Page 1

Installation Manual

LBI-38901T

Orion

™

Mobile Radio

Page 2

CREDIT

M/A-COM and EDACS are registered trademarks and Orion, ProGrammer, and ProVoice are

trademarks of M/A-COM, Inc.

TORX is a registered trademark of CAMCAR/TEXTRON.

POZIDRIV is a registered trademark of Phillips International Company.

IBM is a registered trademark of IBM.

Windows is a registered trademark of Microsoft Corporation.

Molex is a registered trademark of Molex Company.

All other brand and product names are trademarks, registered trademarks or service marks of their

respective holders.

This manual is published by M/A-COM, Inc., without any warranty. Improvements and changes to this

manual necessitated by typographical errors, inaccuracies of current information, or improvements to programs

and/or equipment, may be made by M/A-COM, Inc., at any time and without notice. Such changes will be

incorporated into new editions of this manual. No part of this manual may be reproduced or transmitted in any

form or by any means, electronic or mechanical, including photocopying and recording, for any purpose,

without the express written permission of M/A-COM, Inc.

Copyright© 1993-2004, M/A-COM, Inc. All rights reserved.

2

Page 3

TABLE OF CONTENTS

Page

INTRODUCTION.............................................................................4

UNPACKING AND CHECKING EQUIPMENT ............................ 5

INSTALLATION (Single Control Unit)......................................... 11

STEP 1 – PLAN THE INSTALLATION ................................ 11

STEP 2 - LOCATE TOOLS REQUIRED................................ 12

Vehicles Powered By Liquefied (Lp) Gas ........................ 12

STEP 3 – INSTALL CABLES................................................. 13

Power Cable ...................................................................... 13

Ignition Sense (All Applications)...................................... 14

Accessory Cable (Front Mount)........................................ 16

Accessory and Control Cable (Remote Mount) ................ 24

STEP 4 – MOUNT CONTROL UNIT AND RADIO ............. 34

Control Unit Mounting (Remote Applications Only)........34

Pigtail Bracket................................................................... 34

Radio Front Mount And Final Hook-Up...........................37

Radio Remote Mount and Final Hook-Up........................38

Cassette Mounting (EURO Only) ..................................... 40

STEP 5 - INSTALL OPTIONS AND ACCESSORIES........... 44

Speaker D2LS1F............................................................... 44

Microphone Hanger and/or Hookswitch Mounting .......... 44

Siren and Light..................................................................45

INSTALLATION (Dual Control Units)..........................................47

STEP 1 - PRE-INSTALLATION PROGRAMMING ............. 47

Front Mount Procedure ..................................................... 47

Remote Mount Procedure.................................................. 51

STEP 2 – INSTALL DUAL CONTROL UNITS .................... 55

Front Mount ...................................................................... 55

Remote Mount................................................................... 58

DUAL RADIO UNITS.................................................................... 63

STEP 1 - PRE-INSTALLATION PROGRAMMING ............. 63

Master Radio Programming .............................................. 64

Slave Radio Programming.................................................64

STEP 2 – INSTALL CABLES/EQUIPMENT......................... 67

Front Mount ...................................................................... 67

Remote Mount................................................................... 69

Keyloading the Radio........................................................74

Keyloading a Dual Radio.................................................. 75

TECHNICAL ASSISTANCE ......................................................... 78

3

Page 4

INTRODUCTION

This manual contains installation instructions for th e Orion™ Mobile radio unit

and associated accessories. These instructions cover the mounting and

cabling of the radio. Interconnection and wiring diagrams are provided for

reference. Before the installation, program the radio using the following:

®

• IBM

• TQS3385 – ProGrammer

• TQ3370 - Serial/Flash Programming Interface Module

• One of the following programming cables:

* The field programming cable must be used with one of the following

compatible personal computer

™

PC Software

or

TQS3389 - Conventional ProGrammer PC Software

(required with TQ3377 cable only)

o TQ3377 (19B802554P15) – Shop Programming Cable (requires

TQ3370)

o TQ3409 (CA101288V15) - Shop Programming Cable (does not

require TQ3370)

o *TQ3410 (CA101287V1) - Field Programming Cable (does not

require TQ3370)

accessory cables:

CA101288V2, CA101288V4, CA101288V10

ORION UHF MOBILES

The PC programmer automatically defaults the receiver

oscillator shift to position No. 2. When field programming,

the receive frequencies for Orion UHF mobiles, the oscillator

CAUTION

shift must be programmed to position No. 1 or No. 3. Enter

the CONVENTIONAL and/or TRUNKED FREQUENCY

SET screen of the PC programmer and set the values in the

“OS” column to “1” or “3”.

4

Page 5

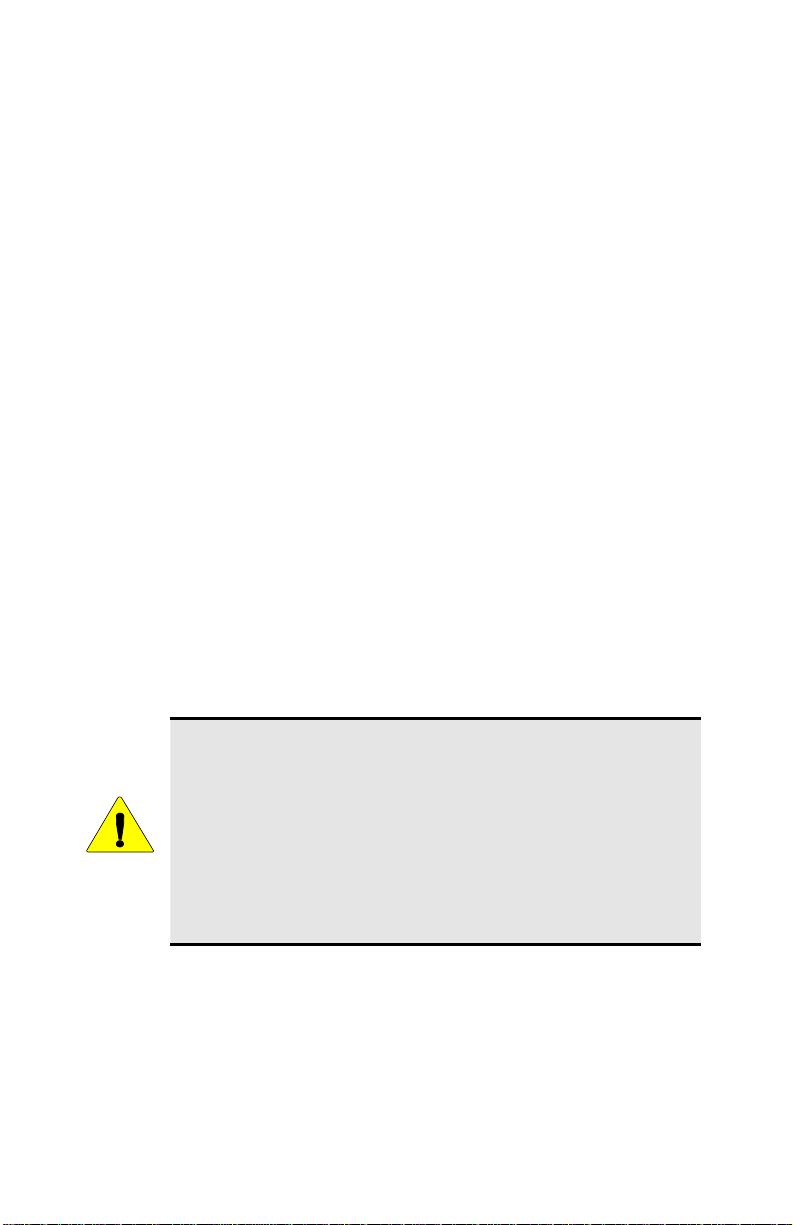

UNPACKING AND CHECKING EQUIPMENT

Carefully unpack the radio and identify each item in the shipping container as

listed below. The available options for the Orion Mobile Radio are covered in

Table 1. If damage has occurred to the equipment during shipment, file a

claim with the carrier immediately.

• Orion Mobile radio unit

• Microphone D2MC3Z

• Speaker D2LS1H

• Power Cable D2CE1V

or D2CF9A

Control Cable D2CE1Y

• Front Mount Bracket Kit or D2MA3N

Remote Mount Kit with D2MA3R

Control Unit Mount Kit D2MA3J

• Operator's Manual LBI-38888

• Installation Manual LBI-38901

Figure 1: Orion Mobile Radio Components

USA EURO

Figure 2: Rear View of Radios

5

Page 6

6

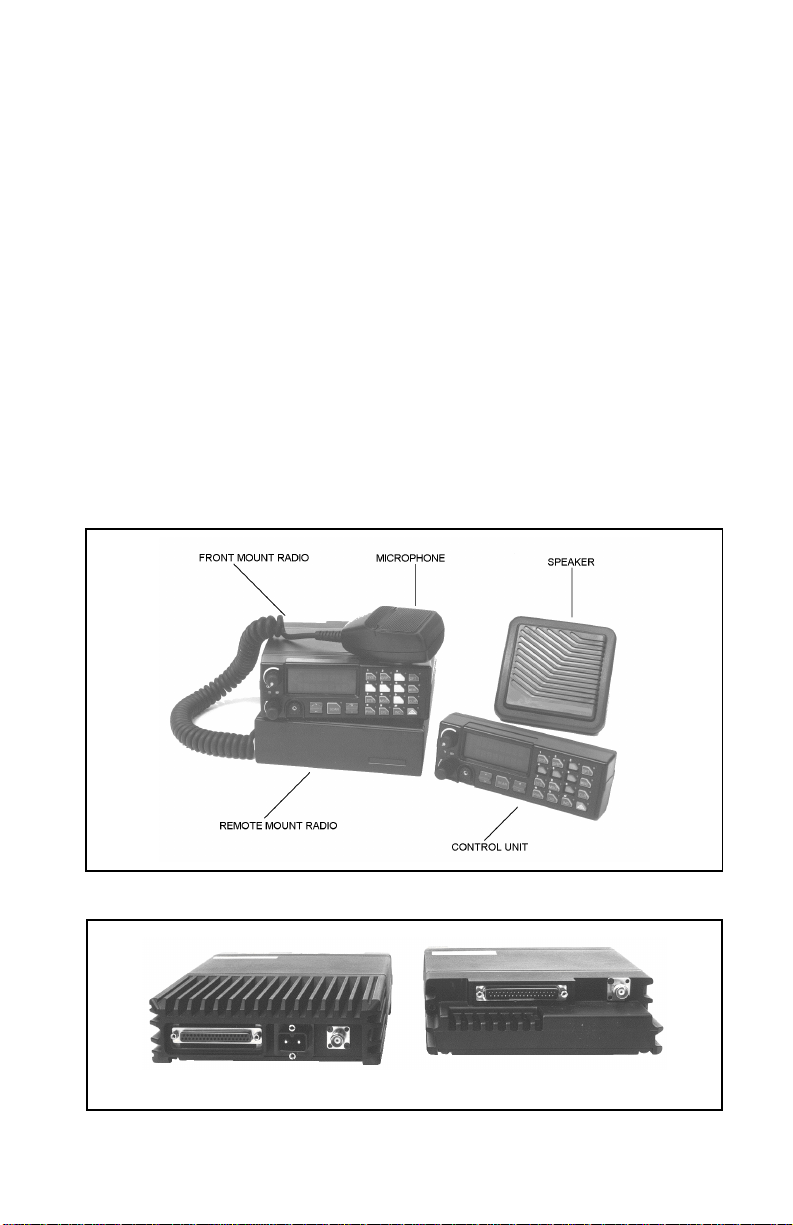

Figure 3: Option Cables

Page 7

NOTE

At the time this manual was published, M/A-COM, Inc. was

in the process of offering additional programming cables and

replacing some of the accessory cables for the Orion mobile

radio. This manual provides information on both the existing

cable offerings and the replacement cables. The following

cables are impacted:

