Page 1

Rhein Tech Laboratories, Inc. Client: M/A-COM, Inc.

360 Herndon Parkway Model:

Suite 1400 ID’s: BV8MBS800B075/3670A-MBS800B

Herndon, VA 20170 Standards: FCC Part 90/IC RSS-119

http://www.rheintech.com

Report #: 2008072

OpenSky 800 MHz Base Station

Appendix K: User Manual

Please refer to the following pages.

38 of 62

Page 2

Installation Manual

MM102225V1

Rev. B, Jul-05

Base Station/Tower Site

Page 3

MM102225V1, Rev. B

MANUAL REVISION HISTORY

REV DATE REASON FOR CHANGE

A 2003 Initial release.

B Jul. 2005 Changed Accuracy Test, Step 7, added Caution added footnote.

M/A-COM Technical Publications would particularly appreciate feedback on any errors that might be found in

this document, and suggestions on how it could be improved. Submit your comments and suggestions to:

Wireless Systems Business Unit

M/A-COM, Inc.

Technical Publications

221 Jefferson Ridge Parkway

Lynchburg, VA 24501

CREDITS

OpenSky is a registere d trademark of M/A-COM, Inc.

MATE-N-LOK is a registered trademark of Tyco Electronics.

PolyPhaser is a registered trademark of PolyPhaser Corporation.

Cisco is a registered trademark of Cisco System s, Inc.

Agilent is a registered trademark of Agilent Technologies, Inc.

All other brand and product names are registered trademarks, trademarks, or service marks of their respective holders.

fax (434) 455-6851

techpubs@tycoelectronics.com

NOTICE!

The voice coding technology embodied in this product is protected by intellectual property rights including patent rights,

copyrights, and trade secrets of Digital Voice Systems, Inc. The user of this technology is explicitly prohibited from

attempting to decompile, reverse engineer, or disassemble the Object Code, or in any other way convert the Object Code

into a human-readable form.

NOTICE!

This manual covers products manufacture d and sol d by M/A- CO M, Inc.

NOTICE!

Repairs to this equipment should be made only by an authorized service technician or facility designated by the supplier.

Any repairs, alterations or substitution of recommended parts made by the user to this equipment not approved by the

manufacturer could void the user's authority to operate the equipment in addition to the manufacturer's warranty.

NOTICE!

The software contained in this device is copyrighted by M/A-COM, Inc. Unpublished rights are reserved under the

copyright laws of the United States.

This manual is published by M/A-COM, Inc. without any warranty. Improvements and changes to this manual necessitated by typographical errors,

inaccuracies of current information, or improvements to programs and/or equipment, may be made by M/A-COM, Inc., at any time and without notice.

Such changes will be incorporated into new editions of this manual. No part of this manual may be reproduced or transmitted in any form or by any

means, electronic or mechanical, including photocopying and recording, for any purpose, without the express written permission of M/A-COM, Inc.

Copyright© 2003-2005, M/A-COM, Inc. All rights reserved.

2

Page 4

MM102225V1, Rev. B

TABLE OF CONTENTS

Page

1.0 GENERAL INFORMATION.............................................................................................................................6

1.1. INTRODUCTION.............................................................................................................................................6

1.2. REFERENCE MATERIAL...............................................................................................................................6

1.3. TOOLS AND TEST EQUIPMENT ...................................................................................................................7

1.4. TOOLS REQUIRED FOR SPECIFIC TASK....................................................................................................9

1.5. SAFETY INFORMATION ...............................................................................................................................9

1.6. SAFETY SYMBOLS ......................................................................................................................................11

1.7. OPENSKY BASE STATION EQUIPMENT SPECIFICATION (GENERAL)....................................................12

2.0 SITE PREPARATION......................................................................................................................................13

2.1 INTRODUCTION...........................................................................................................................................13

2.2 ANTENNA SYSTEM .....................................................................................................................................13

2.2.1 Antenna Mounting ...................................................................................................................................13

2.2.2 Transmission Lines..................................................................................................................................13

2.3 TOWER TOP AMPLIFIER.............................................................................................................................15

2.4 SITE REQUIREMENTS.................................................................................................................................15

2.4.1 Floor Plan ...............................................................................................................................................15

2.4.2 Operating Environment...........................................................................................................................15

2.4.3 Electrical Power......................................................................................................................................16

2.4.4 Equipment Room Grounding...................................................................................................................16

2.5 ANTENNA SYSTEM QUALITY AUDIT......................................................................................................16

3.0 BASE STATION INSTALLATION ................................................................................................................18

3.1 BEFORE INSTALLATION OCCURS ...........................................................................................................18

3.2 BASICS...........................................................................................................................................................18

3.3 SECURING EQUIPMENT RACKS TO THE FLOOR...................................................................................19

3.4 CABLING EQUIPMENT RACK COMPONENTS........................................................................................22

3.4.1 Interrack Cable Connections...................................................................................................................23

3.4.2 Connecting Power Source and External Equipment................................................................................27

3.4.3 Connect Cabling for the Power Source...................................................................................................28

3.4.4 Connect Grounding Cables to Equipment Racks.....................................................................................30

3.4.5 Connect Antenna Cables to Equipment Racks.........................................................................................31

3.4.6 Connect the T1 Network..........................................................................................................................32

3.4.7 Site Clean Up...........................................................................................................................................32

3.5 COMPLETING THE INSTALLATION.........................................................................................................32

4.0 SITE TEST PROCEDURES ............................................................................................................................33

4.1 PURPOSE AND SCOPE.................................................................................................................................33

4.2 OVERVIEW OF OPENSKY BASE SITE EQUIPMENT...............................................................................34

4.3 TEST METHODOLOGY................................................................................................................................34

4.4 PREPARATION..............................................................................................................................................35

4.5 RECORDING TEST RESULTS......................................................................................................................35

4.6 BASE SITE BLOCK DIAGRAM....................................................................................................................35

4.7 INSPECTION..................................................................................................................................................36

4.7.1 Pre-test Inspection...................................................................................................................................36

4.7.2 Interrack Cabling ....................................................................................................................................37

4.7.3 New Cabling............................................................................................................................................39

5.0 EQUIPMENT CONFIGURATION.................................................................................................................42

6.0 PERFORMANCE TESTING...........................................................................................................................43

6.1 ANALOG RECEIVE TESTS (MANDATORY).............................................................................................43

3

Page 5

MM102225V1, Rev. B

TABLE OF CONTENTS

Page

6.1.1 12dB SINAD Receiver Sensitivity ........................................................................................................... 43

6.2 ANALOG PERFORMANCE TESTING OF TOWER TOP AMPLIFIERS................................................... 46

6.2.1 Tower Top Amplifier Performance Test.................................................................................................. 46

6.3 TOWER TOP LOW NOISE AMPLIFIER (TTA) GAIN MEASUREMENT (REQUIRED) ......................... 47

6.4 ANTENNA 20DB QUIETING TEST (MANDATORY)................................................................................49

6.5 BASE STATION TRANSMIT (BSX) FREQUENCY ACCURACY TEST (MANDATORY)..................... 52

6.6 TRANSMIT DEVIATION (MANDATORY)................................................................................................ 53

6.7 TX POWER CALIBRATION (MANDATORY) ...........................................................................................54

6.8 HPA TX POWER BENCHMARKS – BIRD VSWR –57DBM PORT (REQUIRED)................................... 56

7.0 OPERATIONAL TESTING............................................................................................................................ 59

7.1 STANDALONE SITE ACCEPTANCE (MANDATORY)............................................................................ 59

7.1.1 Preparation - Remove ALL Network Connectivity.................................................................................. 59

7.1.2 Procedure for Single Site Trunking.........................................................................................................59

7.2 NETWORK CONNECTIVITY - BACKBONE COMMUNICATIONS (REQUIRED)................................ 60

7.3 T1 QUALITY LINK....................................................................................................................................... 62

7.4 FINAL DEPARTURE CHECK...................................................................................................................... 63

7.4.1 Power Failure......................................................................................................................................... 64

7.4.2 Multi Site Trunking................................................................................................................................. 65

8.0 COMMON TERMS.......................................................................................................................................... 66

APPENDIX A................................................................................................................................................................ 70

ATTACHING MIL-SPEC (MS) CONNECTOR TO END OF CONTROL CABLE/SOLDERING TOWER TOP

AMPLIFIER CONTROL CABLE.............................................................................................................................. 70

APPENDIX B................................................................................................................................................................72

CONNECTING A PC TO A BASE STATION........................................................................................................... 72

APPENDIX C................................................................................................................................................................ 74

EQUIPMENT SERIAL NUMBERS...........................................................................................................................74

APPENDIX D................................................................................................................................................................ 76

SITE ACCESS SERVER CONFIGURATION...........................................................................................................76

APPENDIX E................................................................................................................................................................82

TYPICAL MOBILE CONFIGURATION.................................................................................................................. 82

APPENDIX F................................................................................................................................................................ 84

TYPICAL BASE STATION CONFIGURATION..................................................................................................... 84

APPENDIX G ............................................................................................................................................................... 88

TVARB STATUS....................................................................................................................................................... 88

APPENDIX H ............................................................................................................................................................... 90

VERIFICATION TESTING – TRANSMIT FILTER TUNING................................................................................. 90

APPENDIX J.................................................................................................................................................................92

INSTALLER PROFILE DATA SHEET.....................................................................................................................92

APPENDIX K ............................................................................................................................................................... 94

