Mac Medical SWC243024, SWC243036, SWC242436, SWC182464, SWC242464 Installation Operation & Maintenance

...

INSTRUCTION MANUAL

Installation - Operation - Maintenance

MAN-001 Rev J

D-Series Warming Cabinets

OSHPD

R

C

Read and understand all of the instructions and safety

information in this manual before operating this product.

© 2018 MAC Medical, Inc.

Pre-Approved

10/2018

Instruction Manual

TAble Of COnTenTS

Summary 3

D-Series Warming Cabinet Models

Interior Dimensions, Cubic Foot Capacity, Approximate Capacity

General Specications

Main Features of a Typical Warming Cabinet

Warnings and Cautions

Unpacking Instructions

Receiving Requirements

Installing D-Series Warming Cabinets

Environmental Conditions

Installation

Testing before Using

Installing Warming Cabinet Leg Levelers

Optional Direct Wiring Using Facility Power Supply

Basic Operation

Recommended Settings

Loading Contents in Cabinet

In Case of Power Failure

Explanation of the Controls

Operation of Display Panel

Installing the Shelves

Adjusting the Shelves

Installing and Adjusting Optional Roller Basket Shelves

Unloading the Warming Cabinet

Retrieval of Recorded Temperatures

Turning Off the Warming Cabinet

Troubleshooting

Overheat Alarm (HI) Condition

Cleaning Stainless Steel Warming Cabinets

Preventative Maintenance Checklist

Replacement Parts - General

Replacement Parts - Header Assembly and Electrical Drawer

Optional Cabinet Bases, Mobile Bases and Mobile Stands

Steel or Glass Door Hinge Reversal

Remove Panels

Remove Header Assembly Box & Relocate Cam Lock

Purchase Parts Needed for Cam Lock Reversal

Glass Door Hinge Reversal and Re-installation

Steel Door Hinge Reversal and Re-installation

Purchase Parts Needed for Door Hinge Reversal

Wiring Diagram - Single Chamber Warmers

Wiring Diagram - Dual Chamber Warmers

Wiring Diagram - Triple Chamber Warmers

Index

41

Limited Lifetime Warranty

7

9

11

11

12

12

15

18

18

21

28

44

4

5

8

12

12

13

14

15

15

15

16

17

19

20

20

20

21

22

23

24

25

27

28

29

29

32

35

35

38

39

40

MAN-001

2

www.macmedical.com

Summary

Instruction Manual

DeSCRIPTIOn Of PRODUCT

This manual covers the D-Series (Data

Logging) blanket and uid warming cabinets,

manufactured for commercial use only. These

include the single, dual and triple chamber units.

PURPOSe Of THIS MAnUAl

This manual is to provide the user instructions in

the installation, operation and maintenance of

the D-Series warming cabinets.

This manual also contains general

specications, warnings and cautions.

Indications for Use:

The MAC Medical Inc. Blanket and Solution Warming Cabinets are designed to store and warm blankets,

hospital linens, irrigation uids, and/or injection uids in accordance with recommended warming

temperatures and storage time guidelines provided by the manufacturers of such products.

MAN-001

3

www.macmedical.com

Instruction Manual

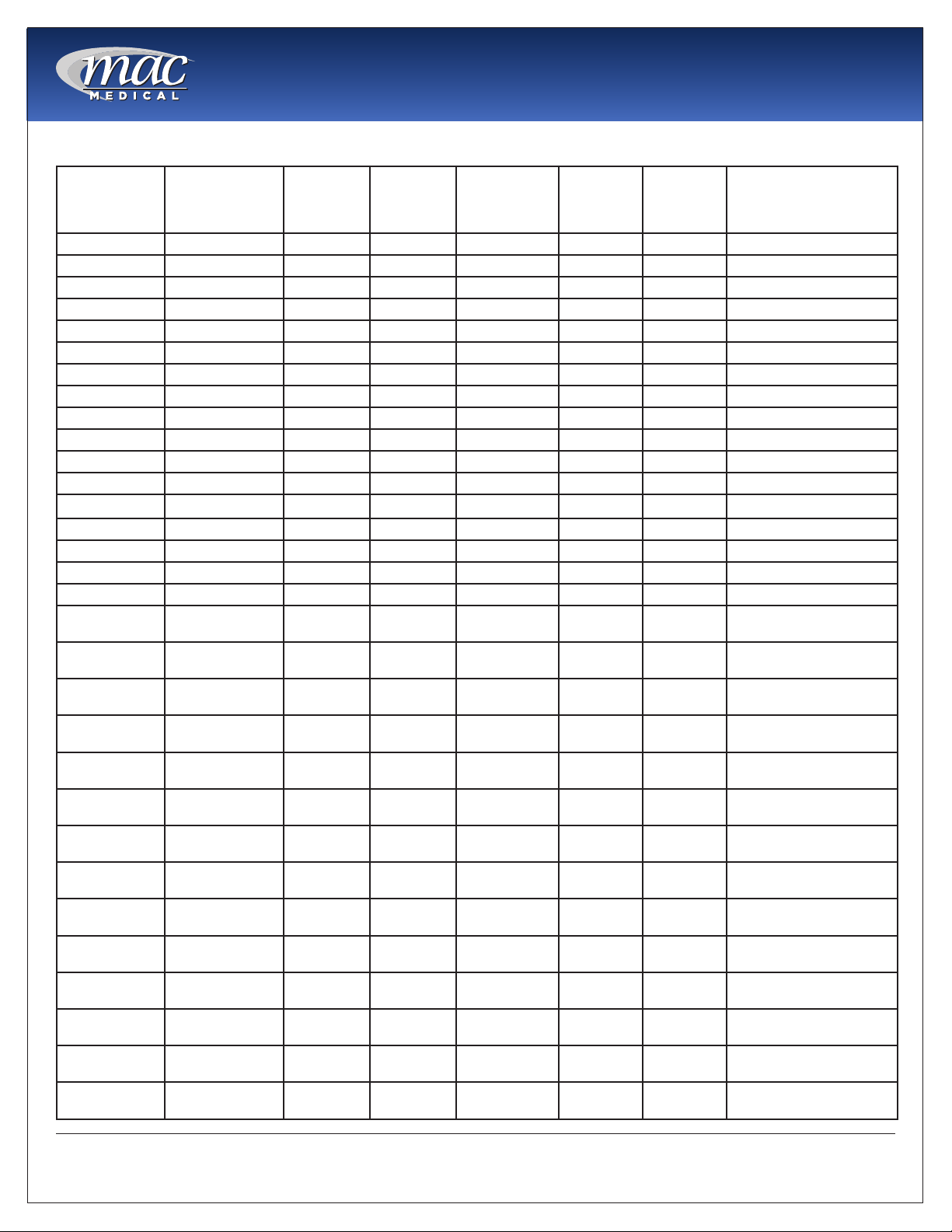

D-Series Warming Cabinet Models

Model # Overall Size Chambers Door Type Door Hinge base Style Other Options

SWC151822 17.25"D x 18"W x 22"H Single G=Glass Door

SWC182424 20.5"D x 24"W x 24.5"H Single

SWC242424 26.5”D x 24”W x 24.5”H Single

SWC183024 20.5"D x 30"W x 24.5"H Single

SWC243024 26.5"D x 30"W x 24.5"H Single

SWC182436 20.5”D x 24”W x 36”H Single

SWC183036 20.5"D x 30"W x 36"H Single

SWC242436 26.5”D x 24”W x 36”H Single

SWC243036 26.5"D x 30"W x 36"H Single

SWC182464 20.5"D x 24"W x 64.75"H Single

SWC242464 26.5"D x 24"W x 64.75"H Single

SWC183064 20.5"D x 30"W x 64.75"H Single

SWC243064 26.5"D x 30"W x 64.75"H Single

SWC182474 20.5”D x 24”W x 74.5”H Single

SWC183074 20.5"D x 30"W x 74.5"H Single

SWC242474 26.5”D x 24”W x 74.5”H Single

SWC243074 26.5"D x 30"W x 74.5"H Single

DWC182464T* 20.5"D x 24"W x 64.75"H Dual

DWC242464T* 26.5"D x 24"W x 64.75"H Dual

DWC183064T* 20.5"D x 30"W x 64.75"H Dual

DWC243064T* 26.5"D x 30"W x 64.75"H Dual

DWC182474T* 20.5"D x 24"W x 74.5"H Dual

DWC242474T* 26.5"D x 24"W x 74.5"H Dual

DWC183074T* 20.5"D x 30"W x 74.5"H Dual

DWC243074T* 26.5"D x 30"W x 74.5"H Dual

DWC182474E** 20.5”D x 24”W x 74.5”H Dual

DWC183074E** 20.5"D x 30"W x 74.5"H Dual

DWC242474E** 26.5”D x 24”W x 74.5”H Dual

DWC243074E** 26.5"D x 30"W x 74.5"H Dual

TWC183078 20.5"D x 30"W x 78.75"H Triple

TWC243078 26.5"D x 30"W x 78.75"H Triple

Blank=Stainless

Steel Door

(Standard)

ţ Only available for Triple Chamber Unit

ţţ Only available for Dual and Triple Chamber Units

LH=Left Hinge

Blank = Right

Hinge (Standard)

2B = 2” Base

4B = 4” Base

6B = 6” Base

NB = No Base

MB = Mobile Base

220 = 220/240V

Power Supply

C = Celsius

R1 = Recessed

Unit with Insulation

Wrap, no Top Panel,

no Side Panels and

no Trim Kit.

R2 = Recessed Unit

with Top Panel, Side

Panels, and Trim Kit.

SB = Seismic Braces

WB = Roll Out

Basket

P = Pass Through

Chamber

IV = IV/Injection

Fluids

ST = Sloped Top

EL = Electronic

Keypad lock

ţ DL = Intermediate

Chamber Door Lock

(triple chamber

units)

ţţ LDL = Lower

Chamber Door

Lock (dual/triple

chamber units)

* = Chambers in Thirds ** = Equal Chambers

1/3

2/3

1/2

1/2

MAN-001

Sloped Top

Roll Out basket

4

www.macmedical.com

Interior Dimensions, Cubic foot Capacity, Approximate Capacity

Instruction Manual

Model # Upper or single

Chamber

(h x w x d) in

inches

SWC151822 14.0 x 14.0 x 11.63 n/a n/a/ 1.30 n/a n/a 5 - 6 blankets, 8 bottles

SWC182424 15.25 x 20.0 x 17.0 n/a n/a 3.0 n/a n/a 9 blankets, 8 bottles

SWC242424 15.25 x 20.0 x 23.0 n/a n/a 4.06 n/a n/a 9 blankets, 12 bottles

SWC183024 15.25 x 26.0 x 17.0 n/a n/a 3.9 n/a n/a 18 blankets, 8 bottles

SWC243024 15,25 x 26.0 x 23.0 n/a n/a 5.27 n/a n/a 18 blankets, 20 bottles

SWC242436 36.0 x 20.0 x 23.0 n/a n/a 6.7 n/a n/a 16 blankets, 25 bottles

SWC182436 25.0 x 20.0 x 17.0 n/a n/a 5.0 n/a n/a 16 blankets, 20 bottles

SWC183036 25.0 x 26.0 x17.0 n/a n/a 6.39 n/a n/a 32 blankets, 36 bottles

SWC243036 25.0 x 26.0 x 23.0 n/a n/a 8.65 n/a n/a 32 blankets, 40 bottles

SWC182464 49.5 x 20.0 x 17.0 n/a n/a 9.74 n/a n/a 32 blankets, 48 bottles

SWC242464 51.0 x 20.0 x 23.0 n/a n/a 13.60 n/a n/a 80 blankets, 120 bottles

SWC183064 51.0 x 26.0 x 17.0 n/a n/a 13.05 n/a n/a 66 blankets, 72 bottles

SWC243064 51.0 x 26.0 x 23.0 n/a n/a 17.65 n/a n/a 80 blankets, 120 bottles

SWC182474 61.0 x 20.0 x 17.0 n/a n/a 12.00 n/a n/a 32 blankets, 60 bottles

SWC183074 61.0 x 26.0 x 17.0 n/a n/a 15.60 n/a n/a 80 blankets, 72 bottles

SWC242474 61.0 x 20.0 x 23.0 n/a n/a 16.24 n/a n/a 80 blankets, 120 bottles

SWC243074 61.0 x 26.0 x 23.0 n/a n/a 21.1 n/a n/a 80 blankets, 120 bottles

DWC182464T* 13.5 x 20.0 x 17.0 n/a 24.5 x 20.0 x

DWC242464T* 13.5 x 20.0 x 23.0 n/a 24.5 x 20.0 x

DWC183064T* 13.5 x 26.0 x 17.0 n/a 24.5 x 26.0

DWC243064T* 13.5 x 26.0 x 23.0 n/a 24.5 x 26.0 x

DWC182474T* 15.25 x 20.0 x 17.0 n/a 34.5 x 20.0 x

DWC242474T* 15.25 x 20.0 x 23.0 n/a 34.5 x 20.0 x

DWC183074T* 15.25 x 26.0 x 17.0 n/a 34.5 x 26.0 x

DWC243074T* 15.25 x 26.0 x 23.0 n/a 34.5 x 26.0 x

DWC182474E** 25.0 x 20.0 x 17.0 n/a 26.0 x 20.0 x

DWC183074E** 25.0 x 26.0 x 17.0 n/a 26.0 x 26.0 x

DWC242474E** 25.0 x 20.0 x 23.0 n/a 26.0 x 20.0 x

DWC243074E** 25.0 x 26.0 x 23.0 n/a 26.0 x 26.0 x

TWC183078 11.25 x 26.0 x 17.0 10.75 x 26.0

TWC243078 11.25 x 26.0 x 23.0 10.75 x 26.0

Middle

Chamber

(h x w x d)

