The primary way to power the control is wit h the key.

Figure 1 – Keys

Place one key into the keyhole at t he back right hand side of the cont rol as pictured below. Turn on the control by

rotating the key and then quickly releasing it.

X15-250 User Manual

1 Turning on the control

Figure 2 – PC Start

There is also a small black backup power on butt on near the power plug behind t he back panel of t he control. See Figure

15 - Control Port Diagram.

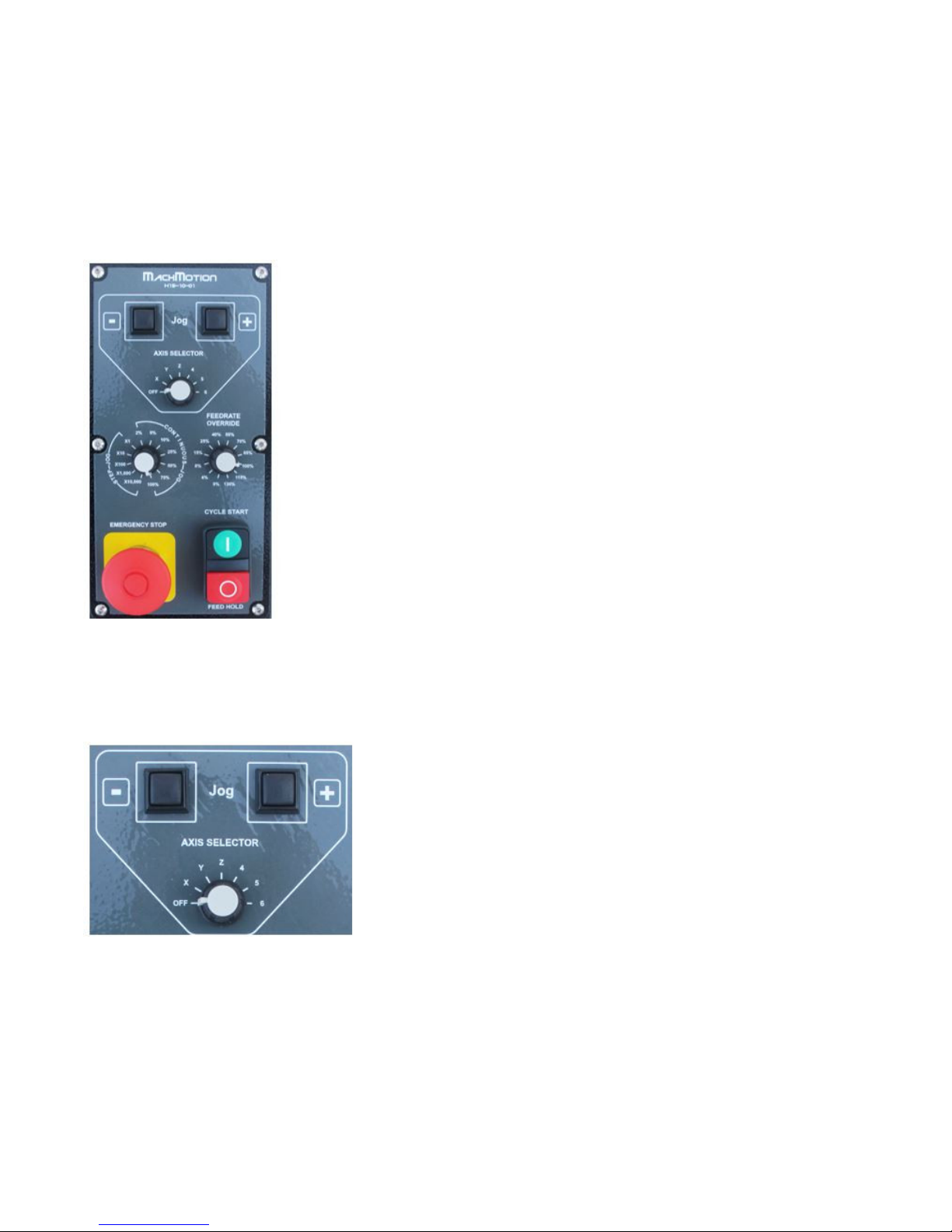

2.1 Operator Panel (X15-10-01)

On t he right hand side of your control there is the operator panel with jog buttons, select or knobs, and a few butt ons

(See Figure 3).

