Page 1

MXEX-INST

Rev 13

10/2019

MX06 - MX100

OVAL GEAR FLOWMETER SERIES

APPROVED FOR USE IN HAZARDOUS AREAS

INSTRUCTION MANUAL

EXPLOSION/ FLAME PROOF

To the Owner

Please read and retain this instruction manual to assist

you in the operation and maintenance of this product.

This manual contains connection and operating

instructions for the MX-Series Flow Meters with Pulse

Outputs.

Liquid Crystal Displays have an additional instruction

manual supplied. If you need further assistance,

contact your local representative or distributor for

advice

This Flow Meter has incorporated the oval gear

principle into its design. This is proven to be a reliable

and highly accurate method of measuring flow.

Exceptional repeatability and high accuracy over a

wide range of fluid viscosities and flow rates are

features of the oval gear design.

INTRINSICALLY SAFE

With low pressure drop and high pressure ratings,

oval gear flow meters are suitable for gravity and (inline) pump applications.

Macnaught offer a comprehensive set of web based

support materials to compliment this instruction

manual.

macnaught.com

Page 1 of 39

Page 2

index

Installation

Important Information

Operating Principle

Installation Procedure

………………………………………………………….

………………………………………………………….

………………………………………………………….

Maintenance Procedure

Disassembly

Reassembly

………………………………………………………….

………………………………………………………….

Flow meter Specifications

Flow meter Specifications

Wiring Diagram

………………………………………………………….

………………………………………………………….

Service

Troubleshooting Guide

………………………………………………………….

Page 3

Page 3

Page 4

Page 4

Page 5

Page 6-8

Page 9-11

Page 12

Exploded Diagrams

Meter Cap Torques

Spare Parts Kits

Wetted Parts

General

Pressure Drop Graphs

Dimensional Diagrams

………………………………………………………….

………………………………………………………….

………………………………………………………….

………………………………………………………….

………………………………………………………….

………………………………………………………….

Page 13-14

Page 15

Page 16-18

Page 19-21

Page 22

Page 23-34

Page 2 of 39

Page 3

IMPORTANT INFORMATION

NOTE

The information contained in this manual relating

to installation is guideline and should be treated

as such.

Please consult all relevant standards and

conditions required by the governing bodies in

area of installation prior to commissioning.

SAFETY BARRIER

The Exia sensors must be installed with an

approved safety barrier

GROUNDING

Improper grounding, poor ventilation, open

flames or sparks can cause a hazardous

condition and result in an explosion or fire and

cause serious injury.

STATIC

If there is static sparking or if you feel an electric

shock while using the meter, stop dispensing

immediately. Identify and correct the problem

before continuing.

NOTE

Equipment must be protected from impact at all

times.

OPERATING PRINCIPLE

Fluid passing through the meter causes the rotors to

turn, as shown below.

One of the rotors (the active rotor) is fitted with

magnets.

The passing of the magnets are picked up by the

electronic sensor.

The excitation of this switch provides a ‘Raw Pulse

Output’ which relates to the K-Factor.

(e.g. KF 36 = 36 pulses per litre of fluid passed)

This Pulse Output Signal can either be fed directly to

an external receiving element (e.g. Data Logger or

PLC) or alternatively to an LC Display which

conditions the Pulse input signal to display volume of

fluid passed. (e.g. Display 1 Litre per for every 36

pulses received)

FLUID COMPATIBILITY

Before use, confirm the fluid to be used is

compatible with the meter. Refer to Industry

fluid compatibility charts or consult your local

representative for advice.

STRAINER

To prevent damage from dirt or foreign matter it

is recommended that a Y or Basket type

mesh strainer be installed as close as

possible to the inlet side of the meter.

When a strainer is installed it should be

regularly inspected and cleaned. Failure to

keep the strainer clean will dramatically effect

flow meter performance.

Contact your local representative for advice.

AIR PURGE / LINE PRESSURE

To prevent damage caused by air purge slowly

fill the meter with fluid.

To reduce pressure build-up turn off the pump

at the end of each day.

Page 3 of 39

Page 4

INSTALLATION PROCEDURE

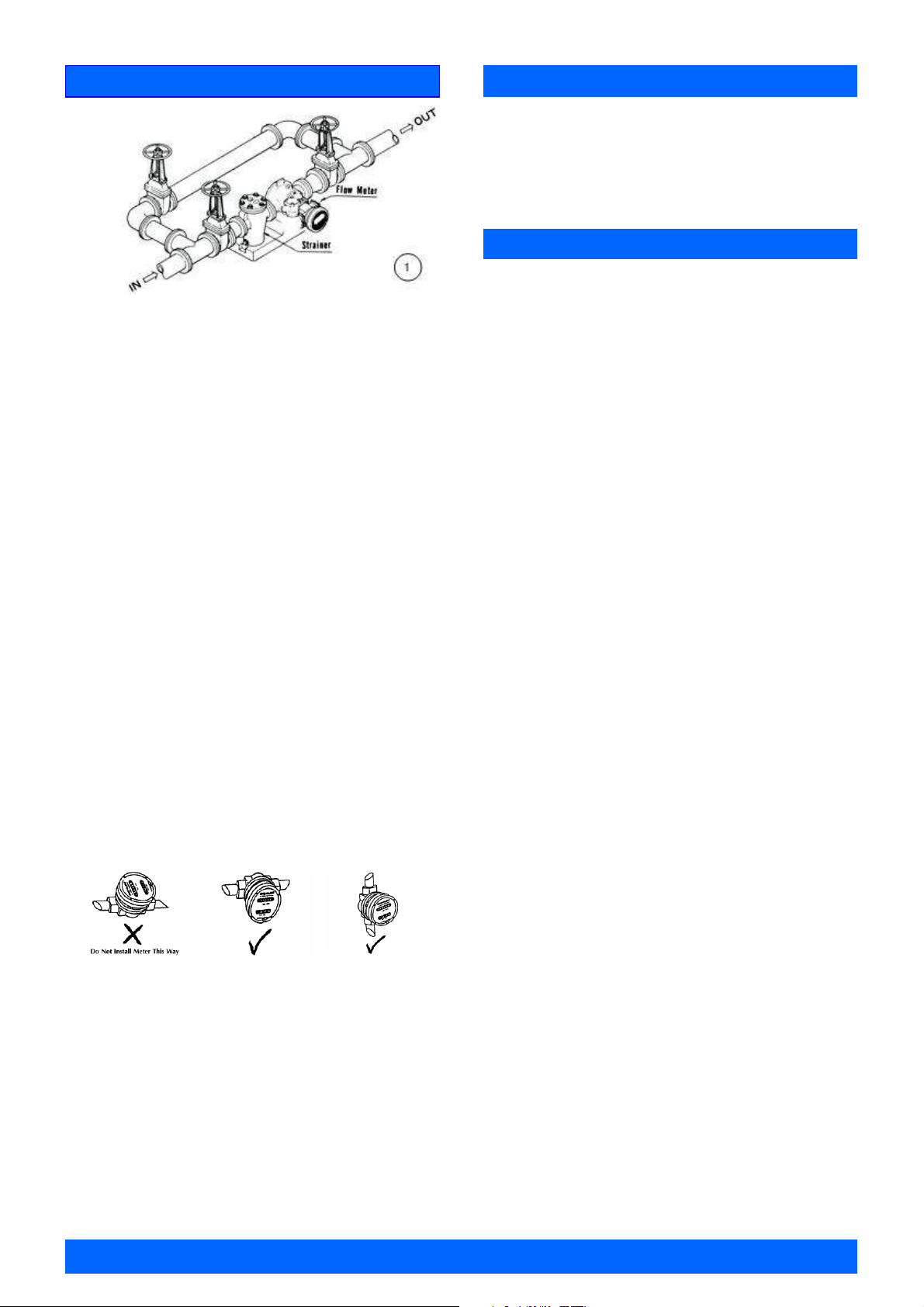

1. It is recommended that when setting up pipe work

for meter installations, a bypass line be included

in the design. This provides the facility for a meter

to be removed for maintenance without interrupt

ing production. (see figure above)

2. Use a thread sealant on all pipe threads.

Caution: Thread tape must not enter flow meter,

stopping flow meters operation.

