Include s models

HG55-01

HG55-02

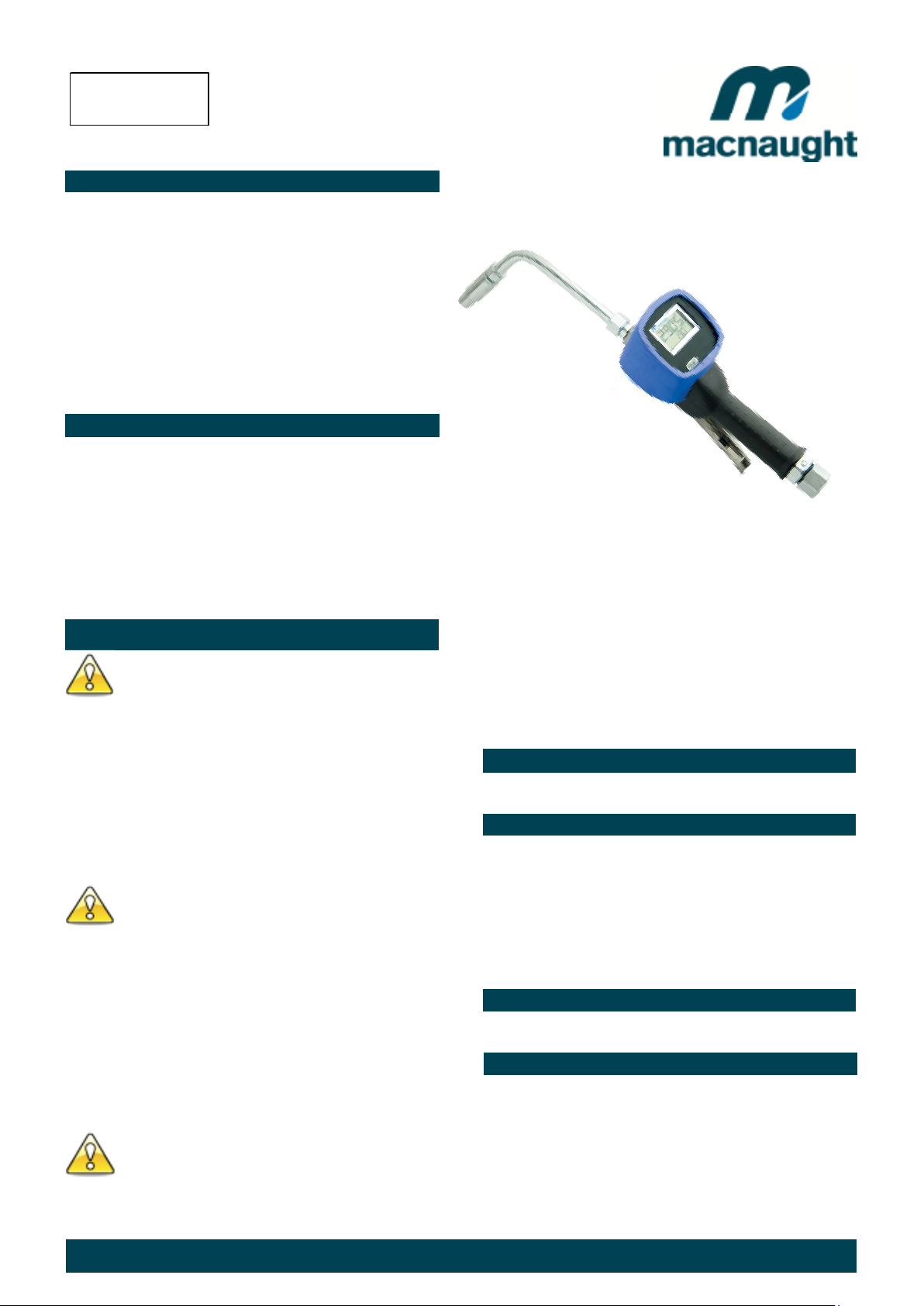

HG 55 OIL CONTROL GUN

WITH ELECTRONIC METER

INSTRUCTION MANUAL

INTRODUCTION

Thank you for purchasing a HG55 Electronic oil

control gun. Macnaught oil control guns have been

designed to accurately dispense, measure and control

oil flow. The control guns are suitable with engine oil,

gear oil, automatic transmission fluid, anti-freeze/antiboil and compatible fluids.