Figure 3 – Operator Panel

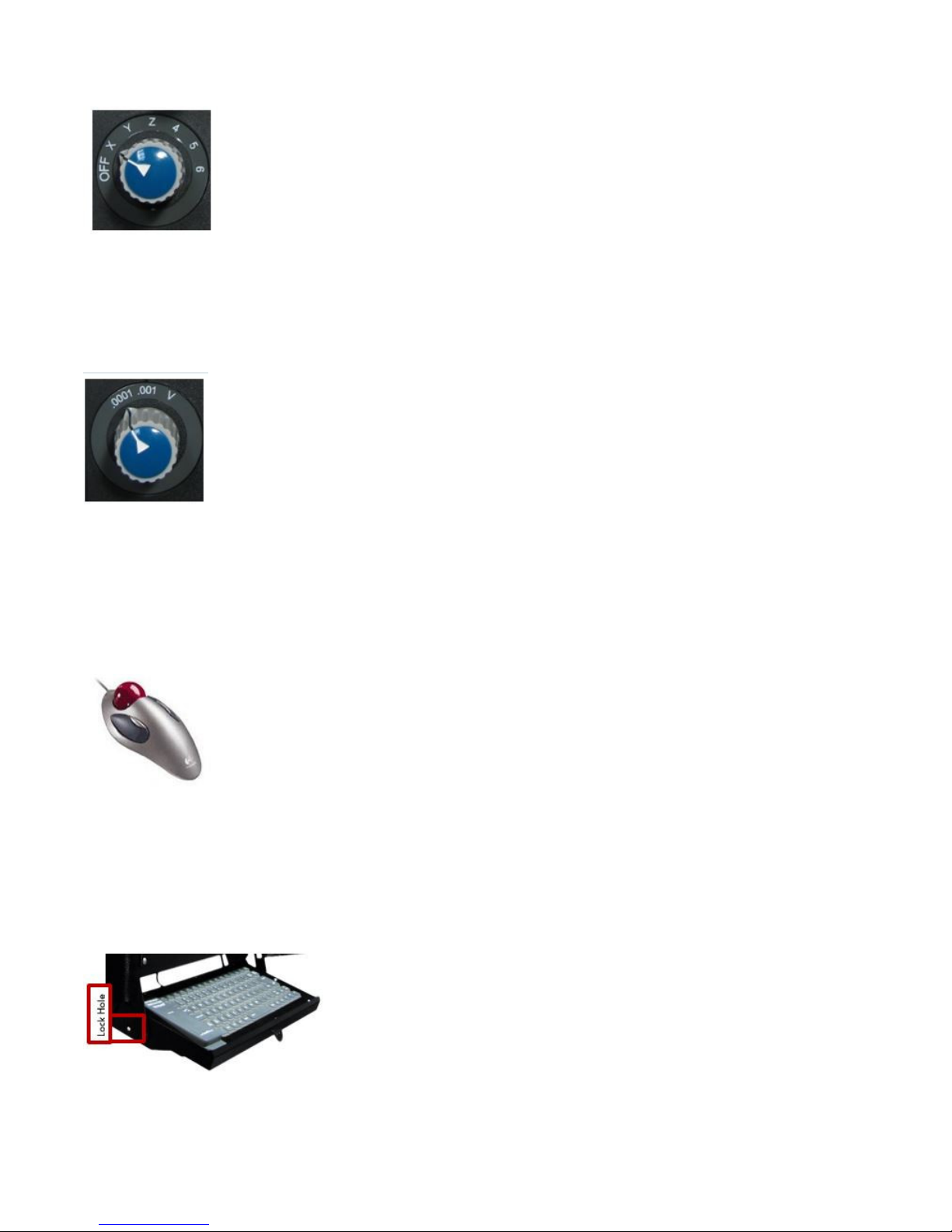

The jog but t ons can be used to move the axes manually. Use t he Axis Select or to choose which axis t o jog. If the Axis

Select or is in the of f position, the jog buttons are disabled (See Figure 4).

Figure 4 – Jog Butt ons and Axis Selector

Note: If the jog buttons do not work, make sure that the Axis Selector on the optional pendant is turned off.

To change the jogging speed or the jog increment s adjust the Jog Selector. The select ions labeled Step Jo g control

which predef ined step or increment t he syst em moves each t ime a jog key is press ed. The system can jog 1 t hrough

10,000 10,000t hs of a unit by selecting X1 t hrough X10,000. See Figure 5 below.

2 Control Components

Figure 5 – Jog Select or

To jog continuously rat her than increment ally, turn the Jog Selector over into t he Continuo us Jog sect ion. The machine

can jog at t he full jog rate (100%) or slow it down to 2%.

The Feedrat e Selector can adjust the feed rate override from 0% all t he way to 130%. It can be used t o slow t he

machine while running a program. Also, in st ep jog mode the speed of t he axis is regulated by the feed rate Selector.

