M A COM MASW6020G Datasheet

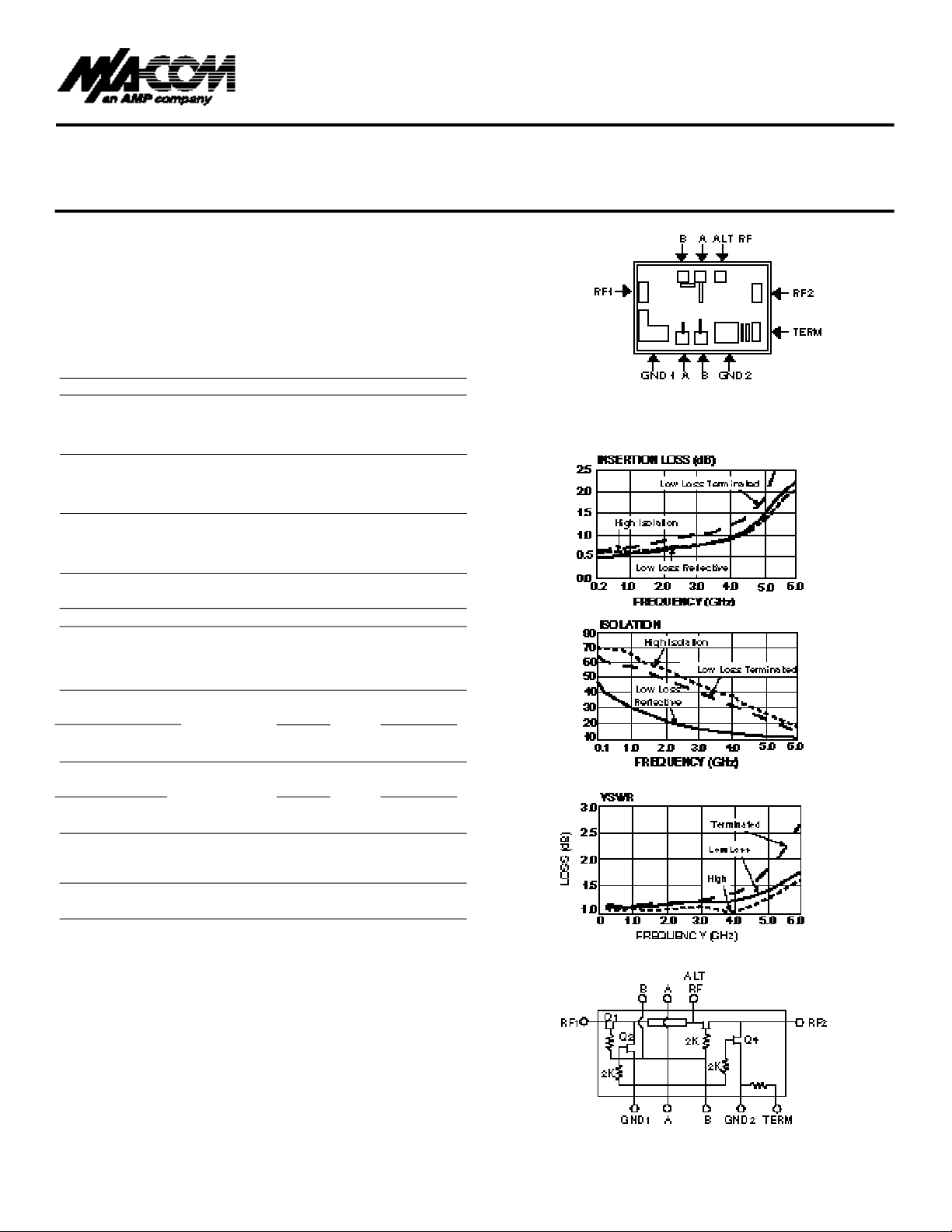

GaAs SPST Switch

DC-6 GHz MASW6020G

Features

• Low Insertion Loss,0.6 dB Typical @ 1 GHz

• Fast Switching Speed,10 ns Typical

• Ultra Low DC Power Consumption

• Integral Static Protection

Guaranteed Specifications** @25°C***

Frequency Range DC - 6000 MHz

Insertion Loss (L) Low Loss Low Loss Matched (H) High Isolation

DC-1.0 GHz 0.8 dB 1.0 dB 0.9 dB

DC-2.0 GHz 0.9 dB 1.1 dB 1.0 dB

DC-6.0 GHz 2.5 dB 2.7 dB 2.5 dB

Isolation (L) Low Loss Low Loss Matched (H) High Isolation

DC-1.0 GHz 30 dB 63 dB 64 dB

DC-2.0 GHz 22 dB 46 dB 52 dB

DC-6.0 GHz 11 dB 14 dB 19 dB

VSWR (L) Low Loss Low Loss Matched (H) High Isolation

DC-1.0 GHz 1.1:1 1.1:1 1.1:1

DC-2.0 GHz 1.3:1 1.2:1 1.1:1

DC-6.0 GHz 2.0:1 2.7:1 2.0:1

Operating Characteristics

Impedance 50 Ω Nominal

Switching Characteristics

Trise, Tfall (10%/90% or 90%/10% RF) 10 ns Typ

Ton, Toff (50% CTL to 90%/10% RF) 10 ns Typ

Transients (In-Band) 10 mV Typ

Input Power for 1 dB Compression

Control Voltages (VDC) 0/-5 0/-8

Above 500 MHz +27 dBm +33 dBm Typ

100 MHz +21 dBm +26 dBm Typ

Intermodulation Intercept Point (for two-tone input power up to +5 dBm)

Intercept Points IP2 IP3

Above 500 MHz +68 dBm +46 dBm Typ

100 MHz +62 dBm +40 dBm Typ

Control Voltages (Complementary Logic)

Vin Low 0 to -0.2V @ 20 µA Max

Vin Hi -5V @ 50 µA Typ to -8V @ 300 µA Max

Die Size 0.031" x 0.051" x 0.010"

(0.80 mm x 01.30 mm x 0.25 mm)

* Equivalent to Microelectronics Division (ANZAC) SW210H

** All specifications apply with 50 Ω impedance connected to all RF

ports, 0 and -8 VDC control voltages.