in inches

x 17.0

x 23.0

lower

Chamber

(h x w x d)

in inches

17.0

23.0

x17.0

23.0

17.0

23.0

17.0

23.0

17.0

17.0

23.0

23.0

18.5 x 26.0

x 17

18.5 x 26.0 x

23.0

Cubic foot

Capacity

Upper or single

Chamber

2.65 n/a 4.82 26 blankets, 36 bottles

3.59 n/a 6.52 52 blankets, 80 bottles

3.45 n/a 6.27 50 blankets, 54 bottles

4.67 n/a 8.48 52 blankets, 96 bottles

2.65 n/a 6.79 32 blankets, 48 bottles

4.06 n/a 9.18 52 blankets, 80 bottles

3.45 n/a 8.82 52 blankets, 72 bottles

5.28 n/a 11.93 52 blankets, 120 bottles

4.97 n/a 5.24 44 blankets, 48 bottles

6.39 n/a 6.65 64 blankets, 72 bottles

6.65 n/a 6.99 64 blankets, 80 bottles

8.65 n/a 8.99 64 blankets, 120 bottles

2.88 2.75 4.73 62 blankets, 54 bottles

3.89 3.72 6.4 62 blankets, 90 bottles

Cubic foot

Capacity

Middle

Chamber

Cubic foot

Capacity

lower

Chamber

Approximate

Capacity

(blankets or 1 liter

solution bottles)

MAN-001

5

www.macmedical.com

Instruction Manual

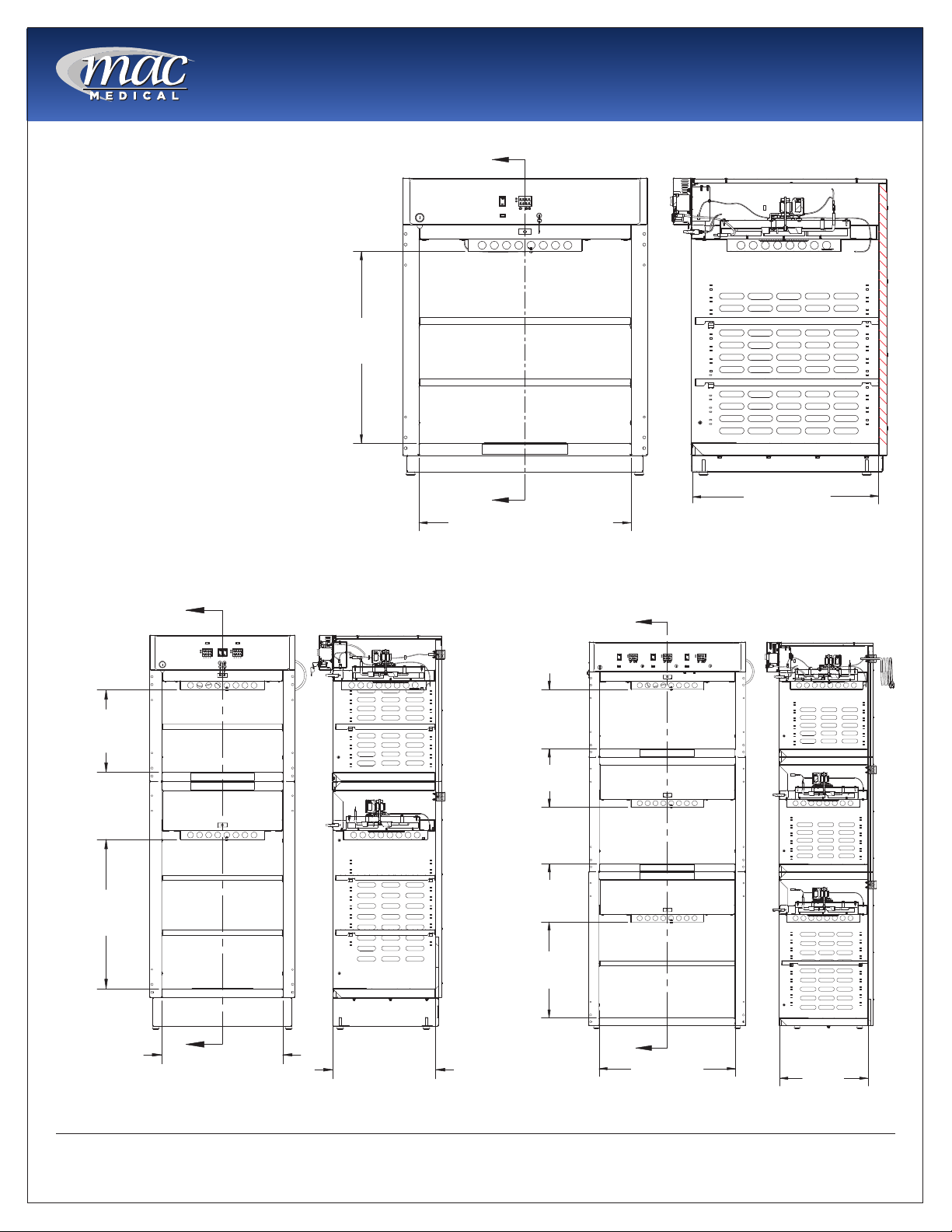

Usable Chamber Space

The usable chamber space of the

single, dual and triple cabinets

is slightly different from the

height, width, and depth interior

dimensions in the table on the

previous page.

Note that the usable chamber

inner height is measured from

the bottom of the air box to the

bottom of the chamber.

(In these views, the doors were

removed for clarity.)

USABLE

INNER HEIGHT

DIMENSION

A

A

CHAMBER WIDTH DIMENSION

Fig. 1: Single Chamber Unit Usable Space

CHAMBER DEPTH

DIMENSION

SECTION A-A

A

USEABLE

INNER HEIGHT

DIMENSION

USEABLE

INNER HEIGHT

DIMENSION

A

CHAMBER

WIDTH

DIMENSION.

Fig. 2: Dual Chamber Unit Usable Space

SECTION A-A

CHAMBER

DEPTH

DIMENSION.

A

USEABLE

INNER HEIGHT

DIMENSION

USEABLE

INNER HEIGHT

DIMENSION

USEABLE

INNER HEIGHT

DIMENSION

A

CHAMBER

WIDTH

DIMENSION

Fig. 3: Triple Chamber Unit Usable Space

SECTION A-A

CHAMBER

DEPTH

DIMENSION

MAN-001

6

www.macmedical.com

Instruction Manual

General Specications

Cabinet Construction and Material

• 300 Stainless Steel (all panels, header and doors) Double walled construction with insulation. Doors are

double pan stainless steel.

• Fully insulated to provide uniform heating

• Optional Glass door are double paned tempered glass framed with aluminum.

• Doors are fully gasketed and hinged on right side or optionally on the left side.

Factory Presets

• All units are preset to measure temperature in Fahrenheit (unless the unit was specically ordered to be

preset for Celsius.)

Power Requirements

• 120VAC, 60Hz, Single Phase, 15 AMP,

Ground Fault Interrupter Circuit (GFIC)

protected electrical outlet, or 220 VAC,

60Hz, Single Phase, 7 AMP, GFIC protected

electrical outlet (by others) installed

per local building codes and provides

protective grounding.

• Cabinets are supplied with a 7 foot (2.3m)

long, 14-3 SJT power cord with a 120V

(NEMA 15P) hospital grade plug. For multichambered units, ON/OFF switches are

supplied for each chamber.

• All individual electronic components are

Underwriter’s Laboratory (UL) approved

and recognized.

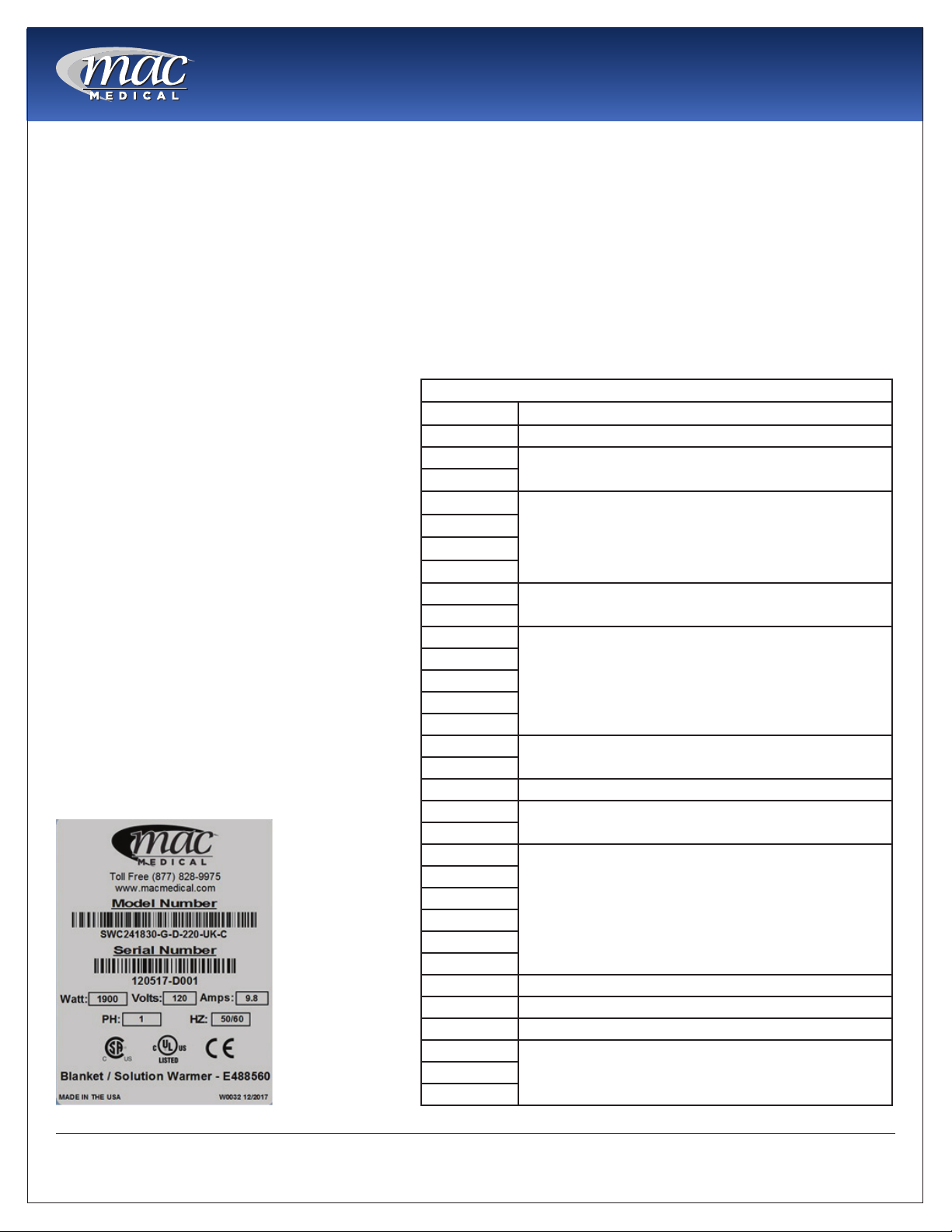

Power Specications are located on the unit

identication rating tag (see Fig. 4) which is

permanently attached on the inside of the

door or on the back of the upper chamber.