Figure 6 - Feedrate Selector

The green button is a cycle start butt on which st arts a file and t he small red butt on is a feed hold which pauses t he file.

Figure 7 - Cycle St art and Feed Hold Butt ons

The red E-Stop button stops the whole syst em and prevents any movement .

2.2 Pendant (X15-20-01, Optional)

The pendant is mounted on t he right side of t he control near the operator panel. See Figure 8 below.

Figure 8 - Pendent

To use t he pendant switch t he Axis Selector (3) to the desired axis. The pendant will not work if the Axis Selector is in

the OFF posit ion. While holding down the enable butt on (see Figure 9, 1), rotate the hand wheel (2, also called t he MPG)

and the select ed axis will move. Change axes by swit ching the Axis Select or to a different axis. The speed can be

adjust ed using the Jog Selector (4).

Figure 9 - Axis Select or

The Jog Selector on t he pendant switches bet ween either 0.0001 or 0.001 unit increments. Each click of the MPG will

move the select ed increment. However, if the Jog Select or is on V t hen the MPG is in velocit y mode. In velocity mode

the axis moves as long as t he MPG is turning and the speed of the axis is regulated by the speed of the hand wheel. In

ot her words, t urning the hand wheel very fast will make the axis move very quickly.

Figure 10 - Jog Select or

When t he pendant is not in use, make sure to turn t he Axis Selector to OFF. Otherwise the operator panel jog

functionality will be disabled.

2.3 Mouse

Below t he operator panel is a ball mouse. Use this for navigating around on the control.