Please read and retain this instruction manual to

assist you in the operation and maintenance of this

quality product.

Note: Batteries are not pre-fitted and are included

separately inside the box. Please refer to “Battery

Replacement” on page 3 for correct procedure.

GENERAL INFORMATION

This manual assists you in operating and maintaining your

new oil control gun. The information contained will help

you ensure many years of dependable performance and

trouble free operation.

Please take a few moments to read through this manual

before installing and operating your new oil control gun. If

you experience problems with this product, refer to the

trouble shooting sections of this manual. If you require

further assistance please contact your local Macnaught

distributor or authorised Macnaught service centre.

IMPORTANT INFORMATION

READ THIS INFORMATION

CAREFULLY BEFORE USE.

Your safety is important to us. Please read and follow

all safety instructions listed inside.

Some of these instructions alert you to the potential

for personal injury. “Cautions” listed throughout this

manual advise of potential practices or procedures

which may cause damage to your equipment.

Ensure all operators have access to adequate

instructions about safe operating and maintenance

procedures.

WARNING

This oil control gun should not be used for in-line

installations or used with a manual a shut off nozzle.

The Safe operating pressure of this nozzle is 500 PSI

The line pressure between the pump and the

dispensing handle trigger valve must not exceed 1500

PSI (103 BAR). Please ensure an adequate pressure

relief valve is installed for operator safety.

The auto non drip nozzle MUST not be modified

CAUTION

Never point the nozzle at yourself or anyone else.

Never exceed the pressure rating of any component

installed in the System.

Before each use check all hoses for signs of wear,

leaks or loose fittings. Tighten all fluid connections

regularly and replace weak or damaged hoses.

Before attempting any repairs or maintenance of this

product firstly disconnect the air supply from the oil

pump, then release the oil line pressure by pressing

the lever on your oil control gun.

ASSEMBLY

Use Teflon tape (or suitable thread sealant ) when

connecting the oil control gun to an oil hose.

Outlet Nozzle.

The outlet nozzle can be fitted either “inline” (forward) or

on the outlet port “pistol style” located under the gun.

The long outlet tube should be used for the “inline” option.

The short adaptor should be used (instead of the long

outlet tube) when using the “pistol style” option.

Note: Use the threaded Plug supplied to seal the outlet

port not in use.

HANDLE OPERATION

To latch the handle, press the lever, push the button and

then release lever.

METER INTRODUCTION

Operating mode description

Sleep Mode: To minimise battery consumption the meter

will revert to sleep mode if left idle for more than 2 minutes,

and will automatically “power up” if the RESET, button is

pressed or there is flow through the meter.

Do not hit the oil control gun if it fails to operate. Refer

to “trouble shooting guide” or return the unit to your

nearest authorised service centre.

The Reset button can be used in two ways:

Press – Press and release the button.

Double click – Press and release the button twice quickly.

