Page 1

HR824

Page 3 is interactive

High Resolution

Active Studio Monitor

SERVICE MANUAL

1999 MACKIE DESIGNS, INC.

820-183-00

Page 2

C AU TIO N

g

g

g

g

g

g

AVIS

RISK OF ELECTRIC SHOCK

DO NOT OPEN

RISQUE DE CHOC ELECTRIQUE

NE PAS OUVRIR

CAUTION: TO REDU CE THE RISK O F

ELECTRIC SHOCK DO NOT REMOVE

THE COVER (OR BACK)

NO US ER SERVICEAB LE PAR TS INS IDE

R EF E R S ER V IC IN G T O Q U AL IFIE D

PERSONNEL

W ARNING: TO RE DUCE THE RISK OF

FIRE OR E LEC TRIC SH OC K, DO NO T

EXPOSE THIS PROD UCT TO RAIN OR

MOISTURE

TO PREVENT ELECTRIC SHOCK, DO

NOT USE THIS POLARIZED PLUG W ITH

AN EXTENSION CORD, RECEPTACLE OR

OTHER OUTLET UNLESS THE BLADES

CAN BE FULLY INSERTED TO PREVENT

BLADE EXPOSURE.

ATTENTION: POUR EVITER LES

RISQUES DE C HOC ELECTRIQUE, NE

PAS ENLEVER LE COUVERCLE. AUCUN

ENTRETIEN DE PIECES INTERIEURES

PAR L'USAGER. CONFIER L'ENTRETIEN

A U P E R S O N N E L QU A L IF IE .

A VIS :P O U R EV IT ER L ES R IS Q UE S

D'INCENDIE OU D'ELECTROCUTION,

N'EXPOSEZ PAS CET ARTICLE A LA

PLUIE O U A L'HUM IDITE.

POUR PREVENIR LES CHOCS

ELE CTRIQ UES N E PA S UTILISER C ETTE

FICHE POLARISEE AVEC UN

PROLONG ATEUR , UN PRISE DE

COUR ANT OU UNE AUTRE SORTIE DE

COURANT, SAUF SI LES LAMES

PEUVENT ETRE INSEREES A FOND

SANS LAISSER A UCUNE PARTIE A

DECOUVERT.

This apparatus does not exceed the C lass A/Cla ss B (whichever is applicable) lim its for radio

noise emissions from di

ital apparatus as set o ut in the radio interfe rence regulations o f th e

Cana dia n Depa rtm ent of C om m unic atio ns .

ATTENTIO N :Le présent appareil num érique n'ém et pas de bruits radioélec triques dépassant

las lim ites applicables aux appareils num ériques de c lass A /d e class B (selon le cas) prescrites

dans le ré

le m e n t s ur le b ro u illage radioélectrique édicté par les m inistere des com munications

du Ca nada.

This equipm ent has been tested and found to com ply with the lim its for a Class A di

device, pursuant to part 15 of the FCC rules. These limits a re desi

protection a

environm ent. This equipm ent

ainst harm ful interference when the equipm ent is operated in a com mercial

enerates, uses, and can radiate radio energy a nd, if no t

ned to provide reasonable

ital

installed properly a nd used in acco rd ance with the instruction m anual, m ay ca use harm ful

int e rfe re n ce to r ad io c om m u nic a tio ns . O p e ra tio n of th is e q uip m e n t in a r es id e ntia l a r ea is lik ely

to c au s e h a rm f ul in te rf er e nc e i n w hic h c a se th e us e r w ill be r e qu ire d to co r re c t th e inte rf e re nc e

at his own expense.

The lightning flash with arrowhead symbol within an equilateral

triangle is intended to alert the user to the presence of uninsulated

"dangerous voltage" within the product's enclosure, that may be

of sufficient magnitude to constitute a risk of electric shock to persons.

Le symbole éclair avec point de flèche à l'intérieur d'un triangle

équilatéral est utilisé pour alerter l'utilisateur de la présence à

l'intérieur du coffret de "voltage dangereux" non isolé d'ampleur

suffisante pour constituer un risque d'éléctrocution.

2

The exclamation point within an equilateral triangle is intended to

alert the user of the presence of important operating and maintenance

(servicing) instructions in the literature accompanying the appliance.

Le point d'exclamation à l'intérieur d'un triangle équilatéral est

employé pour alerter les utilisateurs de la présence d'instructions

importantes pour le fonctionnement et l'entretien (service) dans le

livret d'instruction accompagnant l'appareil.

Page 3

CONTENTS

Click on any item to open that page

SHIPPING ............................................................................................3

INTRODUCTION .................................................................................4

TECHNICAL SUPPORT ................................................................... 4

DISCLAIMER................................................................................... 4

OVERVIEW..................................................................................... 5

REAR PANEL ..................................................................................6

FRONT PANEL ................................................................................ 7

SPECIFICATIONS ................................................................................ 8

BLOCK DIAGRAM ............................................................................. 9

WIRING DIAGRAM ..........................................................................10

PACKAGING PARTS ........................................................................11

QUICK PARTS.............................................................................. 11-12

TEST PROCEDURES ..................................................................... 13-19

PARTS LIST ................................................................................... 21-25

IC AND TRANSISTOR CHARTS .................................................. 25-26

FOLD-OUT SECTIONS:

SCHEMATICS .........................................................................A1-A2

PRINTED CIRCUIT BOARDS REV A ......................................A3-A4

PRINTED CIRCUIT BOARDS REV B ......................................A5-A6

FINAL ASSEMBLY ............................................................... A7-A13

SHIPPING

When shipping this speaker, make sure that all the original packaging is used, including

both the inner and outer boxes, and especially the thin, white sheet material. If shipped

in just one box or without the sheet material, the lovely finish can be damaged. Shipping

damage due to improper packaging is not covered under Warranty!

If you do not have the original packaging, it can be ordered from our parts department.

Never use loose-fill foam pieces (peanuts) as these can damage the finish and get inside

the amplifier section.

3

Page 4

INTRODUCTION

This manual contains service information for the HR824 Powered Studio Monitor. It is

recommended that you also have a copy of the owner’s manual as this contains the

complete operating instructions.

Service on the HR824 must only be

undertaken by experienced

To service the HR824, technicians should be familiar with op-amp based and discrete

amplifier circuitry, speaker repair and speaker performance testing. Presentation of this

manual does not constitute endorsement of qualifications by Mackie Designs.

The HR824 makes extensive use of

surface mount components.

Service technicians should have the

tools, experience and patience to

perform surface mount rework.

WARNING

service technicians.

! SMD!

PROTECT YOUR HEARING

The HR-824 speakers are capable of producing high sound pressure levels. We

recommend the use of hearing protectors to prevent permanent hearing loss.

SERVICE TECHNICAL ASSISTANCE

Mackie Designs, Service Technical Assistance, is available 8AM - 5PM PST, Monday through

Friday for Authorized Mackie Service Centers, at 1-800-258-6883. Feel free to call with any

questions and speak with a carefully-calibrated technician. If one is not available, leave

a detailed message and a qualified Mackoid will return your call asap.

DISCLAIMER

The information contained in this manual is proprietary to Mackie Designs, Inc. The entire

manual is protected under copyright and may not be reproduced by any means without

express written permission from Mackie Designs Inc.

4

Page 5

HR824 OVERVIEW

• The HR824 Studio Monitors are two-way,

bi-amplified active monitors with a rearfiring passive radiator. One amplifier drives

the woofer and another drives the tweeter.

• The crossover point is designed so that the

high and low frequency drivers are fed only

the frequencies they can best reproduce.

