Page 1

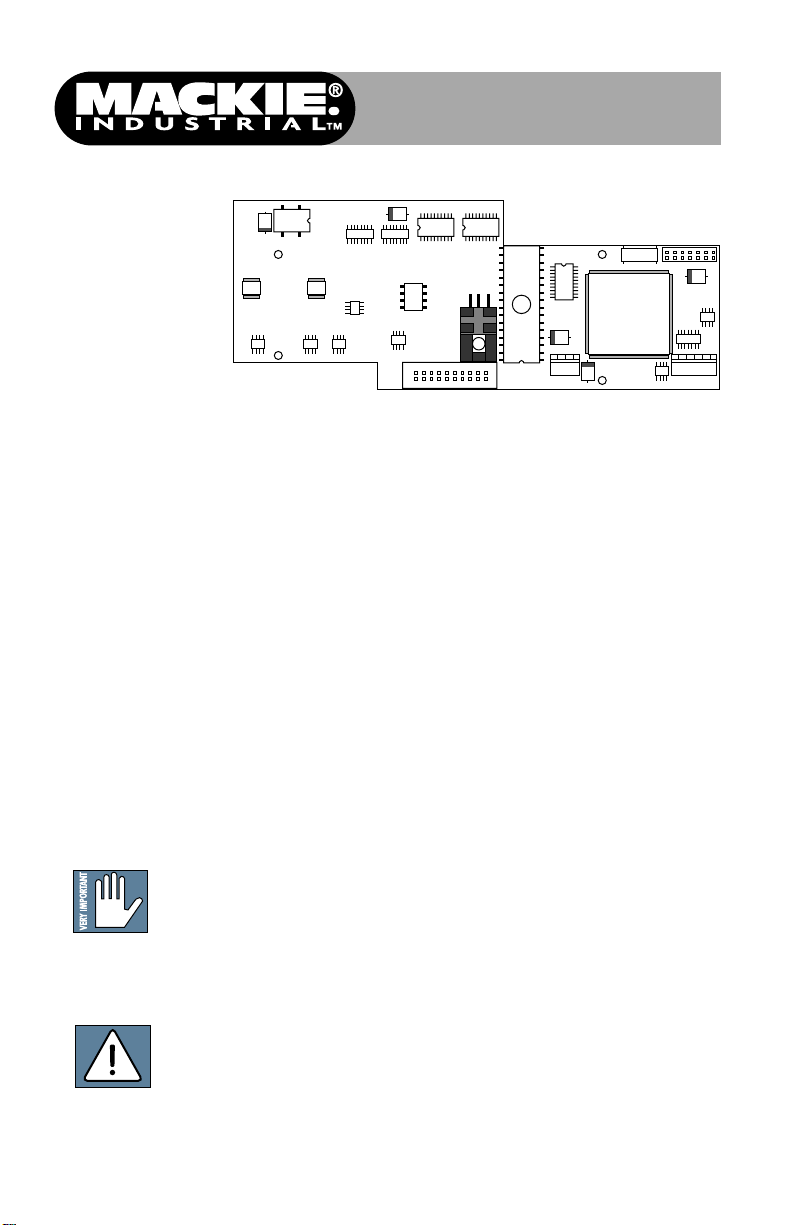

The SP-DSP1 is a

real-time digital

signal processor th at

U3

can be installed in

the SP1200 or

SP2400. It uses a

U1

U4

U5

proprietary algorithm

to sense noise in a

room and adjust the

U7

U6U2

gain of the program

source accordingly.

This unique approach effectively "nulls out"

the music sensed at the ambient microphone,

allowing the DSP to measure the actual

ambient noise level in the room. As the noise

level increases, the gain of the music

automatically increases to compensate for the

increased noise.

Safety First!

Before installing the SP-DSP card, please

read this Quick-Start Guide carefully and keep

it for future reference.

CAUTION! This circuit board is

static sensitive, and is packed in

an anti-static bag. Please use

anti-static precautions when

handling the SP-DSP card, such as the use of

an electrically grounded wrist band and antistatic mat.