3. For pump applications ensure pipe work and

Meter have the appropriate working pressure

rating to match the pressure output of the pump.

Refer to Meter Specifications section for further

details.

4. Install a wire mesh strainer, Y or basket type

as close as possible to the inlet side of the meter.

Meter 1/4” 74 micron / 200 mesh

Meter 1/2”- 2” 250 micron / 60 mesh

Meter 3”- 4” 400 micron / 40 mesh

5. Note: The flow meter can accept flow in any

direction.

6. The meter can be installed in any orientation as

long as the meter shafts are in a horizontal plane.

(Refer to diagram below for correct installation)

.

Note: Incorrect installation can cause premature

wear of meter components.

MAINTENANCE PROCEDURE

Note: Inspection and maintenance of installations

should only be carried out by experienced personnel,

whose training has included instruction on the

various types of protection and installation practices.

DISASSEMBLY

Note: Care should be taken not to drop, damage or

impact equipment due to risk of spark.

Non sparking tools should be used.

Meter should be removed from explosive

atmosphere when maintenance to any part of the

meter is required, the meter must be isolated and the

line pressure released.

Refer to the exploded parts diagram on pg.13-14 for

item numbers.

Note: It is advisable to mark all components with a

marker pen before disassembly, to ensure all the

components are replaced to their correct position

during the reassembly process.

1. Remove the meter cap by loosening the bolts on

the underside of the meter body. (see FIG 1)

2. Remove the O-Ring from the O-Ring groove in the

meter cap.

Wipe clean of grease and store in clean place

3. Remove rotors from the meter body

7. Do not over tighten meter connections.

8. It is important that after initial installation you

fill the line slowly, high speed air purge could

cause damage to the rotors.

9. Test the system for leaks.

Do not continue use if meter is leaking.

10. Check the strainer for swarf or foreign material,

after the first 200 litres check periodically,

particularly if the flow rate is noted to be

decreasing.

Page 4 of 39

Page 5

MAINTENANCE PROCEDURE

REASSEMBLY

1. Before reassembling check the condition of the

rotors and bushes (replace if necessary).

2. There are two Rotor Types. Active and Neutral.

The Active Rotor is fitted with the magnets. They

can be identified by running a metal object over

the face of the rotor (smooth side)

Caution: The active rotor is always fitted

nearest ‘dimple’ on the meter body

(see FIG 3)

Replace Active Rotor.

Check the smooth side of the rotor is the leading

face when fitting onto the shaft and into the meter

body. (see FIG 2).

Replace Neutral Rotor. Check that the smooth

side of the rotor is the leading face when fitting

onto the shaft. (see FIG 2)

Fit the neutral rotor onto the shafts ensuring that

the rotor pair are at 90 degrees to one another.

(see FIG 3)

Check their operation by turning either of the

rotors. If the rotors are not in mesh correctly,

or do not move freely, remove one of the rotors

and replace correctly at 90 degrees to one

another.

3. Check condition of O-Ring and bolts, replace if

damaged.

Smear the O-Ring with a light film of grease.

Grease applied should meet the following

requirements:

Not harden with age.

Not contain an evaporating solvent.

Not cause corrosion of joint surfaces.

Replace the O-Ring into groove in the meter cap.

The O-Ring will need to be replaced if it has

grown or is damaged in anyway.

4. Replace the meter cap.

5. Insert the cap head screws and tighten in a

diagonal sequence 1, 5, 7, 3, etc.

(see Meter Torque Ratings, page 15)

6. Test the meter by turning the rotors with a finger

or by applying very low air pressure (no more

than a good breath) to one end of the meter,

before returning the meter to service.

Note: When reassembling the meter , all joints

should be thoroughly cleaned and smeared with a

suitable grease to prevent corrosion and to assist

weather-proofing.

Blind bolt holes should be kept clear of grease. Only

non metallic scrapers and non corrosive cleaning

fluids should be used to clean flanges.

(see IEC 60079-14)

