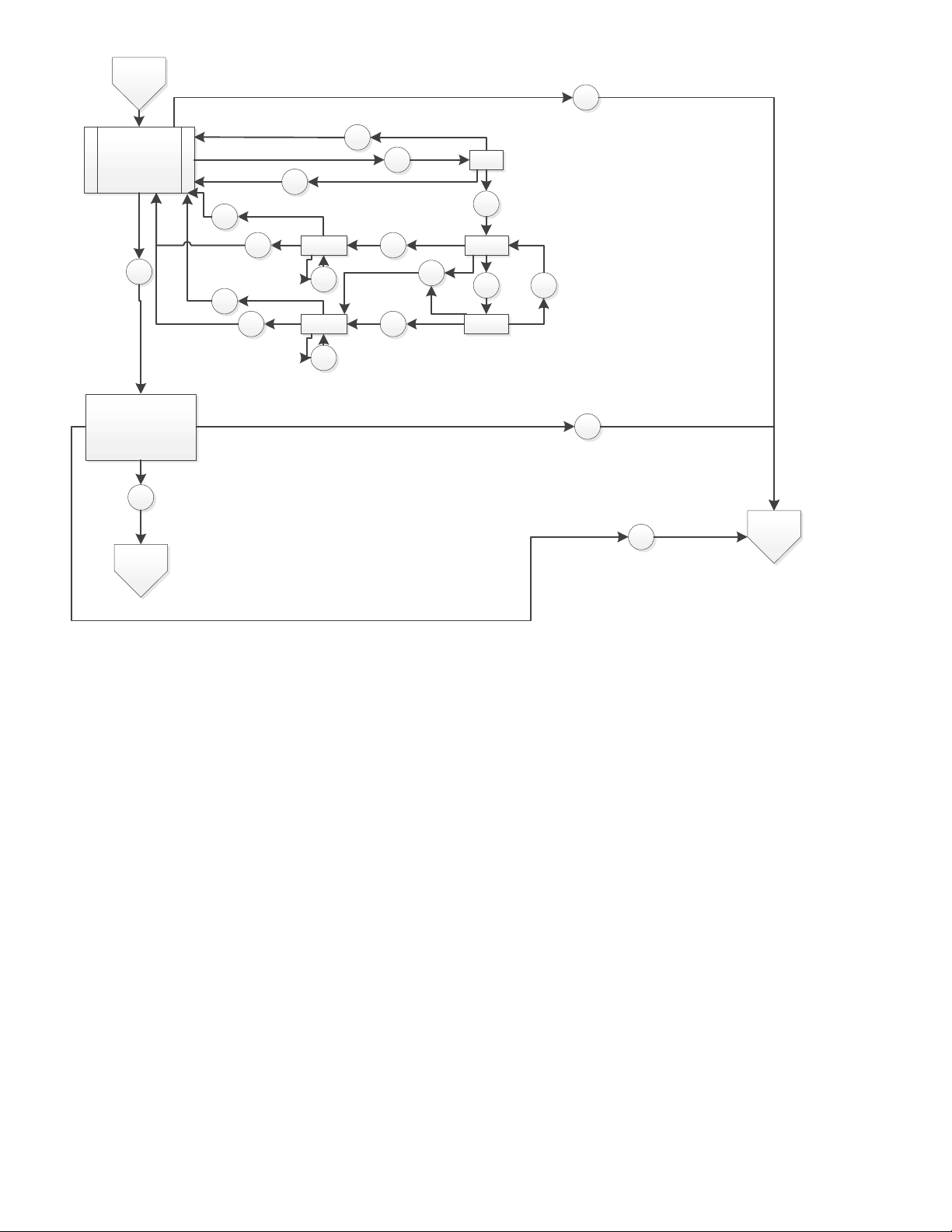

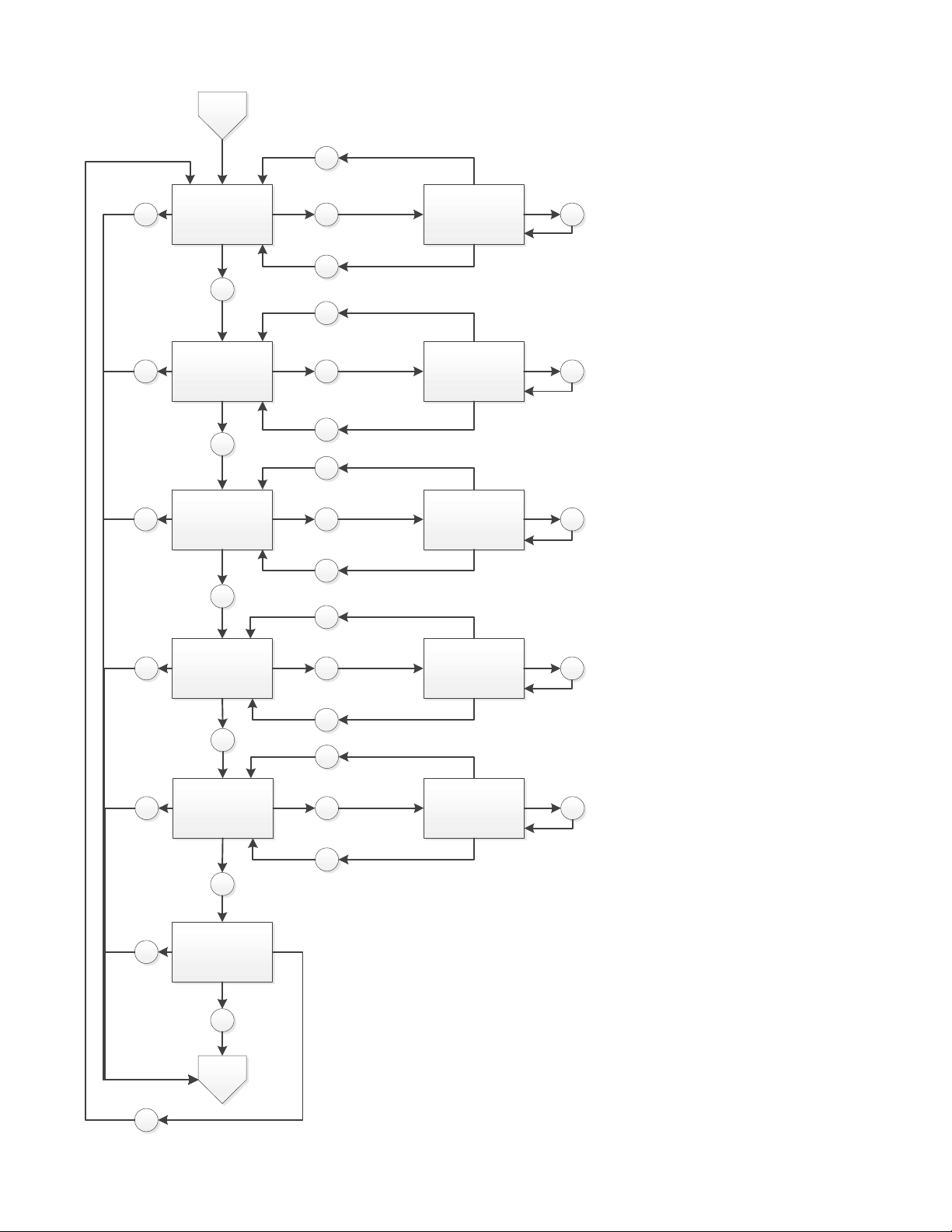

5 Appendix A – Menu Structure .................................................................................................................................................... 22

5.1 Main Menu .......................................................................................................................................................................... 22

5.2 Auto Test Menu “bUZ” ........................................................................................................................................................ 23

5.3 Configuration Menu “CON” ................................................................................................................................................. 24

5.4 Select Test Menu “tst” ......................................................................................................................................................... 30

5.5 CAL Menu * CD-6MC Only ................................................................................................................................................. 31

6 MACURCO PRODUCTS LIMITED WARRANTY ....................................................................................................................... 32

Technical Support Contact Information ............................................................................................................................................. 32

General Contact Information ............................................................................................................................................................. 32

3

Page 4

4

Page 5

1 GENERAL SAFETY INFORMATION

1.1 Intended Use

The Macurco CD-6H and CD-6MC are low voltage, dual relay Carbon Dioxide (CO2) detector, controller, and transducer. The CD-6”x”

has selectable 4-20 mA output, buzzer and digital display options. It is an electronic detection system used to measure the concentration

of Carbon Dioxide and provide feedback and automatic ventilation control to help reduce CO2 concentrations in conference rooms,

classrooms, meeting halls or similar applications. The CD-6”x” is a low-level meter capable of displaying from 0-5000 ppm (parts per

million) of Carbon dioxide. The CD-6”x” is factory calibrated and 100% tested for proper operation.

The CD-6H uses an automated background calibration program to set the clean air level on a regular basis.

The CD-6MC has the same setting and features of the CD-6H with the addition of being able to perform a manual calibration. The CD6MC requires a manual calibration process at a minimum of once per year using the Macurco CD6-FCK calibration kit.

1.2 List of Warnings and Cautions within these User Instructions

WARNING

Each person using this equipment must read and understand the information in these User Instructions before use. Use of this

equipment by untrained or unqualified persons or use that is not in accordance with these User Instructions, may adversely

affect product performance and result in serious injury or death.

Use only for monitoring the gas which the sensor and instrument are designed to monitor. Failure to do so may result in

exposures to gases not detectable and cause serious injury or death. For proper use, see supervisor or User Instructions,

or call Technical Support at 844-325-3050.

This equipment may not function effectively below 32°F or above 122°F (0°C or above 50°C). Using the detector outside of

this temperature range may adversely affect product performance and result in serious injury or death.

This detector helps monitor for the presence and concentration level of a certain specified airborne gas. Misuse may produce

an inaccurate reading, which means that higher levels of the gas being monitored may be present and could result in

overexposure and cause serious injury or death. For proper use, see supervisor or User Instructions, or call Technical

Support at 844-325-3050.

High voltage terminals (120/240 VAC) are located within this detector, presenting a hazard to service technicians. Only

qualified technicians should open the detector case and service the internal circuits. Ensure power is de-energized from the

detector relays prior to servicing the unit. Failure to do so may result in serious injury or death.

Do not disassemble unit or attempt to repair or modify any component of this instrument. This instrument contains no user

serviceable parts, and substitution of components may impair product performance and result in serious injury or death.

Using a certified gas with a concentration other than the one listed for this detector when conducting a calibration verification

test (bump test) will produce inaccurate readings. This means that higher levels of the gas being monitored may be present

and could result in overexposure and cause serious injury or death. For proper use, see supervisor or User Instructions, or

call Technical Support at 844-325-3050.

The following steps must be performed when conducting a calibration verification test (bump test) to ensure proper

performance of the monitor. Failure to do so may adversely affect product performance and result in serious injury or death.

When performing a calibration verification test (bump test) only use certified calibration gas at the required concentration level.

o Do not test with expired calibration gas.

o Do not cover or obstruct display or visual alarm cover.

o Ensure sensor inlets are unobstructed and are free of debris

5

Page 6

2 USER INSTRUCTIONS AND LIMITATIONS

WARNING

Each person using this equipment must read and understand the information in these User Instructions before use. Use of this

equipment by untrained or unqualified persons, or use that is not in accordance with these User Instructions, may adversely affect

product performance and result in sickness or death.

2.1 Use For

The CD-6”x” provides CO2 detection and automatic ventilation control for conference rooms, classrooms, meeting halls or similar

applications. Carbon dioxide is a colorless, odorless gas that is produced both by people exhaling CO2 as well the burning of gasoline,

coal, oil, and wood. The outdoor concentration of carbon dioxide can vary from 350-450 parts per million (ppm) or higher in areas with

high vehicle traffic or industrial activity. The indoor CO2 level depends upon the number of people present, how long an area has been

occupied, the amount of outdoor fresh air entering the area and other factors. CO2 concentrations indoors can vary several hundred parts

per million in areas with many people present for an extended period and where fresh air ventilation is limited. Outdoor "fresh" air

ventilation is important as it can dilute CO2 levels of the indoor environment. The amount of fresh air that should be supplied to a room

depends on the type of facility and room. Ventilation should keep carbon dioxide concentrations below 1000 ppm and create indoor air

quality conditions that are acceptable to most individuals.

For applications storing or using CO2 tanks, the detector will provide notification in the event of a gas leak. Such applications include but

are not limited to food storage, beverage dispensing, agriculture, fire suppression, medical, etc.

The CD-6H uses an automated background calibration program to set the clean air level on a regular basis. The CD-6H will maintain

accuracy if it is exposed to the “clean air reference value” (this reference value is the lowest concentration to which the sensor is exposed)

at least once per week.

The CD-6MC does not perform automated background calibrations and it is suggested to perform a Manual Calibration on the unit no

less than once per year using the Macurco CD6-FCK calibration kit.

Note: This applies when used in typical indoor ambient air. The CD-6”x” can be used stand alone, with the Macurco Detection

and Ventilation Control Panel, other 12 VAC or 24 VDC fire/security panels or building automation systems.

