M A COM MA4SPS302 Datasheet

MA4SPS302 SurMount Series

Surface Mount Monolithic

PIN Diode Chip

Features

• Surface Mount Diode

• No Wirebonds Required

• Rugged Silicon-Glass Construction

• Silicon Nitride Passivation

• Polymer Scratch Protection

• Low Parasitic Capacitance and Inductance

• High Power Handling (Efficient Heatsinking)

Description

M/A-COM’s MA4SPS302 is a silicon-glass PIN diode

fabricated with M/A-COM’s patented HMIC™ process. This

device features two silicon pedestals embedded in a low loss

glass. The diode is formed on the top of one pedestal and

connections to the backside of the device are facilitated by

making the pedestal side walls conductive. Selective backside

metalization is applied producing a surface mount device. The

topside is fully encapsulated with silicon nitride and has an

additional polymer layer for scratch protection. These

protective coatings prevent damage to the junction and the

anode air-bridge during handling and assembly.

Applications

These devices can be used in series and shunt switches for

wireless circuits where smaller area and profile are required.

Low parasitic values of L and C make additional circuit tuning

unnecessary. 2 RS value @ 1 mA makes the devices suitable

for smaller current consumption applications.

Ω

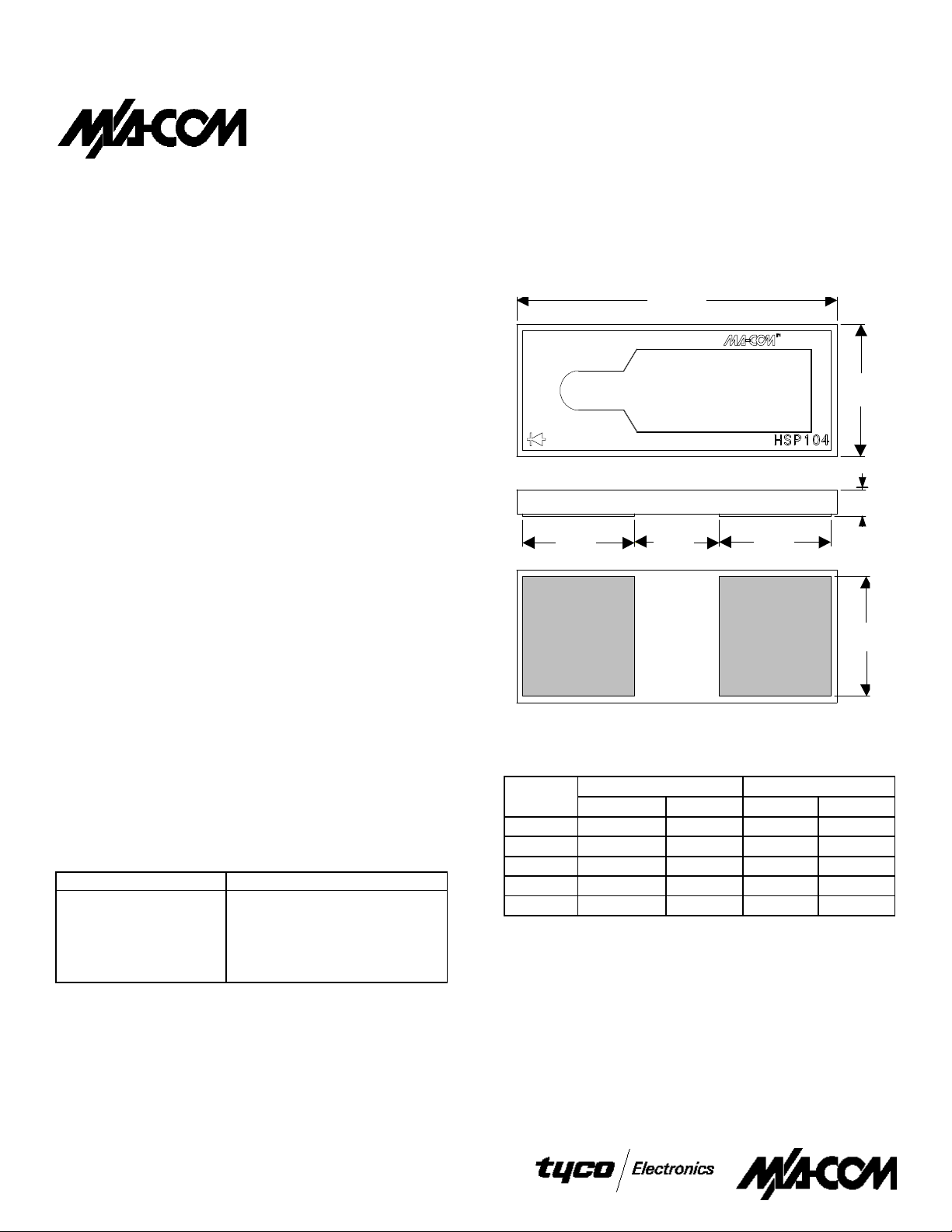

Case Style

ODS-1247

1. Backside metal: 0.1 micron thk. gold.

2. Hatched areas indicate bond pads.

1, 2

A

D E

B

C

D

D

Absolute Maximum Ratings1

@ TA = +25°C (unless otherwise specified)

Parameter Absolute Maximum

Reverse Voltage -70 V

Forward Current 100 mA

Operating Temperature -65°C to +150°C

Storage Temperature -65°C to +150°C

Mounting Temperature +235°C for 10 seconds

1. Exceeding these limits may cause permanent damage.

Specifications subject to change without notice.

n North America: Tel. (800) 366-2266, Fax (800) 618-8883

n Asia/Pacific: Tel.+81-44-844-8296, Fax +81-44-844-8298

n Europe: Tel. +44 (1344) 869 595, Fax+44 (1344) 300 020

Visit www.macom.com for additional data sheets and product information.

INCHES

DIM.

A 0.0520 0.0583 1.320 1.480

B 0.0201 0.0264 0.510 0.670

C 0.0040 0.0080 0.102 0.203

D 0.0180 0.0200 0.457 0.508

E 0.0140 0.0160 0.355 0.406

MIN. MAX. MIN. MAX.

MILLIMETERS

V 2.0

1

Surface Mount Monolithic PIN Diode Chip

MA4SPS302 SurMount Series

Electrical Specifications @ +25°C