HG614 Issue 15 © 2017 1

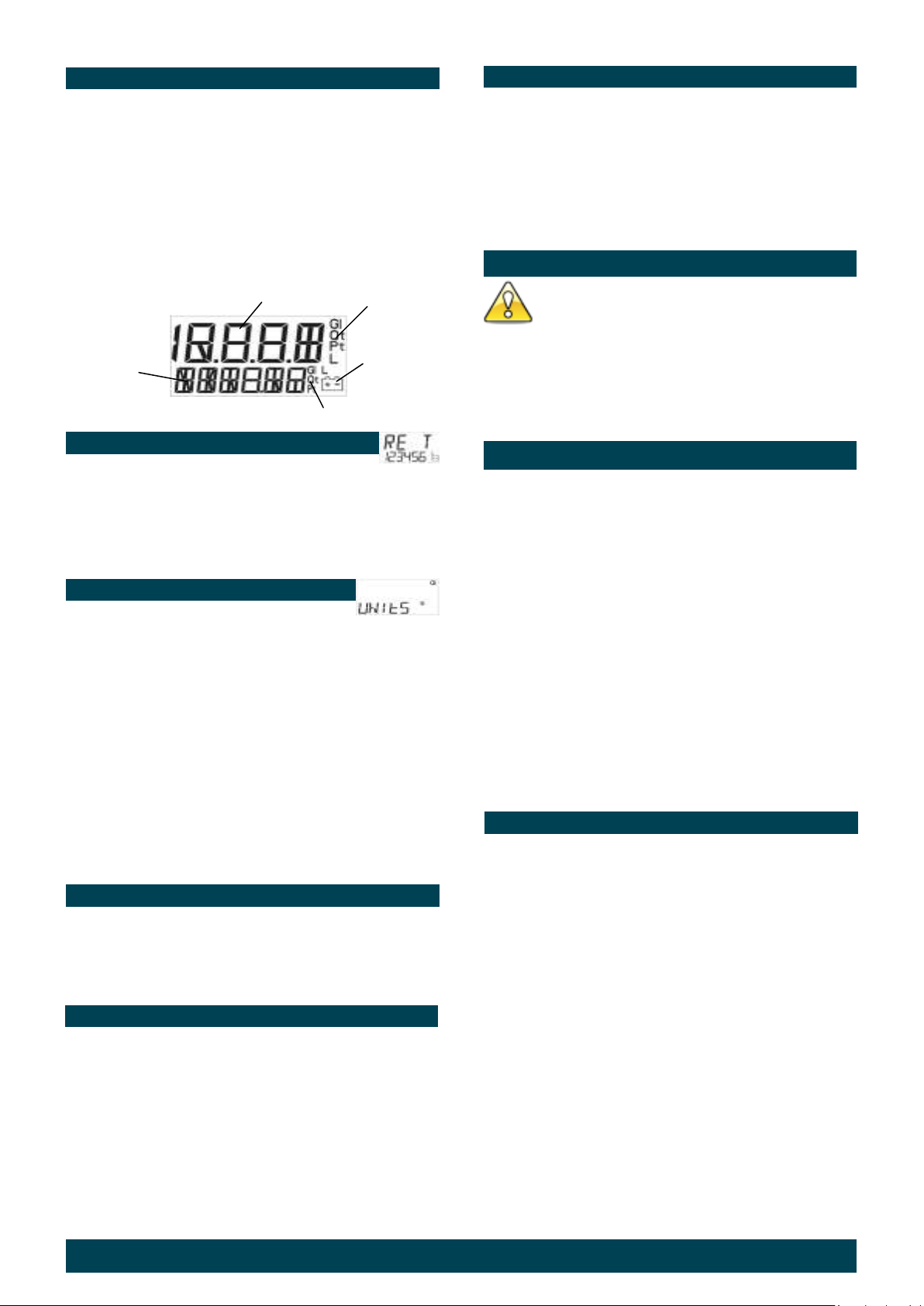

TOTALIZERS

There are three totalizers built in to your meter:

1) Reset-able batch total: Displays the current volume

dispensed. To reset batch total press the reset button.

2) Non reset-able accumulative total is located below

the batch total and displays the total volume the meter has

dispensed.

3) Reset-able accumulative total is hidden from view and

is used to track daily, weekly, or monthly usage.

Batch Total

Batch Total

Accumulative Total Units

TO VIEW OR RESET ACCUMULATIVE TOTAL:

1) Double click the Reset button (the display will enter the

reset-able total area.