WARNING

Use only for monitoring the gas which the sensor and instrument are designed to monitor. Failure to do so may result in exposures to

gases not detectable and cause sickness or death. For proper use, see supervisor or User Instructions, or call Technical Support at

844-325-3050.

2.2 Do Not Use For

The CD-6”x” is not intended for use in hazardous locations or industrial applications such as refineries, chemical plants, etc. Do not mount

the CD-6”x” where the normal ambient temperature is below 32°F or exceeds 122°F (0°C or above 50°C). The CD-6”x” mounts on a

type 4S electrical box supplied by the contractor. Do not install the CD-6”x” inside another box unless it has good air flow through it.

WARNING

This equipment may not function effectively below 32°F or above 122°F (0°C or above 50°C). Using the detector outside of this

temperature range may adversely affect product performance and result in sickness or death.

2.3 General Description

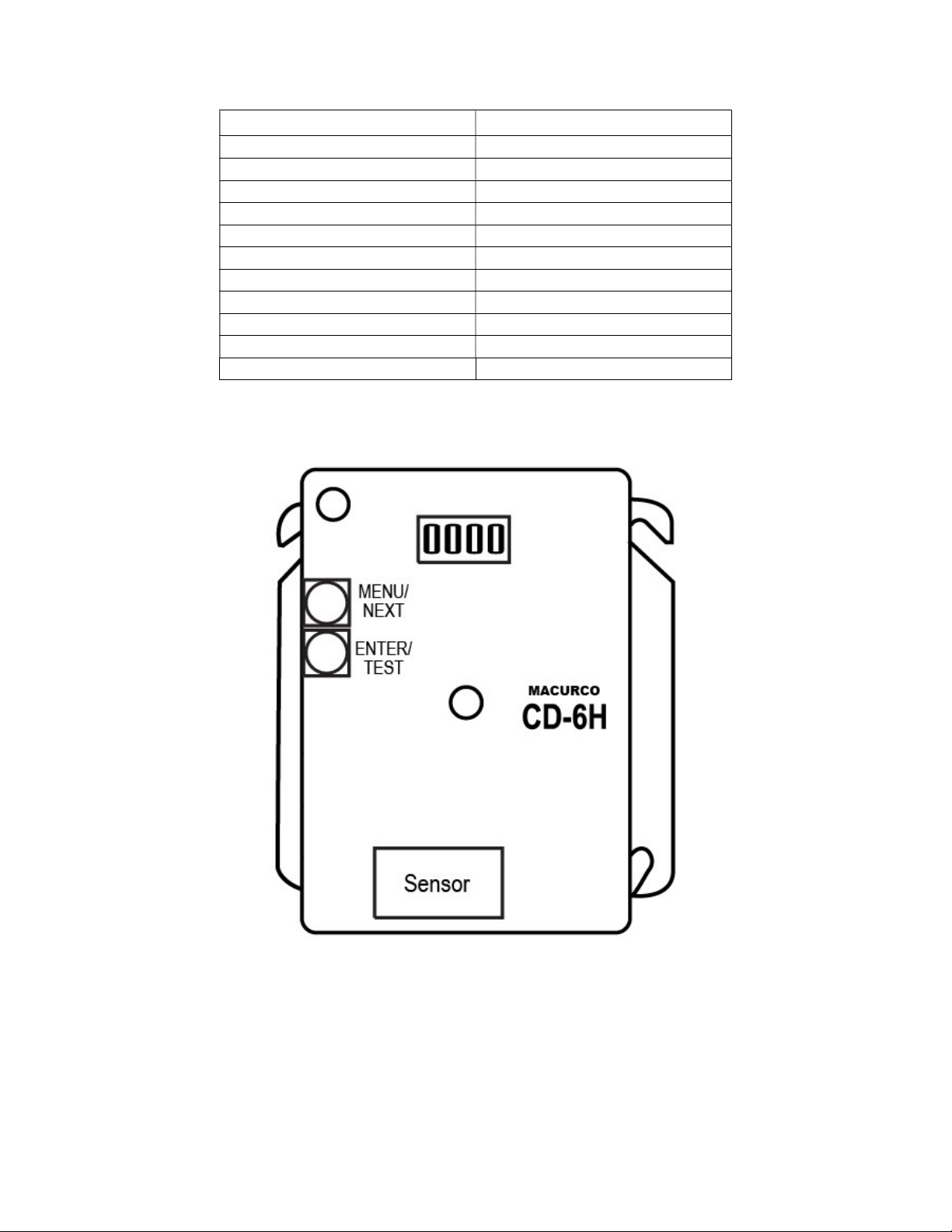

The CD-6H is a low voltage, dual relay Carbon Dioxide (CO2) detector, and automatic ventilation controller. The CD-6”x” uses a

microcomputer controlled, electronic system to measure the concentration of CO2, actuate relays and provide a 4-20 mA output. The

CD-6”x” has a low maintenance long life (15+ years) non-dispersive infrared (NDIR) sensor and optional gas test/calibration kits. The

CD-6”x” is a low-level meter capable of displaying from 0-5000 ppm of carbon dioxide.

6

Page 7

2.4 Features

ETL LISTED to UL 61010-1, Certified to CAN/CSA Std. C22.2 No 61010-1

Low level meter capable of displaying from 0-5000 ppm of CO2

Sensor Resolution of 50 PPM

The CD-6H uses an automated background calibration program to set the clean air level on a regular basis *

The CD-6MC uses a manual Calibration to set clean and polluted air levels using a Calibration Kit **

Selectable fan and alarm relay activation

5 A SPDT fan relay controls starters of ventilation

0.5 A N.O. or N.C. alarm relay connects to warning devices or control panels

4-20 mA Current Loop

Mounts on a standard 4x4 electrical box and becomes cover for the box

Supervised system: any internal detector problem will cause the fan & alarm relay to activate

Carbon Dioxide sensor has an expected 15-year life. EOL indicator after 180 months of sensor power-up

Calibration verification test kit is available. One screw allows access for gas test

*CD-6H Only

**CD-6MC Only

2.5 Specifications

Power: 3 W (max) from 12 to 24 VAC or 12 to 32 VDC

Current (max) @ 24 VDC: 126 mA in alarm (two relays), 108 mA (fan relay only) and 85 mA (standby)

Shipping Weight: 1 pound (0.45 kg)

Size: 4 1/2 x 4 x 2 1/8 in. (11.4 X 11.4 X 5.3 cm)

Color: White or dark gray

Connections: plugs/terminals

Mounting box: (not included) 4x4 electric

Fan relay: 5 A, 240 VAC, pilot duty, SPDT, latching or non-latching

Fan relay actuation: selectable at dIS (disabled), 600, 700, 800, 900, 1000 (default)…, 4800, 4900, 5000 ppm

Fan Delay Settings of 0, 1, 3 (default), 5 and 10 minutes

Fan Relay Minimum Runtime settings are 0 (default), 3, 5, 10 or 15 minutes

Fan relay latching or non-latching (default) selectable

Alarm relay: 0.5A 120 V, 60 VA

Alarm relay actuation: selectable N.O. (default) or N.C.

Alarm relay settings: “dIS” (disabled), 900, 1000, 1100, 1200, …4000(default), ….4900, 5000

Current Loop, 4-20 mA for 0-5000 ppm CO2, selectable to off or on (default)

Buzzer: 85 dBA at 10cm settable to off or on (default)

Digital display: 4-digit LED selectable to off or on (default).

Operating Environment: 32°F to 122° F (0°C to 50°C), 10 to 90% RH non-condensing

7

Page 8

3 INSTALLATION AND OPERATING INSTRUCTIONS

The following instructions are intended to serve as a general guideline for the use of the Macurco CD-6H / CD-6MC Carbon Dioxide

Detector. It is not to be considered all-inclusive, nor is it intended to replace the policy and procedures for each facility. If you have any

doubts about the applicability of the equipment to your situation, consult an industrial hygienist or call Technical Support at 844-325-

3050.

WARNING

This detector helps monitor for the presence and concentration level of a certain specified airborne gas. Misuse may produce an

inaccurate reading, which means that higher levels of the gas being monitored may be present and could result in overexposure and

cause serious injury or death. For proper use, see supervisor or User Instructions, or call Technical Support at 844-325-3050.

3.1 Location

Mounting height will be dependent on the application. For applications with CO2 tanks, mount height should be about one foot above the

floor. For indoor air quality mount detector at breathing level, about 5 feet (1.5 meters) above the floor on a wall or column in a central

area where air movement is generally good. The unit, on average, can cover about 5,000 sq. ft. (465 sq. meters). The coverage depends

on air movement within the room or facility. Extra detectors may be needed near any areas where people work or where the air is

stagnant. The CD-6”x” mounts on a 4x4 electrical box supplied by the contractor. Do not install the CD-6”x” inside another box unless it

has good air flow through it. Do NOT mount the CD-6”x” where the normal ambient temperature is below 32°F or exceeds 122°F (below

0°C or above 50°C).

WARNING

High voltage terminals (120/240 VAC) are located within this detector, presenting a hazard to service technicians. Only qualified

technicians should open the detector case and service the internal circuits. Ensure power is removed from the detector relays prior to

servicing the unit. Failure to do so may result in serious injury or death.

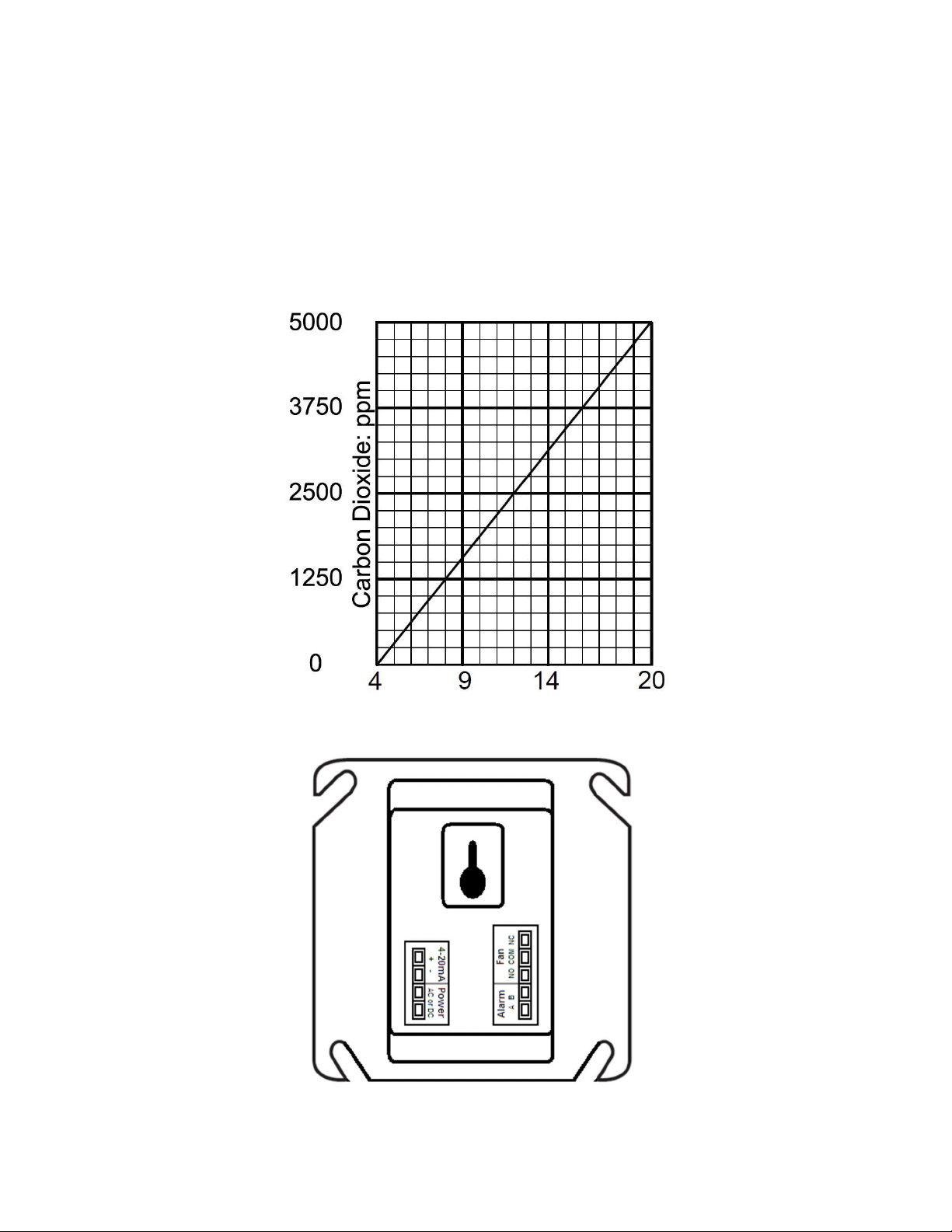

3.2 Installation

1. The CD-6”x” mounts on a 4” square (or 4x4) electrical box supplied by the contractor. Do not mount the CD-6”x” inside

another box, unless it has good air flow through it.

2. Connect the CD-6”x” to Class 2 power supply only. It is suggested to use a dedicated transformer for powering the unit or

units because of possible interferences from other devices on the same power supply.

3. Connect the CD-6”x’ to the control cables with terminal plugs. When making connections, make sure the power is deenergized.

