Mac Medical SWC243024, SWC243036, SWC242436, SWC182464, SWC242464 Installation Operation & Maintenance

...

INSTRUCTION MANUAL

Installation - Operation - Maintenance

MAN-001 Rev J

D-Series Warming Cabinets

OSHPD

R

C

Read and understand all of the instructions and safety

information in this manual before operating this product.

© 2018 MAC Medical, Inc.

Pre-Approved

10/2018

Instruction Manual

TAble Of COnTenTS

Summary 3

D-Series Warming Cabinet Models

Interior Dimensions, Cubic Foot Capacity, Approximate Capacity

General Specications

Main Features of a Typical Warming Cabinet

Warnings and Cautions

Unpacking Instructions

Receiving Requirements

Installing D-Series Warming Cabinets

Environmental Conditions

Installation

Testing before Using

Installing Warming Cabinet Leg Levelers

Optional Direct Wiring Using Facility Power Supply

Basic Operation

Recommended Settings

Loading Contents in Cabinet

In Case of Power Failure

Explanation of the Controls

Operation of Display Panel

Installing the Shelves

Adjusting the Shelves

Installing and Adjusting Optional Roller Basket Shelves

Unloading the Warming Cabinet

Retrieval of Recorded Temperatures

Turning Off the Warming Cabinet

Troubleshooting

Overheat Alarm (HI) Condition

Cleaning Stainless Steel Warming Cabinets

Preventative Maintenance Checklist

Replacement Parts - General

Replacement Parts - Header Assembly and Electrical Drawer

Optional Cabinet Bases, Mobile Bases and Mobile Stands

Steel or Glass Door Hinge Reversal

Remove Panels

Remove Header Assembly Box & Relocate Cam Lock

Purchase Parts Needed for Cam Lock Reversal

Glass Door Hinge Reversal and Re-installation

Steel Door Hinge Reversal and Re-installation

Purchase Parts Needed for Door Hinge Reversal

Wiring Diagram - Single Chamber Warmers

Wiring Diagram - Dual Chamber Warmers

Wiring Diagram - Triple Chamber Warmers

Index

41

Limited Lifetime Warranty

7

9

11

11

12

12

15

18

18

21

28

44

4

5

8

12

12

13

14

15

15

15

16

17

19

20

20

20

21

22

23

24

25

27

28

29

29

32

35

35

38

39

40

MAN-001

2

www.macmedical.com

Summary

Instruction Manual

DeSCRIPTIOn Of PRODUCT

This manual covers the D-Series (Data

Logging) blanket and uid warming cabinets,

manufactured for commercial use only. These

include the single, dual and triple chamber units.

PURPOSe Of THIS MAnUAl

This manual is to provide the user instructions in

the installation, operation and maintenance of

the D-Series warming cabinets.

This manual also contains general

specications, warnings and cautions.

Indications for Use:

The MAC Medical Inc. Blanket and Solution Warming Cabinets are designed to store and warm blankets,

hospital linens, irrigation uids, and/or injection uids in accordance with recommended warming

temperatures and storage time guidelines provided by the manufacturers of such products.