Model # Description

SWC151822 120V, 2.08 Amp, 50/60Hz, .25 kWh (Avg.), 853 BTU/hr (Avg.)

SWC182424

SWC182436

SWC242424

SWC242436

SWC243024

SWC243036

SWC183024

SWC183036

SWC182464

SWC182474

SWC183074

SWC242474

SWC243074

SWC242464

SWC243064

SWC183064 120V, 6.3 Amp, 50/60 Hz, .41 kWh (Avg.), 1400 BTU/hr (Avg.)

DWC183064T

DWC242464T

DWC182464T

DWC182474E

DWC182474T

DWC243064T

DWC242474E

DWC242474T

DWC183074T 120V, 8.3 Amp, 50/60 Hz, .82 kWh (Avg.), 2047 BTU/hr (Avg.)

DWC243074T 120V, 12.5 Amp, 50/60 Hz, .90 kWh (Avg.), 3071 BTU/hr (Avg.)

DWC183074E 120V, 11.4 Amp, 50/60 Hz, .82 kWh (Avg.), 2798 BTU/hr (Avg.)

DWC243074E

TWC243078

Electrical Specications by Model

120V, 2.9 Amp, 50/60 Hz, .23 kWh (Avg.), 785 BTU/hr (Avg.)

120V, 6.3 Amp, 50/60 Hz, .45 kWh (Avg.), 1535 BTU/hr (Avg.)

120V, 5.7 Amp, 50/60 Hz, .45 kWh (Avg.), 1535 BTU/hr (Avg.)

120V, 6.5 Amp, 50/60 Hz, .47 kWh (Avg.), 1604 BTU/hr (Avg.)

120V, 6.5 Amp, 50/60 Hz, .41 kWh (Avg.), 1604 BTU/hr (Avg.)

120V, 8.3 Amp, 50/60 Hz, .60 kWh (Avg.), 2047 BTU/hr (Avg.)

120V, 8.9 Amp, 50/60 Hz, .65 kWh (Avg.), 2218 BTU/hr (Avg.)

120V, 12.9 Amp, 50/60 Hz, .90 kWh (Avg.), 3071 BTU/hr (Avg.)TWC183078

Fig. 4: Power Specication Label

MAN-001

7

www.macmedical.com

Instruction Manual

MAC Medical Warming Cabinet handles are equipped with CuVerro® bactericidal copper surfaces.

° This product is made from a copper surface that continuously kills bacteria* left behind by dirty

hands, killing more than 99.9% of bacteria* within 2 hours.

Laboratory testing has shown that when cleaned regularly this surface:

° Kills more than 99.9% of bacteria* within 2 hours, and continues to kill 99% of bacteria* even after

repeated contamination.

° Delivers continuous and ongoing antibacterial* action, remaining effective in killing greater than

99.9% of bacteria* within 2 hours.

° Helps inhibit buildup and growth of bacteria* within 2 hours of exposure between routine cleaning

and sanitizing steps.

° Kills greater than 99.9% of Gram-negative and Gram-positive bacteria* within 2 hours of exposure.

° Continuously reduces bacterial* contamination, achieving 99.9% reductin within 2 hours of exposure.

* Laboratory testing shows that, when cleaned regulary, CuVerro surfaces kill greater than 99.9% of the following bacteria

within 2 hours of exposure: Methicillin-Resistant Staphylococcus aureus, Staphylococcus aureus, Enterobacter aerogenes,

Pseudomonas aeruginosa, E. coli O157:H7, and Vancomycin-Resistant Enterococcus faecalis (VRE).

The use of CuVerro® bactericidal copper products is a supplement to and not a substitute for standard infection control

practices; users must continue to follow all current infection control practices, including those practices related to cleaning

and disinfection of environmental surfaces. This surface has been shown to reduce microbial contamination, but it does not

necessarily prevent cross contamination.

CuVerro® is a registered trademark of GBC Metals, LLC and is used with permission.

EPA Company No. 92702-IL-1 EPA Registration No. 92701

MAN-001

8

www.macmedical.com

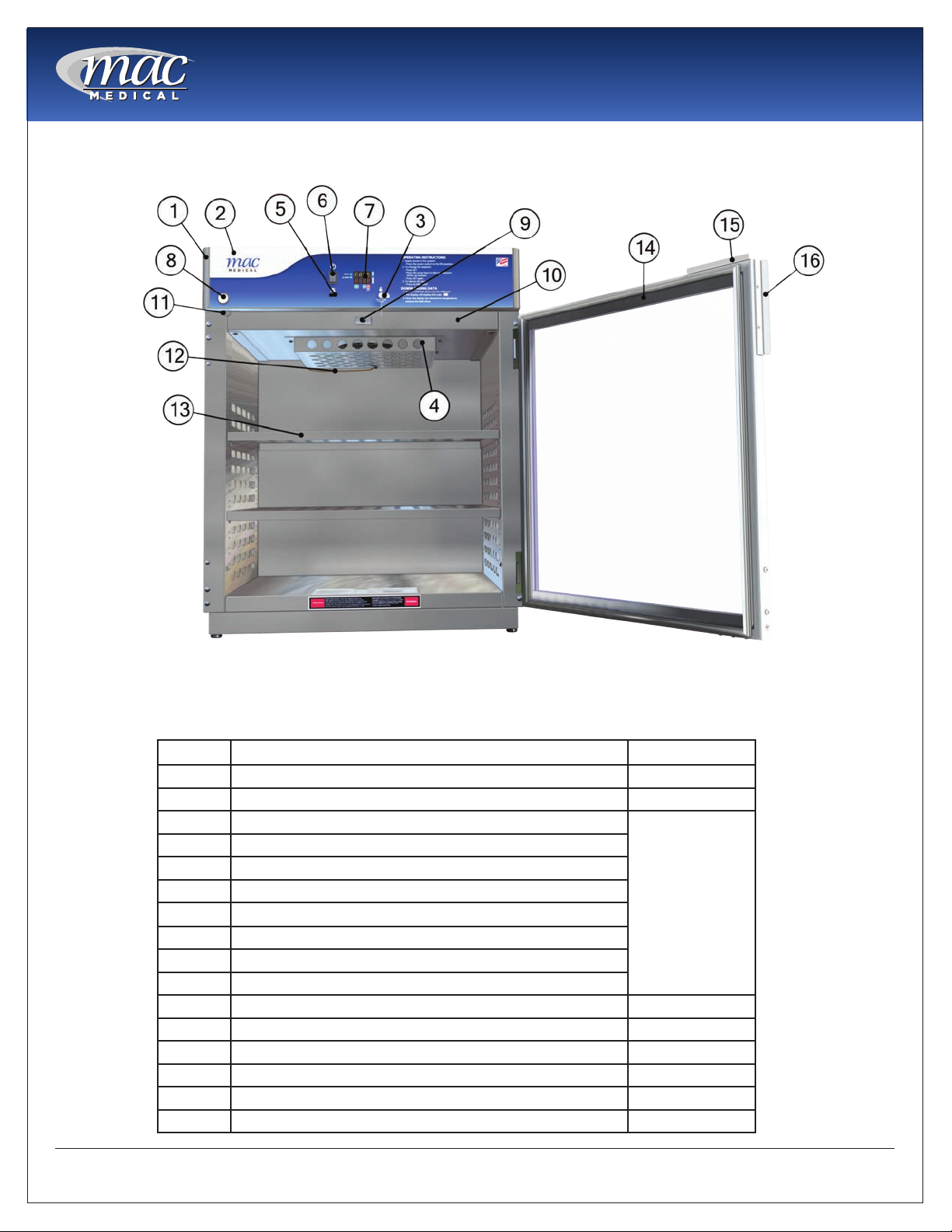

Main features of a Typical Warming Cabinet

(Single Chamber Cabinet shown here)

Instruction Manual

Fig. 5: Main Elements of a Warming Cabinet

This list shows the main elements of a warming cabinet. For a list of replacement parts with their part numbers

and quantities, see”Replacement Parts - General” on page 25 and “Replacement Parts - Header Assembly

and Electrical Drawer” on page 26.

Item # Description Qty

1 Header Assembly (24” and 30”) 1

2 Overlay (24” and 30”) D-Series 1

3 Key Housing

4 Air Box

5 USB cable plug

6 On/Off Switch

7 Display Board -Data (1 for each chamber)

8 Key Lock

9 Door Switch

10 Drawer Assembly (1 for each chamber)

11 Cam Lock Latch 1 per door

12 Probe J Type Thermocouple 1 per chamber

13 Adjustable Perforated Shelf As Required

14 Door (glass or steel) As Required

15 Cam Lock Plate 1 per door

16 Handle 1 per door

1 per chamber

MAN-001

9

www.macmedical.com

Instruction Manual

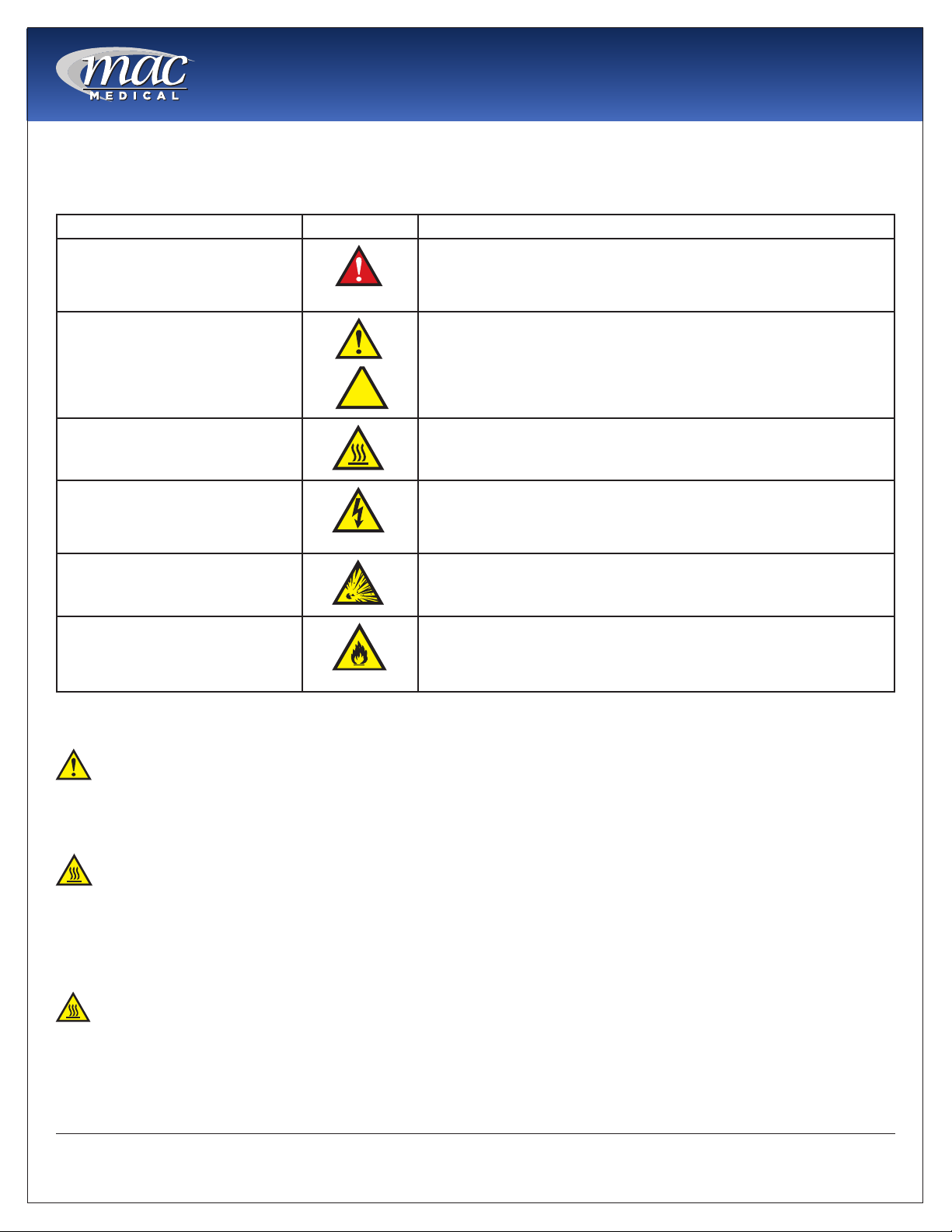

Warnings and Cautions

The following is a list identifying the various warning and caution icon used in this manual.