2) To reset the reset-able total, press and release the

Reset button.

3) The display will return to manual mode after 5 seconds.

Batch Units

Low Battery

Warning

Error signal

If an error is detected, the following error code will appear

on the display.

Err1 – Sensor error

Err3 – Flowrate too high

Err4 – Calibration error

Err5 – Computer error

To reset the meter after an error signal press the Reset

button.

MAINTENANCE

CAUTION

Before carrying out any maintenance disconnect the

air supply to the pump and release the fluid pressure

in the system by pressing the lever on the control gun.

Inspect your oil control gun daily for any signs of damage.

Replace any damaged parts or components as required.

FIELD CALIBRATION

Field calibration will allow a +/- 5% adjustment to the

calibration.

1) In manual mode press the CAL button (located under

the calibration screw on the underside of the gun) for 5

seconds until Opt n 1 appears. (Refer item 16 page 4).

How to change the Units setting:

1) Press and hold down the Reset button for five seconds.

(The unit segment will appear)

2) Press the Reset button to cycle through the unit options.

3) Stop at the required setting.

Batch Total Accumulative Total

Litre Litre

Pint Gallon

Quart Gallon

Gallon Gallon

4) To store the selected units, press and hold down the

Reset button for five seconds until the batch and

accumulative totals appear. If the reset button is not held

down for 5 seconds, the original settings will be restored.

Low Battery

The battery segment will flash when the battery is low and

needs replacing.

Important: When the battery segment starts flashing

replace the battery as soon as possible, use only Alkaline

AA batteries.

Battery replacement

1) Remove the protective rubber boot.

2) Remove the battery cover screw located near the

Inline (forward) outlet port and remove the battery

cover.

3) Replace the two AA Alkaline batteries, note the battery

direction label inside the housing.

4) Inspect the battery cover seal for damage and replace if

necessary.

5) Replace battery cover and tighten screw.

2) Press the CAL button until F Cal appears.

3) Press the CAL button until F CAL starts flashing.

4) Using an accurate measuring container, fill the

container to the desired level. (e.g 5 litres)

5) Insert dispensed volume by:

a) Press reset button to change the numbers.

b) Press Cal button to move to the next number

c) Insert the correct dispensed value (e.g 5 litres)

d) Press Cal button for 5 seconds - F Cal will stop flashing.

6) To store press Reset for 5 seconds until 0.00 appears

CONTROL HANDLE DISASSEMBLY

Use a clean bench to carry out maintenance.

A) Remove the oil hose from the inlet swivel (26).

B) Unscrew and remove swivel (26) washer (24) and

o’ring (25) from the control gun inlet. Clean or replace the

strainer and o’ring.

Caution the swivel is under spring tension

C) Slide off the handle sleeve (23).

D) Remove valve spring (22), seal/valve body assembly

(20) and plunger (19).

Lever and Valve removal

A) Using a 2.5mm allen key, remove the 2 handle screws

(27).

B) Remove lever (29).

C) Remove the washer (18), “O”Ring (17), then push the

valve cam (14) from the gun body (13), and remove

“O”Ring (17).

HG614 Issue 15 © 2017 2

The meter is not registering fluid output

Remove the nozzle and blow out any dirt particles, replace if neces sary.

Oil leak from betw een the body casting

CONTROL HANDLE REASSEMBLY

A) Clean and inspect all parts. Replace any suspect,

worn or damaged components.

Note: Lightly lubricate the valve cam before assembly.

B) Place “O”Ring (17) onto valve cam (14).

Note: The cut out section in the middle of the valve cam

(14) must face the inlet swivel (26).

C) Replace the valve cam (14) into the body (13).

Note the orientation shown on the assembly drawing.

Fit the second “O”Ring (17) and washer (18).

D) Slide lever assembly (29) into position and replace

the two Allen screws (27). (Use Loctite or similar sealant).