Figure 11 - Mouse

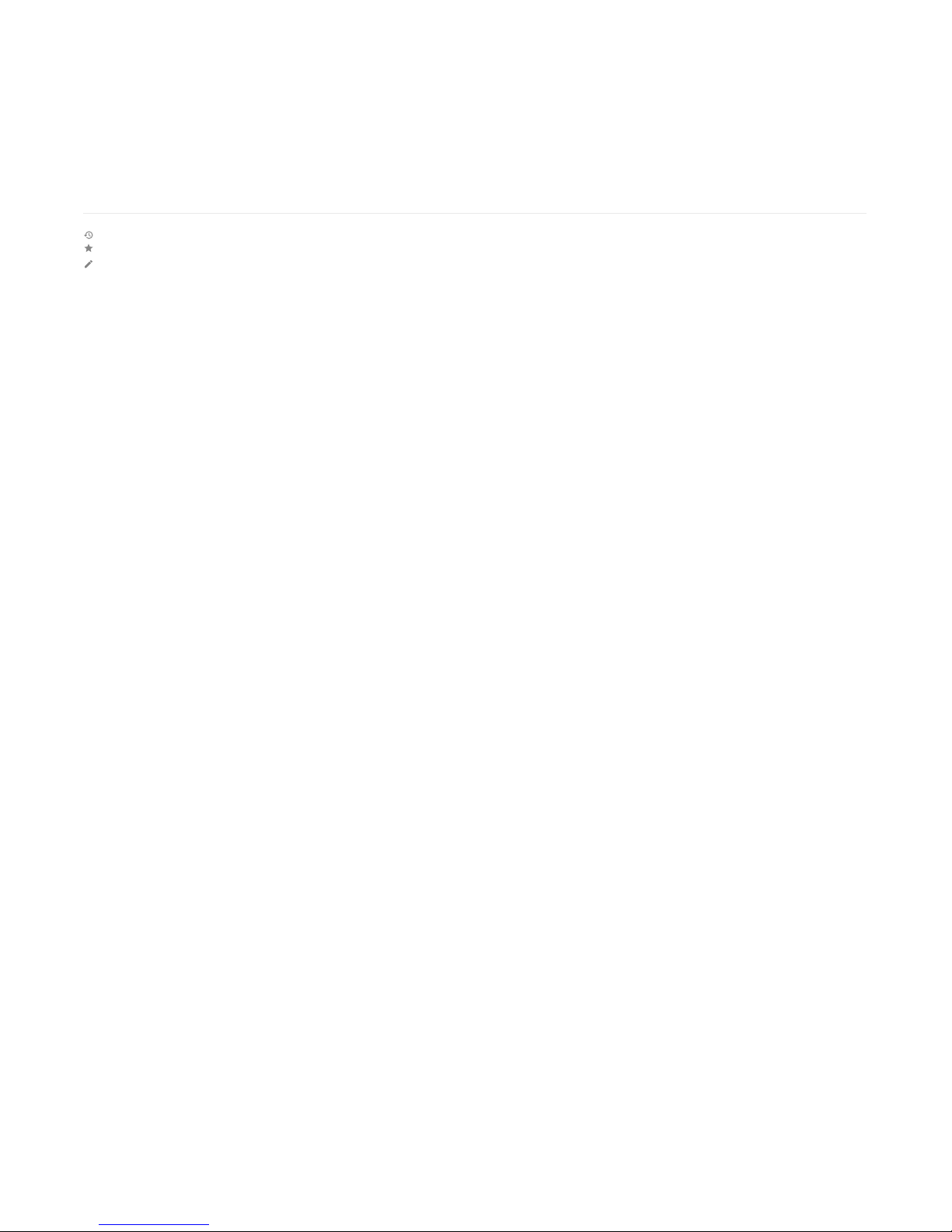

2.4 Keyboard

The keyboard is located at the bot t om of t he control in a flip-out t ray. For security and safet y reasons there is a lock

hole in the back left hand side of t he keyboard tray t o prevent the tray from opening. The lock is not supplied with the

control.

Figure 12 - Keyboard

2.5 External USB Port

On t he right side of t he keyboard there is a USB port. Use t his for transferring programs, files, or any other data to and

from t he control.

Figure 13 - USB Port

Below is a diagram of all the different ports on the control wit h a brief descript ion of each.

Figure 14 - Control Port Diagram

1. Power Board

Three power supplies (24VDC, 12VDC, & 5VDC) for low power applications.

2. Po wer Cable

110VAC-220VAC power for the control.

3. PC St art

To remot ely st art t he control connect these t wo pins t oget her with a momentary push butt on switch.

4. PS2 P o rt wit h USB Convert er

This is used f or the mouse.

5. Parallel Po rt s (O pt io nal)

These are used t o communicate with some breakout boards

6. Ethernet Po rts

These ports are used t o connect to local Et hernet net works and motion cont rollers.

7. Serial P o rt

This can be used for any application. Many of our systems use it t o communicate wit h a PLC.

8. VGA Mo nitor Connector

This is used t o connect the cont rol t o a monitor with a standard VGA cable.

9. Audio

These are the standard audio inputs and out puts.

10. USB P o rt s

These ports are used f or the keyboard, mouse, operator panel, file transf er, and more.

11. Fan Connect o rs

These connectors supply 12VDC for t wo small fans.

12. USB 3.0 Po rt s

These ports can be used like all the ot her USB port s. They are higher performance and have a much higher dat a

transfer speed.

13. DVI

Opt ional monitor connection

14. HDMI P o rt

Opt ional monitor connection

15. Seco ndary Po wer But t o n

Below is the specificat ion for a st andard X15- 250 CNC control.

It em

Spec if icat ion

Powe r Source

AC 115VAC – 220 VAC 50/6 0 Hz

3 Computer Port Diagram

4 Specification

Max P owe r Cons umption

350W

Computer

X15-110 P C

Ope rating Sys tem

Windows 7

Proces sor

Intel® P entium® Dual-Core 2.6GHz

RAM

2 GB

I/O P orts

PS /2 Ke yboard & P S/2 Mous e

1

VGA Po rt

1

DVI Port

1

HDMI Por t

1

Se rial Por t

1

Parallel Por ts

2

Etherne t LAN (RJ45) Port

2

USB Po rts

6 (2 Av ailable )

6 Channe l Audio I/O

1

Monitor

17” Color LCD

Keyboar d

Retractable

Powe r Supply

5VDC, 12VD C, & 24VDC

Enclos ure

Dime ns ions

24"(W) X 15.5"(H) X 6 .5"(D)

Mater ial

18 Gauge S teel, P owde r Coate d

Ope rator Inte rface

X15-10 -0 1 Ope rator Pane l

Jog Buttons, S e le ctor Switche s , Eme rgency S top, Cycle Start, & Fe e d

Hold Buttons

X15-20 -0 1 Pe nda nt (Optional)

Hand-whe e l & Sele ctor Switches

Below is the X15-250 CNC Control drawing.

5 Appendix

Warranty Information

MachMot ion warranty policy is subject to change. Updated information is available at our website:

htt ps ://machmotion.com/warrant y

The MachMot ion Team

htt p://www.machmot ion.com

14518 County Road 7240, Newburg, MO 65550

(573) 368-7399 • Fax (573) 341-2672

Revisio n #3

Cre ate d Fri, Feb 23, 20 18 7:46 PM by MachMotion

Update d S un, Fe b 24, 20 19 9:55 PM by Aaron

Loading...

Loading...