*** Loss change 0.0025 dB/°C. (From -55°C to +85°C)

V 2.00

Typical Performance

Schematic

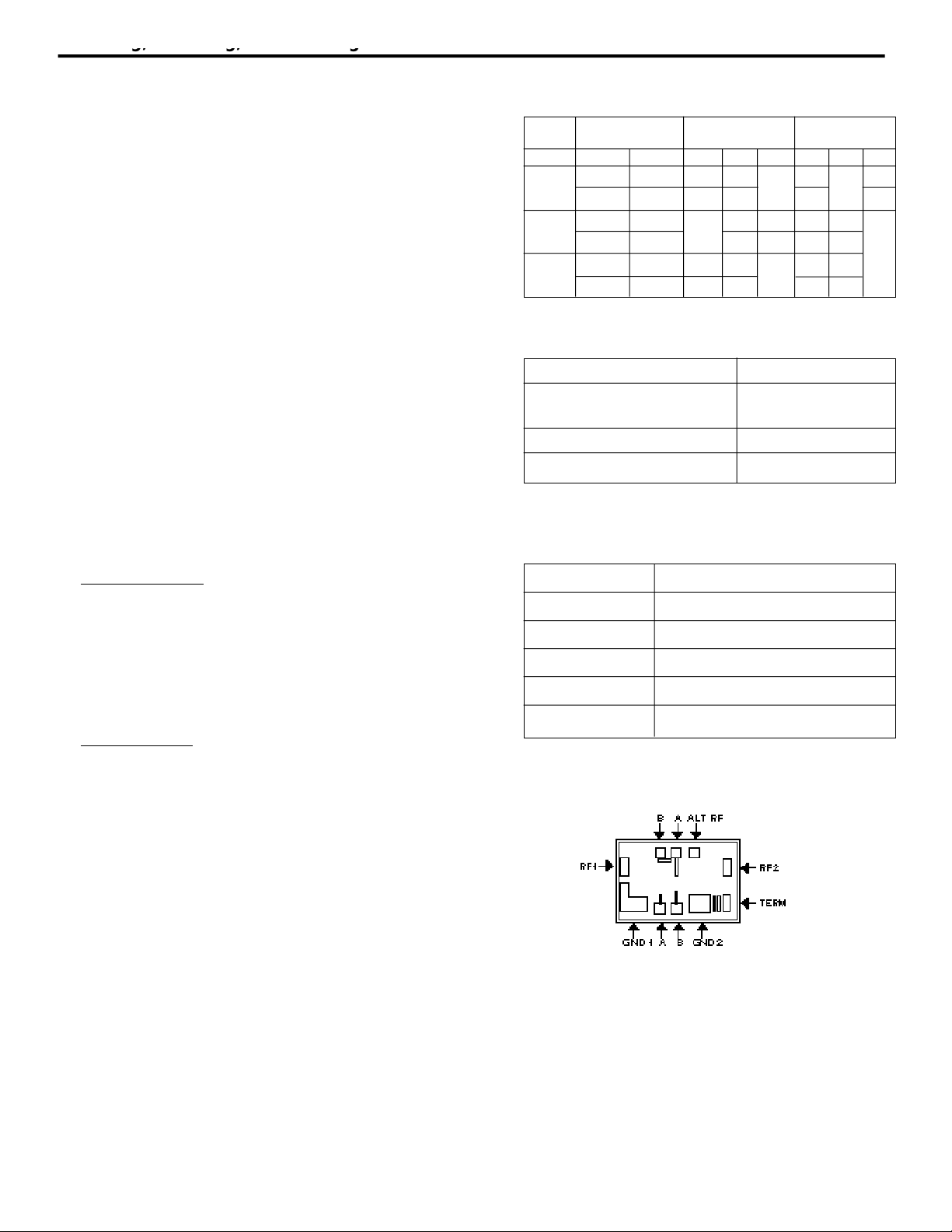

Handling, Mounting, and Bonding Procedure MASW6020G

Truth Table

Maximum Ratings

Control Voltage (A/B): -8.5 VDC

Max Input RF Power: +34 dBm

(500 MHz - 4 GHz)

Storage Temperature: -65°C to +175°C

Maximum Operating Temperature: +175°C

RF1, RF2: 0.004 x 0.006 (0.100 x 0.150)

Alt RF: 0.004 x 0.005 (0.100 x 0.125)

A,B: 0.004 x 0.004 (0.100 x 0.100)

GND1: 0.012 x 0.007 (0.300 x 0.175)

GND2 : 0.009 x 0.008 (0.225 x 0.200)

Term: 0.004 x 0.008 (0.100 x 0.200)

Switch Condition

Option Control Voltage & Bonding Ground Bonds

A B RF1 RF2 ALT GND1 GND2 Term

V Hi V Low on on G G

V Low V Hi off off G G

V Hi V Low on on G G

V Low V Hi off off G G

V Hi V Low on on G G

V Low V Hi off off G G

Handling Precautions

Permanent damage to the MASW6020G may occur if the following

precautions are not adhered to:

A. Cleanliness – The MASW6020G should be handled in a clean

e nv i r o n m e n t . DO NOT attempt to clean unit after the

MASW6020G is installed.

B. Static Sensitivity – All chip handling equipment and personnel

should be DC grounded.

C. Transient – Avoid instrument and power supply transients while

bias is applied to the MASW6020G. Use shielded signal and

bias cables to minimize inductive pick-up.

D. Bias – Apply voltage to either control port A/B or only when the

other is grounded. Neither port should be allowed to “float.”

T

L

H

V 2.00

E. General Handling – It is recommended that the MASW6020G