4. There are two terminals for Power: 12 to 24 VAC or 12 to 32 VDC, with no polarity preference.

5. There are two terminals for the dry alarm relay contacts, again with no polarity preference. The alarm relay can switch up to

0.5 A 120 V, or 60 VA. The alarm relay is activated if gas reaches or exceeds the alarm settings. See section 3.4

OPERATION of these User Instructions for details on relay settings.

6. The alarm relay can be configured to normally open (default) (N.O.) or normally closed (N.C.) and will activate if the gas

concentration exceeds alarm set point. It will deactivate once the gas concentration drops below the alarm set point. Note that

the “disable” setting will cause the alarm relay not to engage at all.

7. The dry contact, SPDT fan relay has three terminals. The common (COM.), normally open (N.O.) and the normally closed

(N.C.) contact. The fan relay can switch up to 5.0 A up to 240 VAC. See section 3.4 OPERATION of these User Instructions

for details on relay settings.

8. The Fan Relay can be configured for latching or non-latching (default) when activated (when the gas concentration exceeds

fan relay setpoint). Once latched in, power will need to be interrupted or the “TEST” button pressed to un-latch the relay

condition.

8

Page 9

9. The Fan Relay will engage if the fan setting Carbon Dioxide concentration is exceeded for longer than the Fan Relay Delay

time. Unless it is configured for latching, the fan relay will disengage once both conditions have been met:

Carbon Dioxide concentration has dropped below fan setting

Fan Relay Runtime has been exceeded

Note that the “disable” fan setting will cause the fan relay to not engage. The fan relay will engage in trouble fault condition (if

the Trouble Fan Setting Option is set to “ON”) and will disengage once trouble fault condition is cleared.

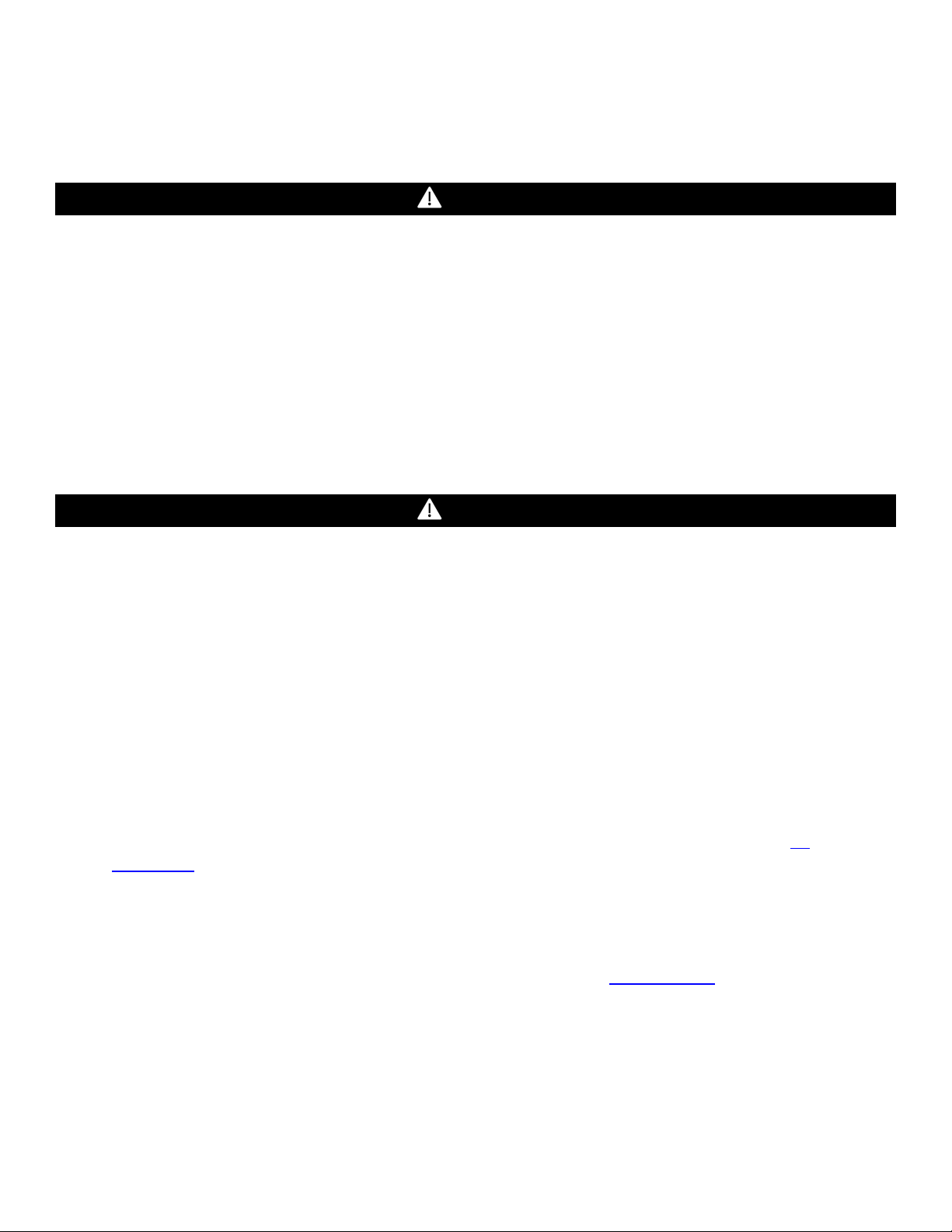

10. The Current Loop is 4 mA in clean air and 4-20 mA for 0-5000 ppm CO2

3.2.1 4-20mA graph

3.2.2 Rear view

9

Page 10

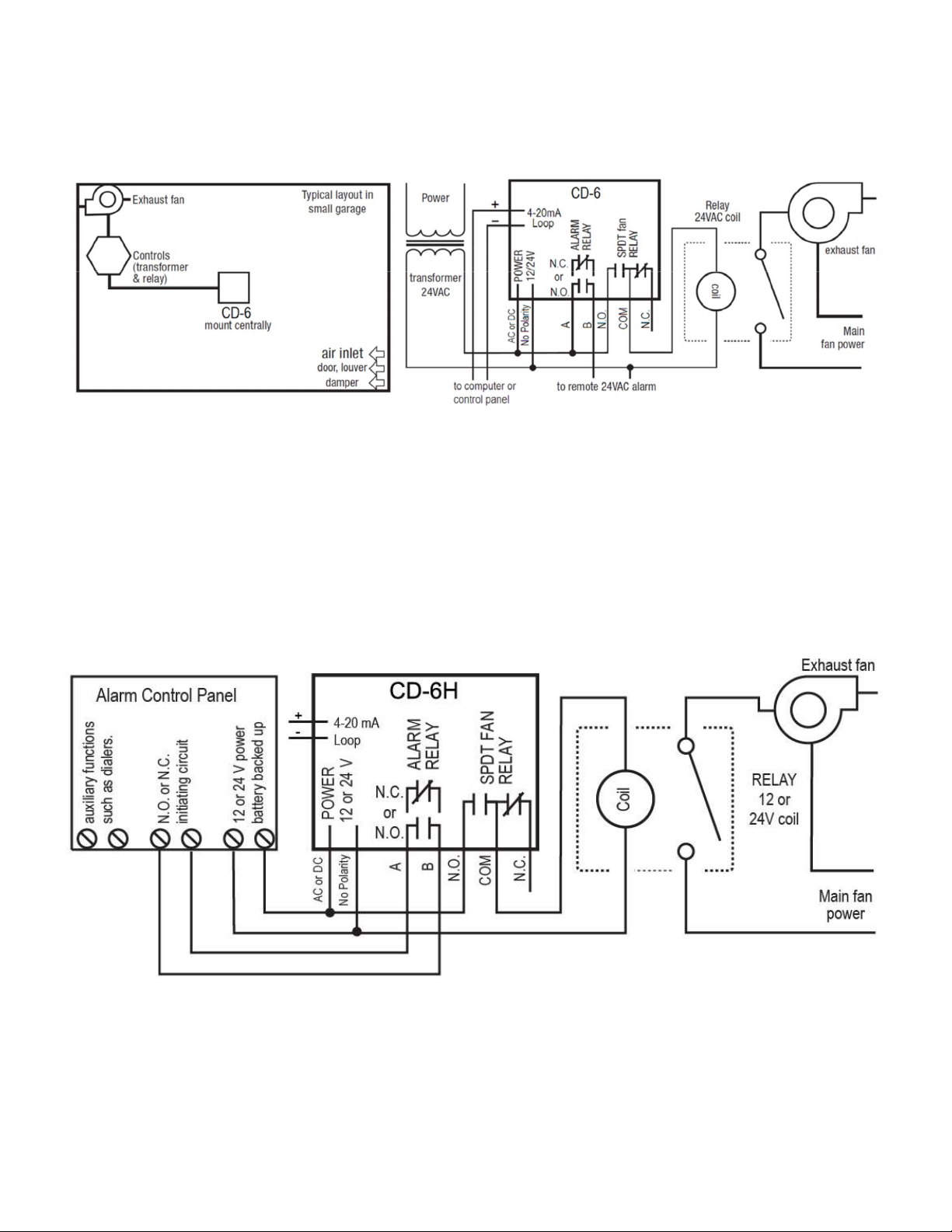

3.2.3 Typical Installation in a room

3.2.4 Use with Alarm Panel

10

Page 11

3.2.5 Multiple CD-6 Installation

3.2.6 DVP-120 Control Panel Connection

11

Page 12

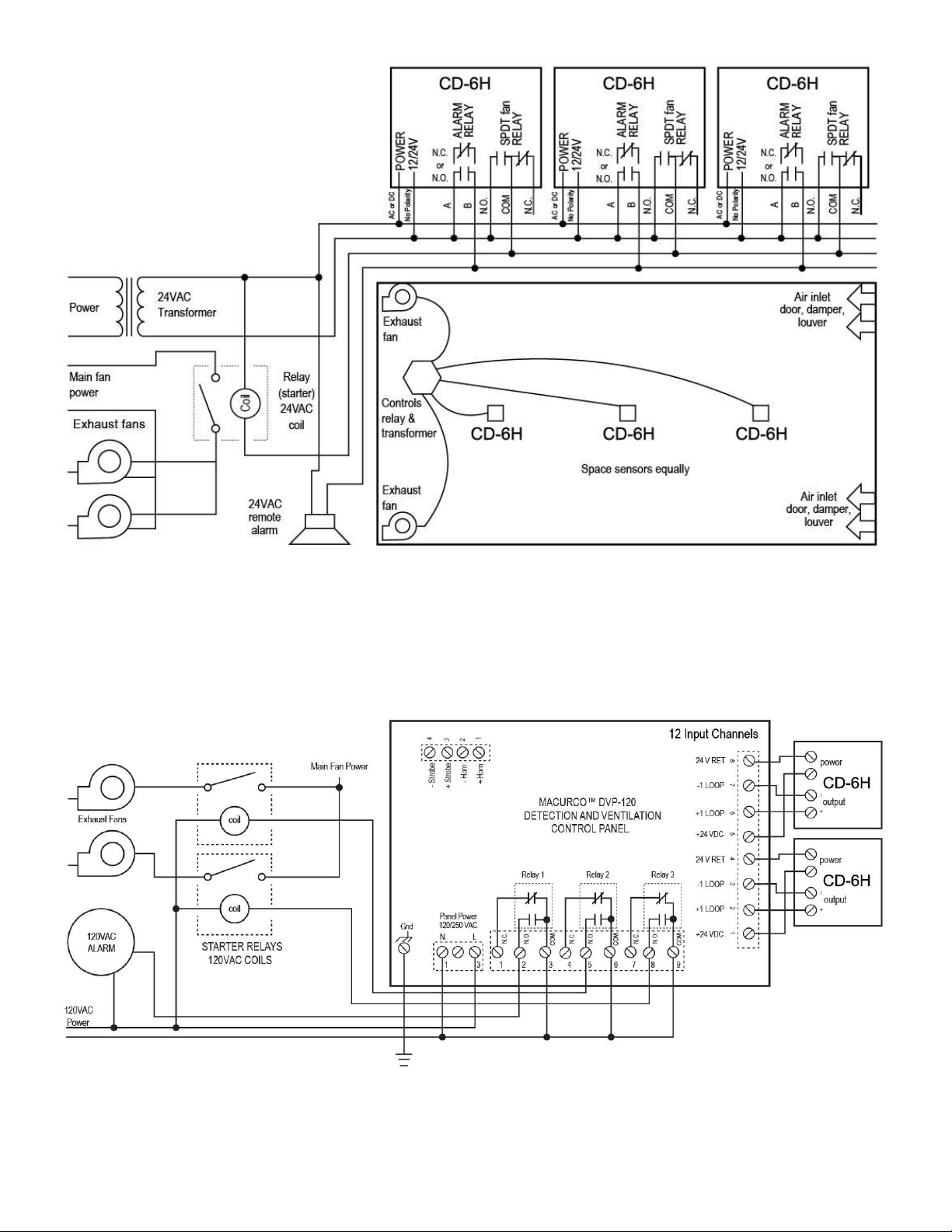

3.2.7 Alternate connection to the alarm panel

In this application (3.2.7 Alternate connection to alarm panel) the Fan or primary relay is used as a low-level alarm relay. The Alarm or

secondary relay is used as a supervisory relay when utilized in the normally closed configuration. The CD-6”x” monitors all critical

functions of the unit through software diagnostics that continually test and verify its operations. If a problem is found, the unit will switch

to a fail-safe/error mode or trouble condition. In this error mode, the Fan* and Alarm relays will be activated indicating the trouble condition

at the panel and the CD-6”x display will flash the error. *See the Trouble Fan Setting Option.

