Page 1

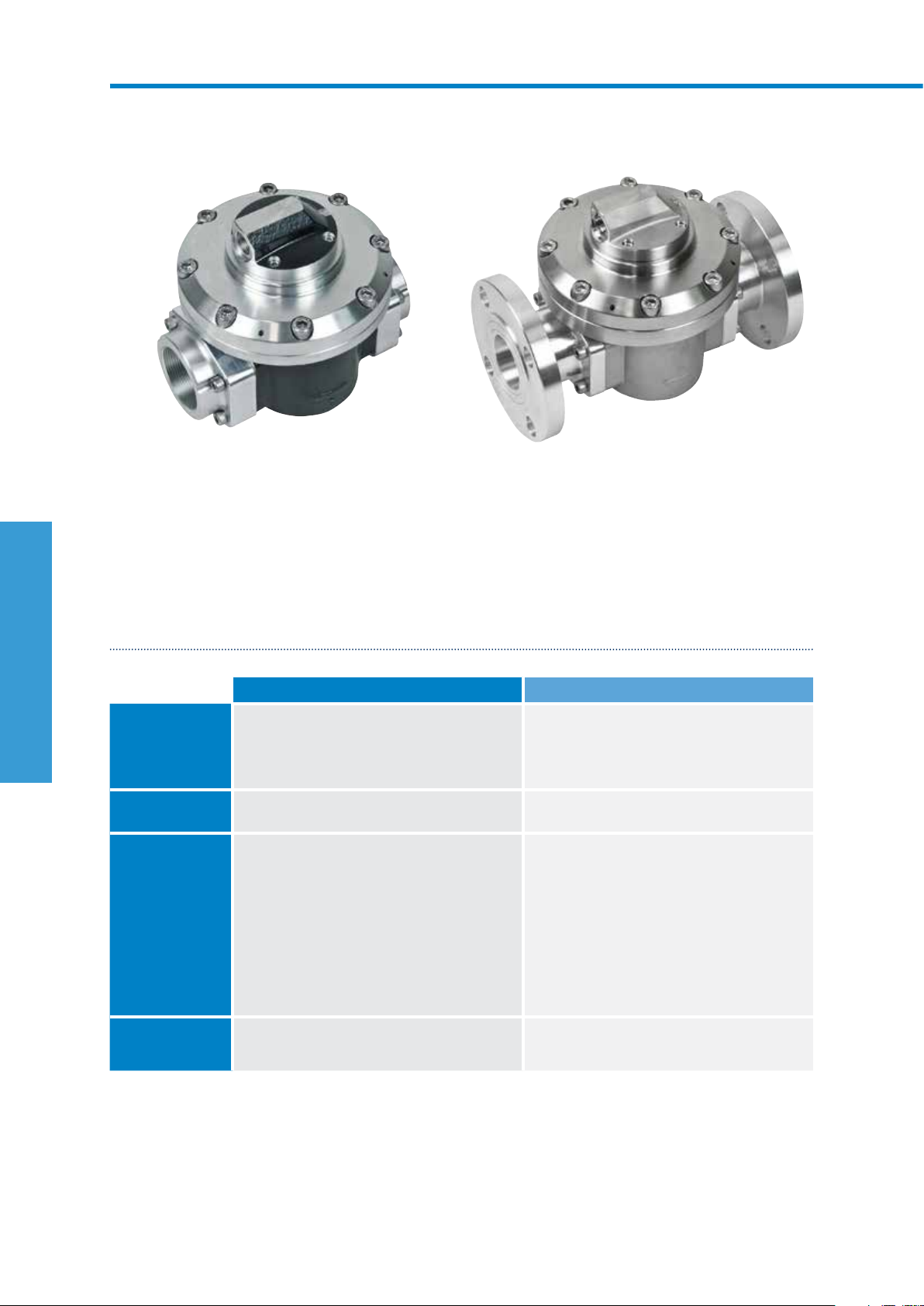

POSITIVE DISPLACEMENT FLOW METERS

Page 2

ABOUT

MACNAUGHT

Macnaught Pty Ltd is a privately owned manufacturing company based

in Australia, established in 1948. Macnaught’s experience in Positive

Displacement Flow Meter technology extends back to 1964. Macnaught’s

mission is to always exceed industry standards with its products and services.

Macnaught continues to work closely with industry practitioners to

deliver product improvements, new technologies and bespoke solutions.

Macnaught has become a highly sought after manufacturer of precision oval

gear meter technology. This has been achieved through decades of industry

experience and innovation derived from its cutting edge in-house Research

and Development facility with full ISO 9001 and 14001 accreditation.

Macnaught also provide region specific accreditation as required.

Macnaught’s Positive Displacement Flow Meters are suitable for a wide range

of industrial applications including fuel and oil distribution, corrosive chemical

or solvent measurement and high pressure applications to name a few.

Macnaught boasts a network of over 60 international distributors and a

highly skilled global sales support network enabling access to its high

performance and valued products simple, fast and efficient.

Decades of experience have resulted in simple, robust and highly

accurate Positive Displacement Flow Meters. Specify Macnaught Positive

Displacement Flow Meters with confidence for your flow measurement

equipment requirements.

Page 3

CONTENTS

INTRODUCTION 2

RANGE OVERVIEW 2

METER SELECTION GUIDE 4

OPERATING GUIDELINES 7

MXSER IES FLOW METERS 9

MX06 ¼” DIGITAL FLOW METERS SUITABLE FOR FLOW RANGE 0.5100L/HR 12

MX09 ¼” DIGITAL FLOW METERS

MX12 ½” DIG ITAL FLOW METERS

MX19 ¾” DIG ITAL FLOW METERS

MX25 1” DIG ITAL FLOW METERS

MX40 1½” DIG ITAL FLOW METERS

MX50 2” DIGITAL FLOW METERS

MX75 3” DIG ITAL FLOW METERS

MX100 4” DIGITAL FLOW METERS

SUITABLE FOR FLOW RANGE 15500L/ HR 14

SUITABLE FOR FLOW RANGE 230L/ MIN 16

SUITABLE FOR FLOW RANGE 380L/ MIN 18

SUITABLE FOR FLOW RANGE 6120L/MIN 20

SUITABLE FOR FLOW RANGE 10250L/MIN 22

SUITABLE FOR FLOW RANGE 15500L/ MIN 24

SUITABLE FOR FLOW RANGE 20733L/MIN 26

SUITABLE FOR FLOW RANGE 1201200L/MIN 28

MSERIES FLOW METERS 31

M1 ¼” PULSE FLOW METERS

¼” HIGH PRESSURE FLOW METERS

M2 ¼” PULSE FLOW METERS

¼” HIGH PRESSURE FLOW METERS

M4 ½” HIGH PRESSURE FLOW METERS

½” MECHANICAL FLOW METERS

M7 1” PULSE FLOW METERS

1” CUSTODY TRANSFER METERS AU ONLY

M10 1” MECHANICAL FLOW METERS

1” CUSTODY TRANSFER METERS AU ONLY

M40 1½” MECHANICAL FLOW METERS

1½” CUSTODY TRANSFER METERS AU ONLY

M50 2” MECHANICAL FLOW METERS

2” CUSTODY TRANSFER METERS AU ONLY

M80 3” MECHANICAL FLOW METERS

3” CUSTODY TRANSFER METERS AU ONLY

M100 4” MECHANICAL FLOW METERS

4” CUSTODY TRANSFER METERS AU ONLY

SUITABLE FOR FLOW RANGE 0.5100L/HR 40

SUITABLE FOR FLOW RANGE 0.5100L/HR 42

SUITABLE FOR FLOW RANGE 15500L/ HR 44

SUITABLE FOR FLOW RANGE 15500L/ HR 46

SUITABLE FOR FLOW RANGE 230L/ MIN 48

SUITABLE FOR FLOW RANGE 230L/ MIN 50

SUITABLE FOR FLOW RANGE 380L/ MIN 52

SUITABLE FOR FLOW RANGE 1470L/MIN 54

SUITABLE FOR FLOW RANGE 6120L/MIN 56

SUITABLE FOR FLOW RANGE 24120L/MIN 58

SUITABLE FOR FLOW RANGE 10250L/MIN 60

SUITABLE FOR FLOW RANGE 50250L/MIN 62

SUITABLE FOR FLOW RANGE 15500L/ MIN 64

SUITABLE FOR FLOW RANGE 70350L/M IN 66

SUITABLE FOR FLOW RANGE 20733L/MIN 68

SUITABLE FOR FLOW RANGE 140700L/M IN 70

SUITABLE FOR FLOW RANGE 1201200L/MIN 72

SUITABLE FOR FLOW RANGE 2401200L/ MIN 74

ACCESSORIES 77

APPENDICES 86

APPENDIX A FLOW METER ACCURACY AND PRESSURE LOSSES 86

APPENDIX B ACCESSORY DIMENSIONAL DATA 88

APPENDIX C VISCOSITY FACTOR 91

APPENDIX D WARRANTIES & CERTIFICATIONS 92

APPENDIX E CHEMICAL COMPATIBILITY GUIDE 93

macnaught.com.au 1

Page 4

INTRODUCTION

INTRODUCTION

RANGE OVERVIEW

Macnaught’s Positive Displacement Flow Meters are suitable for a wide range of industrial

applications including fuel and oil distribution, corrosive chemical, solvent measurement and high

pressure applications to name a few.

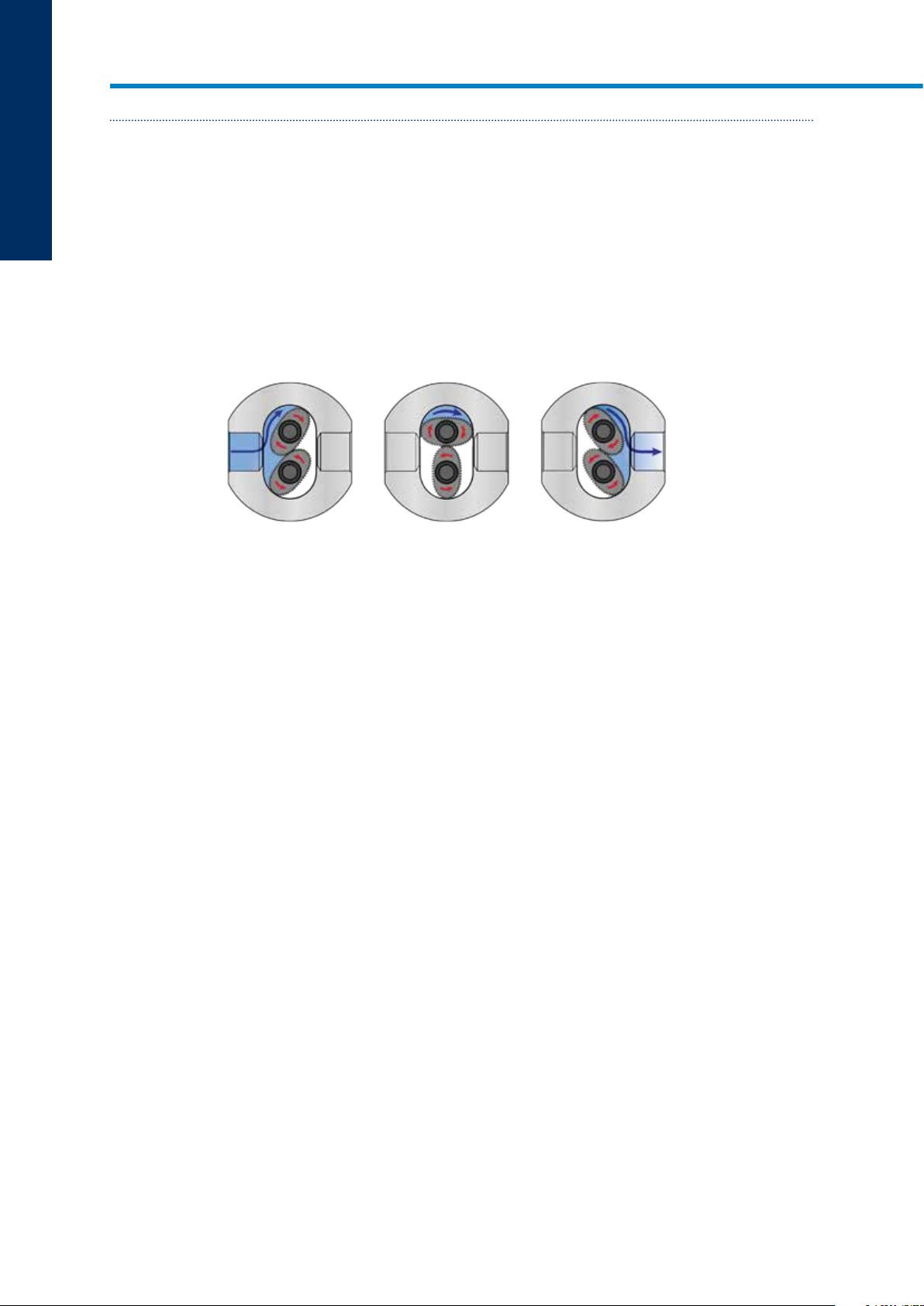

Macnaught offers Positive Displacement Flow Meters featuring Oval Gear technology. The measuring

principle includes two high precision toothed oval gears, which are driven by the flow of the medium and

mesh with each other: in presence of a flow, defined volumes of fluid are transported through the meter

for each rotation of oval gears pair. As the flow rate increases, so does the rotational speed of the rotors.

The number of gear rotations is a measure of the amount of fluid that has passed through the meter;

each rotation is detected by a sensor and the volume is calculated using a conversion factor (K factor).

Figure 1: Macnaught Positive Displacement Flow Meter operation.

A key distinction of positive displacement flow meters is that they offer direct measurement of the

volumetric flow rate. Positive displacement flow meters are frequently specified as they offer high accuracy

and repeatability. They readily provide measurement accuracy within +/-0.5% of the true value.

Additionally, positive displacement flow meters require no power to drive the gear operation with no

special fluid conditioning (e.g. straight lengths of pipe) and are capable of handling high pressure,

large flow variations and plant equipment vibration due to their robust design.

Advantages:

• High accuracy and repeatability

• Suitable for viscous fluids

• Cost-effective

• Accuracy unaffected by changes in viscosity

• Requires minimal maintenance

• Ease of installation

• Exceptional turn-down ratio

Precision engineering and manufacturing methods are used by Macnaught using cutting edge CNC

machining technology and mill certified materials to deliver highly repeatable accuracy and durability.

All critical components are machined in-house with astute quality control monitoring the production

process continuously.*

NOTE: This catalogue is intended to provide general guidance on Macnaught's Positive Displacement Flow Meters. In order to select the most appropriate

meter for your needs, please seek expert advice which is available free-of-charge from Macnaught's Technical Support Team.

2 Macnaught | Positive Displacement Flow Meters

Page 5

As a result of over 50 years experience with Positive Displacement Flow Meter technology, Macnaught

offers two comprehensive ranges that cater for the ever changing market needs. The latest innovation

with the MX-SERIES range to the original M-SERIES range, Macnaught flow meters are designed

to insist upon durability, reliability and excellence.

The MX-SERIES is the latest innovation featuring:

• High precision billet construction for enhanced material integrity and process reliability

• Programmable digital display and Pulse output options

• Unique bayonet assembly for added versatility and flexibility

INTRODUCTION

The M-SERIES is Macnaught’s original range of meters featuring:

Established design and cast construction for proven performance

Mechanical and pulse output options

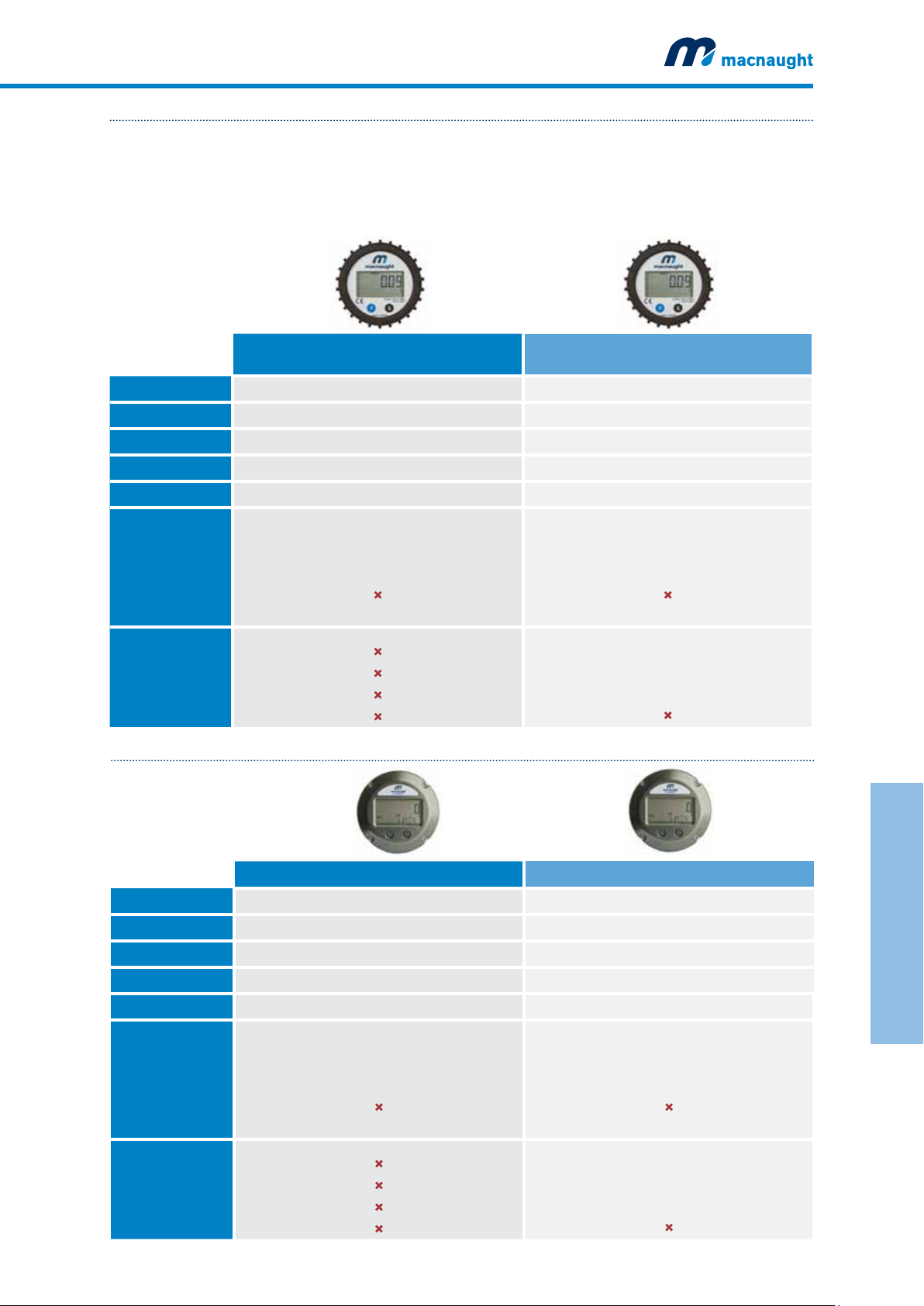

Figure 2: Summary of the key features of Macnaught’s Positive Displacement Flow Meters

MXSERIES MSERIES

Billet construction*

Meter Body

Rotor

Output

Mechanical

Output

Electrical

Stainless Steel

Aluminium

PPS (Hastelloy or Stainless Steel)

Aluminium (Carbon Bushing)

316 Stainless Steel (Carbon Bushing)

High Viscosity Rotors (Stainless Steel with Carbon Bushing)

CHECK

Standard Pulse

Intrinsically Safe Pulse

High Temp. Pulseerature Pulse

4 - 20 mA output

Cast construction**

Stainless Steel

Aluminium

PPS

Standard Mechanical Register

Heavy Duty Mechanical Register

Standard Pulse

Digital Display

*Billet construction across the MX meters up to 2”

**M-SERIES all cast with the exception of the MH High Pressure Flow Meters (these are of billet construction)

Full programmable Meter Mount Digital Displays

(PR & ER)

Remote-mountable Digital Displays (PR & ER)

Full programmable Meter Mount Digital Displays

Remote-mount Digital Display

(DR - CR025 only)

(PR & ER)

macnaught.com.au 3

Page 6

INTRODUCTION

INTRODUCTION

METER SELECTION GUIDE

Correct specification of the appropriate meter is necessary to achieve desired accuracy and suitable

data output, as well as to ensure safety in each application. While for most applications, the specification

of the appropriate meter will be straightforward, using the specification process outlined below, for

some applications there may be additional technical considerations which need to be assessed on a

case-by-case basis. In all circumstances we recommend that you consult with Macnaught's Technical

Support Team to select the most appropriate meter for your needs

The following steps are provided as general guidelines to assist with correct meter specification.