Symbol Test Conditions Units Min. Typ. Max.

CT -40 Volts, 1 MHz 1 pF 0.400 0.450

CT -40 Volts, 1 GHz

RS 10 mA, 100 MHz

RS 10 mA, 1 GHz

VF 10 mA V 0.84 1.00

VR

10 µA

IR -70V

TL 10 mA / 6 mA ns 460

1. Total capacitance is equivalent to the sum of junction capacitance Cj and parasitic capacitance.

2. Series resistance R

3. R

and CP is measured on an HP4291A with die mounted in an ODS-186 package with conductive silver epoxy.

S

is equivalent to the total diode series resistance including the junction resistance Rj.

S

1, 3

pF 0.300

2,

2, 3

Ω

Ω

1.0

1.3

V -70 -120

µA

10

Handling Procedures

All semiconductor chips should be handled with care to avoid

damage or contamination from perspiration and skin oils. The

use of plastic tipped tweezers or vacuum pickups is strongly

recommended for individual components. Bulk handling should

insure that abrasion and mechanical shock are minimized.

ESD

These devices very susceptible to ESD and are rated Class 0

(0-199V) per HBM MIL-STD-883, method 3015.7 [C = 100pF

±10%, R = 1.5kΩ ±1%]. Even though tested die pass 100V

ESD, they must be handled in a static-free environment.

Bonding Techniques

Attachment to a circuit board is made simple through the use of

surface mount technology. Mounting pads are conveniently

located on the bottom surface of these diodes and are removed

from the active junction locations. These diodes are well suited

for solder attachment onto hard and soft substrates. The use of

80/20 Au/Sn and 60/40 Sn/Pb solder is recommended.

Conductive epoxy paste for attachment may also be used, this

can be silk-screened, or used with a conductive sheet apoxy.

When soldering these diodes to a hard substrate, hot gas die

bonding is preferred. We recommend utilizing a vacuum tip and

a force of 60 to 100 grams applied normal to the top surface of

the part. When soldering to soft substrates, it is recommended

to use a lead-tin interface at the circuit board mounting pads.

Position the die so that its mounting pads are aligned with the

circuit board’s mounting pads Reflow the solder by heating the

circuit trace near the mounting pad while applying 60 to 100

grams of force perpendicular to the top surface of the die.

Since the HMIC™ glass is transparent, the edges of the

mounting pads closest to each other can be visually inspected

through the die after attach is completed.