3.3 Power Up

The CD-6”x” cycles through an internal self-test cycle for the first minute that it is powered. The unit will execute the test cycle any time

power is de-energized and re-energized (i.e. power failure). During the self-test cycle, the unit will display the firmware version number,

then

count down from 60 to 0 (if the display setting is “On”) and finally go into normal operation. The alarm relay will be activated for 10

seconds and the fan relay for 60 seconds during the power-up cycle unless the “Power Up Test” (PUt) option is OFF. The indicator light

(LED) will flash green during the self-test cycle. At the end of the 1-minute cycle, the unit will take its first sample of the air and the

indicator light will turn solid green.

3.4 Operation

1. With the display function turned “On”, the CD-6”x” will show the current concentration of CO2 ppm in the air. Normal outdoor

concentration ranges between 350-450 ppm. When the CO2 concentration reaches the Fan Relay setting (2000ppm, for

example) the display will flash back and forth between “FAn” and “2000”. With the display function turned “Off”, the display

does not show the CO2 concentration but will show “FAn” as long as the fan relay is activated.

2. With the display function turned “On” and the CO2 concentration reaching the Alarm Relay setting, (4000 ppm, for example)

the display will flash back and forth between “ALr” and “4000”. The buzzer will sound indicating “Alarm” if the buzzer is turned

“On”. With the display function turned off the display does not show the CO2 concentration, but will show “ALr” when the Alarm

relay is activated.

3. With the 4-20 mA function turned “On” and the CO2 concentration climbing, the 4-20 mA signal will ramp up corresponding to

the concentration (0-5000 ppm, for example). The display will show “FAn” and “ALr” and sound as outlined above.

12

Page 13

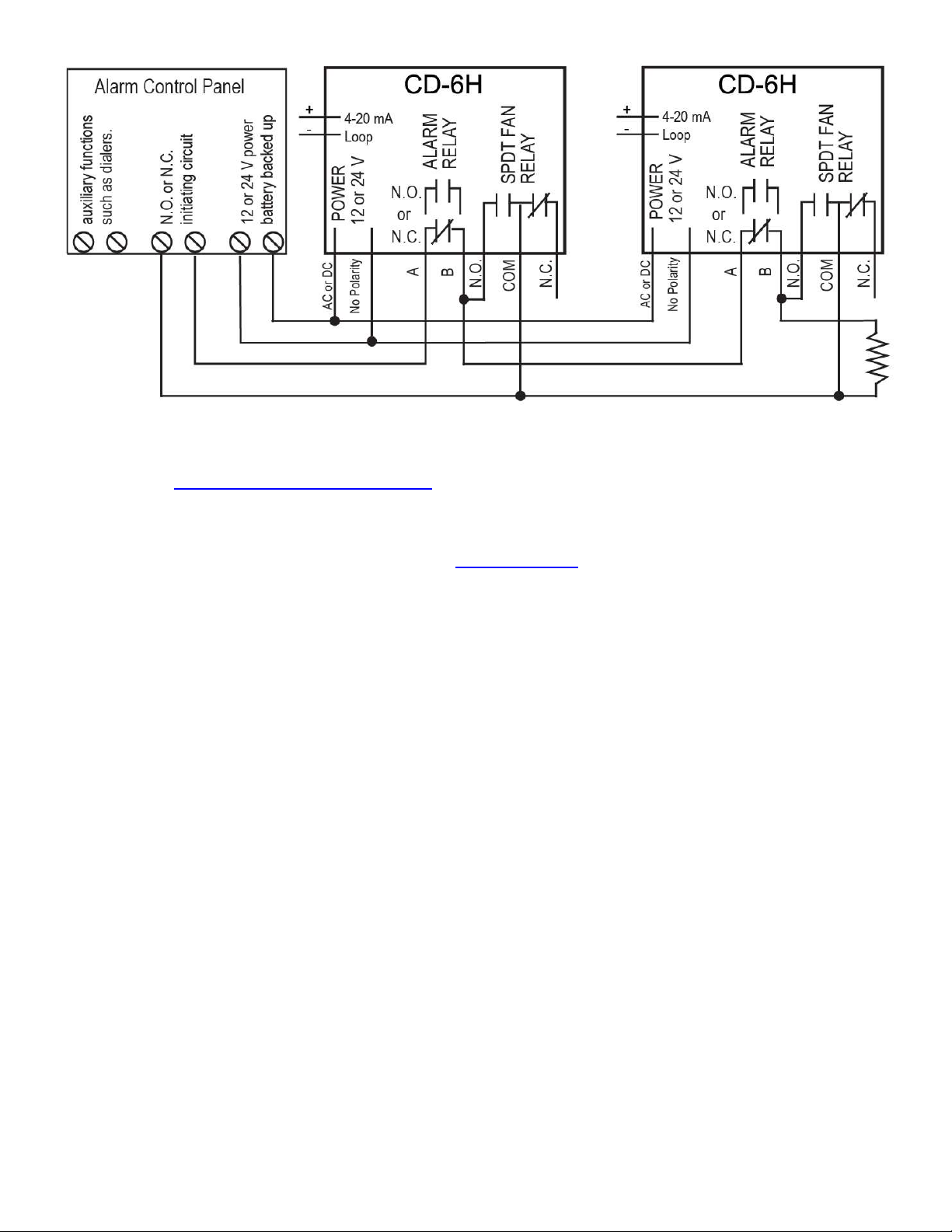

3.5 Default Configuration – Factory Settings

Setting:

Default:

Power Up Test

On

Display

On

Buzzer

On

Alarm Relay Setting

4000 ppm

Alarm Relay Configuration

Normally Open (NO)

Fan Relay Settin

g 1000

ppm

Fan Relay Delay

3 minutes

Fan Relay Minimum Runtime

0 minutes

Fan Relay Latching

Off

Trouble Fan Setting

Off

4-20mA

On

To change settings, remove the Philips screw on the front of the CD-6”x”. Pull off the front cover of the unit.

3.5.1 Selecting Default Configuration – “dEF”

To select the Default Configuration, in normal mode, push the Next button to get to “Con” or the Configuration menu. Then push the

Enter button to enter the Con menu. The first selection is the “dEF” or Default setting. Push Enter. If it is already in Default

configuration, there will be no action. If it is not already in Default configuration, “nO” will be displayed. Push Next to change it to “YES”

(flashing) then push Enter to confirm the change (solid) and push Enter again to return to “dEF” in the con menu. Push Next until “End”

is displayed then push Enter to get back to normal operation.

13

Page 14

3.5.2 Selecting Power Up Test Option – “PUt”

To select the Power Up Test Configuration, in normal mode, push the Next button to get to “Con” or the Configuration menu. Then

push the Enter button to enter the Con menu. Then push the Next button to get to the second selection “PUt” or Power Up Test

setting. Push Enter. If the test is “On” push Next to turn it “OFF” (flashing) then push Enter to confirm the change (solid) and push

Enter again to return to “PUt” in the Con menu. Push Next until “End” is displayed then push Enter to get back to normal operation.

3.5.3 Selecting Display Option – “dSP”

To select the Display Configuration, in normal mode, push the Next button to get to “Con” or the Configuration menu. Then push the

Enter button to enter the Con menu. Then push the Next button to get to the third selection “dSP” or Display setting. Push Enter. If

the display is “On” push Next to turn it “OFF” (flashing) then push Enter to confirm the change (solid) and push Enter again to return to

“dSP” in the Con menu. Push Next until “End” is displayed then push Enter to get back to normal operation.

3.5.4 Selecting Buzzer Option – “bUZ”

To select the Buzzer Configuration, in normal mode, push the Next button to get to “Con” or the Configuration menu. Then push the

Enter button to enter the Con menu. The fourth selection is the “bUZ” or Buzzer setting. Push Next twice to get to “bUZ” then Enter. If

the display is “On” push Next to turn it “OFF” (flashing) then push Enter to confirm the change (solid) and push Enter again to return to

“bUZ” in the Con menu. Push Next until “End” is displayed then push Enter to get back to normal operation.

3.5.5 Selecting Alarm Relay Setting – “ArS”

To select the Alarm Relay Setting, in normal mode, push the Next button to get to “Con” or the Configuration menu. Then push the

Enter button to enter the Con menu. The fifth selection is the “ArS” or Alarm Relay Setting. Push Next three times to get to “ArS” then

Enter. If the display is “dIS” (disabled) push Next to change it to 900, 1000, 1100, 1200, …, 4000 (default), 4800, 4900, 5000 ppm

(flashing) then push Enter to confirm the change (solid) and push Enter again to return to “ArS” in the Con menu. Push Next until “End”

is displayed then push Enter to get back to normal operation.

3.5.6 Selecting Alarm Relay Configuration – “Arc”

To select the Alarm Relay Configuration, in normal mode, push the Next button to get to “Con” or the Configuration menu. Then push

the Enter button to enter the Con menu. The sixth selection is the “Arc” or Alarm Relay Configuration. Push Next four times to get to

“Arc” then Enter. If the relay is “nO” (normally open) push Next to turn it to “nC” (flashing) then push Enter to confirm the change (solid)

and push Enter again to return to “Arc” in the Con menu. Push Next until “End” is displayed then push Enter to get back to normal

operation.

3.5.7 Selecting Fan Relay Settings – “FrS”

To select the Fan Relay setting, in normal mode, push the Next button to get to “Con” or the Configuration menu. Then push the Enter

button to enter the Con menu. The seventh selection is the “FrS” or Fan Relay setting. Push Next five times to get to “FrS” then

Enter. If the fan relay is “dIS” (disabled) push Next to change it to 600, 700, 800, 900…, 2000 (default)…, 4800, 4900, 5000 ppm (flashing)

then push Enter to confirm the change (solid) and push Enter again to return to “FrS” in the Con menu. Push Next until

“End” is displayed then push Enter to get back to normal operation.

3.5.8 Selecting Fan Relay Delay – “Frd”

To select the Fan Relay Delay setting, in normal mode, push the Next button to get to “Con” or the Configuration menu. Then push the

Enter button to enter the Con menu. The eighth selection is the “Frd” or Fan Relay Delay. Push Next six times to get to “Frd” then

Enter. If the delay is “0” (disabled) push Next to change it to 1, 3, 5, or 10 minutes (flashing) then push Enter to confirm the change

(solid) and push Enter again to return to “Frd” in the Con menu. Push Next until “End” is displayed then push Enter to get back to

normal operation.

14

Page 15

3.5.9 Selecting Fan Relay Minimum Runtime – “Frr”

To select the Fan Relay Minimum Runtime setting, in normal mode, push the Next button to get to “Con” or the Configuration menu.

Then push the Enter button to enter the Con menu. The ninth selection is the “Frr” or Fan Minimum Run Time. Push Next seven

times to get to “Frr” then Enter. If the runtime is “0” (disabled) push Next to change it to 3, 5, 10 or 15 minutes (flashing) then push

Enter to confirm the change (solid) and push Enter again to return to “Frr” in the Con menu. Push Next until “End” is displayed then

push Enter to get back to normal operation.

3.5.10 Selecting Fan Relay Latching Option – “FrL”

To select the Fan Relay Latching Option, in normal mode, push the Next button to get to “Con” or the Configuration menu. Then push

the Enter button to enter the Con menu. The tenth selection is the “FrL” or Fan Relay Latching Option. Push Next nine times to get to

“FrL” then Enter. If latching is “OFF” push Next to turn it to “ON” (flashing) then push Enter to confirm the change (solid) and push

Enter again to return to “FrL” in the Con menu. Push Next until “End” is displayed then push Enter to get back to normal operation.

3.5.11 Selecting Trouble Fan Setting Option – “tFS”

To select the Trouble Fan Setting Option, in normal mode, push the Next button to get to “Con” or the Configuration menu. Then

push the Enter button to enter the Con menu. The eleventh selection is the “tFS” or Trouble Fan Setting Option. Push Next ten times

to get to “tFS” then Enter. If Trouble Fan Setting is “OFF” push Next to turn it to “ON” (flashing) then push Enter to confirm the change

(solid) and push Enter again to return to “tFS” in the Con menu. Push Next until “End” is displayed then push Enter to get back to

normal operation.

3.5.12 Selecting 4-20mA Output Option – “420”

To select the 4-20mA Output Option, in normal mode, push the Next button to get to “Con” or the Configuration menu. Then push the

Enter button to enter the Con menu. The twelfth selection is the “420” or 4-20mA Output Option. Push Next eleven times to get to

“420” then Enter. If the 4-20mA is “On” push Next to turn it to “OFF” (flashing) then push Enter to confirm the change (solid) and push

Enter again to return to “420” in the Con menu. Push Next until “End” is displayed then push Enter to get back to normal operation.