CA101288V2 will replace 19B802554P2

CA101288V4 will replace 19B802554P4

CA101288V10 will replace 19B802554P10

CA101287V1, V2 and V3 will be added

CA101288V15 and V30 will be added

Figure 4: Option Cables con’t

7

Page 8

The programming cables shown in Figure 5 do not require the

TQ3370 interface box. The field programming cables shown

in Figure 5 are ONLY compatible with the following

NOTE

accessory cables:

CA101288V2, CA101288V4, CA101288V10

Programming Interface Cable,

CA101287V1 and Mobile Data Interface,

CA101287V3

CA101287V2

Keyloading Interface

8

Figure 5: Programming/Interface Cables

Page 9

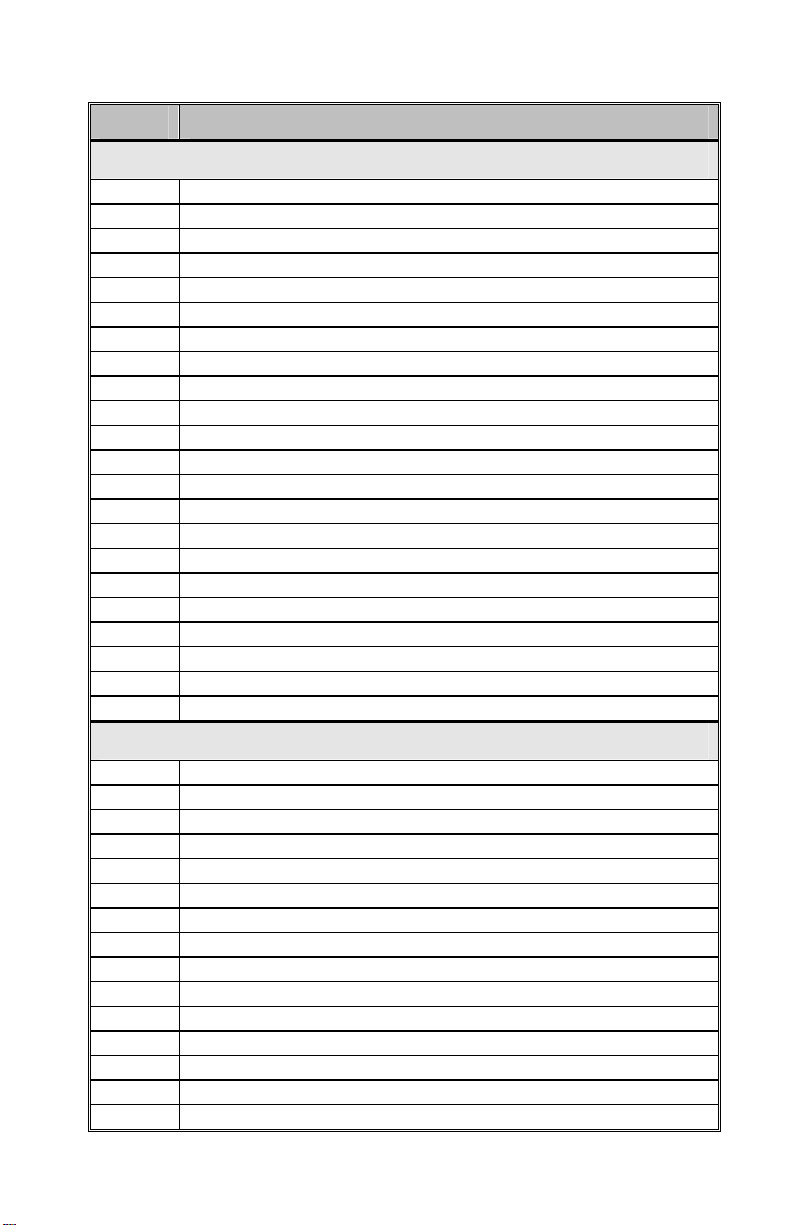

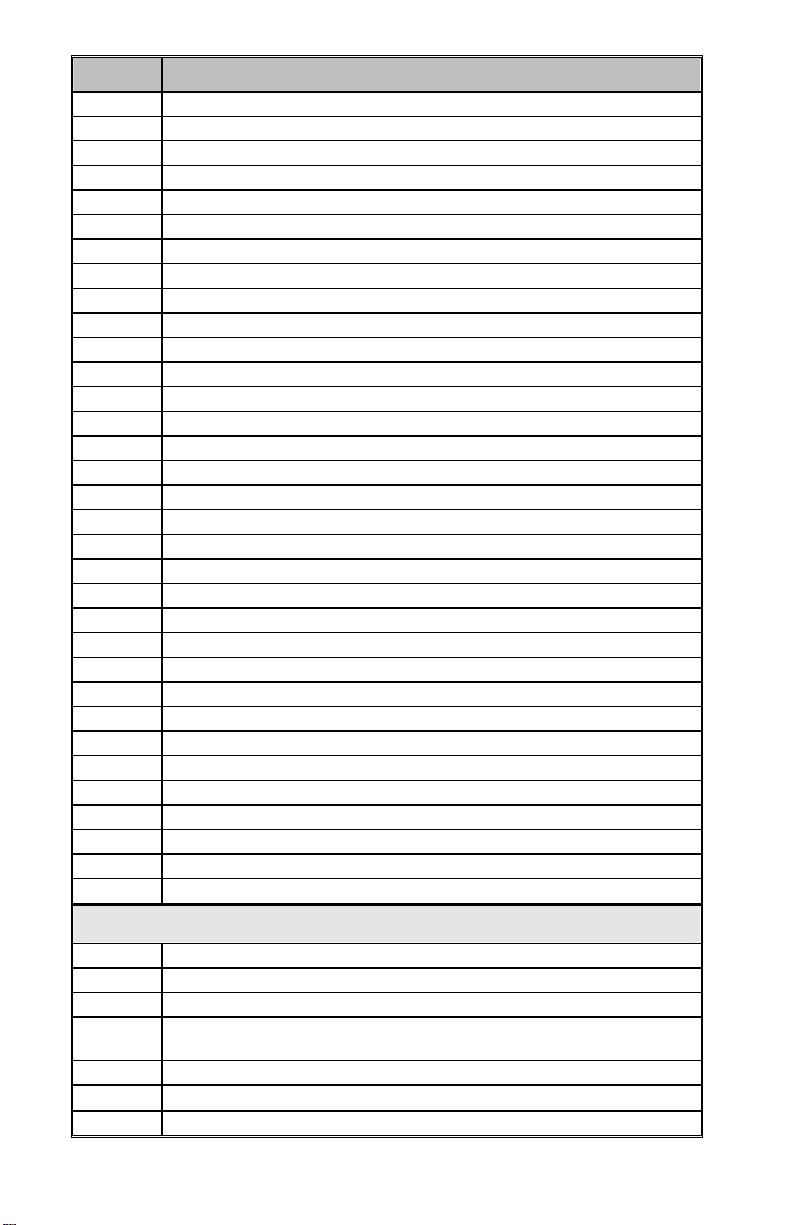

Table 1: Orion Mobile Radio Options And Accessories

OPTION DESCRIPTION

Z OPTIONS

D2ZN1A Accessory Kit–Front Mount with Standard Option Cable

D2ZN1B Accessory Kit–Front Mount with Extended Option Cable

D2ZN1C Accessory Kit–Front Mount Euro with Standard Option Cable

D2ZN1D Accessory Kit–Front Mount Euro with Extended Option Cable

D2ZN1F Accessory Kit–Remote Mount with Standard Option Cable, 50W TX and below

D2ZN1G Accessory Kit–Remote Mount with Standard Option Cable, 60W TX and above

D2ZN1H Accessory Kit–Remote Mount with Extended Option Cable, 50W TX and below

D2ZN1J Accessory Kit–Remote Mount with Extended Option Cable, 60W TX and above

D2ZN1K Accessory Kit–Remote Mount with Standard Option Cable, Low Band

D2ZN1L Accessory Kit–Remote Mount with Extended Option Cable, Low Band

D2ZN1M Accessory Kit–Remote Mount Euro with Standard Option Cable

D2ZN1N Accessory Kit–Remote Mount Euro with Extended Option Cable

D2ZN1P Accessory Kit–Remote Mount Motorcycle with Extended Option Cable

D2ZN1R Accessory Kit–Remote Mount Motorcycle with no Option Cable

D2ZN1S Accessory Kit–Remote Mount Euro Motorcycle with Extended Option Cable

D2ZN1T Accessory Kit–Remote Mount Euro Motorcycle with no Option Cable

D2ZN1U Dual Control, Scan Control Unit

D2ZN1V Dual Control, System Control Unit

D2ZN1W Dual Radio (50 watt TX and below)

D2ZN1X Dual Radio (60 watt TX and above)

D2ZN1Y Motorcycle Conversion, Field Upgrade, Remote Mount Radio

D2ZN1Z Motorcycle Conversion, Field Upgrade, Remote Mount Euro Radio

4 DIGIT OPTIONS

D2AN1E Antenna, Low Band WB, 29.7-38 MHz

D2AN1F Antenna, Low Band WB, 33-43 MHz

D2AN1G Antenna, Low Band WB, 37-49 MHz

D2AN1L Antenna, 800 MHz, ¼ Wave Whip

D2AN1M Antenna, 900 MHz, ¼ Wave Whip

D2AN1R Antenna, VHF/UHF, ¼ Wave Whip

D2CE1V Power Cable, 7.5M (60W TX and above)

D2CE1W Accessory Cable, Front Mount

D2CE1X Accessory Cable, Remote Mount

D2CE1Y Radio Control Cable, Remote Mount, 5.5M

D2CE1Z Accessory Cable, Euro Front Mount

D2CE5R Extended Option Accessory Cable, Front Mount

D2CE5S Radio Control Cable, Extended Option, Remote Mount, 5.5M

D2CE5T Extended Option Accessory Cable, Remote Mount

D2CE5U Extended Option Accessory Cable, Euro Front Mount

9

Page 10

OPTION DESCRIPTION

D2CE5V Radio Control Cable, Euro Remote Mount, 5.5M

D2CE5W Radio Control Cable, Extended Option Euro Remote Mount, 5.5M

D2CE5Z Dual Control Cable, Remote Mount, 9.0M

D2CE7A Dual Radio Cable, Remote Mount, 2.0M

D2CF7B Extended Option Accessory Cable, Motorcycle

D2CF7C Radio Control Cable, Extended Option Remote Mount Motorcycle, 2.3M

D2CF7D Radio Control Cable, Extended Option Euro Remote Mount Motorcycle, 2.3M

D2CF7E Power Cable, Motorcycle, 1.0M

D2CF9A Power Cable, 7.5M (50W T X and below)