chip be handled along the long side of the die with a sharp pair

of bent tweezers. DO NOT touch the surface of the chip with

fingers or tweezers.

Mounting

The MASW6020G is back - m e t a l l i zed with Pd/Ni/Au (100/1,000/

30,000Å) metallization. It can be die-mounted with AuSn eutectic

preforms or with thermally conductive epoxy. The package surface

should be clean and flat before attachment.

Eutectic Die Attach:

A. A 80/20 gold/tin preform is recommended with a work surface

temperature of approximately 255°C and a tool temperature of

265°C. When hot 90/10 nitrogen/hydrogen gas is applied, tool

tip temperature should be approximately 290°C.

B. DO NOT expose the MASW6020G to a temperature greater

than 320°C for more than 20 seconds.No more than 3 seconds

of scrubbing should be required for attachment.

Epoxy Die Attach:

A. Electrically conductive epoxy must be used.

B. Apply a minimum amount of epoxy and place the MASW6020G

into position. A thin epoxy fillet should be visible around the

perimeter of the chip.

Bond Pad Dimensions – Inches (mm)

Bond Pad Layout

C. Cure epoxy per manufacturer's recommended schedule.

Wire Bonding

A. Ball or wedge bond with 1.0 mil diameter pure gold wire.T h e rm o -

sonic wirebonding with a nominal stage temperature of 150°C

and a ball bonding force of 40 to 50 grams or wedge bonding

force of 18 to 22 grams is recommended.U l t rasonic energy and

time should be adjusted to the minimum levels to achieve reliabl e

w i r e b o n d s.

B. Wirebonds should be started on the chip and terminated on the

p a ck a g e.

Loading...

Loading...