However, to ensure accuracy of specification in relation to your application, we recommend seeking

expert advice before making the final selection of the appropriate meter. Please note that Macnaught’s

Technical Support Team is available free-of-charge to assist in the specification and identification of a

suitable meter.

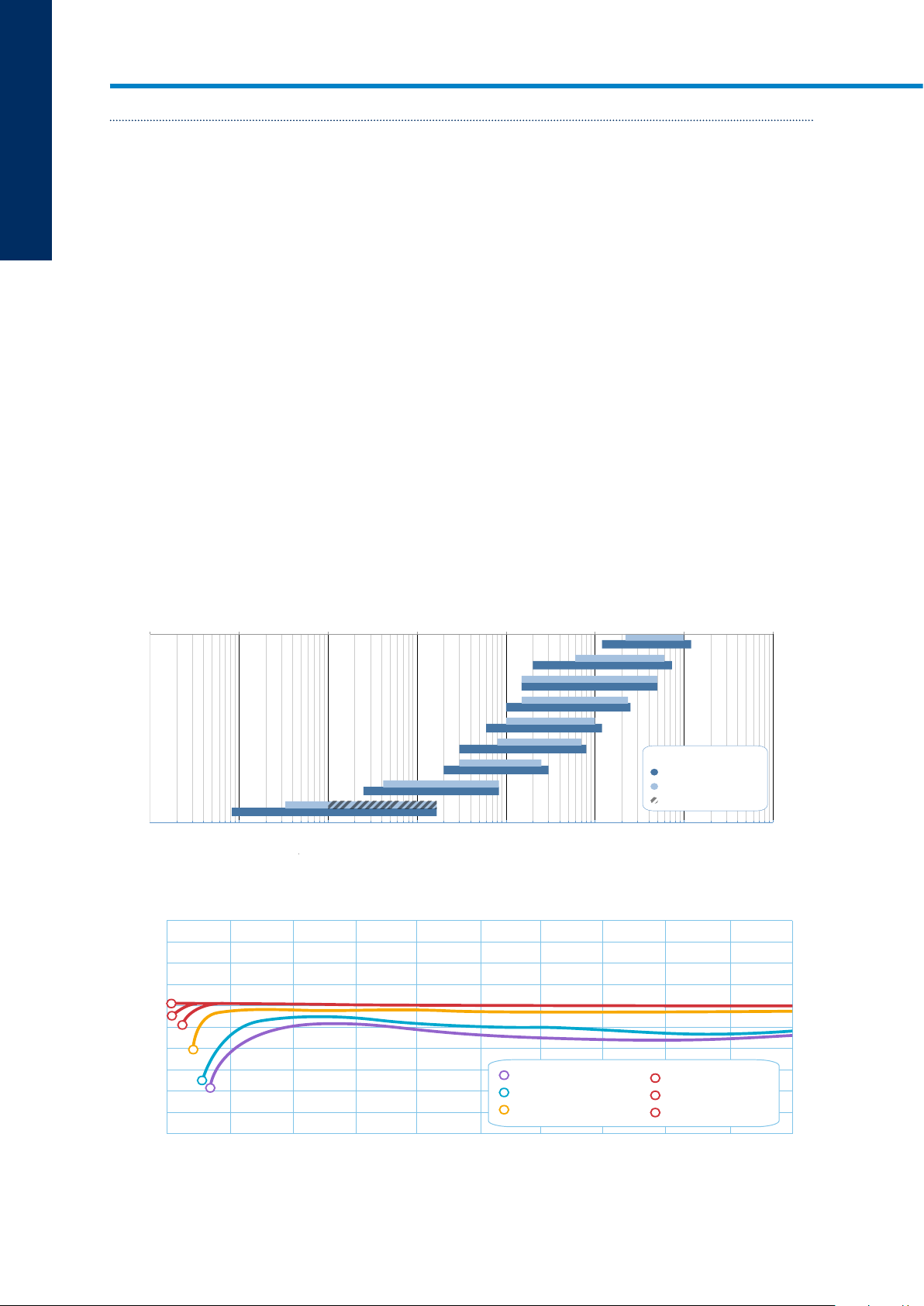

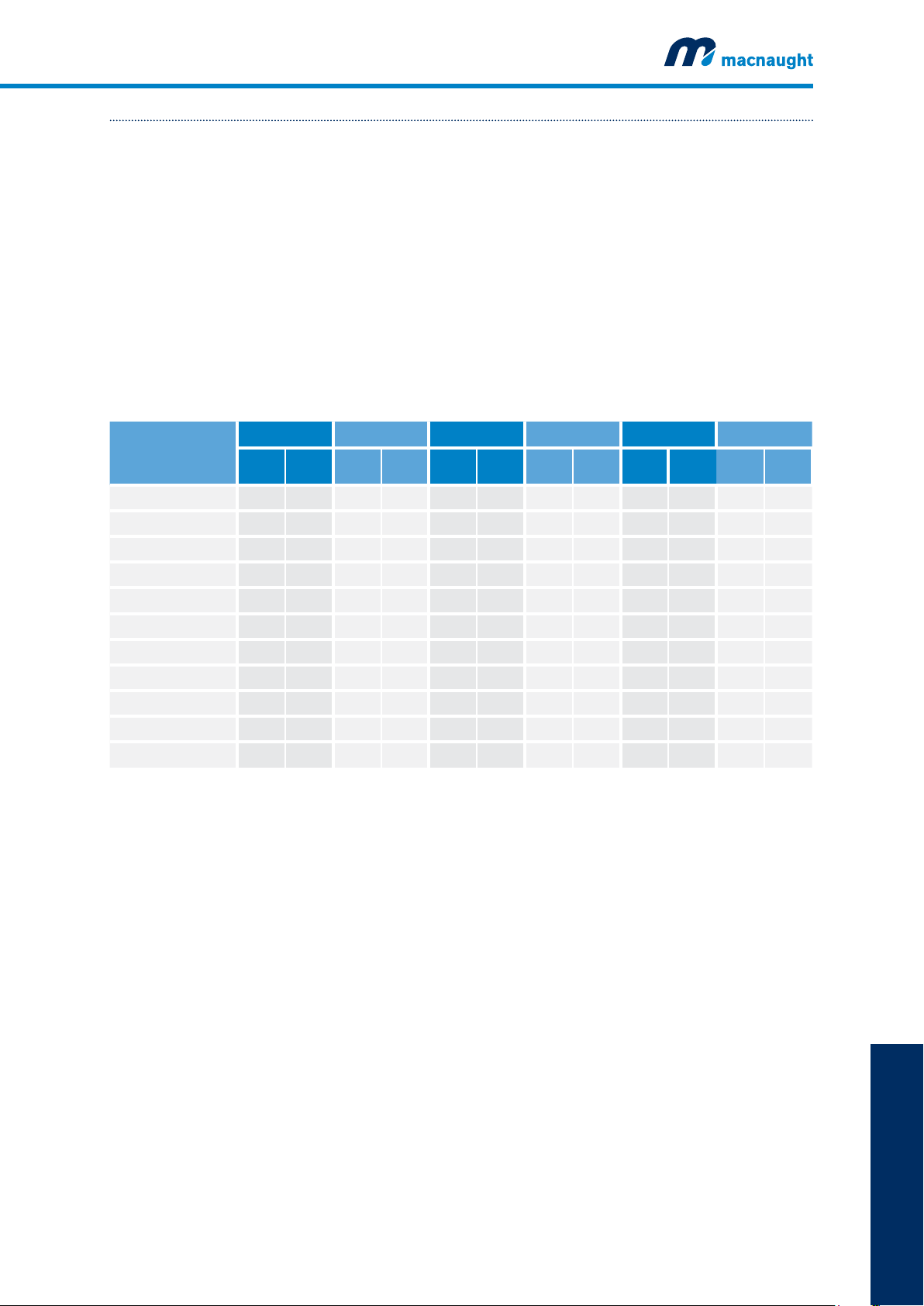

Flow Meter Size

Macnaught Positive Displacement Flow Meters are available in a range of sizes that are engineered

to provide high accuracy across a wide turn down ratio. Figure 3 assists in interpreting your process

flow rate, which is an important determinant to the accuracy of your meter. The size of meter should be

selected for maximum coverage for your operating flow rates. As shown in Figure 4, the accuracy of

the meter is optimal near the mid-range of the meter flow range. In some instances the required flow

rates can fall across two meter options, e.g. if the required flow rate is 3 L/min both the MX09 & the

MX12 are suitable, in such cases it is recommended to select the meter where the flow range is within

the upper 50% of the meter’s flow range limits, i.e. the MX09 is preferred.

Figure 3: Macnaught Positive Displacement Flow Meters flow rate range selection chart

Meter Size Range vs Operating Flowrate

0.001

M100

M80

M50

M40

M10

M-SERIES

M7

M4

M2

M1

0.001 0.01 0.1 10 100 1000

0.01 0.1 1 10 100 1000

Fluid Viscosity Range:

5 - 1000cP

<5cP

<5cP (non lubricating fluids)

1

Operating Flowrate (Q L/min*)

10000

10000

MX100

MX75

MX50

MX40

MX25

MX19

MX12

MX09

MX06

MX-SERIES

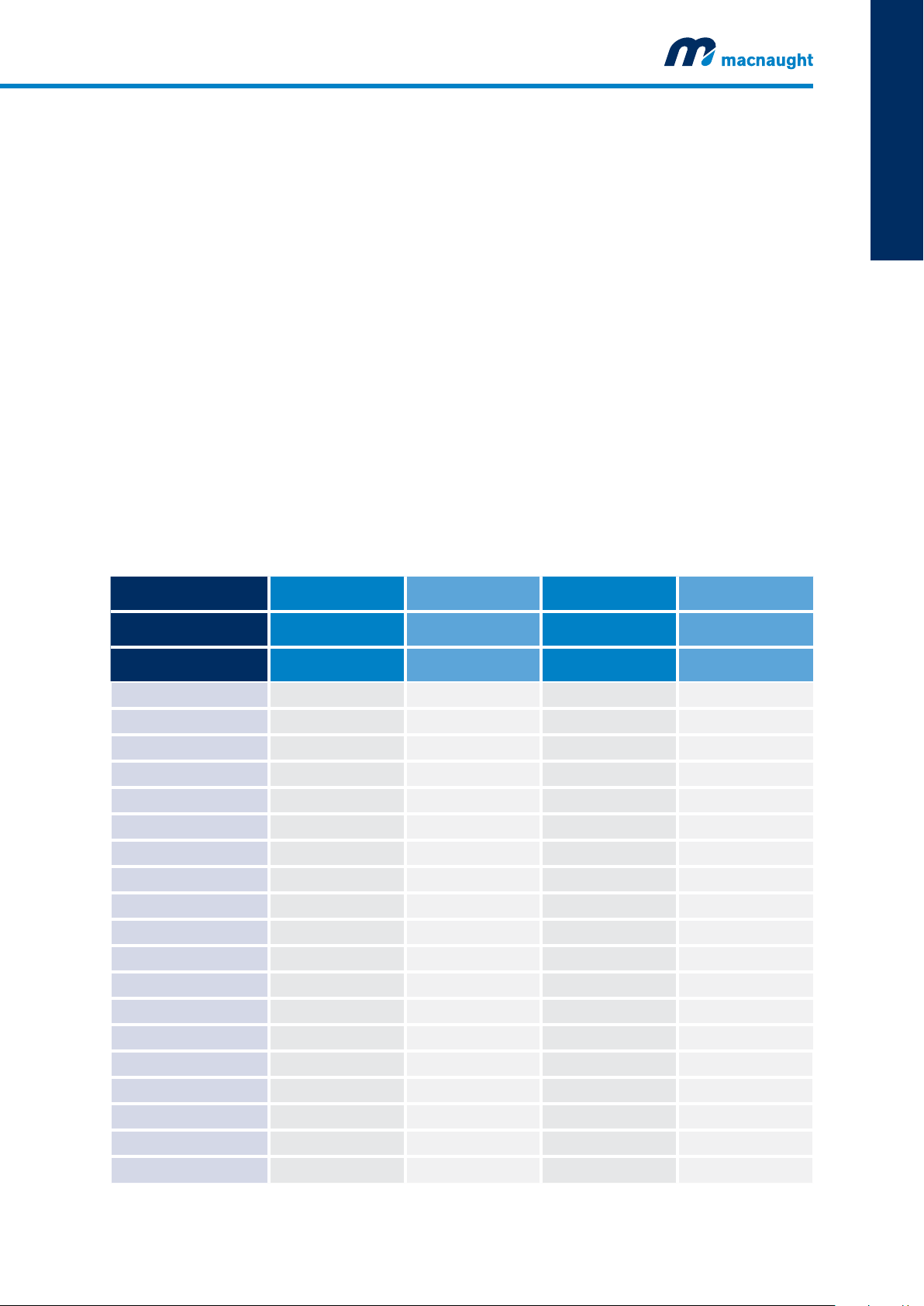

Figure 4: Impact of viscosity and flow range on meter accuracy

Accurracy vs Flowrate

+4.0

+3.0

+2.0

+1.0

6

0

5

–1.0

Accuracy %

–2.0

–3.0

–4.0

NOTE: The above graphs are based on generic industry-sourced data. The graphs are intended to be used for illustrative purposes only and may not be

directly applicable to your specific applications. Please seek expert advice from Macnaught's Technical Support Team before final selection.

IMPORTANT: Do not use the above data for product selection.

4 Macnaught | Positive Displacement Flow Meters

4

3

1

2

1

100 20

Gasoline 0.4 cps

2

Water 1

3

Light Oil >20

30

40 50 60 70 80 90 100

Flow as % of maximum capacity

cps

cps

4

A Heavy Oil <20 cps

5

B Heavy Oil 100 cps

6

C Heavy Oil 300 cps

Note:

For viscosities greater than 1000cps

High Viscosity rotors are required

Page 7

Macnaught standard ‘single point’ calibration is carried out at mid-flow range where the individual

K-factor is assigned to the meter.

Identifying the correct meter size for the operating flow rates will ensure the longevity of the meter

and deliver optimal accuracy during its operation. For instances where operation is necessary outside

the designated mid flow range of the meter, it is recommended that an optional ‘multi-point’ calibration

is performed which will help ensure maximum accuracy is achieved. We recommend consulting

Macnaught's Technical Support Team before final selection.

Chemical Compatibility

To determine the most appropriate materials combination for each application it is essential that the

wetted components of the meter assembly are confirmed for chemical compatibility. Macnaught meters

are available in standard materials configurations, as shown on the quick reference table below (figure 5):

common fluid types are listed and the recommended materials combination for each of them is indicated.

For a more comprehensive chemical compatibility guide, please refer to Appendix E on page 93.

The chemical compatibility guides referred to above are intended to provide general guidance on

chemical compatibility. It is highly recommended that the data is checked on a case-by-case basis, as

individual process variations in chemical concentration and temperatures from those of the reference

data can influence compatibility. We advise seeking expert advice from Macnaught’s Technical Support

Team to confirm the materials selection.

INTRODUCTION

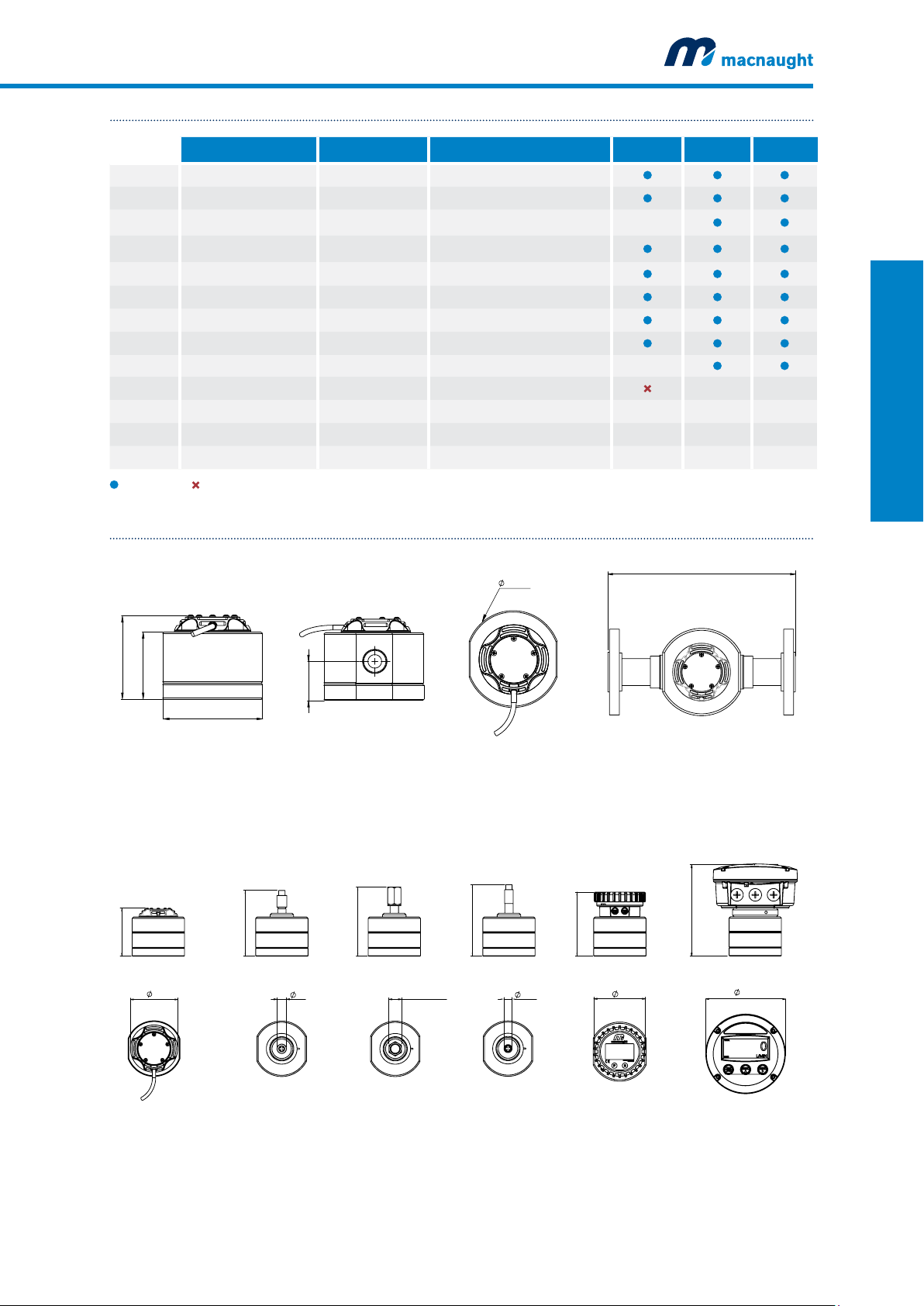

Figure 5: Quick reference chemical compatability guide*

BODY

ROTOR

SEALS

Avgas - Jet Fuel

Diesel Fuel

Ethylene Glycol

Gasoline, Unleaded

Kerosene

®

Adblue

Ammonia, anhydrous

Citric Acid

Methyl Ethyl Ketone

Acetone

Ethanol

Hexane

Methanol

Toluene

Phosphoric Acid

Potassium Hydroxide

Sodium Hydroxide

Sulphuric Acid

Water

*Refer to Appendix E - Chemical Compatibility Guide for general guidance on suitability

NOTE: This chart is intended to provide general guidance on chemical compatibility and should not be used for product selection. The chart is based on

industry data and may not be directly applicable to your specific applications. Macnaught does not accept liability for chemical compatibility outside of the

accuracy of the wetted component list. Please consult Macnaught's Technical Support Team before final selection.