WARNING! These servicing

instructions are for use b y

qualified personnel only. To

avoid electric shock, do not

perform any servicing other than that

contained in the Operating Instructions

U12U8

U9

U10

U13

U11

J1

EEPROM

U14

U16

U15

DSP

J2

+5V

+5V

GND

unless you are qualified to do so. Refer all

servicing to qualified service personnel.

Make sure the power is off and the power cord

disconnected before removing the top cover to

gain access to the inside of the SP2400.

Mackie Industrial strongly recommends that

this circuit board be installed only by a

professional technician, sound installer, or

contractor with electronic servicing experienc e.

1. Never open the SP1200/SP2400 with the

power supply on.

2. After installing the SP-DSP1 card, and before

applying power to the SP1200/SP2400,

make sure the cover is properly installed

and that no wires are pinched between the

cover and chassis.

J3

U17

U18

J4

L/R

+5V

TXD

RXD

GND

Page 2

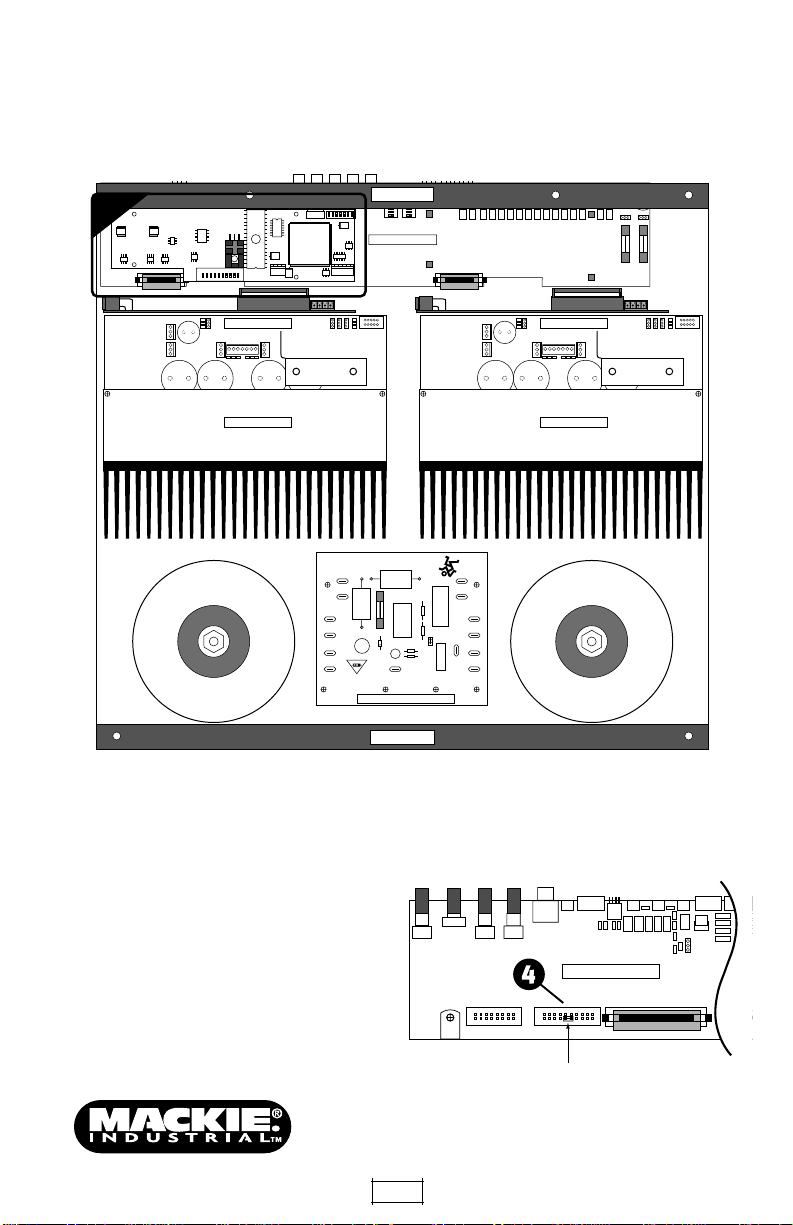

Installing the SP-DSP1 Card

Note: These instructions describe how to install one SP-D SP1 into the Zone A side of the SP2400.