3.6 Onboard Diagnostics

The CD-6”x” monitors all critical functions of the unit through software diagnostics that continuously test and verify unit operations. If a

problem is found, the unit will switch to a fail-safe/error mode or trouble condition. In this error mode, the Alarm relay will be activated,

the 4-20 mA current loop will go to 24 mA, the unit will display the error code, the green status indicator LED light will flash and the

buzzer will chirp intermittently. The Fan relay will also engage if the Trouble Fan Setting Option is set to “ON”. This is a safety

precaution. To clear this mode, simply turn off power to the unit for a few seconds or push the ENTER/TEST switch (inside the unit).

This will cause the unit to restart the 1-minute self-test cycle.

The 4-20 mA signal can be used for troubleshooting:

0 mA is most likely a connection problem

4-20 mA is normal gas reading range (0-5000 ppm)

24 mA indicates a Trouble condition

Error Codes

t001 - Trouble with the sensor signal

t002 - Temperature compensation failed

t004 - EEPROM bad checksum

t008 - IR lamp trouble

t010 - Bad EEPROM

t020 - Bad calibration

t040 - Factory calibration failure

t080 - ADC trouble

t100 - Under range

15

Page 16

t200 - Sensor expired

t400 - Pressure sensor trouble

t800 - PCBA not tested

If the error mode repeats frequently, check for continuous power and proper voltage. If power is not the problem and a unit has

repeating error conditions, it may need to be returned to Macurco for service, per these User Instructions.

If the error mode indicates “Sensor expired” see section 4.1 End-of-life Signal of these User Instructions.

4 Maintenance

The CD-6”x” is low maintenance. The unit uses a long life NDIR sensor that has a 15-year life expectancy (in normal conditions). The

CD-6H uses an automated background calibration program to set the clean air level on a regular basis. The CD-6H will maintain accuracy

if it is exposed to the “clean air reference value” (this reference value is the lowest concentration to which the sensor is exposed) at

least once per week.

Note: This applies when used in the typical indoor ambient air with weekly unoccupied periods.

All maintenance and repair of products manufactured by Macurco are to be performed at the appropriate Macurco manufacturing facility.

Macurco does not sanction any third-party repair facilities.

Note: There is not a field calibration procedure for the Macurco CD-6H.

4.1 End-of-life Signal

The CD-6”x” has a long life, the non-replaceable infrared sensor (IR Sensor). Fifteen (15) years after the CD-6”x” is installed the sensor

end-of-life signal will be activated indicating that the CD-6”x” has reached the end of its typical usable life. The end-of-life signal will cause

an error code t200 “Sensor expired”. See section 3.6.2 Error Codes. The end-of-life signal can be silenced for 48 hours by pressing the

"ENTER/TEST" button or by temporarily dropping power to the unit. The end-of-life signal provides the user an opportunity to test and/or

calibrate the sensor (CD-6MC only) assuring that it is still performing within acceptable parameters though the sensor is nearing the end

of its expected life. The silence function will continue to be available for 29 days after the CD-6”x” initiates the initial end-of-life signal.

After this 29-day period, the CD-6”x” can no longer be silenced and the unit must be replaced.

WARNING

Do not disassemble unit or attempt to repair or modify any component of this instrument. This instrument contains no user serviceable

parts and substitution of components may impair intrinsic safety, which may adversely affect product performance and result in

sickness or death.

CAUTION

Avoid the use of harsh cleaning materials, abrasives and other organic solvents. Such materials may permanently scratch the surfaces

and damage the display window, labels, sensor or instrument housing. High voltage terminals (100-240VAC) are located within this

detector, presenting a hazard to service technicians. Only qualified technicians should open the detector case and service the internal

circuits. Ensure power is removed from the detector prior to cleaning the unit. Failure to do so may result in serious injury or death.

4.2 Cleaning

Cleaning of the external surfaces is best carried out using a damp cloth with a mild detergent or soap. Use a vacuum cleaner with a soft

brush to remove dust or contamination under the cover. Do not blow out the sensor with compressed air.

16

Page 17

4.3 Testing

WARNING

Using a certified gas with a concentration other than the one listed for this detector when conducting a calibration verification test (bump

test) will produce inaccurate readings. This means that higher levels of the gas being monitored may be present and could result in

overexposure and cause sickness or death. For proper use, see supervisor or User Instructions, or call Technical Support at

844-325-3050

All CD-6”x” units are factory calibrated and 100% tested for proper operation. During normal operation, the green status indicator LED

light will be on steady, the fan & alarm relay will be in standby mode and the 4-20 mA output will be at 4mA (in clean air). The unit also

performs a regular automatic self-test during normal operation. If the unit detects an improper voltage or inoperable component, it will

default into Error mode. In this error mode, the Alarm relay will be activated, the 4-20 mA current loop will go to 24 mA, the unit will

display the error code, the green status indicator LED light will flash, and the buzzer will chirp intermittently. The Fan relay will also

engage if the Trouble Fan Setting Option is set to “ON”.

4.3.1 Operation Test

Check that the green CD-6”x” status indicator LED light is illuminated continuously. If not, do not proceed with the tests. If the unit is in

error mode, contact your local representative or Macurco technical support representative for information on resolving the problem.

1. Remove the single screw in the middle of the front cover of the CD-6”x”.

2. Remove the front cover.

3. Observe the LED light on the front of the CD-6”x”.

4. If the light is solid green proceed to step 6.

5. If the green status indicator LED light is off or flashing, refer to the General section above.

6. Locate the switch labeled ENTER/TEST on the left side of the printed circuit board. Press the Test switch once.

7. The CD-6”x” will step through a cycle test:

a. The display progresses through the BUZ (Buzzer Test), Art (alarm relay test), Frt (fan relay test) then 42t (4-20 mA

output test). Make sure that the settings are “on” or not disabled “diS”.

b. During the first 10 seconds of the test cycle, the display will show BUZ and set off the audible buzzer

c. The alarm relay will be closed, so any devices connected to that relay will be tested.

d. The Fan relay will be activated for the next 1 minute of the test, so if the fan circuits are wired in the normal manner,

the fan should run.

e. The 4-20mA output will then ramp up from 4 to 16 mA over the next 130 seconds of the test, so if the circuit is wired

in the normal manner, the control panel or building automation system should respond.

f. At the end of the test cycle, the light will turn green and be on steady (Normal Operation), the fan & alarm relay will

be in standby mode and the 4-20 mA output will return to 4 mA (in clean air).

8. When testing is completed reassemble the unit or units.

4.3.2 Manual Operation Test

This option gives the user the opportunity to manually initiate an individual test for each relay, the analog output and the sensor response

to gas.

From normal operation mode press the Next button 2 times to get to the Test Mode (tSt).

Press the Enter button once to get into the Test Menu.

Press the Next button to scroll through the Five test options and press Enter to initiate the selected test.

Note that if the relay or 4–20 mA output has been disabled, the test selection will not be displayed in the test menu.

bUZ- Buzzer Test, 3 seconds

Art - Alarm Relay Test, 5 seconds

Frt - Fan Relay Test, 60 seconds

42t - 420 loop test, 130 seconds

17

Page 18

gtS - Gas Test, 3 minutes (no output to the panel during the gas test)

The display will flash during the test, or in the case of the gas test, the gas level will alternate with gtS. Once the test is complete, the

display will return to a steady display. To exit the test menu, press the Next button until “End” is displayed then, press Enter to return to

normal mode.

4.3.3 Carbon Dioxide Gas Test

WARNING

The following steps must be performed when conducting a calibration verification test (bump test) to ensure proper performance of the

monitor. Failure to do so may adversely affect product performance and result in serious injury or death.

When performing a calibration verification test (bump test) only use certified calibration gas at the required concentration level.

Do not test with expired calibration gas.

If the instrument cannot be calibrated, do not use until the reason can be determined and corrected.

Do not cover or obstruct display or visual alarm cover.

Ensure sensor inlets are unobstructed and are free of debris.

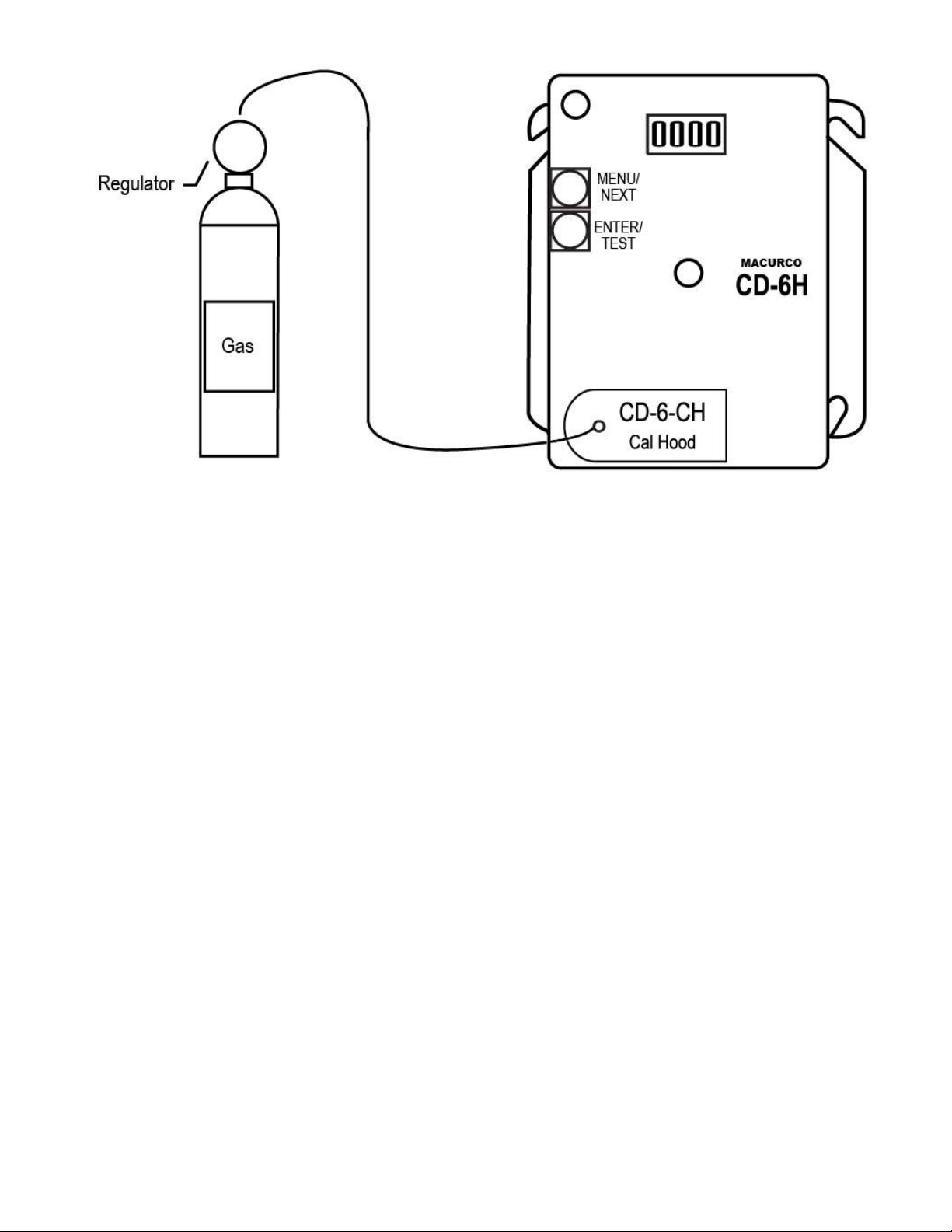

4.3.4 Field Calibration Kit – CD6-FCK

A Field Calibration Kit, CD6-FCK, is needed to complete a CO2 gas test. These are available through local distribution.

CD6-FCK: (2) Gas Cylinders

o (1) 34L 400ppm carbon dioxide (CO2) in air

o (1) 34L 5000ppm carbon dioxide (CO2) in air

Gas regulator 0.2 LPM

About two feet of tubing

CD-6-TH calibration hood

4.3.5 FCK Information

Several detectors can be calibrated with one FCK. The only limitation is the amount of gas in the cylinder. The 34-liter cylinder has

approximately 175 minutes of a continuous test run time. Replacement cylinders are available. The gas cylinder should be replaced when

the pressure gauge on the regulator shows 25-psi or less or has reached its expiration date.

Note: For optimum test results it is suggested that the unit be in clean air, green light on, and be in a low ambient air flow.

4.4 Gas Testing

4.4.1 Testing the Fan Relay

1. Remove the Philips screw on the front of the CD-6”x”. Remove the front cover.

2. Open the FCK. Connect the 5000-ppm gas cylinder to the regulator.

3. Check the pressure gauge on the regulator. If you have 25-psi or less you will need to replace the gas canister. Check the

expiration date on the cylinder, if it has passed the expiration date the cylinder should be replaced.

4. Assemble regulator, hose, and Test Hood and place the Test Hood over the CO2 sensor.

Note: The time to activate the Fan relay depends on the delay setting. See section 3.5.8 Selecting Fan Relay Delay

18

Page 19

5. Turn on the regulator to start the gas flow and wait with the gas applied continuously.

6. With the display function turned “On”, the CD-6”x” will show the current concentration of CO2 in the air. When the CO2

concentration reaches the Fan Relay setting (2000 ppm, for example) the display will flash back and forth between “FAn” and

“2000”. With the display function turned ”Off”, the display does not show the CO2 concentration but will show “FAn” as long as

the fan relay is activated.

