Page 1

© Mach III Clutch, Inc. All Rights Reserved

CLICK on product numbers above

to obtain the product detail sheet

which includes dimensional data

helpful during installation.

Installation & Maintenance Manual

MECHANICAL FRICTION TORQUE LIMITERS

WITH FLEXIBLE COUPLING

Catalog Products:

T3H2H-STL

T4H2H-STL

T5H2H-STL

T6H1G-STL, T6H1H-STL, T6H2H-STL

And non-catalog variations of this clutch design.

Mach III Technical Support

Toll Free: 866-291-0849

International: 001-859-291-0849

Email: engineering@machiii.com

www.machiii.com

Detail sheets and 3D models are available on the Mach III website:

http://www.machiii.com/Products/Torque-Limiter/Flexible-Mechanical-Torque-Limiter-

Couplings.asp

Please contact Mach III to obtain assembly and parts list drawings.

This product includes rotating equipment and should be guarded according to

OSHA requirements and other Federal, State and local regulations. It is the

responsibility of the user to provide necessary guarding.

7/9/2013 TORQLIM_FLEXCOUPL_MANUAL Page 1 of 5

Page 2

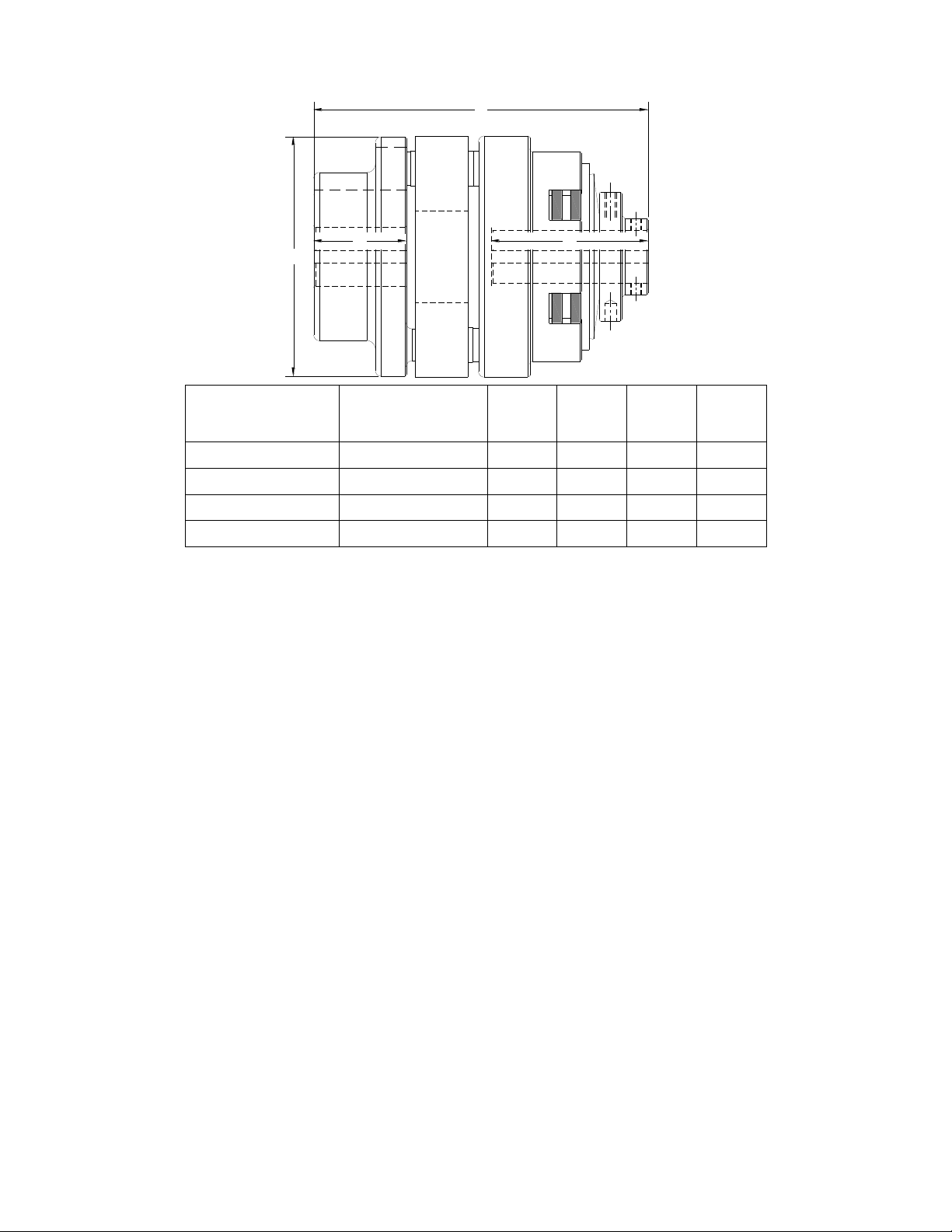

D

B

L

C

Reference Diagram:

Product#

MAX BORE

WITH

SQUARE KEY

B C D

L

T3H2H-STL

0.875

1.75

2.79

4.00

6.27

T4H2H-STL

1.125

2.06

3.50

5.13

7.44

T5H2H-STL

1.375

2.06

3.75

5.69

7.70

T6H1G-STL

2

2.37

4.25

7.34

9.91

I. Torque Setting

Mach III torque limiters are typically shipped to the customer with the torque value they have

specified. (Note: All torque settings are +/- 10%.) If a torque limiter requires setting or resetting in the field, please refer to section VII of this document.

II. Installation

A. SHAFT PREPARATION & MOUNTING

Mach III Clutch products are bored to fit a precision plug gauge for the specified bore size

and should slide fit the mating shaft. Make certain that the shaft is free of burrs or nicks. It

may be necessary to file or sand the shaft to assure a slide fit. Never hammer the torque

limiter onto the shaft. Hammering on the torque limiter may cause evident damage or subtle

injury that will shorten the wear life of the unit, and will void the warranty.

(1) Apply the anti-seize (E-Z Break®) lubricant from the packet provided, or

equivalent, to the shaft.

(2) Insert key (customer supplied) onto the shaft.

