Page 1

Page 1 of 14

INSTRUCTION MANUAL

To the Owner

OVAL GEAR FLOWMETER

MECHANICAL MODEL 050 (2”)

PLEASE READ THIS SAFTEY INFORMATION

CAREFULLY BEFORE USE.

Read and retain this instruction manual to assist you

in the operation and maintenance of this product.

If you have any problems with the meter, refer to the

maintenance and trouble shooting sections of this

manual.

This manual contains connection and operating

instructions for meters with Mechanical Displays

If you need further assistance, contact your local

representative or distributor for advice.

This Flow Meter has incorporated the oval rotor

principal into its design. This has proven to be a

reliable and highly accurate method of measuring

flow.

Exceptional repeatability and high accuracy over a

wide range of fluid viscosities and flow rates are

features of the oval rotor design. With a low pressure

drop and high pressure rating oval rotor flow meters

are suitable for both gravity and pump (in line)

applications.

050 Mech

07.11

Page 2

Page 2 of 14

CAUTION

Important Information

Operating Principle

Installation Procedure

WARNING

Before use, confirm the fluid to be used is

compatible with the meter. Refer to Industry

fluid compatibility charts or consult your local

representative for advice.

To prevent damage from dirt or foreign matter it is

recommended that a Y or Basket type 60 mesh

strainer be installed as close as possible to the

inlet side of the meter. Contact your local

representative for advice.

When a strainer is installed it should be

regularly inspected and cleaned. Failure to

keep the strainer clean will dramatically effect

flow meter performance.

To prevent damage caused by air purge slowly

fill the meter with fluid. To reduce pressure build

up turn off the pump at the end of each day.

Maintenance can be carried out to the liquid crystal

displays and pulse units without removing or

isolating the meter from the line. When

maintenance to any other part of the meter is

required, the meter must be isolated and the line

pressure reduced.

The reed switch pulse unit can cause inaccurate

rate counts when used with high speed counters. It is

advised that a debounce circuit be used. Contact

CAUTION

CAUTION

When fluid passes through the meter the rotors

turn, as shown below. The magnets which are

located in the rotors will pass across the pulser

circuit board (containing either Reed switches or Hall

Effect sensors). A signal is generated which is then

sent by the Pulse Circuit Board (PCB) to the relevant

LC display or receiving instrument..