• The amplifiers are designed with protection

circuits to minimize the danger of speaker

damage due to overdriving.

• The amplifiers’ gain and frequency

responses are individually hand-trimmed by

a host of infernal adjustment pots to

compensate for typical manufacturing

tolerances.

• The adjustments produce a smooth

frequency response from 39Hz to 20kHz

(±1.5dB) with minimal phase difference.

THE DRIVERS

• The monitors feature an 8.75-inch die-cast

magnesium frame woofer and a 1-inch

viscous edge-damped aluminum-alloy

dome tweeter on the front, and a 6-inch x

12-inch elliptical flat piston passive radiator

in the back.

• The high-frequency driver is mounted on a

die-cast zinc exponential waveguide

which results in wide, controlled dispersion

of high-frequency sounds. The unique

passive radiator design provides a smooth

response down to 39Hz.

THE CABINET

• The cabinet is made of high-density MDF

wood from specially grown MDF trees. An

internal “H” brace further increases the

strength and rigidity (stiffness) of the box.

An open-cell adiabatic pillow foam

material gently fills the inside of the box to

absorb internal reflections and dampen

any standing waves.

THE AMPLIFIERS

• The Fast Recovery amplifier design uses low

negative feedback, yet allows the

amplifiers to maintain low distortion and

stability even when driven into clipping.

• The low-frequency amplifier produces up

to 150 watts continuous (350 watts peak)

before clipping, while the high-frequency

amplifier produces up to 100 watts

continuous (210 watts peak).

THE PASSIVE RADIATOR

• The HR824 is a bass reflex 6th-order system,

rotating in geo-synchronous orbit. Rather

than use ports, the vent takes the form of

a passive radiator, a mass-loaded flat

piston coupled to the air trapped within

the enclosure. The passive radiator is

located at the rear of the cabinet, behind

the power amplifier assembly.

• One primary advantage over simple porting

is that a passive radiator can reproduce low

frequencies with lower distortion and at a

higher sound pressure level (SPL).

• The unique passive radiator design uses a

diaphragm made with a composite

honeycomb material providing exceptional

stiffness to the radiating surface.

• The elliptical shape of the passive radiator

takes up nearly the entire surface area

available on the rear of the enclosure,

allowing the passive radiator to move

more air than Congress. This moving air

also helps cool the amplifier.

5

Page 6

REAR PANEL DESCRIPTION

SIGNAL INPUTS

• The XLR female and TRS female connectors

are connected in parallel .

• Both input connectors accept balanced or

unbalanced signals. They are wired as

follows (per the AES/IEC standard):

XLR TRS

Hot (+) Pin 2 Tip

Cold (–) Pin 3 Ring

Shield (Ground) Pin 1 Shield

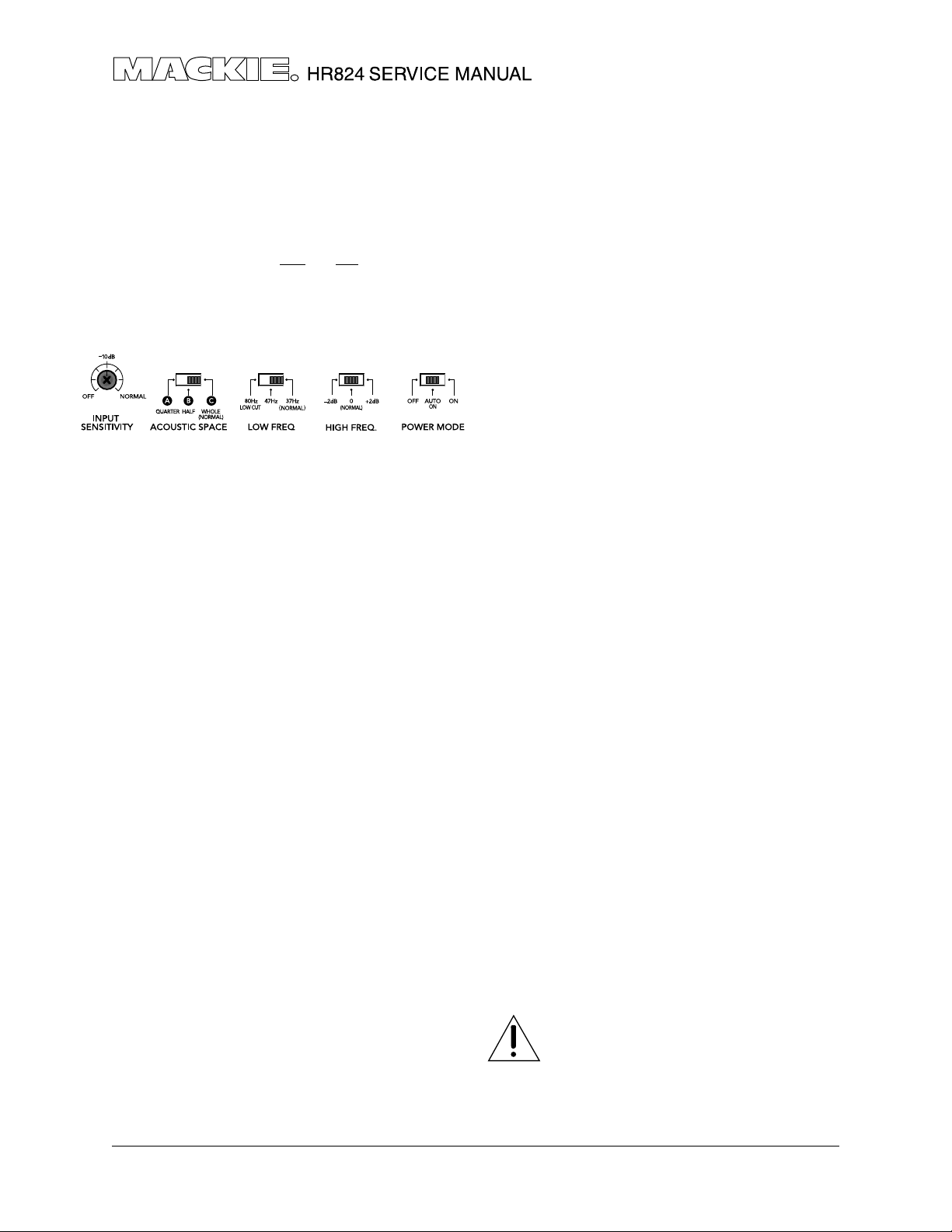

INPUT SENSITIVITY CONTROL

• The HR824 expects a line-level signal at its

input connectors.

• The reference sensitivity is -7.5 dBu = 100 dB

SPL at one meter (39 inches) with the INPUT

SENSITIVITY control set to its NORMAL

position.

• The HR824 is designed to operate with a

+4 dBu signal when the INPUT SENSITIVITY

control is in the NORMAL position.

ACOUSTIC SPACE SWITCH

This is a three-way switch that adjusts the

low-frequency response of the speakers to

compensate for their placement in the

room.

• If you place the monitors against a wall

(half space ), set the ACOUSTIC SPACE

switch to the “B” position. This activates a

shelving filter to reduce the low-frequency

output by 2dB to compensate for the bass

boost from half-space placement.

• If you place the monitors into the corners

of your room (quarter space ), the lowfrequency output approximately doubles

from what it is in half space. Set the

ACOUSTIC SPACE switch to the “A” position

to reduce the low-frequency output by 4dB

to compensate for the bass boost.

• If you use the HR824s free-standing, away

from walls and corners (whole space ), set

the ACOUSTIC SPACE switch to the “C”

position (NORMAL).