PPS AL

SS AL

PPS PPS PPS/SS SS

FFKM FKM FEP FEP

CHECK✓ CHECK✓ CHECK✓ CHECK✓

CHECK✓ CHECK✓ CHECK✓ CHECK✓

CHECK✓ CHECK✓ CHECK✓ CHECK✓

CHECK✓ CHECK✓ CHECK✓ CHECK✓

CHECK✓ CHECK✓ CHECK✓ CHECK✓

CHECK✓

CHECK✓

CHECK✓ CHECK✓ CHECK✓ CHECK✓

CHECK✓

CHECK✓ CHECK✓ CHECK✓ V CHECK✓

CHECK✓ CHECK✓ CHECK✓ V CHECK✓

CHECK✓

CHECK✓

CHECK✓

CHECK✓

CHECK✓

✓

CHECK✓

CHECK✓ V CHECK✓

CHECK✓ CHECK✓

V CHECK✓

CHECK✓

CHECK

CHECK✓

CHECK✓

macnaught.com.au 5

Page 8

Temperature & Pressure Rating

INTRODUCTION

All Macnaught flow meters are designed to be completely safe under normal operating conditions.

However, to ensure user’s safety, it is very important to select a flow meter that will operate within the

process pressure and temperature conditions at all times.

Allowances should be made for any potential ‘spikes’ in pressure (e.g. as a result of sudden valve

closures or as the pump initially starts). If the system pressure is expected to reach the meters maximum

rating it may be necessary to incorporate a pressure relief valve into the system. Macnaught's Technical

Support Team is available to provide advice in this regard.

There are a number of factors that influence the pressure and temperature ratings of a flow meter:

Pressure rating:

• Presence of flanged ports causes a reduction of the pressure rating

• Other modifications to the materials properties

Temperature rating:

• Operational parameters such as the limitations of an attached LCD register and batteries

• Coefficient of expansion or

• Other modifications to the materials properties,

When factors combine, the individual effects could amplify and pose a safety risk. We therefore

recommend seeking expert advice from Macnaught’s Technical Support Team before final selection of

the appropriate meter.

Rotor Type

While Macnaught Positive Displacement Flow Meters are capable of processing a very wide range of

fluid viscosities, the viscosity of fluids still need to be considered to aid the selection process. This value

should always be taken at the applications operating temperature and flow rate. Note that typical fluid

technical data sheets are not usually stated at operating conditions, so further research may be required

to determine this information.

In cases where the fluid is non-Newtonian, additional allowances may be required to compensate for

changes to viscosity between static and dynamic situations.

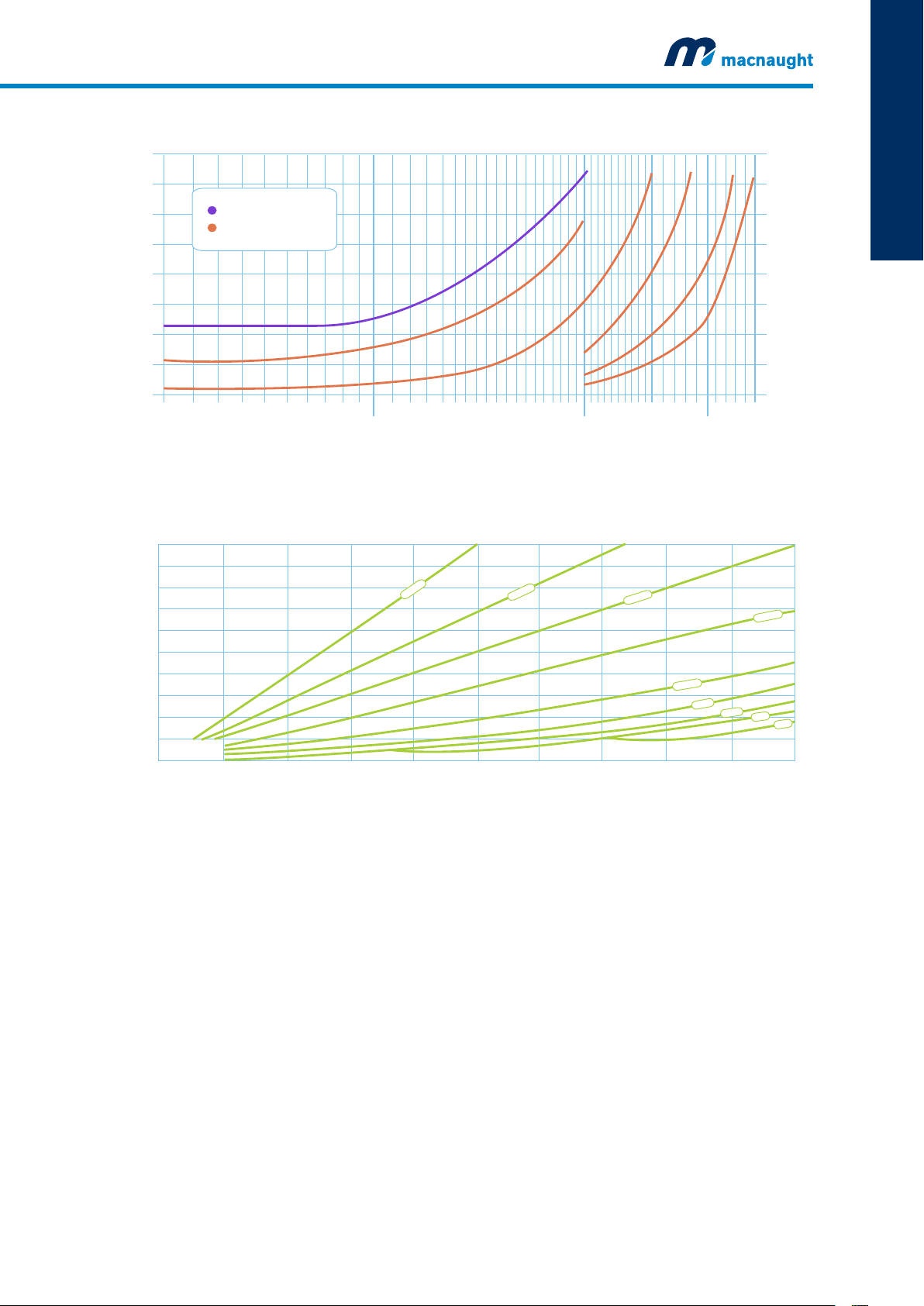

The higher the fluids viscosity the greater the pressure drop it will cause. As shown in Figure 7, the

maximum flow rate will need to be reduced as the viscosity increases. Please contact Macnaught if your

require further assistance. Alternatively, as shown in Figure 6, Macnaught offers High Viscosity (HV)

rotors that have been modified to alleviate this pressure drop and still offer extended flow ranges. As a

general rule if the viscosity is >1000cP it is recommended to use HV rotors, but it is also important to

look for notes on minimum viscosity as this can also affect the meters minimum flow rate.

6 Macnaught | Positive Displacement Flow Meters

Page 9

INTRODUCTION

Figure 6: Benefit of High Viscosity Rotors used to reduce pressure loss impact

Maximum Flow Rate Range

16

INTRODUCTION

110

14

12

Standard Rotors

High Viscosity Rotors

10

%

0

0

8

6

Pressure Loss (psi)

4

1

Flowrate

2

0

0 10,000 1,000,000

Fluid Viscosity (cPs)

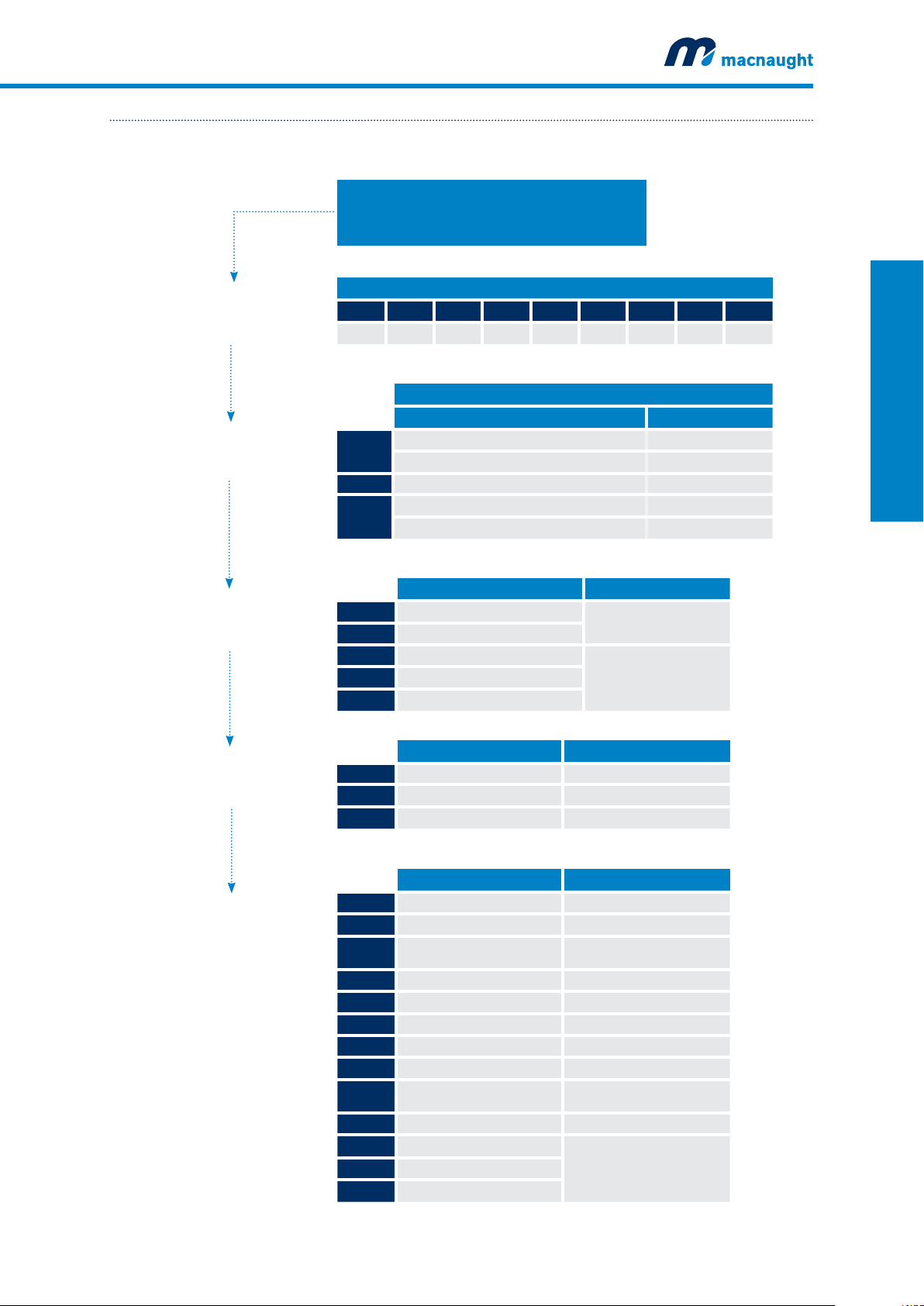

Figure 7: Impact of viscosity on pressure loss for a range of flow rates

Pressure drop vs. % flow rate

15.0

13.2

12.0

10.5

9.0

7.5

6.0

Pressure Drop (psi)

4.5

3.0

1.5

6000 cP

100

Flowrate

2000 cP

%

0

5

%

0

0

1

Flowrate

Flowrate

1,000 100,000

1000 cP

97

83

%

%

%

5

2

Flowrate

0

1

Flowrate

5

69

55

Pressure Loss (kPa)

41

28

14

0

300 cP

100 cP

50 cP

10 cP

5 cP

1 cP

100 20

30

40 50 60 70 80 90 100

Flow as % of maximum capacity

Note:

For viscosities greater

than 1000 cPs High

Vi rscosity otors are required

NOTE: The above graphs are based on generic industry-sourced data. The graphs are intended to be used for illustrative purposes only and may not be

directly applicable to your specific applications. Please seek expert advice from Macnaught's Technical Support Team before final selection.

IMPORTANT: Do not use the above data for product selection.

macnaught.com.au 7

Page 10

INTRODUCTION

OPERATING GUIDELINES

While oval gear flow meters provide exceptional accuracy, reliability and a cost effective solution, there

are some considerations for their usage. For example they should not be used to measure fluids with

particles or air pockets in them and adequate filtration needs to be installed upstream of the meter.

Inside the meter are moving components,

so as good practice a routine inspection

may be required. The frequency of the

Figure 8: Recommended installation components for optimal meter operation

OUT

inspection should be based on the

operating conditions; these will include

the maximum flow rate, viscosity and the

fluids lubricating properties. If the meter

FLOWMETER

is used with a lubricating fluid, such as

oil, and is well within the maximum flow

STRAINER

range, then the meter will operate of

many years maintenance free.

IN

Installation Guidelines

1. It is recommended that when setting up pipe work for meter installations a bypass line be

included in the design. This provides the facility for a meter to be removed for maintenance

without interrupting production

2. Use thread sealant on all pipe threads.

3. For pump applications ensure pipe work has the appropriate working pressure rating to match the

pressure output of the pump. Check specified Meter Technical Data section for further details.

4. Install a wire mesh strainer, Y or basket type (refer to pg.82 for Y strainer options) as close as

possible to the inlet side of the meter.

5. For M-series meters ensure that the meter is installed so that the flow of the liquid is in the

direction of the arrows (if applicable) embossed on the meter body.

6. The meter can be installed in any orientation as long as the meter shafts are in a horizontal plane.

(Refer to Figure 9 below for correct installation). The register assembly may be orientated to suit the

individual. Note: Incorrect installation can cause premature wear of meter components.

7. Do not over-tighten meter connections. It is important that after initial installation you fill the line

slowly, high speed air purge could cause damage to the rotors.

8. Test the system for leaks.

9. Check the strainer for swarf or foreign material after the first 1 hour of operation. Check the

strainer for swarf or foreign material periodically, particularly if the flow rate decrease .

Figure 9: Meter orientation for register assembly

✓ ␡✓

8 Macnaught | Positive Displacement Flow Meters

Page 11

MX-SERIES

FLOW METERS

MX-SERIES FLOW METERS

Page 12

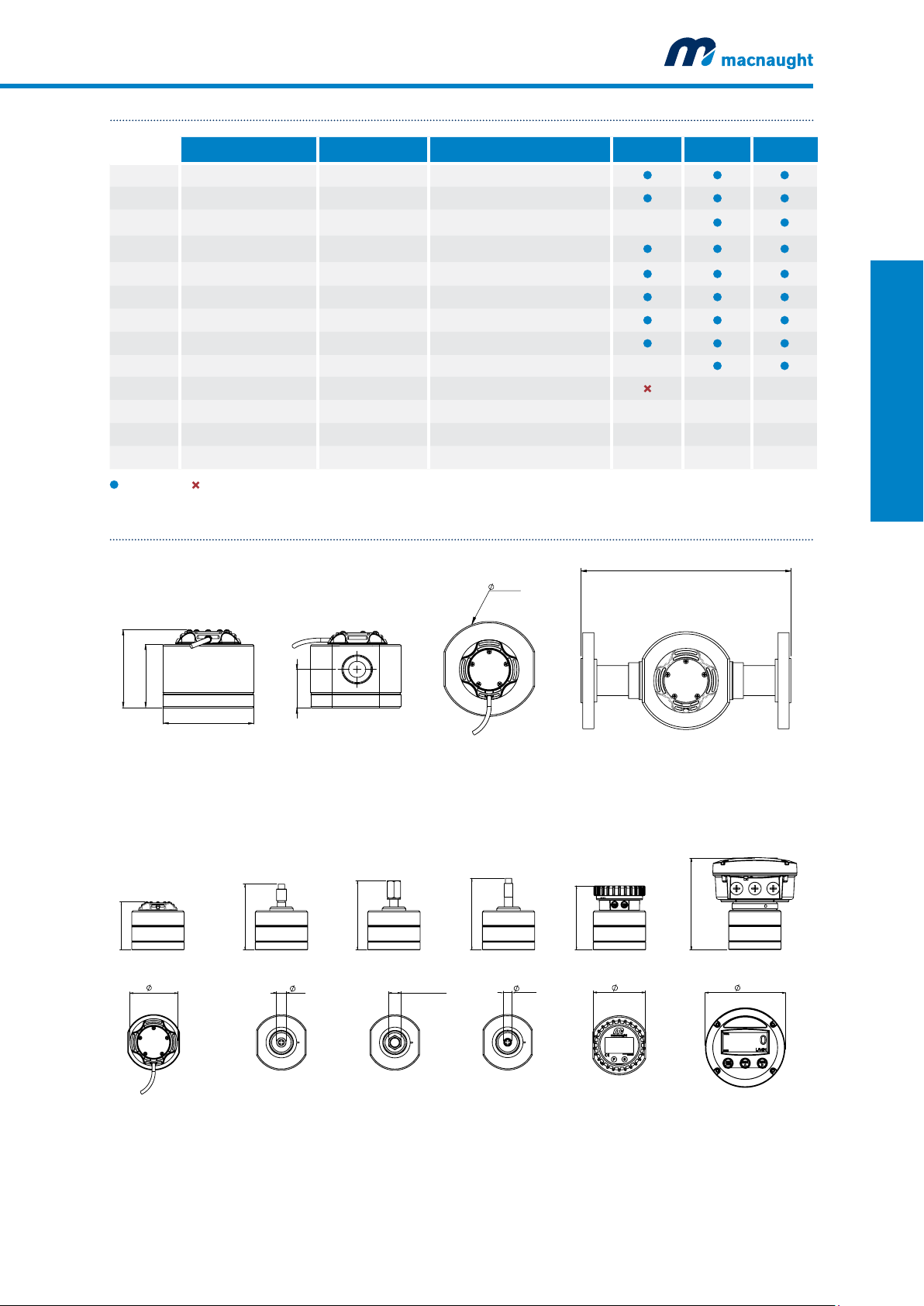

MXSERIES FLOW METERS

DIGITAL FLOW METERS

The Digital Flow Meter range are the latest innovation from Macnaught. They feature billet construction*

offering optimal operational reliability and accuracy. Supplied with an individual Test Report, these meters are

also marked with the actual K factor from calibration testing for an accuracy of +/- 0.5%. Their construction is

modular allowing for simple in situ maintenance and system changes.