ANTENNA SYSTEM INSTALLATION CHECKLIST............................................................................................ 94

4

Page 6

MM102225V1, Rev. B

TABLE OF CONTENTS

Page

APPENDIX L.................................................................................................................................................................96

RECORDED DATA SHEET ......................................................................................................................................96

FIGURES

Figure 3-1: Bolt Assembly Hardware............................................................................................................................20

Figure 3-2: Nylon Washer and Bolt Assembly..............................................................................................................20

Figure 3-3: Concrete Floor Mounting............................................................................................................................20

Figure 3-4: Bolt Assembly Used to Bolt Rack to Concrete Floor................................................................................. 21

Figure 3-5: Raised Floor Rack Attachment...................................................................................................................21

Figure 3-6: Possible Rack-Up of Tower Site Rack #1 For One To Ten Base Stations Plus Backup And ISM Radio

Options........................................................................................................................................................ 22

Figure 3-7: Possible Rack-Up of Tower Site Rack #2 With Separate TX/RX Antenna Option For Base Stations #1

To #4 Of Six Maximum Plus Backup Option.............................................................................................23

Figure 3-8: HPA RF Input Connection..........................................................................................................................24

Figure 3-9: DCX RF Output Connection.......................................................................................................................24

Figure 3-10: Wire Bundles with DCX and Base Station Alarm Wiring........................................................................25

Figure 3-11: DPS Alarm Punchblock Connector .......................................................................................................... 25

Figure 3-12: RS-485 Main Cable and Pigtail Plug Connected to DCX.........................................................................26

Figure 3-13: RS-232 Connector from Alarm Module to Bird Power Monitor (VSWR)............................................... 26

Figure 3-14: Cable Connecting the Tower-Top Amplifier Control Box to the Input port of the Multi-Coupler...........27

Figure 3-15: Cable Tray Layout.................................................................................................................................... 27

Figure 3-16: DC Power Connection Found in Each Rack - Black (DC Return) and Red (-48 Volt) wires...................28

Figure 3-17: -48 Volt Breaker Distribution Panel of the DC Power Supply - Red Wire............................................... 28

Figure 3-18: DC Return Distribution Bar - Black Wires...............................................................................................29

Figure 3-19: Properly Labeled OpenSky Circuit Breakers in the Distribution Panel....................................................29

Figure 3-20: Single Point Ground That is Found on Each Rack................................................................................... 30

Figure 3-21: Ground Bar............................................................................................................................................... 30

Figure 3-22: Dual Antenna PolyPhasers (Surge Protectors)..........................................................................................31

Figure 5-1: 3-Channel Base Station with Tower Top Amplifier Block Diagram..........................................................35

5

Page 7

MM102225V1, Rev. B

1.0 GENERAL INFORMATION1

1.1. INTRODUCTION

This manual specifies procedures for installing and testing OpenSky® Base

Station/Tower equipment racks at a communication site. This manual is intended for

M/A-COM and contracted personnel responsible for supervising or conducting the

equipment rack installation process.

Before attempting to install or checkout this equipment, become familiar with the

contents of this manual. This manual is divided into the following sections:

General Information - includes a list of related reference material, a list of test

equipment required for testing, aligning and maintaining radio equipment, safety

information and OpenSky Base Station equipment specifications.

Site Preparation - identifies antenna system installation practices for the antenna/tower,

transmissions lines connected to the equipment shelter, site requirements and facility

preparation, site requirements and an antenna system audit.

Base Station Installation - provides instructions for unpacking and physically installing

the Base Station equipment cabinets and interrack cabling.

Site Test Procedures - provides verification testing, equipment configuration,

compliance testing, performance testing, operational testing, network connectivity and

final operating capability.

System Configuration - provides detailed instructions for setting up the equipment prior

to applying power.

System Functional Checkout Procedures - provides detailed instructions for verifying

the overall operation of the equipment as a system.

Table of Common Terms - identifies and defines common terms used throughout this

manual.

1.2. REFERENCE MATERIAL

It may be necessary to consult one or more of the following manuals. These manuals will

also provide additional guidance if you encounter technical difficulties during the

installation or testing processes.

Title

Publication Number

• Digital Base Station Controller/Transceiver (DCX)

Maintenance Manual ................................................. MM102425V1

• High Power Amplifier (HPA-75)

Maintenance Manual .................................................

• Antenna System Maintenance Manual.......................

• Standard For Site Grounding and Protection.............

MM102445V1

LBI-38983

AE/LZT 123 4618/1

1

Taken from M/A-COM Drawing, No. AP7079, Rev.-

6

Page 8

Title Publication Number

• OE-100 Outdoor Enclosure........................................

• M/A-COM, Inc. Quality Standards Manual...............

• Rack Breaker Panel Maintenance Manual.................

• RX Amplifier Maintenance Manual ..........................

• Duplexer and Power Sensor

Maintenance Manual .................................................

• TX Combiner Maintenance Manual ..........................

1.3. TOOLS AND TEST EQUIPMENT

The items listed in Table 1-1: Tools and Test Equipment are the tools and test equipment

needed during installation, alignment, testing, and maintenance of the OpenSky Base

Station/Tower equipment racks. Test equipment other than that recommended may be

substituted, providing it is electrically equivalent in accuracy and operating range, and

capable of maintaining the tolerances specified for the recommended test equipment.

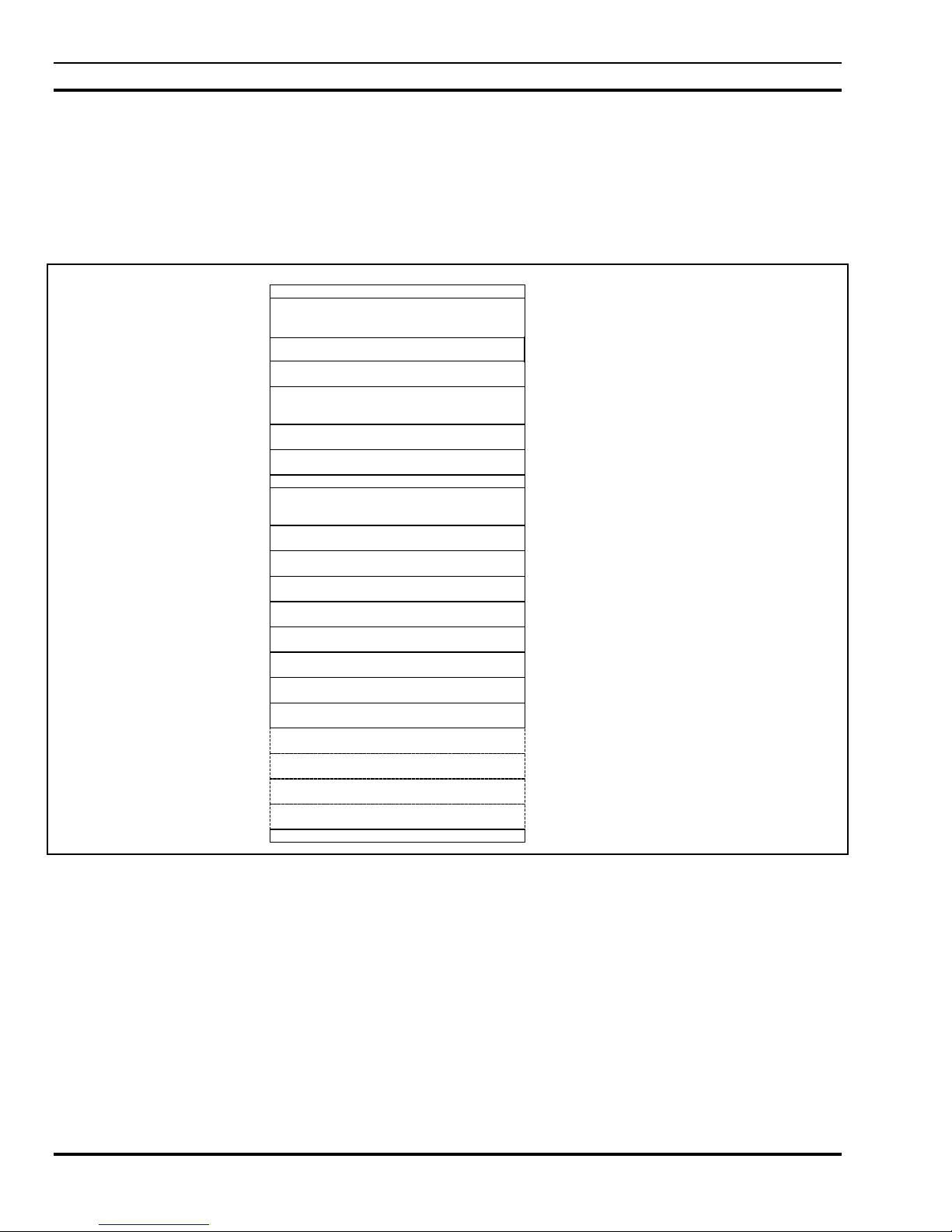

Table 1-1: Tools and Test Equipment

MM102225V1, Rev. B

MM102226V1

GQM0221

(Not Available)

(Not Available)

(Not Available)

(Not Available)

NAME OF TOOL USE/COMMENTS

Assorted Cabling

Hardware (lugs, bolts,

connectors, clamps, and so

on)

Assorted Hand Tools

Assorted Power Tools

Bolting Template

DC Power Cable

Equipment Cart (1,200

pound recommended

capacity)