D2CP5L Scan Control Unit (4 BTN), Front Mount (including Label)

D2CP5M System Control Unit (16 BTN), Front Mount (including Label)

D2CP5R Scan Control Unit (4 BTN), Remote Mount (including Label)

D2CP5S System Contr ol Unit (16 BTN), Remote Mount (including Label)

D2LS1H Speaker (4 OHM)

D2LS1U Speaker (8 OHM, Parallel Audio Appl)

D2MA3J Mounting Bracket Kit, Remote Mount Control Unit

D2MA3N Mounting Bracket Kit, Front Mount Radio/Euro Remote Mount Radio

D2MA3R Mounting Bracket Kit, Remote Mount Radio

D2MA5G Mounting Bracket Kit, Motorcycle CU (Microphone Hanger included)

D2MA5H Mounting Bracket Kit, Motorcycle Radio Case

D2MA5J Mounting Bracket Adapter Kit, Motorcycle Radio Case

D2MC3Z Microphone

D2MC5A Desk Microphone

D2MC5L Noise Canceling Microphone

D2MC5N DTMF Microphone

D2MK3B Radio Front (Remote Mount) (including Label)

D2MK3E Keycap Kit, Scan Control Unit

D2MK3F Keycap Kit, System Control Unit

D2MN1A Microphone Hanger

D2PD1T Filter, Power, Motorcycle Appl

1016 Siren and Light Control Module

1020 100W Speaker TS100

1021 100W Speaker BP100

RADIO PROGRAMMING OPTIONS

TQ3409 Programming Cable, Shop (CA101288V5). Does not require TQ3370

TQ3410 Programming Cable, Field (CA101287V1). Does not require TQ3370

TQ3370 Programming Interface Module Kit 110 VAC, only needed for 19B802554P15

TQ3370-

Programming Interface Module Kit 220 VAC, only needed for 19B802554P15

220

TQ3377 Programming Cable for Orion (19B802554P15). Requir es TQ3370

TQ3385

ProVoice

™

/EDACS® Windows® Radio ProGrammer Only

TQ3389 Conventional Windows Radio ProGrammer Only

10

Page 11

INSTALLATION (SINGLE CONTROL UNIT)

STEP 1 – PLAN THE INSTALLATION

Figure 6 provides an example of a typical mobile radio (remote mount)

installation. Before starting, plan the radio installation carefully so th at it will

be:

• safe for the operator and passengers

• away from airbag deployment area

• convenient for the operator to use

• protected from water damage

• neat and easy to service

• safe and out of the way for passengers and auto mechanics

M/A-COM, Inc. recommends the radio be installed by one of the many M/ACOM, Inc. Authorized Service Centers located throughout the United States.

Experienced service centers can provide a proper radio installation and make

any required final adjustments.

WARNING

Figure 6: Typical Installation (Remote Mount Shown)

• Vehicular Electronics- fuel injection systems, anti-skid

braking systems, cruise control systems, etc., are typical of

the types of electronic devices which may be prone to

malfunction due to the lack of protection from radio

frequency energy present when a radio is transmitting. If the

vehicle contains such equipment, consult dealer to determine

if such electronic equipment will perform normally when the

radio is transmitting.

• For passenger safety, mount the radio securely so the unit

will not break loose in the event of a collision.

11

Page 12

STEP 2 - LOCATE TOOLS REQUIRED

The equipment required for installing the Orion Mobile Radio is listed below:

• Crimping tool for fuse holder

• Electric drill for drilling mounting holes

• Drills and circle cutters as follows:

No. 31 (1/8”) drill

No. 27 (9/64”) drill

5/8” drill or circle cutter

3/4” circle cutter, hole saw or socket punch

• Phillips and flat-blade screwdrivers

• POZIDRIV

• No. 20 TORX

CAUTION

®

driver

®

driver

Be careful to avoid damaging vital part (fuel tank,

transmission housing, etc.) of the vehicle when drilling

mounting holes. Always check to see how far the mounting

screws will extend below the mounting surface before

installing.

If pilot holes must be drilled, remove all metal shavings from

drilling holes before installing screws.

Vehicles Powered By Liquefied (Lp) Gas

Radio installation in vehicles powered by liquefied petroleum gas, where

the LP gas container is located in the trunk or other sealed-off space

within the interior of the vehicle, must conform to the National Fire

Protection Association Standard NFPA 58. This requires that:

• The space containing radio equipment be isolated by a seal from the

space containing the LP gas container and its fittings.

• Outside filling connections be used for the LP gas container.

• The LP gas container space be vented to the outside of the vehicle.

12

Page 13

STEP 3 – INSTALL CABLES

To ensure the feasibility of the planned cable routings , it is recommended that

the cables be run before mounting the radio. The radio can be installed as a

Front Mount, Remote Mount or Cassette Mount. The type of mount, the

application, and the options to be installed should be considered when

planning the cable runs. The following figures should be referenced

throughout the installation:

• Front Mount Installation Diagram - Figure 8 thru Figure 12

• Front Mount Cable Diagrams - Figure 13 thru Figure 17

• Remote Mount Installation Diagrams – Figure 18 thru Figure 24

• Remote Mount Cable Diagrams – Figure 25 thru Figure 29

Be sure to leave some slack in each cable going to the radio, so the radio can

be pulled out for servicing with the power applied and antenna attached. Coil

any surplus cables and secure them out of the way. Try to route the cables

away from locations where they will be exposed to heat (exhaust pipes,

mufflers, tailpipes, etc.), battery acid, sharp edges or mechanical damage or

where they will be a nuisance to automobile mechanics, the driver, or

passengers. In order to prevent interference, keep wiring away from

electronic computer modules, other electronic modules, and ignition circuits.

In addition, try to utilize existing holes in the firewall, trunk wall, and the

channels above or beneath doors. Channels through door and window

columns, convenient for running cables, can also be used unless rigid or

flexible conduit is to be installed for cable runs.

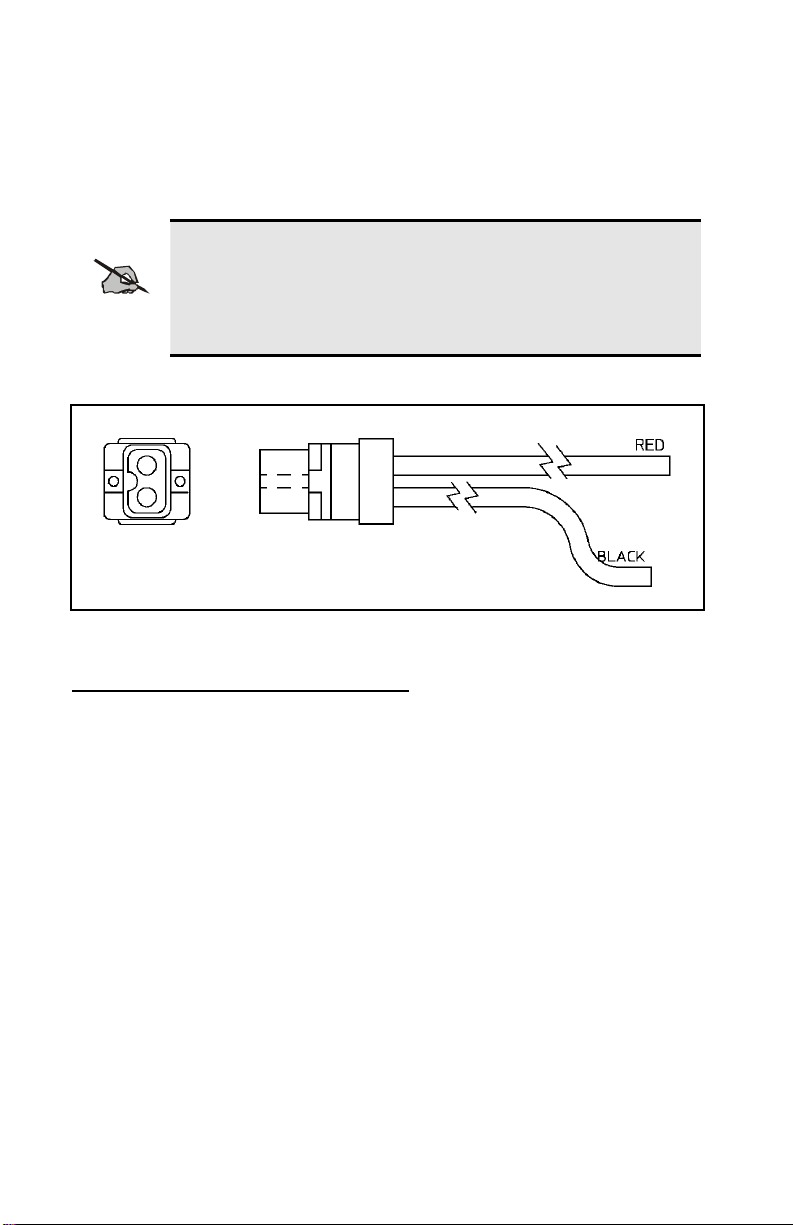

Power Cable

The USA power cable (19B802622P1 or P3) consists of a red lead (A+) and a

black lead (A-) connected to a molded 2-pin power connector and supplied

with ring terminals. The EURO power cable also consists of a red lead (A+) a

black lead (A-) terminated with ring terminals, but it is connected to P1 of the

accessory cable or P1 of the control cable (in remote applications).

To install the power cable:

1. Drill a 5/8” hole in the firewall for the cable run and insert the rubber

grommet. Run the cable through this grommet to the battery location.

Secure the cable at several locations within the engine compartment to

prevent possible damage to cable.

2. Strip back the insulation approximately 3/8″ from the end of the black

lead. Slide one of the large heat shrink sleeves onto the wire and crimp a

battery ring terminal onto this lead. Heat shrink the sleeve over the crimp

connection. Connect the black lead directly to the battery negative (-) or

ground frame member.

13

Page 14

3. Cut off 12-18″ from the red lead. Strip back the insulation approximately

3/8″ on each end of the wires. Insert the wire ends into the small

openings at the end of each fuse holder section and crimp a fuse

connector to each wire. Prepare the other end of the short wire in the

same manner as in (2) and connect to the positive (+) terminal of the

battery.

• Do not install fuse into fuse holder until installation is

completed and all connections have been checked.

NOTE

• USA Power Cable 19B802622P3 is used only with radio

with 50 watts or less RF power output.

Figure 7: Power Cable 19B802622P1 or P3 (USA Only)

Ignition Sense (All Applications)

The fuse holder must be attached to the yellow sense lead along with the ring

terminal as follows:

1. Cut the yellow sense lead approximately 6-12" from the end to be

connected to the power source.

2. Strip the insulation from each end of the short lead and from the end of

the long lead by at least 3/8".

3. Insert the stripped end of the long lead and one end of the short lead into

the narrow end of each fuse holder half.

4. Crimp the leads in the fuse holder halves with a crimping tool.

5. Insert the 3 amp fuse into one end of the fuse holder and join the two fuse

holder halves firmly together.

6. Attach th e ring terminal to the end of the short lead and connect this lead

to the ignition "ON" sense point. (Preferably to an "Accessory" point in

the vehicle fuse panel that is switched on when the vehicle ignition

switch is in the ACCESSORY and RUN positions.)