LOW FREQ SWITCH

• The LOW FREQ switch inserts a steep lowfrequency rolloff into the response curve.

• For most applications, use the 47Hz setting.

• If you want or need the extra low-frequency

capability, use the 37Hz (NORMAL) position.

• You can use the 80Hz position to simulate

a smaller loudspeaker.

HIGH FREQ SWITCH

• The HIGH FREQ switch tailors the overall

high-frequency response by ±2dB at 10kHz.

POWER MODE SWITCH

• In the OFF position, the power amplifiers

are in Standby mode and produce no

sound. Low-level circuitry is still active, but

the power consumption of the circuitry is

minimal (8 watts).

• In the ON position, the power amplifiers

are live and operate normally. (The front

panel ON/OFF switch must also be ON.)

• Since the power supply and low level

circuitry are already active (assuming the

speaker is plugged into a live outlet), this is

an “instant on” function.

• In the AUTO ON position, the amplifiers turn

on and off depending on the presence or

absence of an input signal. An input signal

level of –45dBu (minimum) activates the

auto-on function. A silent period greater

than five minutes activates the auto-off

function. The red PWR LED on the front

panel reflects the state of the amplifiers.

• Normally, use the front panel switch to turn

the monitors on and off.

• If you unplug the power when a signal is

still applied to the input, you may hear

sound from the monitor. This is after about

6 seconds, when the muting circuit

unmutes and the power supply finishes

discharging. This is normal and not harmful

to the monitor.

MAINS INPUT

• Connect the power cord to this IEC

socket, and plug the other end into your

AC outlet.

IMPORTANT: For safety reasons, the AC

source must be a “3-prong” outlet

with hot, neutral, and ground

terminals.

WARNING: Bypassing the plug’s ground

pin can be dangerous. Don’t do it!

6

Page 7

FRONT PANEL DESCRIPTION

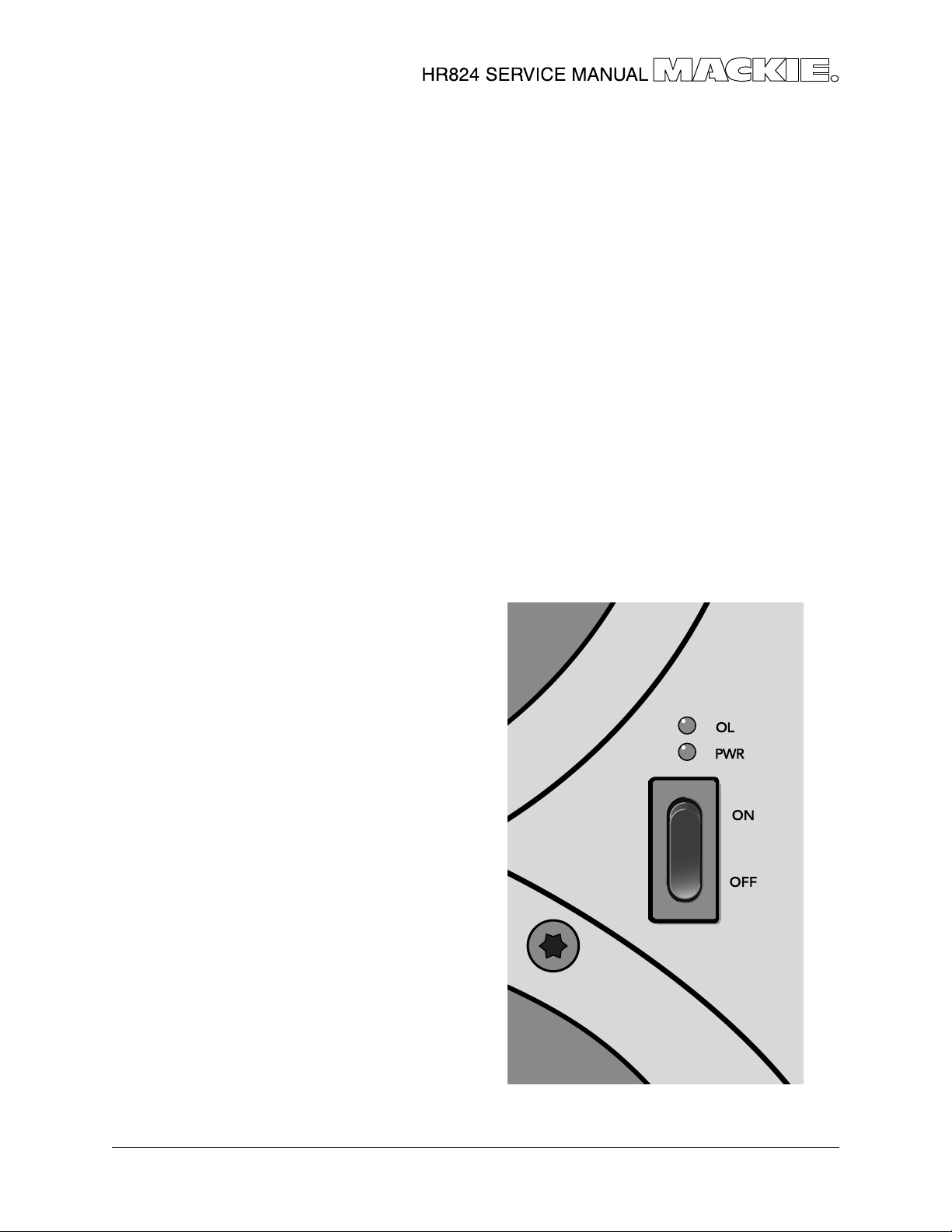

ON/OFF SWITCH

• Use this switch to turn on or off the HR824

from the front. It works with the POWER

MODE switch on the rear panel in the

following way:

• If the rear POWER MODE switch is OFF, the

front panel ON/OFF switch has no effect.

The PWR LED remains off, so there.

• If the rear POWER MODE switch is ON, the

front panel ON/OFF switch turns the HR824

on and off, as indicated by the PWR LED.

• If the rear POWER MODE switch in the AUTO

ON position, the front panel ON/OFF

switch turns the HR824 on and off as long

as there is a signal present.

OL (overload) LED

• This LED blinks when the amplifiers begin to

clip, and lights steadily if the overload

protection circuit has been triggered.

• Occasional blinking of the OL LED

indicates that the loudest transients are

reaching the maximum output capability

of the amplifiers.

• Frequent or continuous blinking of the OL

LED indicates that you have exceeded the

maximum output capability of the

amplifiers and that the amplifiers are

clipping. If you persist, the overload

protection circuit takes over, reducing the

input level. You should reduce the level

from your signal source until the OL LED

blinks occasionally or not at all.

and volume for the monitors. Change the

LOW FREQ switch to 47Hz or 80Hz, if

necessary, to reduce the bass response. This

may allow the HR824s to play louder and

eliminate most amplifier clipping.

THERMAL PROTECTION

• The HR824 is designed to be efficient both

electrically and thermally.

• If the heatsinks get too hot, a thermal

switch activates, placing the HR824 into

Standby mode (indicated when the red

PWR LED turns off).

• Should this happen, make sure that airflow

to the rear of the cabinet is not restricted.

• When the heatsinks cool down to a safe

temperature, the switch resets and normal

operation resumes.

• If your service customer complains that

their HR824s keep thermalling out, make

sure they keep them in the vertical position

for improved ventilation. Also make sure

the bias has been set correctly.

OVERLOAD PROTECTION

• The high and low frequency power

amplifiers have clipping detectors that

light the OL LED when either power

amplifier output clips.