EXPLODED DIAGRAM

Output

Macnaught offer

a range of digital

output and display

MX-SERIES FLOW METERS

options that will suit

most applications.

Choose between

display based on

application needs

Port

connection

Based on

desired pipe

connection

Meter size

Choose meter

size based on

flow rate desired

Materials of

construction

Choose material

based on pressure

and fluid type

Rotor type

Select rotor

type based on

the viscosity

of the fluid

and fluid type

*Billet construction across the MX meters up to 2”

10 Macnaught | Positive Displacement Flow Meters

Page 13

PRODUCT IDENTIFICATION SYSTEM

MX06P-1SE

MX06

P

1

MX PORT SIZE

06 09 12 19 25 40 50 75 100

1/4” 1/4” 1/2” 3/4” 1” 1½” 2” 3” 4”

MATERIALS OF CONSTRUCTION

CATEGORY METER/ROTOR/SEAL MODELS

F

P SS/PPS/FEP MX06-50

S

PORT CONNECTION MODEL

1 G

2 NPT

3 ANSI 150

5 DIN PN16

AL/PPS/FKM MX06-50

AL/AL/FKM MX75-100

AL/SS/FEP MX06-25

AL/AL/FEP MX40-100

All Models

MX25-1004 JIS 10K

MX-SERIES FLOW METERS

S

E

ROTOR TYPE MODELS

S Standard As per category

T High Temp. Pulse MX06P - MX50P

V High Viscosity S and P category

OUTPUT TYPE MODELS

X No Output All Models

A Standard Pulse All Models

B Ex approved (Ex ia)

D PR (LCD 12mm display) All Models

E PRA (LCD 12mm display) All Models

F ER (LCD 17mm display) All Models*

G ERA (LCD 17mm display) All Models*

H ERB (LCD 17mm display) All Models*

N Ex Approved (Ex ia NAMUR)

T High Temperature All Models

I Reed/Reed

J Hall/Hall

K High Resolution (omnipolar)

Consult Macnaught Technical

regarding availability

Consult Macnaught Technical

regarding availability

Consult Macnaught Technical

regarding availability

macnaught.com.au 11

Page 14

MX06 ¼” DIGITAL FLOW METERS

SUITABLE FOR FLOW RANGE 0.5100L/HR

MX-SERIES FLOW METERS

MX06P-1SE

Stainless steel body with LCD register

Output variations:

B - Ex approved (Ex ia)

Intrinsically Safe - NPN

N - Ex approved (Ex ia)

Intrinsically Safe - NAMUR

T - High Temp. Pulse

Max temp- 150ºC

D - PR

LCD Display (12mm)

E - PRA

LCD Display (12mm)

with outputs

F - ER

LCD Display (17mm)

G- ERA

LCD Display (17mm)

H- ERB

LCD Display (17mm)

Batch controller

A - Standard Pulse

Reel/Hall Effect

I - Standard Pulse

Reel/Reed Effect

J - Standard Pulse

Hall/Hall Effect

K - High Resolution

Hall NPN

The MX06 ¼” Digital Flow Meters are suitable for flows between 0.5-100L/hr. The ¼” Digital Flow Meters

have an accuracy of +/- 0.5% and provides exceptional levels of reliability and durability.

SPECIFICATIONS

MX06F MX06S MX06P

Materials of

Construction

Meter Body

Design Specifications

Process Connections ¼” G

Technical

Specifications

Flow rate

Non-lubricating fluids

Operating Temperature

Max. Operating

Pressure

Accuracy

Repeatability

Nominal K-Factor

*Temperature based on standard pulse output - subject to change dependant on rotor and output type, contact Macnaught technical support for further investigations

Rotor

Seals

Range*

Aluminium (6061)

PPS

Fluorocarbon (FKM)

¼” NPT

<5cP

2-100L/hr

0.5-26USG/hr

6-100L/hr

1.58-26USG/hr

-40 - 80ºC

-40 - 176ºF

1000psi

69bar

+/- 0.5%

+/- 0.03%

1000 Pulses/L

>5cP

0.5-100L/hr

0.13-26USG/hr

Aluminium (6061)

Stainless Steel (316)

PTFE Encapsulated (FEP)

¼” G

¼ ” NPT

<5cP

2-100L/hr

0.5-26USG/hr

6-100L/hr

1.58-26USG/hr

-40 - 120ºC

-40 - 248ºF

1000psi

69bar

+/- 0.5%

+/- 0.03%

1000 Pulses/L

>5cP

0.5-100L/hr

0.13-26USG/hr

Stainless Steel (316)

PPS

Stainless Steel (316)

PTFE Encapsulated (FEP)

¼” G

¼” NPT

<5cP

2-100L/hr

0.5-26USG/hr

6-100L/hr

1.58-26USG/hr

-40 - 80ºC (150ºC with high temp. rotors)

-40 - 176ºF (302ºF with high temp. rotors)

1000psi

69bar

+/- 0.5%

+/- 0.03%

1000 Pulses/L

>5cP

0.5-100L/hr

0.13-26USG/hr

12 Macnaught | Positive Displacement Flow Meters

Page 15

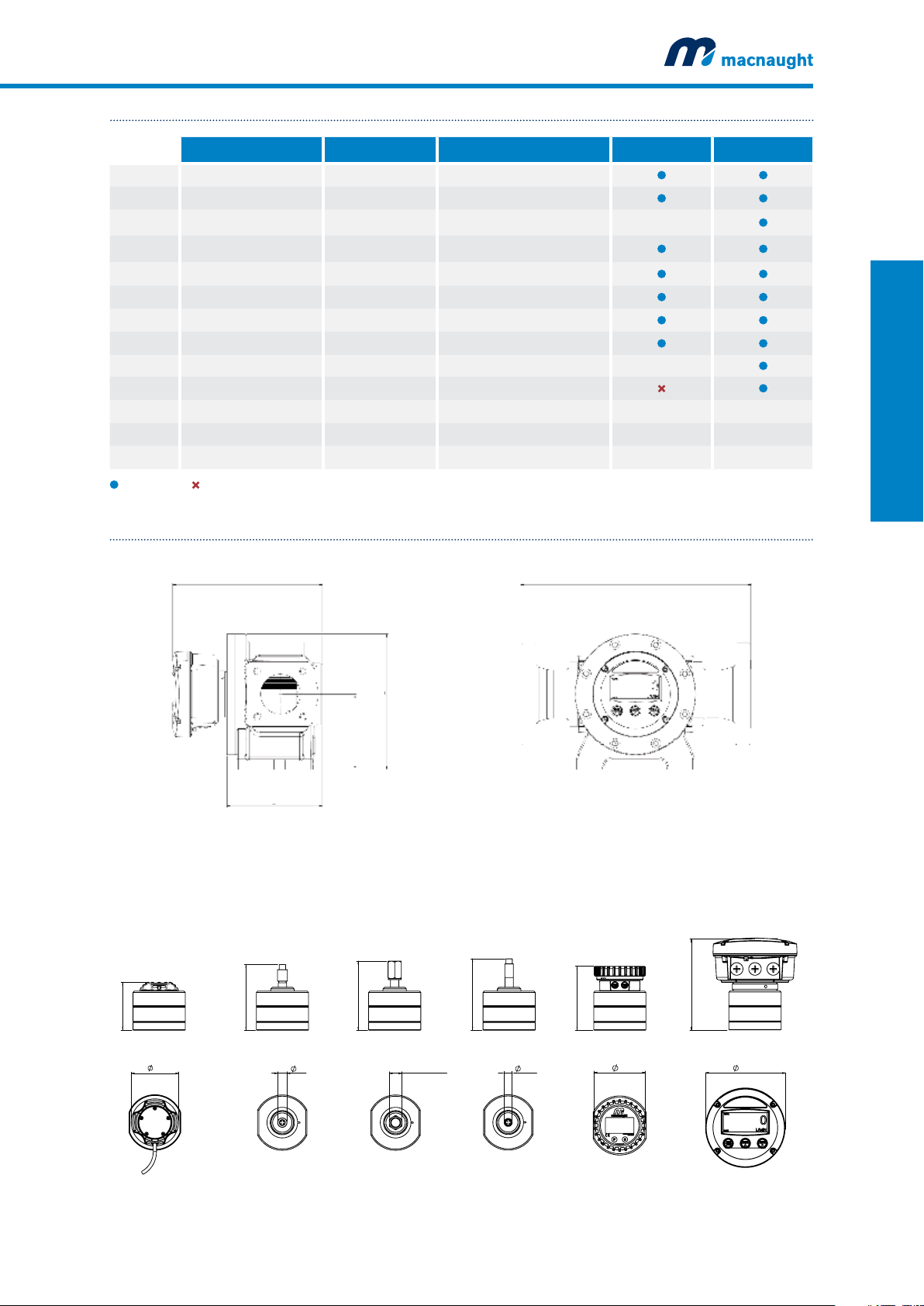

OUTPUTS TYPES

71mm

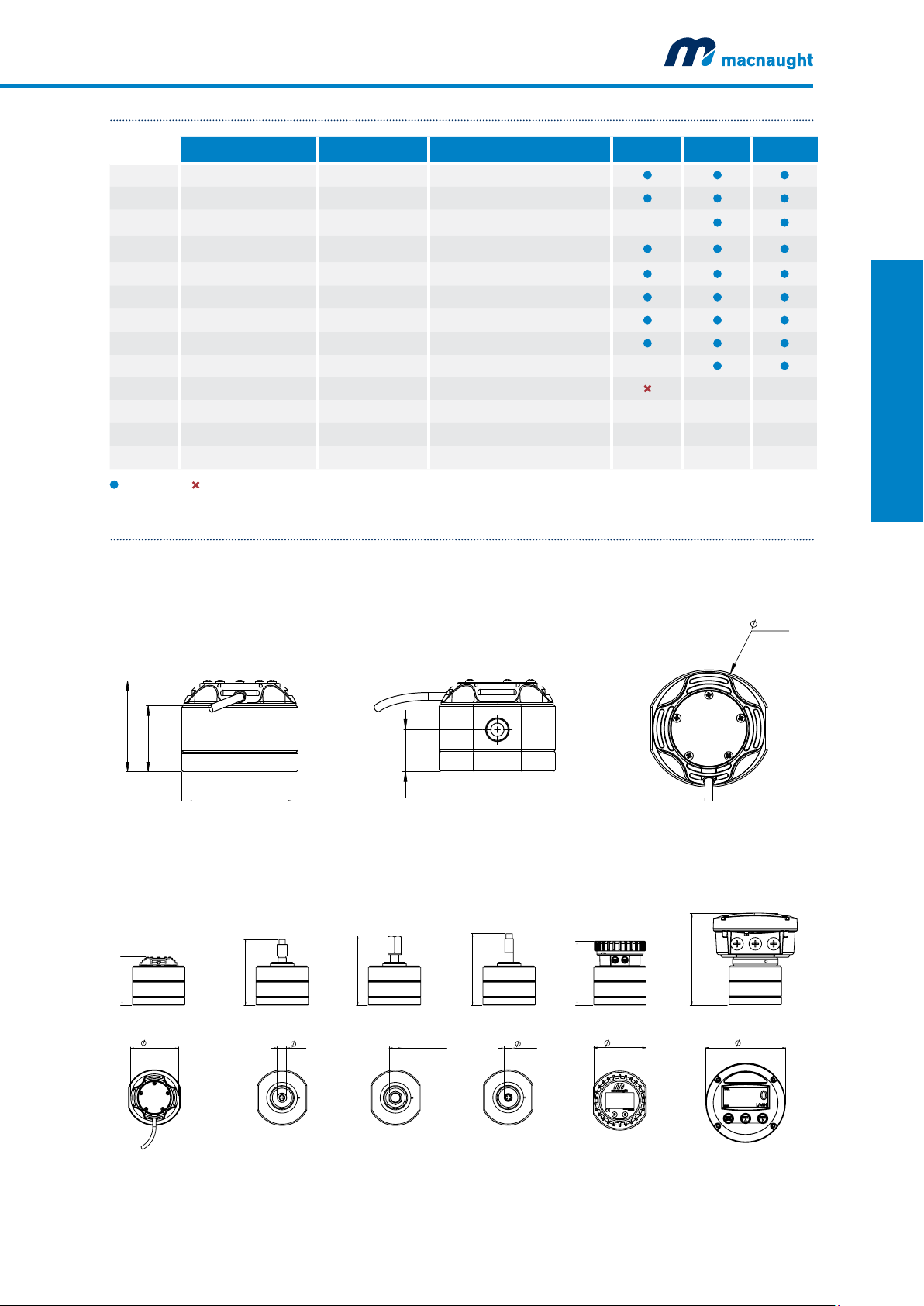

DESCRIPTION SWITCH TYPE OUTPUT TYPE MX06F MX06S MX06P

X No Output - No Output

A Standard Pulse Reed /Hall (NPN) Pulse (1m flying lead)

B Ex approved (Ex ia) Hall (NPN) Pulse (2m DIN cable) —

D PR (LCD 12mm display) - Display 12mm

E PRA (LCD 12mm display) - Display 12mm, 4-20mA output, Pulse

F ER (LCD 17mm display) - Display 17mm

G ERA (LCD 17mm display) - Display 17mm, 4-20mA output, Pulse

H ERB (LCD 17mm display) - Display 17mm + Batch Control

N Ex Approved (Ex ia NAMUR) NAMUR Pulse (2m DIN cable) —

T High Temp. Pulseerature Hall (NPN) Pulse S S

I Reed/Reed Reed/Reed Pulse (1m flying lead) — — —

J Hall/Hall Hall/Hall Pulse (1m flying lead) — — —

K High Resolution (omnipolar) Hall (NPN) Pulse (1m flying lead) — — —

MX-SERIES FLOW METERS

Available Not Available

DIMENSIONS

A

42mm

OUTPUT A

PULSER - Standard

OUTPUT B

PULSER - Exia

S

Only with stainless steel rotors

25mm

PULSER AND DISPLAY HEIGHT - A

OUTPUT

N

PULSER - Exia

—

Consult Macnaught Technical regarding availability

OUTPUT

T

PULSER - High Temp.

OUTPUT D,E

DISPLAY - LCD 12mm

74mm

OUTPUT

F,G,H

DISPLAY - LCD 17mm

59mm

74mm

93mm

19mm

100mm

25.4mm (1") A/F

104mm

16mm

90mm

99mm

143mm

161mm

macnaught.com.au 13

Page 16

MX09 ¼” DIGITAL FLOW METERS

SUITABLE FOR FLOW RANGE 15500L/HR

MX-SERIES FLOW METERS

MX09P-1SE

Stainless steel body with LCD register

Output variations:

B - Ex approved (Ex ia)

Intrinsically Safe - NPN

N - Ex approved (Ex ia)

Intrinsically Safe - NAMUR

T - High Temp. Pulse

Max temp- 150ºC

D - PR

LCD Display (12mm)

E - PRA

LCD Display (12mm)

with outputs

F - ER

LCD Display (17mm)

G- ERA

LCD Display (17mm)

H- ERB

LCD Display (17mm)

Batch controller

A - Standard Pulse

Reel/Hall Effect

I - Standard Pulse

Reel/Reed Effect

J - Standard Pulse

Hall/Hall Effect

K - High Resolution

Hall NPN

The MX09 ¼” Digital Flow Meters are suitable for flows between 15-500L/hr. The ¼” Digital Flow Meters have

an accuracy of +/- 0.5% and provides exceptional levels of reliability and durability.