Note: If the Fan relay does not close within 2 minutes, there are five possibilities:

a. The gas cylinder is empty, check the pressure gauge. Replace the gas cylinder if 25psi or less.

b. Gas cylinder has reached its expiration date. Replace the gas cylinder.

c. Unit needs to be re-calibrated (automated background calibration for CD-6H, Manual Calibration for CD-6MC) then

re-test. The detector is in need of servicing (contact Technical Support for at 844-325-3050 servicing options).

a. The detector has fan relay set to disable (diS). Set fan relay to 2000 ppm and repeat the test.

b. The detector has fan relay delay set to 3 minutes. Set fan relay delay to 0 and repeat the test.

7. Remove the gas from the sensor. Proceed to Test the Alarm relay or replace the top cover.

4.4.2 Testing the Alarm Relay

Note: The CO2 concentration to activate the Alarm relay depends on the setting.

1. Connect the 5000-ppm cylinder of carbon dioxide to the regulator.

2. Check the pressure gauge on the regulator. If you have 25-psi or less, you will need to replace the gas canister. Check the

expiration date on the cylinder, if it has passed the expiration date the cylinder should be replaced.

3. Place the Test Hood over the CO2 sensor. Turn on the regulator to start the gas flow.

4. The Fan relay should activate according to the settings.

5. With the display function turned “On” and the CO2 concentration reaching the Alarm Relay setting, (4000 ppm, for example)

the display will flash back and forth between “ALr” and “4000”. The buzzer will sound indicating “Alarm” if the buzzer is turned

“On”. With the display function turned off the display does not show the CO2 concentration, but will show “ALr” when the Alarm

relay is activated.

Note: If the Alarm relay fails to operate within 2 minutes, there are four possibilities:

a. The gas cylinder is empty, check the pressure gauge. Replace the gas cylinder if 25-psi or less.

b. Unit needs to be re-calibrated (automated background calibration and re-test).

19

Page 20

c. The detector is in need of servicing (return unit to the factory for servicing).

d. The detector has Alarm relay set to disable (diS). Set Alarm relay to 4000 ppm and repeat the test.

6. Remove the gas from the sensor after Test. Proceed to Test the 4-20mA output or replace the top cover.

4.4.3 Testing the 4-20mA current loop

1. Connect the 5000-ppm cylinder of carbon dioxide to the regulator.

2. Check the pressure gauge. If there is 25-psi or less the cylinder should be replaced.

3. Place the cap from the regulator over the CO2 sensor. Turn on the regulator to start the gas flow.

4. The Fan relay should activate according to the settings.

5. The Alarm relay should activate according to the settings.

6. The 4-20 mA output should ramp up from 4mA in clean air to 20mA at 5000 ppm. See 4-20 mA diagram.

Note: If the 4-20mA output does not ramp up within 2 minutes, there are four possibilities:

a. The gas cylinder is empty, check the pressure gauge. Replace the gas cylinder if 25-psi or less.

b. Unit needs to be re-calibrated (automated background calibration and re-test).

c. The detector is in need of servicing (return unit to the factory for servicing).

d. The detector has 4-20 mA option set to “OFF”. Set 4-20mA option to “On” and repeat the test.

7. Remove the gas from the sensor. Re-assemble the CD-“x” (make sure the LED is aligned with the front case hole). You are

done.

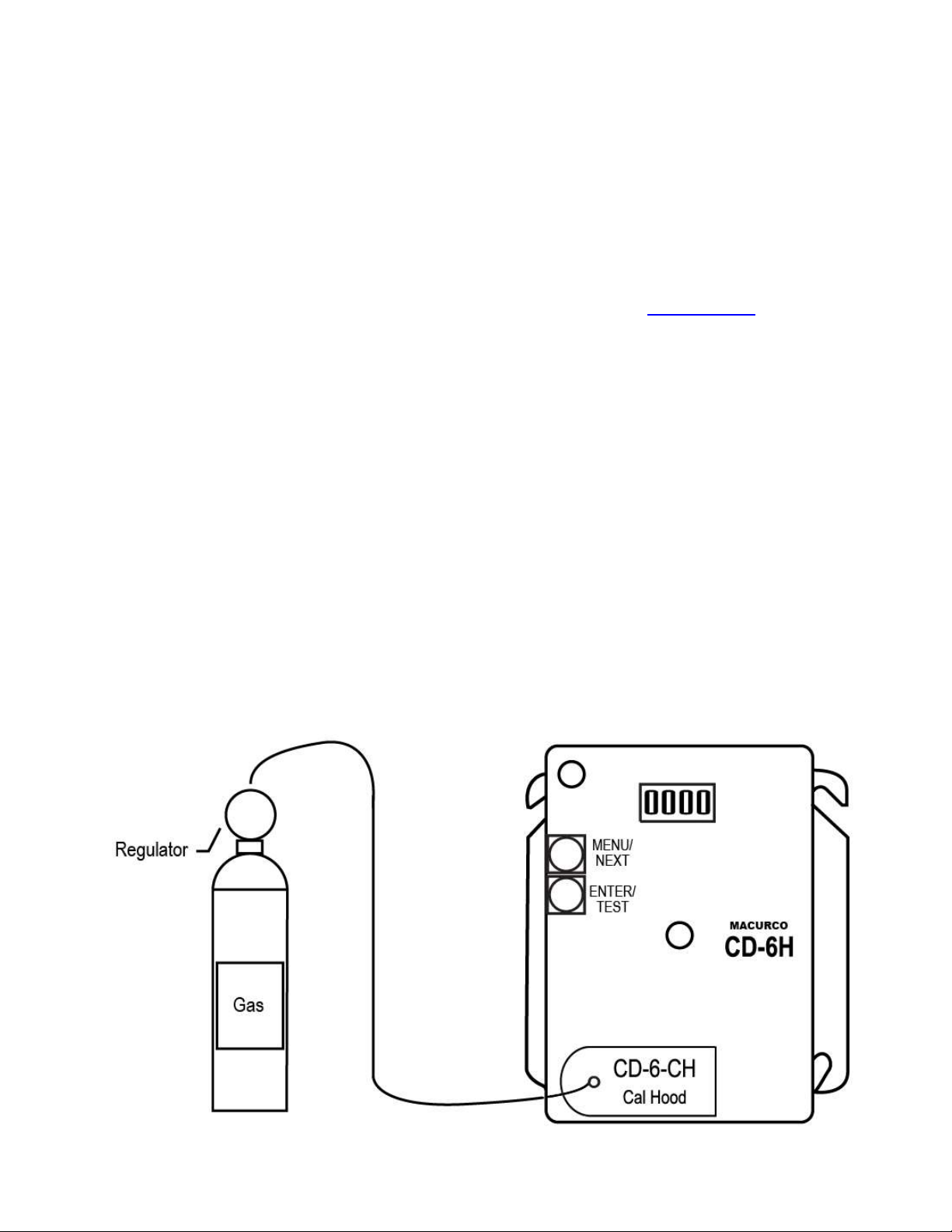

4.4.4 Manual Calibration – CD-6MC ONLY

Note: For optimum calibration results the unit should be in clean air and be in a low ambient air flow.

1. Remove the Philips screw on the front of the CD-6MC. Remove the front cover.

2. Open the FCK. Connect the 400-ppm gas cylinder to the regulator.

3. Check the pressure gauge on the regulator. If you have 25-psi or less, you will need to replace the gas canister. Check the

expiration date on the cylinder, if it has passed the expiration date the cylinder should be replaced.

4. Assemble regulator, hose, and Calibration Hood and place the hood over the CO2 sensor.

20

Page 21

5. On the detector press the Menu / Next button three times to get to the CAL menu. Press Enter / Test button

6. With the display showing “400” press Enter / Test button. The display will begin flashing “400” and “____”.

7. Turn on the regulator to start the gas flow and wait with the gas applied continuously.

Note: The sensor will look for gas for 90 seconds. If no gas is applied or detected in that time, the display will return to “400”.

8. When the sensor detects the gas, the display will flash back and forth between the Gas concentration and CAL, then the

calibration will progress, and the display will show the gas level for a maximum of 165 seconds.

9. When the calibration is successful, the display will flash back and forth between Gas concentration and PAS, then the display

will show the calibration gas level and the calibration is done.

10. If the calibration fails, the display will flash back and forth between the gas concentration and FAiL. If this occurs, check the

pressure gauge on the regulator. If the pressure is less than 25 psi the flow of gas may not be adequate to properly calibrate

the unit. If there is proper pressure in the cylinder repeat steps 6 through 8. If the unit fails to calibrate twice contact Technical

Support: 844-325-3050.

11. Once the calibration has passed, remove gas and disassemble the cylinder and regulator.

12. Re-assemble the CD-6MC (make sure the LED is aligned with the front case hole).

13. See Calibration Flowchart on the inside of the housing, or section 5.5 CAL Menu.

21

Page 22

5 Appendix A – Menu Structure

5.1 Main Menu

Normal

M/N

Wait

Wait

Normal Mode

M/N

“Con”

Configuration Mode

M/N

“tst”

Test Mode

E/T

E/T

E/T

bUZ

Config 1

tst

M/N

Wait

“CAL”

Calibration

(CD6MC only)

E/T

CAL

22

Page 23

5.2 Auto Test Menu “bUZ”

bUZ

M/N

M/N E/T

M/N

“bUZ”

Buzzer test

Wait

“Art”

Alarm relay test

Wait

“Frt”

Fan relay test

E/T

E/T

M/N

Wait

“420”

Current loop test

Wait

Normal

E/T

23

Page 24

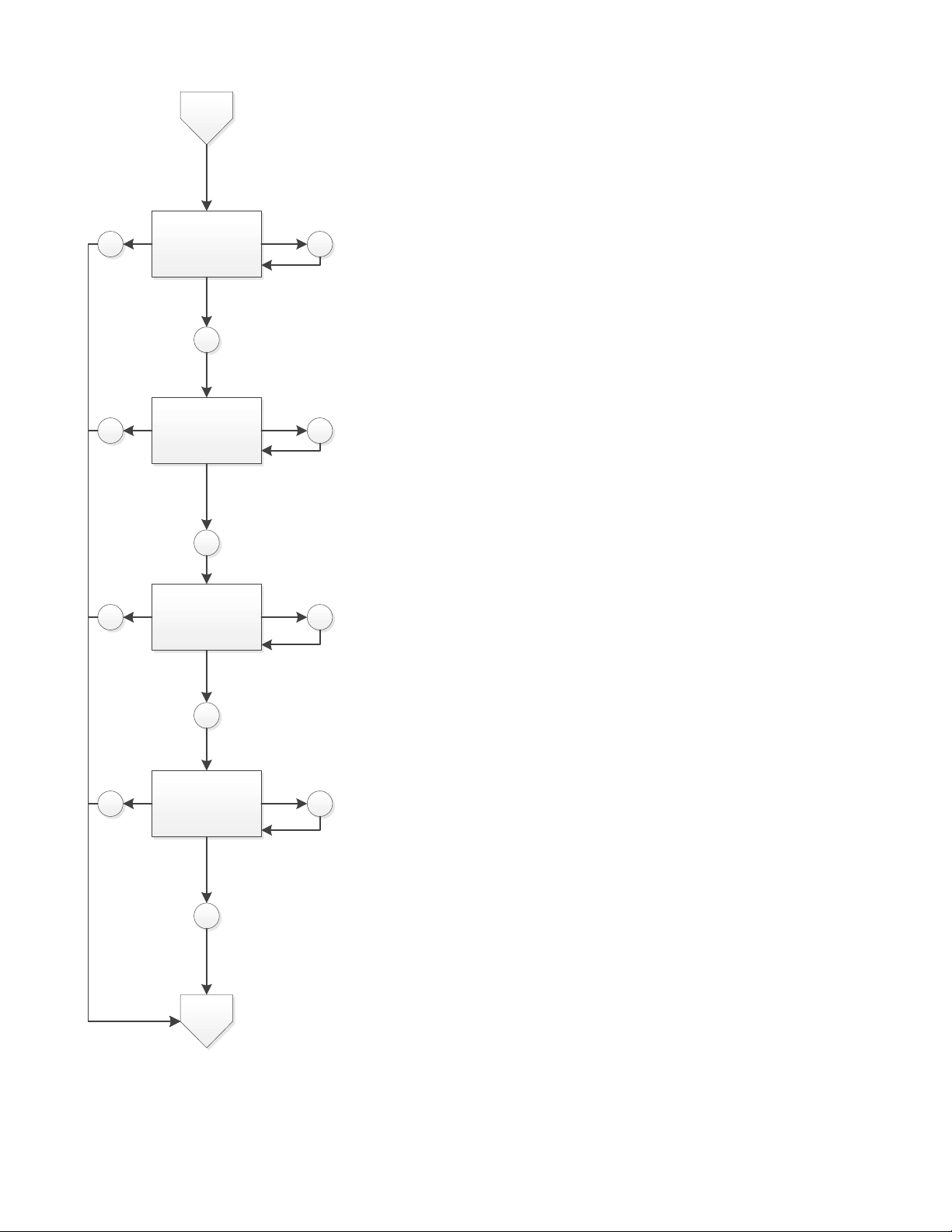

5.3 Configuration Menu “CON”

Config 1

“dEF”

Default

M/N

“Put”

Power up test

M/N

E/T

Wait

E/T

Wait

Wait

Wait

E/T

M/N

M/N

Deafult

values?