FIG 1

FIG 2

Rotor Face

Smooth side

Active Rotor

FIG 3

Dimple

Page 5 of 39

Page 6

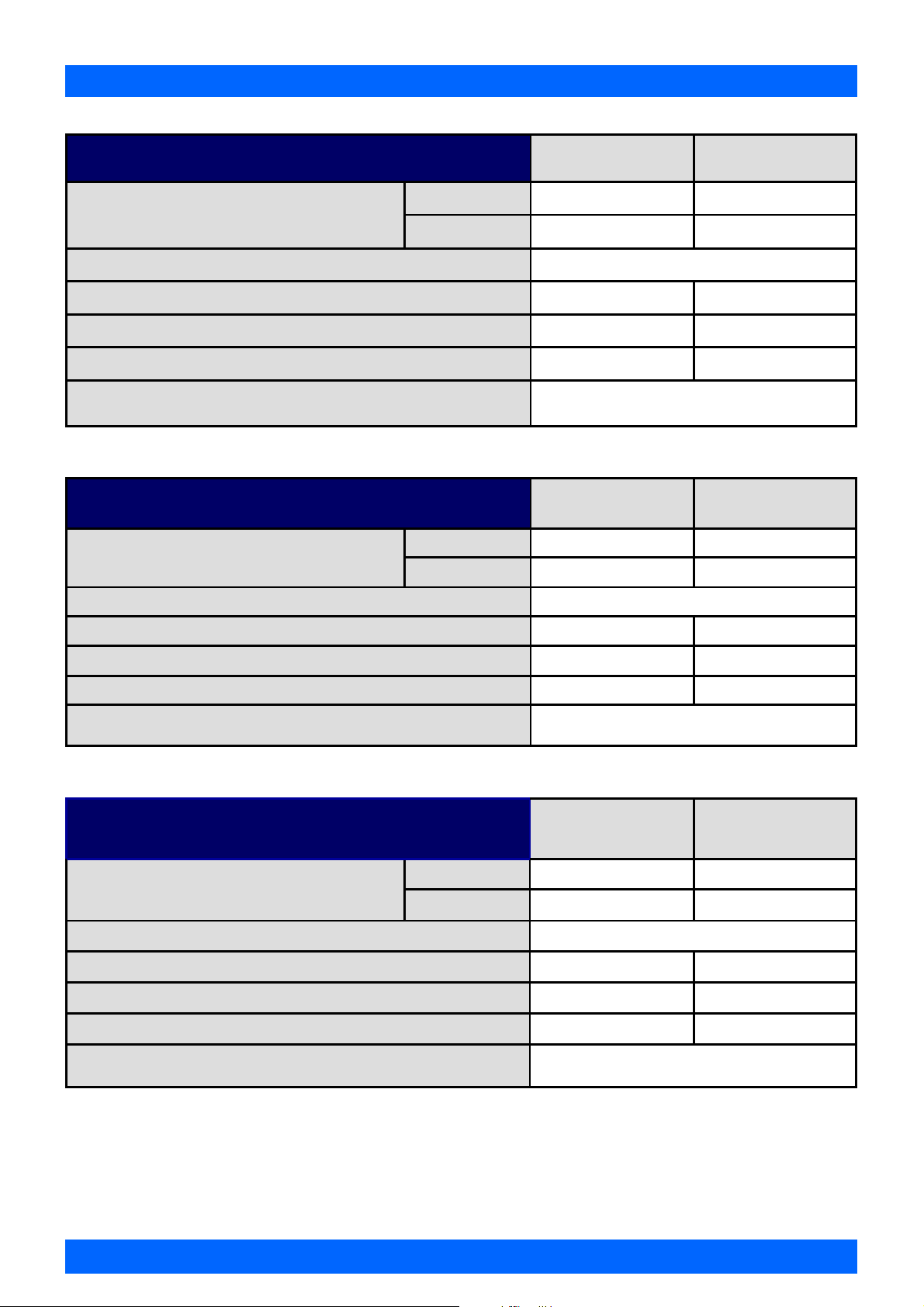

FLOWMETER SPECIFICATIONS

series MX06

Below 5 cP 2 to 100 LPH 0.5 to 26 GPH

Flow Range

K-Factor (Sensor Pulses per Unit of Measure) Refer to flow meter data plate

Temperature Range

Maximum Operating Pressure 6895 kPa

Accuracy of Reading ±0.5% of reading

5 to 1000 cP 0.5 to 100 LPH 0.13 to 26.4 GPH

1

(models MX06S)

(models MX06P)

series MX09

Flow Range

K-Factor (Sensor Pulses per Unit of Measure) Refer to flow meter data plate

Temperature Range

1

(models MX09S)

Below 5 cP 25 to 500 LPH 6.6 to 132 GPH

5 to 1000 cP 15 to 500 LPH 4 to 132 GPH

Metric US

-40°C - 120°C -40°F - 248°F

-40°C - 150°C -40°F - 302°F

1000 psi

Metric US

-40°C - 120°C -40°F - 248°F

(models MX09P)

Maximum Operating Pressure 6895 kPa

Accuracy of Reading ±0.5% of reading

series MX12

Flow Range

K-Factor (Sensor Pulses per Unit of Measure) Refer to flow meter data plate

Temperature Range

Maximum Operating Pressure 13790 kPa

Accuracy of Reading ±0.5% of reading

1

Flow meter process temperature range may be limited to sensor temperature classification. Consult relevant sensor data page

and approval documentation. Further information available from the Macnaught Technical Support Team.

1

(models MX12S)

(models MX12P)

-40°C - 150°C -40°F - 302°F

1000 psi

Metric US

Below 5 cP 3 to 25 LPM 0.8 to 6.6 GPM

5 to 1000 cP 2 to 30 LPM 0.5 to 8 GPM

-40°C - 120°C -40°F - 248°F

-40°C - 150°C -40°F - 302°F

2000 psi

Page 6 of 39

Page 7

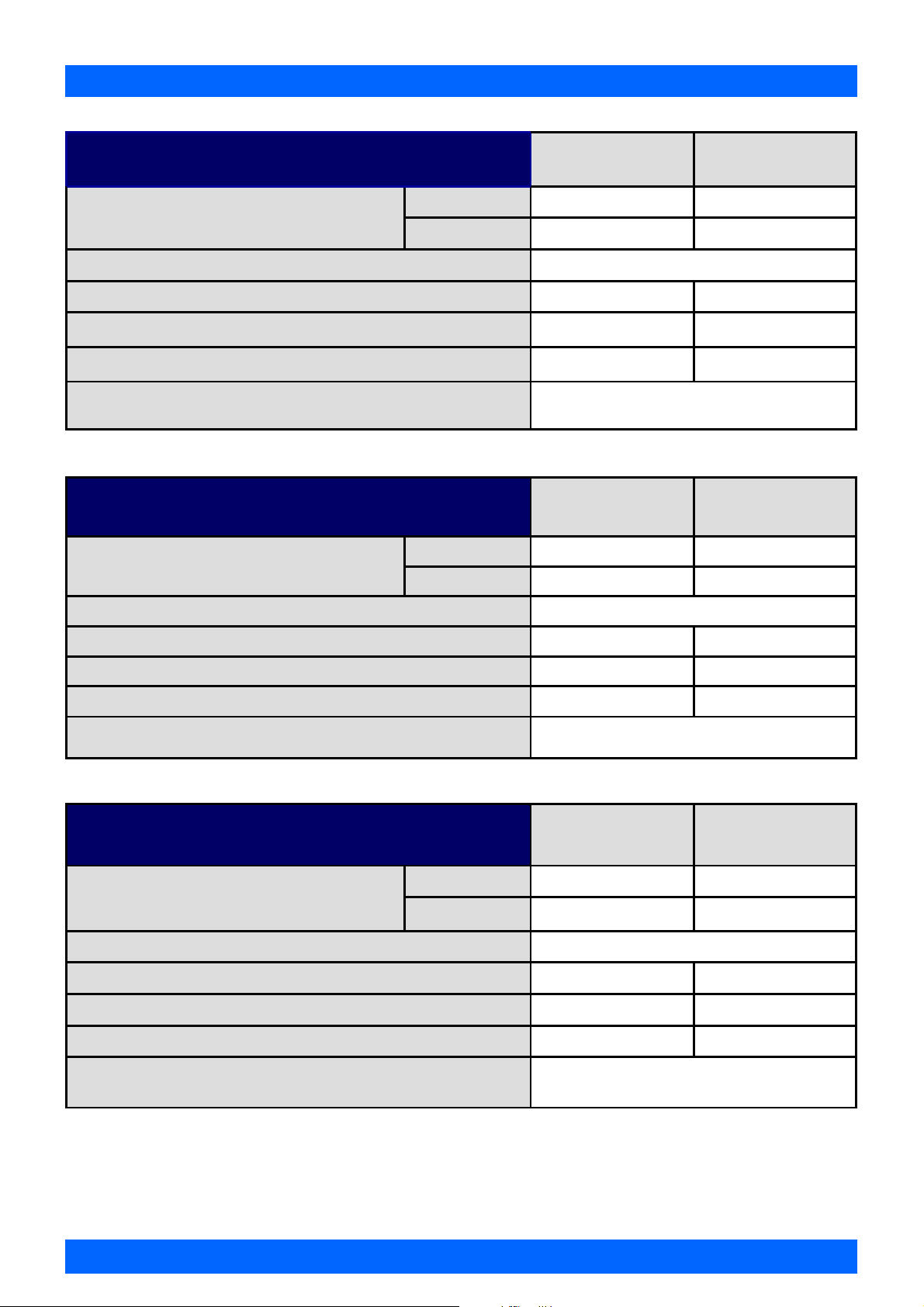

FLOWMETER SPECIFICATIONS

FLOWMETER SPECIFICATIONS

series MX19

Flow Range

K-Factor (Sensor Pulses per Unit of Measure) Refer to Flow meter data plate

Temperature Range

Maximum Operating Pressure 13790 kPa

Accuracy of Reading ±0.5% of reading

1

(models MX19S)