SPECIFICATIONS

MX09F MX09S MX09P

Materials of

Construction

Meter Body

Design Specifications

Process Connections

Technical

Specifications

Flow rate

Operating Temperature

Max. Operating

Pressure

Accuracy

Repeatability

Nominal K-Factor

*Temperature based on standard pulse output - subject to change dependant on rotor and output type, contact Macnaught technical support for further investigations

Rotor

Seals

Range*

Aluminium (6061)

PPS

Fluorocarbon (FKM)

Threaded

¼” G

¼” NPT

<5cP

25-500L/hr

6.6-132USG/hr

-40 - 80ºC

-40 - 176ºF

1000psi

69bar

+/- 0.5%

+/- 0.03%

400 Pulses/L

>5cP

15-500L/hr

4-132USG/hr

Aluminium (6061)

Stainless Steel (316)

PTFE encapsulated (FEP)

Threaded

¼” G

¼” NPT

<5cP

25-500L/hr

6.6-132USG/hr

-40 - 120ºC

-40 - 248ºF

1000psi

69bar

+/- 0.5%

+/- 0.03%

400 Pulses/L

>5cP

15-500L/hr

4-132USG/hr

Stainless Steel (316)

PPS

Stainless Steel (316)

PTFE encapsulated (FEP)

Threaded

¼” G

¼” NPT

<5cP

25-500L/hr

6.6-132USG/hr

-40 - 80ºC (150ºC with high temp. rotors)

-40 - 176ºF (302ºF with high temp. rotors)

1000psi

69bar

+/- 0.5%

+/- 0.03%

400 Pulses/L

>5cP

15-500L/hr

4-132USG/hr

14 Macnaught | Positive Displacement Flow Meters

Page 17

OUTPUTS TYPES

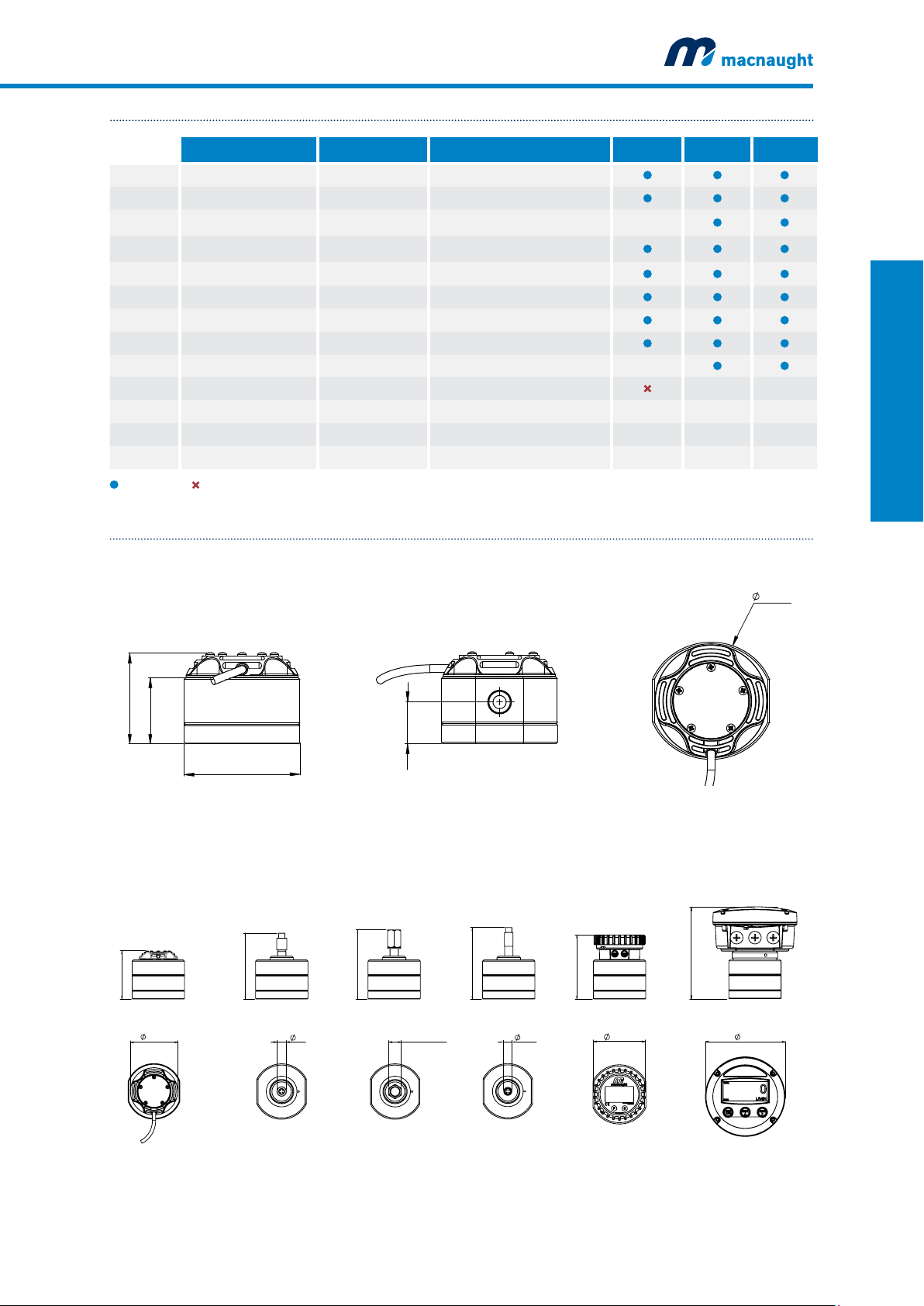

DESCRIPTION SWITCH TYPE OUTPUT TYPE MX09F MX09S MX09P

X No Output - No Output

A Standard Pulse Reed /Hall (NPN) Pulse (1m flying lead)

B Ex approved (Ex ia) Hall (NPN) Pulse (2m DIN cable) —

D PR (LCD 12mm display) - Display 12mm

E PRA (LCD 12mm display) - Display 12mm, 4-20mA output, Pulse

F ER (LCD 17mm display) - Display 17mm

G ERA (LCD 17mm display) - Display 17mm, 4-20mA output, Pulse

H ERB (LCD 17mm display) - Display 17mm + Batch Control

N Ex Approved (Ex ia NAMUR) NAMUR Pulse (2m DIN cable) —

T High Temp. Pulseerature Hall (NPN) Pulse S S

I Reed/Reed Reed/Reed Pulse (1m flying lead) — — —

J Hall/Hall Hall/Hall Pulse (1m flying lead) — — —

K High Resolution (omnipolar) Hall (NPN) Pulse (1m flying lead) — — —

MX-SERIES FLOW METERS

Available Not Available

DIMENSIONS

A

42mm

71mm

OUTPUT A

PULSER - Standard

OUTPUT B

PULSER - Exia

S

Only with stainless steel rotors

25mm

PULSER AND DISPLAY HEIGHT - A

OUTPUT

N

PULSER - Exia

—

Consult Macnaught Technical regarding availability

OUTPUT

T

PULSER - High Temp.

OUTPUT D,E

DISPLAY - LCD 12mm

74mm

OUTPUT

F,G,H

DISPLAY - LCD 17mm

59mm

74mm

93mm

19mm

100mm

25.4mm (1") A/F

104mm

16mm

90mm

99mm

143mm

161mm

macnaught.com.au 15

Page 18

MX12 ½” DIGITAL FLOW METERS

SUITABLE FOR FLOW RANGE 230L/MIN

MX-SERIES FLOW METERS

MX12P-1SE

Stainless steel body with LCD register

Output variations:

B - Ex approved (Ex ia)

Intrinsically Safe - NPN

N - Ex approved (Ex ia)

Intrinsically Safe - NAMUR

T - High Temp. Pulse

Max temp- 150ºC

D - PR

LCD Display (12mm)

E - PRA

LCD Display (12mm)

with outputs

F - ER

LCD Display (17mm)

G- ERA

LCD Display (17mm)

H- ERB

LCD Display (17mm)

Batch controller

A - Standard Pulse

Reel/Hall Effect

I - Standard Pulse

Reel/Reed Effect

J - Standard Pulse

Hall/Hall Effect

K - High Resolution

Hall NPN

The MX12 ½” Digital Flow Meters are suitable for flows between 2-30L/min. The ½” Digital Flow Meters have

an accuracy of +/- 0.5% and provides exceptional levels of reliability and durability.

SPECIFICATIONS

MX12F MX12S MX12P

Materials of

Construction

Meter Body

Design Specifications

Process Connections

Technical

Specifications

Flow rate

Operating Temperature

Max. Operating

Pressure

Accuracy

Repeatability

Nominal K-Factor

*Temperature based on standard pulse output - subject to change dependant on rotor and output type, contact Macnaught technical support for further investigations

Rotor

Seals

Range*

Aluminium (6061)

PPS

Fluorocarbon (FKM)

Threaded

½” G

½” NPT

<5cP

3-25L/min

0.6-6.6USG/min

-40 - 80ºC

-40 - 176ºF

2000 psi

138 Bar

+/- 0.5%

+/- 0.03%

112 Pulses/L

>5cP

2-30L/min

0.5-8USG/min

Aluminium (6061)

Stainless Steel (316)

PTFE encapsulated (FEP)

Threaded

½” G

½” NPT

<5cP

3-25L/min

0.6-6.6USG/min

-40 - 120ºC

-40 - 248ºF

2000 psi

138 Bar

+/- 0.5%

+/- 0.03%

112 Pulses/L

>5cP

2-30L/min

0.5-8USG/min

Stainless Steel (316)

PPS

Stainless Steel (316)

PTFE encapsulated (FEP)

Threaded

½” G

½” NPT

<5cP

3-25L/min

0.6-6.6USG/min

-40 - 80ºC (150ºC with high temp. rotors)

-40 - 176ºF (302ºF with high temp. rotors)

2000 psi

138 Bar

+/- 0.5%

+/- 0.03%

112 Pulses/L

>5cP

2-30L/min

0.5-8USG/min

16 Macnaught | Positive Displacement Flow Meters

Page 19

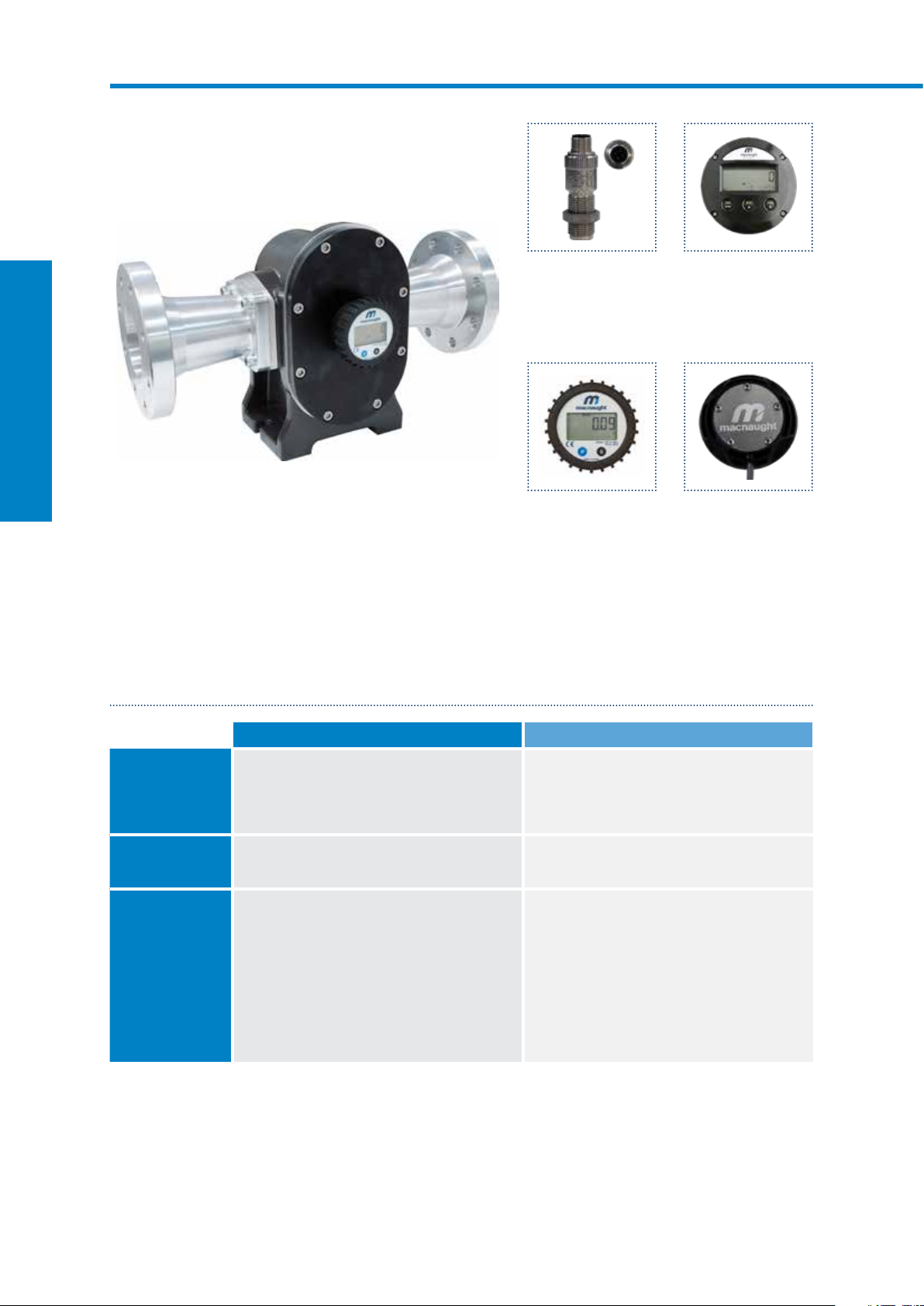

OUTPUTS TYPES

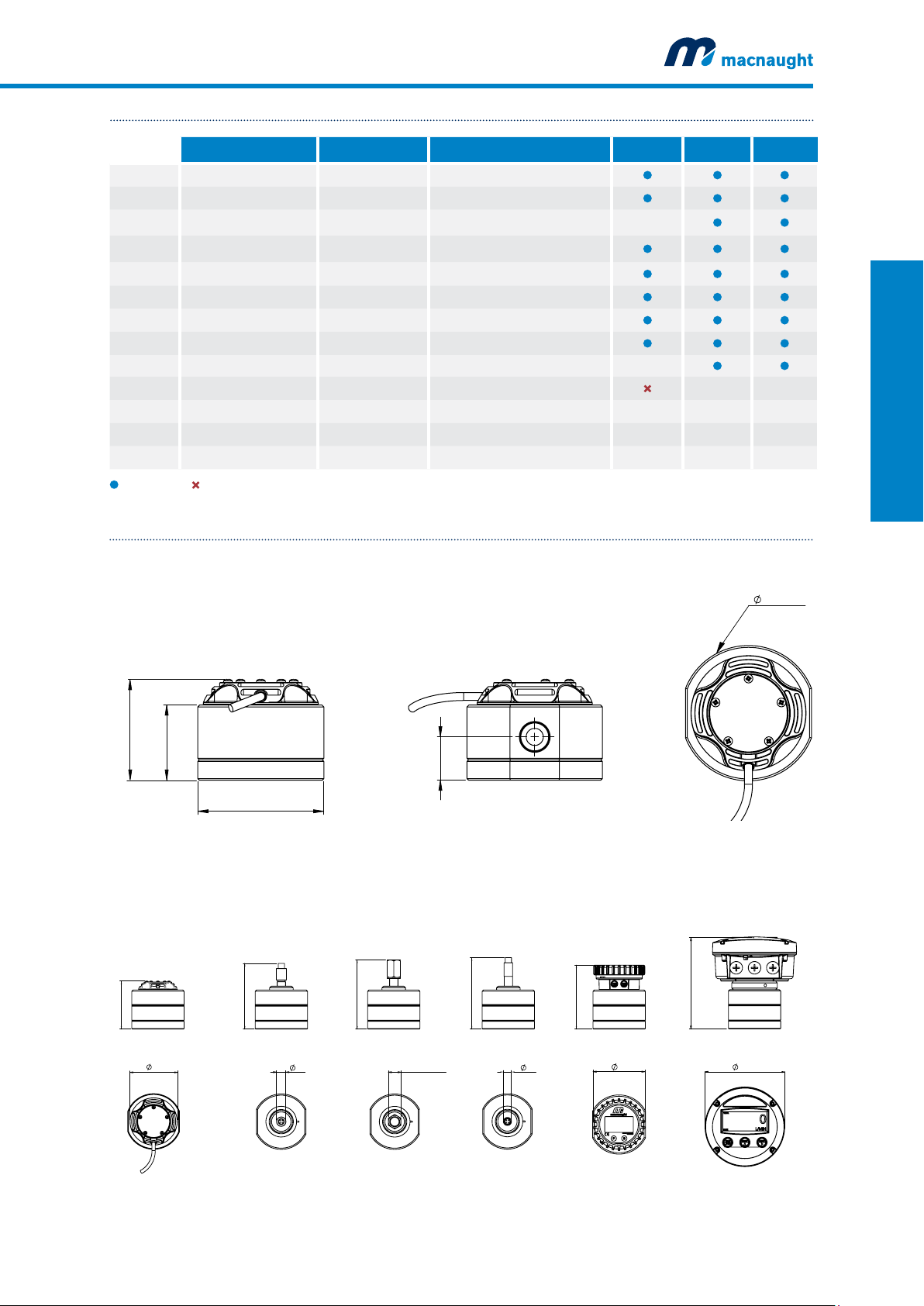

DESCRIPTION SWITCH TYPE OUTPUT TYPE MX12F MX12S MX12P

X No Output - No Output

A Standard Pulse Reed /Hall (NPN) Pulse (1m flying lead)

B Ex approved (Ex ia) Hall (NPN) Pulse (2m DIN cable) —

D PR (LCD 12mm display) - Display 12mm

E PRA (LCD 12mm display) - Display 12mm, 4-20mA output, Pulse

F ER (LCD 17mm display) - Display 17mm

G ERA (LCD 17mm display) - Display 17mm, 4-20mA output, Pulse

H ERB (LCD 17mm display) - Display 17mm + Batch Control

N Ex Approved (Ex ia NAMUR) NAMUR Pulse (2m DIN cable) —

T High Temp. Pulseerature Hall (NPN) Pulse S S

I Reed/Reed Reed/Reed Pulse (1m flying lead) — — —

J Hall/Hall Hall/Hall Pulse (1m flying lead) — — —

K High Resolution (omnipolar) Hall (NPN) Pulse (1m flying lead) — — —

MX-SERIES FLOW METERS

Available Not Available

DIMENSIONS

A

49mm

OUTPUT A

PULSER - Standard

81mm

OUTPUT B

PULSER - Exia

S

Only with stainless steel rotors

PULSER AND DISPLAY HEIGHT - A

OUTPUT

N

PULSER - Exia

28mm

—

Consult Macnaught Technical regarding availability

OUTPUT

T

PULSER - High Temp.

OUTPUT D,E

DISPLAY - LCD 12mm

87mm

OUTPUT

F,G,H

DISPLAY - LCD 17mm

66mm

74mm

100mm

19mm

107mm

25.4mm (1") A/F

111mm

16mm

97

99mm

150

161mm

macnaught.com.au 17

Page 20

MX19 ¾” DIGITAL FLOW METERS

SUITABLE FOR FLOW RANGE 380L/MIN

MX-SERIES FLOW METERS

MX19P-1SE

Stainless steel body with LCD register

Output variations:

B - Ex approved (Ex ia)

Intrinsically Safe - NPN

N - Ex approved (Ex ia)

Intrinsically Safe - NAMUR

T - High Temp. Pulse

Max temp- 150ºC

D - PR

LCD Display (12mm)

E - PRA

LCD Display (12mm)

with outputs

F - ER

LCD Display (17mm)

G- ERA

LCD Display (17mm)

H- ERB

LCD Display (17mm)

Batch controller

A - Standard Pulse

Reel/Hall Effect

I - Standard Pulse

Reel/Reed Effect

J - Standard Pulse

Hall/Hall Effect

K - High Resolution

Hall NPN

The MX19 ¾” Digital Flow Meters are suitable for flows between 3-80L/min. The ¾” Digital Flow Meters have

an accuracy of +/- 0.5% and provides exceptional levels of reliability and durability.