A second SP-DSP1 may be installed in the Zone B side. The instructions for Zone B are the same

unless otherwise indicated.

SP-DSP1

U1

R262

R263

S5

R261

U3

U4

U5

U7

U6U2

U12U8

J5J4

U9

U10

U11

J1

J13

U14

U13

U15

EPROM

J2

+5V

+5V

GND

J3

U16

DSP

U17

U18

J4

L/R

+5V

TXD

RXD

GND

S1 S2

ON

ON

12345678

12345678

J8 J9 J10 J11 J12

REAR PANEL

REAR PANEL

SP2400 INPUT BOARD

S4

S3

J7

J1B J1A

J6

–18 +18

ONOFF

J2 J3

F1 F2

J4

1

C62

C11

2

SP2400 AMP-1 BOARD SP2400 AMP-1 BOARD

3

1

R68

2

3

J1

1

1

2

J9

3

C17 C18

3

2

2

3

1

J6

J3

J2

C1 C2 C3 C4 C5 C6

C7

C8 C10

JP2

R110 R67

J11 J15 J10

1

1

1

2

2

2

3

3

3

C9

JP1

C15

SP2400 AMP-2 BOARD SP2400 AMP-2 BOARD

J1

J3

J8

R2

C2

J5

4A SB 250V

J11

J14

SP2400 POWER SUPPLY BOARD

Remove cover.

1. Remove 12 screws from the top of the

cover using a #2 Phillips-head screwdriver.

These screws are all one size.

2. Remove the front rack mount brackets and

rear support brackets by removing three

screws per bracket. These screws are all

one size.

3. Remove two additional screws on each

side of the unit. These screws are all one

size.

Note: Remember which screws are used for

the top, brackets, and sides so that you can

properly reinstall the top c over.

J4

1

C62

C11

2

3

1

J5

F1

SP2400:SOFT START

055-286-00 REV:__

D2

+

D1

J12

®

© 2000

MACKIE DESIGNS. ™

C1

R1

R5

R6

JP1

K1

R4

BROWN

R3

BLUE

C3

RISK OF FIRE! REPLACE WITH FUSE AS MARKED

R68

2

3

J1

1

1

2

J9

3

C17 C18

J2

J4

J9

J6

J7

J10

J13

3

2

2

3

1

J6

J3

J2

C1 C2 C3 C4 C5 C6

C7

C8 C10

JP2

C15

FRONT PANEL

Install SP-DSP1 Board

4. Using a pair of needlenose pliers,

carefully remove the jumper from J4 pins

10 and 11 on the Filter board (rear of unit,

closest to the bottom).

S2

R150

R131

Install Ribbon Cable (040-470-00)

5. Install the ribbon cable (040-470-00) onto

J4. Make sure the tab on the connector

lines up with the notch in the socket.

J10

R127 R128 R129

J11

SP2400 FILTER BOARD

Remove Jumper and

R133

R136

R134

R137

J4 J5

1

2

3

C9

JP1

R146

R149R148

R110 R67

J11 J15 J10

1

1

2

2

3

3

J5

R145

R147

R142

J9J8

R132

C92C93

C89

L9

R143

L7L5L3

L6

L10

C91

C94 C95 C96

R121 R97

J6

1

R96

2

3

U25

J3

2

Page 3

6. Snap the square end of the four nylon

3

3

standoffs into the four square holes on the

input board. Avoid flexing the circuit board

by supporting the outer edge of the board

while pressing down on the standoffs.