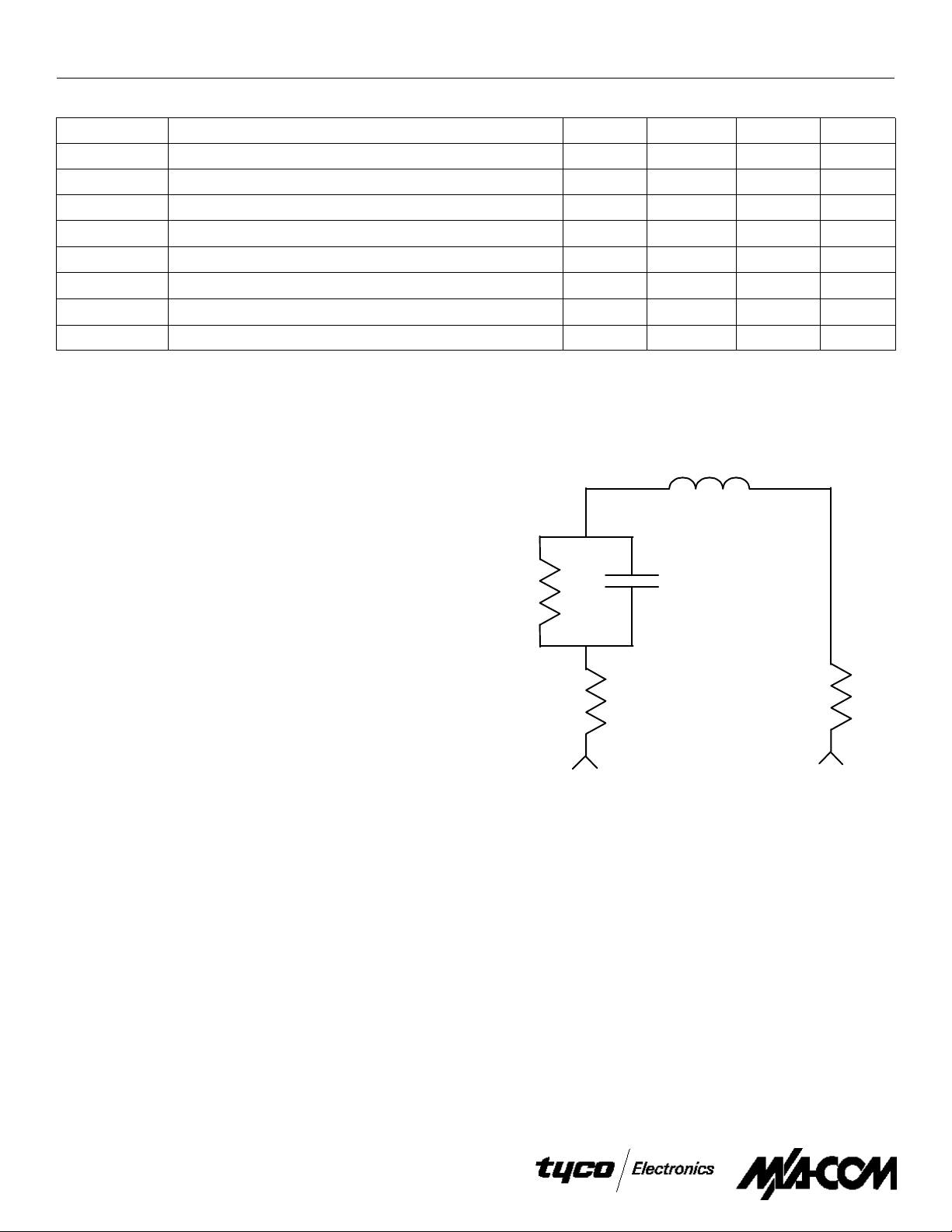

Functional Schematic1

Cp

Rp

Rvia

-

1. Rs = 2 * Rvia + Rp

Ls

Rvia

+

Specifications subject to change without notice.

n North America: Tel. (800) 366-2266, Fax (800) 618-8883

n Asia/Pacific: Tel.+81-44-844-8296, Fax +81-44-844-8298

n Europe: Tel. +44 (1344) 869 595, Fax+44 (1344) 300 020

Visit www.macom.com for additional data sheets and product information.

V 2.0

2

Loading...

Loading...