Ground Cable (#6, green)

Insulating Bushings

Knife, Shears, and so on

Lag Bolts

One (3/4”) inch Drop-Down

Expanding Anchors

As needed for rack installation

As needed for rack installation

As needed for rack installation

Template for bolt placement on enclosure floor for rack

fasteners

For bringing power to equipment racks

Moving equipment racks

For grounding equipment racks

Used to insulate equipment racks from the bolts securing the

racks to cement and raised floors

Cutting strapping around rack packaging

Bolting equipment racks to wood enclosure floor

Bolting equipment racks to enclosure floor

Permanent Marker

Shim Material

7

Marking locations on enclosure floor for rack fasteners

Leveling equipment racks

Page 9

MM102225V1, Rev. B

NAME OF TOOL USE/COMMENTS

Soft Jaw Connector Pliers

Superflex Antenna Cable

Torque Wrench

Trash Bags

Hammer Drill, ½” chuck

Set tool

Basic hammer

Crimpers

Greenlee Knock-Out tool

9/16” Socket

½” Socket

7/16” Socket

Tightening or loosening N-type connectors

Crescent Pliers: M/A-COM Part Number 529-10 or Tessco Part

Number 83040

To convey antenna signals to equipment racks within a shelter

Tightening SMA connectors

Preset to 5/16-inch, 8 inch-pounds of torque: M/A-COM Part

Number 1055419-1 (2098-5065-54) or Tessco Part Number

14682, 1 Newton/Meter torque

For removal of debris from site

Used to drill holes for anchors in concrete floor

Used to expand anchors in the floor

Used with set tool to expand anchors in the floor

Used to crimp on lugs to ground wire and power leads

Used to punch out hole on top of rack for entry of ground wire

Used to secure rack to the floor and power leads to bus bar on

rack

Used to secure ground to bus bar

Used to bolt racks together

Tape measure

Soldering gun

Heat gun

12” wire ties

¾” anchors (tapcon)

1” bolts

Crimp on 1 hole lugs

Crimp on 2 hole lugs

T1 Crimper

Labeling System for field

use

Insulating washers

Service Monitor

Network Analyzer

Used to measure proper distance from wall to rack

Used to solder leads of control cable connector

For shrink tubing with control cable connector

AMP Hand Tool, Part Number 2-231652-0

Recommended unit: P-Touch Labeling System, Model PT-330

Between floor and bottom of rack between anchor bolts and

rack

HP 8920

HP 8752C (Used in conjunction with HP 8920 for Tower Top

Amplifier)

8

Page 10

1.4. TOO LS REQUIRED FOR SPECIFIC TASK

Generally, professional judgment can be used about the fitness of a tool for a given

purpose. In some cases, however, specific tools must be used to complete installation

steps properly. Failing to use the correct tool in these cases could damage equipment or

leave crucial assembly steps incomplete. The tools for specific steps in base station

installation are as follows:

Table 1-2: Tool for Specific Tasks

ASSEMBLY STEP TOOL REQUIRED

MM102225V1, Rev. B

Tightening SMA-Type

connector

Loosening SMA-type

connectors

Tightening or loosening NType connectors

Look for notes and cautions in the installation procedures that remind the installer when

these tools must be used to complete an installation step properly.

1.5. SAFETY INFORMATION

Personnel installing OpenSky rack-mounted components at a communication site should

be aware of a number of potential hazards. These hazards may be associated with

OpenSky electronic and Radio Frequency (RF) equipment, radio antennas used with

these components, or with the environments in which components are housed. Keep in

mind that when working in the field, hazards associated with equipment, antennas, or

environmental conditions that are part of applications other than OpenSky radio may also

present risks.

Hazards you may encounter include the following:

Eight Inch-Pound Torque Wrench

M/A-COM Part Number 1055419-1 (2098-5065-54) or Tessco

Part Number 14682, 1 Newton/Meter torque

5/16" (8mm) Open-End Wrench

SoftJaw Connector Pliers

Crescent Pliers, M/A-COM Part Number 529-10 or Tessco Part

Number 83040

• RF emissions

• Electrical shock

• Lifting of heavy objects

• Falling objects

• Falls

• Poor ergonomic design

• Chemical exposure

Working around the hazards listed above does not necessarily pose any outstanding risk

to health or safety - however, knowledge of these possible hazards is vital to working

safely.

9

Page 11

MM102225V1, Rev. B

The safety guidelines and precautions presented in this manual do not replace M/ACOM's specific requirements. The primary responsibility for health and safety standards,

practices and guides lines in a M/A-COM project lies with the Environmental, Health &

Safety (EHS) department.

All M/A-COM managers, supervisors, or subcontractors responsible for work associated

with OpenSky equipment must be completely familiar with and prepared to comply with

all applicable EHS guidelines and requirements. Although M/A-COM's policy requires

that all contractors and visitors must be adequately trained prior to working on any M/ACOM project, this does not mean M/A-COM is responsible for conducting or providing

this training.

The following safety precautions must be observed during all phases of operation,

service, and repair of this product. Failure to comply with these precautions or with

specific warnings elsewhere in this manual violates safety standards of design,

manufacture, and intended use of the product. M/A-COM assumes no liability for the

customer’s failure to comply with these standards.

1. SAVE THIS MANUAL - It contains important safety and operating instructions.

2. Before using this equipment, please follow and adhere to all warnings, safety and

3. DO NOT expose equipment to rain, snow or other type of moisture.

operating instructions located on the product and in the manual.

4. Care should be taken so objects do not fall or liquids do not spill into the equipment.

5. DO NOT expose equipment to extreme temperatures.

6. DO NOT use auxiliary equipment not recommended or sold by M/A-COM. To do so

may result in a risk of fire, electric shock or injury to persons.

7 GROUND THE EQUIPMENT-To minimize shock hazard, the station equipment

cabinet must be connected to an electrical ground.

IF the equipment supplied is equipped with three-conductor AC power cords, these

power cords must be plugged into approved three-contact electrical outlets with the

grounding wires firmly connected to an electrical ground (safety ground) at the

power outlet. The power cords must also meet International Energy Commission

(IEC) safety standards.

8. To reduce risk of damage to electrical cords, pull by plug rather than cord when

disconnecting a unit.

9. Make sure all power cords are located so they will not be stepped on, tripped over or

otherwise subjected to damage or stress.

10. An extension cord should not be used unless absolutely necessary. Use of an

improper extension cord could result in a risk of fire and electric shock. If an

extension cord must be used, ensure:

a. The pins on the plug of the extension cord are the same number, size, and shape

as those of the plug on the power supply.

b. The extension cord is properly wired, in good condition, and

c. The wire size is large enough for the AC ampere rating of unit.

10

Page 12

MM102225V1, Rev. B

11. DO NOT operate equipment with damaged power cords or plugs - replace them

immediately.

12. DO NOT operate this product in an explosive atmosphere.

13. To reduce risk of electric shock, unplug unit from outlet before attempting any

maintenance or cleaning.

14. DO NOT operate this product with covers or panels removed. Refer all servicing to

qualified service personnel.

15. Use only fuses of the correct type, voltage rating and current rating as specified in the

parts list. Failure to do so can result in fire hazard.

16. GROUNDING AND AC POWER CORD CONNECTION - To reduce risk of

electrical shock use only a properly grounded outlet. The system components are

equipped with electric cords having an equipment grounding conductor and a

grounding plug. Be sure all outlets are properly installed and grounded in accordance

with all local codes and ordinances.

17. DANGER - Never alter the AC cord or plug. Plug into an outlet properly wired by a

qualified electrician. Improper connection or loss of ground connection can result in

risk of an electrical shock.

18. ELECTROSTATIC DISCHARGE SENSITIVE COMPONENTS - This station

contains CMOS and other circuit components, which may be damaged by

electrostatic discharge. Proper precaution must be taken when handling circuit

modules. As a minimum, grounded wrist straps should be used at all times when

handling circuit modules.

1.6. SAFETY SYMBOLS

The WARNING symbol calls attention to a procedure, practice, or the like,

which, if not correctly performed or adhered to, could result in personal

injury. Do not proceed beyond a WARNING symbol until the conditions

WARNING

CAUTION

NOTE

identified are fully understood or met.

The CAUTION symbol calls attention to an operating procedure, practice, or

the like, which, if not performed correctly or adhered to, could result in

damage to the equipment or severely degrade the equipment performance.

The NOTE symbol calls attention to supplemental information, which may

improve system performance or clarify a process or procedure.

11

The ESD symbol calls attention to procedures, practices, or the like, which

could expose equipment to the effects of Electro-Static Discharge. Proper

precautions must be taken to prevent ESD when handling circuit modules.

Page 13

MM102225V1, Rev. B

1.7. OpenSky BASE STATION EQUIPMENT SPECIFICATION

(General)

Type: Indoor Cabinet 83 Inch Floor Mount

Size:

Height: 83 inches (77 inches usable)

Width: 22 inches

Depth: 24 inches

Number of Rack Units (RU): 44 RU available

Weight (Approximate) Depending on the number of RF

channels installed, the weight could

range from 350 to 500 LBS for the

rack with the HPA's. Usually Rack #2

is the HPA rack.