14

Page 15

CAUTION

NOTE

• The radio, as shipped from the factory, has the

"ignition sense" feature disabled. As such, the radio

is powered ON or OFF as determined by the front

panel ON/OFF/ VOLUME control only (assuming

A+ and A- are connected). To enable "ignition

sense" feature, open top cover of radio and remove

shield from logic PWB. Slide switch SW601 from

position 3-2 to 1-2. Replace shield and top cover.

Be sure to apply correct torque to screws holding top

cover in place. See Maintenance Manual.

• The "Accessory" point should drop to ZERO volts

when the engine is cranked and return to +12 volts

after the engine is started. If a point is chosen that

drops to a voltage between zero and +12 volts, the

radio may execute a power-up cycle several times

during start up. It is recommended that the terminal

be measured with a voltmeter to ensure it shuts off

(goes to zero volts) during engine cranking.

Certain problems may be encountered when accessory

equipment is connected to the ignition or accessory lines of

the vehicle, where these lines may have large filter capacitors

and a leakage path present. If the radio does not turn off

within a reasonable amount of time after the ignition is turned

off, first try a different accessory or ignition sense pick up

point in the vehicle. Many vehicles have more than one

circuit that is switched by the ignition switch, and one may be

available that does not have large filter capacitors or a leakage

path present.

If a different pickup point cannot be found, add a 470-ohm, 1watt resistor from the ignition sense pick point to ground.

This will discharge the capacitor(s) or reduce the leakage

voltage to a low value. Current drain through this resistor

will be minimal (less than 0.03A) when the ignition is

switched on.

15

Page 16

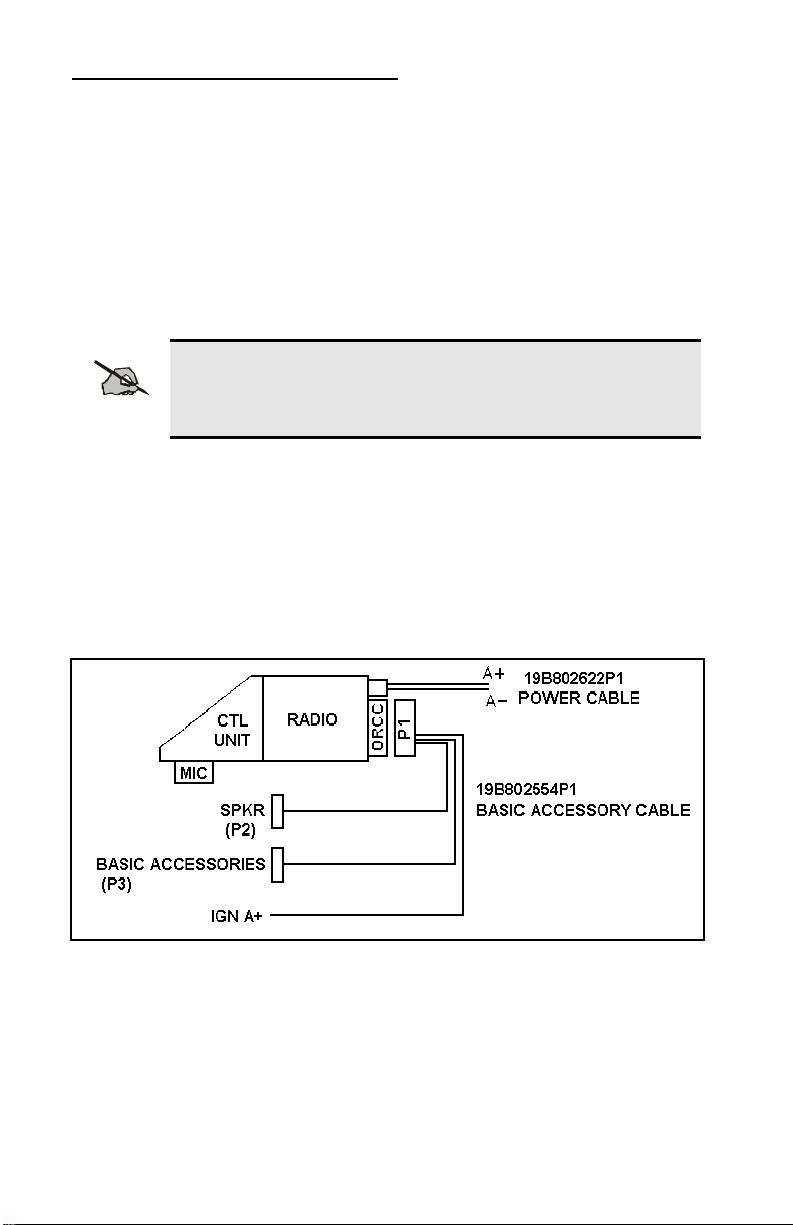

Accessory Cable (Front Mount)

The basic accessory cable consists, at one end, the basic accessories connector

(P3), the speaker connector (P2), and the ignition sense lead. At the other

end, plug P1 connects to the Option/Remote Control connector (ORCC),

which is mounted on the back of the radio. The EURO accessory cable

contains the red and black leads of the power cable.

The Extended Option accessory cable is the same as the basic accessory cable,

but has an Extended Option plug (P4). The CA101288V2 Extended Option

Accessory Cable has a pigtail (P5) at P1 that provides easy access to the front

of the radio for programming, keyloading, and mobile data.

The EURO ORCC is the opposite gender from the USA

ORCC. Interconnect diagrams for each of these cables are

NOTE

The following cables are available for Front Mount applications:

• 19B802554P1 - Basic Accessory Cable (USA Models)

• 19B802554P11 - Basic Accessory Cable (EURO Models)

• 19B802554P2 - Extended Option Accessory Cable (USA Models)

• CA101288V2 - Extended Option Accessory Cable (USA Models)

• 19B802554P12 - Extended Option Accessory Cable (EURO Models)

provided on pages 19-23.

16

Figure 8: Front Mount Basic Accessory Interconnections

(USA Models Only)

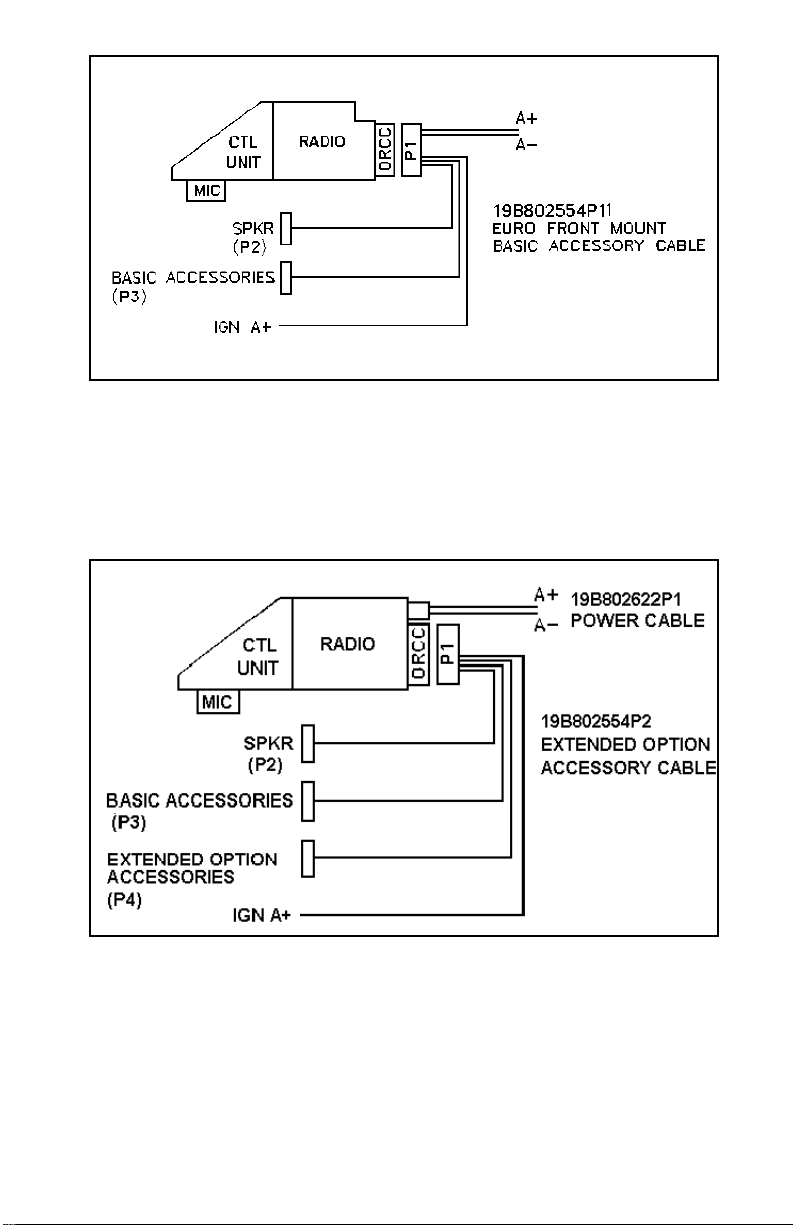

Page 17

Figure 9: Front Mount Basic Accessory Interconnections

(EURO Models Only)

Figure 10: Front Mount Extended Option Accessory Interconnections

using 19B802554P2 (USA Models Only)

17

Page 18

*(P5) Provides access for Programming/ Keyloading/ Mobile Data

Figure 11: Front Mount Extended Option Accessory Interconnections

using CA101288V2 (USA Models Only)

Figure 12: Front Mount Extended Option Accessory Interconnections

(EURO Models Only)

18

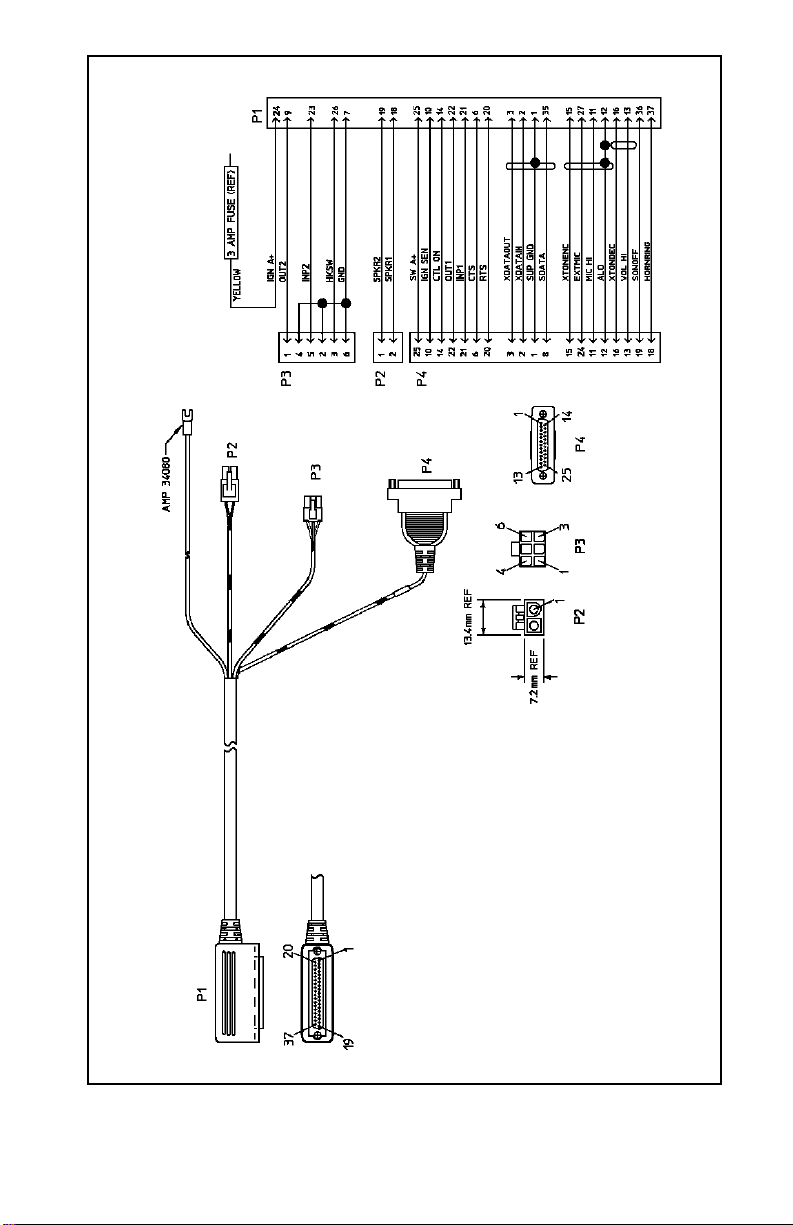

Page 19

(

19B802554, Sh.1, Rev. 23)