MAN-001

3

www.macmedical.com

Instruction Manual

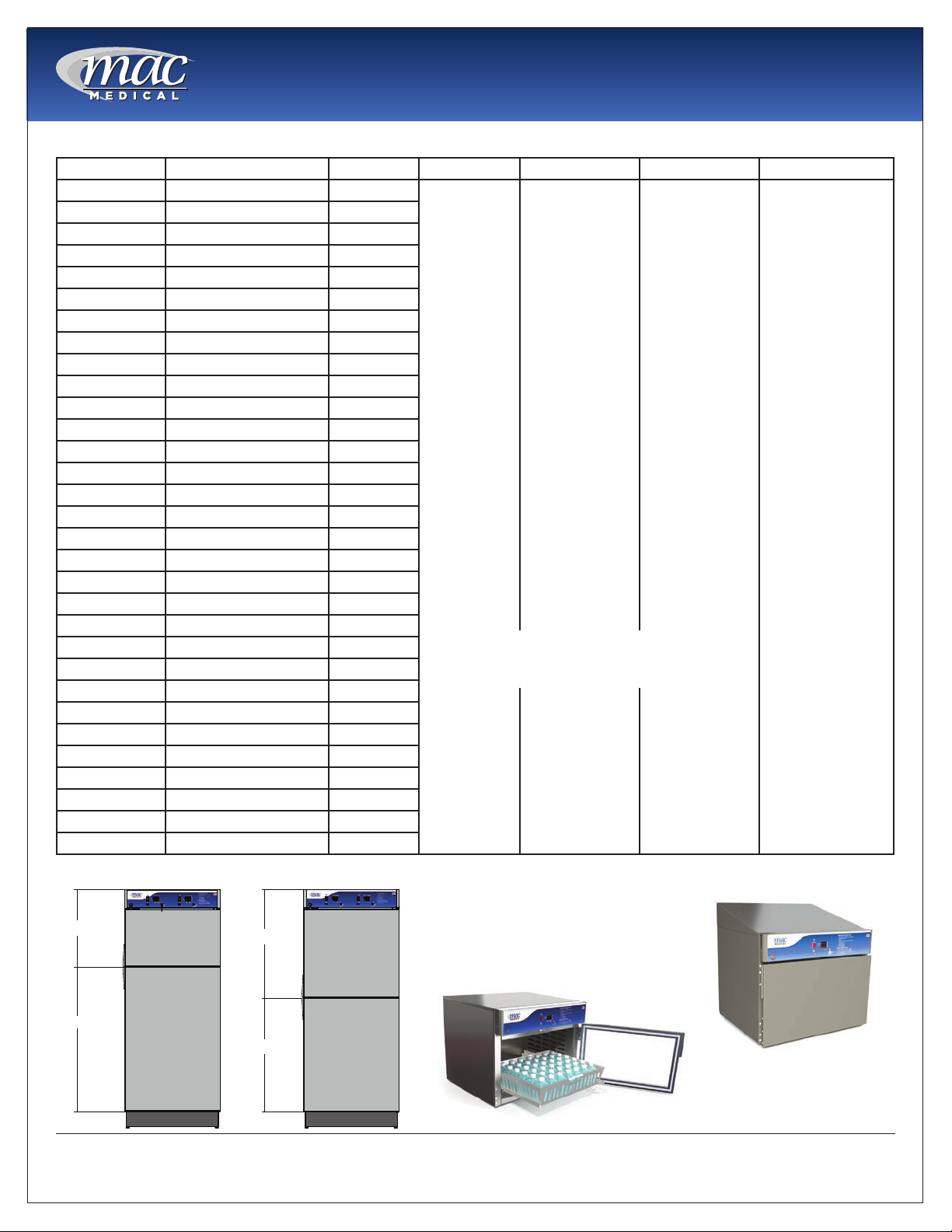

D-Series Warming Cabinet Models

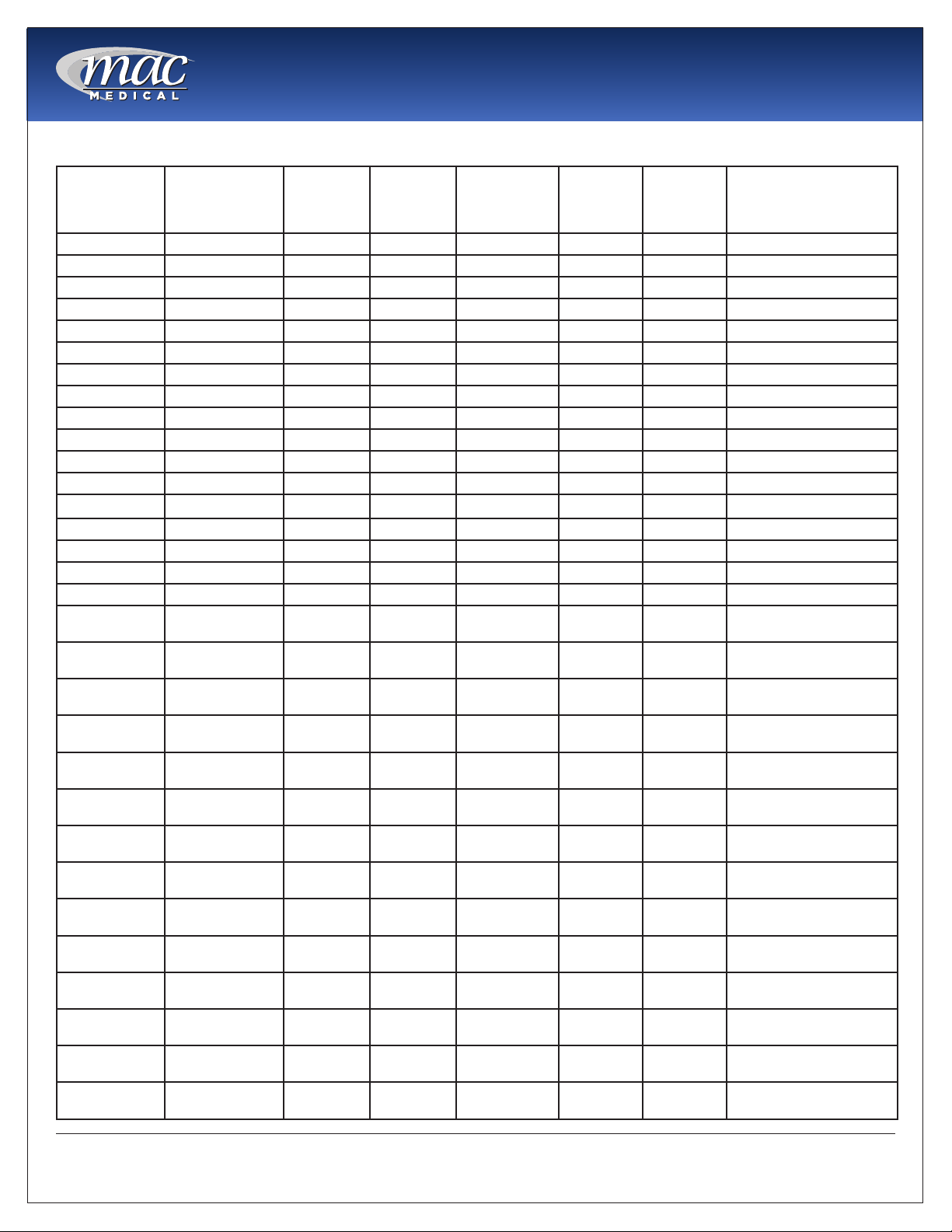

Model # Overall Size Chambers Door Type Door Hinge base Style Other Options

SWC151822 17.25"D x 18"W x 22"H Single G=Glass Door

SWC182424 20.5"D x 24"W x 24.5"H Single

SWC242424 26.5”D x 24”W x 24.5”H Single

SWC183024 20.5"D x 30"W x 24.5"H Single

SWC243024 26.5"D x 30"W x 24.5"H Single

SWC182436 20.5”D x 24”W x 36”H Single

SWC183036 20.5"D x 30"W x 36"H Single

SWC242436 26.5”D x 24”W x 36”H Single

SWC243036 26.5"D x 30"W x 36"H Single

SWC182464 20.5"D x 24"W x 64.75"H Single

SWC242464 26.5"D x 24"W x 64.75"H Single

SWC183064 20.5"D x 30"W x 64.75"H Single

SWC243064 26.5"D x 30"W x 64.75"H Single

SWC182474 20.5”D x 24”W x 74.5”H Single

SWC183074 20.5"D x 30"W x 74.5"H Single

SWC242474 26.5”D x 24”W x 74.5”H Single

SWC243074 26.5"D x 30"W x 74.5"H Single

DWC182464T* 20.5"D x 24"W x 64.75"H Dual

DWC242464T* 26.5"D x 24"W x 64.75"H Dual

DWC183064T* 20.5"D x 30"W x 64.75"H Dual

DWC243064T* 26.5"D x 30"W x 64.75"H Dual

DWC182474T* 20.5"D x 24"W x 74.5"H Dual

DWC242474T* 26.5"D x 24"W x 74.5"H Dual

DWC183074T* 20.5"D x 30"W x 74.5"H Dual

DWC243074T* 26.5"D x 30"W x 74.5"H Dual

DWC182474E** 20.5”D x 24”W x 74.5”H Dual

DWC183074E** 20.5"D x 30"W x 74.5"H Dual

DWC242474E** 26.5”D x 24”W x 74.5”H Dual

DWC243074E** 26.5"D x 30"W x 74.5"H Dual

TWC183078 20.5"D x 30"W x 78.75"H Triple

TWC243078 26.5"D x 30"W x 78.75"H Triple

Blank=Stainless

Steel Door

(Standard)

ţ Only available for Triple Chamber Unit

ţţ Only available for Dual and Triple Chamber Units

LH=Left Hinge

Blank = Right

Hinge (Standard)

2B = 2” Base

4B = 4” Base

6B = 6” Base

NB = No Base

MB = Mobile Base

220 = 220/240V

Power Supply

C = Celsius

R1 = Recessed

Unit with Insulation

Wrap, no Top Panel,

no Side Panels and

no Trim Kit.

R2 = Recessed Unit

with Top Panel, Side

Panels, and Trim Kit.

SB = Seismic Braces

WB = Roll Out

Basket

P = Pass Through

Chamber

IV = IV/Injection

Fluids

ST = Sloped Top

EL = Electronic

Keypad lock

ţ DL = Intermediate

Chamber Door Lock

(triple chamber

units)

ţţ LDL = Lower

Chamber Door

Lock (dual/triple

chamber units)