• If frequent clipping occurs, the driver

thermal overload protection activates a

compressor that reduces the input level to

the amplifiers. During this time the OL LED

lights continuously.

• The compressor was designed to protect

the speakers and its action is highly

audible.

• When listening at a very high volume, you

may find that the OL LED lights frequently.

Since the majority of the power

requirements in any monitor are the low

frequencies, selectively reducing the low

end can provide a little more headroom

7

Page 8

SPECIFICATIONS

Amplifier Section

Low-frequency amplifier:

Rated power output: 150 watts, 4Ω load

Burst power output: 350 watts

Distortion: THD: < 0.035%

SMPTE IMD: < 0.035%

DIM 100: < 0.035%

Slew Rate: > 35V/µs

Signal-to-Noise Ratio: > 102 dB, referenced to

150 watts into a 4Ω load

High-frequency amplifier:

Rated power output: 100 watts, 6Ω load

Burst power output: 210 watts

Distortion: THD: < 0.035%

SMPTE IMD: < 0.035%

DIM 100: < 0.035%

Slew Rate: > 35V/µs

Signal-to-Noise Ratio: > 102 dB, referenced to

100 watts into a 6Ω load

Crossover Section

Crossover Type:

Modified Linkwitz-Riley, 24dB/octave @ 2kHz

Input Impedance:

20kΩ, balanced bridging

Compressor:

Independent high and low frequency overload

detection

Acoustic Space Equalization:

A position: –4 dB @ 100Hz, shelving

B position: –2 dB @ 100Hz, shelving

C position: flat

Low Freq Filter:

–3 dB @ 35Hz

–3 dB @ 47Hz

–3 dB @ 80Hz

High Freq Equalization:

± 2 dB @ 10kHz, shelving

Transducers

Low-frequency driver:

8.75-inch (222mm) die-cast magnesium frame,

mineral-filled polypropylene cone.

High-frequency driver:

1-inch (25.4mm) viscous edge-damped aluminumalloy dome with ferrofluid-cooled voice coil.

Passive Radiator:

6-inch x 12-inch (152mm x 305mm) mass-loaded

elliptical flat piston.

Acoustic Section:

Free-Field Frequency Response:

±1.5 dB, 39Hz to 20kHz

Lower cutoff frequency: –3 dB @ 37Hz

Upper cutoff frequency: –3 dB @ 22kHz

Sound Pressure Level at 1 meter,

–7.5dBu into balanced input: 100 dB SPL @ 1m

Maximum short term SPL on axis,

half space 80Hz to 2.5kHz: 110 dB SPL @ 1m

Residual noise (maximum gain, 600

20Hz-20kHz bandwidth): < 8 dB SPL @ 1m

Maximum peak SPL per pair: 120 dB SPL @ 1m

Enclosure

Materials and Construction:

3/4- inch (19mm) thick MDF construction with

1-inch (25.4mm) thick MDF front panel.

Proprietary die-cast zinc exponential wave

guide for high-frequency driver.

Open cell adiabatic “foam fill” acoustical

damping material.

General:

Power Consumption:

135 watts with musical program, loud mix

18 watts quiescent (idle)

8 watts in Standby mode

AC Dropout Voltage:

120V AC versions: 80V AC

240V AC versions: 160V AC

Weight: 33 lbs. 10 oz. (15.25 kg)

Dimensions (HxWxD):

15.75" (400mm) x 10.00" (254mm) x 12.20"

(310mm)

Mackie Designs is always striving to improve our

products by incorporating new and improved

materials, components and manufacturing

methods. Therefore, we reserve the right to

change these specifications at any time without

notice.

ΩΩ

Ω source,

ΩΩ

8

Page 9

BLOCK DIAGRAM

9

Page 10

WIRING DIAGRAM

J8&9

J7

J4

J5

RED

J5-1

BLACK

PCB (J5)

PCB GROUND (GD1) TO REAR COVER

PCB GROUND (GD2)

PCB (J7)

WAVEGUIDE PCB

TRANSFORMER

J5-2

J5-4

WHITE

BLUE

J5-3

J7-1

J7-2

J7-3

J7-4

E-29

E-41

BRN

RED

GRY

RED

YEL

*

BLK

YELLOW FOR 120V TRANSFORMERS

*

WHITE FOR 230V TRANSFORMERS

*

BLUE FOR 100V TRANSFORMERS

*

J11-1

J11-2

J11-3

J11-4

J4-1

J4-2

J4-3

J4-4

J4-5BRN

J8

J9

WOOFER

WOOFER

TWEETER

TWEETER

TO BRACKET

WAVEGUIDE

PCB J11

SWITCH

PCB (J4)

PCB (J8)

PCB (J9)

10

WIRING DIAGRAM

Page 11

PACKAGING

Note: Use only the exact

packaging shown here.

Do not substitute any part

or the speaker will be

damaged.

1. Place speaker inside

the packing foam

bag.

2. Add cardboard collars.

3. Slide into inner box

and secure shut.

4. Add corners and slide

into outer box and

secure shut for

shipping.

CARDBOARD

COLLAR #2

810-060-00

MANUAL

INNER

BOX

MANUAL

CARDBOARD

COLLAR #1

810-059-00

PACKING FOAM

790-019-00

(VERY IMPORTANT)

INNER BOX

800-067-00

CORNERS X 8

810-058-00

INNER

BOX

QUICK PARTS

TWEETER

GASKET

PART OF

480-103-00

500-016-00

SWITCH

490-003-00

TWEETER

551-501-00

WAVEGUIDE

Note: When ordering the woofer or

tweeter, order the bucking magnet and

the gaskets as well. You will then

receive the assembly, with the bucking

magnet already glued in place.

The woofer gasket comes with the

tweeter gasket and a little tiny gasket

for the LEDs. The gaskets must be

replaced whenever the woofer, tweeter

or the LED assembly is changed.

LED BOARD

PART OF

MAIN BOARD

(LED GASKET

IS PART OF

480-103-00)

490-016-00

BUCKING

MAGNET

780-102-00

WAVEGUIDE

GASKET

490-001-00

WOOFER

480-103-00

WOOFER

GASKET

490-017-00

BUCKING

MAGNET

OUTER BOX

800-068-00

490-010-00

SPEAKER

CABINET

OUTER

BOX

11

Page 12

QUICK PARTS

AMPLIFIER SUB ASSY

080-039-00 (120 VAC)

080-039-01 (230 VAC)

080-039-02 (100 VAC)

PASSIVE RADIATOR

ASSEMBLY

080-029-00

WOOFER

FOAM

810-050-00

WIRING

HARNESS

080-046-00

PASSIVE RADIATOR

GASKET

780-110-00

TWEETER

FOAM

810-052-00

12

Page 13

TEST PROCEDURES

REQUIRED TESTS

The following pages contain the test procedures for the amplifier section disconnected

from the woofer and tweeter. For minor repairs, there is no need to run through all tests

but you MUST at least do the following:

• Adjust the bias, and check the rails and current draw as shown below.

• Verify that both amplifiers meet full power into resistive loads, as shown on page 19.

• Operate all the switches and verify their effect.

• Manually (and gently) check the woofer for any sticking or rubbing in its travel.

NOTE:

The four adjustment pots VR2, VR3, VR5 and VR6 are set and glued at the Mackie Factory

for optimum performance and should not be touched. The factory settings are made

when the speaker is all assembled and its output measured in an anechoic chamber

with a calibrated microphone. The setting of these pots takes into account

manufacturing tolerances of the complete assembly, not just the amplifier on its own.