“YES”

M/N

Wait

E/T

E/T

“oFF”

M/N

“_On”

“_nO”

E/T

E/T

E/T

Wait

E/T

“_On”

M/N

“ /oFF”

M/N

“ /_On”

M/N

“ /_nO”

M/N

Wait

E/T

Wait

Go to current setting – ON i n

M/N

“YES”“ /YES”

“_no”

M/N

this exa mple

Wait

WaitE/T

E/T

Wait

E/T

Wait

“dSP”

Display mode

M/N

“bUZ”

Buzzer mode

M/N

Config 2

Wait

Wait

E/T

E/T

Wait

Wait

M/N

Wait

E/T

E/T

Wait

“oFF”

M/N

“_On”

M/N

Wait

E/T

E/T

M/N

E/T

“oFF”

M/N

“_On”

E/T

Wait

E/T

E/T

E/T

“_On”

M/N

“ /oFF”

M/N

“ /_On”

E/T

Wait

“_On”

M/N

“ /oFF”

M/N

“ /_On”

Go to current setting – ON i n

this example

M/N

Wait

Go to current setting – ON in

this exa mple

M/N

Normal

24

Page 25

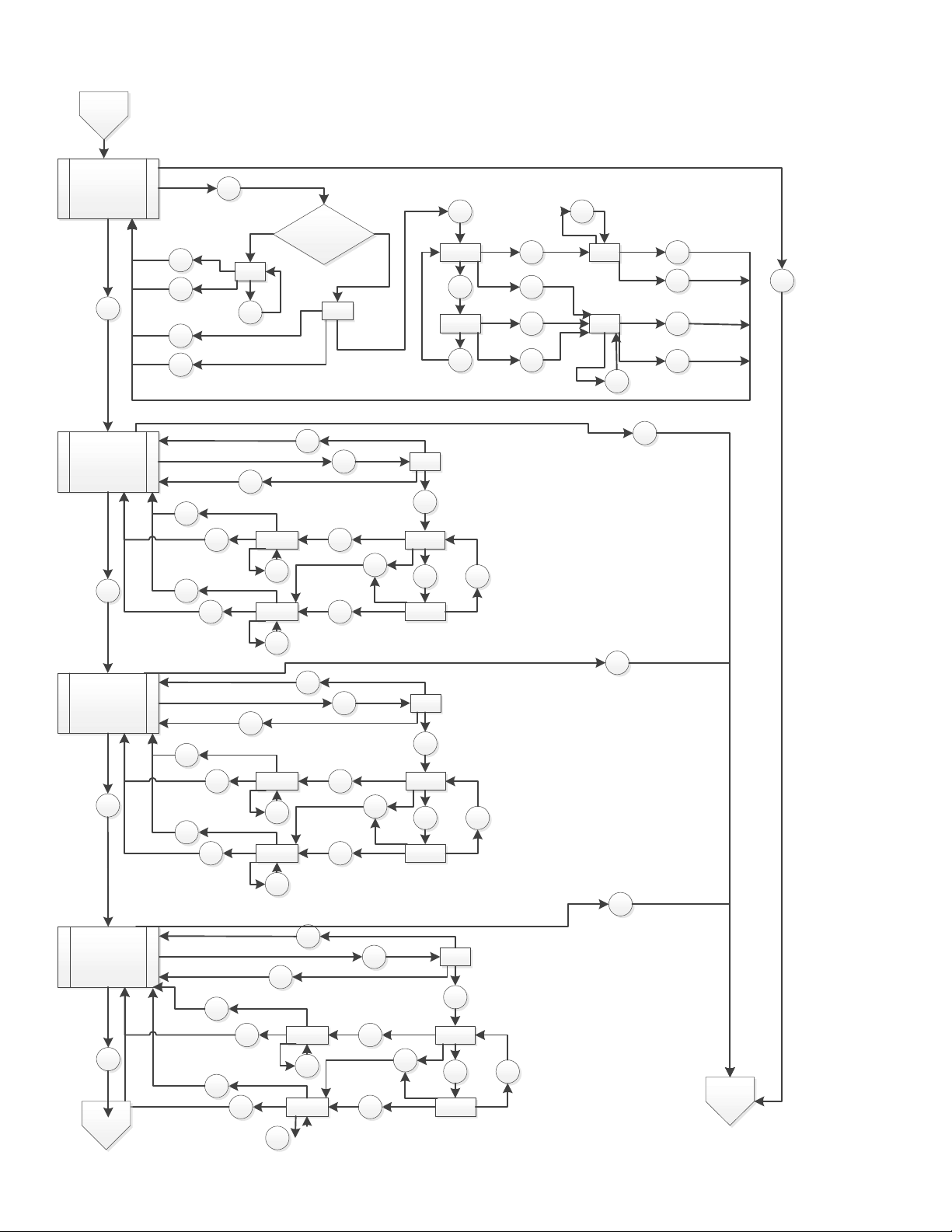

Config 2

ArS

Alarm Relay

Setting

Wait

Wait

E/T

E/T

“4000”

M/N

Wait

Go to current setting – 4000

in this example

M/N

Wait

Wait

Wait

Wait

E/T

E/T

E/T

E/T

“4100”

M/N

“5000”

M/N

M/N

“_900”

M/N

“1000”

M/N

E/T

“ /4100”

Wait

8 more options: 4200, 4300,

…..4900

M/N

E/T

E/T Wait

E/T

E/T Wait

“ /5000”

M/N

“ /_diS”“diS”E/T

M/N

“ /_900”

M/N

“ /1000”

Wait

Wait

28 more options: 1100, 1200,

…..3800

M/N

M/N

Wait

E/T Wait

M/N

“ /3900”“3900E/T

Normal

Config 3

25

Page 26

Config 3

Wait

“Arc”

Alarm relay

configuration

M/N

“FrS”

Fan Relay

Setting

Wait

Wait

Wait

E/T

E/T

E/T

Wait

Wait

“_nC”

M/N

“_nO”

M/N

“2100”

E/T

E/T

E/T

E/T

E/T

E/T

E/T

Wait

“_nO”

M/N

“ /_nC”

M/N

“ /_nO”

“2000”

M/N

“ /2100”

Go to current setting – nO in

this exa mple

M/N

Wait

Go to current setting – 2000

in this exa mple

Wait

M/N

Wait

Wait

Wait

Wait

Wait

E/T

E/T

E/T

M/N

“5000”

M/N

M/N

“_600”

M/N

M/N

“2000”

M/N

38 more options: 2200, 2300,

…...4800, 4900

E/T

E/T Wait

E/T

E/T Wait

“ /5000”

M/N

“ /_diS”“_diS”E/T

M/N

“ /_600”

M/N

“ /_700”“_700”E/T

M/N

Wait

Wait

12 more options: 800,

900…….1800, 1900

E/T Wait

“ /2000

M/N

Config 4 Normal

M/N

26

Page 27

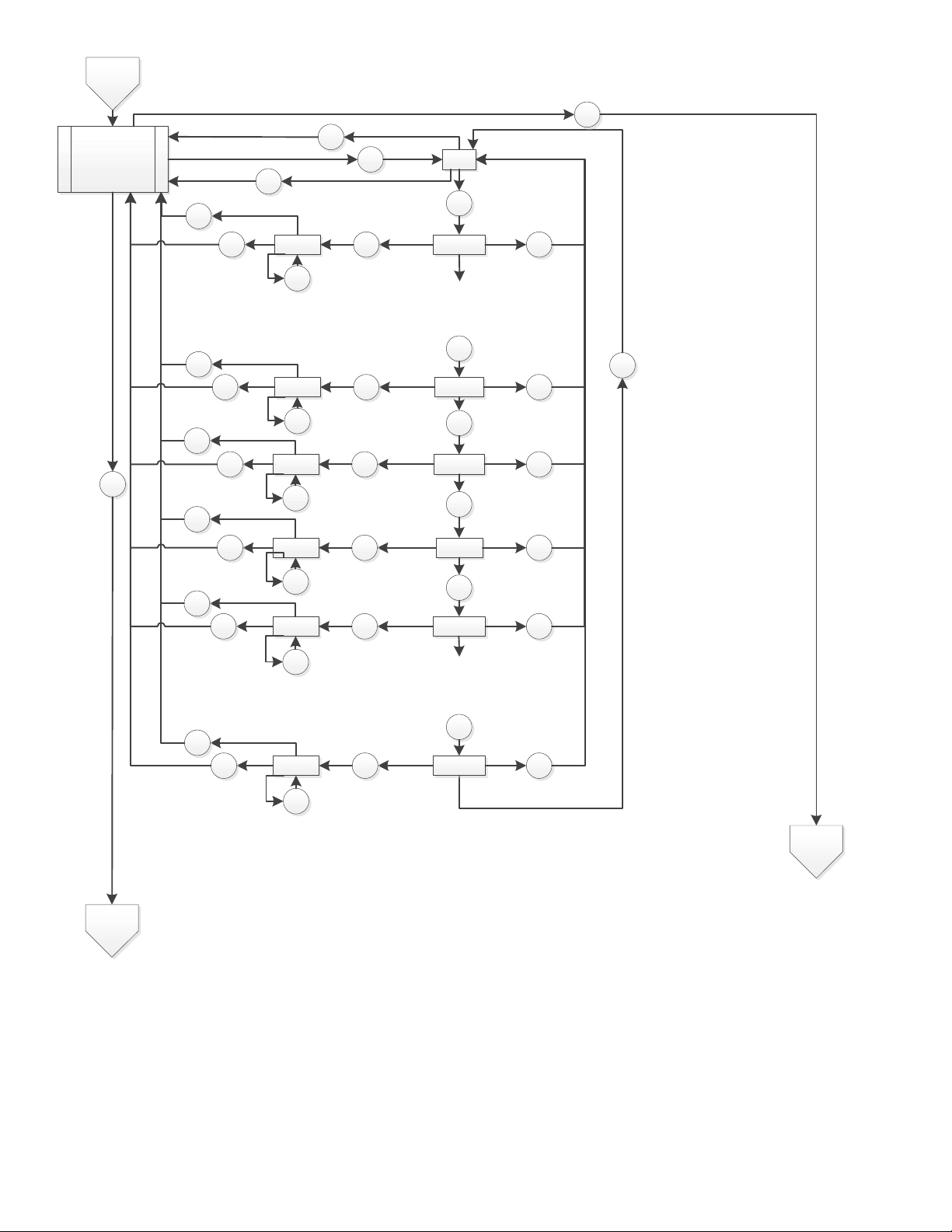

Config 4

“Frd”

Fan relay de lay

Wait

Wait

E/T

E/T

“__3”

M/N

Wait

Go to current setting – 3 in

this example

“ /_5”

M/N

“ /_10”

M/N

“ /_0”“__0”E/T

M/N

“ /_1”

M/N

“ /_3”

Wait

Wait

Wait

M/N

Normal

M/N

Config 5

Wait

Wait

Wait

Wait

E/T

E/T

E/T

E/T

“__5”

M/N

“__10”

M/N

M/N

“__1”

M/N

“__3”

M/N

E/T

E/T

E/T Wa it

E/T

E/T Wa it

27

Page 28

Config 5

Wait

“Frr”

Fan relay

runtime

M/N

Wait

Wait

Wait

Wait

Wait

E/T

E/T

E/T

E/T

Wait

“__3”

M/N

“__5”

M/N

M/N

“_15”

M/N

“__0”

E/T

E/T

E/T

E/T

E/T Wait

E/T

E/T Wait

“__0”

M/N

“ /_3”

M/N

“ /_5”

M/N

“ /_10”“_10”E/T

M/N

“ /_15”

M/N

“ /_0”

Go to current setting – 0 in

this exa mple

Wait

Wait

M/N

Wait

“FrL”

Fan relay latch

M/N

“tFS”

Trouble fault

setting

M/N

Wait

Wait

Wait

Wait

E/T

E/T

E/T

E/T

Wait

Wait

M/N

“_On”

M/N

“_OFF”

M/N

“_On”

M/N

“_OFF”

E/T

E/T

E/T

E/T

E/T

E/T

E/T

E/T

Wait

Wait

“OFF”

M/N

“ /_On”

M/N

“ /OFF”

“OFF”

M/N

“ /_On”

M/N

“ /_OFF”

Wait

Go to current setting – OFF in

this example

M/N

Wait

Go to current setting – OFF in

this example

M/N

Config 6

M/N

28

Normal

Page 29

Config 6

“420”

Current loop

Wait

Wait

E/T

E/T

“_On”

M/N

Wait

Go to current sett ing – On in

this example

“ /OFF”

M/N

“ /_On”

M/N

Wait

E/T

Normal

M/N

“End”

M/N

Wait

E/T

E/T

“_OFF”

M/N

“_On”

M/N

E/T

Wait

E/T

Config 1

29

Page 30

5.4 Select Test Menu “tst”

tst

10

Wait

Wait

Wait

“bUZ”

Buzzer t est

M/N

“Art”

Alarm relay test

M/N

“Frt”

Fan relay t est

M/N

E/T

M/N

10

E/T

M/N

60

E/T

M/N

120

“___/bUZ”

Buzzer t est

“___/Art”

Alarm relay test

“___/Frt”

Fan relay t est

E/T

E/T

E/T

Wait

Wait

Wait

“420”

Current loop test

M/N

“gSt”

Gas test

M/N

“End”

E/T

Normal

E/T

M/N

180

E/T

M/N

“___/420”

Current loop test

“___/gSt”

Gas test

E/T

E/T

M/N

30

Page 31

5.5 CAL Menu * CD-6MC Only

CAL

E/T

M/N

“400”

Cal mode

(CD6MC only)

M/N

“End”

E/T

Normal

E/T

NO YES

“400/___”

Waiting for gas

Gas OK within

90 secs?

