HG 20R(Rigid) and HG20F (Flexible) OIL CONTROL GUNS

0003

INTRODUCTION

Thank you for purchasing a Macnaught oil dispensing gun

complete with either a flexible or rigid extension. The

Macnaught oil dispensing guns have been designed for use

with engine oil, gear oil, automatic transmission fluid,

anti-freeze/anti-boil and compatible fluids.

Macnaught also manufacture a complete range of ratio oil

pumps and retractable oil hose reels, greasing equipment

and accessories to fulfill all your fluid handling and greasing

needs requirements.

GENERAL INFORMATION

This manual assists you in operating and maintaining your

new oil control gun. The information contained will help you

ensure many years of dependable performance and trouble

free operation.

Please take a few moments to read through this manual before

installing and operating your new oil control gun. If you

experience problems with this product, refer to the trouble

shooting sections of this manual. If you require further

assistance please contact your local Macnaught distributor

or authorised Macnaught service centre.

IMPORT ANT INFORMA TION

READ THIS INFORMATION

CAREFULL Y BEFORE USE.

Your safety is important to us. Please read and follow all

safety instructions listed inside.

Some of these instructions alert you to the potential for

personal injury. “Cautions” listed throughout this manual

advise of potential practices or procedures which may

cause damage to your equipment.

Ensure all operators have access to adequate instructions

about safe operating and maintenance procedures.

Do not exceed the maximum working pressure of 6900

kPa / 1000 psi / 69 bar .

CAUTION

Do not hit the oil control gun if it fails to operate. Refer to

“trouble shooting guide” or return the unit to your nearest

authorised service centre.

Never point the nozzle at yourself or anyone else.

Never exceed the pressure rating of any component

installed in the System.

Before every use check all hoses for signs of wear, leaks

or loose fittings. Tighten all fluid connections regularly and

replace weak or damaged hoses

Before attempting any repairs or maintenance of this

product firstly disconnect the air supply from the oil pump,

then release the oil line pressure by squeezing the lever on

your oil control gun.

ASSEMBLY

Use teflon tape (or suitable thread sealant ) when connecting

the oil control gun to an oil hose.

1

OUTLET NOZZLE OPERA TION

When fluid flows through the gun the outlet nozzle will

automatically open. When the fluid flow stops the outlet

nozzle will automatically shut

HANDLE OPERATION

To latch the handle, squeeze the lever, push the button and

then release lever.

To release the latch in manual mode simply squeeze and

release lever.

Please read and retain this instruction manual to assist

you in the operation and maintenance of this quality product.

INSTRUCTION MANUAL

HG616

0206

Before carrying out any maintenance disconnect

the air supply to the pump and release the fluid

pressure in the system by pressing the lever on the

control gun.

Inspect your oil control gun daily for any signs of damage.

Replace any damaged parts or components as required.