R262

R261

R263

R131

S5

R127 R128 R129

J11

STANDOFFS

REAR PANEL

J5J4

S2

R150

J10

R133

R136

R134

R137

SP2400 FILTER BOARD

J4 J5

R149R148

12345678

L9

L7L5L3

L4

L2

L6

SP2400 INPUT BOARD

C54

U25

C23

D3

J8 J9 J10 J11 J12

S1

Q1

D22

J1

J13

R146

R145

R147

R142

J9J8J7

R132

C92C93

C89

R143

L10

C91

C94 C95 C96

R121 R97

J6

1

R96

2

3

J3

7. Place the SP-DSP1 circuit board on top of

the four standoffs so the four holes in the

DSP board align with the standoffs. The

large square multi-pin integrated circuit

should be on the right side of the board

when facing the front of the unit. Make

sure the ribbon connector (from step 5) is

sticking straight up so that it clears the

front edge of the DSP board.

U9

R127 R128 R129

S5

J11

STANDOFFS

SCREWS

U11

REAR PANEL

U12U8

J5J4

R150

J10

R133

R136

EEPROM

R134

R137

U10

U13

SP2400 FILTER BOARD

J1

J4 J5

12345678

J13

S2

R146

R145

R149R148

R147

R142

J9J8J7

R132

C92C93

C89

L9

U14

R143

L7L5L3

U16

L10

C91

C94 C95 C96

R121 R97

J6

1

R96

2

3

DSP

U15

J2

J3

+5V

+5V

GND

L4

L2

J3

L6

SP2400 INPUT BOARD

U17

C54

U18

J4

U25

C23

D3

L/R

+5V

TXD

RXD

GND

J8 J9 J10 J11 J12

S1

Q1

D22

J2

J1

R262

R261

R263

U3

R131

U4

U1

U5

U7

U6U2

8. Insert the four 1" screws through the holes

in the top of the DSP board and into the

four standoffs. Use a #1 Phillips-head

screwdriver to secure the screws into the

standoffs.

Warning: Do not press down while tightening

the screws or you coul d inadvertently crack

the Input board. Use one hand to support the

Input board from the bottom while tightening

the screw with the other hand.

9. Connect the ribbon cable from J4 on the

Filter board to J1 on the DSP board. Make

sure the tab on the connector lines up

with the notch in the socket.

R262

R261

R263

U3

U9

R131

R127 R128 R129

J11

U4

U1

U5

U7

U6U2

Connect Ribbon Cable to J1

S5

J5J4

R150

J10

U10

U13

STANDOFFS

U11

SP2400 FILTER BOARD

J1

U12U8

R137

J4 J5

REAR PANEL

R136

EEPROM

R134

J13

S2

R146

R149R148

U14

R133

C94 C95 C96

U15

J2

J2 J4

+5V

+5V

GND

R145

R142

C92C93

R143

U16

C91

R121 R97

R96

R147

J9J8J7

R132

C89

L9

L7L5L3

L10

J6

1

2

3

DSP

J3

Install Power Supply Expansion

Board

10. Remove two screws from the main Power

Supply board, nearest the front of the unit.

ON

S1 S2

ON

12345678

S4

Place the Power Supply Expansion board

so the angle brackets align with the holes

on the power supply. Reinstall the screws

through the holes in the angle brackets

C40

J2

S1 S2

ON

ON

12345678

S4

and the main Power Supply board.

B J1A

TO POWER

TO DSP BOARD

TRANSFORMER

J1

J3

J8

J5

J11

J14

J2

11. Locate the pair of blue wires exiting the

toroidal transformer that aren’t connected t o

C40

anything. Plug the connector on the end of

B J1A

the blue wires into the two-pin connector

(J1) on the Power Supply Expans ion board.

The lip on the connector faces the tab on J1.

12. Connect one end of the 3-conductor cable

that came with the SP-DSP1 kit to J2 on

the Power Supply Expansion board.

Connect the other end of the cable to J2

on the DSP board. Route the cable

between the two heatsinks.