Operating Temperature

(Full spec performance per EIA/TIA603)

Note: Some third party equipment is

only rated for 0ºC to +50ºC

Input Power Source: 120 VAC (±20%), 60 Hz Or

-48 VDC

-30ºC to +50ºC (-22ºF to +122ºF)

12

Page 14

MM102225V1, Rev. B

2.0 SITE PREPARATION

2.1 INTRODUCTION

This section provides instructions for preparing the site and other installation items,

which must be completed prior to installing OpenSky Communication equipment. The

areas covered include the following:

Antenna System - This includes installation of the antenna tower, receive and transmit

antennas, tower top amplifier and the installation of the transmission lines from the

antenna to the tower top amplifier to the equipment shelter.

Site Requirements - Information is provided concerning various factors, which may

affect the physical location of the equipment facility.

Facility Preparation - This section provides information for preparing the facility prior

to installing the equipment. This information includes proposed equipment layout,

environment, electrical power, equipment room grounding and telephone line installation.

2.2 ANTENNA SYSTEM

This section covers installation of the antenna system, including RF cables from the

antennas to the equipment room wall feedthrough.

Antenna systems are generally installed by crews trained and equipped for working on

antenna towers. As a result, this manual assumes the Antenna systems are installed by

crews with the specialized equipment and skills required for working on towers and

installing the antenna cables. However, it may be necessary for the system installer to

provide information and directions to the crew installing the antenna system and to verify

proper installation.

2.2.1

The antenna tower must allow antenna mounting that provides isolation of at least 25 dB

between the TX and RX antennas. This is necessary to avoid interference in the trunked

receivers caused by the trunked transmitters. An isolation of greater than 25 dB is easily

obtained by placing one antenna directly above the other on the tower (minimum 10-foot

separation).

2.2.2

When installing the transmissions lines, refer to the diagrams contained in Antenna

System Maintenance Manual LBI-38983.

2.2.2.1 Length

Antenna Mounting

Transmission Lines

The length of the main coaxial cable for each antenna is planned as a continuous run with

no connectors or splices between the antenna and the equipment room. Each cable

includes a 50-foot allowance for the distance from the bottom of the tower to the

equipment room. Smaller diameter, more flexible coaxial cables are used at both ends of

the main coaxial cable to facilitate installation.

13

Page 15

MM102225V1, Rev. B

2.2.2.2 Minimum Bending Radius

Always adhere to the minimum bending requirements provided by the manufacturer. For

Andrew Products, the values are:

CABLE SIZE BENDING RADIUS

1/4-inch

1/2-inch

7/8-inch

1-5/8-inch

1-inch (25 mm)

1.25-inch (32 mm)

10-inches (250 mm)

20-inches (510 mm)

2.2.2.3 Hoisting Grips

Hoisting grips provide the means to attach a lifting mechanism to the coaxial cable

without damaging the cable. Each hoisting grip is capable of safely lifting 200 feet of

cable without causing damage. Therefore, one hoisting grip is required for every 200-foot

section of cable. The grips may be left attached to the cable after the cable installation is

completed.

Some situations may require more hoisting grips, such as:

• An installation to a tower which is on top of another structure.

• Any installation where the length of cable that must be lifted is greater than the

height of the tower.

In these situations, additional hoisting grips should be ordered.

14

WARNING

Under NO conditions should RF connectors be used to attach a rope or cable.

2.2.2.4 Hangers and Adapters

Coaxial cables on the tower should be secured at intervals of 3 feet (maximum).

Securing 7/8-inch and 1 5/8-inch diameter coaxial cables is accomplished by using either

hangers or hanger-adapter combinations. The hangers secure the cables to the tower

structure by using prepunched holes or attachment adapters.

When the tower structure is prepunched with 3/4-inch holes, snap-in hangers are used

(preferred method).

When the tower is prepunched with 3/8-inch holes, the hanger is secured by a 3/8-inch

bolt.

For towers without prepunched holes, the hangers are attached with adapters. The type of

adapter depends on the type of tower structure. Adapters are available for either angle

tower members or round tower members.

Page 16

MM102225V1, Rev. B

Adapters for each antenna system are selected when ordering the system. If the coaxial

cable must be attached to a structure that is not compatible with any of the above hangers

or adapters, then additional materials or other special considerations may be required.

To secure 1/4-inch or 1/2-inch vertical or horizontal coaxial cables of any size, use UV

resistant, black nylon cable ties.

2.2.2.5 Weatherproofing

A kit of weatherproof tape is provided to protect coaxial connectors from the outside

elements. One roll of tape is sufficient to weatherproof four exposed outside connector

joints (More than four are required with a Top Tower Antenna).

2.2.2.6 Antenna Grounding

Grounding kits are installed to prevent the radio system from being damaged by

lightning. A grounding point should be installed at the top end of each coaxial cable run

on the tower. A second grounding point should be installed on each cable at the bottom of

the tower and a third grounding point on the cable at the point where the cable enters the

building, if the tower-to-building length is greater than 20 feet. For cable runs on the

tower greater than 200 feet, additional grounding points should be installed at each 200foot interval. Grounding points should be installed at the Tower Top Amplifier as well.

2.3 TOWER TOP AMPLIFIER

The Tower Top Amplifier (TTA) should be installed near the receive antenna in order to

improve the receive (inbound) channel performance. The amplifier should be mounted to

the tower structure with corrosion resistant hardware and grounded to the tower structure

with a #6 AWG solid or stranded copper conductor. All TTA ground connections,

whether to tower frame (angular or circular) or a tower ground buss, should be made with

corrosion resistant hardware.

For the TTA a "drip loop" in the RF cable from the antenna is recommended.

2.4 SITE REQUIREMENTS

This section provides information for preparing the facility prior to installing the

equipment. This information includes proposed equipment layout, environment, electrical

power and telephone line installation.

2.4.1

Direct access to the area (for antenna cables and personnel) between the tower and the

equipment room is necessary. Standard floor plans for the equipment cabinets are sideby-side cabinets. Lengths of interconnect cables supplied are based on these standard

floor plans. If a floor plan other than a standard floor plan is used, longer interconnect

cables may be required.

Floor Plan

2.4.2

The equipment room where the base station equipment is installed must meet the

environmental conditions listed in the Station Specifications section of this manual.

15

Operating Environment

Page 17

MM102225V1, Rev. B

Although the temperature requirements for individual pieces of trunked equipment may

be broader, when several units are assembled together in a cabinet more heat is generated.

Because of this condition, the ambient room temperature outside the cabinet must be

lowered to ensure the temperature inside the cabinet does not exceed the limits for the

equipment.

2.4.3

Normally, OpenSky equipment is powered by –48 VDC. If the OpenSky cabinet is

equipped with an AC power supply and an AC power cord, a 20-amp circuit breaker for

each AC supply is recommended.

Receptacles must be installed within reach of the power cord(s). This can be on the wall

behind the cabinets, in the floor under the cabinets, or in the cabinet top cable ducts. Each

station power supply power cord is about 3 meters (9.8 feet) long, starting at the back of

each power supply (two or three different heights) within the rear of each station cabinet.

Each cord plugs into an AC Outlet which has a cord length of about 3 meters (9.8 feet)

long.

When required, the AC power supplies are omitted from the station cabinet. In this case,

DC power must be supplied to the base stations from an external -48 VDC power source

through a separate 30-amp circuit breaker for each base station.

Additional equipment may be required if other types of power sources are used, or if the

power source is not within reach of the individual AC power cords.

2.4.4

Ensure all equipment and facilities meet the requirements for grounding and lightning

protection.

Installation Manual AE/LZT 123 4618/1 - Standard For Site Grounding and Protection

provides instructions for proper grounding of sites and radio equipment. These

procedures should be observed in order to protect the equipment and service personnel

from lightning and other sources of electrical surges. This manual is included as part of

system documentation.

Electrical Power

Equipment Room Grounding

2.5 ANTENNA SYSTEM QUALITY AUDIT

Before installation of the antenna begins fill out APPENDIX J- INSTALLER PROFILE

DATA SHEET. After the Antenna System is installed it should be inspected before the

installers leave. A checklist of tasks performed on the antenna system is provided in

APPENDIX K - ANTENNA SYSTEM INSTALLATION CHECKLIST. Be sure to

complete this visual inspection before

corrected.

1. Using field glasses (if necessary) view the Antenna System from various positions on

the ground. Using copies of the Antenna System Installation Checklist found in

APPENDIX K, fill out a checklist for each antenna as you go through the following

inspection procedure. This will provide a record of the inspection, and of some

antenna information for future reference.

2. Record the make of antenna.

3. Record the type of antenna (omni or directional).

16

the installers leave, so any obvious errors can be

Page 18

MM102225V1, Rev. B

4. Record the design gain of the antenna.

5. If the antenna is directional, record the bearing of the main lobe, using the magnetic

declination for True North. If it is Omni, write "Omni" in the data entry line.

6. Record the height of the antenna above ground.

7. Confirm that cable-hoisting grips were installed as required to prevent damage to the

coaxial cable. Hoisting grips should have been installed at the antenna end of the

cable plus one for each 200 feet of cable length.

8. Confirm the cable is secured to the tower at intervals, which do not exceed 3 feet.

9. Confirm the cable is grounded at the top of the tower.

10. Confirm the cable is grounded at the point where it leaves the tower.

11. Confirm the cable is grounded at the point where it enters the building.

12. Confirm the coaxial cable run looks OK. The cable must be tight (nothing to flap in

the breeze), have no dings or kinks, be one continuous run (no connectors or splices),

and not exceeding the minimum bending radius on any bend.

13. Confirm the cable weather tight feedthrough is properly installed where the cable

enters the building.