* = Chambers in Thirds ** = Equal Chambers

1/3

2/3

1/2

1/2

MAN-001

Sloped Top

Roll Out basket

4

www.macmedical.com

Interior Dimensions, Cubic foot Capacity, Approximate Capacity

Instruction Manual

Model # Upper or single

Chamber

(h x w x d) in

inches

SWC151822 14.0 x 14.0 x 11.63 n/a n/a/ 1.30 n/a n/a 5 - 6 blankets, 8 bottles

SWC182424 15.25 x 20.0 x 17.0 n/a n/a 3.0 n/a n/a 9 blankets, 8 bottles

SWC242424 15.25 x 20.0 x 23.0 n/a n/a 4.06 n/a n/a 9 blankets, 12 bottles

SWC183024 15.25 x 26.0 x 17.0 n/a n/a 3.9 n/a n/a 18 blankets, 8 bottles

SWC243024 15,25 x 26.0 x 23.0 n/a n/a 5.27 n/a n/a 18 blankets, 20 bottles

SWC242436 36.0 x 20.0 x 23.0 n/a n/a 6.7 n/a n/a 16 blankets, 25 bottles

SWC182436 25.0 x 20.0 x 17.0 n/a n/a 5.0 n/a n/a 16 blankets, 20 bottles

SWC183036 25.0 x 26.0 x17.0 n/a n/a 6.39 n/a n/a 32 blankets, 36 bottles

SWC243036 25.0 x 26.0 x 23.0 n/a n/a 8.65 n/a n/a 32 blankets, 40 bottles

SWC182464 49.5 x 20.0 x 17.0 n/a n/a 9.74 n/a n/a 32 blankets, 48 bottles

SWC242464 51.0 x 20.0 x 23.0 n/a n/a 13.60 n/a n/a 80 blankets, 120 bottles

SWC183064 51.0 x 26.0 x 17.0 n/a n/a 13.05 n/a n/a 66 blankets, 72 bottles

SWC243064 51.0 x 26.0 x 23.0 n/a n/a 17.65 n/a n/a 80 blankets, 120 bottles

SWC182474 61.0 x 20.0 x 17.0 n/a n/a 12.00 n/a n/a 32 blankets, 60 bottles

SWC183074 61.0 x 26.0 x 17.0 n/a n/a 15.60 n/a n/a 80 blankets, 72 bottles

SWC242474 61.0 x 20.0 x 23.0 n/a n/a 16.24 n/a n/a 80 blankets, 120 bottles

SWC243074 61.0 x 26.0 x 23.0 n/a n/a 21.1 n/a n/a 80 blankets, 120 bottles

DWC182464T* 13.5 x 20.0 x 17.0 n/a 24.5 x 20.0 x

DWC242464T* 13.5 x 20.0 x 23.0 n/a 24.5 x 20.0 x

DWC183064T* 13.5 x 26.0 x 17.0 n/a 24.5 x 26.0

DWC243064T* 13.5 x 26.0 x 23.0 n/a 24.5 x 26.0 x

DWC182474T* 15.25 x 20.0 x 17.0 n/a 34.5 x 20.0 x

DWC242474T* 15.25 x 20.0 x 23.0 n/a 34.5 x 20.0 x

DWC183074T* 15.25 x 26.0 x 17.0 n/a 34.5 x 26.0 x

DWC243074T* 15.25 x 26.0 x 23.0 n/a 34.5 x 26.0 x

DWC182474E** 25.0 x 20.0 x 17.0 n/a 26.0 x 20.0 x

DWC183074E** 25.0 x 26.0 x 17.0 n/a 26.0 x 26.0 x

DWC242474E** 25.0 x 20.0 x 23.0 n/a 26.0 x 20.0 x

DWC243074E** 25.0 x 26.0 x 23.0 n/a 26.0 x 26.0 x

TWC183078 11.25 x 26.0 x 17.0 10.75 x 26.0

TWC243078 11.25 x 26.0 x 23.0 10.75 x 26.0

Middle

Chamber

(h x w x d)

in inches

x 17.0

x 23.0

lower

Chamber

(h x w x d)

in inches

17.0

23.0

x17.0

23.0

17.0

23.0

17.0

23.0

17.0

17.0

23.0

23.0

18.5 x 26.0

x 17

18.5 x 26.0 x

23.0

Cubic foot

Capacity

Upper or single

Chamber

2.65 n/a 4.82 26 blankets, 36 bottles

3.59 n/a 6.52 52 blankets, 80 bottles

3.45 n/a 6.27 50 blankets, 54 bottles

4.67 n/a 8.48 52 blankets, 96 bottles

2.65 n/a 6.79 32 blankets, 48 bottles

4.06 n/a 9.18 52 blankets, 80 bottles

3.45 n/a 8.82 52 blankets, 72 bottles

5.28 n/a 11.93 52 blankets, 120 bottles

4.97 n/a 5.24 44 blankets, 48 bottles

6.39 n/a 6.65 64 blankets, 72 bottles

6.65 n/a 6.99 64 blankets, 80 bottles

8.65 n/a 8.99 64 blankets, 120 bottles

2.88 2.75 4.73 62 blankets, 54 bottles

3.89 3.72 6.4 62 blankets, 90 bottles

Cubic foot

Capacity

Middle

Chamber

Cubic foot

Capacity

lower

Chamber

Approximate

Capacity

(blankets or 1 liter

solution bottles)

MAN-001

5

www.macmedical.com

Instruction Manual

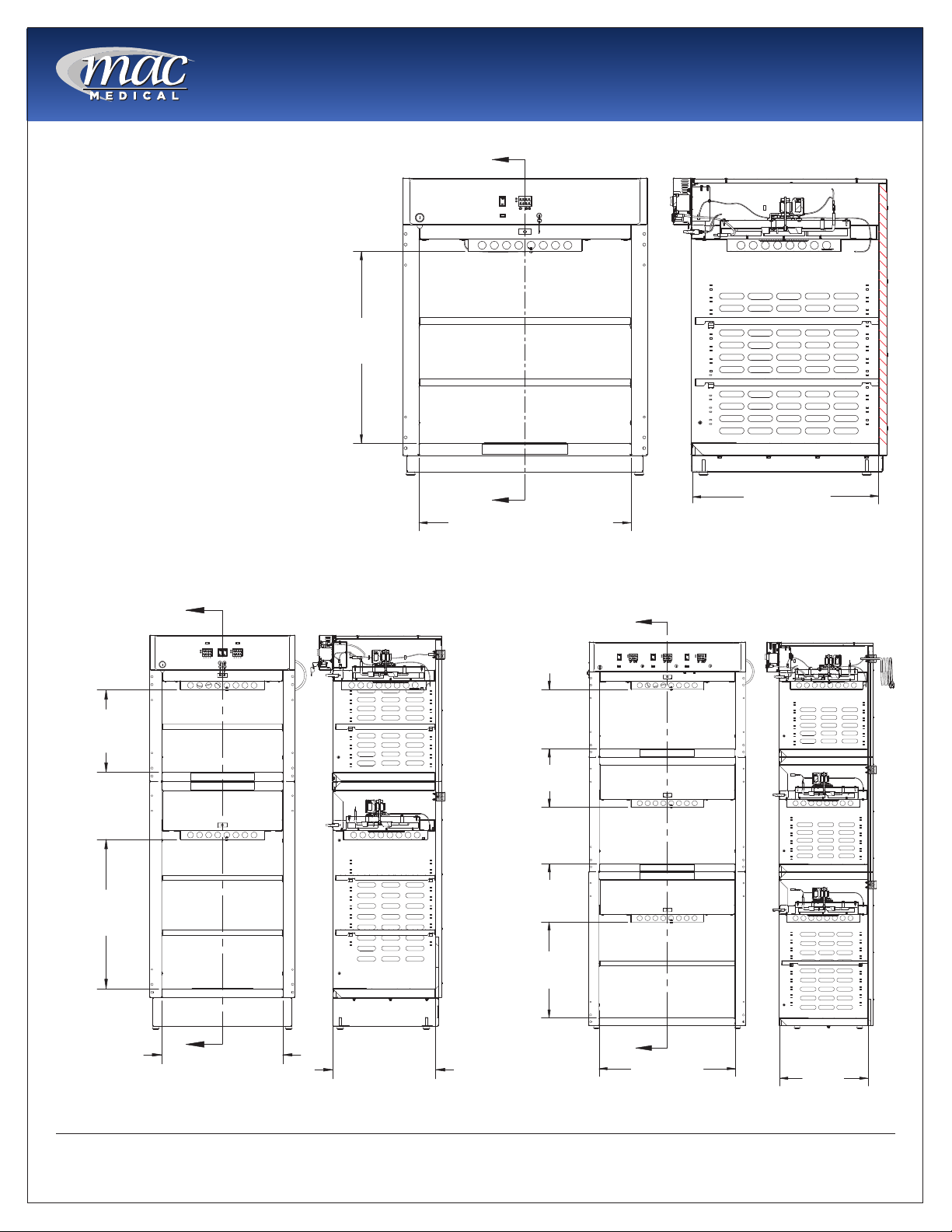

Usable Chamber Space

The usable chamber space of the

single, dual and triple cabinets

is slightly different from the

height, width, and depth interior

dimensions in the table on the

previous page.