(models MX19P)

Below 5 cP 8 to 70 LPM 2 to 18.5 GPM

5 to 1000 cP 3 to 80 LPM 0.8 to 21 GPM

series MX25

Flow Range

K-Factor (Sensor Pulses per Unit of Measure) Refer to flow meter data plate

Temperature Range

1

(models MX25S)

Below 5 cP 10 to 100 LPM 2.6 to 26 GPM

5 to 1000 cP 6 to 120 LPM 1.6 to 32 GPM

Metric US

-40°C - 120°C -40°F - 248°F

-40°C - 150°C -40°F - 302°F

2000 psi

Metric US

-40°C - 120°C -40°F - 248°F

(models MX25P)

Maximum Operating Pressure 13790 kPa

Accuracy of Reading ±0.5% of reading

series MX40

Flow Range

K-Factor (Sensor Pulses per Unit of Measure) Refer to flow meter data plate

Temperature Range

Maximum Operating Pressure 10342 kPa

Accuracy of Reading ±0.5% of reading

1

Flow meter process temperature range may be limited to sensor temperature classification. Consult relevant sensor data page

and approval documentation. Further information available from the Macnaught Technical Support Team.

1

(models MX40S)

(models MX40P)

-40°C - 150°C -40°F - 302°F

2000 psi

Metric US

Below 5 cP 15 to 235 LPM 4 to 62 GPM

5 to 1000 cP 10 to 250 LPM 2.6 to 66 GPM

-40°C - 120°C -40°F - 248°F

-40°C - 150°C -40°F - 302°F

1500 psi

Page 7 of 39

Page 8

FLOWMETER SPECIFICATIONS

series MX50

Flow Range

K-Factor (Sensor Pulses per Unit of Measure) Refer to flow meter data plate

Temperature Range

Maximum Operating Pressure

Accuracy of Reading ±0.5% of reading

1

(models MX50S)

(models MX50P)

Below 5 cP 15 to 500 LPM 4 to 130 GPM

5 to 1000 cP 15 to 500 LPM 4 to 130 GPM

series MX75

Flow Range

K-Factor (Sensor Pulses per Unit of Measure) Refer to flow meter data plate

Temperature Range

Maximum Operating Pressure

1

(models MX75S)

Below 5 cP 60 to 600 LPM 17 to 170 GPM

5 to 1000 cP 20 to 733 LPM 5 to 194 GPM

Metric US

-40°C - 120°C -40°F - 248°F

-40°C - 150°C -40°F - 302°F

8274 kPa

1200 psi

Metric US

-40°C - 120°C

1200 kPa

-40°C - 248°F

175 psi

Accuracy of Reading ±0.5% of reading

series MX100

Flow Range

K-Factor (Sensor Pulses per Unit of Measure) Refer to flow meter data plate

Temperature Range

Maximum Operating Pressure

Accuracy of Reading ±0.5% of reading

1

Flow meter process temperature range may be limited to sensor temperature classification. Consult relevant sensor data page

and approval documentation. Further information available from the Macnaught Technical Support Team

1

(models MX100S)

Below 5 cP 220 to 1000 LPM 60 to 250 GPM

5 to 1000 cP 120 to 1200 LPM 30 to 300 GPM

Metric US

-40°C - 120°C

1200 kPa

-40°C - 248°F

175 psi

High Viscosity Applications

Ensure the flow meter is fitted with ‘High Viscosity Rotors’ if the fluid being metered is typically 1000 cP or above. For further

information, contact the Macnaught Technical Support Team

High Viscosity Rotors For Fluids above 1000 Centipoise (cP)

Page 8 of 39

Page 9

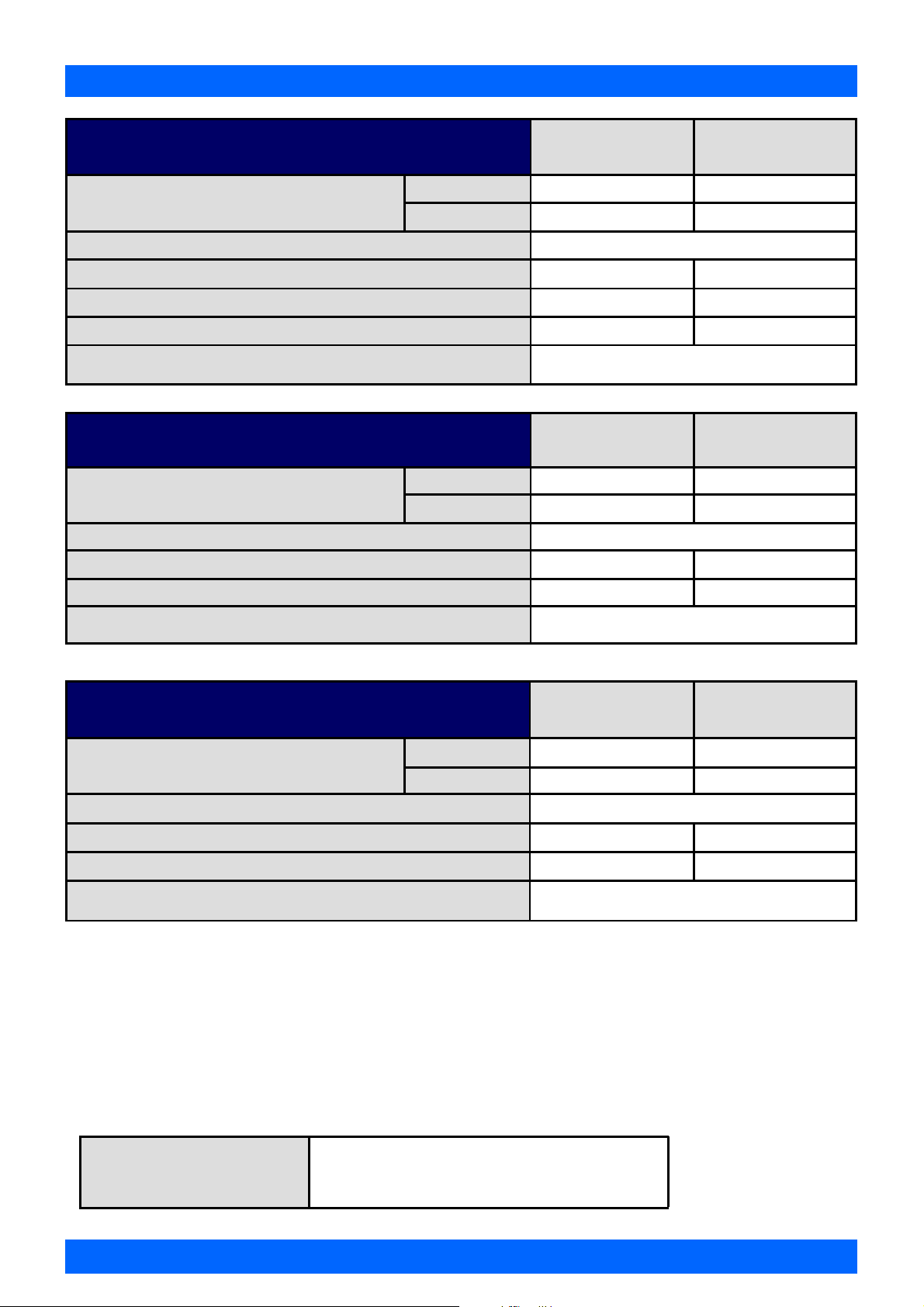

WIRING DIAGRAM Intrinsically Safe (Ex ia)

Output type ‘B’

CAUTION: This sensor must be installed with an approved safety barrier.