Icon Type Icon Description

Warnings

(Red triangle with an exclamation point) indicates the potential for

minor to severe injuries up to and including death to personnel.

Cautions

Burn Hazard Warnings

Electrical Warnings

Explosion Hazard

Fire Hazard

(Yellow triangle with an exclamation point) indicates the potential

minor injury to personnel and damage to equipment.

Note: The exclamation point will not be visible where only

equipment damage is present.

(Yellow triangle with radiating lines) indicates a potential burn injury

to personnel.

(Yellow triangle with a lightning bolt) indicates a possible shock

hazard is present. Severe shock hazards shall be a lightning bolt in a

red triangle.

(Yellow triangle with the explosion icon) indicates the equipment

should not be operated in areas where explosions could occur.

(Yellow triangle with the re icon) indicates the warning cabinet

should not be loaded with materials or liquids that are ammable or

use in the presence of ammable anesthetics or solvents.

The following is a list of safety precautions that must be observed when operating this equipment.

Warning - Injury Hazard

REPAIRS AND ADJUSTMENTS should be attempted only by experienced service representatives. Use of

unqualied persons to work on this equipment could result in personal injury or costly damage.

Warning - Burn Hazard

• Do NOT use in the presence of ammable anesthetics.

• Do NOT heat liquids in the presence of ammable solvents.

• Failure to observe this Warning can result in severe personal injury and even death.

Warning - Burn Hazard

• Do NOT exceed 150° F (65.56 C) for non-vented closures; (screw caps, crimp seals, plastic pouches, etc.).

Do not exceed pre-sterile solution manufacturer’s temperature requirements.

• Do NOT raise set temperature to increase rate of heating. Allow approximately 4-6 hours for solutions to

reach desired temperatures.

MAN-001

10

www.macmedical.com

Instruction Manual

• Do NOT use liquids on or inject into living tissue, unless actual liquid temperature has been measured

and is acceptable. Temperature of the warming cabinet’s contents may be hotter than the displayed

air temperature. For patient safety, in accordance with good medical practice, always check liquid

temperature prior to using.

Warning - Electric Shock Hazard

Do NOT remove control tray. Contact a qualied service representative. Some of the troubleshooting

procedures can require access to live electrical circuitry. Dangerous accidental contact with line voltage is

possible. Only qualied service personnel should be allowed to perform these procedures.

Warning - Explosion Hazard or Fire Hazard

• Do not warm ammable materials or liquids.

• Do Not use in the presence of ammable anesthetics.

• Do Not heat liquids in the presence of ammable solvents.

Caution - Possible Equipment Damage

Some items are not acceptable in these warming cabinets. If in doubt as to whether an item can be safely

processed, have the facility supervisor contact the manufacturer of the item.

Caution: Repairs And Adjustments should only be attempted by experienced service personnel

who are fully acquainted with this equipment. Use of unqualied or inexperienced personnel to work on the

equipment, or the installation of unauthorized parts, could result in serious personal injury, or result in costly

damage. Always unplug power cord from power source before attempting any repairs or servicing of this

equipment.

Special User Attention

Prior to use, all personnel who will operate the Warming Cabinet must be instructed in the correct usage and

operation. All personnel who will use the Warming Cabinet should be aware that sensible care must be

exercised to maintain patient safety and to keep the Warming Cabinet performing at peak efciency.

Intended Use Notice

This product is intended to be used by medical personnel for the purpose of providing heated storage of

blankets, sterile water and saline solutions used in the care of patients in surgery, recovery, OB/GYN, ICU,

ER and trauma areas in healthcare facilities where al operators are instructed on the usage, limitations and

hazards. No other use is authorized or recommended.

This product is to be used strictly for the purpose for which it was designed. Using this product in a manner

not specied by MAC Medical, Inc. can void the protection provided by the equipment manufacturer. MAC

Medical, Inc. disclaims all liability for the consequences of this product being used for other than what it was

designed for. Product modication or misuse can be dangerous. MAC Medical, Inc. disclaims all liability for

the consequences of product alterations or modications, as well as for the consequence that can result

from the combination of this product with other products, whether supplied by MAC Medical, Inc. or by other

manufacturers, unless such a combination has been specically endorsed, in writing, by MAC Medical, Inc.

MAN-001

11

www.macmedical.com

Instruction Manual

Unpacking Instructions

Receiving Requirements

The customer is responsible for making sure the

loading dock at their facility can accommodate a

shipping carton approximately 70” inches (1.778 m)

long and 40” (1.016m) inches wide.

The customer must also provide transportation

equipment (forklift, etc) for a carton weighing

approximately 500 lbs (227 kg).

Inspection

1. Receiving area must meet all State and Local

regulations prior to unpacking.

2. Customer must inspect carton both before and

after unpacking to determine if any items were

damaged during shipping.

A. All damaged items must be listed on the Bill of

Lading.

B. The serial number and model number shown

on the carton label must match the numbers

on the Bill of Lading and the Invoice.

3. Customer is responsible for the proper disposal of

all packing materials. The disposal of these items

must meet all State and Local regulations.

plastic protective wrapping around the

Warming Cabinet. These items can scratch

the protective coating on the stainless steel

allowing the surface to rust.

9. The Warming Cabinet is now ready for use.

10. Discard shipping and packing materials in

compliance with local and state regulations.

11. Warmers, when not in use, must NOT be doublestacked while in storage. Warmers, while still in

shipping cartons, must not be double-stacked

when not in use.

Unpacking the Warming Cabinet

Retain all shipping materials until warming cabinet is

completely unpacked and inspected for damage.

1. Remove metal bands holding the bottom and

top of the shipping carton together.

2. Remove all metal staples holding the top and

bottom of the carton to its sides.

3. Remove the top of the carton.

4. Remove metal staples making the aps around

the top edge of the carton.

5. Remove metal staples attaching the sides of the

carton to the bottom of the carton.

6. Remove the sides of the carton by lifting them

straight up from the bottom tray.

7. Lift Warmer straight up from bottom tray of the

shipping carton and remove it.

8. Remove all protective packing material.

A.

Caution: DO NOT use a box cutter

or any other cutting utensil to remove the

Fig. 6: Warming Cabinet in Shipping Container

MAN-001

12

www.macmedical.com

Installing D-Series Warming Cabinets

environmental Conditions

This unit is intended for use in a stable ambient

environment, with an ideal temperature of 72° F

(22.22° C) or less. The unit should never be used

directly next to any appliance that may produce

heat, such as an autoclave.

During Transport and Storage (in original packaging

materials) -

• Ambient Temperature: -40° - 159°F (-40° - 70°C)

• Relative Air Pressure: 10% - 100%, including

condensation

• Air Pressure: 500 hPa (14 inHg - 31.3 inHg)

During Use - for Dry Locations

• Ambient Temperature: 60° - 85°F (15° - 30°C)

• Relative Air Moisture: 30% - 60% non-condensing

• Air Pressure: 700 hPa - 1060 hPa (20.7 inHg - 31.3

inHg)

Instruction Manual

1. Carefully uncrate the D-Series Warming Cabinet.

2. Inspect for any damage. If there is damage,

please contact MAC Medical, Inc. at (1-877-828-

9975).

3. Check your 120V, 60 Hz, Single Phase 15 AMP

GFIC Protected electrical outlet or 220V, 60 Hz,

Single Phase, 7 AMP GFIC Protected electrical

outlet. Be sure the outlet is safely accessible and

in proper working condition.

4. Plug the 3-prong electrical plug into the 120VAC,

60Hz, 15 AMP, GFIC Protected Outlet or a 220

VAC, 60Hz, Single Phase, 7 AMP GFIC protected

electrical outlet. Make sure the electrical outlet is

safely accessible and in proper working condition.

5. Place Warming Cabinet on a solid, level platform

where external movement will not interfere with

loose contents used by the warmer.

6. Make sure the shelving is correctly located as

desired and level. If not, adjust their height (see

“Adjusting the Shelves” on page 19).

7. Before use, remove any items that have been

stored in the cabinet.

Installation

Before starting the installation, review the local

electric codes including the Occupational Health

and Safety Act for any requirements pertaining to the

proper installation of this equipment.

Contact your MAC Medical representative for seismic

calculations and tie-down hardware, if applicable.

Testing before Using

All warming cabinets have been calibrated and

tested before leaving the factory. There is no need

for the user to do additional testing after installation

prior to use.

After six month of use, it is recommended that the

user test the warming cabinet for temperature

accuracy. See “Semi-Annual Checklist” on page

24.

MAN-001

13

www.macmedical.com

Instruction Manual

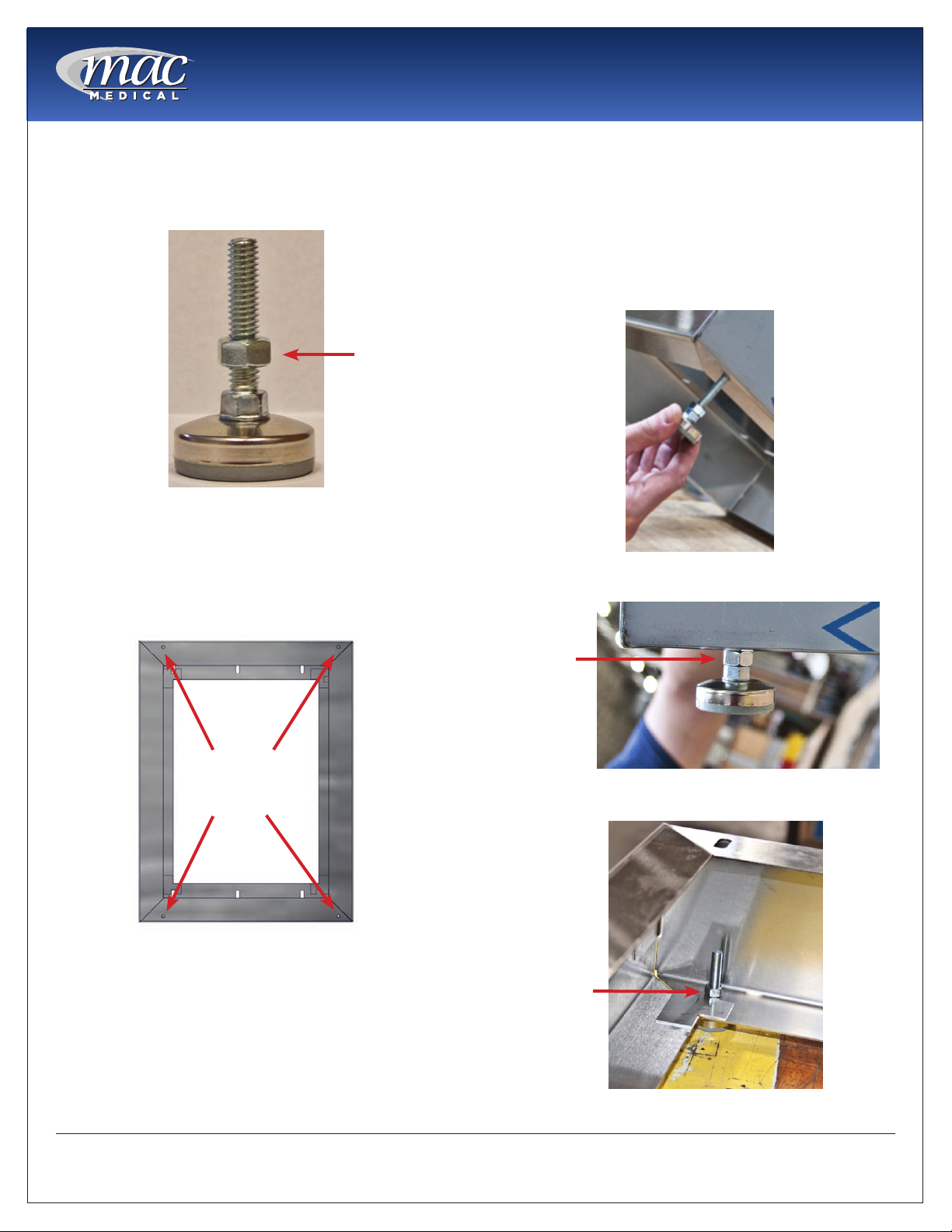

Installing Warming Cabinet leg levelers

Warming Cabinets are shipped with 4 Leg Levelers

which must installed by the customer (Fig. 7).