SPECIFICATIONS

MX19F MX19S MX19P

Materials of

Construction

Meter Body

Design Specifications

Process Connections

Technical

Specifications

Flow rate

Operating Temperature

Max. Operating

Pressure

Accuracy

Repeatability

Nominal K-Factor

*Temperature based on standard pulse output - subject to change dependant on rotor and output type, contact Macnaught technical support for further investigations

Rotor

Seals

Range*

Aluminium (6061)

PPS

Fluorocarbon (FKM)

Threaded

¾” G

¾” NPT

<5cP

8-70L/min

2-18.5USG/min

-40 - 80ºC

-40 - 176ºF

2000 psi

138 Bar

+/- 0.5%

+/- 0.03%

52 Pulses/L

>5cP

3-80L/min

0.8-21USG/min

Aluminium (6061)

Stainless Steel (316)

PTFE encapsulated (FEP)

Threaded

¾” G

¾” NPT

<5cP

8-70L/min

2-18.5USG/min

-40 - 120ºC

-40 - 248ºF

2000 psi

138 Bar

+/- 0.5%

+/- 0.03%

52 Pulses/L

>5cP

3-80L/min

0.8-21USG/min

Stainless Steel (316)

PPS

Stainless Steel (316)

PTFE encapsulated (FEP)

Threaded

¾” G

¾” NPT

<5cP

8-70L/min

2-18.5USG/min

-40 - 80ºC (150ºC with high temp. rotors)

-40 - 176ºF (302ºF with high temp. rotors)

2000 psi

138 Bar

+/- 0.5%

+/- 0.03%

52 Pulses/L

>5cP

3-80L/min

0.8-21USG/min

18 Macnaught | Positive Displacement Flow Meters

Page 21

OUTPUTS TYPES

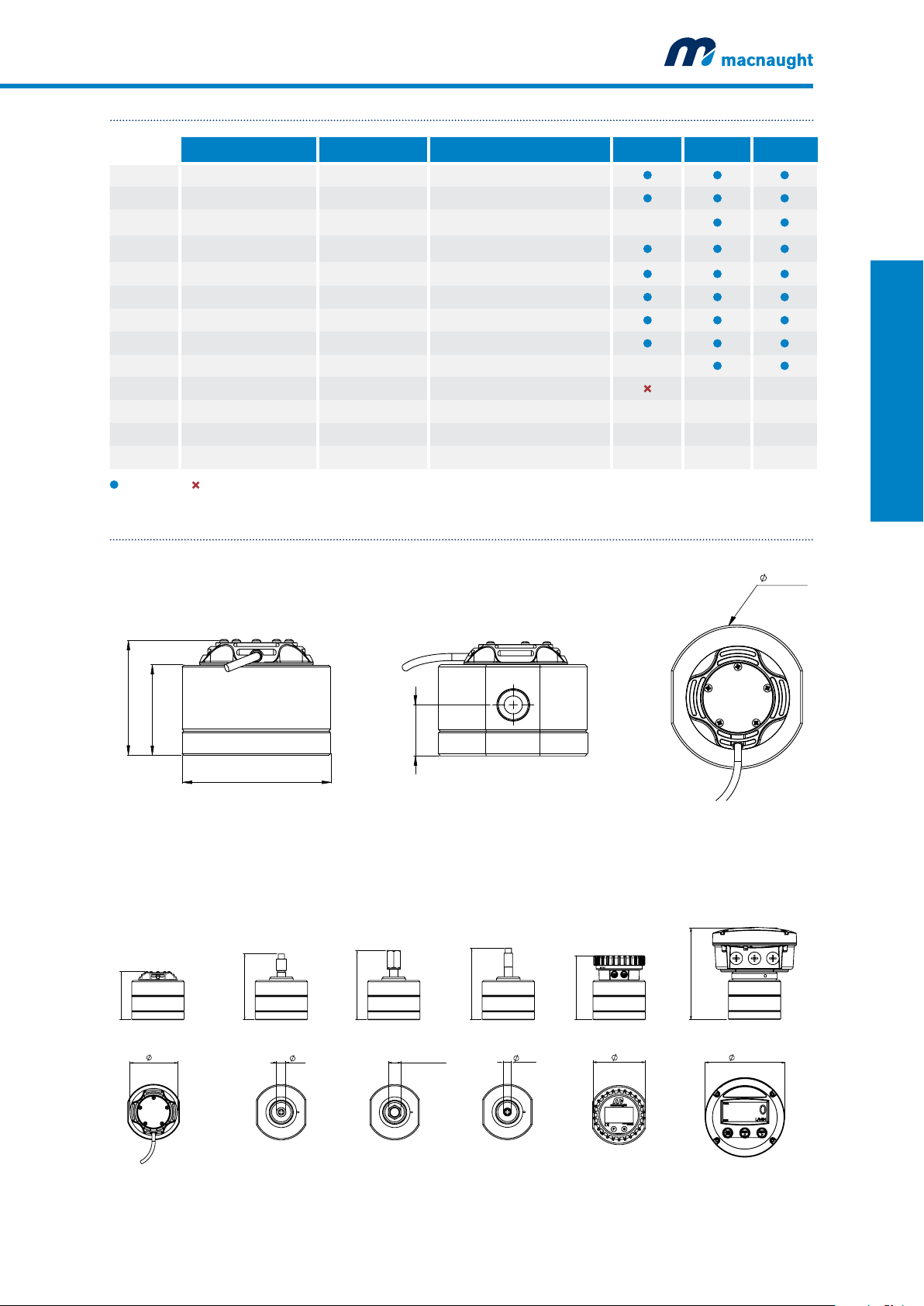

DESCRIPTION SWITCH TYPE OUTPUT TYPE MX19F MX19S MX19P

X No Output - No Output

A Standard Pulse Reed /Hall (NPN) Pulse (1m flying lead)

B Ex approved (Ex ia) Hall (NPN) Pulse (2m DIN cable) —

D PR (LCD 12mm display) - Display 12mm

E PRA (LCD 12mm display) - Display 12mm, 4-20mA output, Pulse

F ER (LCD 17mm display) - Display 17mm

G ERA (LCD 17mm display) - Display 17mm, 4-20mA output, Pulse

H ERB (LCD 17mm display) - Display 17mm + Batch Control

N Ex Approved (Ex ia NAMUR) NAMUR Pulse (2m DIN cable) —

T High Temp. Pulseerature Hall (NPN) Pulse S S

I Reed/Reed Reed/Reed Pulse (1m flying lead) — — —

J Hall/Hall Hall/Hall Pulse (1m flying lead) — — —

K High Resolution (omnipolar) Hall (NPN) Pulse (1m flying lead) — — —

MX-SERIES FLOW METERS

Available Not Available

DIMENSIONS

A

62mm

100mm

OUTPUT A

PULSER - Standard

OUTPUT B

PULSER - Exia

S

Only with stainless steel rotors

37mm

PULSER AND DISPLAY HEIGHT - A

OUTPUT

N

PULSER - Exia

—

Consult Macnaught Technical regarding availability

OUTPUT

T

PULSER - High Temp.

OUTPUT D,E

DISPLAY - LCD 12mm

112mm

OUTPUT

F,G,H

DISPLAY - LCD 17mm

79mm

74mm

113mm

19mm

120mm

25.4mm (1") A/F

124mm

16mm

110mm

99mm

163mm

161mm

macnaught.com.au 19

Page 22

MX25 1” DIGITAL FLOW METERS

SUITABLE FOR FLOW RANGE 6120L/MIN

MX-SERIES FLOW METERS

MX25P-1SE

Stainless steel body with LCD register

Output variations:

B - Ex approved (Ex ia)

Intrinsically Safe - NPN

N - Ex approved (Ex ia)

Intrinsically Safe - NAMUR

T - High Temp. Pulse

Max temp- 150ºC

D - PR

LCD Display (12mm)

E - PRA

LCD Display (12mm)

with outputs

F - ER

LCD Display (17mm)

G- ERA

LCD Display (17mm)

H- ERB

LCD Display (17mm)

Batch controller

A - Standard Pulse

Reel/Hall Effect

I - Standard Pulse

Reel/Reed Effect

J - Standard Pulse

Hall/Hall Effect

K - High Resolution

Hall NPN

The MX25 1” Digital Flow Meters are suitable for flows between 6-120L/min. The 1” Digital Flow Meters have

an accuracy of +/- 0.5% and provides exceptional levels of reliability and durability.

SPECIFICATIONS

MX25F MX25S MX25P

Materials of

Construction

Meter Body

Design Specifications

Process Connections

Technical

Specifications

Flow rate

Operating Temperature

Max. Operating

Pressure**

Accuracy

Repeatability

Nominal K-Factor

*Temperature based on standard pulse output - subject to change dependant on rotor and output type, contact Macnaught technical support for further investigations

** Pressure rating subject to change as per flange rating

Rotor

Seals

Range*

Aluminium (6061)

PPS

Fluorocarbon (FKM)

Threaded

1” G

1” NPT

<5cP

10-100L/min

2.6-26USG/min

-40 - 80ºC

-40 - 176ºF

2000 psi

138 Bar

+/- 0.5%

+/- 0.03%

36 Pulses/L

Flange

ANSI CLASS 150

DIN PN16

JIS 10k

>5cP

6-120L/min

1.6-32USG/min

Aluminium (6061)

Stainless Steel (316)

PTFE encapsulated (FEP)

Threaded

1” G

1” NPT

<5cP

10-100L/min

2.6-26USG/min

-40 - 120ºC

-40 - 248ºF

2000 psi

138 Bar

+/- 0.5%

+/- 0.03%

36 Pulses/L

Flange

ANSI CLASS 150

DIN PN16

JIS 10k

>5cP

6-120L/min

1.6-32USG/min

Stainless Steel (316)

PPS

Stainless Steel (316)

PTFE encapsulated (FEP)

Threaded

1” G

1” NPT

<5cP

10-100L/min

2.6-26USG/min

-40 - 80ºC (150ºC with high temp. rotors)

-40 - 176ºF (302ºF with high temp. rotors)

2000 psi

138 Bar

+/- 0.5%

+/- 0.03%

36 Pulses/L

Flange

ANSI CLASS 150

DIN PN16

JIS 10k

>5cP

6-120L/min

1.6-32USG/min

20 Macnaught | Positive Displacement Flow Meters

Page 23

OUTPUTS TYPES

DESCRIPTION SWITCH TYPE OUTPUT TYPE MX25F MX25S MX25P

X No Output - No Output

A Standard Pulse Reed /Hall (NPN) Pulse (1m flying lead)

B Ex approved (Ex ia) Hall (NPN) Pulse (2m DIN cable) —

D PR (LCD 12mm display) - Display 12mm

E PRA (LCD 12mm display) - Display 12mm, 4-20mA output, Pulse

F ER (LCD 17mm display) - Display 17mm

G ERA (LCD 17mm display) - Display 17mm, 4-20mA output, Pulse

H ERB (LCD 17mm display) - Display 17mm + Batch Control

N Ex Approved (Ex ia NAMUR) NAMUR Pulse (2m DIN cable) —

T High Temp. Pulseerature Hall (NPN) Pulse S S

I Reed/Reed Reed/Reed Pulse (1m flying lead) — — —

J Hall/Hall Hall/Hall Pulse (1m flying lead) — — —

K High Resolution (omnipolar) Hall (NPN) Pulse (1m flying lead) — — —

MX-SERIES FLOW METERS

Available Not Available

DIMENSIONS

A

75mm

100mm

OUTPUT A

PULSER - Standard

92mm

OUTPUT B

PULSER - Exia

126mm

S

Only with stainless steel rotors

45mm

PULSAR AND DISPLAY HEIGHT - A

OUTPUT

N

PULSER - Exia

133mm

—

Consult Macnaught Technical regarding availability

112mm

OUTPUT

T

PULSER - High Temp.

137mm

OUTPUT D,E

DISPLAY - LCD 12mm

123mm

240mm

176mm

OUTPUT

F,G,H

DISPLAY - LCD 17mm

74mm

19mm

25.4mm (1") A/F

16mm

99mm

161mm

macnaught.com.au 21

Page 24

MX40 1½” DIGITAL FLOW METERS

SUITABLE FOR FLOW RANGE 10250L/MIN

MX-SERIES FLOW METERS

MX40P-1SE

Stainless steel body with LCD register

Output variations:

B - Ex approved (Ex ia)

Intrinsically Safe - NPN

N - Ex approved (Ex ia)

Intrinsically Safe - NAMUR

T - High Temp. Pulse

Max temp- 150ºC

D - PR

LCD Display (12mm)

E - PRA

LCD Display (12mm)

with outputs

F - ER

LCD Display (17mm)

G- ERA

LCD Display (17mm)

H- ERB

LCD Display (17mm)

Batch controller

A - Standard Pulse

Reel/Hall Effect

I - Standard Pulse

Reel/Reed Effect

J - Standard Pulse

Hall/Hall Effect

K - High Resolution

Hall NPN

The MX40 1½” Digital Flow Meters are suitable for flows between 10-250L/min. The 1½” Digital Flow Meters

have an accuracy of +/- 0.5% and provides exceptional levels of reliability and durability.

SPECIFICATIONS

MX40F MX40S MX40P

Materials of

Construction

Meter Body

Design Specifications

Process Connections

Technical

Specifications

Flow rate

Operating Temperature

Max. Operating

Pressure**

Accuracy

Repeatability

Nominal K-Factor

*Temperature based on standard pulse output - subject to change dependant on rotor and output type, contact Macnaught technical support for further investigations

** Pressure rating subject to change as per flange rating

Rotor

Seals

Range*

Aluminium (6061)

PPS

Fluorocarbon (FKM)

Threaded

1½” G

1½” NPT

<5cP

15-235L/min

4-62USG/min

-40 - 80ºC

-40 - 176ºF

1500 psi

103 Bar

+/- 0.5%

+/- 0.03%

14.5 Pulses/L

Flange

ANSI CLASS 150

DIN PN16

JIS 10k

>5cP

10-250L/min

2.6-66USG/min

Aluminium (6061)

Aluminium (6061)

PTFE encapsulated (FEP)

Threaded

1½” G

1½” NPT

<5cP

15-235L/min

4-62USG/min

-40 - 120ºC

-40 - 248ºF

1500 psi

103 Bar

+/- 0.5%

+/- 0.03%

14.5 Pulses/L

Flange

ANSI CLASS 150

DIN PN16

JIS 10k

>5cP

10-250L/min

2.6-66USG/min

Stainless Steel (316)

PPS

Stainless Steel (316)

PTFE encapsulated (FEP)

Threaded

1½” G

1½” NPT

<5cP

15-235L/min

4-62USG/min

-40 - 80ºC (150ºC with high temp. rotors)

-40 - 176ºF (302ºF with high temp. rotors)

1500 psi

103 Bar

+/- 0.5%

+/- 0.03%

14.5 Pulses/L

Flange

ANSI CLASS 150

DIN PN16

JIS 10k

>5cP

10-250L/min

2.6-66USG/min

22 Macnaught | Positive Displacement Flow Meters

Page 25

OUTPUTS TYPES

DESCRIPTION SWITCH TYPE OUTPUT TYPE MX40F MX40S MX40P

X No Output - No Output

A Standard Pulse Reed /Hall (NPN) Pulse (1m flying lead)

B Ex approved (Ex ia) Hall (NPN) Pulse (2m DIN cable) —

D PR (LCD 12mm display) - Display 12mm

E PRA (LCD 12mm display) - Display 12mm, 4-20mA output, Pulse

F ER (LCD 17mm display) - Display 17mm

G ERA (LCD 17mm display) - Display 17mm, 4-20mA output, Pulse

H ERB (LCD 17mm display) - Display 17mm + Batch Control

N Ex Approved (Ex ia NAMUR) NAMUR Pulse (2m DIN cable) —

T High Temp. Pulseerature Hall (NPN) Pulse S S

I Reed/Reed Reed/Reed Pulse (1m flying lead) — — —

J Hall/Hall Hall/Hall Pulse (1m flying lead) — — —

K High Resolution (omnipolar) Hall (NPN) Pulse (1m flying lead) — — —

MX-SERIES FLOW METERS

Available Not Available

DIMENSIONS

A

103mm

120mm

OUTPUT A

PULSER - Standard

120mm

OUTPUT B

PULSER - Exia

154mm

S

Only with stainless steel rotors

61mm

PULSER AND DISPLAY HEIGHT - A

OUTPUT

N

PULSER - Exia

161mm

—

Consult Macnaught Technical regarding availability

137mm

OUTPUT

T

PULSER - High Temp.

165mm

OUTPUT D,E

DISPLAY - LCD 12mm

151mm

240mm

204mm

OUTPUT

F,G,H

DISPLAY - LCD 17mm

74mm

19mm

25.4mm (1") A/F

16mm

99mm

161mm

macnaught.com.au 23

Page 26

MX50 2” DIGITAL FLOW METERS

SUITABLE FOR FLOW RANGE 15500L/MIN

MX-SERIES FLOW METERS

MX50P-1SE

Stainless steel body with LCD register

Output variations:

B - Ex approved (Ex ia)

Intrinsically Safe - NPN

N - Ex approved (Ex ia)

Intrinsically Safe - NAMUR

T - High Temp. Pulse

Max temp- 150ºC

D - PR

LCD Display (12mm)

E - PRA

LCD Display (12mm)

with outputs

F - ER

LCD Display (17mm)

G- ERA

LCD Display (17mm)

H- ERB

LCD Display (17mm)

Batch controller

A - Standard Pulse

Reel/Hall Effect

I - Standard Pulse

Reel/Reed Effect

J - Standard Pulse

Hall/Hall Effect

K - High Resolution

Hall NPN

The MX50 2” Digital Flow Meters are suitable for flows between 15-500L/min. The 2” Digital Flow Meters

have an accuracy of +/- 0.5% and provides exceptional levels of reliability and durability.

SPECIFICATIONS

MX50F MX50S MX50P

Materials of

Construction

Meter Body

Design Specifications

Process Connections

Technical

Specifications

Flow rate

Operating Temperature

Max. Operating

Pressure**

Accuracy

Repeatability

Nominal K-Factor

*Temperature based on standard pulse output - subject to change dependant on rotor and output type, contact Macnaught technical support for further investigations

** Pressure rating subject to change as per flange rating

Rotor

Seals

Range*

Aluminium (6061)

PPS

Fluorocarbon (FKM)

Threaded

2” G

2” NPT

<5cP

15-500L/min

4-130 USG/min

-40 - 80ºC

-40 - 176ºF

1200 psi

82 Bar

+/- 0.5%

+/- 0.03%

6.7 Pulses/L

Flange

ANSI CLASS 150

DIN PN16

JIS 10k

>5cP

15-500L/min

4-130 USG/min

Aluminium (6061)

Aluminium (6061)

PTFE encapsulated (FEP)

Threaded

2” G

2” NPT

<5cP

15-500L/min

4-130 USG/min

-40 - 120ºC

-40 - 248ºF

1200 psi

82 Bar

+/- 0.5%

+/- 0.03%

6.7 Pulses/L

Flange

ANSI CLASS 150

DIN PN16

JIS 10k

>5cP

15-500L/min

4-130 USG/min

Stainless Steel (316)

PPS

Stainless Steel (316)

PTFE encapsulated (FEP)

Threaded

2” G

2” NPT

<5cP

15-500L/min

4-130 USG/min

-40 - 80ºC (150ºC with high temp. rotors)

-40 - 176ºF (302ºF with high temp. rotors)

1200 psi

82 Bar

+/- 0.5%

+/- 0.03%

6.7 Pulses/L

Flange

ANSI CLASS 150

DIN PN16

JIS 10k

>5cP

15-500L/min

4-130 USG/min

24 Macnaught | Positive Displacement Flow Meters

Page 27

OUTPUTS TYPES

DESCRIPTION SWITCH TYPE OUTPUT TYPE MX50F MX50S MX50P

X No Output - No Output

A Standard Pulse Reed /Hall (NPN) Pulse (1m flying lead)

B Ex approved (Ex ia) Hall (NPN) Pulse (2m DIN cable) —

D PR (LCD 12mm display) - Display 12mm

E PRA (LCD 12mm display) - Display 12mm, 4-20mA output, Pulse

F ER (LCD 17mm display) - Display 17mm

G ERA (LCD 17mm display) - Display 17mm, 4-20mA output, Pulse

H ERB (LCD 17mm display) - Display 17mm + Batch Control

N Ex Approved (Ex ia NAMUR) NAMUR Pulse (2m DIN cable) —

T High Temp. Pulseerature Hall (NPN) Pulse S S

I Reed/Reed Reed/Reed Pulse (1m flying lead) — — —

J Hall/Hall Hall/Hall Pulse (1m flying lead) — — —

K High Resolution (omnipolar) Hall (NPN) Pulse (1m flying lead) — — —

MX-SERIES FLOW METERS

Available Not Available

DIMENSIONS

A

124mm

140mm

OUTPUT A

PULSER - Standard

141mm

OUTPUT B

PULSER - Exia

175mm

S

Only with stainless steel rotors

72mm

PULSER AND DISPLAY HEIGHT - A

OUTPUT

N

PULSER - Exia

182mm

—

Consult Macnaught Technical regarding availability

163mm

OUTPUT

T

PULSER - High Temp.