Pulser Specifications

SENSOR TYPE

SPECIFICATIONS

1

Refer to sensor certificates for complete markings, temperature ranges and approval codes

Omni Polar Supply Tracking , NPN with 3.1kΩ pull-up resistor

II 1 G Ex ia IIC T6...T4 Ga, T6@ -40°c ≤T

Markings

Construction 303 Stainless Steel Housing

Operating Voltage 5V to 30V DC @ ≤ 15mA

Maximum Sinking Current 25mA

Process Temperature Range

Approvals

Entity Parameters Ui = 30V, Ii = 100mA, Pi = 0.66W, Ci = 12nF, Li = 0

I.S Barrier (Associated Equipment)

1

Class 1, Zone 0, AEx/Ex ia IIC T6...T5

1

1

ATEX, IECEx, US & CAN (THROUGH FM)

ATEX & IECEx:

US & CAN:

Class 1, Division 1

GROUP ABCD T6...T5

T6 @ -40°c ≤T

-40°C - 65°C or -40°F - 149°F

Vmax, Ui ≥ Uo, Voc or Vt

Imax, Ii ≥ Io, Isc, It

Co or Ca ≥ Ci + Cc

Lo or La ≥ Li + Lc

amb

Pt or Po ≤ Pi

≤+65°c

Brown

≤+65°c

amb

Blue

End of Sensor

Brown

Black

Black

Blue

End of Mating Cable

Page 9 of 39

Page 10

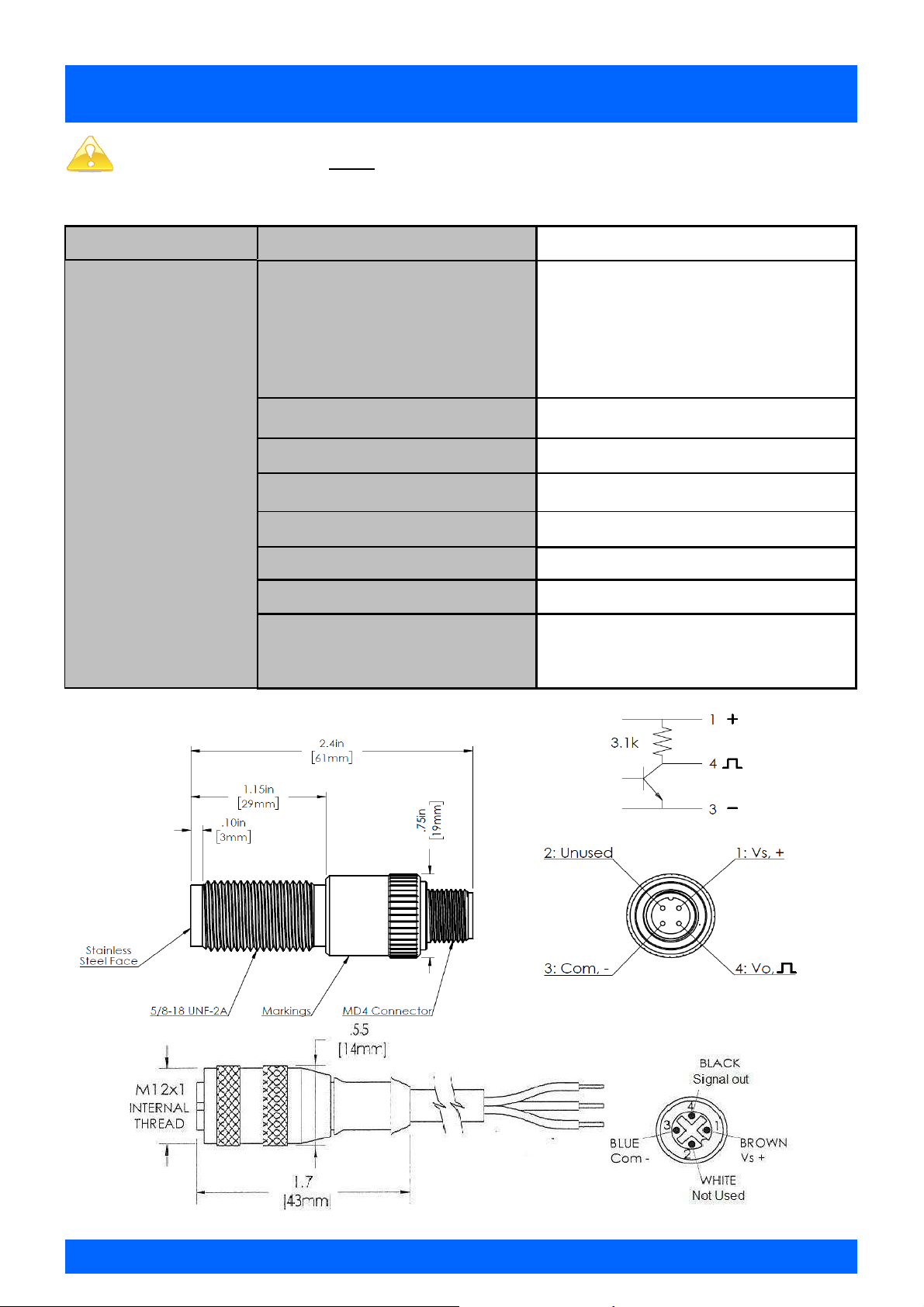

WIRING DIAGRAM Flame Proof (Ex D)

Output type ‘C’

Pulser Specifications

SENSOR TYPE Omni Polar Supply Tracking , NPN with 3.1kΩ pull-up resistor

ATEX & IECEx:

USA & CAN:

Class 1 Division 1

GROUP ABCD T6...T3

T3 @ Ta = -50°C… +140°C

Markings

II 2 G Ex db IIC T6...T3 Gb, T3@ Ta = -55°C… +140°C

1

Class 1, Zone 1, AEx/Ex db IIC T6...T3 Gb

SPECIFICATIONS

1

Refer to sensor certificates for complete markings, temperature ranges and approval codes