TEST EQUIPMENT

The amplifer performance must be tested into resistive loads:

4 ohm, 200 watt resistor for the low frequency amplifier

8 ohm, 200 watt resistor for the high frequency amplifier

Other equipment required:

Audio range sinewave generator, oscilloscope, dc millivolt/volt meter, Vrms meter,

THD meter.

NOTE: Take care as the amplifier will turn on using the rear panel power switch even

when the front panel switch is not connected.

INITIAL SIGNS OF HAPPINESS

• The amplifier is on and cold, NO loads, NO input signal

• See the next page for the location of the test points

BIAS:

Measure the dc voltage across the two pins of J1, and adjust VR1 for a reading of 2.5 mV

Measure the dc voltage across the two pins of J6, and adjust VR4 for a reading of 2.5 mV

Don’t stop, there is more:

IMPORTANT NOTE: After the amplifier has been on for 30 minutes and if the rails and

current draw seem good (as shown below), set both bias voltages to 9 mV (with no

signal, no load).

RAILS:

Verify the various dc voltages are present, relative to ground (see the diagram on the

next page):

-56V, +56V, -49V, +49V, -15V, +15V.

CURRENT DRAW

The current should be less than 200mA with no loads attached.

13

Page 14

TEST POINTS

+15V

E1

+49V

E13

-49V

E32

R22

EMITTER

END

VR1

J1

NOTE:

INSTEAD OF USING J1,

YOU CAN MEASURE THE BIAS

ACROSS THE EMITTER ENDS

OF R22 AND R24 AS SHOWN.

R24

EMITTER

END

R184

SW2

GROUND

-15V

E80

R166

EMITTER

END

J6

VR4

EMITTER

R170

END

-56V

E34

SW5 SW3 SW4

+56V

E89

NOTE:

INSTEAD OF J6, YOU CAN

MEASURE THE BIAS ACROSS

THE EMITTER ENDS OF R166

AND R170 AS SHOWN.

14

Page 15

WOOFER

LOAD RESISTOR

4 ohm, 200 Watt

TWEETER

LOAD RESISTOR

8 ohm, 200 Watt

Blue

Red

Black

White

J5

CONNECTING THE LOADS

J5 is your time portal vortex to another

realm of audio excitement. If you have

a suitable connector, then wire the test

loads as shown on the right.

If you are not blessed with a spare

connector of this type, you can

connect your loads carefully to the

larger resistors of the circuit board as

shown below. Use crocodile (alligator)

clips, or better still, use them little hook

things.

TWEETER NEGATIVE

(=GROUND, BLUE J5)

View from the

top, looking

down onto the

connector

plugged into the

board.

R184

(= WHITE J5)

TWEETER

SW2

POSITIVE

WOOFER

POSITIVE

(=RED J5)

SW5 SW3 SW4

WOOFER NEGATIVE

(=BLACK J5)

15

Page 16

LOW FREQUENCY AMPLIFIER TESTS

ACOUSTIC SPACE SWITCH

Disable the compressor circuit by shorting together pins 1 and 2 of J12.

Turn off the amplifier and connect the two resistor loads as shown on the previous page.

Set all switches to the NORMAL position and turn on the amplifier.

Set your audio signal generator for an output of 300mVrms(-10.46dBV).

Measure the output into the 4 ohm load for the three positions of the ACOUSTIC SPACE switch.

Do these measurements fairly quickly because the amplifier will be warming up.

The level of the output may be different from that shown, due to the factory settings of the

calibration pots. Just make sure that the speaker under test follows the overall shape and the

switch is working.

THD

Measure the THD at 400 Hz and verify it is less than 0.1%

AMPL(dBV)

30

25

20

15

10

5

0.0

20

15

10

5

1

Vrms

LOW FREQUENCY AMPLIFIER OUTPUT

ACOUSTIC SPACE

(Vary during this test)

100 200 300 500 1k 2k30 50

FREQ(Hz)

LOW FREQ

(keep on 37Hz)

Vrms

20

15

10

5

1

AMPL(dBV)

30

25

20

15

10

5

0.0

16

Page 17

LOW FREQUENCY AMP TESTS continued

LOW FREQ SWITCH TEST

Set your audio signal generator for an output of 300mVrms (-10.46dBV)

Set the Acoustic Space switch to position A (Quarter Space).

Measure the output into the 4 ohm load for the three positions of the LOW FREQ switch.

Do these measurements fairly quickly because the amplifier will be warming up.

The level of the output may be different from that shown, due to the factory settings of

the calibration pots. Just make sure that the speaker under test follow the overall shapes

and the switch is working.

NOTE: the graph of the 37 Hz position is the same as measured on the previous page

(position A), so no need to repeat it, just do 47 Hz and 80 Hz.

AMPL(dBV)

30

25

20

15

10

5

0.0

20

15

10

5

1

LOW FREQUENCY AMPLIFIER OUTPUT

Vrms

ACOUSTIC SPACE

(Keep on A)

20 30 40 50 60 70 80 90

FREQ(Hz)

LOW FREQ

(Vary during test)

Low Earth Orbit

100 200

Vrms

20

15

10

5

1

AMPL(dBV)

30

25

20

15

10

5

0.0

17

Page 18

HIGH FREQUENCY AMPLIFIER TESTS.

NORMAL RESPONSE TEST

Disable the compressor circuit by shorting together pins 1 and 2 of J12.

Set your audio signal generator for an output of 300mVrms (-10.46dBV)

Set the ACOUSTIC SPACE, LOW FREQ and HIGH FREQ switches to NORMAL.

Do these measurements fairly quickly because the amplifier will be warming up.

The level of the output may be different from that shown, due to the factory settings of

the calibration pots. Just make sure that the speaker under test follows the overall shape

and that the switch works as follows:

HIGH FREQUENCY SWITCH TEST

Switch the HIGH FREQ switch to +2dB and verify a 2dB increase at 20 kHz.

Switch the HIGH FREQ switch to -2db and verify a 2dB decrease at 20 kHz.

THD

Measure the THD at 3 kHz and verify it is less than 0.1%

AMPL(dBV)

30

25

20

15

10

5

0.0

20

15

10

5

1

HIGH FREQUENCY AMPLIFIER OUTPUT

Vrms

NORMAL

1k 3k

HIGH FREQ

5k2k

FREQ(Hz)

10k

Base

Camp

+2dB

-2dB

30k20k

Vrms

20

15

10

5

1

AMPL(dBV)

30

25

20

15

10

5

0.0

18

Page 19

POWER TESTS

Disable the compressor circuit by shorting together pins 1 and 2 of J12.

Set all of the switches to NORMAL and measure the output power of both amplifiers into

their respective load resistors.

Quickly verify that the output power is as least as follows:

High Frequency amplifier

75 Watts @ 3 kHz into 8 ohms (=24.5 Vrms)

Low Frequency amplifier

110 Watts @ 400 Hz into 4 ohms (=21 Vrms)

Quickly verify that both amplifiers clip symmetrically.

Verify that the OL (overload) LED turns on.

Remove the short from J12 when finished.

J12

R184

SW2

WOOFER AND TWEETER TESTS

• Carefully inspect the woofer and tweeter cones for any signs of damage. The

speakers do not have front grills, so any cosmetic damage should be easily

indentifiable.

• Measure the dc resistance of each driver and verify nothing is shorted. The resistance

should be around 6 ohms.

• Carefully and gently check by hand that the woofer moves in and out without any

rubbing or scraping of the voice coil.

• Connect the woofer and tweeter to the HR824 amplifier.

• Conduct a listening test and play some low frequency (30 to1kHz) test tones to verify

the performance of the woofer driver.

• Sweep from 15 Hz to 110 Hz and listen carefully for any air leaks at front and back.