Jamb Nut

Fig. 7: Leg Leveler

The Warming Cabinet base has 4 holes into which

the Leg Levelers can be installed (Fig. 8).

Working with at least two people, carefully tilt the

Warming Cabinet back slightly and insert the 4 Leg

Levelers up into the 4 provided holes (Fig. 9).

IMPORTAnT: The Jamb Nut must go on the outside of

the Cabinet Base, not the inside. Fig.10 shows a Leg

Leveler correctly installed with the Jamb Nut outside

the base. Fig. 11 shows the Leg Leveler incorrectly

installed with the Jamb Nut inside the base.

Fig. 9: Insert Leg Leveler into base

Holes for

Leg Levelers

Fig. 8: Holes in Cabinet base

Jamb Nut

Fig. 10: Leg Leveler - Correct installation

Jamb Nut

Fig. 11: Leg Leveler - Incorrect installation

MAN-001

14

www.macmedical.com

Instruction Manual

2

5

2

3

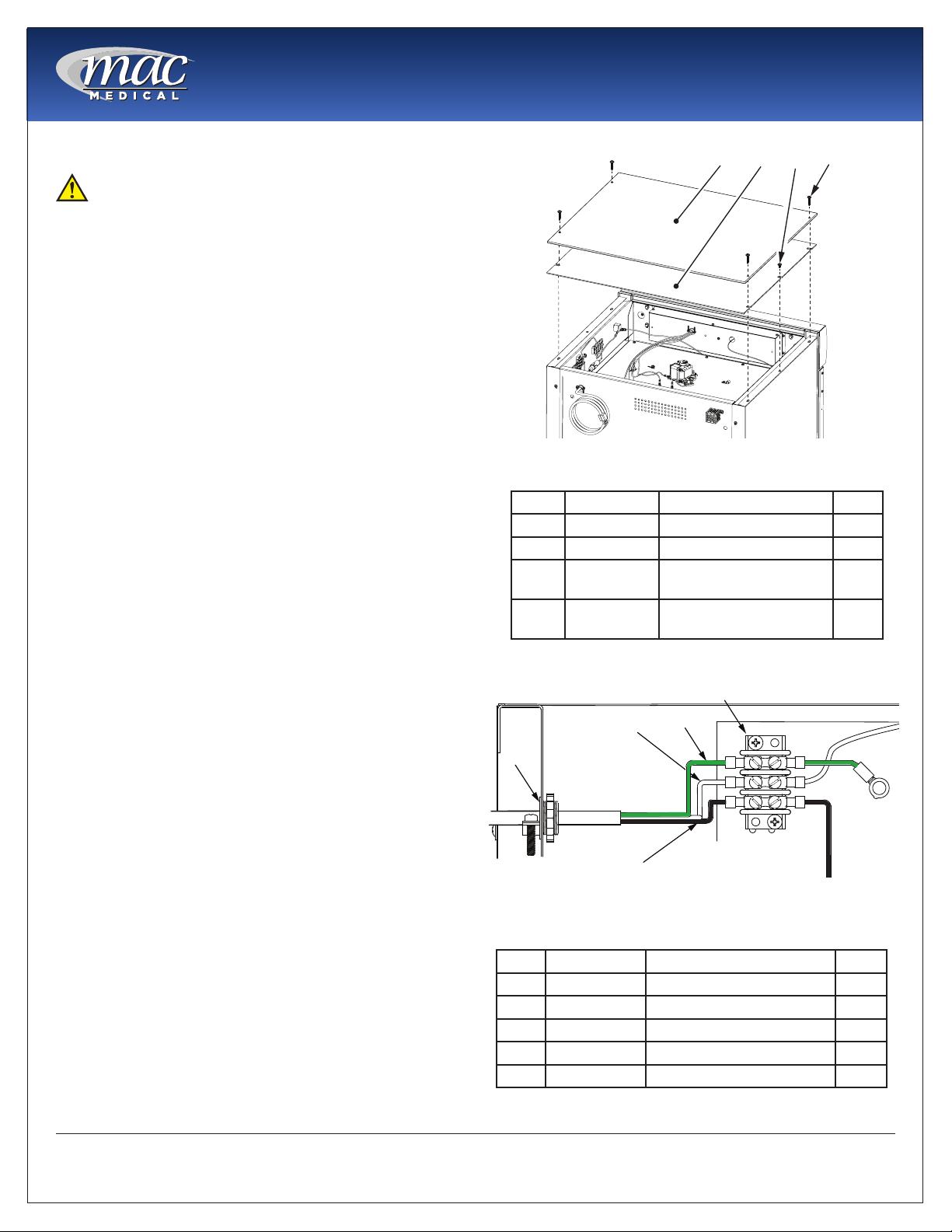

Optional Direct Wiring Using facility Power Supply

NOTE: The following procedure must be performed

by a qualied electrical technician to avoid personal

injury or damage to the unit.

Warming Cabinets can be wired directly into the

facility’s wiring by following these steps:

1. Remove four 8 X 1-5/8” self tapping screws and lift

off the Top Outer Panel. See Fig. 7.

2. Remove two 8 X 1/2” self tapping screws and lift off

the Top Inner Panel. See Fig. 7.

3. Loosen the 3/8” straight-thru connector (See Figure

4, Item 1) and disconnect wiring from terminal

board (Figure 4, Item 5) and from Fig. 8, Items 2, 3, 4.

4. Remove existing power cable (See Figure 4, Items

2, 3, and 4) from terminal block and pull out of

Warming Cabinet through 3/8” connector (See Fig.

8, Item 1).

5. Feed facility wiring cable back through the 3/8”

connector (See Fig. 8, Item 1) in the back of the

cabinet and wire onto terminal board as shown in

Fig. 8. Tighten the 3/8” to securely hold the facility

wiring in place.

6. On the terminal board, The green wire (Item 4)

connects with the green ground wire.

7. The white wire (Item 3) connects opposite with the

white wire, or neutral wire, on the terminal board.

8. The black wire (Item 2) connects opposite of the

black or positive wire on the terminal board.

9. Re-install the Inside Top Panel using two 8 X 1/2” selftapping screws. See Fig. 7.

10. Re-install the Outside Top Panel using four 8 X 1-5/8”

self-tapping screws. See Fig. 7.

11. Carefully slide the unit into its permanent location.

1

Fig. 12: Remove Top Covers

Item P/n Description Qty

1 SMW0027 Outside Top Panel 1

2 SMW0028 Inside Top Panel 1

3 H0012-01 Screw, Self-Tapping, 8

X 1/2”

4 H0012-02 Screw, Self-Tapping, 8

X 1-5/8”

3

4

1

4

2

4

MAN-001

Fig. 13: Unwiring Terminal Block

Item P/n Description Qty

1 W0140 Connector, Straight, 3/8” 1

2 W0077 Wire, Black, Positive 1

3 W0077 Wire, White, Neutral 1

4 W0077 Wire, Green, Ground 1

5 W0005 Terminal Strip, 3-Position 1

15

www.macmedical.com

basic Operation

1" OF

1" OF

SPACE

SPACE

1" OF

SPACE

This cabinet has been designed to heat:

• Liquids in vented containers.

• Liquids in non-vented containers to a temperature

of 150° F maximum (65.6°).

• Metal objects

• Muslin or 100% cotton sheets and wool blankets.

• Glass containers must be annealed borosilicate

glass (Pyrex type).

• Only plastic containers rated Thermal and

capable of withstanding temperatures in excess

of 300° F (149° C)

Instruction Manual

Fig. 14: Content Spacing

DO NOT WARM -

• Synthetic blend fabrics

• Flammable liquids

• Items containing non-thermal plastic, rubber,

metal snaps, studs, hooks, etc.

Recommended Settings

MAC Medial, Inc. does not recommend chamber

set points for any items that are to be warmed. For

appropriate heating temperatures, please contact

the item manufacturers. For more information, please

contact MAC Medical, Inc.

For blankets, follow blanket manufacturer’s

instructions for the set point.

For intravenous and irrigation uids, follow

temperature guidelines printed on the container or

contact your supplier for temperature and expiration

periods.

loading Contents in Cabinet

Load contents into the chamber with a minimum of 1

inch of space between all walls and fan to allow for

evenly distributed circulation (as seen here).

Allow 1” of spacing between uid containers for

evenly distributed heating (Fig. 9). Avoid stacking

uid bags as this increases the heating time required

to achieve set temperatures.

Blankets must be folded and stacked to allow a one

inch minimum space from the sides, back and top

of the compartment or the shelf above. Do not let

blanket protrude past the front edge of the shelf.

DO nOT OVeRlOAD.

Once a set temperature is selected and obtained

it will be controlled throughout the operations

within ± 1°F to 3°F (-1.7°C to -1.6°C) of the selected

temperature.

From a cold start, each compartment’s loaded

contents will be evenly heated to a set point within 2

to 6 hours (depending on the load). In the event of

power loss, the warmer will resume normal function

once power is restored.

For multi-chambered units, each chamber can be

loaded with different goods and set at different

temperature settings.

In Case of Power failure

In case of power failure, the unit will resume normal

operation when power is restored.

Follow the uid manufacturer’s guidelines for unused

solutions that have cooled or have been removed

from heated storage.

MAN-001

16

www.macmedical.com

explanation of the Controls

Instruction Manual

2

1

OFF

4

ON

5

9

3

7

6

8

Fig. 15: Controller Display

The Controls are located on the upper panel (Fig. 10) on the front of the cabinet. For multi-chamber cabinets,

there are sets of controls for each individual chamber. Each control set is clearly labeled UPPER CHAMBER and

LOWER CHAMBER for dual chamber cabinets and UPPER CHAMBER, MIDDLE CHAMBER and LOWER CHAMBER

for the triple chamber cabinets.

Item Control

Components

1 ON/OFF Switch/

Circuit Breaker

2 HEAT light Visual indicator that the heating system is active

3 ALARM light Visual indicator of an overheat condition

4 Display Panel Shows the current chamber temperature (Actual) and the Setpoint temperature in

Provides power to the warming compartment and control

Fahrenheit (F) or Celsius (C). The upper readout row indicates what mode will be dened/

changed (i.e. top/bottom chamber, date, etc). It also continually indicates the actual

temperature. The lower readout row indicates the settings for the mode. It also continually

indicates the setting temperature. The display also provides Loss of Power and Overheat

(Alarm). The overheat alarm is an audble and visual display “HI”.

function

Numbers/letters are entered in reverse order, working from right to left across the controller.

5 UP arrow Adjusts the setpoint of the chamber and silence the audible overheat alarm.

6 DOWN arrow Adjust the setpoint of the chamber

7 SET buttom Press to change the setpoint temperature. Press again to save a setpoint temperature. SET is

also used to move to the next setting parameter/mode

8 DATA port USB port used to retrieve temperature values for a set period of time.

9 Key Switch Used to lock out any changes to the control, such as adjusting the setpoint temperature.

MAN-001

17

www.macmedical.com

Operation of Display Panel

Instruction Manual

Start

Press the power switch to the “ON” position. (For multichamber units, each chamber has its own power

switch). The upper readout display will show the

actual chamber temperature.

Set Processing Temperature

1. Press “SET” and release.

2. Press the UP ▲ arrow key up (to raise the setpoint)

or the down ▼ arrow key (to lower the setpoint).

The setpoint is indicated in the lower row of the

display.

3. Press “SET” again to complete the change (If dual

or triple chamber unit, steps must be completed

for all chambers). The setpoint temperature will

change and the last digit will ash.

4. To prevent adjustment to the setpoint

temperature, the control may be locked with the

Key Switch (see #9, Fig. 10)

NOTE: See the Maximum/Minimum Limits Temperature

Set Points table below for various warming cabinets

and chambers.

NOTE: The temperature setting may be changed

at any time. However, if the setpoint is changed

more than 10° below the actual temperature, the HI

temperature alarm will activate.

If alarm is activated and the control panel reads “HI”,

complete the following steps:

1. Press “ALARM RESET” (UP ▲ arrow) until the alarm

stops.

2. Open door(s) to release heated air.

3. If the display reads “HI” and alarm remains, open

door(s) and allow more cooling time.

NOTE: If the alarm is activated under normal

operating conditions, turn power to specic chamber

off and call your Mac Medical representative at

1-877-828-9975.

Caution Burn Hazard: DO NOT raise the

setpoint temperature to increase the rate of heating.