Note that the usable chamber

inner height is measured from

the bottom of the air box to the

bottom of the chamber.

(In these views, the doors were

removed for clarity.)

USABLE

INNER HEIGHT

DIMENSION

A

A

CHAMBER WIDTH DIMENSION

Fig. 1: Single Chamber Unit Usable Space

CHAMBER DEPTH

DIMENSION

SECTION A-A

A

USEABLE

INNER HEIGHT

DIMENSION

USEABLE

INNER HEIGHT

DIMENSION

A

CHAMBER

WIDTH

DIMENSION.

Fig. 2: Dual Chamber Unit Usable Space

SECTION A-A

CHAMBER

DEPTH

DIMENSION.

A

USEABLE

INNER HEIGHT

DIMENSION

USEABLE

INNER HEIGHT

DIMENSION

USEABLE

INNER HEIGHT

DIMENSION

A

CHAMBER

WIDTH

DIMENSION

Fig. 3: Triple Chamber Unit Usable Space

SECTION A-A

CHAMBER

DEPTH

DIMENSION

MAN-001

6

www.macmedical.com

Instruction Manual

General Specications

Cabinet Construction and Material

• 300 Stainless Steel (all panels, header and doors) Double walled construction with insulation. Doors are

double pan stainless steel.

• Fully insulated to provide uniform heating

• Optional Glass door are double paned tempered glass framed with aluminum.

• Doors are fully gasketed and hinged on right side or optionally on the left side.

Factory Presets

• All units are preset to measure temperature in Fahrenheit (unless the unit was specically ordered to be

preset for Celsius.)

Power Requirements

• 120VAC, 60Hz, Single Phase, 15 AMP,

Ground Fault Interrupter Circuit (GFIC)

protected electrical outlet, or 220 VAC,

60Hz, Single Phase, 7 AMP, GFIC protected

electrical outlet (by others) installed

per local building codes and provides

protective grounding.

• Cabinets are supplied with a 7 foot (2.3m)

long, 14-3 SJT power cord with a 120V

(NEMA 15P) hospital grade plug. For multichambered units, ON/OFF switches are

supplied for each chamber.

• All individual electronic components are

Underwriter’s Laboratory (UL) approved

and recognized.

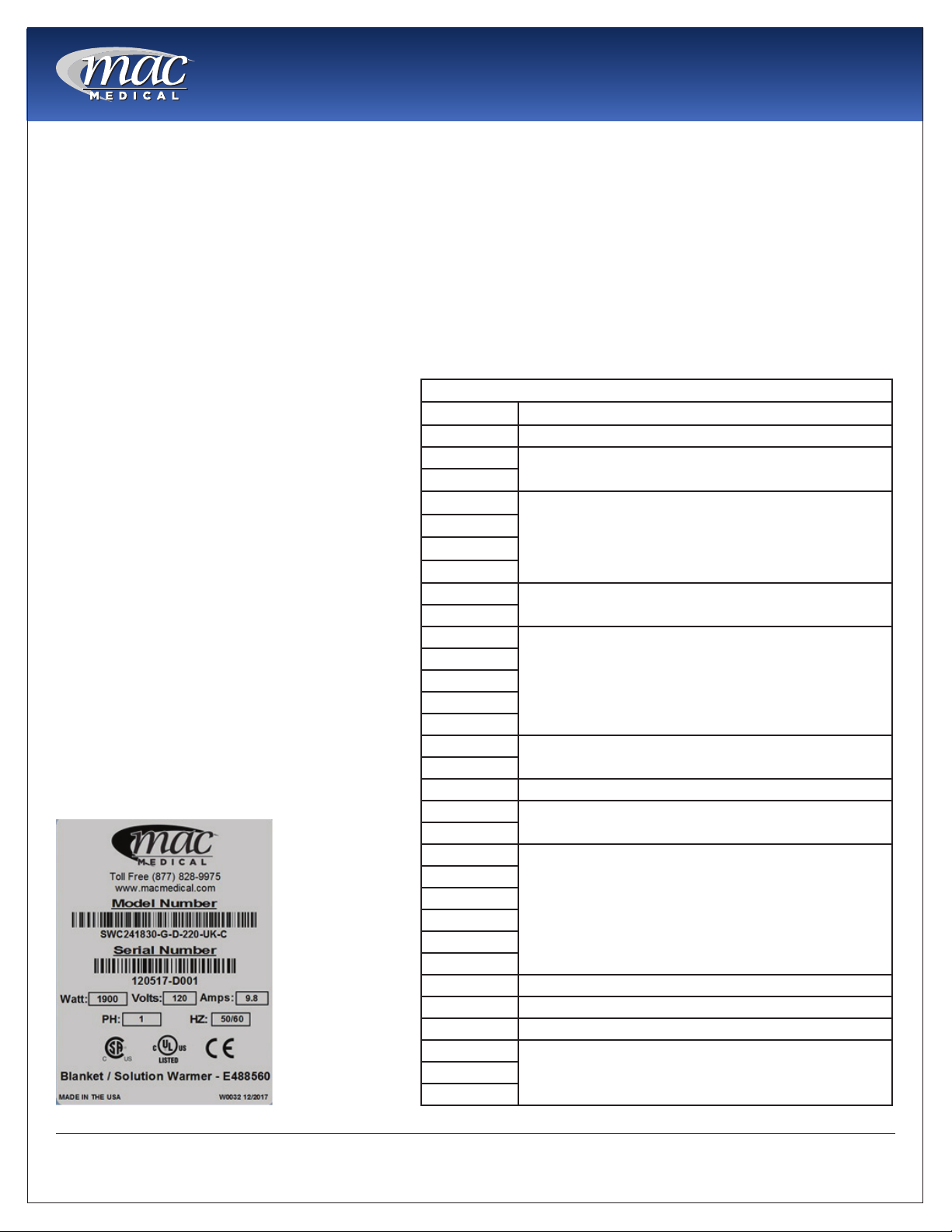

Power Specications are located on the unit

identication rating tag (see Fig. 4) which is

permanently attached on the inside of the

door or on the back of the upper chamber.

Model # Description

SWC151822 120V, 2.08 Amp, 50/60Hz, .25 kWh (Avg.), 853 BTU/hr (Avg.)

SWC182424

SWC182436

SWC242424

SWC242436

SWC243024

SWC243036

SWC183024

SWC183036

SWC182464

SWC182474

SWC183074

SWC242474

SWC243074

SWC242464

SWC243064

SWC183064 120V, 6.3 Amp, 50/60 Hz, .41 kWh (Avg.), 1400 BTU/hr (Avg.)

DWC183064T

DWC242464T

DWC182464T

DWC182474E

DWC182474T

DWC243064T

DWC242474E

DWC242474T

DWC183074T 120V, 8.3 Amp, 50/60 Hz, .82 kWh (Avg.), 2047 BTU/hr (Avg.)

DWC243074T 120V, 12.5 Amp, 50/60 Hz, .90 kWh (Avg.), 3071 BTU/hr (Avg.)

DWC183074E 120V, 11.4 Amp, 50/60 Hz, .82 kWh (Avg.), 2798 BTU/hr (Avg.)

DWC243074E

TWC243078

Electrical Specications by Model

120V, 2.9 Amp, 50/60 Hz, .23 kWh (Avg.), 785 BTU/hr (Avg.)

120V, 6.3 Amp, 50/60 Hz, .45 kWh (Avg.), 1535 BTU/hr (Avg.)

120V, 5.7 Amp, 50/60 Hz, .45 kWh (Avg.), 1535 BTU/hr (Avg.)

