M A COM MADA2030G Datasheet

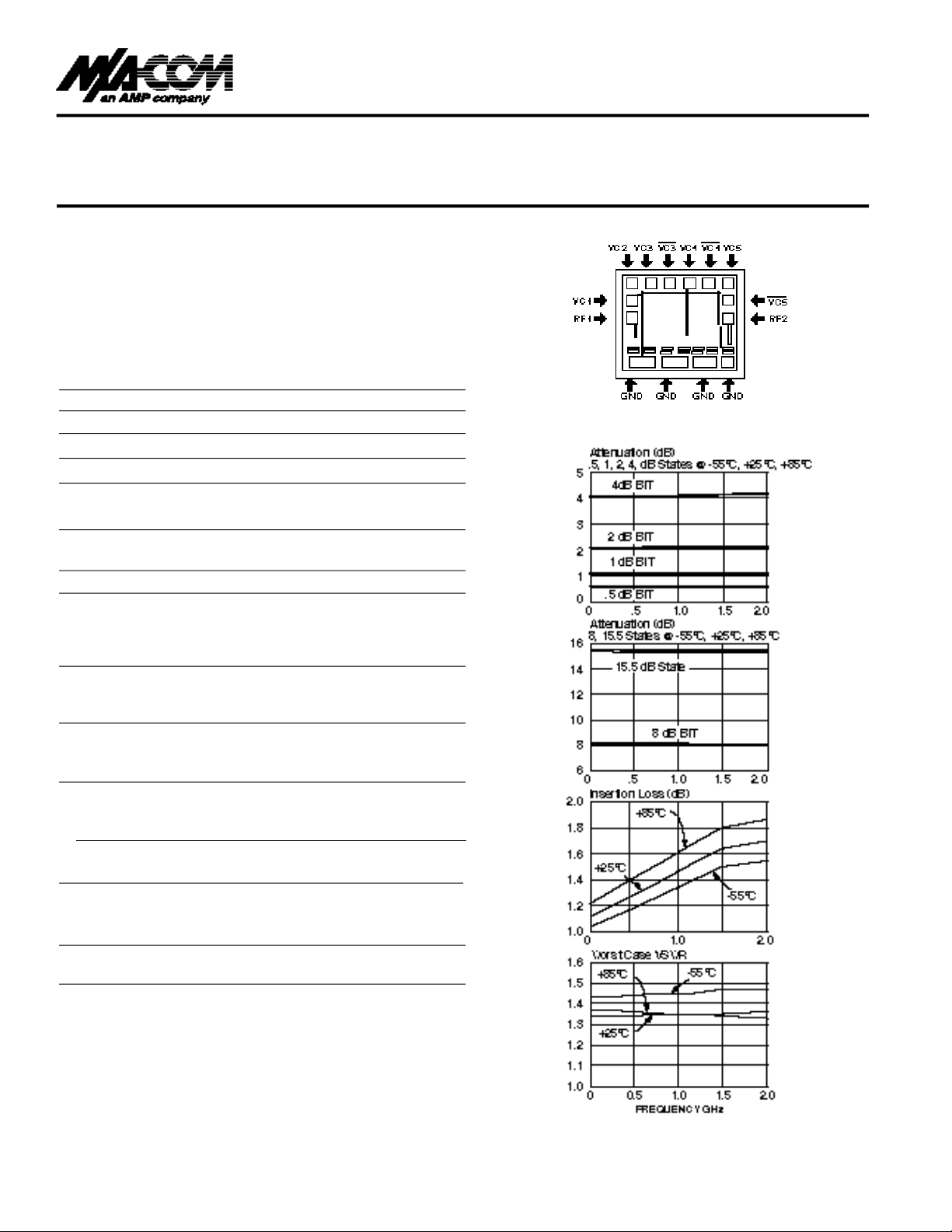

5-Bit GaAs Digital Attenuator

DC - 2 GHz MADA2030G

V 2.00

Features

●

Attenuation 0.5-dB Steps to 15.5 dB

●

Temperature Stability ±0.1 dB from -55° to

+85°C Typical

●

Fast Switching Speed, 3 ns Typical to 90%

Guaranteed Specifications (From -55°C to +85°C)

Frequency Range DC - 2.0 GHz

Nominal Attenuation 0.5 dB Steps to 15.5 dB Max

Attenuation Accuracy ±0.15 dB ±3% of Attenuation Setting

VSWR Worst Case Setting DC - 2 GHz 1.6:1 Max

Reference Insertion Loss DC - 2 GHz 2.3 dB Max

DC - 1 GHz 1.9 dB Max

Operating Characteristics

Impedance 50 Ω Nominal

Phase Balance (For any bit or combinations of bits per unit)

