M A COM MA4BPS201, MA4BPS101, MA4BPS301 Datasheet

PIN Diode Chips With Offset Bond Pads MA4BPS101, MA4BPS201, MA4BPS301

g

MA4BPS101, MA4BPS201, MA4BPS301

PIN Diode Chips with

Offset Bond Pads

Features

•

Bond Pads Removed From Active Junction

•

Large Bond Pads Support Multiple Bond Wires

•

Rugged Silicon-Glass Construction

•

Silicon Nitride Passivation

•

Polyimide Scratch Protection

Description

These silicon - glass PIN diode chips are fabricated with

M/A-COM’s patented HMIC™ process. They contain a single

shunt silicon PIN diode embedded in a glass s ubstrate with dual

75 x 150 micron bond pads located near the chip edges. The large

pads allow use of multiple bond wires. The location of these pads

on a glass substrate results in low parasitic capacitance. The

diode junction is passivated with silicon nitride and a layer of

polyimide has been added for scratch protection during assembly.

The devices are available on industry standard tape frame for

automatic insertion and assembly in high volume applications.

Applications

These diodes are designed for use as general PIN elements in

switches and switched pad attenuators. The chips can handle up

to 10 watts of RF power, and are well suited for use in T/R

switches for subscriber phones, particularly the higher power and

higher frequency systems for satellite based systems. They are

also useful for the switching element in phased array radar applications. The larger bond pad allows for two (2) 1 mil dia contact

wires which reduces the bond wire inductance almost in half.

Chip Layout

Absolute Maximum Ratin

Parameter Absolute Maximum

Operating Temperature

Storage Temperature

Forward Current 100mA

Reverse Voltage 70 V

Incident RF Power +40 dBm (CW)

Mounting Temperature

1. Exceeding these limits may cause permanent damage.

1

-60°C to +150°C

-65°C to +175°C

+320°C for 10 seconds

Electrical Specifications @ +25°C

MA4BPS101 MA4BPS201 MA4BPS301

Parameters Symbol Units Test Conditions M in. Typ. Max. Min. Typ. Max. Min. Typ. Max.

Total Capacitance C

Series Resistance

Parallel Resistance

Breakdown Voltage Vb Volts -10 uA 70 110 70 110 70 110

Carrier Lifetime

Thermal Impedance

1. Guaranteed by correlation to 2 MHz on-wafer measurements.

2. Tested on a sample basis only.

M/A-COM Division of AMP Incorporated Q North America: Tel. (800) 366-2266, Fax (800) 618-8883 Q Asia/Pacific: Tel.+85 2 2111 8088, Fax +85 2 2111 8087

Q Europe: Tel. +44 (1344) 869 595, Fax+44 (1344) 300 020

www.macom.com

1

2

2

2

T

Rs

Rp

T

L

jc

θ

AMP and Connecting at a Higher Level are trademarks.

Specifications subject to change without notice.

pF -5 Volts at 1 MHz 0.13 0.17 0.20 0.25 0.30 0.35

Ω

+10 mA at 1 GHz 1.9 2.4 1.0 1.3 0.9 1.2

K

Ω

0 Volts at 1 GHz 14 6 6

nS +10mA/-6mA 300 300 300

C/W

°

1A/.01A, 10 mS 38 28 24

V2.01

PIN Diode Chips With Offset Bond Pads MA4BPS101, MA4BPS201, MA4BPS301

)

(

)

Hanlding and Mounting Information

Handling

All semiconductor dice should be handled with care to avoid

damage or contamination. For an individual die, the use of

plastic tipped tweezers or vacuum pick-up tool is recommended.

When using automatic pick and place, abrasion and mechanical

shock should be minimized.

Mounting

The dice have Ti-Pt-Au back metal, with a final gold thickness

of 0.1 micron. They can be die mounted with a gold-tin eutectic

solder preform or conductive epoxy. The mounting surface

must be clean and flat.

Eutectic Die Attachment

An 80/20 gold-tin eutectic solder preform is recommended with

a work surface temperature of 255

°

of 265

should be 290

tures greater than 320

C. When hot gas is applied, the tool tip temperature

°

C. The chip should not be exposed to tempera-

°

C for more than 20 seconds. No more

than three seconds should be required for attachment.

Epoxy Die Attachment

A minimum amount of epoxy should be used. A thin epoxy

fillet should be visible around the perimeter of the chip after

placement. Cure epoxy per manufacturer’s schedule.

Wire Bonding

The two bond pads on these die have a Ti-Pt-Au metalization

scheme, with a final gold thickness of 2.5 microns. Th e pa ds are

75 x 150 microns; up to two wires or a 100 micron wide ribbon

can be bonded to each pad. Thermosonic wedge wire bonding of

0.001” diameter gold wire is recommended with a stage temperature of 150

°

C and a force of 25 to 40 grams. Ultra sonic e n e rgy

should be adjusted to the minimum required.