Figure 13: USA Front Mount Standard Accessory Cable 19B802554P1

19

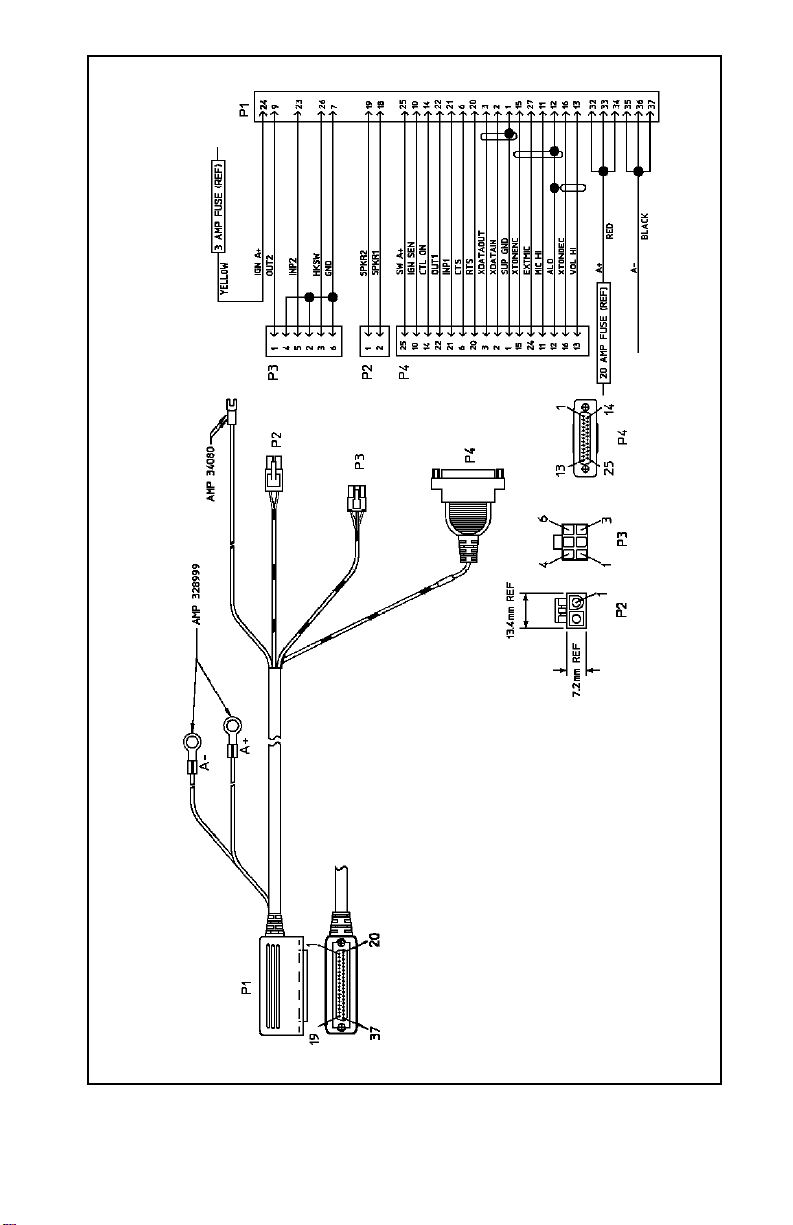

Page 20

20

(19B802554, Sh.9, Rev. 23)

Figure 14: EURO Front Mount Standard Accessory Cable

19B802554P11

Page 21

(19B802554, Sh.2, Rev. 23)

Figure 15: USA Front Mount Extended Option Accessory Cable

19B802554P2

21

Page 22

Figure 16: Front Mount Extended Option Accessory Cable CA101288V2

22

Page 23

(19B802554, Sh.10, Rev. 23)

Figure 17: EURO Front Mount Extended Option Accessory Cable

19B802554P12

23

Page 24

Accessory and Control Cable (Remote Mount)

The control cable connects the Control Unit (through the R1A) to the Radio

Transceiver in remote applications. Plug P2, at one end, connects to the

Remote Control Cable connector (RCCC) mounted on the back of the R1A.

The Ignition Sense wire is also part of P2. The other end of the control cable

(P1) connects to the ORCC mounted on the back of the radio. P1 of the

EURO control cable contains the power cable leads.

The CA101288V4 Extended Option Control Cable has a pigtail (P5) at P2

that provides easy access to the front of the remote control unit for

programming, key loading and mobile data. The Extended Option accessory

cable is the same as the basic accessory cable, but has an Extended Option

plug (P4).

The EURO ORCC is the opposite gender from the USA

ORCC. Interconnect diagrams for each of these cables are

NOTE

The following cable combinations are available for Remote Mount

applications:

• 19B802554P6 - Basic Accessory Cable (USA Models)

provided on pages 27 - 33.

19B802554P3 - Remote Control Cable (USA Models)

• 19B802554P6 - Basic Accessory Cable (EURO Models)

19B802554P13 - Remote Control Cable (EURO Models)

• 19B802554P7 - Extended Option Accessory Cable

19B802554P4 - Remote Control Extended Option (USA Models)

• 19B802554P7 - Extended Option Accessory Cable

CA101288V4 - Remote Control Extended Option (USA Models)

• 19B802554P7 - Extended Option Accessory Cable

19B802554P14 - Remote Control Extended Option (EURO Models)

24

Page 25

Figure 18: Remote Mount Basic Accessory Interconnections

(USA Models Only)

Figure 19: Remote Mount Basic Accessory Interconnections

(EURO Models Only)

Figure 20: Remote Mount Extended Option Accessory Interconnections

(USA Models Only)

25

Page 26

*(P5) Provides access for

Programming/Keyloading/Mobile Data

Figure 21: Remote Mount Extended Option Accessory Interconnections

using CA101288V4 (USA Models Only)

Figure 22: Remote Mount Extended Option Accessory Interconnections

(EURO Models Only)

26

Page 27

(19B802554, Sh.5, Rev. 23)

Figure 23: Remote Mount Standard Accessory Cable 19B802554P6

27

Page 28

Figure 24: Remote Mount Extended Option Accessory Cable

19B802554P7

28

(19B802554, Sh.6, Rev. 23)

Page 29

(19B802554, Sh.3, Rev. 23)

Figure 25: USA Remote Control Cable 19B802554P3

29

Page 30

(19B802554, Sh.4, Rev. 23)

Figure 26: USA Remote Extended Option Control Cable 19B802554P4

30

Page 31

Figure 27: Remote Extended Option Control Cable CA101288V4

31

Page 32

Figure 28: EURO Extended Options Remote Control Cable

19B802554P13

32

(19B802554, Sh.11, Rev. 23)

Page 33

(19B802554, Sh.12, Rev. 23)

Figure 29: EURO Extended Options Remote Control Cable

19B802554P14

33

Page 34

STEP 4 – MOUNT CONTROL UNIT AND RADIO

Control Unit Mounting (Remote Applications Only)

1. Use the bracket as a template and mark and drill the mounting holes. Be

sure to leave enough room at the rear of the control unit for the cable

connector. Refer to Figure 30 for control unit mounting bracket

installation.

2. Secure the mounting bracket using the four No. 10 x 3/4 self-tapping

screws supplied. (Use No. 10 x 1 ½ if needed.)

3. Secure the control unit to the bracket with the two 1/4-20 x 5/8 hex head

screws and lock washers provided.

Top Mount Bottom Mount

Figure 30: Control Unit Mounting Brackets

Pigtail Bracket

The Pigtail Bracket mounts the DB15 connector for easier user access. The

DB15 connector facilitates radio programming and keyloading by the

customer without the need to dismantle the radio or Control Unit. There are

two Pigtail brackets, one for use with the Control Unit and one for use with

the radio-mounting bracket. This section includes procedures to mount the

Pigtail Brackets in each of these configurations.

Control Unit Mounting

For Control Unit mounting, attach the pigtail bracket to the side of the Control

Unit bracket using existing mounting bracket hardware. The Pigtail Bracket

can be mounted to the left or right side of the Control Unit. Hardware Kit,

KT101533V6, contains Pigtail mounting bracket and hardware required to

attach Pigtail to bracket.

34

Page 35

When mounting two DB-15 connectors to the control unit,

mount one pigtail bracket on each side of the existing

NOTE

mounting hardware of the control unit.

1. Attach DB15 connector to the rectangular end of bracket with 2 pan head

machine screws and washers. See Figure 31.

2. Remove the ¼-20 x 5/8 hex head screw and washer from the side of the

Control Unit bracket where the Pigtail installation is desired. Retain the

hardware for Step 4.

3. Align the single hole at the end of the Pigtail Bracket with the holes in the

Control Unit bracket and the Control Unit.

4. Replace washer and insert hex head screw and tighten. See Figure 31.

Figure 31: DB15 connector mounted on Control Unit Pigtail Bracket and

Pigtail Bracket installed on Control Unit

CONTROL UNIT WITH

BRACKET FOR PIGTAIL

Figure 32: Control Unit with Bracket for Pigtail

35

Page 36

Radio Bracket Mounting

For Radio Bracket mounting, the Pigtail Bracket is attached to either side of

the Radio mounting bracket. Hardware Kit, KT101533V5, contains the

Pigtail

Bracket hardware to attach the Pigtail to the bracket.

1. Remove the plastic spacer/glide from the left or right side of the Orion

transceiver mounting bracket. This will get reapplied to the other side of

bracket where it is currently installed.

2. Slide the Orion into the transceiver bracket.

3. Slide the pigtail mounting bracket between the Orion radio casting and

the transceiver bracket (right or left).

4. Place the plastic spacer/glide you removed in step #1 back on the

transceiver bracket.

5. Re-use the Orion mounting hardware to fasten the Pigtail Bracket to th e

side of the Orion. Make sure you use a flat washer under each screw (See

Figure 33).

6. Before tightening Pigtail Bracket down, position the bracket up or down

to suit the installation requirements. Then tighten down all screws using

the proper torque specifications.