This could overheat the contents leading to possible

patient burns.

Warning Explosion Hazard: DO NOT exceed

150° for non-vented closures (screw caps, crimp seals,

plastic pouches, etc. DO NOT exceed pre-sterile

solution manufacturer’s temperature requirements.

Minimum/Maximum limits Temperature Set Points and Temperature Tolerances on Warming Cabinet Units

Warmer Cabinet Model Minimum

SWC151822

Single chamber units SWC182424, SWC182436, SWC183024,

SWC182464, SWC242436, SWC243024, SWC242424

Single chamber units SWC183036, SWC243036 ±2°F

Single chamber units SWC182474, SWC183064, SWC183074,

SWC242464, SWC242474, SWC243064, SWC243074

Dual Chamber units (Upper Chamber) DWC182464T, DWC183064T,

DWC182474T, DWC183074T, DWC242474T, DWC243074T

Dual Chamber units (Upper Chamber) DWC182474E, DWC183064T,

DWC183074E, DWC242464T, DWC242474E, DWC243064T, DWC243074E

Dual Chamber units (Lower Chamber) DWC182464T, DWC182474E,

DWC183064T, DWC182474T, DWC183074T, DWC183074E,

DWC242464T, DWC242474E, DWC243064T, DWC243074E

Dual Chamber units (Lower Chamber) DWC242474T, DWC243074T ±3°F

Triple chamber models

Temperature

Set Point

90°F (32°C)

Maximum

Temperature

Set Point

135°F (57°C)

160°F (71°C)

110°F (43°C) top

chamber

135°F (57°C)

middle chamber

160°F (71°C)

bottom chamber

blankets Irrigation

30°C to 71°C

(86°F to 160°F)

fluids

30°C to 66°C

(86°F to 150°F)

Injection

fluids

30°C to 40°C

(86°F to 104°F)

Temperature

±1°F

±1°F

±3°F

±1°F

±2°F

±2°F

±1°F

±1°F

±1°F

Tolerance

MAN-001

18

www.macmedical.com

Instruction Manual

Installing the Shelves

1. Where applicable, turn the power OFF to the

heating chamber that needs a shelf installed in it.

A. Allow the heating chamber to cool. Then

unload any contents.

2. Install the 4 shelf support clips into the desired

location by inserting the top tab into the upper

wall slot of that position (Fig. 12 & Fig. 13). Push

up slightly on the inserted top tab and push the

bottom half of the clip in until the bottom tab

snaps into the lower slot.

3. Count the mounting locations at each corner of

the chamber to be sure that the shelf will be level

and install the remaining support clips.

4. Install the shelf with the notches on the bottom of

the shelf aligned with the shelf supports (Fig. 13 &

Fig. 14).

5. Pull outward on the shelf to insure it is locked

properly on the supports.

Adjusting the Shelves

1. Turn the power OFF to the heating chamber that

needs its shelf adjusted.

A. Allow the chamber to cool. Then unload the

contents.

2. Remove the shelf and determine its new position.

3. Remove the four (4 per shelf) shelf supports clips

by tilting the clip upwards and lifting out.

4. Install the shelf support into the new location by

inserting the top tab into the upper slot of the new

position. Push up slightly on the inserted top tab

and push the bottom half of the clip in until the

bottom tab snaps into the lower slot..

5. Count the mounting locations at each corner of

the chamber to be sure that the shelf will be level

and install the remaining supports.

6. Re-install the shelf with the notches on the bottom

of the shelf aligned with the shelf supports.

7. Pull outward on the shelf to insure it is locked

properly on the supports.

Fig. 16: Shelf Support

Wall Slots

Fig. 18: Support Clip Fitted in Notch

Shelf Support showing tabs

Fig. 17:

NOTE: Shelves are notched at each

corner to rest on 4 shelf support clips

that are inserted into the cabinet wall

slots (Figure 14).

Shelf Notch

Fig. 19:

MAN-001

19

www.macmedical.com

Instruction Manual

Installing and Adjusting Optional Roller basket Shelves

Install the roller basket shelf by rst attaching the two roller channels to the cabinet walls.

1. First, insert the top tab of one end of the roller channel into a slot (the roller channel width spans 4 slots). Fig.

15 & Fig. 16.

2. After inserting the top tab , push up slightly on it while snapping in the bottom tab into a slot located 3 slots

below the top slot. (Fig. 17)

3. Snap in the other end (make sure it is level with the rst end) and attach the other roller channel to the

opposite side in the same manner. Be sure both channels are level with each other.

4. Set the 2 sets of rollers of the roller basket into the channel tracks on both sides and slide the shelf in (Fig. 18 Fig. 19).

Fig. 20: Inserting Top Channel Tab

Fig. 23: Rollers in Channel Track

Adjust the Roller Basket Shelf

Fig. 21: Cabinet Wall Slots

Fig. 24: Roller Basket Shelf Installed

Fig. 22: Inserting Bottom Channel Tab

1. To adjust the roller basket shelf, slide the shelf out and lift up to clear the rollers from the roller channel track.

Set the shelf aside.

2. Remove the roller channels by pushing up slightly on the top tab of the channel and pull out the channel

from the bottom.

3. Re-install the roller channels in another location using the same installation process described above.

4. After re-installing the roller channels, re-install the shelf by aligning its rollers in the roller channel track and

sliding the shelf in.

Note: For information on basket dimensions and part numbers pertaining to warmer cabinet models, see page

26.

MAN-001

20

www.macmedical.com

Unloading the Warming Cabinet

Instruction Manual

Caution Injury and Burn Hazard: Avoid injury

by using proper personal protective equipment when

loading or unloading the Warming Cabinet. Internal

surfaces are hot, glass may shatter when cooled

suddenly and solution bags or bottles may burst when

picked up. Rotate warmed contents on a rst-in,

rst-out basis. Failure to do so may present cold or

discolored contents.

Maximum Warming Temperature limit for Patient Safety (as recommended by eCRI)

Items to be Warmed Maximum Temperature limit

Liquid Solutions for use on living tissue 110°F (43°C)

Blankets 130° (54°C)

Retrieval of Recorded Temperatures

AORN recommends the cabinet temperature

should be routinely monitored and documented on

a temperature log or on a record provided by an

electronic recording system, according to facility

policy.

All MAC Medical D-series warming cabinets are

equipped with a temperature monitoring program

that stores actual chamber temperatures in 30 minute

intervals. The information recorded may be down

loaded to a USB ash drive at any time. To retrieve

the stored data:

1. Insert the MAC Medical ash drive (W0600-S)

or equivalent into the USB port marked DATA

(located on the front face of the control panel).

For multi-chambered units, insert a ash drive into

the USB port marked DATA for each chamber.

2. The digital display will change from displaying the

actual temperature to displaying the code shown

in Fig. 20.

Warning Injury or Burn Hazard: DO nOT

use heated liquids on, or inject in, living tissue unless

actual liquid temperature has been measure and

found acceptable. The temperature of the Warming

Cabinet contents may be hotter than the displayed

temperature. For patient safety (in accordance

with optimal medical practice), always verify liquid

temperature with a themometer at the point of use.

Important: See Maximum Warming Temperature Limit

for Patient Safety table below

3. Once the transfer is complete, the digital display

will show the temperature again.

4. Remove the ash drive. The data is saved on

the ash drive as a .CSV le for import into most

Windows-based spreadsheet programs. The

example below shows the Fahrenheit temperature

variation within a certain date and time period as

shown in Fig. 21.

Fig. 25: Data Download Code

Fig. 26: Data extracted

Turning Off the Warming Cabinet

Switch the ON/OFF Switch to the OFF position for each chamber to be shut down.

MAN-001

21

www.macmedical.com

Instruction Manual

Troubleshooting

The following alert messages and operating conditions will occur when the warming cabinet is operating

outside of acceptable conditions.

Troubleshooting Guide

Alerts & Description Action Required

HI with audible alarm

LLLL

HHHH with audible alarm

OPEn with audible alarm

JIC continuous or ashing

Unit will not power up 1. Check outlet for power

Chamber does not heat 1. Is the power turned on?

Over temperature alarm

activated

Cabinet temperature is 10°F (or 5°C) higher than setpoint. Silence the alarm by pressing

ALARM RESET (Up ▲ arrow) and open door(s) to allow the chamber(s) to cool.

Input temperature is lower than input range. Check temperature probe and

connections. See below for additional troubleshooting.

Input temperature is higher than input range. Check temperature probe and

connections. See below for additional troubleshooting.

Temperature probe is at fault. Check connection, then replace and calibrate.

Control failure. Check connection rst, then replace and calibrate.

2. Check if warmer is plugged in

3. Check if the ON/OFF switch/circuit breaker is turned on

4. Check the fuse on the incoming supply

5. Check for power at the junction box in the control panel

6. Contact your MAC Medical authorized service representative

2. Is the temperature set above chamber ambient temperature?

3. Is the circulation fan operational? Open the door and press in on the door switch

4. Is there voltage on the output terminal of the controller?

5. Is the door(s) closed?

6. Contact your MAC Medical authorized service representative

7. Is the circulating fan operational?

HI is

8. Are the contents loaded properly?

9. Has the chamber set temperature been lowered?

10. Temperature of the lower chamber cannot be in excess of +30°F (+1.1°C) above the

upper chamber

11. Contact your MAC Medial authorized service representative

Overheat Alarm (HI) Condition

When the cabinet temperature exceeds the setpoint by 10°F (or by 5°C) or the set temperature is lowered

by more than 10°F (or by 5°C), the display will red HI and the audible alarm will sound. Silence the alarm by

pressing ALARM RESET (Up ▲ arrow) until the alarm quits.

Turn off the Warming Cabinet chamber and wait for the contents to cool adequately. Then unload the

contents using personal protective equipment to avoid injury. Reload the contents using the proper loading

guidelines as previously mentioned in this manual.

Turn on the chamber and monitor performance. If the chamber continues to overheat into an alarm (HI)

condition, turn off the chamber and contact your MAC Medical authorized service personnel.

MAN-001

22

www.macmedical.com

Instruction Manual

Cleaning Stainless Steel Warming Cabinets

Stainless steel Warming Cabinets must be cleaned on a regular basis to prevent any unnecessary damage to

the stainless steel surfaces. Spilled liquids and standing water should be cleaned up immediately.

When cleaning stainless steel Warming Cabinets, make sure to use the proper approved cleaning agents and

cleaning materials to protect the surface and prevent damage or corrosion.

CAUTION:

DO nOT USe

these Cleaning

CAUTION:

DO nOT USe these

Cleaning Agents

Materials

Abrasive Pads Hard Water (water with a pH

reading above 7.0).

Scrapers (metal or

plastic)

Steel Wool Steam or high pressure water

Wire Brushes Bleach or any compounds

Cleaning Stainless Steel Surfaces

Hydrochloric Acid

containing chlorine or Sodium

hypochlorate, or ammonium

chloride salts.

• Using a damp, lint-free cloth and approved

cleaner, wipe down the entire exterior surface

of the stainless steel warming cabinet. Using a

damp, lint-free cloth with distilled water and a mild

detergent, wipe down the entire exterior surface

of the stainless steel sinks.

• Clean the Warming Cabinet with the stainless steel

surface grain as shown here.

• Let cleaned Warming Cabinet air dry.

Cleaning Decals or Printed Labels

• Use only distilled water and a mild detergent

applied with a clean, dry lint-free cloth to clean

decals or printed labels.

• Cleaning agents can remove or smear any

printing from decals and print labels.

• Cleaning agents can damage plastic materials

used in manufacturing covers for electronic items

such as touch-screen pads.

Approved cleaning materials and agents

Soft, clean lint-free

cloth

Mild detergents Sodium

White vinegar (in a

spray bottle)

Cleaners

approved for use

on stainless steel

Disinfecting Stainless Steel

Non-abrasive

cleaning pads

Bicarbonate

(baking soda)

Isopropyl

Alcohol

Soft bristle brush

Distilled water (pH

rating 7) alone

or with a mild

detergent

Hospital-grade

non-bleach

disinfectants

• Use a hospital grade non-bleach disinfectant.

Always follow the manufacturer’s instruction for

proper use of these products.

Cleaning the Warming Cabinet Interior:

• Unplug and remove the Warming Cabinet from its

power supply.

• CAUTION: Turn OFF Circuit Breaker if Warming

Cabinet is hard wired into the facility’s electrical

supply.

• Open the door and remove all adjustable shelves

and shelf clips.