E) Replace plunger (19).

Note: The end hole in the plunger must face the meter.

F) Assemble the seal/valve body (20), and spring (22) and

replace into the gun body.

Note: Install the spring, small end first.

G) Replace handle sleeve (23).

H) Replace washer (24), o’ring (25) swivel assembly

(26), and screw firmly into place (Use Loctite or similar

sealant).

Note: After assembly ensure the handle latch is operating

correctly.

METER DISASSEMBLY

1) Unscrew the swivel assembly (26) two complete

turns to allow easy disassembly and assembly of the

meter and remove boot (1).

2) Remove battery cover screw (3), the battery cover

(5) and batteries (7).

4) Carefully remove the computer module (2) from the

module housing (8).

Note: The computer module is non repairable and will

need to be replaced if damaged.

5) Remove the four Allen screws (15) from the

underside of the meter and remove the module housing

(8).

6) Remove the rotors (11) and the body ‘o’ ring (12).

3) Remove the three Phillips screws (9) and the

calibration port screw (16) from the underside of the meter.

METER REASSEMBLY

1) Clean and inspect all parts. Replace any suspect, worn

or damaged components.

2) Replace rotors (11) ( Refer to Fig 1 ).

(Fig 1)

Note: Ensure the rotor with the magnets is assembled with

the magnets facing up and positioned on the correct side

of the meter. Both rotors must also be positioned at 90deg

to each other ( Refer Fig 1 ).

3) Replace the gun body ‘o’ring (12).

4) Carefully position the module housing (8) on top of the

gun body (13), replace and tighten the four Allen screws

(15).

5) Ensure the handle latch is working correctly.

6) Test the oil control gun for correct operation.

7) Replace the computer module (2).

8) Replace and tighten the three Phillips head screws (9)

and calibration port screw (16).

9) Replace the two AA Alkaline batteries (7). (use the

directions on the label found inside the battery housing for

correct battery orientation).

10) Replace battery cover assembly (4,5,6) and tighten the

screw (3).

11) Firmly tighten the swivel assembly (26).

12) Replace the boot (1).

13) Test oil control gun for correct operation.

TROUBLE SHOOTING GUIDE

No fluid passing through a) Blocked strainer a) Clean or replace strainer

the meter b) Dirt particles jamming the rotors b) Dismantle meter assembly and clean

Meter display reads Err 1 Sensor error Press the reset button to reset the computer.

Meter display reads Err 3 Flow rate to high Adjust the flow rate to 1–30 l/mim ( 0.26-8 US gal/min )

Meter display reads Err 4 Calibration error Press the reset button to reset the computer

Meter display reads Err 5 Computer error Press the reset button to reset the computer

Constant oil leak from the nozzle Damaged plunger seal (20) Replace plunger seal ( check for damage )

Intermittent drip from the nozzle Dirt in the nozzle

Oil leak from the lever ass embly area Damaged o’rings (17) Replace damaged o’rings

and the computer module casting

Low flow rate Blocked strainer (32) Replace strainer

Oil leaking from the sw ivel inlet Damaged o’ring or sw ivel Replace sw ivel

TROUBLE CAUSE REMEDY

c) Damaged plunger seal c) Replace damaged plunger seal

a) Flat battery a) Replace battery

b) No signal from the magnets b) Check magnets and replace rotors if required

c) Damaged computer module c) Replace computer module

Damaged o’ring (12) Replace damaged o’ring

HG614 Issue 15 © 2017 3

( ref er to meter disassembly )

(If the error repeats, c heck the magnets in the rotor)

Eliminate air from the sys tem

Note: Alw ays pr es s th e re set button to re se t the com pute r

SPARE PARTS DIAGRAM SPARE PARTS LIST

Orde r for re placem en t

HG50-1K (KIT A) M ajor s er vice kit

HG50-2K (KIT B) incl Valve se rvice k it

1

2

3

4

7

8

Calibration Screw

9

6

5

10

12

17

16

11

17

14

18

13

27

19

28

20

30

15

27

29

* ORDER HGREX for a Rigid Tube Extension incl. outlet adapter set (not shown).