Listen at any screw holes, at the power switch and the leds.

• Tighten any screws, or replace gaskets if required.

• Play some high frequency (2kHz to 20 kHz) tones to check the tweeter.

Listen for crystal clear highs, deep bass from two stories down, and the effervescent,

detail-revealing openness so beloved by Hi-Fi gurus.

Servere ear/hearing damage can be caused by continous exposure to high level sounds.

Take every precaution to preserve your hearing.

SW5 SW3 SW4

19

Page 20

PARTS LIST

• When ordering the woofer or tweeter, you must order the bucking magnet as well. Then you

will receive the assembly, with the bucking magnet already glued in place.

• Always order the woofer gasket at the same time, because during disassembly, this gasket

can get torn. The tweeter gasket (and the small gasket for the LEDs) comes with the woofer

gasket.

• Always use the inner box, the outer box and the thin white foam when shipping the HR824

and use all other means of safe-shipping protection. This will protect the finish from getting

scuffed up or the woofers from being damaged.

• The assembly diagrams in the fold out sections of this manual also show the part numbers, so

check there first for easier parts identification.

• Pages 22-26 show all the parts of the PCB assembly, including two charts of transistor and IC

information.

Parts Numbering guide

040- Cables

055- Finished PCB Assy

100- Pots and resistors

200- Capacitors

300- Semiconductors

400- Jacks/Connectors

500- Switches

510- Fuses

550- Chassis Metalwork

600- Transformers

601- Inductors

610- Wires and Cables

640- AC line cords

700- Hardware

760- Knobs/Plastic

770- Fans

790- Misc./Packing

800- Printed Material

20

860- EPROM

Page 21

SAFETY CRITICAL PARTS,

USE EXACT REPLACEMENT

Final Assembly Parts

PARTS ONLY.

PART NO. DESCRIPTION QTY NOTES

080-029-00 PASSIVE RADIATOR ASSEMBLY 1 (ORDER AS A COMPLETE ASSEMBLY)

055-094-00 PCB ASSEMBLY 1 (SEE PAGES 22-24 FOR THE DETAILS)

550-231-00 HEATSINK BRACKET 2

730-001-00 THERMAL JOINT COMPOUND (DON’T USE ON THE TRANSISTORS WITH SIL-PADS)

550-228-00 REAR COVER 1

550-230-00 INTERCONNECT BRACKET 1 (BOTTOM BRACKET)

550-248-00 XFMR PLATE (SPLD W/XFMR)

600-019-00 XFMR HR824 120V 1 120V UNITS

600-019-01 XFMR HR824 230V 1 230V UNITS

600-019-02 XFMR HR824 100V 1 100V UNITS

700-005-00 SEMS 8-32xl/2 PHP BLKZC 10 FOR REAR PANEL FITTING TO PCB ASSEMBLY

700-030-04 MCH 6-32X3/8 PHP BLKZC 2 FOR IEC CONNECTOR

700-031-02 MCH 6-32X3/8 BTNPIN BLKZC 2 2 FOR GROUND SCREWS

700-052-00 MCH 10-32X2-1/4 PHP BLKZC 1 FOR TRANSFORMER MOUNTING

700-055-00 MCH 4-24X3/8 PHP BLK HILO 2 FOR XLR

705-001-00 KEPNUT 6-32 4 2 FOR IEC, 2 FOR GROUND SCREW

705-011-00 NUT, LOCK 10-32 1 FOR TRANSFORMER SCREW

705-015-00 NUT SLOT NCKL 1 FOR PHONE JACK

710-019-00 WASH FIBRE BLK 1 FOR PHONE JACK

740-001-00 TYRAP 3-1/4L SEE ASSEMBLY DRAWINGS FOR LOCATIONS

780-107-00 RUBBER WASHER 3.55 DIA 2 FOR TRANSFORMER MOUNTING

080-046-00 CABLE HARNESS ASSEMBLY 1

611-028-03 WIRE 18GA RED 39 INCH 1 HARNESS ASSEMBLY WIRES

611-029-04 WIRE 18GA BLACK 39 INCH 1 HARNESS ASSEMBLY WIRES

611-041-01 WIRE 18G WHITE 35 INCH 1 HARNESS ASSEMBLY WIRES

611-042-01 WIRE 18G BLUE 35 INCH 1 HARNESS ASSEMBLY WIRES

490-001-00 WOOFER 8.75 INCH 4 OHM 1

490-003-00 TWEETER 1 INCH 6 OHM 1

490-010-00 SPEAKER CABINET 1

490-016-00 BUCKING MAGNET, TWEETER 1

490-017-00 BUCKING MAGNET, WOOFER 1

500-016-00 SWITCH ROCKER SPST 6A/250V 1 FRONT POWER SWITCH

551-501-00 CAST WAVE GUIDE 1

640-001-00 LINECORD IEC SJT 10A/125V 6FT 1 FOR 120 V MODELS

640-002-01 LINECORD, 230V 1 FOR 230 V MODELS

640-002-02 LINECORD, 100V 1 FOR 100 V MODELS

700-010-04 TF 6-32X3/8 PHP BLKZC 5 (4 TWEETER SCREWS AND 1 FOR LED)

701-012-05 SCREW SM 8xl PAN TORX BLKOX 17 (9 WAVEGUIDE, 2 PASSIVE RAD, 6 REAR PANEL)

710-005-00 WASHER INT STAR NO.6 BLK 5 (4 TWEETER SCREWS AND 1 FOR LED)

730-019-00 ACCEL BLACK MAGIC 737 (FOR FOAM)

750-002-00 BUMPON FLT RND BLK .14H 4

780-102-00 GASKET FOR WAVEGUIDE 1

780-103-00 GASKET FOR WOOFER 1 (INCLUDES TWEETER AND LED GASKET)

780-110-00 GASKET FOR PASSIVE RADIATOR 1

790-019-00 P/FOAM 48X28X1/32 P/F SHT PACKING FOAM “THE WHITE STUFF”

800-067-00 BOX INNER - HR824 1

800-068-00 BOX OUTER - HR824 1

810-050-00 FOAM CABINET HR824 1

810-052-00 FOAM TWEETER HR824 1

810-058-00 INST CORNER - HR824 8

810-059-00 INST COLLAR - HR824 1

810-060-00 INST COLLAR 2 - HR824 1

840-074-00 LBL MACKIE LOGO 3D 1

21

Page 22

PCB Assy 055-094-00 Rev A and B (A/B differences marked in bold print)

PART NO. DESCRIPTION REFERENCE DESIGNATORS

040-127-00 DIS 22GA BLK 1C 2.SIN QD

400-091-00 TERM ODISC .187 F 18-22GA

610-012-00 WIR 22GA 1007 BLK 2.5 ST2

040-135-00 DIS 18G 1010 GRNYL 4 LGTM

400-172-00 TERM SOLDER-IN 18AWG

611-038-00 WIR 18GA 1010 GN/YL 4 ST2

711-001-00 LUG NO.6 SOLDER STAR

110-065-00 RESISTOR CF, 1/4 WATT 4K7 5% R179

110-083-00 RESISTOR CF, 1/4 WATT 27K 5% R178

120-097-00 RESISTOR CF, 1/2 WATT 10K 5% R99

121-081-00 RESISTOR MF, 1WATT 2 K2 5% R21 R130

123-001-00 RESISTOR MF, 3WATT .1 OHM 5% R101

123-009-00 RESISTOR MOF, 3WATT .22 5% R22 R24 R166 R170

123-049-00 RESISTOR MOF, 3WATT 10 5% R64 R100

130-038-00 RES POT TRIM HORIZ 500-B VR1 VR4

130-043-02 RES POT 9MM HORIZ 10KA R184

130-044-00 RES POT TRIM VERT 500-B VR6 VR5 (REV A)