“GR/FAil” alternate

gas reading with

FAil

NO YES

E/T

“GR/CAL"

Gas reading

alternates with CAL

until stable (165 s)

Cal OK?

“GR/PAS” gas

reading alternating

with PAS

31

Page 32

6 MACURCO PRODUCTS LIMITED WARRANTY

Macurco warrants the CD-6H / CD-6MC gas detector will be free from defective materials and workmanship for a period of two (2) years

from the date of manufacture (indicated on the inside cover of the CD-6H / CD-6MC), provided it is maintained and used in accordance

with Macurco instructions and/or recommendations. If any component becomes defective during the warranty period, it will be replaced

or repaired free of charge, if the unit is returned in accordance with the instructions below. This warranty does not apply to units that have

been altered or had repair attempted, or that have been subjected to abuse, accidental or otherwise. The above warranty is in lieu of all

other express warranties, obligations or liabilities. THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR

PARTICULAR PURPOSE ARE LIMITED TO A PERIOD OF TWO (2) YEARS FROM THE PURCHASE DATE. Macurco shall not be

liable for any incidental or consequential damages for breach of this or any other warranty, express or implied, arising out of or related to

the use of said gas detector. The manufacturer or its agent’s liability shall be limited to replacement or repair as set forth above. Buyer’s

sole and exclusive remedies are the return of the goods and repayment of the price, or repair and replacement of non-conforming goods

or parts.

Macurco Gas Detection

3601 N. St. Paul Avenue

Sioux Falls, SD 57104

Technical Support Contact Information

Phone: 844-325-3050

Email: support@macurco.com

Website: www.support.macurco.com

General Contact Information

Phone: 877-367-7891

Fax : 512-524-3415

Email : info@macurco.com

Website: www.macurco.com

Rev. A

Issue Date: 03-07-2018

Document No: 34-2900-0134-9

© Aerionics 2018. All rights reserved.

Macurco is a trademark of Aerionics, Inc.

32

Page 33

Macurco™ CD-6H /CD-6MC

Detector de dióxido de carbono, controlador y

transductor

Instrucciones para el usuario

Importante: Guarde estas instrucciones de uso para la referencia.

Page 34

2

Page 35

Tabla de contenidos

1 Información general de seguridad ............................................................................................................................................... 5

1.1 Uso previsto .......................................................................................................................................................................... 5

1.2 Lista de advertencias y precauciones dentro de estas instrucciones de usuario ................................................................. 5

2 Instrucciones y limitaciones del usuario ....................................................................................................................................... 6

2.1 Utilizar para........................................................................................................................................................................... 6

2.2 No utilice para ....................................................................................................................................................................... 6

2.3 Descripción general .............................................................................................................................................................. 7

2.4 Características ...................................................................................................................................................................... 8

2,5 Especificaciones ................................................................................................................................................................... 8

3 Instrucciones de instalación y funcionamiento ............................................................................................................................. 9

3.1 Ubicación .............................................................................................................................................................................. 9

3.2 Instalación............................................................................................................................................................................. 9

3.3 Encendido ........................................................................................................................................................................... 14

3.4 Operación ........................................................................................................................................................................... 14

3.5 Configuración predeterminada: configuración de fábrica ................................................................................................... 15

3.5.1 Seleccionando Configuración predeterminada – "def" .............................................................................. 16

3.5.2 Selección de la opción de prueba de encendido – "PUt" .......................................................................... 16

3.5.3 Selección de la opción de visualización – "DSP" ...................................................................................... 16

3.5.4 Selección de la opción zumbador – "bUZ" ................................................................................................ 16

3.5.5 Selección del ajuste del relé de alarma – "ARS"....................................................................................... 16

3.5.6 Selección de la configuración de relé de alarma – "Arc" ........................................................................... 17

3.5.7 Selección de los ajustes del relé del ventilador – "FRS" ........................................................................... 17

3.5.8 Selección del retardo del relé del ventilador – "FRD" ............................................................................... 17

3.5.9 Selección del relé del ventilador en tiempo de ejecución mínimo – "FRR" ............................................... 18

3.5.10 Selección de la opción de bloqueo del relé del ventilador – "FrL" ............................................................ 18

3.5.11 Selección de problemas opción de ajuste del ventilador – "tFS" .............................................................. 18

3.5.12 Selección de la opción de salida 4-20mA-"420" ....................................................................................... 18

3.6 Diagnóstico a bordo ............................................................................................................................................................ 18

4 Mantenimiento ........................................................................................................................................................................... 19

4.1 Señal de fin de vida ............................................................................................................................................................ 19

4.2 Limpieza ............................................................................................................................................................................. 20

4.3 Pruebas .............................................................................................................................................................................. 21

4.3.1 Prueba de operación ................................................................................................................................. 21

4.3.2 Prueba de operación manual .................................................................................................................... 22

4.3.3 Prueba de gas de dióxido de carbono ...................................................................................................... 22

4.3.4 Kit de calibración de campo – CD6-FCK .................................................................................................. 22

4.3.5 Información FCK ....................................................................................................................................... 22

4.4 Pruebas de gas................................................................................................................................................................... 23

4.4.1 Prueba del relé del ventilador ................................................................................................................... 23

4.4.2 Prueba del relé de alarma ......................................................................................................................... 24

4.4.3 Probando el bucle de corriente de 4-20mA ............................................................................................... 24

4.4.4 Calibración manual – sólo CD-6MC .......................................................................................................... 24

5 Apéndice A – estructura del menú ............................................................................................................................................. 26

5.1 Menú principal .................................................................................................................................................................... 26

5.2 Menú auto test "bUZ" .......................................................................................................................................................... 27

5.3 Menú de configuración "con" .............................................................................................................................................. 28

5.4 Seleccione test MENU "TST".............................................................................................................................................. 34

5.5 Menú Cal * sólo CD-6MC ................................................................................................................................................... 35

6 Garantía limitada de productos MACURCO .............................................................................................................................. 36

Información de contacto de soporte técnico ..................................................................................................................................... 36

Información general de contacto ....................................................................................................................................................... 36

3

Page 36

4

Page 37

1 Información general de seguridad

1.1 Uso previsto

La Macurco CD-6H y CD-6MC son baja tensión, bióxido de carbono de doble relé (Co2) detector, regulador, y transductor. La CD-6 "x"

tiene seleccionable 4-20 mA salida, zumbador y opciones de pantalla digital. Es un sistema de detección electrónico utilizado para medir

la concentración de carbono Dióxido y proporcionar retroalimentación y control automático de ventilación para ayudar a reducir Co2

concentraciones en salas de conferencias, aulas, salas de reuniones o aplicaciones similares. La CD-6x" es un bajo nivel medidor capaz

de mostrar desde 0-5000 ppm (partes por millón) de carbono dióxido. La CD-6x" está calibrado de fábrica y el 100% probó para la

operación apropiada.

La CD-6H utiliza una calibración de fondo automatizada Programa para establecer el nivel de aire limpio sobre una base regular.

El CD-6MC tiene el mismo ajuste y características del CD-6H con la adición de poder realizar una calibración manual. El CD-6MC

requiere un proceso de calibración manual a un mínimo de una vez por año utilizando el Macurco Kit de calibración CD6-FCK.

1.2 Lista de advertencias y precauciones dentro de estas instrucciones de usuario

ADVERTENCIA

Cada persona que utilice este equipo debe leer y entender la información de estas instrucciones de uso antes de usarla. Uso

de este equipo por no entrenado o no cualificado personas o uso que no está de acuerdo con estas instrucciones de usuario,

puede afectar adversamente el rendimiento del producto y resultar en lesiones graves o la muerte.

Úselo solamente para monitorear el gas que el sensor y el instrumento están diseñados para monitorear. El no hacerlo puede

dar lugar a que las exposiciones a los gases no sean perceptibles y causa lesiones graves o la muerte. Para un uso

adecuado, consulte el supervisor o instrucciones del usuario, o llame al técnico Apoyo en 844-325-3050.

Este equipo puede no funcionar con eficacia debajo de 32°F o superior a 122°F (0°C o superior a 50°C). el uso del detector

fuera de este rango de temperatura puede afectar adversamente el rendimiento del producto y resultar en lesiones graves

o la muerte.

Este detector ayuda a monitorear para el nivel de presencia y concentración de un determinado gas aéreo especificado. El

mal uso puede producir una lectura incorrecta, lo que significa que los niveles más altos del gas que se monitorean pueden

estar presentes y pueden resultar en una sobreexposición y causa lesiones graves o la muerte. Para un uso adecuado,

consulte el supervisor o instrucciones del usuario, o llame al técnico Apoyo en 844-325-3050.

Los terminales de alto voltaje (120/240 VAC) se encuentran dentro de este detector, presentando un peligro para los técnicos

de servicio. Sólo los técnicos cualificados deben abrir la caja del detector y servir los circuitos internos. Asegúrese de que la

energía de-energizado de los relés del detector antes de dar servicio a la unidad. Si no lo hace puede resultar en slesión

erious o la muerte.

No desarme la unidad ni intente reparar o modificar ningún componente de este instrumento. Este instrumento no contiene

piezas reparables por el usuario, y la sustitución de componentes puede perjudicar el rendimiento del producto y resultar en

lesiones graves o la muerte.

El uso de un gas certificado con una concentración distinta de la indicada para este detector al realizar una prueba de

verificación de calibración (prueba de choque) producirá lecturas inexactas. Esto significa que los niveles más altos del gas

que se monitorean pueden estar presentes y pueden resultar en sobreexposición y causa lesiones graves o la muerte.

Para un uso adecuado, consulte el supervisor o instrucciones del usuario, o llame al técnico Apoyo en 844-325-3050.

Los siguientes pasos deben realizarse al realizar una prueba de verificación de calibración (prueba de choque) para asegurar

el correcto funcionamiento del monitor. Si no lo hace, puede afectar adversamente el rendimiento del producto y resultar en

lesiones graves o la muerte. Cuando realice una prueba de verificación de calibración (prueba de choque), utilice

únicamente gas de calibración certificado en el nivel de concentración requerido.

o No pruebe con gas de calibración expirado.

o No cubra ni obstruya la pantalla ni la cubierta visual de la alarma.

o Asegúrese de que las entradas del sensor no estén obstruidas y son libre de escombros

5

Page 38

2 Instrucciones y limitaciones del usuario

ADVERTENCIA

Cada persona que utilice este equipo debe leer y entender la información de estas instrucciones de uso antes de usarla. Uso de este

el equipo por personas no entrenadas o no cualificadas, o el uso que no esté de acuerdo con estas instrucciones del usuario, puede

afectar adversamente

rendimiento del producto y resultado en la enfermedad o la muerte.

2.1 Utilizar para

La CD-6x" proporciona Co2 detección y control automático de la ventilación para las salas de conferencias, las aulas, las salas de reunión

o similares

aplicaciones. El dióxido de carbono es un gas incoloro, inodoro que se produce tanto por la gente exhalando Co2 así como la quema de

gasolina,

carbón, aceite, y madera. La concentración exterior de dióxido de carbono puede variar de 350-450 partes por millón (ppm) o más en

áreas con

alto tráfico vehicular o actividad industrial. El co de interior2 depende del número de personas presentes, cuánto tiempo ha sido un área

ocupado, la cantidad de aire fresco al aire libre que entra en la zona y otros factores. Co2 las concentraciones en interiores pueden variar

varios cientos de partes por millón en áreas con muchas personas presentes durante un período prolongado y donde el aire fresco la

ventilación es limitada. La ventilación de aire "fresca" al aire libre es importante ya que puede diluir Co2 niveles de el ambiente interior.

La cantidad de aire fresco que se debe suministrar a una habitación depende del tipo de instalación y habitación. La ventilación debe

mantener concentraciones de dióxido de carbono debajo 1000 ppm y crear condiciones de calidad del aire interior que son aceptables

para la mayoría de los individuos.

Para las aplicaciones que almacenan o utilizan tanques de CO2, el detector proporcionará notificación en caso de una fuga de gas.

Tales aplicaciones incluyen pero no son limitadas Para almacenaje del alimento, dispensación de la bebida, agricultura, supresión de

fuego, médico, etc.