• Clean the adjustable shelves and shelf clips

separately.

• Using a damp, lent free, cloth and approved

cleaner, wipe down the interior of the cabinet.

• Use a lint free dry cloth to dry the cabinet’s interior

or let air dry. If air drying, ALWAYS leave the

cabinet door open.

Cleaning Glass Doors (if applicable):

Use a commercially prepared ammonia-free glass

cleaner or use distilled water and a mild detergent

applied with a lint-free cloth.

MAN-001

23

www.macmedical.com

Preventative Maintenance Checklist

Operator Maintenance

Users are responsible for the thorough inspection of the

equipment before and after each use. Should any

problems or deciencies arise, the results must be reported

to the facilities maintenance personnel. The safety of

personnel and patients relies on the proper and routine

maintenance of this equipment.

Daily Checklist

1. Ensure that the correct operation and maintenance

manual is available to all users.

2. Ensure that all personnel using this appliance have

been properly trained in the warmer cabinet operation

and safety instructions.

3. DO NOT overload cabinet. Load contents (blankets

or uids) into the chamber with a minimum of 1 inch of

space between walls and fan to allow for circulation

(as seen below).

" OF

PACE

1" OF

SPACE

1" OF

SPACE

Instruction Manual

6. Periodically check the alarm by setting the

temperature ±15° from set point to test the alarm. If

the temperature rises or drops 15° below its set point,

the alarm should buzz and its light goes on. (Note:

90° is the lowest temperature point. To test alarm

from this point, heat the unit up 15° beyond its lowest

temperature, then bring the set point down to test the

alarm.)

Monthly Checklist

1. Check condition of casters or feet. Ensure components

are secure and tightly threaded.

2. Check control panel overlay condition. Are there any

tears or excessive wear on the graphic? Does the

control work properly when buttons are pushed?

3. Is the set temperature comparable to the actual

temperature displayed? Check chamber air

temperature with a quality thermocouple placed 1”

(25mm) from the chamber. Do not allow the sensor to

touch any surface. Monitor for approximately one hour

in an empty chamber.

Weekly Checklist

1. Inspect condition of plug and cord. Replace if

damaged.

2. Clean dust from back and side vents.

3. If any of the chamber shelves are unstable when

setting objects on them, check the shelf clips that the

shelves sit upon. Make sure these are not loose. If any

are loose, snap back into place.

4. Check basket shelves (if applicable) and side rail

condition. Do the baskets move smoothly and freely?

5. Check that all control indicators (heat and alarm)

and LED display light up. LED Display panel must show

lighted top and bottom displays. Heat light will stay

on solid while the unit is heating up to its Set Point

Temperature. Once the Set Point temp is reached, the

light will begin to pulsate, and will continue to pulsate

to maintain the Set Point temp.

MAN-001

Semi-Annual Checklist

1. Check the temperature accuracy on a semi-annual

basis by placing an IR Temp probe or thermocouple

on calibrated meter near the fan inlet. In general,

air temperature should be ±1°F for upper chamber

and counter top units and ±3°F for lower chambers

and large single cabinet units. See table column

“Temperature Tolerance” on page 18 for details. If

the cabinet is not within these guidelines, contact MAC

Medical for further assistance.

2. Inspect the Fan blades for buildup of lint and other

debris. Clean as necessary. nOTe: MAC Medical

recommends replacing the Fan Motor with Fan blade

(Part # - W0036 (120V)/ W0106 (220V)) every 2 years to

ensure uninterrupted service.

24

www.macmedical.com

Instruction Manual

Replacement Parts - General

D-Series Warming Cabinet replacement parts listed on this page have been identied by MAC Medical as

serviceable by facility personnel and are available for purchase. To obtain MAC Medical certied parts and

authorized services, contact your MAC Medical representative.

Item Part # Description QTY

1 W0102 - Key Key only - Key Lockout (2 keys per set)

Single Chamber (1 set), Dual Chamber (2 sets), Triple Chamber (3 sets)

2 SWW0055 Adjustable Shelf As Required

3 W0050 Handle, Stainless Steel Door , LH Upper, RH Lower (Dual/Triple Upper

Chamber)

W0051 Handle, Stainless Steel Door, LH Lower, RH Upper (Dual Lower Chamber, Triple

Middle Chamber)

W0052 Handle, Stainless Steel Door Single Chamber & Triple Lower Chamber 1

W0053 Handle, Glass Door 1

4 H0006-1 8-32 X 1/2” Undercut Flat Head Screw (used with W0050, W0052, W0052) 3 per handle

H0008-1 8-32 X 1/2” Screw (used with W0053) 2 per handle

5 W0043 Clip, Shelf 4 per shelf

6 W0135 Leg Leveler 4

7 W0600-S USB Drive, Data Retrieval (1 per chamber) As Required

MAN-001

25

www.macmedical.com

As Required

1

1

Replacement Parts - Header Assembly and electrical Drawer

The Parts identied in this section require an authorized

MAC Medical service technician.

Injury Hazard: The design of the Warming Cabinet

allows limited user serviceable parts or procedures. For

optimal usage, safety and durability of the product,

service must be performed by a MAC Medical authorized

service technicians using MAC Medical authorized

replacement parts and service techniques.

Instruction Manual

Fig. 27: Replacement parts in header assembly

MAN-001

Fig. 28: Replacement Parts in drawer assembly

26

www.macmedical.com

Instruction Manual

Table 1

Item # Part # Header Assembly and electrical

Drawer Parts Description

1 W0011 Power Switch 10 See table 2 Heating Element

2 W0083 Solid State Relay 11 W0010 Ceramics

3 W0137 Heat Sink Pad 12 W0037 Thermocouple

4 W0102 Key Lock Housing 13 W0042 Overtemp Thermostat

5 W0084-D Control W/Data Display Logger 14 See Table 3 Fuses

6 W0108 10” Data Cable 15 W0004

7 H0141 Cam Lock 16 W0013

8 H0708-07 Cam Lock Latch 17 W0012

9 W0036

W0106

Fan Motor with Fan blade (120V)

Fan Motor with Fan blade (220V)

Table 2 (Heating Element - Item 10)

Part # Size Volt/Watt Where Used

W0131 8” 110V/350W SWC151822

W0313-220 8” 220V/350W SWC151822-220

W0069 9” 110V/350W SWC182424, SWC243024, DWC182464, DWC182474E, DWC243024, DWC242474T,

W0069-220 9” 220V/350W SWC182424-220, DWC182464T-220

W0069-01 9” 110V/750W SWC183064, SWC183074, SWC243074, SWC182464, DWC242474T

W0069-01-220 9” 220V/750W SWC183064-220 SWC183074-220, SWC243074-220, SWC182464-220, DWC242474T-220,

W0302 9” 110V/650W SWC243036, SWC182424, SWC182436, SWC182474, SWC183036, SWC242424, SWC242436,

W302-220 9” 220V/650W SWC183036-220, SWC243036-220, DWC183074E-220, DWC182474T-220, DWC183064T-220,

W0003 12” 110V/750W SWC243024, SWC243036, SWC243074, DWC243024, DWC243064T, DWC243074E

W0107 12” 220V/750W SWC182424-220, SWC182464-220, SWC183024-220, SWC242474-220, SWC243024-220,

DWC183064T, DWC243074T, TWC243078

TWC243078-220

SWC242464, SWC243064, DWC182474E, DWC183074E, DWC183064T, DWC183074T,

DWC182464T, DWC182474T, DWC242474E, DWC243074T, TWC243078

DWC243074T-220, DWC182464T-220, TWC243078-220

SWC243074-220, DWC182464T-220, DWC243074T-220, DWC242464T-220, DW242474T-220,

DWC183064T-220

Item # Part # Header Assembly and electrical

Drawer Parts Description

W0188

W0013-220

W0012-01

18 W0525-04 USB Plug to Panel Recept 12”

Fuse Holder

Fuse Holder (for 1518 models)

Buzzer 110V

Buzzer 220V

Door Switch

Door Switch w/long stem (bottom glass

doors on dual chamber units, all stainless

steel doors)

Table 3 (Fuses - Item 14)

Part # Description Where Used

W0395

(220V)

W0396

(220V)

W0124

(110V)

W0125

(110V)

MAN-001

Fuse 7A

(2 needed)

Fuse 10A

(2 needed)

Fuse 15A All 110V Single chamber cabinets

Fuse20A All 110V Dual and Triple chamber cabinets

All 220V Single Chamber Cabinets

All 220V Dual/Triple Chamber Cabinets

27

www.macmedical.com

Instruction Manual

Optional Cabinet bases, Mobile bases

and Mobile Stands

All warming cabinets are shipped with

a standard 4” base unless otherwise

specied. The table on the right lists the

base part number and sizes for various

SWM0307-02 shown here

sized cabinets.

The two tables below list the mobile

bases/stand part numbers for the single,

dual and triple cabinets.

Single Cabinet Model # Mobile Stand/

basePart #

SWC151822 MS1518 18”D x 21”W x 34”H

SWC182424, SWC182436 MS1824 20”D x 28”W x 34”H

SWC183024, SWC183036 MS1830 20”D x 34”W x 34”H

SWC242424, SWC242436, MS2424 26”D x 26”W x 34”H

SWC243024, SWC243036 MS2430 26”D x 34”W x 34”H

SWC182464, SWC182474 MB1824 21”D x 25”W x 6.75”H

SWC183064, SWC183074 MB1830 21”D x 31”W x 6.75”H

SWC242464, SWC242474 MB2424 27”D x 25”W x 6.75”H

SWC243064, SWC243074 MB2430 27”D x 31”W x 6.75”H

Overall

Dimensions

Dual/Triple Cabinet Model # Mobile base

Part #

DWC182474E, DWC182464T,

DWC182474T

DWC183064T, DWC183074T,

DWC183074E, TWC183078

DWC242474E, DWC242464T,

DWC242474T

DWC243064T, DWC243074E,

DWC243074T, TWC243078

MB1824

MB2424

MB1830

MB1824 21”D x 25”W x 6.75”H

MB1830 21”D x 31”W x 6.75”H

MB2424 27”D x 25”W x 6.75”H

MB2430

MB2430

Overall

Dimensions

27”D x 31”W x 6.75”H

Roll Out

basket

Part #

WB1518 SWC151822 11.5”D x 8.5”W x 2.5”H

WB1824 SWC182424, SWC182436,

WB1830 SWC183024, SWC183036,

WB2424 SWC242424, SWC242436,

WB2430 SWC243024, SWC243064,

Part # base

SMW0307-02 4” base for 18 x 24 cabinets

SMW0359-02-WM 2” base for 18 x 24 cabinets

SMW0359-03-WM 6” base for 18 x 24 cabinets

SMW0062-02 4” base for 18 x 30 cabinets

SMW0047-08 2” base for 18 x 30 cabinets

SMW0062-03 6” base for 18 x 30 cabinets

SMW0308-01 4” base for 24 x 24 cabinets

SMW0308-05 2” base for 24 x 24 cabinets

SMW0308-04 6” base for 24 x 24 cabinets

SMW0047-03 4” base for 24 x 30 cabinets

SMW0047-10 2” base for 24 x 30 cabinets

SMW0047-09 6” base for 24 x 30 cabinets

MS1518 & MS1824 MS1830 & MS2430

WB1518, WB1824,

MS2424

Warming Cabinet Model # basket Overall Dimensions

SWC182464, SWC182474,

DWC182464T, DWC182474T,

DWC182474E

SWC183064, SWC183074,

DWC183064T, DWC183074T,

DWC183074E, TWC183078

SWC242464, SWC242474,

DWC242464T, DWC242474T,

DWC242474E

SWC243074, DWC243036,

DWC243064T, DDWC243074T,

DWC243074E, TWC243078

WB1830, WB2424,

WB2430

16”D x 16.92”W x 5”H

15.88”D x 22.98”W x 5”H

21.75”D x 16.98”W x 5”H

21.75”D x 23.10”W x 5”H

MAN-001

28

www.macmedical.com

Instruction Manual

Steel or Glass Door Hinge Reversal

Before the Door Hinges can be reversed, the top and side

panels of the cabinet must be removed, and the Cam Lock must be

relocated.

Remove Panels

The Following steps for panel removal apply to cabinets with either

steel or glass doors.

1. For both glass and stainless steel doors, remove the outside top

panel by unscrewing the 4 top panel screws and lifting the panel

out. Remove the inside top panel by unscrewing the 2 screws and

lift the panel out (Fig. 29).