186mm

OUTPUT D,E

DISPLAY - LCD 12mm

172mm

264mm

225mm

OUTPUT

F,G,H

DISPLAY - LCD 17mm

74mm

19mm

25.4mm (1") A/F

16mm

99mm

161mm

macnaught.com.au 25

Page 28

MX75 3” DIGITAL FLOW METERS

SUITABLE FOR FLOW RANGE 20733L/MIN

MX-SERIES FLOW METERS

MX75F-1SE

Aluminium body with LCD register

Output variations:

B - Ex approved (Ex ia)

Intrinsically Safe - NPN

N - Ex approved (Ex ia)

Intrinsically Safe - NAMUR

T - High Temp. Pulse

Max temp- 150ºC

D - PR

LCD Display (12mm)

E - PRA

LCD Display (12mm)

with outputs

F - ER

LCD Display (17mm)

G- ERA

LCD Display (17mm)

H- ERB

LCD Display (17mm)

Batch controller

A - Standard Pulse

Reel/Hall Effect

I - Standard Pulse

Reel/Reed Effect

J - Standard Pulse

Hall/Hall Effect

K - High Resolution

Hall NPN

The MX75 3” Digital Flow Meters are suitable for flows between 20-733L/min. The 3” Digital Flow Meters

have an accuracy of +/- 0.5% and provides exceptional levels of reliability and durability.

SPECIFICATIONS

MX75F MX75S

Materials of

Construction

Meter Body

Design Specifications

Process Connections

Technical

Specifications

Flow rate

Operating Temperature

Max. Operating

Pressure**

Accuracy

Repeatability

Nominal K-Factor

*Temperature based on standard pulse output - subject to change dependant on rotor and output type, contact Macnaught technical support for further investigations

** Pressure rating subject to change as per flange rating

Rotor

Seals

Range*

Cast Aluminium (6061)

Aluminium (6061)

Fluorocarbon (FKM)

Threaded

3” G

3” NPT

<5cP

60-600L/min

17-170USG/min

-40 - 120ºC

-40 - 248ºF

175 psi

12 bar

+/- 0.5%

+/- 0.03%

2.58 Pulses/L

Flange

ANSI CLASS 150

DIN PN16

JIS 10k

>5cP

20-733L/min

5-194USG/min

Cast Aluminium (6061)

Aluminium (6061)

PTFE encapsulated (FEP)

Threaded

3” G

3” NPT

<5cP

60-600L/min

17-170USG/min

-40 - 120ºC

-40 - 248ºF

175 psi

12 bar

+/- 0.5%

+/- 0.03%

2.58 Pulses/L

Flange

ANSI CLASS 150

DIN PN16

JIS 10k

>5cP

20-733L/min

5-194USG/min

26 Macnaught | Positive Displacement Flow Meters

Page 29

OUTPUTS TYPS

436mm*

DESCRIPTION SWITCH TYPE OUTPUT TYPE MX75F MX75S

X No Output - No Output

A Standard Pulse Reed /Hall (NPN) Pulse (1m flying lead)

B Ex approved (Ex ia) Hall (NPN) Pulse (2m DIN cable) —

D PR (LCD 12mm display) - Display 12mm

E PRA (LCD 12mm display) - Display 12mm, 4-20mA output, Pulse

F ER (LCD 17mm display) - Display 17mm

G ERA (LCD 17mm display) - Display 17mm, 4-20mA output, Pulse

H ERB (LCD 17mm display) - Display 17mm + Batch Control

N Ex Approved (Ex ia NAMUR) NAMUR Pulse (2m DIN cable) —

T High Temp. Pulseerature Hall (NPN) Pulse

I Reed/Reed Reed/Reed Pulse (1m flying lead) — —

J Hall/Hall Hall/Hall Pulse (1m flying lead) — —

K High Resolution (omnipolar) Hall (NPN) Pulse (1m flying lead) — —

MX-SERIES FLOW METERS

Available Not Available

DIMENSIONS

OUTPUT A

PULSER - Standard

A

179mm

OUTPUT B

PULSER - Exia

S

Only with stainless steel rotors

254mm

141mm

PULSER AND DISPLAY HEIGHT - A

OUTPUT

N

PULSER - Exia

—

Consult Macnaught Technical regarding availability

436mm*

OUTPUT

T

PULSER - High Temp.

OUTPUT D,E

DISPLAY - LCD 12mm

OUTPUT

F,G,H

DISPLAY - LCD 17mm

196mm

74mm

230mm

19mm

237mm

25.4mm (1") A/F

241mm

*Length subject to change refer to appendix B (pg. 88) for full dimension variations

16mm

227mm

99mm

280mm

161mm

macnaught.com.au 27

Page 30

MX100 4” DIGITAL FLOW METERS

SUITABLE FOR FLOW RANGE 1201200L/MIN

MX-SERIES FLOW METERS

MX100F-1SE

Aluminium steel body with LCD register

Output variations:

B - Ex approved (Ex ia)

Intrinsically Safe - NPN

N - Ex approved (Ex ia)

Intrinsically Safe - NAMUR

T - High Temp. Pulse

Max temp- 150ºC

D - PR

LCD Display (12mm)

E - PRA

LCD Display (12mm)

with outputs

F - ER

LCD Display (17mm)

G- ERA

LCD Display (17mm)

H- ERB

LCD Display (17mm)

Batch controller

A - Standard Pulse

Reel/Hall Effect

I - Standard Pulse

Reel/Reed Effect

J - Standard Pulse

Hall/Hall Effect

K - High Resolution

Hall NPN

The MX100 4” Digital Flow Meter are suitable for flows between 120-1200L/min. The 4” Digital Flow Meters

have an accuracy of +/- 0.5% and provides exceptional levels of reliability and durability.

SPECIFICATIONS

MX100F MX100S

Materials of

Construction

Meter Body

Design Specifications

Process Connections

Technical

Specifications

Flow rate

Operating Temperature

Max. Operating

Pressure**

Accuracy

Repeatability

Nominal K-Factor

*Temperature based on standard pulse output - subject to change dependant on rotor and output type, contact Macnaught technical support for further investigations

** Pressure rating subject to change as per flange rating

Rotor

Seals

Range*

Cast Aluminium (6061)

Aluminium (6061)

Fluorocarbon (FKM)

Threaded

3” G

3” NPT

<5cP

220-1000L/min

60-250USG/min

-40 - 120ºC

-40 - 248ºF

175 psi

12 bar

+/- 0.5%

+/- 0.03%

2.3 Pulses/L

Flange

ANSI CLASS 150

DIN PN16

JIS 10k

>5cP

120-1200L/min

31.7-317USG/min

Cast Aluminium (6061)

Aluminium (6061)

PTFE encapsulated (FEP)

Threaded

3” G

3” NPT

<5cP

220-1000L/min

60-250USG/min

-40 - 120ºC

-40 - 248ºF

175 psi

12 bar

+/- 0.5%

+/- 0.03%

2.3 Pulses/L

Flange

ANSI CLASS 150

DIN PN16

JIS 10k

>5cP

120-1200L/min

31.7-317USG/min

28 Macnaught | Positive Displacement Flow Meters

Page 31

OUTPUTS TYPS

DESCRIPTION SWITCH TYPE OUTPUT TYPE MX100F MX100S

X No Output - No Output

A Standard Pulse Reed /Hall (NPN) Pulse (1m flying lead)

B Ex approved (Ex ia) Hall (NPN) Pulse (2m DIN cable) —

D PR (LCD 12mm display) - Display 12mm

E PRA (LCD 12mm display) - Display 12mm, 4-20mA output, Pulse

F ER (LCD 17mm display) - Display 17mm

G ERA (LCD 17mm display) - Display 17mm, 4-20mA output, Pulse

H ERB (LCD 17mm display) - Display 17mm + Batch Control

N Ex Approved (Ex ia NAMUR) NAMUR Pulse (2m DIN cable) —

T High Temp. Pulseerature Hall (NPN) Pulse

I Reed/Reed Reed/Reed Pulse (1m flying lead) — —

J Hall/Hall Hall/Hall Pulse (1m flying lead) — —

K High Resolution (omnipolar) Hall (NPN) Pulse (1m flying lead) — —

MX-SERIES FLOW METERS

Available Not Available

DIMENSIONS

OUTPUT A

PULSER - Standard

A

179mm

OUTPUT B

PULSER - Exia

S

Only with stainless steel rotors

254mm

141mm

PULSER AND DISPLAY HEIGHT - A

OUTPUT

N

PULSER - Exia

—

Consult Macnaught Technical regarding availability

436mm*

OUTPUT

T

PULSER - High Temp.

OUTPUT D,E

DISPLAY - LCD 12mm

OUTPUT

F,G,H

DISPLAY - LCD 17mm

242mm

74mm

276mm

19mm

283mm

287mm

25.4mm (1") A/F

*Length subject to change refer to appendix B (pg. 88) for full dimension variations

16mm

273mm

99mm

326mm

161mm

macnaught.com.au 29

Page 32

Page 33

M-SERIES

FLOW METERS

Page 34

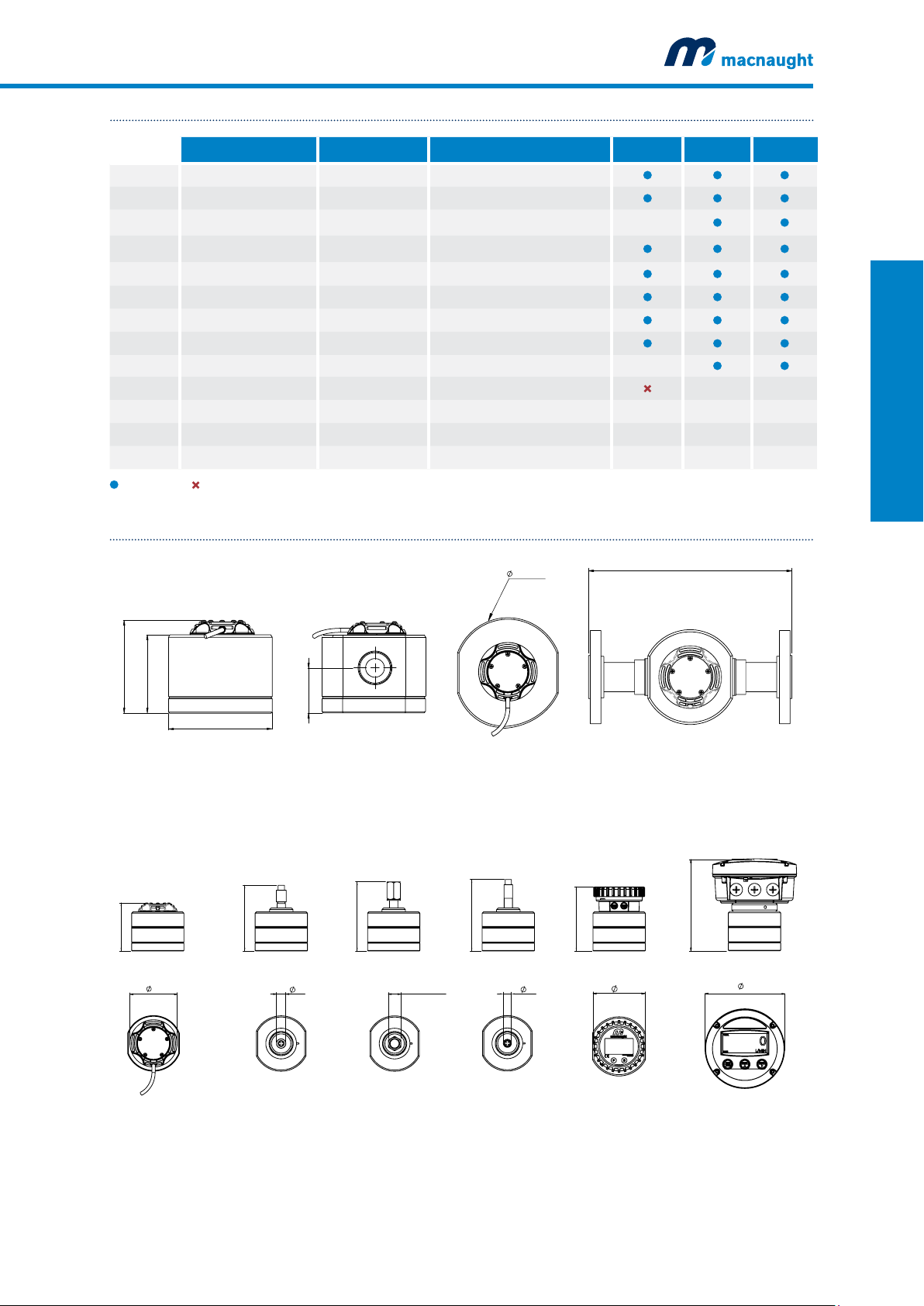

MSERIES FLOW METERS

MECHANICAL FLOW METE RS

The Mechanical Flow Meters range is the original meter range from Macnaught. They are available with

reliable mechanical displays offer a measurement option for unpowered or remote sites. All Macnaught Flow

Meters are supplied with an individual Test Report.

EXPLODED DIAGRAM

Output

Choose between standard

mechanical or heavy duty

mechanical register

Materials of

construction

Choose material

based on pressure

and fluid type

M-SERIES FLOW METERS

Rotor type

Select rotor type based

on the viscosity of the

fluid and fluid type

Port size

Choose meter port

size based on flow

rate desired

Port connection

Based on desired pipe

connection

32 Macnaught | Positive Displacement Flow Meters

Page 35

PRODUCT IDENTIFICATION SYSTEM

F012-1S3

CATEGORY METER/ROTOR/SEAL MODELS

F

F

M SS/PPS/FEP M012 - 050

S

012 1/2”

025 1”

012

040 1½”

050 2”

075 3”

100 4”

MATERIALS OF CONSTRUCTION

AL/PPS/FKM F012 - 050

AL/AL/FKM F075 -100

AL/SS/FEP S025

AL/AL/FEP S040 - 100

PORT SIZE

M-SERIES FLOW METERS

1

S

3

PORT CONNECTION MODELS

1 G (Litres Display)

2 NPT (US Gallons Display)

3 NPT (Litres Display)

4 BSP Rc (Litres Display)

ROTOR MODELS

S Standard Rotors Category F and M

T* High Temperature Category M and S025

V High Viscosity

*T type rotors are offered in Aluminium for category S040 to S100

OUTPUT MODELS

3 Standard Mechanical 012-050

4 Heavy Duty Mechanical All Models

AL material for F075-F100, S040-S100

All Models

PPS material for F012-F050

SS material for M025-M050

macnaught.com.au 33

Page 36

MSERIES FLOW METERS

PULSE FLOW METE RS STANDARD

The Macnaught Pulse Flow Meter range are the original meter range from Macnaught. They offer a compact

and robust metal body, manufactured from high quality grades of cast aluminium and stainless steel. For

highly corrosive chemical applications, BR42B grade PPS material is used to deliver superior stability*.

EXPLODED DIAGRAM

Output

Choose between Hall

Effect or Reed Switch

M-SERIES FLOW METERS

Rotor type

Select rotor type based

on the viscosity of the

fluid and fluid type

Port size

Choose meter port

size based on flow

rate desired

Materials of

construction

Choose material

based on pressure

and fluid type

Port connection

Based on desired pipe

connection

34 Macnaught | Positive Displacement Flow Meters

Page 37

PRODUCT IDENTIFICATION SYSTEM

F006-1SA

CATEGORY BODY/ROTOR/SEAL MODELS

F AL/SS/FKM All Models

F

M SS/SS/FFKM M006/M009

S AL/SS/FFKM S006/S009

CR

MATERIALS OF CONSTRUCTION

PPS/PPS/FFKM CR006 and CR009

PPS/PPS/FEP CR025

006

1

S

A

PORT SIZE MODELS

006 1/4” All models

009 1/4” All models

025 1” Category CR only

PORT CONNECTION MODELS

1 G Category F, M and S only

2 NPT All models

4 Rc All models

ROTOR TYPE MODELS

S Standard F and CR category only

T High Temp. Pulse M and S category only

V High Viscosity 009 only; Not available for CR

OUTPUT TYPE MODELS

1 Reed/Hall

2 Reed/Reed 006/009 Single reed ONLY

A Reed/Hall DIN connection

B

Reed/Reed DIN

connection

Flying lead for 006/009

User connection for CR025

Not Available for CR025

M-SERIES FLOW METERS

macnaught.com.au 35

Page 38

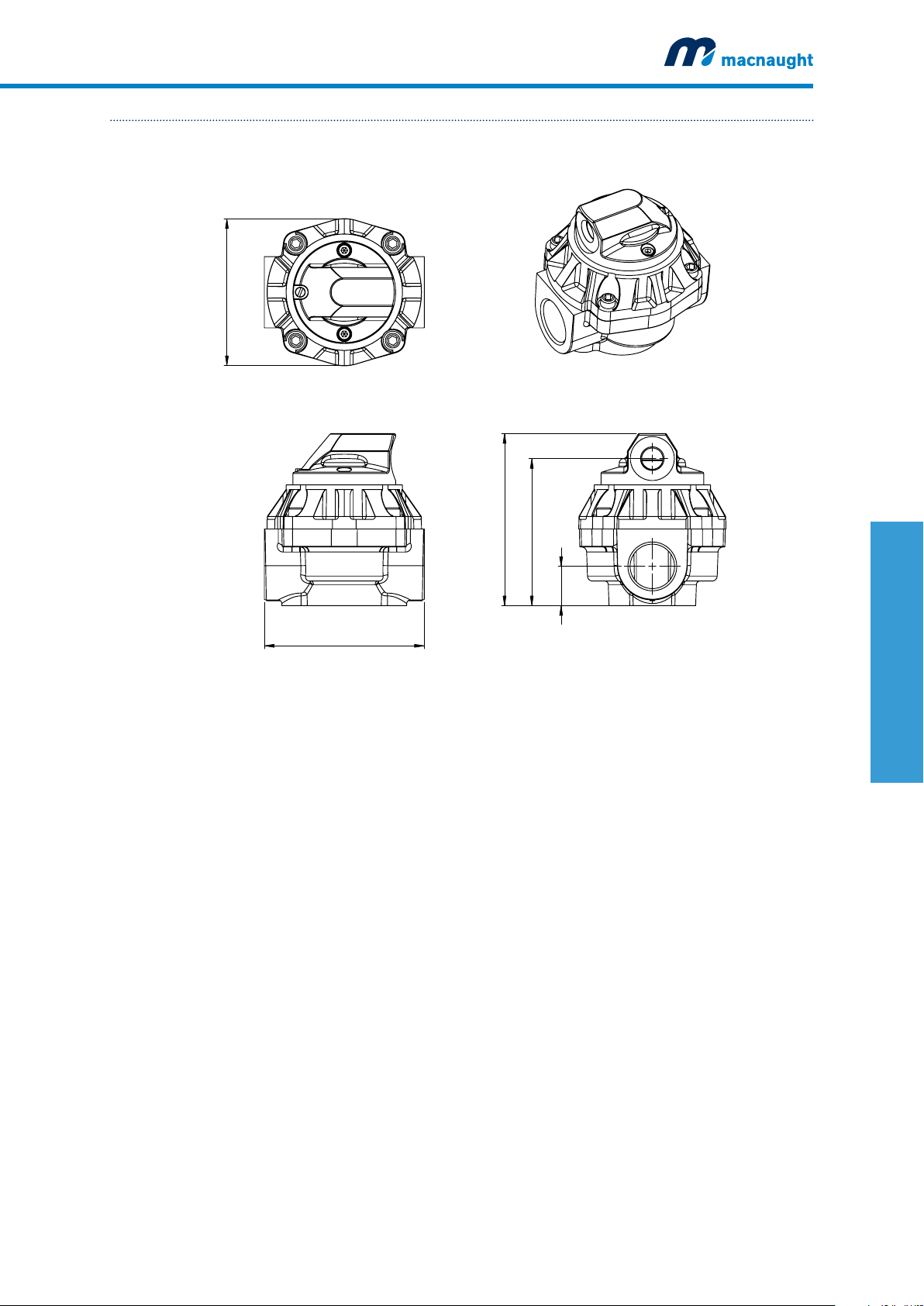

MSERIES FLOW METERS

PULSE FLOW METERS HIGH PRESSURE

Macnaught High Pressure Flow Meters are manufactured from robust stainless steel body utilizing high quality

billet suitable for use in the harshest environments. Designed to withstand pressures from 3000psi to 8000psi,

the Macnaught High Pressure Flow Meters fit virtually any high pressure liquid measurement requirements. All

Macnaught Flow Meters are supplied with an individual Test Report.