130-046-00 RES POT TRIM VERT 1K VR5 (REV B)

130-046-00 RES POT TRIM VERT 1K VR3

130-052-00 RES POT TRIM VERT 50K VR2

140-041-00 RESISTOR TF SMT 47 5% R146

140-053-00 RESISTOR TF SMT 15 0 5% R25 R40 R161 R173

140-057-00 RESISTOR TF SMT 22 0 5% R3 R9 R162 R175

140-060-00 RESISTOR TF SMT 30 0 5% R28 R37 R131 R133 R139

140-065-00 RESISTOR TF SMT 47 0 5% R77

140-070-00 RESISTOR TF SMT 75 0 5% R6 R90 R168

140-073-00 RESISTOR TF SMT 1K0 5% R122 R148-149

140-080-00 RESISTOR TF SMT 2K 5% R20

140-082-00 RESISTOR TF SMT 2K4 5% R19 R155

140-096-00 RESISTOR TF SMT 9K1 5% R15

140-097-00 RESISTOR TF SMT 10K 5% R123

140-104-00 RESISTOR TF SMT 20K 5% R126

140-109-00 RESISTOR TF SMT 30K 5% R1 R10 R160 R177

140-123-00 RESISTOR TF SMT 100K 5% R111 R116 R125

145-162-00 RESISTOR MF SMT 47R5 1% R29-30 R33-34 R59 R74 R79 R134-135

R140-141

145-193-00 RESISTOR MF SMT 10 0 1% R62-63 R158

145-204-00 RESISTOR MF SMT 13 0 1% R80

145-226-00 RESISTOR MF SMT 22 1 1% R157

145-239-00 RESISTOR MF SMT 30 1 1% R67 R71 R103-104

145-269-00 RESISTOR MF SMT 61 9 1% R32

145-285-00 RESISTOR MF SMT 90 9 1% R124

145-289-00 RESISTOR MF SMT 1K00 1% R35 R49 R95 R137

145-293-00 RESISTOR MF SMT 1K10 1% R118 R73 (REV A)

145-294-00 RESISTOR MF SMT 1K13 1% R96

145-300-00 RESISTOR MF SMT 1K30 1% R73 (REV B)

145-306-00 RESISTOR MF SMT 1K50 1% R75 R138

145-314-00 RESISTOR MF SMT 1K82 1% R14 R43 R47 R70 R102 R195

145-326-00 RESISTOR MF SMT 2K21 1% R5 R169

145-331-00 RESISTOR MF SMT 2K49 1% R11 R26-27 R39 R53 R119 R159 R164 R174

R176

145-338-00 RESISTOR MF SMT 2K94 1% R55 R97

145-339-00 RESISTOR MF SMT 3K01 1% R13

145-346-00 RESISTOR MF SMT 3K57 1% R94

145-354-00 RESISTOR MF SMT 4K32 1% R84

22

Page 23

PART NO. DESCRIPTION REFERENCE DESIGNATORS

145-358-00 RESISTOR MF SMT 4K75 1% R44-45 R66 R85 R87 R98 R121 R128 R185-186

145-361-00 RESISTOR MF SMT 5K11 1% R16-17 R60-61 R145

145-367-00 RESISTOR MF SMT 5K90 1% R57

145-381-00 RESISTOR MF SMT 8K25 1% R41 R51 R113

145-383-00 RESISTOR MF SMT 8K66 1% R193

145-389-00 RESISTOR MF SMT 10K0 1% R42 R86 R89 R91-92 R109 R115 R153 R183

R46 (REV A)

145-393-00 RESISTOR MF SMT 11K0 1% R190

145-397-00 RESISTOR MF SMT 12K1 1% R36 R52 R46 (REV B)