120V, 6.5 Amp, 50/60 Hz, .47 kWh (Avg.), 1604 BTU/hr (Avg.)

120V, 6.5 Amp, 50/60 Hz, .41 kWh (Avg.), 1604 BTU/hr (Avg.)

120V, 8.3 Amp, 50/60 Hz, .60 kWh (Avg.), 2047 BTU/hr (Avg.)

120V, 8.9 Amp, 50/60 Hz, .65 kWh (Avg.), 2218 BTU/hr (Avg.)

120V, 12.9 Amp, 50/60 Hz, .90 kWh (Avg.), 3071 BTU/hr (Avg.)TWC183078

Fig. 4: Power Specication Label

MAN-001

7

www.macmedical.com

Instruction Manual

MAC Medical Warming Cabinet handles are equipped with CuVerro® bactericidal copper surfaces.

° This product is made from a copper surface that continuously kills bacteria* left behind by dirty

hands, killing more than 99.9% of bacteria* within 2 hours.

Laboratory testing has shown that when cleaned regularly this surface:

° Kills more than 99.9% of bacteria* within 2 hours, and continues to kill 99% of bacteria* even after

repeated contamination.

° Delivers continuous and ongoing antibacterial* action, remaining effective in killing greater than

99.9% of bacteria* within 2 hours.

° Helps inhibit buildup and growth of bacteria* within 2 hours of exposure between routine cleaning

and sanitizing steps.

° Kills greater than 99.9% of Gram-negative and Gram-positive bacteria* within 2 hours of exposure.

° Continuously reduces bacterial* contamination, achieving 99.9% reductin within 2 hours of exposure.

* Laboratory testing shows that, when cleaned regulary, CuVerro surfaces kill greater than 99.9% of the following bacteria

within 2 hours of exposure: Methicillin-Resistant Staphylococcus aureus, Staphylococcus aureus, Enterobacter aerogenes,

Pseudomonas aeruginosa, E. coli O157:H7, and Vancomycin-Resistant Enterococcus faecalis (VRE).

The use of CuVerro® bactericidal copper products is a supplement to and not a substitute for standard infection control

practices; users must continue to follow all current infection control practices, including those practices related to cleaning

and disinfection of environmental surfaces. This surface has been shown to reduce microbial contamination, but it does not

necessarily prevent cross contamination.

CuVerro® is a registered trademark of GBC Metals, LLC and is used with permission.

EPA Company No. 92702-IL-1 EPA Registration No. 92701

MAN-001

8

www.macmedical.com

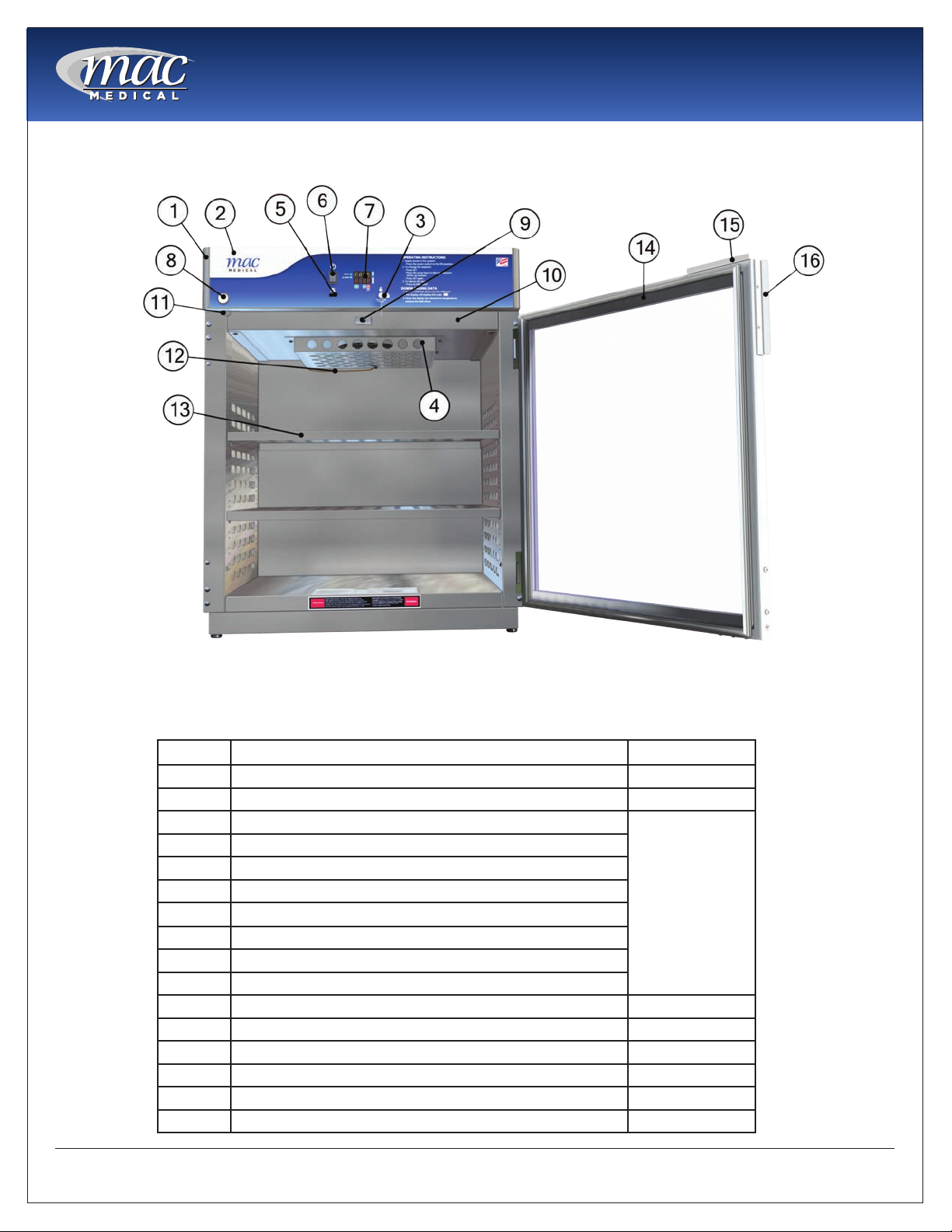

Main features of a Typical Warming Cabinet

(Single Chamber Cabinet shown here)

Instruction Manual

Fig. 5: Main Elements of a Warming Cabinet

This list shows the main elements of a warming cabinet. For a list of replacement parts with their part numbers

and quantities, see”Replacement Parts - General” on page 25 and “Replacement Parts - Header Assembly

and Electrical Drawer” on page 26.