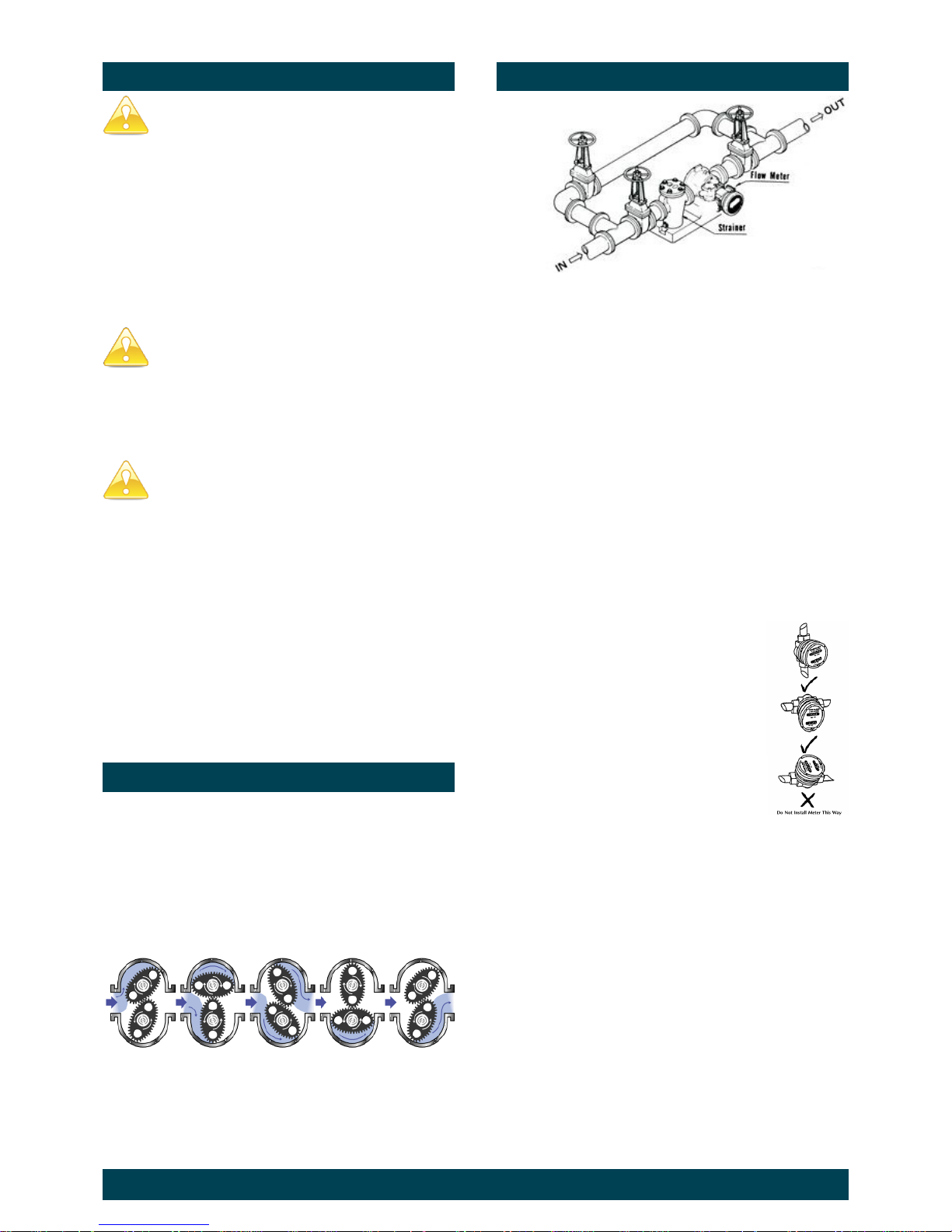

1) It is recommended that when setting up pipe work

for meter installations a bypass line be included in

the design. This provides the facility for a meter to

be removed for maintenance without interrupting

production. (see figure above)

2) Use thread sealant on all pipe threads.

3) For pump applications ensure pipe work has

the appropriate working pressure rating to match

the pressure output of the pump. See Meter

Specifications section for further details.

4) Install a wire mesh strainer, Y or basket type

60 mesh (250 micron), as close as possible to

the inlet side of the meter.

5) Ensure that the meter is installed so that the

flow of the liquid is in the direction of the

arrows embossed on the meter body.

6) The meter can be installed in any

orientation as long as the meter

shafts are in a horizontal plane.

(Refer to figures to the right for

correct installation) The register

assembly may be orientated to suit

the individual.

Note: Incorrect installation can

cause premature wear of meter

components.

7) Do not over tighten meter connections. Note:

Incorrect installation can cause premature wear

of meter components.

8) It is important that after initial installation you

fill the line slowly, high speed air purge could

cause damage to the rotors.

9) Test the system for leaks.

10) Check the strainer for swarf or foreign material,

after the first 200 litres check periodically,

particularly if the flow rate decreases.

Page 3

Page 3 of 14

Maintenance Procedures

Disassembly - Flow Meter

Ensure that the fluid supply to the meter is

disconnected, and the line pressure is released

before disassembly.