(3) Slide torque limiter over key on the shaft, align the sprocket or pulley.

(4) Tighten set screws to secure the torque limiter to the shaft.

B. FINAL INSPECTION & TESTING

After a short run, check set screws and alignment.

III. Operation:

This is a manually adjusted torque limiter. Torque is proportional to the amount of spring

compression.

Special Note Regarding Friction Disc Contamination:

The friction material used in this product will absorb oil, water, chemicals and other

contaminants. Depending on the type of contamination, torque limiter may either seize up

entirely or lose torque capacity. If friction discs become contaminated, they should be

replaced. See repair kit ordering information below.

7/9/2013 TORQLIM_FLEXCOUPL_MANUAL Page 2 of 5

Page 3

SET SCREW

SET SCREW

DRIVE DISCS

FRICTION DISCS

SPRING

SET SCREW

NUT

ELASTOMERIC ELEMENT

COUPLING

SET SCREWS

W/JAM NUT (some models)

Kits Available

Contents

Part Numbers

Facing Kit

Friction Disc

T3H2H-STL-FCGK, T4H2H-STL-FCGK, Etc. . . .

Repair Kit

Friction Disc, Spring(s)

T3H2H-STL-RPRK, T4H2H-STL-RPRK, Etc. . . .

Tools Needed

Hex wrench set

Retainer (snap) ring pliers

Spanner Wrench

Compounds Required

Anti-Seize Lubricant

IV. Routine Maintenance

When installed and operated according to the preceding guidelines, Mach III Clutch products

should require little or no routine maintenance. A repair kit is available which contains all

parts subject to typical wear: friction discs, springs.

V. Parts Diagram

For part numbers of components not included in the kits above, please contact Mach III Clutch,

Inc. or your distributor. Factory repair is also available. A return materials authorization (RMA)

number must be obtained prior to sending any unit in for repair. Mach III Clutch is not

responsible for products returned without authorization.

VI. Repair Kit Installation Procedure

7/9/2013 TORQLIM_FLEXCOUPL_MANUAL Page 3 of 5

A. DISASSEMBLY

Loosen set screws using appropriate hex wrench and slide the clutch off of the shaft. Place the

clutch on a work surface with the adjustment nut facing upward. Loosen the set screw in the

adjustment nut and set screws and jam nuts (some models) and remove nut using a wrench or

channel lock pliers. The spring, drive discs and friction discs can now be removed.