CAUTION: The green wire MUST be connected to an Earth ground

CAUTION: A poured conduit seal MUST be applied within 0.45m/18” of the sensor

Construction 303 Stainless Steel

Operating Voltage 5V to 27V DC @ ≤ 15mA

Maximum Sinking Current 25mA

Process Temperature Range

Approvals

1

1

-50°C - 140°C or -58°F - 284°F

ATEX, IECEx, US & CAN (THROUGH FM)

Flow Meter Process Connection Conduit Thread

G Thread

M20x1.5-6H

ANSI(AUS) / DIN / JIS

NPT Thread 1/2-14 NPT

ANSI (US)

Page 10 of 39

Page 11

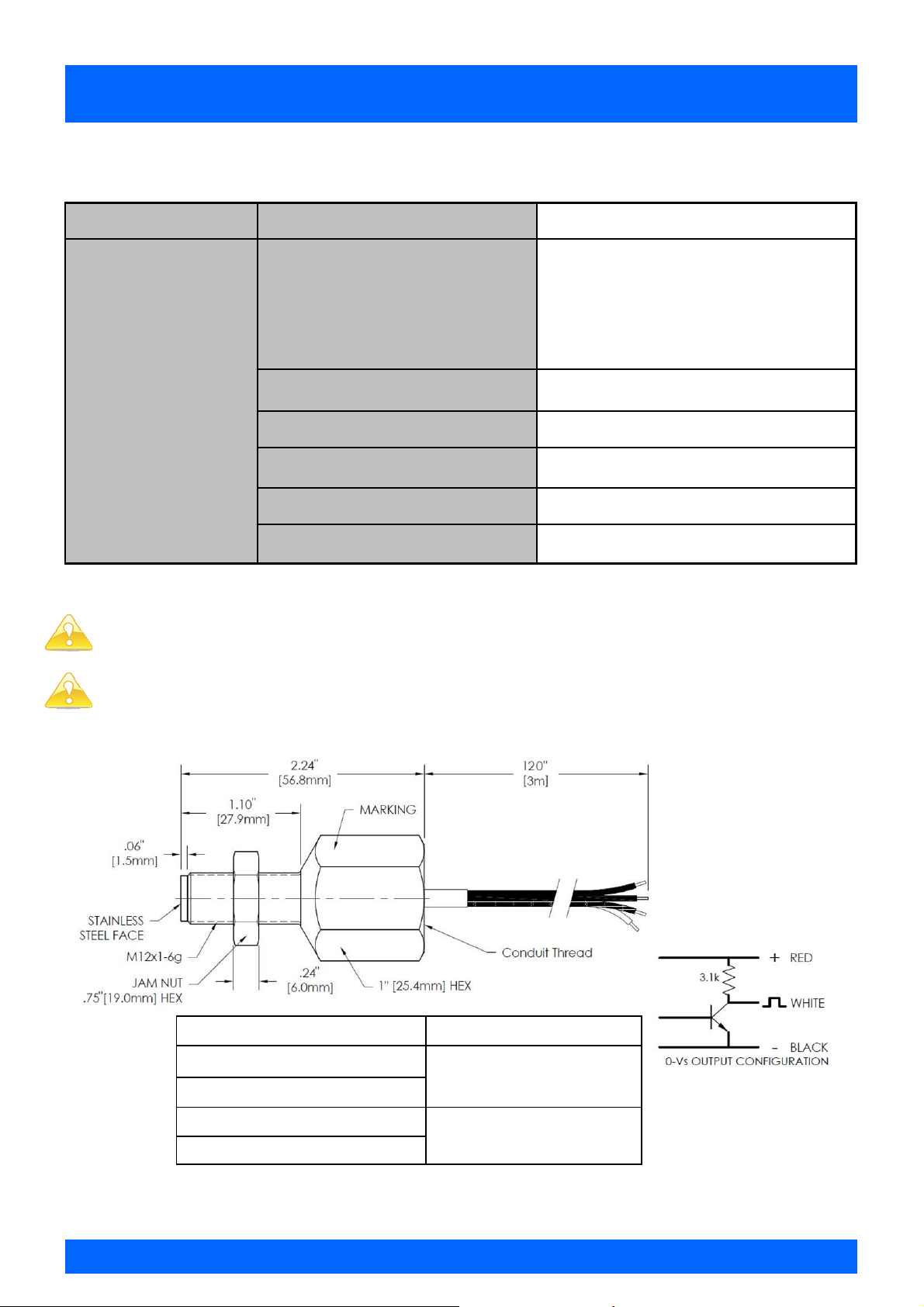

WIRING DIAGRAM Intrinsically Safe (Ex ia)

Output type ‘N’

CAUTION: This sensor must be installed with an approved safety barrier.

Pulser Specifications

SENSOR TYPE Magnet-inductive Proximity Sensor NAMUR

ATEX & IECEx:

SPECIFICATIONS

II 1 G Ex ia IIC T4...T6 Ga

Markings

Construction CuZn, Chrome-plate

Operating Voltage 8V to 15V DC

Maximum Current 5mA

Process Temperature Range

Approvals

Entity Parameters Ui = 20V, Ii = 60mA, Pi = 200mW, Ci = 150nF, Li = 150uH

1

Class 1, Zone 0, AEx/Ex ia IIC T5...T4

1

1

ATEX, IECEx, US (THROUGH FM AND CSA)

Class 1, Division 1

GROUP ABCD T4 resp. T5

T5 @ -25°c ≤T

-25°C - 70°C or -13°F - 158°F

US:

≤+70°c

amb

1

Refer to sensor certificates for complete markings, temperature ranges and approval codes