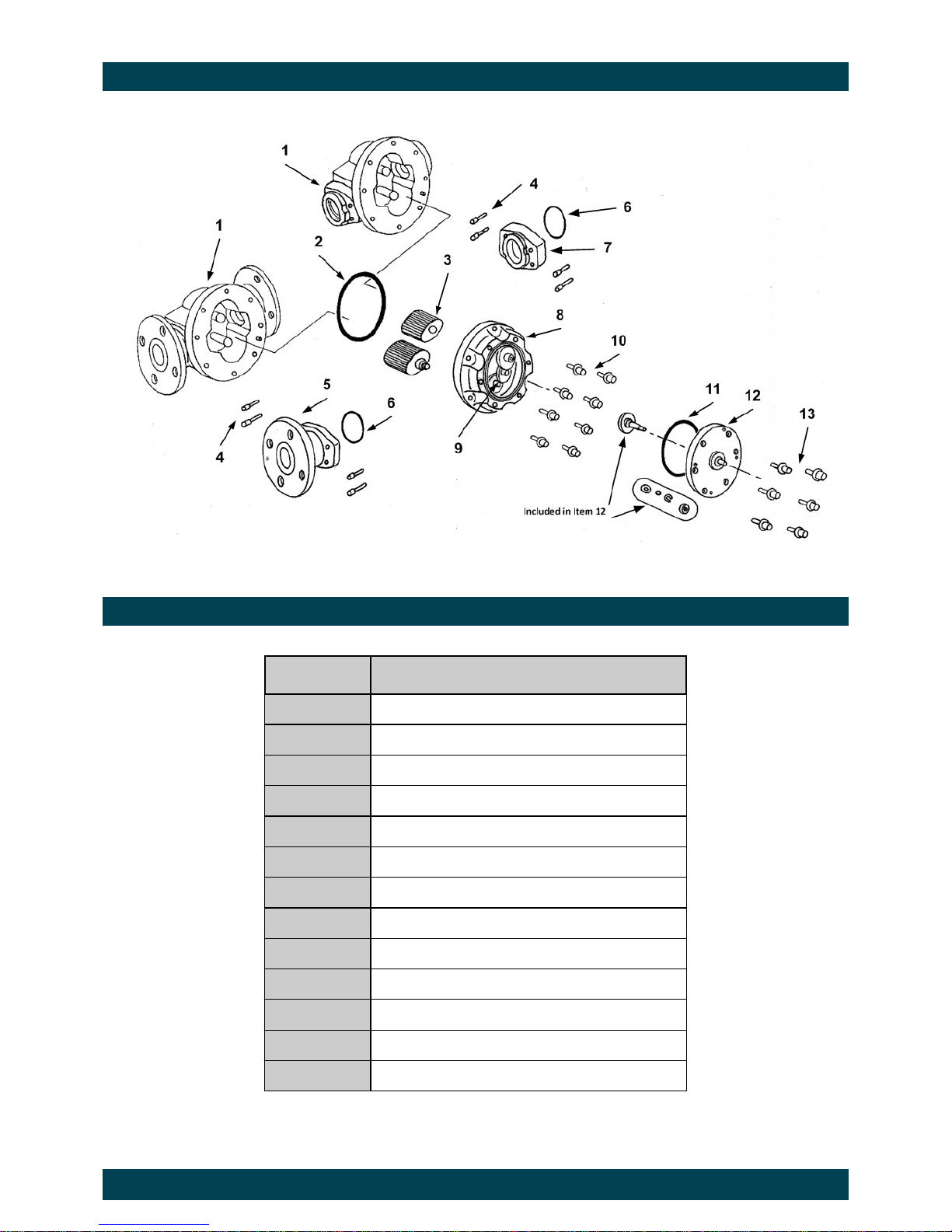

Refer to the exploded parts diagram and parts list,

for item numbers.

1) Remove the four screws located on the face of the

register. Then remove the face plate cover

including register assembly.

2) Remove the four register mounting screws and

remove the lower half of the register housing.

3) Remove the six cover plate screws (Item 12) and

remove the cover plate (Item 11).

4) Remove the six meter cap screws (Item 5) and

remove the meter cap (Item 4).

5) Remove rotors (Item 3).

Reassembly - Flow Meter

1) Before reassembling check the condition of

the rotors (replace if necessary).

2) Check that the smooth side of the rotors (not

the plug side) is facing you when inserting

the rotors, the smooth side of the rotor is the

magnet side. There is no difference between rotor

one or rotor two.

3) Replace the rotors (Item 3) onto the shafts at 90

degrees to each other (refer Fig) and check

their operation by turning either of the rotors.

If the rotors are not in mesh correctly or do

not move freely, remove one of the rotors

and replace correctly at 90 degrees to the other

rotor.

4) Re-check the operation of the rotors

5) Inspect the gears (Item 6) in the meter cap (Item

4) for wear. (Replace if required, refer to parts on

page 4)

6) Replace the o’ring (Item 2) into groove In the

meter cap, if the o’ring has grown or is damaged

in any way replace it with a new part.

7) Replace the meter cap making sure that the gear

on the rotor is meshing correctly with the gear in

the meter cap (Item 4). Insert the cap head

screws (Item 5) and tighten in a diagonal

sequence 1, 4, 2, 5, 3, 6.

8) Replace the cover plate inspect the o-ring

(item 10), bevel gear (Item 7), for wear or

damage. (Replace if necessary).