Fig. 29: Remove Top Panels

2. Remove the 2 screws located inside the cabinet (one on each side) near the bottom. (Fig. 30 and Fig. 31.

Door removed for clarity in these illustrations.)

Fig. 30: Remove Interior Cabinet Screws - Glass Door Unit

3. Remove the screws at the back of the

cabinet and slide out both side panels

MAN-001

Fig. 31: Remove Interior Cabinet Screws - Steel Door Unit

Fig. 32: Remove Side Panels

29

www.macmedical.com

Remove Header Assembly box & Relocate Cam lock

Purchase Parts needed for Cam lock Reversal

• Felt Strip ST0014

• Plug W0098

The following steps apply to cabinets with steel or glass doors.

Cabinets are equipped with a cam lock in the header

assembly. This must be moved to the other side of the

header assembly box when the door hinges are reversed.

The door itself has a cam lock plate which also must be

moved near the new location of the cam lock (Note: Only

top doors on multi-chambered have a cam lock plate.)

4. To remove the Header Assembly Box, unscrew 4 hex

locking bolts from the header assembly box mounting

plates and remove the header assembly box. (Fig. 33)

Instruction Manual

Fig. 33: Remove Header Assembly Box

5. To access the cam lock and

its new location, cut an area

out of the gasket cover in the

location shown by the red

rectangles (Fig. 34)

Fig. 34: Cut Out Rectangular Sections from Gasket

Fig. 35 shows the header assembly interior (gasket removed for clarity). The cam lock (in red rectangle) will be

moved to the 2 oblong knock-out areas circled in red and highlighted in blue (Fig. 36).

Fig. 35: Cam Lock to be Moved to New Location

Fig. 36: Knock out areas

MAN-001

30

www.macmedical.com

Instruction Manual

6. At the new cam lock location, remove the 2 oblong knock-out areas. Cut an oblong shape in the plastic

overlay covering the short-wide oblong knock-out area to accomodate the cam lock when it is re-installed

(Fig. 37 and Fig. 38). The narrow-long oblong knock-out area will be the slot the cam lock latch ts in.

Fig. 37: Overlay - Cam Lock Location - Right Hand Fig. 38: Overlay-Cam Lock Location - Left Hand

7. To detach the Cam Lock assembly, unscrew the Phillips head screw from the Cam Lock Latch (Fig. 39).

8. Unscrew the Hex Nut and remove the Lock Washer.

9. Pull the Cam Lock body out from the face of the Header Assembly.

10. Insert purchased Plug (W0098) into the hole originally occupied by the lock.

11. To re-install at the new position, slide the Trim ring onto the barrel of the Cam lock, insert Cam Lock body

through the oblong hole at the new position in the face of the header (Fig. 40).

Fig. 39: Detach Cam Lock Assembly

Fig. 40: Re-assemble and Re-install Cam Lock

MAN-001

31

www.macmedical.com

Fig. 41: Assembled Cam Lock

Instruction Manual

12. Secure the Cam Lock body to the header by attaching the Lock Washer, then

the Hex Nut.

13. Afx the Cam Lock Latch to the Cam Lock body and secure it with a 8-32

Phillips head screw.

14. Insert the purchased Felt Adhesive Strip (ST0014) between the Cam Lock Latch

and the header. Position it to keep the cam lock latch from falling down when

the key is in the lock (Fig. 42). When activating the lock, the latch will rub the

felt strip.

15. Use a piece of Felt Adhesive Strip to cover up the old oblong hole where the

cam lock latch passed through the bottom of the header.

16. Re-install the Header Assembly and secure to the cabinet with its 4 screws.

Fig. 42: Assembled Cam Lock with Felt Adhesive Strip Fig. 43: Cam Lock Assembly Parts

MAN-001

32

www.macmedical.com

Glass Door Hinge Reversal and Re-installation

Following are instructions for the removal, hinge

reversal, and re-installation of Glass Doors.

note: No additional parts are required to perform

Glass Door hinge reversal. However, it may be necessary to drill holes in the bottom of the Glass Door

to enable relocation of the Cam Lock Plate to its

new position. The following tools will be necessary

for this procedure:

• 1/8” Drill Bit

• 8/32 Tap

Instruction Manual

Fig. 44: Glass Door Hinge Parts

1. Using a drift pin (or a small headed screwdriver) and a

hammer, detach the glass door from the unit by tapping

lightly on the hinge pins, driving them through the two

halves of the hinges. Then pull the door away from the

unit to remove it (Fig. 45).

2. Detach the male halves of the glass door hinge by

unscrewing them from the warming cabinet. The hinge

halves on the door should remain in place (Fig. 46).

Fig. 45: Remove Door Hinge Pins

MAN-001

33

Fig. 46: Detach Glass Door Hinge - Male Half

www.macmedical.com

Instruction Manual

3. Unscrew the Door Handle and Cam Lock Plate from their present position and move them to the other

side of the door. Make sure to “mirror” the Cam Lock Plate so that its top ange will be ush against the

warming cabinet when the door is re-installed in its new position (Fig. 47).

Fig. 47: Remove Cam Lock and Handle

4. If it is necessary to drill holes for the relocation of the Cam Lock Plate on the other side of the door,use the

Cam Lock plate as a guide to mark the proper location of the holes to be drilled (Figure 48). The Cam Lock

Plate should be positioned 1/8” from the outer edge of the door (Figure 49).

Door Inner Face

Fig. 48: Use Cam Lock for hole guide Fig. 49: Proper position of Cam Lock

MAN-001

34

Cam Lock Plate set back

1/8” from outer face of door

www.macmedical.com

Instruction Manual

5. Once the holes are drilled for the Cam Lock Plate, move both the Cam Lock Plate and the Door Handle to

their new positions (Figure 50). When installed, there should be at least a 1/4” gap between the Cam Lock

Plate and the face of the Cabinet (Figure 51).

Fig. 50: Attach Cam Lock Plate and Door Handle

Fig. 51: Cam Lock Plate door gap

6. With the door handle and the cam lock plate in their new positions, rotate the door 180° (Fig. 52). Fig.53

shows its orientation when re-installing the door on its new hinge position.

Fig. 52: Rotate Modied Door

MAN-001

Fig. 53: Door Rotated to New Installation Position

35

www.macmedical.com

Instruction Manual

7. Use a athead screwdriver to remove the 2 smaller satin plugs (circled in red) from the top and bottom of

the opposite side of the cabinet. These are the new hinge positions (Fig. 54).

8. Re-insert the 2 satin plugs (that were removed from the new hinge positions) in the old hinge positions.

Fig. 54: Remove Satin Plugs from New Hinge Position

9. Re-install the male halves of the door hinges in these positions. Do not tighten the screws at this point (Fig.

55).

10. Attach the glass door to the unit by tting the two halves of the glass door hinges together, Before securing

the door to its hinges, square the door by checking the door’s alignment with the header assembly box.

Then tighten the hinge screws (Fig. 56).

Fig. 55: Install Male Hinge Halves in New Position Fig. 56: Check Alignment - Square Door

MAN-001

36

www.macmedical.com

Instruction Manual

11. To secure the door to its hinges, drive the hinge pins through the two halves of the hinges. Both pins should

be driven into the hinges from the inside to the outside as shown in Fig. 57.

12. Re-attach and secure the side panels to the warming cabinet with its screws.

13. Re-insert the 2 interior cabinet screws near the bottom of the cabinet chamber.

14. Re-install the inner and outer top panels and secure with its screws.

Fig. 57: Insert Hinge Pins

MAN-001

37

www.macmedical.com

Steel Door Hinge Reversal and Re-installation

Purchase Parts needed for Door Hinge Reversal

• Intermediate Hinge (for multiple door units only) W0015 (Right Hand)

or W0016 (Left Hand). Obtain the intermediate hinge opposite of the

currently installed hinge.

1. Loosen the nuts on the bolts that hold the top door hinge onto the

unit. Hold the door as you remove the nuts so the door does not fall

on you. Once the nuts are removed, the door can be leaned away

from the unit and lifted off the bottom hinge (Fig. 58).

Instruction Manual

Fig. 58: Remove Steel Door

2. Remove the nuts that fasten the bottom hinge to the unit and remove

the screws and bottom hinge (Fig. 59).

Fig. 59: Remove Bottom Hinge

Fig. 60: Steel Door Hinge Parts

W0016

Left hand

Fig. 61: Intermediate Door Hinge

W0015

Right hand

note: For warming cabinets with more than one door, an

intermediate hinge (Fig. 61) ts between the bottom of the top

door and the top of the bottom door of the dual chambered

warming cabinet (shown in blue in Fig. 62. (Middle doors on Triple

chamber warming cabinets use only intermediate hinges for both

top and bottom.)

Fig. 62: Intermediate Door Hinge in Place

Intermediate hinges come as either right hand (part #W0015) or left hand (part #W0016) hinges. Purchase the

intermediate hinge that is the opposite of the current one on your warming cabinet.

If the unit has multiple doors, remove the intermediate hinges by unscrewing them from the cabinet.

MAN-001

38

www.macmedical.com

3. After the door is removed, unscrew the Door Handle and Cam

Lock Plate from their present position and move them to the

bottom of the door. Be sure to “mirror” the Cam Lock Plate

so that its top ange will be ush against the warming cabinet

when the door is re-installed in its new position (Fig. 63).

4. With the door handle and the cam lock plate transferred

to their new positions, rotate the door 180°. This will be its

orientation when re-installing the door on its new hinge position.

Instruction Manual

Fig. 63: Move Door Handle and Cam Lock Plate

5. From the opposite side of the cabinet, use a athead

screwdriver to remove the 2 top satin plugs (Fig. 64) from the

top and the 2 lowest bottom satin plugs. These are the new

hinge positions.

6. Re-insert the 2 satin plugs (that were removed from the new

hinge positions) in the old hinge positions.

Fig. 64: Remove Satin Plugs

7. Attach the bottom hinge in the new position to the bottom

of the unit using the hardware provided (Fig. 65).

MAN-001

39

Fig. 65: Install Bottom Hinge in New Position

www.macmedical.com

8. Look at the socket located on both the top and bottom of the door

(circled in red in Fig. 66). The pins of the door hinges will insert into these.

Fit the bottom socket of the door onto the bottom hinge pin. Support

the door on its bottom hinge while you prepare to afx the door to the

top hinge.

9. Insert the screws into the top hinge (or intermediate hinge, if

applicable). Then insert the hinge pin into the top socket of the door,

aligning the hinge screws with the top (or intermediate) hinge holes on

the unit as shown in Fig. 67.

Fig. 66: Door Hinge Socket

10. From the side of the unit, secure the door

and top hinge with the hinge nuts shown

circled in red in Fig. 67.

Instruction Manual

Fig. 67: Install Top Hinge and Secure Door

11. Square the door by checking its alignment with

the header (Fig. 68 shows a glass door, but the

same applies for the steel door). Then tighten

the hinge nuts.

12. Re-attach both side cabinet panels with its

screws

13. Re-insert the 2 interior cabinet screws near the

bottom of the cabinet chamber.

14. Re-attach the inner and outer top cabinet

plates.

MAN-001

40

Fig. 68: Check Alignment - Square Door

www.macmedical.com

Wiring Diagram - Single Chamber Warmers

Instruction Manual

MAN-001

41

www.macmedical.com

Wiring Diagram - Dual Chamber Warmers

Instruction Manual

MAN-001

42

www.macmedical.com

Wiring Diagram - Triple Chamber Warmers

Instruction Manual

MAN-001

43

www.macmedical.com

Instruction Manual

Index

C

Cabinet bases, Mobile bases and Mobile Stands 26

Cleaning 21

Approved cleaning materials and agents 21

Decals or Printed Labels 21

Disinfecting Stainless Steel 21

Glass Doors 21

Prohibited Cleaning Materials & Agents 21

Stainless Steel Surfaces 21

Controls 15

Control Components 15

D

Door Hinge Reversal 27

Glass Doors 30

Steel Doors 33

I

Installation 12

Direct Wiring to Facility Power Supply 13

Environmental Conditions 12

M

Maintenance 22

Daily Checklist 22

Monthly Checklist 22

Semi-Annual Checklist 22

Weekly Checklist 22

O

Operation 14

Display Panel 16

Set Processing Temperature 16

Items permitted for warming 14

Items prohibited for warming 14

Power Failure 14

Proper Content Loading 14

Recommended Settings 14

P

Patient Safety

Maximum Warming Temperature Limit 19

R