36

Figure 33 – Pigtail Bracket Mounted on Radio

Page 37

Radio Front Mount And Final Hook-Up

Typically, the bracket shown in Figure 34 is used for Front Mount

applications. The bracket can be mounted so that it is either above or below

the radio as convenient. The bracket shown in Figure 30 can also be used for

Remote Mount applications but is

radios or 100 watt UHF radios. The following instructions are for a Front

Mount installation using the bracket shown in Figure 34.

1. Using the bracket as a template, mark and drill the mounting holes using

a No. 27 drill. Be sure to leave enough room at the front and rear of the

radio for cable connections.

2. Mount bracket using four 1/4"-14 x 3/4" sheet metal screws. (Use 1/4"14 x 1-1/2" screws if needed.)

3. Place radio into mounting bracket and secure using four M4 x 10 mm hex

head screws, M4 flat washers and M4 lock washers (supplied) using the

No. 20 Torx Driver.

4. Connect antenna coaxial cable to antenna connector (TNC).

5. Connect front mount accessory cable connector P1 to the Option/Remote

Control Connector (ORCC) and secure with the two captive screws in the

connector to the radio.

6. Connect front mount accessory cable connector P2 to speaker cable

connector.

not recommended for 110 watt VHF

7. Connect power cable to power connector on rear of radio unit and secure

with the two captive screws to the radio unit.

8. Connect microphone connector to connector on front panel and secure

with captive screw.

Do not torque microphone connector screw greater than 2 in-

NOTE

lb. Alternatively, finger tight plus ¼ turn is acceptable.

9. If there are no other accessory connections, tie back plug P3 to main

cable.

10. Recheck all connections before inserting fuse into transmit fuse assembly.

37

Page 38

Top Mount

Bottom Mount

Figure 34: Mounting Bracket Installation

Radio Remote Mount and Final Hook-Up

The bracket shown in Figure 35 is used for Remote Mounting (USA only). In

some applications, the bracket shown in Figure 34 can also be used. The

following instructions are for a Remote Mount installation using the bracket

shown in Figure 35.

1. Using the bracket as a template, mark and drill the mounting holes using

a No. 27 drill. Be sure to leave enough room at the rear of the radio unit

for the cable connections.

2. Mount bracket using four 1/4"-14 x 3/4" sheet metal screws. (Use 1/4"14 x 1" if needed.) The bracket can be mounted so that it is either above

or below the radio as convenient.

3. Slide the radio unit into the bracket by aligning bracket guides with

grooves on each side of radio (rear of radio should be inserted first).

Slide radio back until screw holes in front of bracket align with screw

holes in side of radio. See Figure 35.

4. Secure radio to the bracket with two M4 x 10 mm socket head screws

provided.

5. Connect antenna coaxial cable to antenna connector (TNC).

6. Connect remote control cable connector P1 to the ORCC connector on

the radio unit and secure with the two captive screws.

38

Page 39

7. Connect other end of the remote control cable to the remote control cable

connector (RCCC) on the remote control unit.

8. Connect remote mount accessory cable connector P1 to the option

connector (OPT) on control unit. Then, connect the speaker to connector

P2 and accessory connector P3 to any options (hookswitch, etc.). If

connector P3 is not used, insulate and tie back to main cable.

9. Recheck all connections and cables before inserting fuse into transmit

fuse assembly.

Top Mount

Bottom Mount

Figure 35: Remote Mounting Bracket Installation (USA Only)

39

Page 40

Cassette Mounting (EURO Only)

The cassette mounting assembly is designed to mount in a standard DIN space

in the instrument panel or console. This mounting permits rapid insertion and

removal of the radio unit from the vehicle. All connections are made through

a quick disconnect connector at the rear of the cassette mounting assembly to

the radio unit. This connector is part of the cassette assembly. The cassette

assembly is shown in Figure 36.

Figure 36: Cassette Assembly (EURO Only)

Cassette Assembly Mounting

1. Insert the cassette assembly in the mounting location. Secure the cables

with the sheet metal screws and retaining straps provided.

2. Secure the back of the cassette assembly using the mounting stud (located

at the back of the cassette assembly), No. 6 flat washer, No. 6 sp lit lock

washer and No. 6 wing nut.

3. Several tabs are located on the top, bottom and sides of the cassette

assembly. These tabs are conveniently located near the front of the

assembly and can be bent out as needed to further secure the cassette

assembly to the vehicle.

4. Next, install the handle assembly:

a. Turn the radio upside down. Remove the two small machine screws

on the bottom of the radio, near the front. Use upward pressure on

screws to engage captivated threads for removal.

40

Page 41

b. Using the machine screws and flat washers provided with the handle

assembly, attach the handle to the bottom of the radio. The two holes

on the handle should align with the two holes on the radio created by

step (A). Once installed, the rubber handle should rotate freely from

over top of the radio to just out in front of the control unit

(approximately 90 degrees). Be sure to torque the two mounting

screws within 6.5 to 8.25 in/lb limits.

5. Connect the antenna coaxial cable to the cassette mounting assembly rear

connector.

6. Connect the power leads and the ignition sense leads as described in

previous sections. See Figure 38.

7. Connect the speaker cable connector P2 to the speaker and the basic

accessory connector P3 to the following options (if used, see Figure 38.)

OPTION PLUG AND PIN

Ext. Hookswitch P3-3 (HOT)

Foot Switch P3-5 (HOT)

P3-2 (GND)

Horn Relay P3-1 (HOT)

P3-6 (GND)

P3-4 (GND)

8. Connect the extended option accessory plug P4 to the following options

(if used, see Figure 36.)

• Mobile Data Terminal

• Public Address (External Amplifier)

• External Microphone

• External Tone Encoder

• External Tone Decoder

• Output (User Defined)

• Input (User Defined)

Refer to accessory manual supplement for details regarding

the extended options listed above. DO NOT CONNECT

CAUTION

DIRECTLY TO A PC OR DATA TERMINAL. DAMAGE

COULD RESULT!

41

Page 42

9. W ith the handle assembly in the UNLOCKED position (out in front of

the control unit), insert the radio into the cassette assembly. Slide the

radio into the cassette assembly until the back o f the radio meets the back

of the cassette assembly.

Caution should be used while engaging the radio in the

cassette the first few times until the cabling in the cassette

mount assembly has settled into its permanent location. To

insure proper first time engagement, the following procedure

should be followed:

Insert radio into cassette mount opening and slide in until

some spring resistance is felt. Holding the handle, move the

radio gently from side to side until the unit locates the

NOTE

necessary connectors. Engage the radio handle in the sheet

metal hooks, which protrude from the lower corners of the

cassette mount casing. Rotate the handle upward to fully

engage the radio. See Figure 37. DO NOT FORCE THE

CONNECTOR ENGAGEMENT.

If the radio does not engage using the above method, a large

flat blade screwdriver may be used to slightly re-position the

37-pin connector.

10. Recheck all connections and cables before inserting fuse into transmit

fuse assembly.

42

Figure 37: Handle Assembly in LOCKED Position

Page 43

(19C852366, Sh.2, Rev.2)

Figure 38: Cassette Assembly Schematic Diagram

43

Page 44

STEP 5 - INSTALL OPTIONS AND ACCESSORIES

Speaker D2LS1F

The speaker kit includes the speaker, mounting bracket and connecting cable.

Mount the speaker so it is directed to the operator but does not present a

hazard in the event of an accident. The speaker can be mounted on the lower

edge of the instrument panel, the firewall or above the windshield in some

trucks.

1. Use the mounting bracket as a template for locating the mounting holes

and mount the speaker as shown in Figure 39.

2. To connect the speaker to the accessory cable, refer to the applicable

installation procedures.

Microphone Hanger and/or Hookswitch Mounting

The microphone hanger, or hookswitch, should be mounted in a location

convenient to the operator where it will not interfere with the safe operation of

the vehicle or pose a hazard to vehicle passengers. The hanger or hookswitch

is designed to be mounted with the open end of the mounting button slot

pointed upward. Use the hanger or hookswitch as a template to mark and drill

the mounting holes. Mount with the self-tapping screws provided.

44

Figure 39: Speaker Mounting Bracket

Page 45

Siren and Light

For instructions about installing the Federal Signal Corporation Siren and

Light Kit, refer to the Federal Signal Corporation Installation Instructions

(Federal Systems part number 255287B, rev. B or higher).

Program the radio to work with the Federal Systems Siren and Light Kit,

using the instructions outlined in the ProGrammer On-Line Help under “Siren

and Light Options.”

The following issues have been reported on some Orion

Siren/Light installations using the Federal Signal Corporation

Siren and Light Kit:

• Occasional false activation of Siren and Light functions

when the ignition is turned to the “on” position and/or

when the vehicle is started.

NOTE

control head, which can be temporarily resolved by either

power cycling the radio or turning the car ignition “off”

and then “on” again.

• Occasional re-activation of Siren and Light function after

siren module has been turned off

To resolve the first two issues, modify the Federal Systems control cable

as follows:

1. Remove the outer shell from the DB25 side of the Federal Systems

control cable.

• Occasional failure to enable Siren or Light functions via

2. Add a jumper from pin 1 to pin 19.

This modification to the SS2000 cable harness will disable the Orion’s

capability to turn on and off the SS2000 from the front of the control head.

The SS2000 will now be turned on and off strictly by its own ignition switch

trigger line. (Red wire from 12 pin Molex

®

connector on SS2000 siren box.)

Follow the SS2000 Federal Signal installation instructions to attach the red

ignition line correctly.

45

Page 46

To resolve false activation, refer to TSM Vol. 25, #2 problem/solution

below:

Problem: Siren/Light functions change or turn off when switching

between radios in Dual Radio installations with a SS2000 siren

box.

Solution: Keyboard maps and Siren/Light configuration must be identical

in both radio personalities to prevent this.

Additionally, in a Remote Mount Installation, there are three jumpers that

must be reconfigured in the Orion Remote control Unit for Siren/Light

operation. These jumpers are located on the Remote Interface Adapter (RIA),

a PC board in the back half of the unit. To access these jumpers, the RIA

must be removed from the control unit, as follows:

1. Disassemble the Orion control unit using steps given in LBI-38909, page

4, “Disassembly Procedures”.

2. Flex circuit PC2 does not need to be disengaged from J2, providing care

is taken to avoid excessive bending.

3. Reconfigure jumper “AB” from center to “B”, jumper “CD” from center

to “D”, and jumper “EF” from center to “F”.

4. Carefully reassemble RIA to the front control panel making sure that

there is adequate alignment and lubricant for the black O-ring gasket at

the mechanical interface between the RIA and the control panel. This

maintains the moisture seal of the control panel. Refer to LBI-38909,

figure 1B.

46

Page 47

INSTALLATION (DUAL CONTROL UNITS)

The Dual Control feature can be configured for either front or remote mount

radio units. Each configuration provides for a Main Control Unit and an

Auxiliary Control Unit. In front mount configurations, the Main Control Unit

is mounted to the radio unit and the Auxiliary Control Unit is located in a

convenient location. In remote mount configurations, the Main Control Unit

is mounted separate from the radio unit, typically located in the vehicle cab

and the Auxiliary Control Unit located in a convenient location.