Page 4

Page 4 of 14

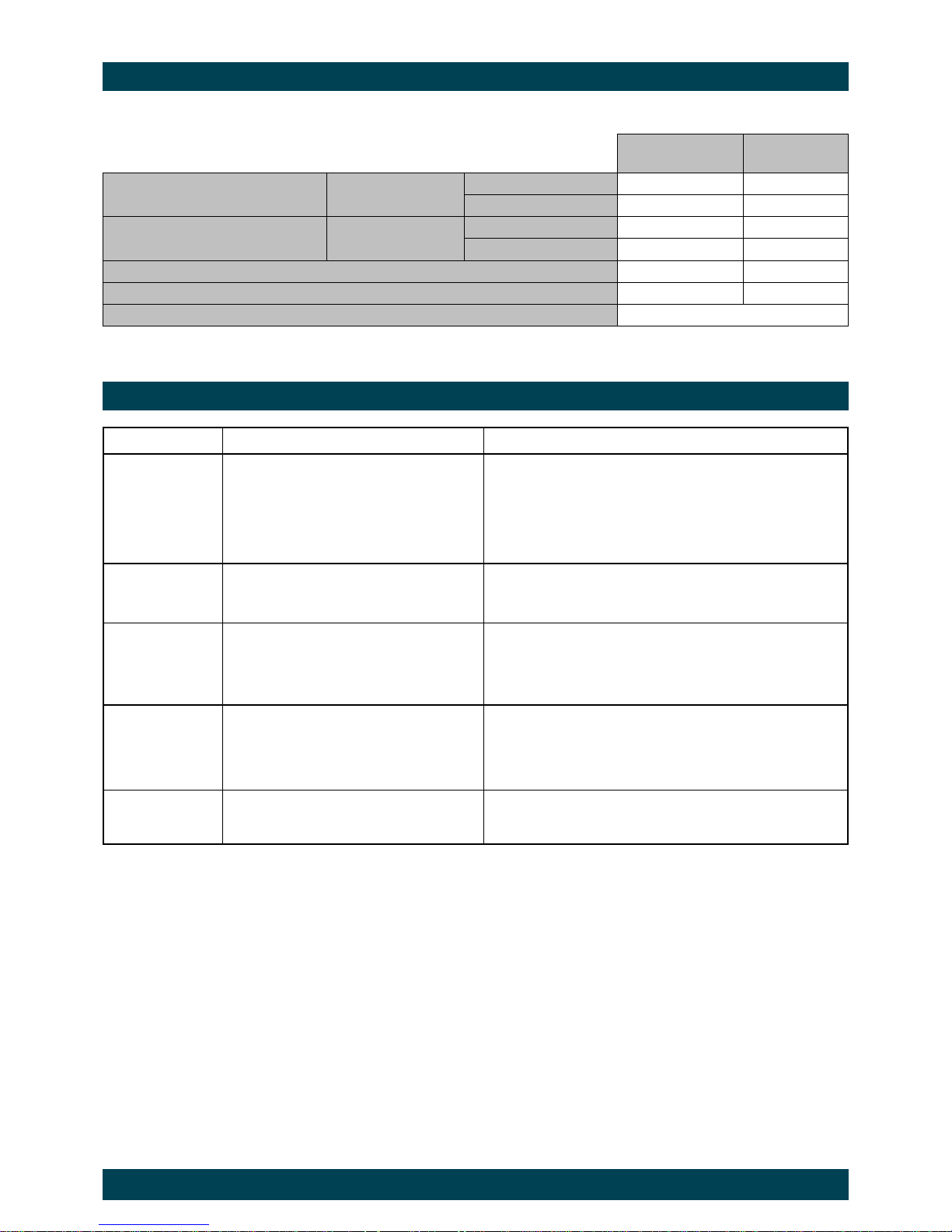

Product Specifications

Problem Cause Remedy

Fluid will not flow

through meter

a) Foreign matter blocking rotors

b) Line strainer blocked

c) Damaged rotors

d) Meter connections over tightened

e) Fluid is too viscous

a) Dismantle meter, clean rotors (strainer must be fitted in

line)

b) Clean strainer

c) Replace rotors (Strainer must be fitted in line)