2 GHz +4/-6 Degrees Typ

1 GHz +2/-3 Degrees Typ

500 MHz +1/-2 Degrees Typ

Switching Characteristics

Switching Time (50% CTL to 90/10% RF) 3 ns Typ

Switching Transients (Unfiltered) 7 mV Typ

Input Power for 1 dB Compression

Above 500 MHz +27 dBm Typ

100 MHz +24 dBm Typ

Intermodulation Intercept Point (for

two-tone input power up to +5 dBm)

Intercept Points IP

Above 500 MHz +68 dBm Typ +45 dBm Typ

100 MHz +45 dBm Typ +40 dBm Typ

Control Voltages (Complementary Logic)

VINLow 0 to -0.2 V @ 5 µA Max

VINHi -5 V @ 75 µA Typ to -8 V @ 250 µA Max

Die Size 0.045" x 0.039" x 0.010"

(1.14mm x 0.99mm x 0.25mm

2

IP

3

Typical Performance

Handling, Mounting and Bonding Procedure MADA2030G

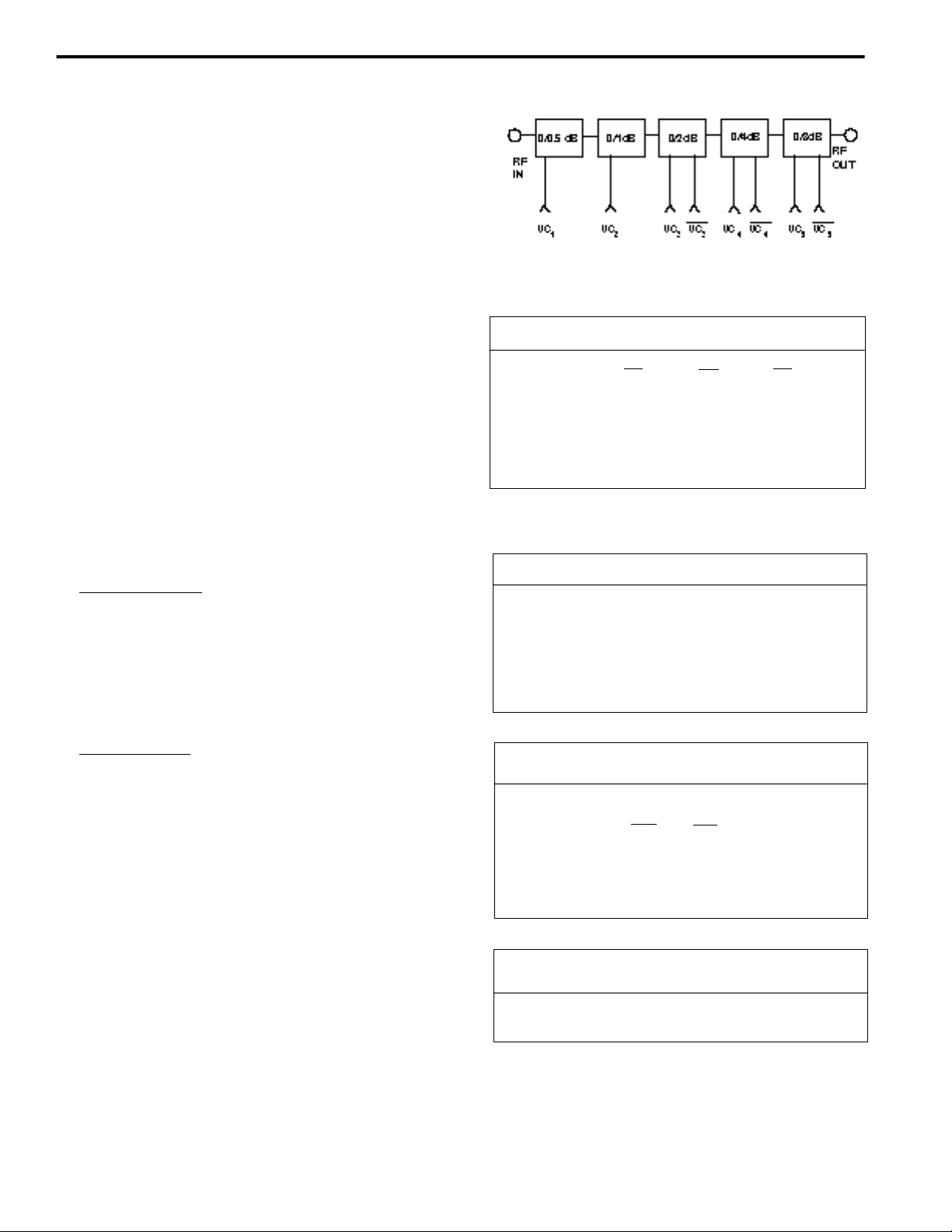

DA2030 Truth Table

Control Input

Attenuation

VC1 VC2 VC3 VC3 VC4 VC4 VC5 VC5 Settings

VinHi VinHi VinHi VinLow VinHi VinLow VinHi VinLow Reference

VinLow VinHi VinHi VinLow VinHi VinLow VinHi VinLow .5dB

VinHi VinLow VinHi VinLow VinHi VinLow VinHi VinLow 1dB

VinHi VinHi VinLow VinHi VinHi VinLow VinHi VinLow 2dB

VinHi VinHi VinHi VinLow VinLow VinHi VinHi VinLow 4dB

VinHi VinHi VinHi VinLow VinHi VinLow VinLow VinHi 8dB

Maximum Ratings

A. Control Voltage : -8.5 Vdc

B. Max Input RF Power: +34 dBm

(500 MHz - 4 GHz)

C. Storage Temperature: -65°C to +175°C

D. Maximum Operating Temperature: +175°C

BondPad Dimensions

Inches (mm)

Die Size

Inches (mm)

0.045" x 0.039" x 0.010"

(1.14mm x 0.99mm x 0.25mm)

Schematic

Handling Precautions

Permanent damage to the MADA2030 may occur if the following

precautions are not adhered to:

A. Cleanliness – The MADA2030 should be handled in a clean

e nv i r o n m e n t . DO NOT attempt to clean unit after the

MADA2030 is installed.

B. Static Sensitivity – All chip handling equipment and personnel

should be DC grounded.

C. Transient – Avoid instrument and power supply transients

while bias is applied to the MADA2030. Use shielded signal

and bias cables to minimize inductive pick-up.

D. Bias – Apply voltage to either complementary control ports