Page 4

A

B

C

D

E

B. DRIVE SURFACE INSPECTION & FRICTION DISC REPLACEMENT

Inspect the surface of the steel or iron dive discs. This surface must be free from grooves, burrs

and foreign materials in order for the clutch to operate properly. If damage is pronounced,

please contact Mach III Clutch or your distributor about replacing the drive discs. In addition,

clutch should be inspected for discoloration (turning blue). If discoloration is present, the unit is

being operated beyond its capacity and Mach III Clutch should be contacted for assistance.

C. INSPECTION OF BEARINGS

Check bearings for external damage (missing seals, etc.). Make sure the bearings rotate freely

and smoothly by hand. If bearing replacement is necessary, consult Mach III or your distributor

for the bearing sizes and replacement procedures.

D. REASSEMBLY

Place drive discs, friction discs and spring over drive hub in their proper order making sure they

slide freely on the hub and in the slots. Replace adjustment nut with the shoulder fitting into the

bore of the spring. Adjust torque and tighten set screw.

See “torque Limiter Installation” portion of these instructions for the proper procedure for

reinstalling the clutch.

VII. Torque Setting Instructions

A. Product Numbers: T3H2H-STL, T4H2H-STL, T5H2H-STL and non-catalog

variations of this torque limiter design.

(1) Make sure the nylon-tipped set screw (REF. C) in the outside diameter of the adjustment nut

(REF. A) is loose.

(2) Make sure the adjustment nut (REF. A) is snug against the disc spring (REF. B).

(3) Using a spanner wrench, tighten the adjustment nut (REF. A) against the disc spring

(4) Check torque value after each 1/4-turn increment of the adjustment nut (REF. A) while holding

adapter/sleeve (REF. D) stationary and turning drive hub (REF. E) with a torque wrench.

(5) Tighten the nylon-tipped set screw (REF. C) in the outside diameter of the adjustment nut

(REF. A).

7/9/2013 TORQLIM_FLEXCOUPL_MANUAL Page 4 of 5

Page 5

B. Product Numbers: T6H1G-STL, T6H1H-STL, T6H2H-STL and non-catalog

A

B

C

D

E

F

G

variations of this torque limiter design.

(1) Make sure the adjustment nut (REF. A) is snug against the disc spring (REF. B).

(2) Make sure the six jam nuts (REF. C) mounted on the six set screws (REF. D) which are placed axially

in adjustment nut (REF. A) are loose.

(3) Screw the six set screws (REF. D) in the adjustment nut (REF. A) until they contact the disc spring

(REF. B).

(4) Using a circular pattern, tighten the six set screws (REF. D) in the adjustment nut (REF. A) one 1/4-

turn each.

NOTE: If needed, fine tune the torque value of the unit in 1/8-turn increments of the six set screws

(REF. D).

(5) Check torque value after each 1/4-turn increment of all six set screws (REF. D) while holding

adapter/sleeve (REF. F) stationary and turning drive hub (REF. G) with a torque wrench.

NOTE: A torque wrench with a multiplier may be needed for higher torque settings.

(6) Once desired torque is reached, confirm each of the six set screws (REF. D) are in contact with the

disc spring (REF. B).

(7) Tighten the jam nuts (REF. C) mounted on the six set screws (REF. D) firmly against the adjustment

nut (REF. A).

(8) Tighten the nylon-tipped set screw (REF. E) in the outside diameter of the adjustment (REF. A).

Technical assistance is available by contacting Mach III Clutch, Inc.

Mach III Product Warranty

http://www.machiii.com/Resources/Warranty-Info.asp

Mach III Clutch, Inc.

101 Cummings Drive ● Walton, KY 41094

Toll free 866.291.0849 ● International 859.291.0849 ● Fax 859.655.8362

info@machiii.com ● engineering@machiii.com ● www.machiii.com

7/9/2013 TORQLIM_FLEXCOUPL_MANUAL Page 5 of 5

Loading...

Loading...