Connect the COMM PORT

13. Connect the 9-conductor cable that came

with the SP-DSP1 kit to J4 on the LED

board. On the other end of the cable,

connect the 5-wire 5-pin connector to J4

on the Zone A DSP board. Connect the 3wire 5-pin connector to J4 on the Zone B

S1 S2

ON

ON

12345678

12345678

J8 J9 J10 J11 J12

L4

S1

L2

J3

L6

Q1

SP2400 INPUT BOARD ZONE B POSITION

U17

C54

C40

U18

J4

U25

C23

D22

D3

L/R

+5V

TXD

RXD

GND

J2

J1

S3

S4

J1B J1A

R2

J1

C2

4A SB 250V

SP2400:SOFT START

055-286-00 REV:__

F1

D2

+

D1

J12

J7

K1

R4

R3

BLUE

®

© 2000

MACKIE DESIGNS. ™

C1

R1

R5

RISK OF FIRE! REPLACE WITH FUSE AS MARKED

J2

J4

R6

J9

JP1

J6

J7

J10

BROWN

C3

J13

J6

–18 +18

J2 J3

F1 F2

TO POWER SUPPLY

EXPANSION BOARD

TO LED BOARD

3

Page 4

DSP board (leave disconnected if installing

only one DSP card). Route the cable

between the two heatsinks.

TO DSP BOARD

TO CPU BOARDS

J4

LED BOARD

FRONT PANEL

Reinstall the Top Cover

14. When placing the top cover back onto the

chassis, be sure all the wiring is properly

routed between and beside the heatsinks

to avoid pinching the wires between cover

and chassis. Replace the screws in the

same order in which they were removed.

Using the SP-DSP1 Card

It is important to understand that the

SP-DSP1 does not add gain to the signal path,

but rather attenuates the signal at its input by

a user-adjustable amount, and then applies

less attenuation to the signal to achieve an

increase in volume as determined by the

Ambient Noise Sensing Algorithm.

The default Minimum Gain setting is –40 dB,

so the signal level is 40 dB lower with the

SP-DSP1 card installed than it is without the

card installed (or with the circuit bypassed).

At first, you may wonder why the signal level is

so low when you first turn on the SP2400

because of this additional att enuation.

However, after the parameters are properly

adjusted and you run the Auto Calibration

procedure, the SP2400 will operate with

sufficient volume.

Note: The SP-DSP1 requires connecting a

microphone to the AMBIENT MIC connection

on the rear panel of the SP2400. We

recommend using the Mackie Industrial

MT-3100 omnidirectional condenser

microphone. However, if the installer

determines that a directional microphone i s

better suited to the application, such as the

Mackie Industrial MT-3200 semi-cardioid

condenser microphone, it may be used as well.

Be sure to move the AMP ADDRESS switch

#8 up to activate the ambient microphone.

Installing the Software

The SP-DSP1 is designed to run under the

Palm™ OS. The SP-Control™ Palm

application is included on a 3.5" floppy disk,

and it can also be downloaded from the

Mackie Industrial website

(www.mackieindustrial.com).

Copy the "SP-Control.prc" file from the

floppy disk to the hard drive on your computer

where the Palm Desktop Application is

installed. Double-click on the "SP-Control.prc"

file, and the "Install Tool" dialog box opens to

let you know that the file will be installed on

your handheld Palm the next time you

perform a HotSync operation.

Using the SP-Control Application

Once the "SP-Control.prc" file has been

installed on the Palm, you can connect the

Palm to the COMM PORT on the SP2400. Use

the supplied 9-pin “null-modem” adapter

between the Palm’s HotSync cable and the

SP2400’s COMM PORT. This switches pins 2

and 3 (RXD and TXD) on the RS-232

connection so the two devices can

communicate properly.

Select the "SP-Control" application on the

Palm to launch it, and the main SP-Control

window appears on the screen. Click the

“Connect” box to begin communication

between the application and the SP-DSP1.

There are six user-adjustable parameters and

four bar graphs indicating relevant levels.