Item # Description Qty

1 Header Assembly (24” and 30”) 1

2 Overlay (24” and 30”) D-Series 1

3 Key Housing

4 Air Box

5 USB cable plug

6 On/Off Switch

7 Display Board -Data (1 for each chamber)

8 Key Lock

9 Door Switch

10 Drawer Assembly (1 for each chamber)

11 Cam Lock Latch 1 per door

12 Probe J Type Thermocouple 1 per chamber

13 Adjustable Perforated Shelf As Required

14 Door (glass or steel) As Required

15 Cam Lock Plate 1 per door

16 Handle 1 per door

1 per chamber

MAN-001

9

www.macmedical.com

Instruction Manual

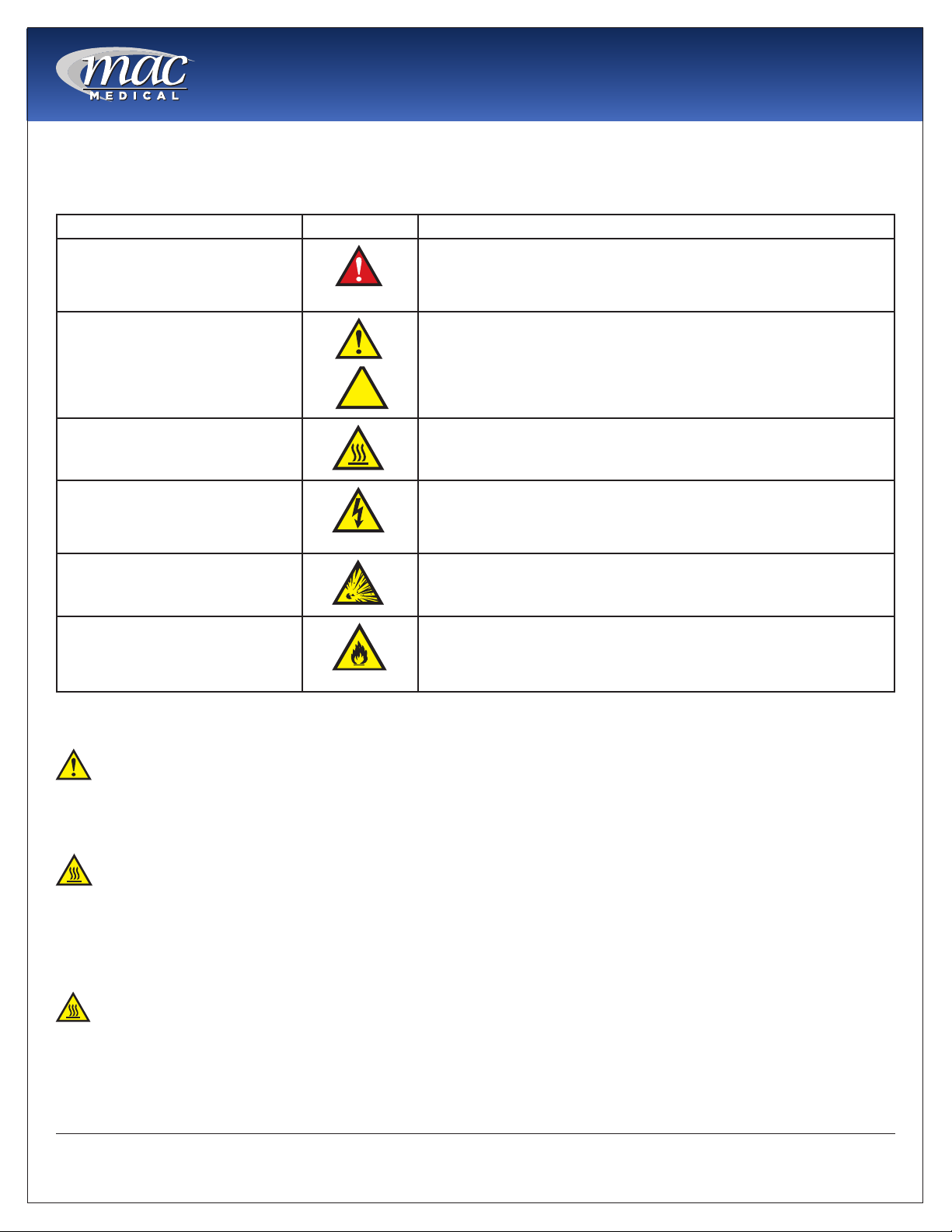

Warnings and Cautions

The following is a list identifying the various warning and caution icon used in this manual.

Icon Type Icon Description

Warnings

(Red triangle with an exclamation point) indicates the potential for

minor to severe injuries up to and including death to personnel.

Cautions

Burn Hazard Warnings

Electrical Warnings

Explosion Hazard

Fire Hazard

(Yellow triangle with an exclamation point) indicates the potential

minor injury to personnel and damage to equipment.

Note: The exclamation point will not be visible where only

equipment damage is present.

(Yellow triangle with radiating lines) indicates a potential burn injury

to personnel.

(Yellow triangle with a lightning bolt) indicates a possible shock

hazard is present. Severe shock hazards shall be a lightning bolt in a

red triangle.

(Yellow triangle with the explosion icon) indicates the equipment

should not be operated in areas where explosions could occur.

(Yellow triangle with the re icon) indicates the warning cabinet

should not be loaded with materials or liquids that are ammable or

use in the presence of ammable anesthetics or solvents.

The following is a list of safety precautions that must be observed when operating this equipment.

Warning - Injury Hazard

REPAIRS AND ADJUSTMENTS should be attempted only by experienced service representatives. Use of

unqualied persons to work on this equipment could result in personal injury or costly damage.

Warning - Burn Hazard

• Do NOT use in the presence of ammable anesthetics.

• Do NOT heat liquids in the presence of ammable solvents.

• Failure to observe this Warning can result in severe personal injury and even death.

Warning - Burn Hazard

• Do NOT exceed 150° F (65.56 C) for non-vented closures; (screw caps, crimp seals, plastic pouches, etc.).

Do not exceed pre-sterile solution manufacturer’s temperature requirements.

• Do NOT raise set temperature to increase rate of heating. Allow approximately 4-6 hours for solutions to

reach desired temperatures.

MAN-001

10

www.macmedical.com

Instruction Manual

• Do NOT use liquids on or inject into living tissue, unless actual liquid temperature has been measured

and is acceptable. Temperature of the warming cabinet’s contents may be hotter than the displayed

air temperature. For patient safety, in accordance with good medical practice, always check liquid

temperature prior to using.

Warning - Electric Shock Hazard

Do NOT remove control tray. Contact a qualied service representative. Some of the troubleshooting

procedures can require access to live electrical circuitry. Dangerous accidental contact with line voltage is

possible. Only qualied service personnel should be allowed to perform these procedures.

Warning - Explosion Hazard or Fire Hazard

• Do not warm ammable materials or liquids.

• Do Not use in the presence of ammable anesthetics.

• Do Not heat liquids in the presence of ammable solvents.

Caution - Possible Equipment Damage

Some items are not acceptable in these warming cabinets. If in doubt as to whether an item can be safely

processed, have the facility supervisor contact the manufacturer of the item.

Caution: Repairs And Adjustments should only be attempted by experienced service personnel

who are fully acquainted with this equipment. Use of unqualied or inexperienced personnel to work on the

equipment, or the installation of unauthorized parts, could result in serious personal injury, or result in costly

damage. Always unplug power cord from power source before attempting any repairs or servicing of this

equipment.

Special User Attention

Prior to use, all personnel who will operate the Warming Cabinet must be instructed in the correct usage and

operation. All personnel who will use the Warming Cabinet should be aware that sensible care must be

exercised to maintain patient safety and to keep the Warming Cabinet performing at peak efciency.

Intended Use Notice

This product is intended to be used by medical personnel for the purpose of providing heated storage of

blankets, sterile water and saline solutions used in the care of patients in surgery, recovery, OB/GYN, ICU,

ER and trauma areas in healthcare facilities where al operators are instructed on the usage, limitations and

hazards. No other use is authorized or recommended.

This product is to be used strictly for the purpose for which it was designed. Using this product in a manner

not specied by MAC Medical, Inc. can void the protection provided by the equipment manufacturer. MAC

Medical, Inc. disclaims all liability for the consequences of this product being used for other than what it was

designed for. Product modication or misuse can be dangerous. MAC Medical, Inc. disclaims all liability for

the consequences of product alterations or modications, as well as for the consequence that can result

from the combination of this product with other products, whether supplied by MAC Medical, Inc. or by other

manufacturers, unless such a combination has been specically endorsed, in writing, by MAC Medical, Inc.