Com, Blue Vs, Brown

End of Sensor

Brown

Blue

End of Mating Cable

Page 11 of 39

Page 12

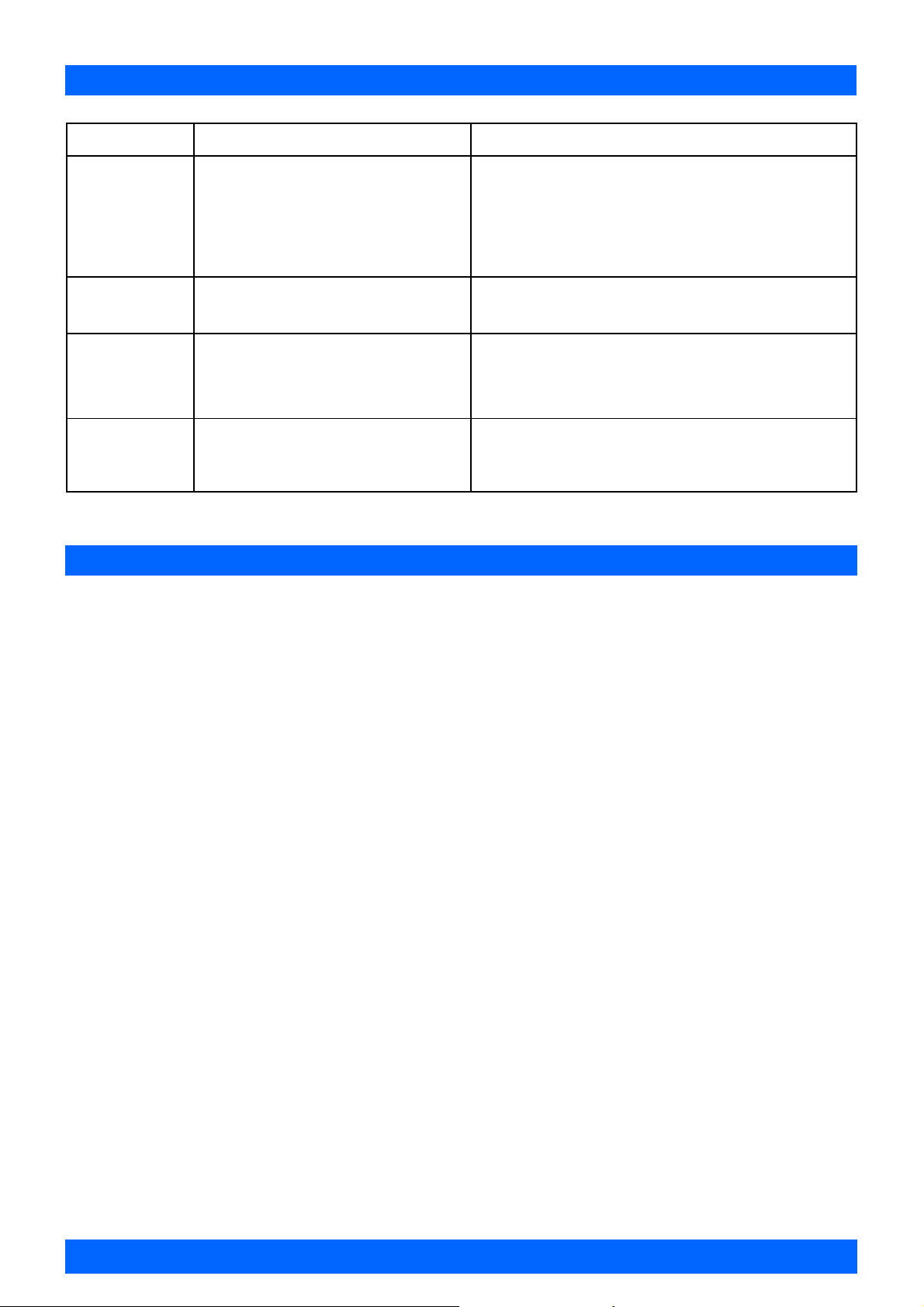

TROUBLESHOOTING GUIDE

Problem Cause Remedy

Fluid will not flow

through meter

Reduced flow

through meter

Meter reading

inaccurate

Meter not giving a

pulse signal

a) Foreign matter blocking rotors

b) Line strainer blocked

c) Damaged rotors

d) Meter connections over tightened

e) Fluid is too viscous

a) Strainer is partially blocked

b) Fluid is too viscous

a) Fluid flow rate is too high or too low

b) Air in fluid

c) Excess wear caused by incorrect

installation

a) Faulty sensor

b) Magnets failed

a) Contact Macnaught

b) Clean strainer

c) Re-adjust connections

d) See specifications for maximum viscosity

a) Clean strainer

b) See specifications for maximum viscosity

a) See specifications for minimum and maximum flow rates

b) Bleed air from system

c) Check meter body and rotors. Replace as required. Refer

to installation instructions

a) Replace sensor

b) Replace magnets

Page 12 of 39

Page 13

EXPLODED DIAGRAM models MX06-MX50

PARTS IDENTIFICATION

METER COMPONENTS

SENSOR HOLDER

METER CAP O-RING

MAGNET HOUSING

SENSOR

CIRCLIP

METER BODY

ROTORS

MAGNETS

ROTOR SHAFTS

ITEM NO.

1

2

3

4

5

6

7

8

9

LOCATING PIN

METER CAP

METER CAP SCREWS

10

11

12

Page 13 of 39

Page 14

EXPLODED DIAGRAM models MX75-MX100

PARTS IDENTIFICATION

METER COMPONENTS

METER BODY

ROTOR SHAFTS

METER CAP O-RING

METER CAP

METER CAP BOLTS

FLANGE SEALS

ROTORS

CAM

CIRCLIP

PROCESS CONNECTION (FLANGED OR

THREADED)

ITEM NO.

1

2

3

4

5

6

7

8

9

10

FLANGE WASHERS

FLANGE BOLTS

11

12

Page 14 of 39

Page 15

METER TORQUE

Series

MX06 1000

MX09 1000

MX12 2000

MX19 2000

MX25 2000

MX40 1500

MX50 1200

MX75 175

MX100 175

Pressure

(psi)

Meter Torque Ratings

Torque (Nm) Lubrication -

6.5 Nm Yes

15 Nm Yes

33 Nm Yes

SPARE PARTS KITS

Spare Kit options, for both flow meter and pulser modules, are available as replacement components.

• Pulser Kit

- Replacement Intrinsically safe sensor.

• Rotor Kit

- Rotor assembly (includes Meter Cap bolts and O-Ring)