4

Page 5

Adjustable Parameters

MG (Minimum Gain)

This control defines the lowest level to

which the system can attenuate the program

signal. It has a minimum setting of –40 dB

and a maximum setting of 0 dB.

GR (Gain Range)

This control defines the amount of gain

change allowed b y the Aut omatic Level Control.

It has a minimum setting of 0 dB and a maximum setting of 40 dB. The Gain Range setting

can never be greater than the Minimum Gain

setting, because the system gain from the

input to the output of the SP-DSP can never be

greater than 0 dB. Because of this, the Gain

Range control “re-scales” itself if the Minimum Gain control is increased toward 0 dB.

As an example of how these control s work

together, if the user wanted his music levels

to operate in a range ±10 dB around –15 dB

down from the input level, he would set

MG = –25 dB and GR = 20 dB.

NT (Noise Threshold)

This control sets the point at which the

noise level “triggers” the Automatic Level

Control to begin working. It has a minimum

setting of –80 dB and a maximum setting of 0

dB. The lower the Noise Threshold setting, the

more sensitive the algorithm is to ambient

noise levels in the room.

NR (Noise Range)

This control adjusts the ratio of how much

the program level changes as a function of

how much the noise level changes. It has a

minimum setting of 1 dB and a maximum

setting of 60 dB.

For example, if you set the Noise Range to

20 dB and the Gain Range to 30 dB, then a 20

dB change in the noise level causes a 30 dB

change in the program output level (assuming

the noise level has crossed the Noise

Threshold). These settings represent a 2:3

noise level to program level change. For every

2 dB change in noise level, the output l evel

changes by 3 dB. However, if you accept the

default settings of NR = 40 dB and GR = 40

dB, the settings represent a 1:1 noise level to

program level change. For every 1 dB change

in noise level, the output level ch ang es by 1 dB.

Attack Time and Release Time

The Attack parameter defines the time, in

seconds, it takes for the Program Gain to

increase by 40 dB. Likewise, the Release

parameter defines the time it takes for the

Program Gain to decrease by 40 dB. These

parameters have a maximum value of 300

seconds (5 minutes). A short Attack Time

allows the program level to respond to every

shift in noise level. Increasing the Attack Time

allows the algorithm to “average” the noise

level and provide a relatively constant

Program Gain over time. To keep impulsive

bursts of noise from affecting the program

level, a good setting might be Attack = 20

seconds and Release = 20 seconds.

Bar Graphs/Metering

PI (Program Input)

This indicates the input level into the DSP.

It is important that the Program Input signal

level is sufficient prior to running the Auto

Calibration procedure. The input level should

be between 0 and –10 dB during the loudest

portions of the program material. Adjust the

level with the front panel up/down buttons.

MI (Microphone Input)

This indicates the ambient microphone

input level into the DSP. Again, it is important

that the ambient microphone signal l evel is

sufficient prior to running the Auto Calibration

procedure. The input level should be between

0 and –10 dB for the loudest noise plus

program expected.

It may be necessary to adjust the gain of

the ambient microphone. A good way to set

the MI level is to click the “Bypass” box on the

main screen. You may need to turn down the

program level if there is a lot of attenuation

set with the Minimum Gain (MG) control, or the

music will become very loud in bypass mode.

There is a trim pot located through an unmarked hole just above the AMBIENT MIC

connector on the rear panel of the SP2400.

Use a nonconductive alignment tool to adjust

the pot until the meter indication is between

0 and –10 dB for the loudest noise plus

program expected.

PG (Program Gain)

This indicates the amount of gain the algorithm applies to the program input. This can

never exceed the Minimum Gain (MG) setting.

PO (Program Output)

This indicates the output level from the

SP-DSP1. The Program Output is equal to the

Program Input (PI) level plus the Program

Gain (PG).

5

Page 6

Additional Main Screen Options

Preset Save/Recall

The SP-Control has the ability to save up to

10 presets in the SP-DSP1 EEPROM. A preset

consists of the following parameters:

Minimum Gain (MG), Gain Range (GR), Noise

Threshold (NT), Noise Range (NR), Attack Time,

and Release Time.