MAN-001

11

www.macmedical.com

Instruction Manual

Unpacking Instructions

Receiving Requirements

The customer is responsible for making sure the

loading dock at their facility can accommodate a

shipping carton approximately 70” inches (1.778 m)

long and 40” (1.016m) inches wide.

The customer must also provide transportation

equipment (forklift, etc) for a carton weighing

approximately 500 lbs (227 kg).

Inspection

1. Receiving area must meet all State and Local

regulations prior to unpacking.

2. Customer must inspect carton both before and

after unpacking to determine if any items were

damaged during shipping.

A. All damaged items must be listed on the Bill of

Lading.

B. The serial number and model number shown

on the carton label must match the numbers

on the Bill of Lading and the Invoice.

3. Customer is responsible for the proper disposal of

all packing materials. The disposal of these items

must meet all State and Local regulations.

plastic protective wrapping around the

Warming Cabinet. These items can scratch

the protective coating on the stainless steel

allowing the surface to rust.

9. The Warming Cabinet is now ready for use.

10. Discard shipping and packing materials in

compliance with local and state regulations.

11. Warmers, when not in use, must NOT be doublestacked while in storage. Warmers, while still in

shipping cartons, must not be double-stacked

when not in use.

Unpacking the Warming Cabinet

Retain all shipping materials until warming cabinet is

completely unpacked and inspected for damage.

1. Remove metal bands holding the bottom and

top of the shipping carton together.

2. Remove all metal staples holding the top and

bottom of the carton to its sides.

3. Remove the top of the carton.

4. Remove metal staples making the aps around

the top edge of the carton.

5. Remove metal staples attaching the sides of the

carton to the bottom of the carton.

6. Remove the sides of the carton by lifting them

straight up from the bottom tray.

7. Lift Warmer straight up from bottom tray of the

shipping carton and remove it.

8. Remove all protective packing material.

A.

Caution: DO NOT use a box cutter

or any other cutting utensil to remove the

Fig. 6: Warming Cabinet in Shipping Container

MAN-001

12

www.macmedical.com

Installing D-Series Warming Cabinets

environmental Conditions

This unit is intended for use in a stable ambient

environment, with an ideal temperature of 72° F

(22.22° C) or less. The unit should never be used

directly next to any appliance that may produce

heat, such as an autoclave.

During Transport and Storage (in original packaging

materials) -

• Ambient Temperature: -40° - 159°F (-40° - 70°C)

• Relative Air Pressure: 10% - 100%, including

condensation

• Air Pressure: 500 hPa (14 inHg - 31.3 inHg)

During Use - for Dry Locations

• Ambient Temperature: 60° - 85°F (15° - 30°C)

• Relative Air Moisture: 30% - 60% non-condensing

• Air Pressure: 700 hPa - 1060 hPa (20.7 inHg - 31.3

inHg)

Instruction Manual

1. Carefully uncrate the D-Series Warming Cabinet.

2. Inspect for any damage. If there is damage,

please contact MAC Medical, Inc. at (1-877-828-

9975).

3. Check your 120V, 60 Hz, Single Phase 15 AMP

GFIC Protected electrical outlet or 220V, 60 Hz,

Single Phase, 7 AMP GFIC Protected electrical

outlet. Be sure the outlet is safely accessible and

in proper working condition.

4. Plug the 3-prong electrical plug into the 120VAC,

60Hz, 15 AMP, GFIC Protected Outlet or a 220

VAC, 60Hz, Single Phase, 7 AMP GFIC protected

electrical outlet. Make sure the electrical outlet is

safely accessible and in proper working condition.

5. Place Warming Cabinet on a solid, level platform

where external movement will not interfere with

loose contents used by the warmer.

6. Make sure the shelving is correctly located as

desired and level. If not, adjust their height (see

“Adjusting the Shelves” on page 19).

7. Before use, remove any items that have been

stored in the cabinet.

Installation

Before starting the installation, review the local

electric codes including the Occupational Health

and Safety Act for any requirements pertaining to the

proper installation of this equipment.

Contact your MAC Medical representative for seismic

calculations and tie-down hardware, if applicable.

Testing before Using

All warming cabinets have been calibrated and

tested before leaving the factory. There is no need

for the user to do additional testing after installation

prior to use.

After six month of use, it is recommended that the

user test the warming cabinet for temperature

accuracy. See “Semi-Annual Checklist” on page

24.

MAN-001

13

www.macmedical.com

Instruction Manual

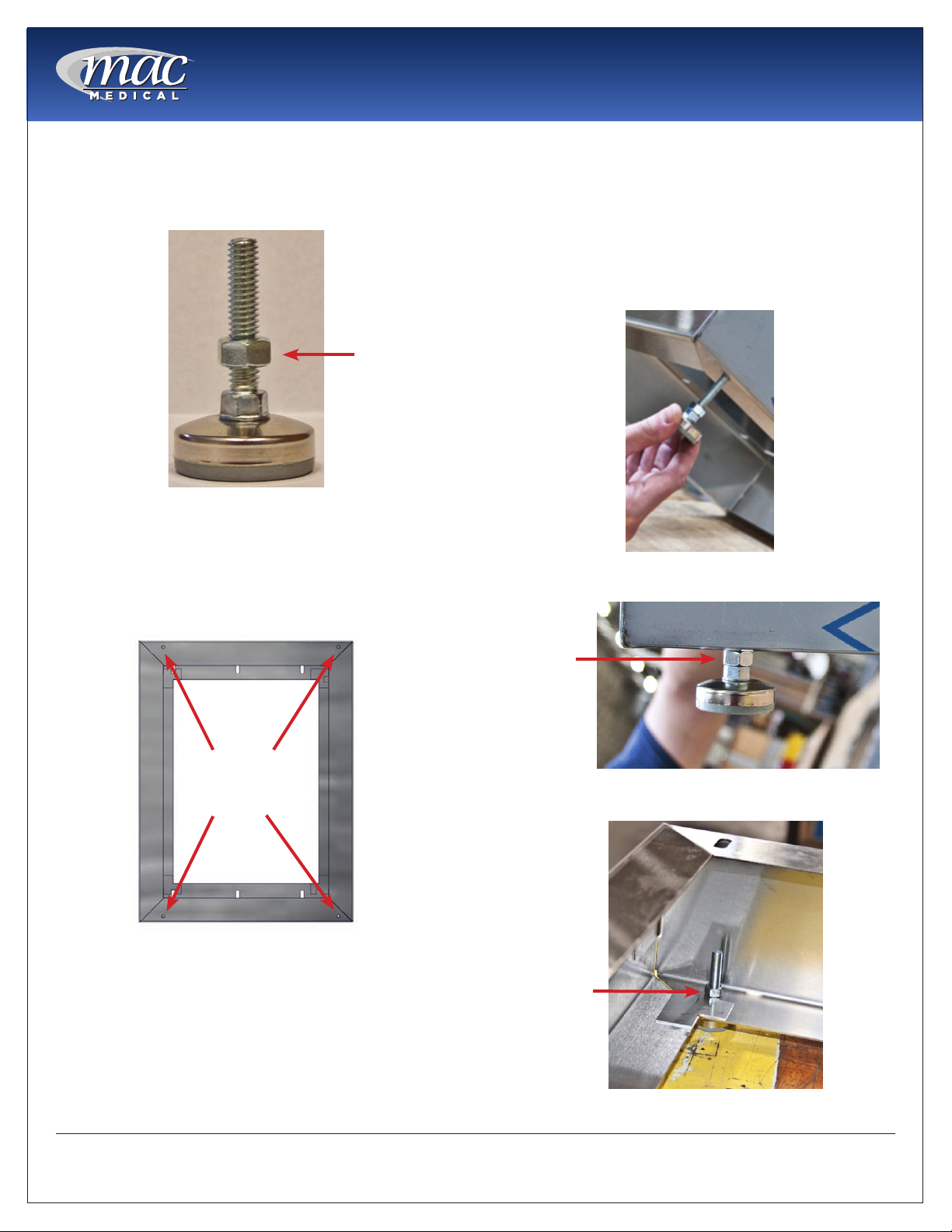

Installing Warming Cabinet leg levelers

Warming Cabinets are shipped with 4 Leg Levelers

which must installed by the customer (Fig. 7).