°

C and a tool tip temperature

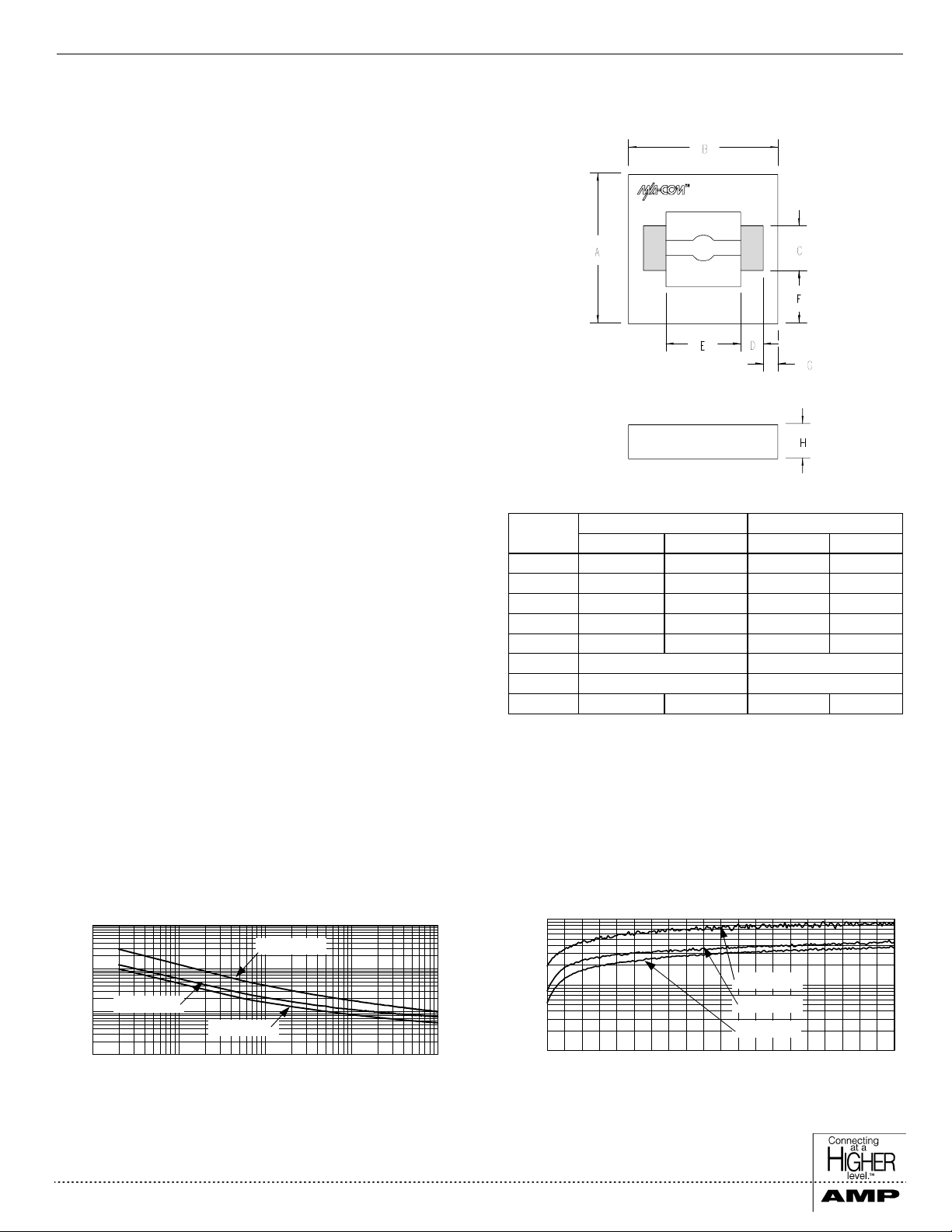

Chip Outline Drawing (ODS-1244

INCHES MILLIMETERS

DIM

A

B

C

D

E

F

G

H

Notes: 1. Bond pad material: 2.5 micron thick gold.

MIN MAX MIN MAX

0.019 0.0213 0.480 0.540

0.019 0.0213 0.480 0.540

0.0055 0.0063 0.140 0.160

0.0026 0.0033 0.065 0.085

0.0094 0.0102 0.240 0.260

0.007 Ref. 0.180 Ref.

0.002 Ref. 0.050 Ref.

0.0043 0.0055 0.110 0.140

2. Shaded areas indicate wire bonding pads

3. Backside metal: 0.1 micron thick gold.

Typical Resistance Curves

Series Resistance vs. Forward Current at 1 GHz Parallel Resistance vs. Reverse Voltage at 1 GHz

100.0

MA4BPS101

10.0

MA4BPS201

1.0

Series Resistance (Ohms)

0.1

0.0 0.1 1.0 10.0 100.0

M/A-COM Division of AMP Incorporated Q North America: Tel. (800) 366-2266, Fax (800) 618-8883 Q Asia/Pacific: Tel.+85 2 2111 8088, Fax +85 2 2111 8087

Q Europe: Tel. +44 (1344) 869 595, Fax+44 (1344) 300 020

www.macom.com

MA4BPS301

F o r w a r d C u r r e n t ( m A )

AMP and Connecting at a Higher Level are trademarks.

Specifications subject to change without notice.

100,000

Ohms

10,000

Parallel Resistance

1,000

0.0 2.0 4.0 6.0 8.0 10.0

R e v e r s e V o l t a g e ( V o l t s )

MA4BPS101

MA4BPS201

MA4BPS301

V2.01

Loading...

Loading...