To save or recall a preset, click the arrow

next to the Preset button to select which

preset number to save, then click the Preset

Save or Preset Recall button.

DSP1/2

The SP2400 can support

two SP-DSP1 cards; one for

each zone. Click this button

to toggle control between

DSP1 and DSP2.

Auto Calibration Function

Click on the "SP-Control"

button at the top of the main

screen and a drop-down

menu appears. Select "Auto

Calibration" to begin the Auto Calibration

procedure. This should be performed once the

ambient microphone and the loudspeakers

are in their fixed positions, and the

microphone gain and input levels have been

properly adjusted. For best results, the Auto

Calibration procedure should be performed

when the room noise is at a minimum.

During the calibration, a countdown timer i s

initiated at 90 seconds and a progres s meter is

displayed. If the algorithm finds th at adaptation

improvements are possible, the timer resets to

90 seconds. A typical calibration period is 2-3

minutes. It is advised to monitor the m ain four

meter levels during calibration to ensure that all

levels are in their target range. If you find th at the

microphone and input levels are too low or too

high, you may want to "Abort" the calibration by

selecting the appropriate button and then

readjust the levels acc ordingly . Ther e is also an

“End & Save” button if the user finds that

calibration is taking too long or music br eaks are

causing countdown timer re sets.

Once the calibration is complete, the CAL

value will update. At default, this value is +10

(with a range of +20 to –80 dBr). This number

is a measure of how much of the program

material is getting rejected in the environment

that the Auto Calibration was performed. The

closer the number is to +10, the less the

rejection. A CAL value = –15 dBr would be an

excellent rejection value, which would be

expected in a small room. A larger room would

have a CAL value closer to 0 dBr, indicating a

lower rejection due to room reflections.

Any of the user parameters can be adjusted

after the Auto Calibration procedure is

completed (MG, GR, NT, NR, Attack Time,

Release Time). These settings do not affect

the calibration of the SP-DSP1. However, if the

placement of the ambient microphone or

speakers should change for any reason, you

should run the Auto Calibration procedure

again to allow the SP-DSP1 t o reevaluate the

room transfer function.

Likewise, if any level

changes are made in the

signal chain after the SP-D SP1

card, the noise sensor

perceives this as an ac ou s tic

noise disturbance, and the

Auto Calibration procedure

should be performed again.

Note that all the level

controls in the SP2400 are

before the SP-DSP1 and have

no effect on the calibration.

Factory Restore

Select Factory Restore from the drop-down

menu to restore all the settings in the SPDSP1 to their default values.

Upload/Download From/To EEPROM

Occasionally, it is necessary to backup

SP-DSP1 presets and parameters or to transfer

settings from one DSP to another. To copy the

contents of the EEPROM, simply select

“Upload from EEPROM” from the drop-down

menu. The EEPROM contents are stored in

your Palm. If you would like to copy contents

of the Palm into another SP-DSP1 card, select

“Download to EEPROM.” This will completely

erase the existing contents of the EEPROM

and replace it with what was stored in the

Palm. It is advised that you do an “Upload

from EEPROM” before doing a “Download to

EEPROM” to ensure that the current settings

are saved in the Palm.

industrial@mackie.com

www.mackieindustrial.com

16220 Wood-Red Road NE Woodinville, WA 98072

TEL +888.337.7404, FAX +425.487.4337

UK +44.1268.570.808, FAX +44.1268.570.809 +industrial@rcf-uk.com

ITALY +39.0522.354.111, FAX +39.0522.332.294 +industrial@rcf.it

FRANCE +33.3.8546.9160, FAX +33.3.8546.9161 +industrial@rcf.fr

GERMANY +49.2572.96042.0, FAX +49.2572.96042.10 +industrial@mackie.de

Part No. 910-300-20 Rev. A 12/00

© 2000 Mackie Industrial. All Rights Reserved. Printed in the USA.

6

Loading...

Loading...