Jamb Nut

Fig. 7: Leg Leveler

The Warming Cabinet base has 4 holes into which

the Leg Levelers can be installed (Fig. 8).

Working with at least two people, carefully tilt the

Warming Cabinet back slightly and insert the 4 Leg

Levelers up into the 4 provided holes (Fig. 9).

IMPORTAnT: The Jamb Nut must go on the outside of

the Cabinet Base, not the inside. Fig.10 shows a Leg

Leveler correctly installed with the Jamb Nut outside

the base. Fig. 11 shows the Leg Leveler incorrectly

installed with the Jamb Nut inside the base.

Fig. 9: Insert Leg Leveler into base

Holes for

Leg Levelers

Fig. 8: Holes in Cabinet base

Jamb Nut

Fig. 10: Leg Leveler - Correct installation

Jamb Nut

Fig. 11: Leg Leveler - Incorrect installation

MAN-001

14

www.macmedical.com

Instruction Manual

2

5

2

3

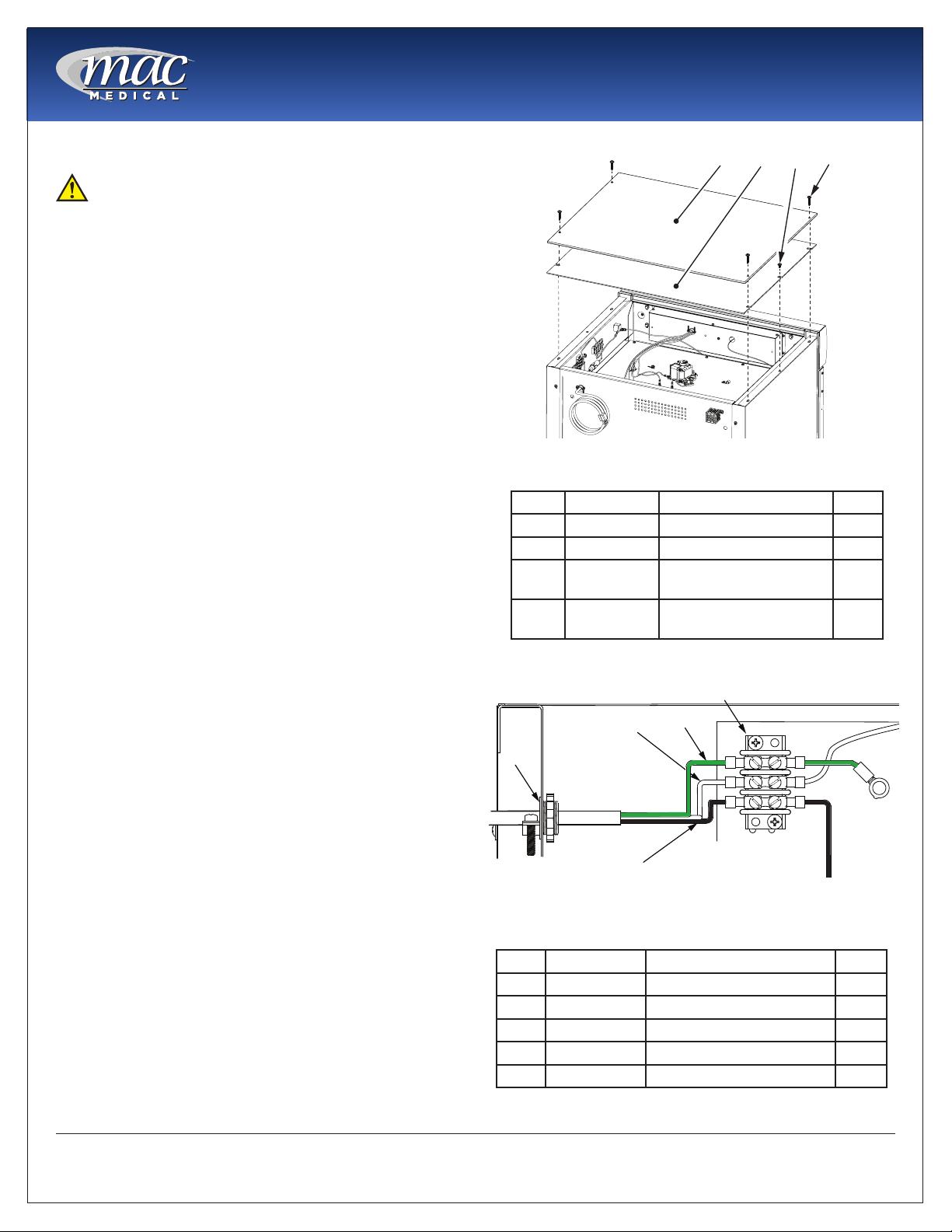

Optional Direct Wiring Using facility Power Supply

NOTE: The following procedure must be performed

by a qualied electrical technician to avoid personal

injury or damage to the unit.

Warming Cabinets can be wired directly into the

facility’s wiring by following these steps:

1. Remove four 8 X 1-5/8” self tapping screws and lift

off the Top Outer Panel. See Fig. 7.

2. Remove two 8 X 1/2” self tapping screws and lift off

the Top Inner Panel. See Fig. 7.

3. Loosen the 3/8” straight-thru connector (See Figure

4, Item 1) and disconnect wiring from terminal

board (Figure 4, Item 5) and from Fig. 8, Items 2, 3, 4.

4. Remove existing power cable (See Figure 4, Items

2, 3, and 4) from terminal block and pull out of

Warming Cabinet through 3/8” connector (See Fig.

8, Item 1).

5. Feed facility wiring cable back through the 3/8”

connector (See Fig. 8, Item 1) in the back of the

cabinet and wire onto terminal board as shown in

Fig. 8. Tighten the 3/8” to securely hold the facility

wiring in place.

6. On the terminal board, The green wire (Item 4)

connects with the green ground wire.

7. The white wire (Item 3) connects opposite with the

white wire, or neutral wire, on the terminal board.

8. The black wire (Item 2) connects opposite of the

black or positive wire on the terminal board.

9. Re-install the Inside Top Panel using two 8 X 1/2” selftapping screws. See Fig. 7.

10. Re-install the Outside Top Panel using four 8 X 1-5/8”

self-tapping screws. See Fig. 7.

11. Carefully slide the unit into its permanent location.

1

Fig. 12: Remove Top Covers

Item P/n Description Qty

1 SMW0027 Outside Top Panel 1

2 SMW0028 Inside Top Panel 1

3 H0012-01 Screw, Self-Tapping, 8

X 1/2”

4 H0012-02 Screw, Self-Tapping, 8

X 1-5/8”

3

4

1

4

2

4

MAN-001

Fig. 13: Unwiring Terminal Block

Item P/n Description Qty

1 W0140 Connector, Straight, 3/8” 1

2 W0077 Wire, Black, Positive 1

3 W0077 Wire, White, Neutral 1

4 W0077 Wire, Green, Ground 1

5 W0005 Terminal Strip, 3-Position 1

15

www.macmedical.com

Loading...

Loading...