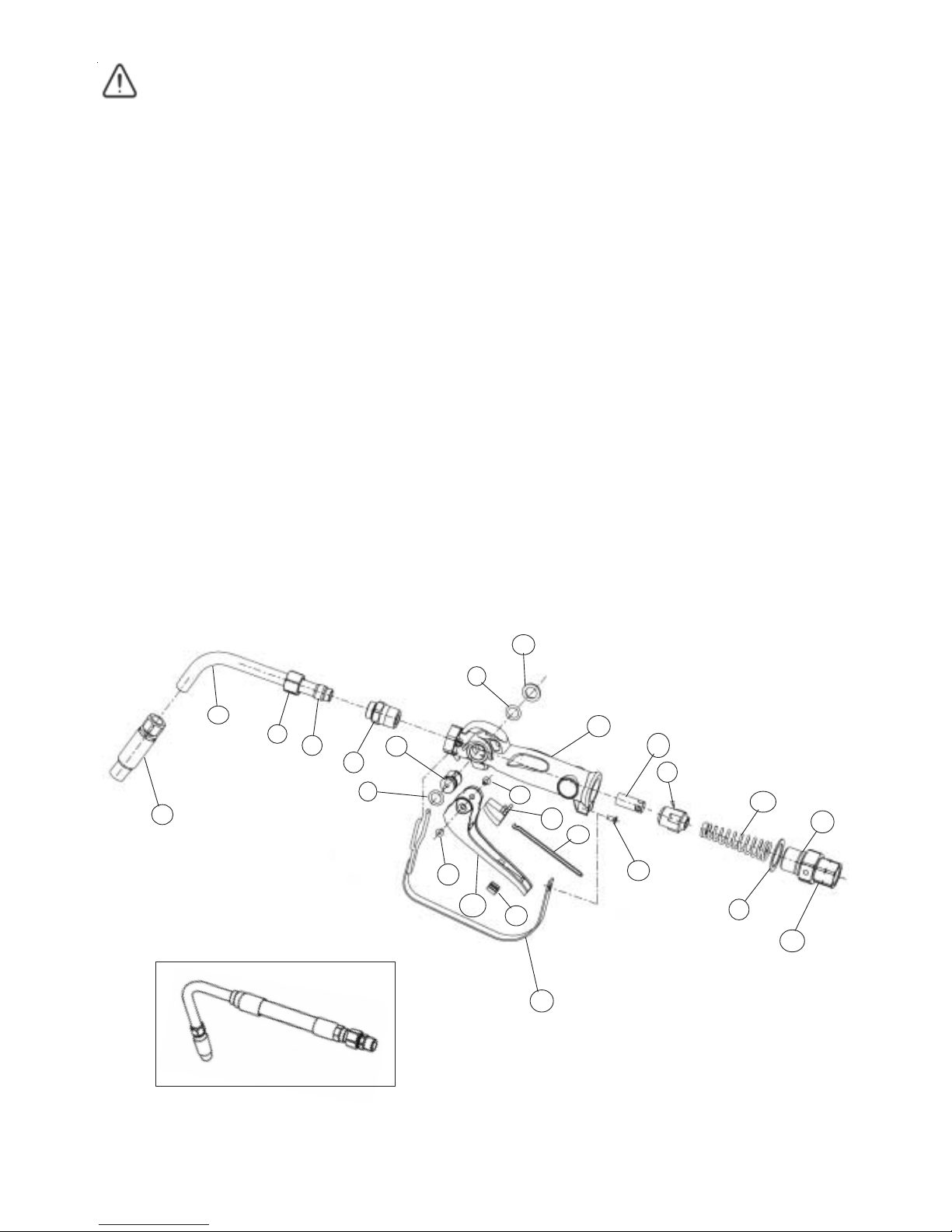

CONTROL HANDLE DISASSEMBLY

Use a clean bench to carry out maintenance.

A) Remove the oil hose from the control gun inlet swivel

(21).

B) Unscrew and remove swivel (21) washer (19) and o’ring

(20) from the control gun inlet. (Clean or replace the

swivel strainer and o’ring if required).

Caution the swivel is under spring tension

D) Remove the screw (23), then unclip and remove the

trigger guard (22).

C) Remove valve spring (18), seal/valve body assembly (17).

and plunger (15).

LEVER and VALVE REMOVAL

A) Using a 2.5mm allen key, remove the 2 handle screws

(10).

B) Remove lever (11), ease downwards.

C) Remove the washer (7), “O”Ring (8), then push the valve

cam (9) from the gun body (6), and remove “O”Ring (8).

CONTROL HANDLE REASSEMBLY

A) Clean and inspect all parts. Replace any suspect, worn or

damaged components.

Note: Lightly lubricate the valve cam before assembly.

B) Place “O”Ring (8) onto valve cam (9).

Note: The cutout section in the middle of the valve cam (9)

must face the inlet swivel (21).

C) Replace the valve cam (9) into the body (6). Note the

orientation shown on the assembly drawing. Fit the

second “O”Ring (8) and washer (7).

D) Slide lever assembly (11) into position and replace the two

allen screws (10). (Use Loctite or similar sealant).

E) Replace plunger (15).

Note: The end hole in the plunger must face the gun outlet.

F) Replace the seal/valve body assembly (17), and spring

(18) and replace into the gun body (6).

Note: Install the spring, small end first.

H) Replace washer (19), o’ring (20) on to the swivel assembly

(21), and screw firmly into place (Use Loctite or similar

sealant).

Note: After assembly ensure the handle latch is operating

correctly.

2

G) Re-fit the trigger guard (22) and replace screw (23).

P ARTS DIAGRAM

HGFNZ

1

2

3

4

5

6

7

8

9

10

11

8

10

12

13

14

15

18

19

20

21

22

23

Note: If the plunger has not been removed the cam will not

release from the body.

17

3

SPARE PARTS LIST

** Order HGFEX for Flexible Extension

TROUBLE SHOOTING GUIDE

TROUBLE CAUSE REMEDY

No fluid passing through the g un Block ed strainer Clean or replace str ainer

Constant oil leak from the nozzle Damaged plunger seal Replace plunger seal ( chec k for damage )

Intermittent dr ip f r om t he nozzle Dirt in the noz zle (50) Remove t he nozzle and blow out any dirt par ticles,

replace if nec essary .