• Seal Kit

- O-Rings/Gaskets

Page 15 of 39

Page 16

SPARE PARTS KITS

spare kits Series MX06

ROTOR KIT Standard

SEAL KIT

Ex ia, NPN

PULSER KIT

Ex ia, NAMUR

Ex D

spare kits Series MX09

Standard

ROTOR KIT

High Viscosity

MX06P

MXS06P-HTrotor MXS06S-rotor

MXS06P-seal MXS06S-seal

MXD-BS MXD-BS

MXD-NS MXD-NS

MXD-CS MXD-CS

MX09P

MXS09P-HTrotor MXS09S-rotor

MXS09P-HVrotor MXS09S-HVrotor

MX06S

MX09S

SEAL KIT

Ex ia, NPN

PULSER KIT

Ex ia, NAMUR

Ex D

spare kits Series MX12

Standard

ROTOR KIT

High Viscosity

SEAL KIT

Ex ia, NPN

MXS09P-seal MXS09S-seal

MXD-BS MXD-BS

MXD-NS MXD-NS

MXD-CS MXD-CS

MX12P

MXS12P-HTrotor MXS12S-rotor

MXS12P-HVrotor MXS12S-HVrotor

MXS12P-seal MXS12S-seal

MXD-BS MXD-BS

MX12S

PULSER KIT

Ex ia, NAMUR

Ex D

MXD-NS MXD-NS

MXD-CS MXD-CS

Page 16 of 39

Page 17

SPARE PARTS KITS

spare kits Series MX19

Standard

ROTOR KIT

High Viscosity

SEAL KIT

Ex ia, NPN

PULSER KIT

Ex ia, NAMUR

Ex D

spare kits Series MX25

Standard

ROTOR KIT

High Viscosity

MX19P

MXS19P-HTrotor MXS19S-rotor

MXS19P-HVrotor MXS19S-HVrotor

MXS19P-seal MXS19S-seal

MXD-BS MXD-BS

MXD-NS MXD-NS

MXD-CS MXD-CS

MX25P

MXS25P-HTrotor MXS25S-rotor

MXS25P-HVrotor MXS25S-HVrotor

MX19S

MX25S

SEAL KIT

Ex ia, NPN

Ex ia, NAMUR

Ex D

spare kits Series MX40

Standard

ROTOR KIT

High Viscosity

SEAL KIT

Ex ia, NPN

PULSER KIT

Ex ia, NAMUR

MXS25P-seal MXS25S-seal

MXD-BS MXD-BS

MXD-NS MXD-NS PULSER KIT

MXD-CS MXD-CS

MX40P

MXS40P-HTrotor MXS40S-rotor

MXS40P-HVrotor MXS40S-HVrotor

MXS40P-seal MXS40S-seal

MXD-BS MXD-BS

MXD-NS MXD-NS

MX40S

Ex D

MXD-CS MXD-CS

Page 17 of 39

Page 18

SPARE PARTS KITS

spare kits Series MX50

Standard

ROTOR KIT

High Viscosity

SEAL KIT

PULSER KIT

Ex ia, NPN

Ex ia, NAMUR

Ex D

spare kits Series MX75

Standard

ROTOR KIT

High Viscosity

MX50P

MXS50P-HTrotor MXS50S-rotor

MXS50P-HVrotor MXS50S-HVrotor

MXS50P-seal MXS50S-seal

MXD-BS MXD-BS

MXD-NS MXD-NS

MXD-CS MXD-CS

MX75S

MXS75S-rotor

MXS75S-HVrotor

MX50S

SEAL KIT

Ex ia, NPN

PULSER KIT

Ex ia, NAMUR

Ex D

spare kits Series MX100

Standard

ROTOR KIT

High Viscosity

SEAL KIT

Ex ia, NPN

MXS75S-seal

MXD-BS

MXD-NS

MXD-CS

MX100S

MXS100S-rotor

MXS100S-HVrotor

MXS100S-seal

MXD-BS

PULSER KIT

Ex ia, NAMUR

Ex D

MXD-NS

MXD-CS

Page 18 of 39

Page 19

WETTED PARTS

Wetted parts series MX06

METER BODY

METER CAP

ROTORS

ROTOR SHAFTS

ROTOR BUSHES

O-RINGS

Wetted parts series MX09

METER BODY

METER CAP

ROTORS

MX06P

SS316

SS316

SS316

SS316

Carbon

FEP

MX09P

SS316

SS316

SS316

MX06S

AL 6061

AL 6061

SS316

SS316

Carbon

FEP

MX09S

AL 6061

AL 6061

SS316

High Viscosity

ROTOR SHAFTS

ROTOR BUSHES

O-RINGS

Wetted parts series MX12

METER BODY

METER CAP

ROTORS

High Viscosity

ROTOR SHAFTS

SS316

SS316

Carbon

MX12P

SS316

SS316

SS316

SS316

SS316

FEP

SS316

SS316

Carbon

FEP

MX12S

AL 6061

AL 6061

SS316

SS316

SS316

ROTOR BUSHES

O-RINGS

Carbon

FEP

Carbon

FEP

Page 19 of 39

Page 20

WETTED PARTS

Wetted parts series MX19

METER BODY

METER CAP

ROTORS

High Viscosity

ROTOR SHAFTS

ROTOR BUSHES

O-RINGS

Wetted parts series MX25

METER BODY

METER CAP

MX19P

SS316

SS316

SS316

SS316

SS316

Carbon

FEP

MX25P

SS316

SS316

MX19S

AL 6061

AL 6061

SS316

SS316

SS316

Carbon

FEP

MX25S

AL 6061

AL 6061

ROTORS

High Viscosity

ROTOR SHAFTS

ROTOR BUSHES

O-RINGS

Wetted parts series MX40

METER BODY

METER CAP

ROTORS

High Viscosity

SS316

SS316

SS316

Carbon

MX40P

SS316

SS316

SS316

SS316

FEP

SS316

SS316

SS316

Carbon

FEP

MX40S

AL 6061

AL 6061

AL 6061

AL 6061

ROTOR SHAFTS

ROTOR BUSHES

O-RINGS

SS316

Carbon

FEP

SS316

Carbon

FEP

Page 20 of 39

Page 21

WETTED PARTS

Wetted parts series MX50

METER BODY

METER CAP

ROTORS

High Viscosity

ROTOR SHAFTS

ROTOR BUSHES

O-RINGS

Wetted parts series MX75

METER BODY

METER CAP

MX50P

SS316

SS316

SS316

SS316

SS316

Carbon

FEP

MX75S

AL 6061

AL 6061

MX50S

AL 6061

AL 6061

AL 6061

AL 6061

SS316

Carbon

FEP

ROTORS

ROTOR SHAFTS

ROTOR BUSHES

O-RINGS

High Viscosity

Wetted parts series MX100

METER BODY

METER CAP

ROTORS

High Viscosity

AL 6061

AL 6061

SS316

Carbon

FEP

MX100S

AL 6061

AL 6061

AL 6061

AL 6061

ROTOR SHAFTS

ROTOR BUSHES

O-RINGS

SS316

Carbon

FEP

Page 21 of 39

Page 22

PRESSURE DROP v VISCOSITY

100%

50%

100%

50%

10%

25%

5%

Page 22 of 39

Page 23

DIMENSIONS series MX06-MX09

Page 23 of 39

Page 24

DIMENSIONS series MX12

Page 24 of 39

Page 25

DIMENSIONS series MX19

Page 25 of 39

Page 26

DIMENSIONS series MX25

Page 26 of 39

Page 27

DIMENSIONS series MX40

Page 27 of 39

Page 28

DIMENSIONS series MX50

Page 28 of 39

Page 29

DIMENSIONS series MX75

Page 29 of 39

Page 30

DIMENSIONS series MX100

Page 30 of 39

Page 31

WALL MOUNT ADAPTOR Series MX06 and MX09

Aluminium Wall Mount bracket to suit model MX06-MX09

Page 31 of 39

Page 32

Aluminium Wall Mount bracket to suit model MX12

WALL MOUNT ADAPTOR Series MX12

Page 32 of 39

Page 33

Aluminium Wall Mount bracket to suit model MX19

WALL MOUNT ADAPTORS Series MX19

Page 33 of 39

Page 34

Aluminium Wall Mount bracket to suit model MX25

WALL MOUNT ADAPTORS Series MX25

Page 34 of 39

Page 35

EU Declaration of Conformity

Page 35 of 39

Page 36

EU Declaration of Conformity

Page 36 of 39

Page 37

CERTIFICATES

Certificates for Approved Switches can be downloaded at MACNAUGHT.com,

through your Macnaught Flow Meter distributor, or contact

metersinfo@macnaught.com

WEEE Directive - Waste Electrical and Electronic Equipment

The WEEE Directive requires the recycling of waste electrical and electronic

equipment in the European Union.

Whilst the WEEE Directive does not apply to some of Macnaught’s products, we

support its policy and ask you to be aware of how to dispose of this product.

The crossed out wheelie bin symbol illustrated and found on our products signifies that

this product should not be disposed of in general waste or landfill.

Please contact your local dealer national distributor or Macnaught Technical Services

for information on product disposal.

Page 37 of 39

Page 38

Notes

Page 38 of 39

Page 39

Macnaught Americas

614 South Ware Boulevard

Tampa Florida USA, 33619

T: +1813 628 5506

E: info@macnaughtusa.com

W: www.macnaughtusa.com

Note:

This product should be disposed of according to all

applicable local and national government environment

Page 39 of 39

Loading...

Loading...