It is recommended that the units be programmed at a Service Center first, and

then transferred to the user's installation. However, some installation and

programming cables are designed to facilitate field programming, see Figure

40 thru Figure 43. All radio units in the Dual Control Unit configuration

MUST BE PROGRAMMED PRIOR to final installation.

STEP 1 - PRE-INSTALLATION PROGRAMMING

In order to provide each control unit with the proper identification code, the

radio and control units must be programmed sequentially. The following

sections provide the personality parameters settings required for installing

dual control units. These parameters are defined in the personality by the

radio programming software (ProGrammer - TQS3385).

Front Mount Procedure 1

Setup the Front Mount radio with one of the three programming cables as

shown in Figure 40. Program the radio and main control unit with the

following control configurations:

NETWORK OPTIONS

Dual Control Enable

Audio Mode Active

Switching Mode Independent

Siren Light Controller Unit A

Siren Light Connection Unit A

Speaker Disable

Multiple Radio Disable

PROGRAM RADIO SETUP

Mobile Options Push Button

ORION OPTIONS

Write Orion System Keypad File Enable (System control unit)

Write Scan Keypad File Enable (Scan control unit)

47

Page 48

Figure 40: Step A Programming Diagram for Front Mount Dual Control

Unit

48

Page 49

Front Mount Procedure 2

Setup the Front Mount radio and the Auxiliary Control Unit with one of the

three programming cables as shown in Figure 41. Program the auxiliary

control unit with the following control configurations:

NETWORK OPTIONS

Dual Control Enable

Audio Mode Active

Switching Mode Independent

Siren Light Controller Unit A

Siren Light Connection Unit A

Speaker Disable

Multiple Radio Disable

PROGRAM RADIO SETUP

Mobile Options Push Button

ORION OPTIONS

Write Orion System Keypad File Enable (System control unit)

Write Scan Keypad File Enable (Scan control unit)

49

Page 50

Figure 41: Step B Programming Diagram Front Mount Dual Control

50

Page 51

Remote Mount Procedure 1

Setup the remote mount radio and the main control unit with one of the three

programming cables as shown in Figure 42. Program the radio and main

control unit with the following control configurations:

NETWORK OPTIONS

Dual Control Enable

Audio Mode Active

Switching Mode Independent

Siren Light Controller Unit A

Siren Light Connection Unit A

Speaker Disable

Multiple Radio Disable

PROGRAM RADIO SETUP

Mobile Options Push Button

ORION OPTIONS

Write Orion System Keypad File Enable (System control unit

Write Scan Keypad File Enable (Scan control unit)

51

Page 52

Figure 42: Step A Programming Diagram Remote Mount Dual Control

52

Page 53

Remote Mount Procedure 2

Setup the Remote Mount radio and the Auxiliary Control Unit with one of the

three programming cables as shown in Figure 43. Program the auxiliary

control unit with the following control configurations:

NETWORK OPTIONS

Dual Control Enable

Audio Mode Active

Switching Mode Independent

Siren Light Controller Unit A

Siren Light Connection Unit A

Speaker Disable

Multiple Radio Disable

PROGRAM RADIO SETUP

Mobile Options Push Button

ORION OPTIONS

Write Orion System Keypad File Enable (System control unit)

Write Scan Keypad File Enable (Scan control unit)

53

Page 54

Figure 43: Step B Programming Diagram Remote Mount Dual Control

54

Page 55

STEP 2 – INSTALL DUAL CONTROL UNITS

Front Mount

The Dual Control Unit feature is configured such that only one Control Unit

can be used for Extended Option accessories. Connect all Extended Option

accessories through the Main Control Unit.

1. Referring to Figure 44 and Figure 45, run the Dual Control Cable

(19B802554P9) between locations for the Radio Unit and Auxiliary

Control Unit. Be sure to locate the P2/P3 con necto r assembly at the radio

unit.

2. After installing radio unit mounting hardware in the normal fashion,

connect the Dual Control Cable connector (P3) to the radio unit. Tighten

the two jackscrews on P3. Next, connect the Accessory cable

(19B802554P1, 19B802554P2, or CA101288V2) connector (P1) to the

Dual Control Cable connector (P2), and tighten the jackscrews on P2.

Connect the power cable, and install radio unit in mounting bracket.

3. After installing the Auxiliary Control Unit in the normal fashion, connect

the Dual Control Cable (P1) to Auxiliary Control Unit, and tighten

jackscrews.

4. Connect the Remote Mount Accessory cable (19B802554P6) to the

Auxiliary Control Unit.

5. A yellow Ignition Sense lead is provided on the Dual Control Cable and

the Front Mount Accessory cable. If the “Ignition Sense” feature is

enabled on the radio unit, it is necessary to connect only one of the

yellow leads provided, whichever is convenient. Tape back the unused

yellow lead. (See page 14 for details.)

6. Install the Speakers in convenient locations near each radio unit.

Parallel Audio Installation Requirements

In special configurations that require both speakers to operate at

the same time (simultaneous audio), install the speakers for

parallel audio operation. For wiring information, refer to the

Parallel Audio Setup Insert section of Figure 44 and Figure 45.

Perform the following steps to install parallel audio speakers:

NOTE

1. Use the two 8Ω speakers, part number 19A149590P12, in

place of the two 4Ω speakers, part number LS 102824V1.

2. Hardwire each speaker directly (without relays) as shown

in Figure 44 and Figure 45.

It is very important to use the correct speakers for this

application. Wiring 4Ω speakers in this configuration may cause

damage to the radio.

55

Page 56

7. Install a relay (19A149299P1) from the kits supplied at a location near

the leads from each speaker. For mounting, use the #8 x 3/4” sheet metal

screw and nut plate supplied with each kit.

8. At a convenient point, cut one of the wires in each of the 2-wire speaker

cables, spread the leads, and strip the ends. Crimp a ¼” tab receptacle to

each end.

9. Radio Unit Speaker: Connect the lead nearest the speaker to Pin 87A of

the relay. Connect the lead nearest the connector to Pin 30 of the relay.

Connect the speakers connector to the Accessory cables P2. See Figures

47 and 48.

10. Auxiliary Control Unit Speaker: Connect the lead nearest the speaker to

Pin 87 of the relay. Connect the lead nearest the connector to Pin 30 of

the relay. Connect the speakers connector to the Accessory cables P2.

See Figure 44 and Figure 45.

11. For each relay: Connect a #18 AWG black wire between the relay, Pin 85

and Accessory cable P3-1 (labeled “OUT2” on the schematic diagrams

in the service manual). Use a ¼” tab receptacle on the relay side and

mating Molex connector and pins on the accessory cable side. Connect

the mating Molex connector to the Accessory cables P3 when finished.

See Figure 44 and Figure 45.

12. For each relay: Connect a #18 AWG red wire to the relay, Pin 86. Cut to

length, and connect to the 1 amp fuse holder supplied. Use crimp on

connectors supplied. Connect the other side of the 1 amp fuse holder to

A+ battery source or vehicle A+ fuse block. Use #18 AWG red wire and

ring lug supplied, if needed. See Figure 44 and Figure 45.

13. Check the dual control operation using the operator’s manual as a test

guide. In the PC programming software, make sure the “DUAL

CONTROL SPEAKER” is programmed to “ACTIVE LOW”.

56

Page 57

Figure 44: Dual Control Unit Front Mount Installation Configuration

using 19B802554P1 or P2

57

Page 58

Figure 45: Dual Control Unit Front Mount Installation Configuration

using CA101288V2

Remote Mount

1. Referring to Figure 46 and Figure 47, run the Remote Control Cable

(19B802554P3, 19B802554P4 or CA101288V4) between locations for

the Radio unit and Main Control unit.

2. Run the Dual Control Cable (19B802554P9) between locations for the

radio unit and Auxiliary Control unit. Be sure to locate the P2/P3

connector assembly at the radio unit.

3. After installing the radio unit in the normal fashion, connect the dual

control cable connector (P3) to the radio unit. Tighten the two

jackscrews on P3. Next, connect the Remote Control Cable connector

(P1) to the Dual Control Cable connector (P2), and tighten jackscrews on

(P2).

4. After installing the Main Control Unit in the no rmal fashion, connect the

Remote Control Cable (P2) to the Main Control Unit and tighten

jackscrews.

58

Page 59

5. After installing the Auxiliary Control Unit in the normal fashion, connect

the Dual Control Cable (P1) to the Auxiliary Con trol Unit and tigh ten the

jackscrews.

6. Connect the accessory cable (19B802554P6) to the Auxiliary Control

Unit. Connect either the accessory cable (19B802554P6) or the extended

option accessory cable (19B802554P7) to the Main Control Unit as

appropriate.

7. A yellow ignition sense lead is provided on each control cable. If the

“Ignition Sense” feature is enabled on the radio unit, it is necessary to

connect only one of the yellow leads provided, whichever is convenient.

Tape back the unused yellow lead. See page 24 for details.

8. Install the speakers in convenient locations near each control unit.

Parallel Audio Installation Requirements

In special configurations that require both speakers to operate

at the same time (simultaneous audio), install the speakers for

parallel audio operation.

For wiring information, refer to the Parallel Audio Setup

Insert section of Figure 46 and Figure 47. Perform the

following steps to install parallel audio speakers:

1. Use the two 8Ω speakers, part number 19A149590P12,

NOTE

in place of the two 4Ω speakers, part number LS

102824V1.

2. Hardwire each speaker directly (without relays) as shown

in Figure 46 and Figure 47.

It is very important to use the correct speakers for this

application. Wiring 4Ω speakers in this configuration may

cause damage to the radio.

9. Install a relay (19A149299P1) from the kits supplied at a location near

the leads from each speaker. Use the #8 x 3/4” sheet metal screw and nut

plate supplied with each kit for mounting.

10. At a convenient point, cut one of th e wires in each of the 2-wire speaker

cables, spread the leads, and strip the ends. (Crimp a ¼” tab receptacle to

each end.)

11. Main Control Unit Speaker: Connect the lead nearest the speaker to Pin

87 of the relay. Connect the lead nearest the connector to Pin 30 of the

relay. Connect the speaker connector to the accessory cables P2. Refer

to Figure 46 and Figure 47.

12. Auxiliary Control Unit Speaker: Connect the lead nearest the speaker to

Pin 87A of the relay. Connect the lead nearest the connector to Pin 30 of

the relay. Connect the speaker connector to accessory cables P2. Refer

to Figure 46 and Figure 47.

59

Page 60

13. For Each Relay: Connect a #18 AWG black wire between the relay, Pin

85 and accessory cable P3-1 (labeled “OUT2” on schematic diagrams in

the service manual). Use a ¼” tab receptacle on the relay side and a

mating Molex connector and pins on the accessory cable side. Connect

the mating Molex connector to the accessory cable P3 when finished.

(Refer to Figure 46 and Figure 47.)

14. For Each Relay: Connect one end of a #18 AWG red wire to the relay,

Pin 86. Cut the lead to length, and connect the other end to the 1 amp

fuse holder supplied. Use crimp on connectors supplied. Connect the

other side of the 1 amp fuse holder to the A+ battery source or a vehicle

A+ fuse block. Use a #18 AWG red wire and a ring lug supplied, if

needed. (Refer to Figure 46 and Figure 47.)

15. Check dual control operation, using the operator’s manual as a test guide.

In the PC programming software, make sure the “DUAL CONTROL

SPEAKER is programmed to “ACTIVE HIGH”.