Oil leak from the lever assembly ar ea

Damaged o’rings (19) Replace damaged o’rings

Low flow r ate Block ed strainer ( 37) Replace strainer

Oil leak ing f r om the swiv el inlet Damaged o’ring or swive l Replace damaged o’ring or swiv el

ORDER FOR REPLACEMENT

ITEM PART NO. NO OFF PART/SET No KIT. REF DESCRIPTION

HG20- 1 K (Kit A) Se a l Kit

1 HG570 1 HG570s Automatic Nozzle

2 HG510 1 Ridgid Tube

3 N429 1 HG505 s Compres sion Fitting

4N428 1 Olive

5 HG512 1 1/2" NPT Outlet Adaptor

6 HG265 1 HG265s Body Casting

7 HG036 1 A Washer

8BS111 2 A O'Ring

9HG030 1 A Camshaft

10 N55 2 A C'sk Sc rew

11 HG266 1 HG010As Handle (Latching)

11 HG269 1 HG012As Handle (Non-Latc hing)

12 HG025 1 Lever Plug

13 HG024 1 HG022s Button Spring

14 HG022 1 Lever Button

15 HG032 1 Plunger Cage

17 HG038 1 HG032s Valve body and Seal assy

18 HG033 1 A Spring

19 HG045 1 A Was her

20 BS117 1 A O'Ring

21 HG040A 1 HG040As incl HG045 / BS117 Swivel Assembly (BSP)

21 HG043A 1 HG043As incl HG045 / BS117 Swivel Assembly (NPT)

22 HG268A 1 HG268s Guard A ssembly

23 N46 1 C'sk Screw

24 TD81 1 A Filter Mesh

25 BS113 1 A Filter O'Ring

4

SPECIFICATIONS:

Flow Range: 1-25 l/min ( 0.26 – 6.6 US gal/min)

Maximum Pressure: 69 BAR / 6900 kPa / 1000 PSI

Weight:

Swivel Inlet: 1/2” BSPT or 1/2” NPT

Outlet: 1/2” NPT

Wetted Parts: Aluminium, Mild Steel, Nitrile Rubber

Fluid Compatibility:

Engine Oil, Diesel Oil, AutomaticTransmission Fluid,

Mixture. (Maximum Viscocity SAE140)

0.8 kg

Macnaught Pty Ltd

PO Box 90 Arncliffe NSW 2205 Australia

T elephone (02) 9567 0401

Facsimile (02) 9597 7773

Email: sales@macnaught.com.au

Web: www.macnaught.com.au

Macnaught Pty Ltd (“Macnaught”) warrants that all Products manufactured by Macnaught and

purchased after 1st of July 1999 will be free from any defects caused by faulty materials or

workmanship for a period of (5) years from the date of purchase of the product, provided that

during the Warranty period:

1) Macnaught receives notice setting out full details of any defect in any product and

details of the time and place of purchase.

2) The Purchaser, at their own cost returns the product to the nearest authorized Macnaught

service center.

For componentry contained in the product, (such as o’rings, seals, springs and hoses ) which

are subject to wear, the warranty period will be (12) months from the date of purchase of the

product.

Macnaught shall, at its option repair or replace any product found defective by its inspection.

This warranty does not cover failure of parts or components which, in the judgment of Macnaught,

arises from misuse, abrasion corrosion, negligence, accident, substitution of non-Macnaught

parts, faulty installation or tampering.

If Macnaught inspection discloses no defect in material or workmanship, repair or replacement

and return will be made at customary charges.

Macnaught’s liability and the purchaser’s rights under this Warranty shall be limited to such

repair or replacement and in particular, shall not extend to any direct, special, indirect or

consequential damage or losses of any nature.

The foregoing warranty supersedes, voids and is in lieu of all or any other warranties.

“Note: This warranty does not form part of, nor does it constitute, a contract between Macnaught

and the end-user or purchaser. It is additional to any warranty given by the seller of the products.

This warranty does not exclude, limit, restrict or modify the non-excludable rights or remedies

conferred upon the end-user or purchaser, or the non-excludable duties or liabilities imposed

on the seller or Macnaught, by Part V, Divisions 2 and 2A of the Trade Practices act 1974

(Commonwealth) or other legislative provisions. Macnaught otherwise excludes, to the extent

permitted by law, any rights conferred on the end-user or duties or liabilities imposed upon it.”

WARRANTY POLICY

Loading...

Loading...