* ORDER HGNZL for a Automatic non Drip nozzle

WEEE Directive - Waste Electrical and Electronic Equipment

31

* ORDER HGFNZ for a Flexible Extension assembly, incl.

flexible extension, non drip nozzle and adaptor (not shown).

22

23

26

32

24

33

25

Item No. off Part or se t Kit ref Des cript ion

1 1 HG381BKs Electronic boot (STD)

2 1 HG369As Electronic module

3 1 A Battery cover s crew

4 1 A O'ring (BS007)

5 1 Battery cover

6 1 A Battery cover insert

7 2 n/a AA Alkaline batteries

8 1 n/a Module housing

9 3 A M3x6 Taptite screw s

10 2 Magnets

11 2 HG005s Oval gear set

12 1 A O'ring (BS035)

13 1 n/a - new gun req'd Gun body

14 1 A & B V alve cam

15 4 A M6x20 Taptite screw s

16 1 A & B Calibration screw

17 2 A & B O'ring (BS111)

18 1 A & B Washer

19 1 A Plunger

20 1 A & B V alve body and seal assy

22 1 A & B V alve spring

23 1 Handle sleeve

24 1 A & B Washer

25 1 A & B O'ring (BS117)

26 1 HG040As incl item 24 / BS117 Sw ivel assy (BSP)

26 1 HG043As incl item 24 / BS117 Sw ivel assy (NPT)

27 2 A & B M4x6 Counter sink screw s

28 1 Push button manual

29 1 HG010As Lever latching

30 1 A Button spring

31 1 A Lever plug

32 1 A & B Mesh

33 1 A & B O'ring (BS113)

The WEEE Directive requires the recycling of waste electrical and electronic equipment in the European

Union. Whilst the WEEE Directive does not apply to some of Macnaught’s products, we support its policy

and ask you to be aware of how to dispose of this product. The crossed out wheelie bin symbol illustrated

and found on our products signifies that this product should not be disposed of in general waste or landfill.

Please contact your local dealer national distributor or Macnaught Technical Services for information on

product disposal.

SPECIFICATIONS:

Accuracy:

Flow Range:

Maximum Supply Pressure:

Pressure Loss:

Weight:

Swivel Inlet:

Outlet:

Operating Temperature:

Storage Temperature:

Battery:

Wetted Parts:

Fluid Compatibility:

Dimensions:

+ - 0.5% (of Reading) (ISO100 @ 10 l/min)

1-30 l/min ( 0.26 – 8 US gal/min)

103.50 BAR / 10350kPa / 1500 PSI

1Bar/ 100kPa / 14.4PSI @ 12 l/min (3.2 US gal/min) with calibration fluid (6 Centipoise

Viscosity) without extension.

1.16kg ( 2.55lbs)

½” BSPT or ½” NPT

3/8” NPT

-0 to +50 degrees Celsius (32 – 122 degrees F)

-10 to +60 degrees Celsius (14 – 140 degrees F)

2 x 1.5Volt AA Batteries ( Alkaline batteries are essential for HG60 version)

Aluminium, Acetal, Steel, Nitrile Rubber

Engine Oil, Diesel Oil, Automatic Transmission Fluid, Anti-freeze / Anti-Boil Mixture.

(Maximum Viscosity SAE140)

25.8cm (10inch) Long x 9.5 cm ( 3.7inch) High, 11cm(4.33inch) wide (Dimensions without

extension)

Note:

This product should be disposed of according to all applicable local

and national government environment regulations and guidelines.

For Warranty Terms and Conditions see macnaught.com.au

For a list of Australian Service Centres see macnaught.com.au

HG614 Issue 15 © 2017 4

Loading...

Loading...