14. Confirm the coaxial connectors have been properly weather sealed.

15. Confirm the cable entrance to the building has been properly weather sealed.

17

Page 19

MM102225V1, Rev. B

3.0 BASE STATION INSTALLATION

The following sections present the steps required for installation of populated OpenSky

base station equipment racks at a communications site.

To a certain extent, installations must be planned site-by-site, because of the wide variety

of installation conditions and configurations. Installers will encounter many types of

equipment enclosures and tower site equipment configurations. The Site Deployment

Order (SDO) should include an accurate site layout map, information to designate rack

locations, and other necessary installation information.

3.1 BEFORE INSTALLATION OCCURS

Before the antenna installation date, collect the information from the Site Deployment

Order specific to site access. Site-specific information includes the following:

• Per mission to access the site

• Directions to the site

• Keys and lock combinations to access the site and equipment shelter, or points of

contact to obtain them

• A drawing or description of each sit e showing where the equipment is to be installed

inside the enclosure

• Information about work practices needed to work safely at the site

The installation procedure below assumes that the installation team has secured

permission to access the communications site and has obtained the necessary keys or lock

combinations.

Keep working environment clean!

Control dust, dirt, and shavings for safety, and to protect equipment.

CAUTION

Be sure to follow installation procedures carefully!

3.2 BASICS

Generally, the OpenSky base station fits into two or more equipment racks. Each rack is

nominally seven feet high and twenty-four inches wide. The populated racks must be

installed inside a weatherproof enclosure near the base of a communications tower. If an

OE-100 Outdoor Enclosure is used, the OpenSky equipment is mounted to the mounting

rails provided within the enclosure (Refer to OE-100 Outdoor Enclosure Maintenance

Manual MM102226V1). The Base Station installation procedure addresses the following:

• Installing the equipment racks after they have been transported to the

communications site and moved into the equipment shelter

• Making inter-rack cabling connections

18

Page 20

MM102225V1, Rev. B

• Connecting the power supply and site subsystems external to the OpenSky equipment

racks

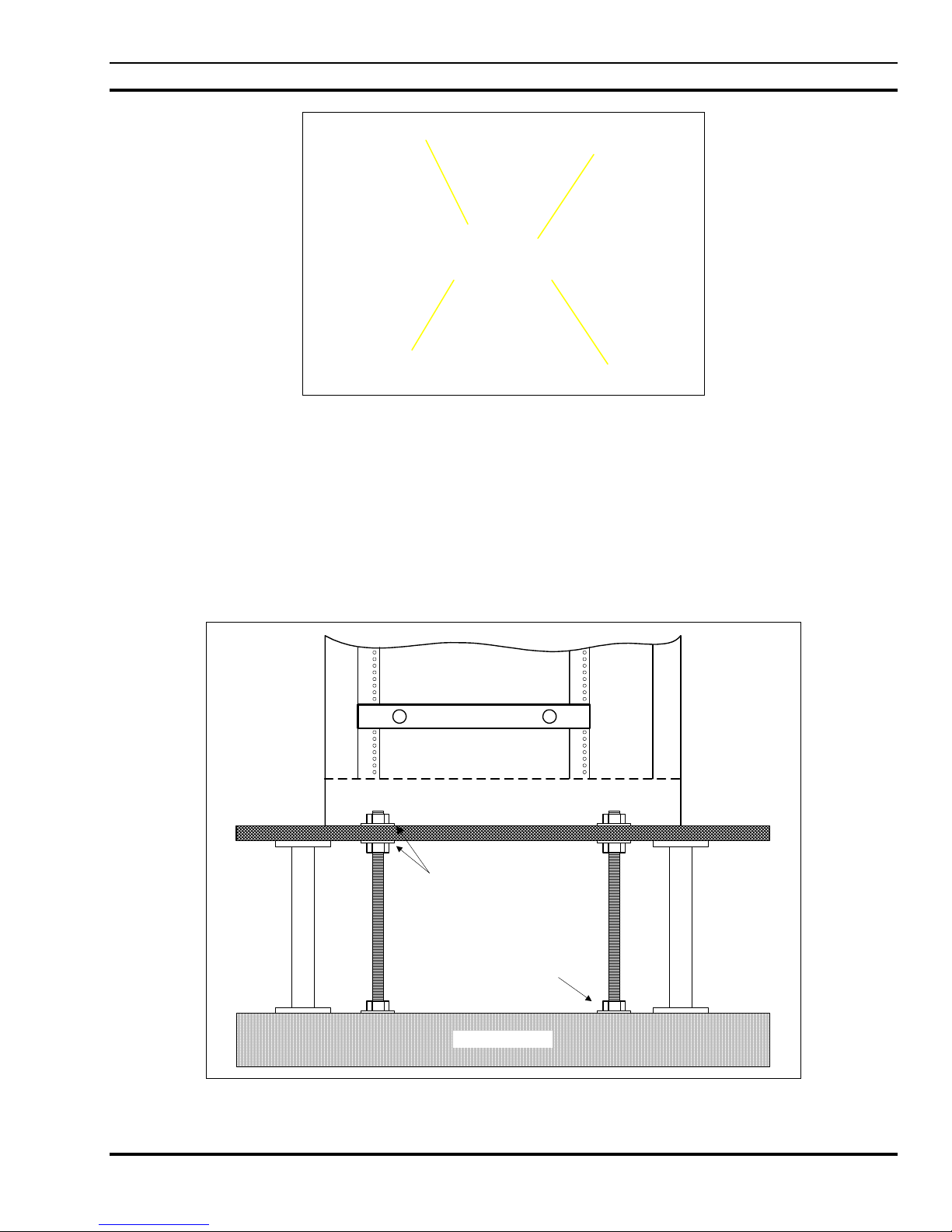

3.3 SECURING EQUIPMENT RACKS TO THE FLOOR

Move the racks into the designated positions and prepare to bolt them to the floor. In rare

cases, bolting to the floor may be prohibited. In those cases, bolt the racks to each other

for stability.

Procedure

:

1. Using a template, mark bolt locations for each equipment rack to be installed.

2. Drill pilot holes (Drill any required pilot holes to the specified depth of 1-1/2").

3. Drill 1/2" diameter holes for wood and concrete floors.

4. Move racks into position over bolt marks. In general, racks are placed side-by-side in

numerical order, with Rack #1 leftmost when viewed from the front.

5. If necessary, level the racks. The racks should be, at a minimum, approximately

level. If necessary, shim the racks so they are level by eye (use of an actual level i s

better).

6. Align the front of the racks.

7. Bolt equipment racks to the floor. Follow the procedure below corresponding to the

type of floor in the shelter. In general, equipment installers will encounter four types

of floor: concrete, concrete covered with linoleum, wood, and raised floors. The

procedure for each type is as follows:

• For concrete floors, use 1/2" drop-in expanding anchors with an insulating nylon

washer under the fastener head to anchor the racks (see Figure 3-1: Bolt

Assembly Hardware and Figure 3-2: Nylon Washer and Bolt Assembly).

1. Drill pilot holes for the anchors using the appropriate-sized carbide-tipped

drill bit. The pilot holes must not exceed 1-1/2" in depth.

2. Insert the anchors into the pilot holes.

2

3. Place insulating phenolic strip(s)

and under the cabinets/racks before bolting

them in place.

4. Place the cabinet/rack over the holes.

5. Assembly the bolts, fender washers and nylon washers.

6. Insert the bolt and washer assemblies into the pilot holes.

7. Tighten the bolts until firmly set (see Figure 3-3: Concrete Floor Mounting

and Figure 3-4: Bolt Assembly Used to Bolt Rack to Concrete Floor).

Be careful not to over tighten bolts to avoid breaking the phenolic bushings.

CAUTION

2

Phenolic strips are only required if the floor is pure concrete. Concrete floors covered with linoleum do not require phenolic

strips.

19

Page 21

MM102225V1, Rev. B

LEAD ANCHOR

Top View

BOLT

NYLON WASHER

FENDER WASHER

Figure 3-1: Bolt Assembly Hardware

Side View

Bottom View

Bolt Assembly

NYLON WASHER

EXPANDABLE

CONCRETE ANCHOR

Figure 3-2: Nylon Washer and Bolt Assembly

BOLT

BOTTOM OF CABINET

FENDER WASHER

CONCRETE FLOORING

PHENOLIC STRIP

Figure 3-3: Concrete Floor Mounting

20

Page 22

MM102225V1, Rev. B

BOLT

ASSEMBLIES

Figure 3-4: Bolt Assembly Used to Bolt Rack to Concrete Floor

• For wood floors, use a lag bolt with an insulating nylon washer under the head to

bolt the racks to the floor. Insulating phenolic strips under the racks are not

required. No pilot hole is needed on wood floors.

• For raised floors, the rack attach ment procedure is quite different. The first and

last racks in the row are bolted to the sub-floor as shown below. The remaining

racks are bolted to the end racks, to each other, or both. Insulating phenolic strips

must be placed under each rack (see Figure 3-5: Raised Floor Rack

Attachment).