only when the other is grounded. Neither port should be

allowed to “float”.

E. General Handling – It is recommended that the MADA2030

chip be handled along the long side of the die with a sharp

pair of bent tweezers. DO NOT touch the surface of the chip

with fingers or tweezers.

Mounting

The MADA2030 is back - m e t a l l i zed with Pd/Ni/Au (100/1,000/10,000Å)

metallization. It can be die-mounted with AuSn eutectic preforms

or with thermally conductive epoxy. The package surface should

be clean and flat before attachment.

Eutectic Die Attach:

A. A 80/20 gold/tin preform is recommended with a work surface

temperature of approximately 255°C and a tool temperature

of 265°C. When hot 90/10 nitrogen/hydrogen gas is applied,

tool tip temperature should be approximately 290°C.

B. DO NOT expose the MADA2030 to a temperature greater

than 320°C for more than 20 seconds. No more than 3 seconds of scrubbing should be required for attachment.

Epoxy Die Attach:

A. Apply a minimum amount of epoxy and place the MADA2030

into position. A thin epoxy fillet should be visible around the

perimeter of the chip.

B. Cure epoxy per manufacturer’s recommended schedule.

C. Electrically conductive epoxy may be used but is not required.

Wire Bonding

A. Ball or wedge bond with 1.0 mil diameter pure gold wire.

T h e rmo- sonic wirebonding with a nominal stage temperature of

150°C and a ball bonding force of 40 to 50 grams or we d g e

bonding force of 18 to 22 grams is recommended. U l t ra s o n i c

energy and time should be adjusted to the minimum levels to

a c h i eve reliable wirebonds.

B. Wirebonds should be started on the chip and terminated on the

p a ck a g e. GND bonds should be as short as possibl e ; at least

three and no more than four bond wires from ground pads to

p a ckage are recommended.

V 2.00

VinLow 0 to -0.2V

VinHi -5V to -8V

RFin, RFout: 0.004" x 0.004"

(0.100mm x 0.100mm)

VC1,VC2,VC3,VC3,VC4,VC4: 0.004" x 0.004"

(0.100mm x 0.100mm)

GND1,GND2,GND3: 0.009" x 0.004"

GND4: 0.004" x 0.004"

(0.100mm x 0.100mm)

Loading...

Loading...