145-406-00 RESISTOR MF SMT 15K0 1% R18 R50 R78 R110 R112

145-409-00 RESISTOR MF SMT 16K2 1% R82

145-411-00 RESISTOR MF SMT 16K9 1% R187

145-414-00 RESISTOR MF SMT 18K2 1% R58

145-415-00 RESISTOR MF SMT 18K7 1% R188

145-418-00 RESISTOR MF SMT 20K0 1% R31 R38 R54 R56 R65 R68-69 R72 R106

R114 R120 R132 R136

145-422-00 RESISTOR MF SMT 22K1 1% R143 R151

145-424-00 RESISTOR MF SMT 23K2 1% R192

145-426-00 RESISTOR MF SMT 24K3 1% R129

145-435-00 RESISTOR MF SMT 30K1 1% R76

145-437-00 RESISTOR MF SMT 31K6 1% R189

145-439-00 RESISTOR MF SMT 33K2 1% R181

145-452-00 RESISTOR MF SMT 45K3 1% R194

145-454-00 RESISTOR MF SMT 47K5 1% R142 R144 R150 R180

145-472-00 RESISTOR MF SMT 73K2 1% R191

145-473-00 RESISTOR MF SMT 75K0 1% R83

145-479-00 RESISTOR MF SMT 86K6 1% R81

145-480-00 RESISTOR MF SMT 88K7 1% R117 R127

145-485-00 RESISTOR MF SMT 100K 1% R105 R152 R154

145-500-00 RESISTOR MF SMT 143K 1% R12

145-510-00 RESISTOR MF SMT 182K 1% R48

145-518-00 RESISTOR MF SMT 221K 1% R93 R147 R156

145-522-00 RESISTOR MF SMT 243K 1% R107

145-553-00 RESISTOR MF SMT 511K 1% R88 R108

145-581-00 RESISTOR MF SMT 1M0 1% R182

150-009-00 RES, FUSIBLE, 1/4W 2.2 5% R4 R7 R165 R171

150-037-00 RES, FUSIBLE, 1/4W 33 5% R2 R8 R163 R172

150-045-00 RES, FUSIBLE, 1/4W 68 5% R23 R167

200-023-00 CAP, POLY BOX, 250 V .001uF 20% C81-82

200-024-00 CAP, POLY BOX, 250 V .01uF 20% C83

200-027-02 CAP MYLAR T&R .1 5% C2 C15 C24 C44 C47 C50 C66 C68 C85 C97

200-028-02 CAP MYLAR T&R .01 5% C45-46 C64-65

200-037-02 CAP MYLAR T&R .033 5% C48 C87

212-001-00 CAP CERAMIC SMT .01 10% C6 C8-10 C32 C70 C72 C75-76 C101

212-003-00 CAP CERAMIC SMT 100P 5% C13 C33

212-014-00 CAP CERAMIC SMT 180PF 5% C4 C7 C98 C103

212-019-00 CAP CERAMIC SMT 150PF 5% C30 C54 C110-111

212-020-00 CAP CERAMIC SMT 750PF C18 C26 C99 C102

212-021-00 CAP CERAMIC SMT 27pF C19 C88

212-023-00 CAP CERAMIC SMT .001 10% C22 C41-43 C90

220-001-02 CAP LYTIC RADIAL TAPE 22UF 10% C69 C71

220-002-02 CAP LYTIC RADIAL TAPE 47UF 10% C14 C37 C89 C93-94

220-005-02 CAP LYTIC RADIAL TAPE 470UF 10% C17 C86

220-012-02 CAP LYTIC RADIAL TAPE 4.7UF 10% C49 C79

220-027-02 CAP LYTIC RADIAL TAPE 10UF 10% C1 C3 C 5 C23 C67 C80 C92 C95-96 C100

220-030-00 CAP LYTIC RADIAL 1000UF 10% C91

220-036-00 CAP LYTIC RADIAL 10,000UF 20% C16 C84

PRIMARY CIRCUIT CAPS

FUSIBLE

RESISTORS

23

Page 24

PART NO. DESCRIPTION REFERENCE DESIGNATORS

224-004-00 CAP FILM SMT .0022 2.0% C31

224-006-00 CAP FILM SMT .0047 2.0% C11 C34 C38 C40

224-007-00 CAP FILM SMT .0068 2.0% C35 C53

224-009-00 CAP FILM SMT .01 2.0% C20-21 C25 C27 C29 C36 C51

224-010-00 CAP FILM SMT .1 2.0% C39 C56-60 C62 C104-109

224-011-00 CAP FILM SMT .022 2.0% C12 C55

224-014-00 CAP FILM SMT .033 2.0% C28

224-015-00 CAP FILM SMT .047 2.0% C77

224-016-00 CAP FILM SMT 470pf 2.0% C52 C78

224-017-00 CAP FILM SMT .0015 2.0% C73-74

224-019-00 CAP FILM SMT .15 5% C61

224-020-00 CAP FILM SMT .39 5% C63

300-003-00 DIODE SIGNAL SMD DL4148 D1-12 D20-21 D26-33 D37-41 D43-51

301-009-00 DIODE POWER 1N4004 D14-19 D24-25 D34-36

301-013-00 DIODE BRIDGE 6A BR1

302-003-00 DIODE ZENER 1N4745 D13 D42

304-001-00 DIODE LED T1 RED D22-23

310-023-02 TRANSISTOR NPN T&R 2SC2362K Q14-15 Q28 Q39

310-024-00 TRANSISTOR PNP 2SB817 Q7 Q3 5

310-025-00 TRANSISTOR NPN 2SD1047 Q5 Q37

310-028-00 TRANSISTOR PNP 2SB940A Q9 Q30 Q32

310-029-00 TRANSISTOR NPN 2SD1264A Q1-2 Q41

310-032-02 TRANSISTOR PNP T&R 2SA1016K Q16-17 Q27 Q38

310-035-00 TRANSISTOR PNP 2SA1478 Q3 Q 42

310-036-00 TRANSISTOR NPN 2SC3788 Q10 Q33

310-037-00 TRANSISTOR NPN MJE340 Q6 Q36

311-001-00 X-SISTOR NPN SMD IMBT4401 Q19-20 Q43

311-002-00 X-SISTOR PNP SMD IMBT4403 Q21-23

311-005-00 X-SISTOR NPN SMD IMBTA06 Q8 Q11-12 Q24 Q29 Q31 Q34

311-006-00 X-SISTOR PNP SMD IMBTA56 Q4 Q13 Q18 Q25-26 Q40

320-004-00 I.C. LINEAR SMD NJM4560 U1-14

329-012-00 OPTO-ISOLATOR,LED/CDS VTL5C10 LDR1

400-060-00 FUSE CLIP PCMT Z1 Z3

400-131-00 CON XLR PC MTG HORIZ FML SML J3

400-132-00 CONNECTOR, IEC, RIGHT ANGLE, J10 PC MT

400-163-00 HDR, VERT, 4P, .165X2, M, J5 W/PEGS

400-165-00 HDR ,VERT, 5P, .165X1, M , J4 W/PEGS

400-166-00 CONNECTOR, STEREO, JACK 1/4" J2 HORIZ SLIM

400-171-00 CONN, HDR, 2-PIN, UN-SHROUDED, J1 J6 J12 0 .100

400-173-00 CONN QUICK DISC .250 J8-9 W/STABLE-LOK TABS

400-178-00 CONNECTOR,STR,4P,.098 X 1,SHRD J7 J11

410-004-00 SIL PAD, TO-126 Z12-13 (FOR SMALL TRANSISTORS)

410-005-00 SIL PAD, TO-220 Z14-17 (FOR LARGE TRANSISTORS)

450-094-00 PCB, MONITOR Z2

500-025-00 SWITCH, SLIDE, 2P3T SW 2 -5

500-026-00 THERMOSTAT 67F070 TH1

500-033-02 SWITCH, TACT 6MM SQR 260GF SPST SW1

550-231-00 HEATSINK BRACKET Z4-5

700-023-00 SCREW, PHP, BLK, 6-32X1/2 Z30 Z59 (FOR IEC SOCKET)

700-028-00 SCREW, PHP, BLK, 6-32X1/4 SEMS Z6-7 Z10-11 (MOUNTING BOARD)

700-058-03 SCREW, SKT HD, 4-40X5/8 Z8-9 Z18-28 (FOR TRANSISTORS)

705-001-00 NUT, KEP, 6-32 Z60-61 (FOR IEC SOCKET)

705-016-00 NUT, 4-40 Z31-38 Z43 Z96-99 (FOR TRANSISTORS)

706-044-00 SPACER, LED .440 Z44-45 (FOR LED)

24

Page 25

PART NO. DESCRIPTION REFERENCE DESIGNATORS

710-020-00 WASHER, COMPRESSION Z46-58 (FOR TRANSISTORS)

710-022-00 WASHER, FLAT Z62-74 (FOR TRANSISTORS)

730-003-00 ADHESIVE, 3M 4799

730-025-00 LOCKTITE 222

510-025-00 FUSE SB 1.25A 5X20 250V UL 1 230V UNITS

510-026-00 FUSE SB 3.15A 5X20 250V UL 1 100V UNITS

510-029-00 FUSE SB 2.5A 5X20 250V UL 1 120V UNITS

780-043-00 INSULATOR PCB 1 (FITS ON PCB)

712-038-00 RIVET NYLON .123-.127HOLE 1 (FOR PCB INSULATOR)

400-135-00 TERM 11A/600V F 18-20GA 5

400-164-00 5P .165X1 F VERT 1

400-210-00 TERM QDISC .250 F 18-22GA 2

FUSES

IC and Transistor charts

STYLE REF DESIG. PART NUMBER DESCRIPTION

U1-14

320-004-00 NJM4560

DUAL OP AMP

4

1

+15V

8

1

-15V

2

3

4

7

6

5

STYLE REF DESIG. PART NUMBER DESCRIPTION

LDR1 329-012-00 VTL5C10

OPTO ISOLATOR

43

-LED+

CELL

4

3

1

2

21

25

Page 26

STYLE REF DESIG. PART NUMBER DESCRIPTION TYPE

310-023-02Q14,15,28,39 2SC2362K NPN

3

1

B

E

310-032-02Q16,17,27,38 2SA1016K PNP

Q5, Q37 310-025-00 2SD1047 NPN

Q7, Q35 310-024-00 2SB817 PNP

3

1

E

B

Q1, Q2, Q41 310-029-00 2SD1264A NPN

1

E

3

Q9, Q30, Q32 310-028-00 2SB940A PNP

B

BLAH

Q6, Q36 310-037-00 MJE340 NPN

26

1

B

E

Q10, Q33 310-036-00 2SC3788 NPN

3

BLAH

1

B

3

Q3, Q42 310-035-00 2SA1478 PNP

E

Q19, Q20, Q43

311-001-00 IMBT4401 NPN

3

C

Q21, Q22, Q23 310-002-00 IMBT4403 PNP

2

1

B

E

Q8, Q11, 12, 24,

Q29, Q31, Q34

Q4, Q13, Q18,

Q25, Q26, Q40

310-005-00 IMBTA06

310-006-00

IMBTA56

NPN

PNP

Loading...

Loading...