21

Rack Cutaway

Nylon Washers

Concrete Anchor

Concrete Subfloor

Figure 3-5: Raised Floor Rack Attachment

Page 23

MM102225V1, Rev. B

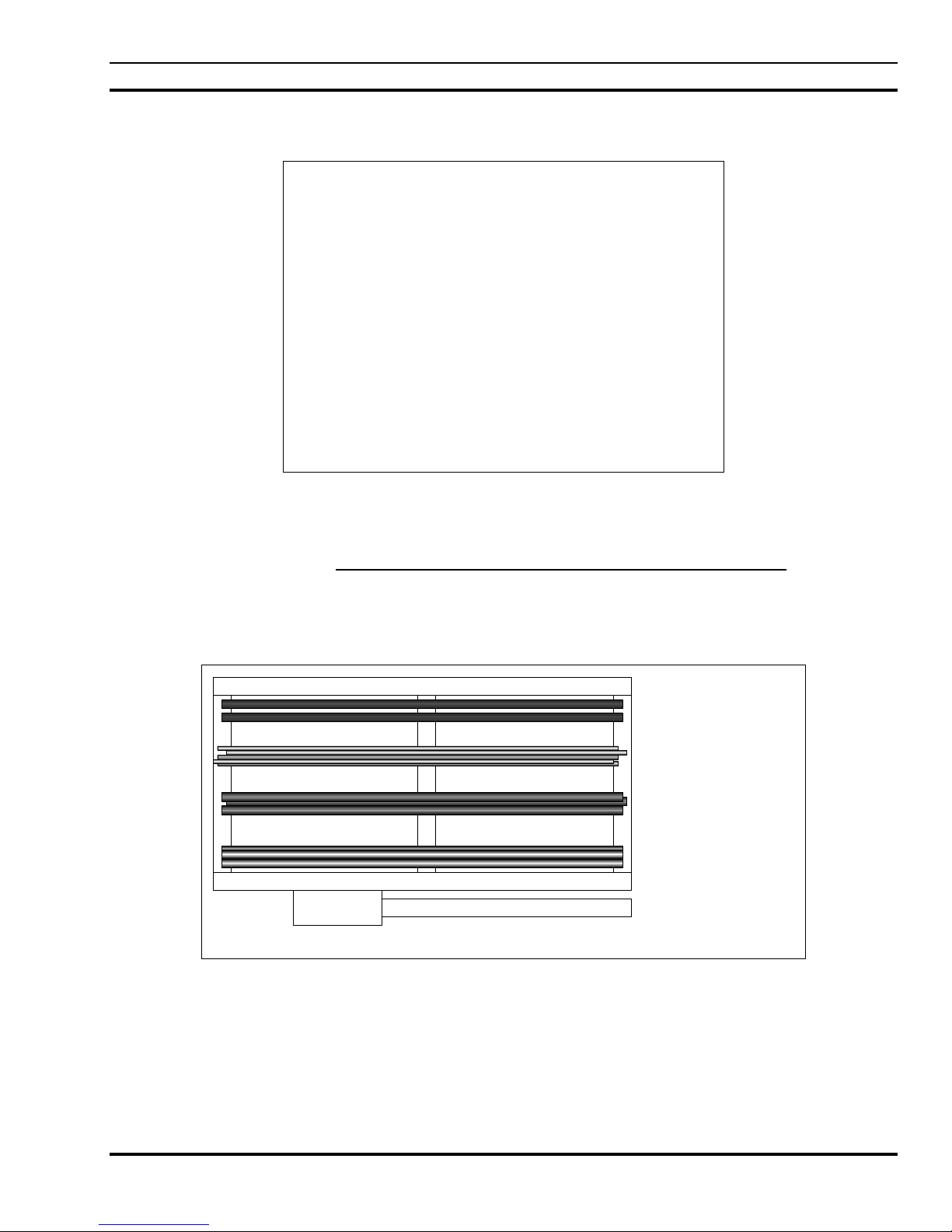

3.4 CABLING EQUIPMENT RACK COMPONENTS

Once the racks have been installed, interrack cable connections must be made, and racks

must be connected to a power source and grounded, as well as connected to external

communications sub-systems such as antennas. Follow this procedure in accordance with

M/A-COM, Inc. Quality Standards Manual GQM0221. Possible rack-ups of equipment

cabinets are shown in Figures 6 and 7.

44 RU---

40 RU---

35 RU---

30 RU---

25 RU---

20 RU---

15 RU---

10 RU---

5 RU---

0 RU---

1 RU

3 RU

2 RU

2 RU

3 RU

1 RU

3 RU

2 RU

2 RU

2 RU

2 RU

2 RU

2 RU

2 RU

2 RU

2 RU

2 RU

2 RU

2 RU

1 RU

RACK LABEL

RACK BREAKER PANEL

BLANK

ION OR DPS ALARM MODULE

ISM RADIO INTERFACE

BLANK2 RU

SITE ACCESS SERVER2 RU

BLANK (required)

BLANK

RX SPLITTER

BACKUP DCX

DCX #1

BLANK OR DCX #2

BLANK OR DCX #3

BLANK OR DCX #4

BLANK OR DCX #5

BLANK OR DCX #6

BLANK OR DCX #7

BLANK OR DCX #8

BLANK OR DCX #9

BLANK OR DCX#10

BLANK

44 RU available

Rack total height is 83" of

which 77" is usable.

Rack Depth is 24"

Rack Width is 22"

Notes:

Need cable lacing

guides in rack

Need grounding for all

rack equipment

DCX #7 through #10

are currently not

required

A Digital Controller/

XTransceiver (DCX)

contains two cards: a

Base Station

Controller (BSC) and

a Base Station

Transceiver (BSX)

Figure 3-6: Possible Rack-Up of Tower Site Rack #1

For One To Ten Base Stations Plus Backup And ISM Radio Options

22

Page 24

MM102225V1, Rev. B

44 RU---

40 RU---

35 RU---

30 RU---

25 RU---

20 RU---

15 RU---

10 RU---

1 RU

3 RU

2 RU

3 RU

10 RU

4 RU

4 RU

4 RU

4 RU

RACK LABEL

RACK BREAKER PANEL

BLANK

RX AMPLIFIER2 RU

TT AMP CONTROLLER

TX COMBINER

6 5 4 3 2 1

HPA #1

HPA #2

HPA #3

HPA #4

44 RU available

Rack total height is 83" of

which 77" is usable.

Rack Depth is 24"

Rack Width is 22"

Notes:

Need cable lacing

guides in rack

Need grounding for all

rack equipment

5 RU---

0 RU---

3 RU

4 RU

DUPLEXER AND POWER SENSOR

BACKUP HPA

Figure 3-7: Possible Rack-Up of Tower Site Rack #2

With Separate TX/RX Antenna Option For Base Stations #1 To #4 Of Six Maximum Plus Backup Option

Use the right tool for the job!

Eight Inch-Pound Torque Wrench or Newton/Meter Wrench for SMA-Type

connectors

CAUTION

Soft Jaw Connector Pliers for N-Type connectors

3.4.1 Interrack Cable Connections

1. On the back of each High-Power Amplifi er (HPA) is an RF cable attached to the RF

Input port. Attach each of these cables to the RF Output port on the companion

Digital Controller/(X)Transceiver

3

(DCX) (see Figure 3-8: HPA RF Input

Connection and Figure 3-9: DCX RF Output Connection).

3

Digital Controller/(X) Transceiver (DCX) contains two cards: a Base Station Controller (BSC) and as Base Station

(X)Transceiver (BSX).

23

Page 25

MM102225V1, Rev. B

Figure 3-8: HPA RF Input Connection

Figure 3-9: DCX RF Output Connection

2. Racks that hold the HPA's have two large unconnected wire bundles covered with a

split loom. Pull these bundles to the adjacent rack, which contains the DCXs and the

Base Station Alarm Module

4

(see Figure 3-10: Wire Bundles with DCX and Base

Station Alarm Wiring).

4

The Base Station Alarm Module can be an ION Alarm manufactured by Sentinel or a NetGuardian Alarm, model D-PK-

NETGD-12053 manufactured by DPS Telecom.

24

Page 26

ION Alarm

Bundle with

Lock-n-Mate

Connectors

MM102225V1, Rev. B

Figure 3-10: Wire Bundles with DCX and Base Station Alarm Wiring

(This figure is for the ION Alarm only. The DPS Alarm uses punchblock connections.)

3. Included in the wire bundle above, is a wiring harness with the female half of a

MATE-N-LOK® connector. Locate the male half (it connects to the harness that runs

to the Contact Closure Inputs plug on the Base Station Alarm Module) and connect

the MATE-N-LOK connectors (see Figure 3-11: DPS Alarm Punchblock

Connector).

25

Figure 3-11: DPS Alarm Punchblock Connector

Page 27

MM102225V1, Rev. B

4. The remaining cables in this wiring bundle are data cables that attach to each DCX.

Dress these cables into the cable tray. Each data cable terminates in a pigtail with an

RS-485 connector on both the main cable and its pigtail. Following the labels on each

data cable, plug the main cable and its pigtail into the two RS-485 ports on each

DCX. The main cable plugs into the bottom (RF) half of the DCX (BSX) and the

pigtail plugs into the top (digital) half of the DCX (BSC) (see Figure 3-12: RS-485

Main Cable and Pigtail Plug Connected to DCX).

Pigtail Plug

Main Cable

Figure 3-12: RS-485 Main Cable and Pigtail Plug Connected to DCX

5. Locate the cable attached to one of the host ports on the Alarm Module that has an

RS-232 connector on the free end. Plug this connector into the RS-232 port on the

Bird Electronic Corporation Power Monitor (VSWR) in the adjacent rack (see Figure

3-13: RS-232 Connector from Alarm Module to Bird Power Monitor (VSWR).