d) Re-adjust connections

e) See specifications for maximum viscosity

Reduced flow

through meter

a) Strainer is partially blocked

b) Fluid is too viscous

a) Clean strainer

b) See specifications for maximum viscosity

Meter reading

inaccurate

a) Fluid flow rate is too high or too low

b) Fluid is too viscous

c) Excess wear caused by incorrect

installation

a) See specifications for minimum and maximum flow rates

b) Bleed air from system

c) Check meter body and rotors. Replace as required. Refer

to installation instructions

Fluid flows but no

reading on meter

a) Bevel gear is loose on shaft

b) Rotor drive gear is damaged

c) Transmission gears damaged

d) Register gears damaged

a) Tighten grub screws

b) Replace rotor

c) Replace gears

d) Replace register assembly

Fluid leaks into

register

a) Seal worn or damaged on the cover

plate

a) Replace seal (Check seal compatibility with fluid)

Troubleshooting Guide

Flowmeter Mech

Metric US

‘F’ and ‘M’ Meters

Flow Range

Below 5 cP 15 to 500 L/min 4 to 130 G/min

5 to 1000 cP 15 to 500 L/min 4 to 130 G/min

‘S’ Meters

Flow Range

Below 5 cP 30 to 300 L/min 8 to 80 G/min

5 to 1000 cP 15 to 350 L/min 4 to 93 G/min

Maximum Operating Temperature (Standard / High Temperature) 80°C / 120°C 176°F / 248°F

Maximum Operating Pressure

1

3400 kPa 500 psi

Accuracy of Reading ±0.5%

1. Conforms to Directive 97/23/EC—Cat 1

Page 5

Page 5 of 14

Exploded Diagram

Parts Identification

Item No. Part Description

1

Meter Body

2

Meter Cap 0-Ring

3

Rotor Set

4

Adaptor Bolts

5

Flanged Process Connection

6

Adaptor O-Rings

7

Threaded Process Connection

8

Meter Cap

9

Gear Set

10

Meter Cap Screws

11

Cover Plate O-Ring

12

Cover Plate and Gear Set

13

Cover Plate Screws

Page 6

Page 6 of 14

Spare Parts Kits

Output Gear - (GKit)

There are 4 Spare Kit options available for the purchase of replacement components:

Output Gear Kit (GKit) - Replacement Drive Gear Set to Mechanical Register.

Flange Kit (FSKit) - O-Ring set for Flanges

Rotor Kit (RKit) - Complete Rotor assembly

Seal Kit (SKit) - Complete set of O-Rings/Gaskets

Spare Kit Coding Procedure.

1. Determine what type of Spare Parts Kit is required (e.g. Rotor Kit)

2. Use the ‘Coding Sequence’ to construct a part number according to the meter type.

Flange Seal Kit - (FSKit)

FSKit — Type Size

F 050 — 1 S 4

Customer Model Number

Order Code Components Qty Items

e.g FSKit – F050

O-Rings 2 6

Kit Components

Coding Sequence

GKit — Type Size — 4 1

F 050 — 1 S 4

Customer Model Number

Order Number Components Qty Items

e.g GKit – F050 – 14

O-Rings 1 11

Complete Gear Set 1 set 9

Cover Plate 1 12

Cover Plate Screws 1 set 13

Kit Components

Coding Sequence

Page 7

Page 7 of 14

SKit — Type Size —

1/2 = P

3/4/5 = M

F 050 — 1 S 4

Customer Model Number

Seal Kit - (SKit)

Rotor Kit - (RKit)

Customer Model Number

Order Number Components Qty Items

Cover Plate O-Ring 1

e.g SKit – F050 – M

11

Meter Body O-Ring 1 2

Order Number Components Qty Items

Complete Rotor Assembly 1 set

e.g RKit – F050 – SM

3

Meter Body O-Rings 1 2

RKit — Type Size

Rotor

Type

1/2 = P

3/4/5 = M

—

F 050 — 1 S 4

Kit Components

Kit Components

Coding Sequence

Coding Sequence

Page 8

Page 8 of 14

Wetted Parts

K - FEP/PTFE Encapsulated

Br - Brass

SS - Stainless Steel 316 /304

Al - Aluminium AA610

CA - Carbon

FKM - Viton ®

PPS - Polyphenylene Sulphide

PVDF - Polyvinylidene Flouride

POM - Acetal

PTFE - Polytetrafluoroethylene

FFKM - Perfluoro Elastomer

Component Type 'F' Type 'S' Type 'M'

Meter Body

Al Al SS

Rotor Shaft

SS SS SS

Rotors - Standard

PPS SS PPS

- High Temp.