Figure 46: Dual Control Unit Remote Mount Installation Configuration

using 19B802554P3 or P4

60

Page 61

Figure 47: Dual Control Unit Remote Mount Installation Configuration

using CA101288V4

61

Page 62

(19B802554, Sh.7, Rev. 23)

Figure 48: Remote Mount Dual Control Cable 19B802554P9

62

Page 63

DUAL RADIO UNITS

Configure the Dual Radio feature for two remote mount radio units, or one front

mount unit and one remote mount unit. In remote mount configurations, the

control unit is typically located in the vehicle cab, with the radio units located

side-by-side in vehicle trunk. In front mount configurations, the front mount

radio unit is located in the vehicle cab, with the remote mount radio unit located

in a convenient location nearby. The remote mount configuration is the preferred

installation, since a separate control unit is required to pro gram the remote unit in

a front mount configuration.

The following Dual Radio configurations will not work:

• Any configuration using a DIN cassette mount.

• Any installation where Extended Options are required from both radio units.

Extended Options are supported in one radio unit only.

STEP 1 - PRE-INSTALLATION PROGRAMMING

All radio units in the Dual Radio configuration MUST BE PROGRAMMED

PRIOR to final instal lation. These configurations provide for a Master radio

unit and a Slave radio unit. In the front mount configuration, the control unit is

mounted to the master radio unit. In the remote mount configuration, both radio

units are installed separate from the control unit and the master radio unit is

always the radio most directly connected to the control unit. Connect extended

options to the Master radio unit only.

Both the Orion Master and Orion Slave mobiles must be

programmed with the same Group version of Flash code. The

Group version must be G30 or later. Failure to do so may

NOTE

One radio is programmed as a master, and one radio is programmed as a slave.

It is recommended that the units be programmed at a Service Center first, and

then transferred to the user's installation. However, some installation and

programming cables are designed to facilitate field programming, see Figure

49 and Figure 50. The radios and control unit must be programmed in a

sequential order to provide each radio with the proper identification code.

Use one of the three programming cables listed on page 4, to program the

Master radio unit and the Slave radio unit as described in the following

sections.

result in inadvertent lockup states in the Dual Radio

configuration.

63

Page 64

Master Radio Programming

Decide which radio unit shall be the Master Unit. For shop programming, setup

the Master radio unit for programming as described in the Service Manual or in

the ProGrammer On-Line Help. For field programming, setup the Master radio

unit for programming as shown in Figure 49 . THE SLAVE RADIO MUST

BE DISCONNECTED. Program the Master radio and control unit with the

control configurations shown in Table 1.

Slave Radio Programming

Decide which radio unit shall be the Slave radio unit. For shop programming,

setup the Slave radio unit for programming as described in the Service Manual or

in the ProGrammer On-Line Help. For field programming, setup the Slaver radio

unit for programming as shown in Figure 50. THE MASTER RADIO

MUST BE DISCONNECTED. Program the Slave radio unit with the control

configurations shown in Table 1.

Table 1 – Dual Radio Control Configuration Programming

NETWORK OPTIONS

Dual Control Disable

Speaker Disable

Multiple Radio Enable

Radio type Slave or Master

Power Up Volume 5

Mute Time Out 30.0

Termination Enable

Display Selected for Master radio only

Power Up Enable for Master radio only

Power Up Radio Enable for Master radio only

Receive Emergency Enable for Master radio only

Receive Only Enable for Master radio only

MuRPS Disable for Master radio only

PROGRAM RADIO SETUP

Mobile Options Push Button

ORION OPTIONS

Write Orion System Keypad File Enable (System control unit)

Write Scan Keypad File Enable (Scan control unit)

64

Page 65

Figure 49: MASTER Radio Field Programming Configuration

(Dual Radio)

65

Page 66

Figure 50: SLAVE Radio Field Programming Configuration

(Dual Radio)

66

Page 67

STEP 2 – INSTALL CABLES/EQUIPMENT

Front Mount

1. Plan the mounting locations of the two radio units. Note that the maximum

cable length allowed between the two radios is two meters. Referring to

Figure 53 and Figure 54, run Dual Radio cable (19B802554P10 or

CA101288V10) between locations for Master and Slave radio units. Be sure

to locate the P2/P3 connector assembly at the Master radio unit.

CA101288V10 has a pigtail (P5) at P1, an optional extension

cable (CA101288V30) can be connected to P5 and ran to the

remote control unit as the pigtail used for easy access. See

Figure 54.

NOTE

For instructions on mounting connector P5 to the Control

Unit or the Radio refer to “Pigtail Bracket” section on page

34.

2. After installing Master radio unit mounting hardware, connect the Dual

Radio cable connector (P3) to the Master radio unit. Tighten the two

jackscrews on P3. Next, connect the accessory cable (19B802554P1,

19B802554P2 or CA101288V2) connector (P1) to the Dual Radio cable

connector (P2), and tighten to jackscrews on P2.

3. Connect microphone and accessories. Refer to Accessory Installation

Manual for proper connection of accessories.

4. Connect power cable and antenna, then install Master radio unit in mounting

bracket.

5. Connect "IGN A+" lead, if option is desired. Be sure internal switch SW601

is set properly. Refer to NOTE on Page 14 of this manual for detail s.

6. After installing Slave radio unit in its mounting hardware, connect Dual

Radio cable (P1), and tighten jackscrews. Be sure SW601 setting on Slave

radio unit is same as for Master radio unit. Connect power cable and antenna

to Slave radio.

6. Check Dual Radio operation, using operator's manual as test guide.

67

Page 68

RADIO #2

(SLAVE)

P1

O

R

C

C

DUAL RADIO ADAPTER CABLE

19B802554P10

O

R

C

C

P3

P2

P1

1

P2

2

P3

P4

ACCESSORY CABLE

19B802554P1 or

19B802554P2

SPKR

RADIO #1

(MASTER)

CU

OPTIONS

EXTENDED OPTIONS

(OPTIONAL)

Figure 51: Orion Dual Radio Front Mount Installation Configuration

*Provides access for Programming/ Keyloading/ Mobile Data

**(A + B) Optional Extension Cable for Remote Dual Radio (CA101288V30)

provides access flexibility for Programming and Keyloading to the second radio of a dual configuration.

Figure 52: Orion Dual Radio Front Mount Installation Configuration

using CA101288V30, CA101288V10 and CA101288V2

68

Page 69

Remote Mount

1. Plan the mounting locations of the two radio units. Note that the

maximum cable length allowed between the two radios is two meters.

Referring to Figure 53 and Figure 54, run Dual Radio cable

(19B802554P10 or CA101288V10) between locations for Master and

Slave radio units. Be sure to locate the P2/P3 connector assembly at the

Master radio unit.

CA101288V10 has a pigtail (P5) at P1, an optional extension

cable (CA101288V30) can be connected to P5 and ran to the

NOTE

2. After installing Master radio unit mounting hardware, connect the Dual

Radio cable connector (P3) to the Master radio unit. Tighten the two

jackscrews on P3.

3. Next, route the remote control cable (19B802554P3, 19B802554P4 or

CA101288V4) between Control Head and Master radio locations. After

installing Control Head, connect remote control cable connector (P2) to

Control Head.

4. Connect "IGN A+" lead, if option is desired. Be sure internal switch

SW601 on master radio is set properly. Refer to page 14 of this manual

for details.

remote control unit as the pigtail, used for easy access for

programming, keyloading and mobile data. See Figure 55.

5. Connect accessory cable (19B802554P6 or 19B802554P7) connector

(P1) to Control Head.

6. Connect microphone and accessories. Refer to Accessory Installation

Manual for proper connection of accessories.

7. Now connect Remote Control Cable connector (P1) to the Dual Radio

cable connector (P2), and tighten to jackscrews on P2.

8. Connect power cable and antenna, then install Master radio unit in

mounting bracket.

9. After installing Slave radio unit in its mounting hardware, connect Dual

Radio cable (P1), and tighten jackscrews. Be sure SW601 setting on

Slave radio unit is same as for Master radio unit. Connect power cable

and antenna to Slave Radio.

10. Check Dual Radio operation, using operator's manual as test guide.

69

Page 70

(

)

(

)

REMOTE CONTROL CABLE

19B802554P3 or

19B802554P4

P1

O

R

C

C

P3

P2

DUAL RADIO ADAPTER CABLE

19B802554P10

P1

O

R

C

C

SPKR

OPTIONS

EXTENDED OPTIONS

(OPTIONAL

IGN A+

R

CU #B

1

P2

2

P3

P4

OPT

P1

ACCESSORY CA BLE

19B802554P6 OR

19B802554P7

P2

C

C

C

RIA

RADIO #1

MASTER

RADIO #2

SLAVE

Figure 53: Orion Dual Radio Remote Mount Installation Configuration

*Provides access for Programming/ Keyloading/ Mobile Data

**(A + B) Optional Extension Cable for Remote Dual Radio (CA101288V30)

provides access flexibility for Programming and Keyloading to the second radio of a dual configuration.

Figure 54: Orion Dual Radio Remote Mount Installation Configuration

using CA101288V30, CA101288V10, and CA101288V4

70

Page 71

(19B802554, Sh.8, Rev. 23)

Figure 55: Dual Radio Control Cable 19B802554P10

71

Page 72

72

Figure 56: Dual Radio Control Cable CA101288V10

Page 73

Figure 57: Programming Interface Cable CA101287V1

73

Page 74

Keyloading the Radio

1. Attach the Keyloading Interface Cables’, Male DB-15, connector to

connector P5 of CA101288V2, V4 or V10 and the Male RJ-45 to the

Keyloader.

2. Turn on power of radio to be keyloaded from the control unit.

3. Access the KEYLOAD function via the radio’s menu. This enables the

radio to accept the loading of encryption keys. The parameter settings are

up to 8 banks of 7 keys.

74

Figure 58: Keyloading Interface Cable CA101287V2

Page 75

Keyloading a Dual Radio

1. Attach the Keyloading Interface Cables’ DB-15 to the radio to be

keyloaded through connector P5, and the RJ-45 connector to the

Keyloader.

2. Select the radio to be keyloaded from the control unit by accessing the

RADIO function via the radio’s menu. Toggle to the radio to be

keyloaded.

3. Access the KEYLOAD function via the radio’s menu. This enables the

radio to accept the loading of encryption keys.

Figure 59: Mobile Data Terminal Interface Cable CA101287V3

75

Page 76

76

Figure 60: Shop Programming Cable CA101288V15

Page 77

Figure 61: Extension Cable for Dual Remote Radio CA101288V30

77

Page 78

TECHNICAL ASSISTANCE

M/A-COM’s Technical Assistance Center (TAC) resources are available to

help you with the overall system’s operation, maintenance, and product

support. TAC is your point of contact when you need technical questions

answered. For more information about technical assistance services, contact

your sales representative, or call the Technical Assistance Center directly at:

North America: 1-800-528-7711

International: 434-385-2400

FAX: 1-434-455-6712

E-mail: tac@tycoelectronics.com

78

Page 79

NOTES

79

Page 80

M/A-COM Wireless Systems

221 Jefferson Ridge Parkway

Lynchburg, Virginia 24501

(Outside USA, 434-385-2400) Toll Free 800-528-7711

www.macom-wireless.com

Printed in U.S.A.

Loading...

Loading...