Figure 3-13: RS-232 Connector from Alarm Module to Bird Power Monitor (VSWR)

6. For Sites with a dual antenna, locate the Tower-Top Amplifier Control Box. In the

adjacent rack, locate the cable attached to the Input port of the TX/RX multi-coupler.

Connect the free end of that cable to the Tower-Top Amplifier Controller's Receiver

26

Page 28

MM102225V1, Rev. B

Multi-Coupler port (see Figure 3-14: Cable Connecting the Tower-Top Amplifier

Control Box to the Input port of the Multi-Coupler).

Figure 3-14: Cable Connecting the Tower-Top Amplifier Control Box to the Input port of the Multi-

Coupler

3.4.2

Connecting Power Source and External Equipment

Once rack-to-rack cables have been connected, the racked equipment in the enclosure

must be connected to external equipment and to the power source. For a layout of the

cable tray refer to Figure 3-15: Cable Tray Layout.

AC Conduit

*

* May not be present for -48VDC Sites.

Figure 3-15: Cable Tray Layout

RF Cables

Control / Data Cables

Ground Wires

DC Power Cables

27

Page 29

MM102225V1, Rev. B

3.4.3 Connect Cabling for the Power Source

1. Run two DC power cables (#6 insulated red connected to -48 volts) and ground (DC

Return

return insulated black) from the site's -48VDC Distribution Panel (see Figure 3-17: 48 Volt Breaker Distribution Panel of the DC Power Supply - Red Wire

5

and Figure

3-18: DC Return Distribution Bar - Black Wires) to each rack, attaching the cables

to the racks.

Red

–48VDC

Black

Figure 3-16: DC Power Connection Found in Each Rack - Black (DC Return) and Red (-48 Volt) wires

Figure 3-17: -48 Volt Breaker Distribution Panel of the DC Power Supply - Red Wire

5

The DC supply may not be the make shown here.

28

Page 30

MM102225V1, Rev. B

Figure 3-18: DC Return Distribution Bar - Black Wires

2. If not already labeled, label OpenSky circuits in the breaker panel to identify each

rack (see Figure 3-19: Properly Labeled OpenSky Circuit Breakers in the

Distribution Panel - OpenSky Rack 1, OpenSky Rack 2, etc.)

Figure 3-19: Properly Labeled OpenSky Circuit Breakers in the Distribution Panel

3. Route cables as specified by the installation procedure, using existing cable trays and

overhead ladders, routing cables under raised floors, and so on.

4. Route DC power cables together and maintain at least two inches (2") spacing

between the DC power cable bundle and other types of cables.

29

Page 31

MM102225V1, Rev. B

3.4.4 Connect Grounding Cables to Equipment Racks

1. Run #6 Green grounding cable (stranded copper) from each rack ground directly to

Attach a ground cable to each rack.

the single-point ground bar in each enclosure.

All bends in the grounding cables must be < 70-degrees.

All bends in the grounding cables must have minimum bend radius of 8 inches.

CAUTION

See the M/A-COM Quality Standards Manual (GQM0221) for more information.

2. At a single point cabinet ground, use a two-hole lug to attach the ground cable. Route

the cables as specified by the installation procedure, using existing cable trays and

overhead ladders, routing cables under raised floors, and so on (see Figure 3-20:

Single Point Ground That is Found on Each Rack and Figure 3-21: Ground Bar).

Figure 3-20: Single Point Ground That is Found on Each Rack

30

Figure 3-21: Ground Bar

Page 32

MM102225V1, Rev. B

3. Route the ground cables together and maintain at least two inches (2") spacing

between the ground cable bundle and other types of cables.

3.4.5

Connect Antenna Cables to Equipment Racks

Attach the antenna cables to the communications equipment.

1. Prior to the communications equipment installation, one or two antennas will have

been installed at the site. The antenna cables will have been terminated inside the

enclosure onto a metal plate (ground plane).

• For single antenna sites, the incoming antenna cable terminates in a

PolyPhaser® (surge protector) attached to the ground plane.

• For dual antenna sites, both the transmission and receiving antennas' incoming

cables terminate in a PolyPhaser (surge protector). Systems with tower-top

amplifiers require a special DC Injection/DC Path Protector (PolyPhaser

#DC50LNZ+30-MA). The 1-5/8" cable is the TX cable and the 7/8" cable is the

RX cable when used with a Tower Top Receive Amplifier.

Figure 3-22: Dual Antenna PolyPhasers (Surge Protectors)

2. Attach drop cables from the PolyPhaser to the appropriate antenna connection points

in the OpenSky equipment racks.

3. Route the cables appropriately, or as specified by the installation procedure, using

existing cable trays and overhead ladders, routing cables under raised floors, and so

on.

4. Maintain at least two inches (2") spacing between the antenna cables and other

cables.

31

Page 33

MM102225V1, Rev. B

3.4.6 Connect the T1 Network

Connect the high-speed digital T1 (telephone) network Interface to the Site Access Server

as defined by the Site Deployment Order.

In most installations, this connection goes to microwave equipment.

NOTE

3.4.7 Site Clean Up

Before leaving, remove any debris, such as wire clippings, metal shavings, dust mounds,

etc. from the site.

3.5 COMPLETING THE INSTALLATION

Once the OpenSky equipment has been installed, perform field testing as detailed in

Section 4.0 SITE TEST PROCEDURES to verify operation according to specifications of

installed equipment racks with externally connected subsystems such as antennas.

Procedures

:

1. Perform testing to verify correct operation and performance of the installed

equipment racks, following the procedures specified in Section 4.0 SITE TEST

PROCEDURES.

2. Set HPA transmission power level, following the procedure specified in Section

7.06.7 -TX POWER CALIBRATION (MANDATORY).

3. If problems occur during installation, describe them and detail how they were

resolved. If the installation could not be completed, describe the obstacles and clearly

explain what was done and what remains to be done.

32

Page 34

4.0 SITE TEST PROCEDURES

4.1 PURPOSE AND SCOPE

This section describes post installation tests required for compliance testing of the M/ACOM Wireless Systems OpenSky Digital Base Station. This section defines and details

the test plan and methodology for each test.

Objective: This test confirms a base site receive channel is not corrupted by site specific

noise or interference. Site installation and site gain optimization should be completed

before this test is performed. The NIMCAS site optimization program provides an

expected difference between terminated and antenna connected quieting tests. Measured

results should be within 2 dB of this value.

This section covers tests that perform two functions:

• Verify that all contractual requirements as detailed in the system Requirements

Traceability Verification Matrix, (RTVM), are met. These tests are identified as

mandatory and are linked to the relevant section for the RTVM.

• Ensure that the site, as installed, is operating at optimum perfor mance. Thes e tests are

not mandatory but clearly have impact on some of those that are.

MM102225V1, Rev. B

To ensure that the system is installed and configured correctly, the following procedures

must be performed. In addition, several tests are performed to validate the RF

performance of the station and to ensure compliance with the station FCC license.

This section is therefore divided into the following areas:

• Verification Testing

• Equipment Configuration

• Co mpliance Testing

• Performance Testing

• Operational Testing

• Network Connectivity

• Final Operating Capability

• Appendices: Supplemental information on equipment configuration and control

access.

⇒ Base Site Configuration Procedure should also be consulted for configuration

questions (see APPENDIX F - TYPICAL BASE STATION

CONFIGURATION).

⇒ Installed Site Cavity Tuning Procedure should also be consulted for Filter Tuning

(see APPENDIX H - VERIFICATION TESTING – TRANSMIT FILTER

TUNING).

33

Page 35

MM102225V1, Rev. B

4.2 OVERVIEW OF OPENSKY BASE SITE EQUIPMENT

An OpenSky base station consists of a variety of products and includes radio transmitting

and receiving equipment, RF distribution equipment and network communications

system interface equipment.

OpenSky is a digital system and has some significant differences in terms of fixed

network connectivity to that commonly seen with conventional analog systems. In

particular, base station controllers (BSCs) communicate via an access server and are

connected back to a central office or dispatch center via digital circuits.

OpenSky base station equipment is available in five primary RF configurations. This

document covers Types 1, 2, 3, and 4 listed below. Type 5 is covered separately.

1. Primary site with separate transmit and receive antennas: Referred to as a Tower Top

2. Primary site with a single antenna for transmit and receive: Referred to as a Duplexed

3. Outdoor Enclosure with separate transmit and receive antenna.

4. Outdoor Enclosure with a single antenna for transmit and receive.

5. Low profile site providing coverage fill: Referred to as a Cell Site.

Site.

Site.

4.3 TEST METHODOLOGY

Equipment configuration and testing must be performed in accordance with the

instruction given in this document. Tests must also be conducted in the order given in this

document as adjustments made during certain procedures may affect the results of other

tests.

Testing an installed base site comprises performing standard forward and reverse channel

tests to ensure correct operation of the entire installation. Testing also verifies physical

and application layer connectivity to the Regional Operations Center serving the site

under test via a communications link.

Required specifications are verified using one of the following methods:

1. Inspection: An observation or examination of an item against the applicable

documentation to confirm compliance with the requirements.

2. Analysis: Interpretation, interpolation, or extrapolation of analytical or empirical data

under defined conditions of reasoning to show theoretical compliance with stated

requirements.

3. Demonstration: Verification of an operational or functional capability by one or

more performances before qualified witnesses, as designated by the customer.

Instrumentation or data recording beyond that provided indigenously by the elements

to be verified shall generally not be required.