- - SS

- High Viscosity.

PPS SS SS

Rotor Bushes

- CA CA

Meter Cap

Al Al SS

Gear Assembly

SS/POM SS/POM SS/POM

Cover Plate

SS SS SS

Output Gear and Shaft assy.

SS/FFKM/POM SS/FFKM/POM SS/FFKM/POM

O Rings

FKM K K

Page 9

Page 9 of 14

Pressure Drop v’s Viscosity

100%

50%

25%

10%

5%

100%

50%

Page 10

Page 10 of 14

Meter Dimensions

Page 11

Page 11 of 14

Air Eliminator / Strainer Combination

2” Flange

2” Threaded Connection

Page 12

Page 12 of 14

Notes

Page 13

Page 13 of 14

Warranty

macnaught warranty

Macnaught Pty Ltd (“Macnaught”) warrants that all products manufactured by Macnaught and/or supplied by

Macnaught under the “Macnaught” brand, excluding Macnaught Flow Measurement products, components

subject to wear and electronic or electrical components, will be free from any defects caused by faulty

materials or workmanship (“Warranty”) for a period of 5 years from the date of purchase of the product.

For products (excluding Macnaught Flow Measurement products) which carry the “Macnaughtdesign” endorsement, an

additional Warranty period of 5 years applies to all mechanical components, giving a total Warranty period of 10 years

for mechanical components.

For Macnaught Flow Measurement products, the Warranty period is 2 years from the date of purchase of that

product.

For components contained in all products which are usually subject to wear from normal operation of the

products (such as o-rings, seals, bushes, springs (excluding Retracta coil spring), hoses and rechargeable

batteries), the Warranty period is 12 months from the date of purchase of the relevant product.

For any electronic or electrical component which may be contained in a product, the warranty period is 2 years

from the date of purchase of the relevant product.

For products and components which are not manufactured by Macnaught and are supplied by Macnaught under a

brand name other than “Macnaught”, the Warranty period is the longer of 12 months from the date of

purchase of the relevant product and the period of the manufacturer’s warranty.

The warranties contained in clauses 1, 2, 3, 4, 5 and 6 above are conditional on the purchaser, during the

relevant Warranty period:

delivering to Macnaught a detailed notice setting out full details of any defect in any product and

details of the date and place of purchase (together with copies of purchase receipts and/or other

supporting documents); and

at the purchaser’s own cost, returning the defective product to the nearest authorised Macnaught

service centre.

Subject to compliance by the purchaser with clause 6, Macnaught shall, at its option, repair or replace any product or

component found defective by its inspection by reason of faulty materials or workmanship of Macnaught.

This Warranty does not cover the failure of products, parts or components which, in the sole judgment of Macnaught, arises

other than from faulty materials or workmanship of Macnaught, including misuse, abrasion, corrosion, negligence,

accident, substitution of non-Macnaught parts, unauthorised modification, improper use, storage or handling, faulty

installation or tampering by the purchaser or any third party.

If Macnaught’s inspection discloses no defect in material or workmanship, repair or replacement and return (at

Macnaught’s sole option) will be made at customary charges, which will be advised to the purchaser.

Macnaught’s liability and the purchaser’s rights under this Warranty shall be limited to the repair or replacement of defecti ve

products or components and in particular, shall not extend to any direct, special, indirect or consequential damage or

losses of any nature.

The foregoing Warranty supersedes, voids and is in lieu of all or any other warranties.

This Warranty does not form part of, nor does it constitute, a contract between Macnaught and the end-user or purchaser. It is

additional to any warranty given by the seller of the products. This Warranty does not exclude, limit, restrict or modify the

non-excludable rights or remedies conferred upon the end-user or purchaser, or the non-excludable duties or liabilities

imposed on the seller or Macnaught, by Part V, Divisions 2, 2A and Part VA of the Trade Practices Act 1974

(Commonwealth) or other legislative provisions. Macnaught otherwise excludes, to the extent permitted by law, any rights

conferred on the end-user or purchaser or duties or liabilities imposed upon Macnaught.

Page 14

Page 14 of 14

Loading...

Loading...