EXPLODED DIAGRAM

Output

Choose between Hall

Effect or Reed Switch

M-SERIES FLOW METERS

Rotor type

Select rotor type based

on the viscosity of the

fluid and fluid type

Port size

Choose meter port

size based on flow

rate desired

Port connection

Based on desired pipe

connection

Materials of

construction

Choose material

based on pressure

and fluid type

36 Macnaught | Positive Displacement Flow Meters

Page 39

PRODUCT IDENTIFICATION SYSTEM

MH009-1T1

CATEGORY METER/ROTOR/SEAL MODELS

MH

MH

MATERIALS OF CONSTRUCTION

SS/SS/FFKM MH006-009

SS/SS/FEP

SS/PPS/FEP

M H 012

009

1

T

1

PORT SIZE MODELS

006 1/4”

009 1/4”

012 1/2”

PORT CONNECTION MODELS

1 G

2 NPT

ROTOR TYPE MODELS

T High Temp. Pulseerature All Models

V High Viscosity MH009 and MH012

OUTPUT SWITCH TYPE

1 Pulse Output Single Hall for MH006/009. Reed/Hall for MH012

2 Pulse Output Single Reed for MH006/009. Dual Reed for MH012

All Models

All Models

M-SERIES FLOW METERS

macnaught.com.au 37

Page 40

MSERIES FLOW METERS

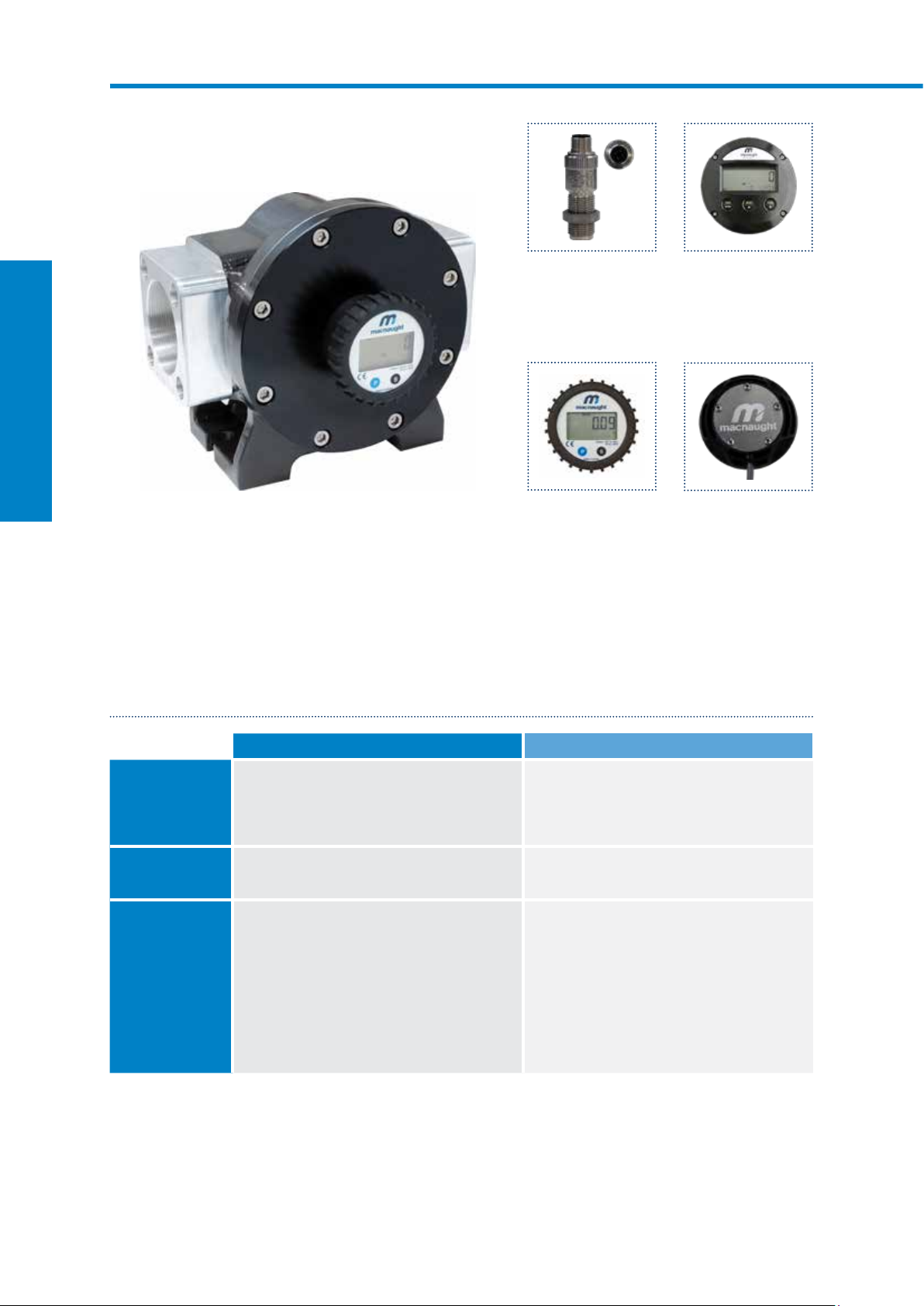

PULSE FLOW METERS CUSTODY TRANSFER

The Macnaught Custody Transfer meter range are the original meter range from Macnaught. They offer a

compact and robust body manufactured from high quality grades of cast Aluminium and Stainless steel.

Macnaught Custody Transfer meters are certified and approved by the National Measurement Institute (NMI)

and supplied with an individual Test Report.

EXPLODED DIAGRAM

Output

Choose between

Dual Sensor options

M-SERIES FLOW METERS

Rotor type

Select rotor type based

on the viscosity of the

fluid and fluid type

Port size

Choose meter port

size based on flow

rate desired

Port connection

Based on desired pipe

connection

Materials of

construction

Choose material

based on pressure

and fluid type

38 Macnaught | Positive Displacement Flow Meters

Page 41

PRODUCT IDENTIFICATION SYSTEM

WM10SSP-1S9

WM10

SS

7 10 40 50 80 100

1” 1” 1½” 2” 3” 4”

RR PPS/PPS/FKM WM7

AR AL/PPS/FKM WM10-WM50

AA AL/AL/FKM WM80-WM100

SS SS/SS/FEP WM10-WM50

WM PORT SIZE

MATERIALS OF CONSTRUCTION

CATEGORY BODY/ROTOR/SEAL MODELS

M-SERIES FLOW METERS

P

1

C9

OUTPUT* MODELS

P Dual Reed All models

FB Encoder WM50-WM100

PORT CONNECTION MODELS

1 Rp *Rc for WM7

2 NPT WM10-100

3 ANSI WM10-80

14 3” ANSI WM100 only

OPTIONAL CONFIGURATION MODELS

C Foot mount WM50-100

C9 Foot mount, Air eliminator and strainer WM50-WM100

*Additional output options also available as accessories. Contact Macnaught Technical Support Team for more information

macnaught.com.au 39

Page 42

M1 ¼” PULSE FLOW METERS

SUITABLE FOR FLOW RANGE 0.5100L/HR

F006-1S1

Aluminium body with flying lead

CR006-1SA

PPS body with DIN variation

Macnaught ¼” Pulse Flow Meters are a small capacity meter in the M-SERIES range. Differentiated by its

flow rate capabilities. Suitable for flows between 0.5-100L/hr. The ¼” Pulse Flow Meters have an accuracy

of +/- 0.5% and provides exceptional levels of reliability and durability.

SPECIFICATIONS

F006 S006 M006 CR006

Materials of

Construction

Meter Body

M-SERIES FLOW METERS

Design

Specifications

Process Connections

Technical

Specifications

Flow rate

Non-lubricating fluids

Operating Temperature

Max. Operating

Pressure

Accuracy

Repeatability

Nominal K-Factor

Rotor

Seals

Range*

Aluminium

Stainless Steel

Fluorocarbon (FKM)

¼” G

¼” NPT

<5cP

2-100L/hr

0.5-26USG/hr

-40 - 80ºC

-40 - 176ºF

800 psi

55 bar

+/- 0.5%

+/- 0.03%

1000 Pulses/L

>5cP

0.5-100L/hr

0.13-26USG/hr

6-100L/hr

1.58-26USG/hr

Aluminium

Stainless Steel

Perfluoroelastomer (FFKM)

¼” G

¼” NPT

<5cP

2-100L/hr

0.5-26USG/hr

-40 - 120ºC

-40 - 248ºF

800 psi

55 bar

+/- 0.5%

+/- 0.03%

1000 Pulses/L

>5cP

0.5-100L/hr

0.13-26USG/hr

6-100L/hr

1.58-26USG/hr

Stainless Steel

Stainless Steel

Perfluoroelastomer (FFKM)

¼” G

¼” NPT

<5cP

2-100L/hr

0.5-26USG/hr

-40 - 120ºC

-40 - 248ºF

800 psi

55 bar

+/- 0.5%

+/- 0.03%

1000 Pulses/L

>5cP

0.5-100L/hr

0.13-26USG/hr

6-100L/hr

1.58-26USG/hr

PPS

PPS

Perfluoroelastomer (FFKM)

¼” BSP (Rc)

¼” NPT

<5cP

2-100L/hr

0.5-26USG/hr

-40 - 80ºC

-40 - 176ºF

75 psi

5 bar

+/- 0.5%

+/- 0.03%

1000 Pulses/L

>5cP

0.5-100L/hr

0.13-26USG/hr

6-100L/hr

1.58-26USG/hr

*Temperature based on standard pulse output - subject to change dependant on rotor and output type, contact Macnaught technical support for further investigations

40 Macnaught | Positive Displacement Flow Meters

Page 43

OUTPUTS

17mm

PREFIX OUTPUT SWITCH TYPE F006 S006 M006 CR006

1

2

A

B

Available Not Available

Pulse output Reed/Hall Flying Lead

Pulse output Reed Flying Lead

Pulse output Reed/Hall DIN Connection

Pulse output Reed/Reed DIN Connection

DIMENSIONS

M006/F006/S006

DIN variation

M006/F006/S006

Flying Lead

CR006

DIN variation

50mm

50mm

64mm

51mm

51mm

51mm

13mm

13mm

1m

59mm

59mm

59mm

42mm

17mm

M-SERIES FLOW METERS

45mm

17mm

42mm

17mm

CR006

Flying Lead

64mm

51mm

1m

59mm

45mm

macnaught.com.au 41

Page 44

M1 ¼” HIGH PRESSURE FLOW METERS

SUITABLE FOR FLOW RANGE 0.5100L/HR

MH006-1T1

Stainless steel body with pulser cap

Also available as optional accessories:

DR

LCD Display (12mm)

DRA

LCD Display (12mm) with

outputs

Macnaught ¼” High Pressure Flow Meters are a small capacity meter in the M-SERIES range. Suitable for

flows between 0.5-100L/hr. The ¼” High Pressure Flow Meters are manufactured from high quality billet

for enhanced material reliability with pressure ratings of up to 8000psi and have an accuracy of +/- 0.5% to

provide exceptional levels of reliability and durability.

SPECIFICATIONS

MH006

Materials of

Construction

M-SERIES FLOW METERS

Design Specifications

Operating Temperature

Pulse Output Options

Local Display Options

*Temperature based on standard pulse output - subject to change dependant on rotor and output type, contact Macnaught technical support for further investigations

Meter Body

Process Connections ¼” G

Technical

Specifications

Flow rate

Non-lubricating fluids

Pressure

Accuracy

Repeatability

Nominal K-Factor

Type DR

Type DRA

Stainless Steel

Rotor

Stainless Steel

Seals

Perfluoroelastomer (FFKM)

¼” NPT

<5cP

2-100L/hr

0.5-26USG/hr

6-100L/hr

1.58-26USG/hr

-40 - 120ºC

Range*

-40 - 248ºF

8000 psi

557 bar

+/- 0.5%

+/- 0.03%

1000 Pulses/L

Pulser

Single Hall Effect

Pulser

Single Reed Switch

LCD display (12mm)

LCD display (12mm)

>5cP

0.5-100L/hr

0.13-26USG/hr

No Outputs

Outputs: Scaled Pulse,

4-20mA and Hi/Lo Flow Alarm

42 Macnaught | Positive Displacement Flow Meters

Page 45

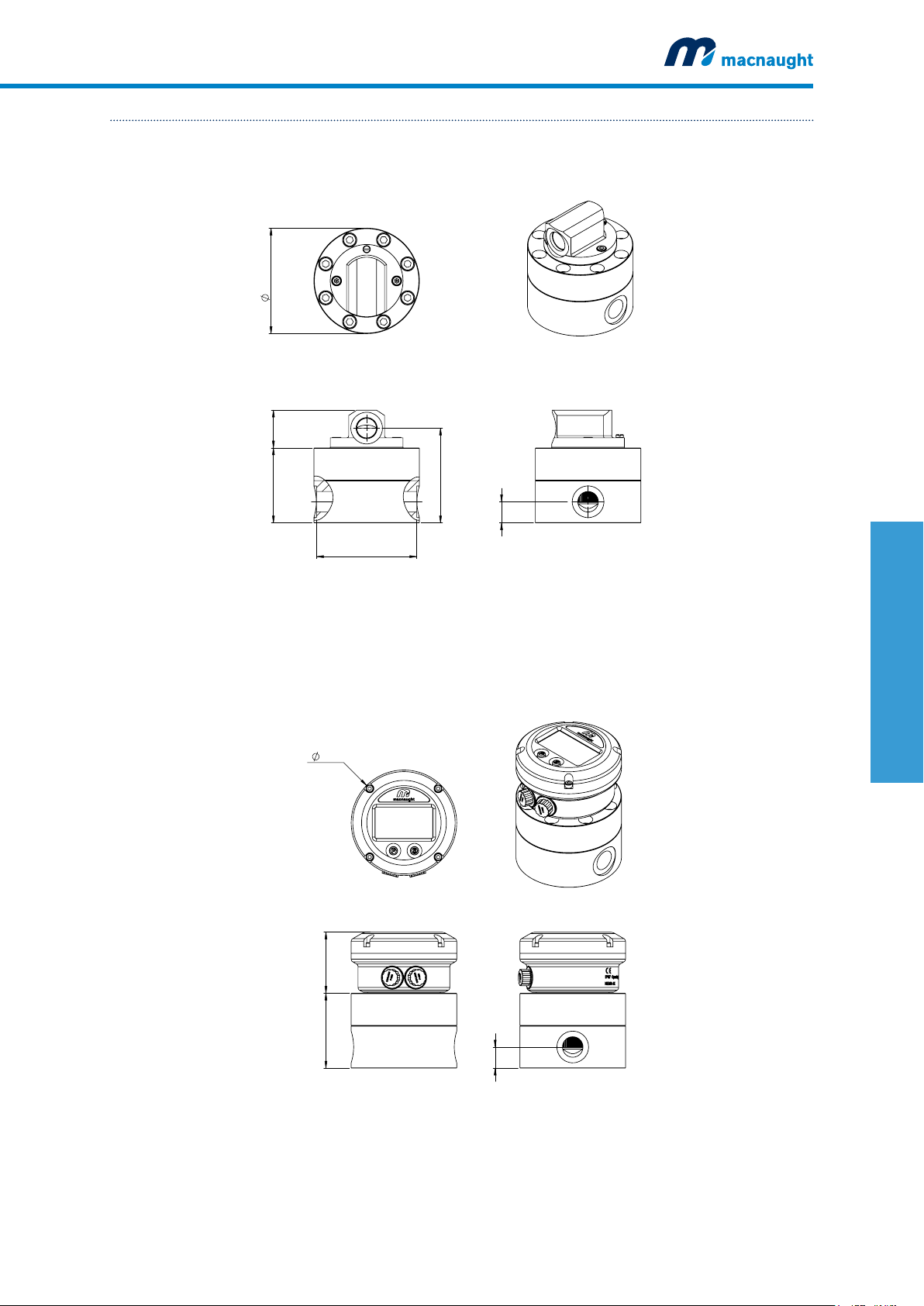

DIMENSIONS

100

69 79

23

ISOMETRIC VIEW

MH006

86

ISOMETRIC VIEW

MH006 with DR

Display

69 39

83

100

89

23

ISOMETRIC VIEW

M-SERIES FLOW METERS

69 79

23

macnaught.com.au 43

Page 46

M2 ¼” PULSE FLOW METERS

SUITABLE FOR FLOW RANGE 15500L/HR

F009-1S1

Aluminium body with flying lead

CR009-1SA

PPS body with DIN variation

Macnaught ¼” Pulse Flow Meters are a small capacity meter in the M-SERIES range. Differentiated by its

flow rate capabilities. Suitable for flows between 15-500L/hr. The ¼” Pulse Flow Meters have an accuracy of

+/- 0.5% and provides exceptional levels of reliability and durability.

SPECIFICATIONS

F009 S009 M009 CR009

Materials of

Construction

Meter Body

M-SERIES FLOW METERS

Design Specifications

Process Connections ¼” G

Technical

Specifications

Flow rate

Operating Temperature

Max. Operating

Pressure

Accuracy

Repeatability

Nominal K-Factor

*Temperature based on standard pulse output - subject to change dependant on rotor and output type, contact Macnaught technical support for further investigations

Rotor

Seals

Range*

Aluminium