4. Objective Test: Performance of a functional operation under specific conditions

involving the use of instrumentation, special test software, and/or special test

equipment to generate, acquire, and/or record data. This method may include an

analysis of test data.

34

Page 36

4.4 PREPARATION

To prepare for the start of testing, it is important that all test equipment be powered up

now and allowed to thermally stabilize. Begin by powering up the Communications Test

Set HP 8920.

Record the specifics of each of the system components.

Before testing the complete system, verify that the system is cabled correctly. The tower-

mounted receive amplifier will not power up until it senses that the indoor control panel

has been connected via the RF feed cable and the multi-conductor control cable. The

initial sections of this procedure describe how to check for correct installation,

particularly those areas that were disturbed as part of the shipping process.

4.5 RECORDING TEST RESULTS

The main body of this document provides space for the recording of all test results and

equipment configuration parameters. These must be supplemented where indicated by

equipment configuration hardcopy printouts taken for each RF channel being tested.

4.6 BASE SITE BLOCK DIAGRAM

MM102225V1, Rev. B

Figure 4-1: 3-Channel Base Station with Tower Top Amplifier Block Diagram, shows

the Block Diagram for a three-channel site installation.

To SAS

network38.4 kbps

inter-BSC

terminal

network38.4 kbps

inter-BSC

terminal

network38.4 kbps

inter-BSC

terminal

DCX 1

Base

Station

Controller

DCX 2

Base

Station

Controller

Alarm Module

DCX 3

Base

Station

Controller

X

C

V

R

X

C

V

R

X

C

V

R

RS485

High Power Amp 1

RS485

High Power Amp 2

RS485

High Power Amp 3

RS232

Alarm

Cables

Transmitter

Combiner

(3 CH)

Power Sensor

VSWR Monitor

Rx

Splitter

(4 CH)

Feeder

Lightning Protector

Tower-Top

LNA Controller

To Tx

Antenna

From RF network

for mobile radios

PolyPhasers

Feeder

Tower Top LNA

Power and Control

Tower-Top

LNA

Rx Antenna

Site Access Server

(SAS)

Figure 4-1: 3-Channel Base Station with Tower Top Amplifier Block Diagram

35

Page 37

MM102225V1, Rev. B

4.7 INSPECTION

In this section, the location of the installation is recorded and equipment configuration

parameters are verified against the As Built. In addition, general workmanship and

quality of assembly and installation are inspected

Only selected parameters are checked against the recorded factory configuration as all

parameters are programmed into equipment before leaving the factory and hence should

NOTE

not require to be modified.

4.7.1 Pre-test Inspection

Objective: To verify that the site installation has been satisfactorily completed and that

newly installed cable interfaces have been correctly connected, especially inter-rack

cabling disconnected during shipment.

Before commencing this section of tests, ENSURE THAT ALL RACK CIRCUIT

NOTE

BREAKERS ARE IN THE OFF POSITION.

PRE-TEST

INSPECTION

1.

ACTION MISCELLANEOUS

A two rack three channel base station is

as shown in the figure to the right. Rack

1 (on left) contains system transceivers,

communication interfaces and control

and monitoring equipment; Rack 2 (on

right) contains transmit path RF power

amplifiers and combining equipment

.

36

Page 38

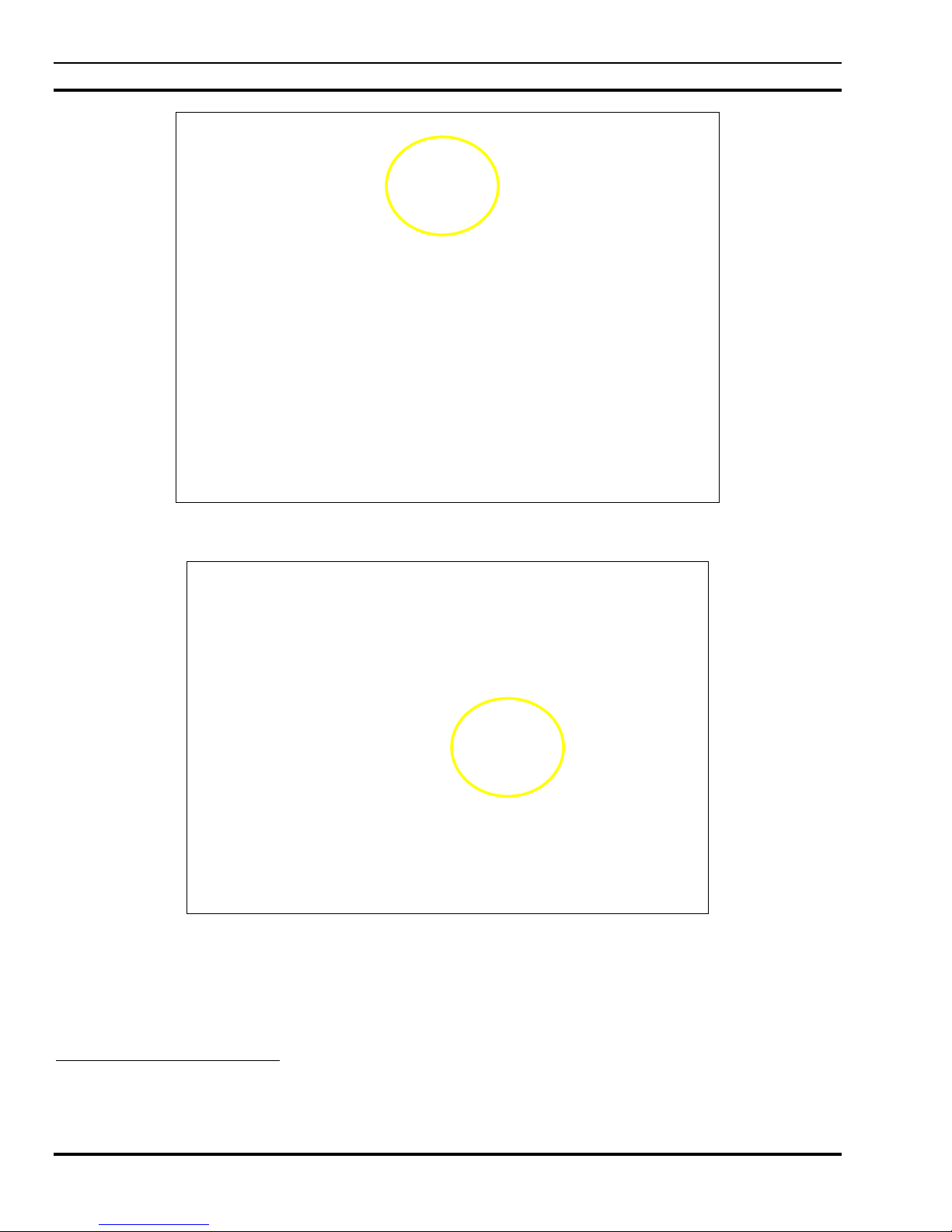

4.7.2 Interrack Cabling

MM102225V1, Rev. B

ALARM

CABLING

2.

RECEIVE

MULTICOUPLER

INPUT

ACTION MISCELLANEOUS

The photograph to the right shows the

location of the inter-rack alarm

interconnect cable.

Verify that it has been connected as

shown where the circle is located

ACTION MISCELLANEOUS

.

The photograph to the right shows the

source and destination points for the

receive Multicoupler feed. Verify that it

3.

is connected as shown.

Also, verify that unused output ports are

terminated with a 50-Ohm terminator.

37

Page 39

MM102225V1, Rev. B

HPA RF

INPUT

4.

HPA CONTROL

CONNECTION

ACTION MISCELLANEOUS

The photograph to the right shows the

destination point for the HPA RF Input.

Verify that they are connected as shown

ACTION MISCELLANEOUS

.

The photograph to the right shows the

5.

destination point for the HPA control

cable. Verify that they are connected as

shown.

38

Page 40

4.7.3 New Cabling

MM102225V1, Rev. B

RACK POWER

CONNECTION

6.

RACK

GROUNDING

7.

ACTION MISCELLANEOUS

The photograph to the right shows the

connection points and polarity of the DC

power connection to each power

distribution panel. Verify that they are

connected as shown.

: The red cable is the most

Note

negative, i.e. -48VDC. The black cable is

the return.

ACTION MISCELLANEOUS

The photograph to the right shows the

connection point for rack to halo

grounding. The halo is located inside the

shelter and is part of the shelter

grounding system that is fed to an earth

ground. Connect a black ground cable

from the halo to the two hole lug shown

here.

Black

Red

39

Page 41

MM102225V1, Rev. B

SYSTEM

COMMUNI-

CATIONS

8.

RECEIVE

ANTENNA

CONNECTION

ACTION MISCELLANEOUS

The photograph to the right shows the

in-rack connection point for T1

communications.

The destination of this connection will

vary by site; however, verify that a

modular style plug wired (T568B) is

used to connect the site communications

interface with the base site T1.

If equipped with ISM Backhaul, the

Orange cable is the 10BaseT connection

to the ISM Backhaul Router.

: Actual cables may be different

Note

colors

.

ACTION MISCELLANEOUS

9.

TTA

CONTROL

CABLE

10.

The photograph to the right shows the

in-rack connection point for the system

receive antenna. Verify that the jumper

cable to the receive antenna is present

and disconnect it from the receive input.

: This is only for Tower Top

Note

Amplifier sites.

ACTION MISCELLANEOUS