Mace HydroMace 3000 Product Manual

PRODUCT MANUAL

www.macemeters.com

MACE HydroMace 3000 Product Manual

Product Support

Should you experience diculty in using this product, please contact your

supplier.

We also welcome feedback from customers who feel that their experience may

provide an improvement to the product or may be benecial to other users.

Please go to www.macemeters.com

Disclaimer

No warranties of any nature are extended by this document.

Measuring and Control Equipment Co. Pty. Ltd. (MACE) will not accept any

nancial or other responsibility that may be the result of your use of this

information, including direct, indirect, special or consequential damages.

You must be careful to ensure that the use of this information complies with

the laws, rules and regulations of the jurisdictions with respect to which it is

used.

MACE assumes no responsibility for personal or property damage caused by

the misuse of this equipment.

Copyright

Information in this document is subject to change without notice. The

software described in this document is furnished under a license agreement

or nondisclosure agreement. The software may be used or copied only in

accordance with the terms of those agreements. No part of this publication

may be reproduced, stored in a retrieval system, or transmitted in any form or

any means electronic or mechanical, including photocopying and recording

for any purpose other than the purchaser’s personal use without the written

permission of Measuring & Control Equipment P/L.

Copyright © 1996-2009. MACE P/L. All rights reserved.

Part No. 825-319 Rev. 1.4 Code. 080209

40 years of innovation from the inventors

of solid state data logging

DFR-77 DATA LOGGER

1977 - The world’s first commercial EPROM

data loggers, the MACE DFR-77 were delivered.

Hundreds of these instruments were used

throughout Australia and Papua New Guinea

working under the harshest imaginable

conditions. The EPROM data recording technique

proved to be the most reliable method of

electronic data storage.

HYDROMACE TRS

1984 - MACE introduced the Hydromace system

which gave environmental field stations the combined

capabilities of data logging, control, telemetry via

telephone, radio or satellite and intelligent response to

both computer or human interrogation.

HYDROMACE 2000

1992 - The HydroMace 2000 data logger provided

multi-channel logging and control in water

catchments, sewer treatment plants and industrial

pollution applications. A leader in its time, many

are still in use in catchment management and flood

warning networks across Australia.

1.0 Introduction to HydroMace 3000 1

2.0 Warnings 2

3.0 Installing HM 3000 power options 3

3.1 Solar panel installation on a 2” pole 3

3.2 Installing a MACE mains powered trickle charger 6

3.3 Powering the HM 3000 with an external battery 7

4.0 Electronics module 8

5.0 Installing the HM3000 on a 2” pole 10

5.1 Sensor and power cables routed inside the pole 10

5.2 Sensor and power cables routed through conduit 12

6.0 Installing the HM3000 on a wall 13

7.0 The I/O (Input/Output) card 14

8.0 Wiring digital inputs 15

9.0 Wiring analogue inputs 16

10.0 Wiring digital outputs 18

11.0 Wiring analogue outputs 18

12.0 Installing additional cards 19

13.0 Installing a Series3 FloSI card 20

14.0 Maintenance 21

14.1 Battery maintenance 21

14.2 Solar panel maintenance 21

14.3 Sensor maintenance 22

14.4 Depth sensor reference lter maintenance 22

Section A: Hardware Manual

CHAPTER PAGE

This is an interactive PDF

This user manual is setup as an interactive PDF. The user can click on

any of the “Chapters” in the Table of contents to navigate directly to the

corresponding page. To return to the Table of contents click on the “Return to

TOC” button at the bottom of each page.

References to chapters in the body text are hyperlinks.

Section B: Software Manual

CHAPTER PAGE

21.2 The order and removal of channels 50

21.3 Editing a channel 51

21.3.1 Edit “Depth” channel type 52

21.3.2 Edit “4-20mA” input type - I/O card 55

21.3.3 Edit “Frequency”, “Voltage” and “Shaft encoder” input type - I/O card 56

21.3.4 Edit “Flowrate (Velocity)” channel type 57

21.3.5 Edit a “Flowrate (Weir)” channel type 62

21.3.6 Edit a “Total” channel type 66

21.3.7 Edit a “Event - pulse” channel type 67

21.3.8 Edit a “Event - status change” channel type 68

21.3.9 Edit a “Input total pulse” channel type 69

21.3.10 Edit a “Binary” channel type 70

22.0 Congure outputs 71

22.1 Adding outputs 71

22.2 Editing outputs 73

23.0 Conguring FloSI Card 75

23.1 Conguring a FloSI 75

23.2 Serial Interface Settings 76

23.3 Ordering the SDI-12 or ASCII Output String 80

24.0 Real time data 81

25.0 Start/Stop device 82

26.0 Disconnect 82

27.0 View totals 83

28.0 Downloading stored data 84

29.0 View downloaded data le 84

Appendix A - Flume/weir coecients 88

Section B: Software Manual

CHAPTER PAGE

15.0 Introduction to FloCom+ 25

16.0 Installing the software 26

17.0 Connecting to the device 28

17.1 Connecting to the device using the serial port 28

17.2 What to do if the password is lost/forgotten 29

18.0 System information 30

19.0 HM3000 settings dialogue box 32

19.1 General settings 33

19.2 Sensor power 34

19.3 View conguration 34

19.4 Reset conguration 34

20.0 Congure modules 35

20.1 Adding a module 35

20.2 Removing a congured module 35

21.0 Congure channels 36

21.1 Adding a new channel 36

21.1.1 Add a “Velocity” channel type - I/O card (4-20mA) 37

21.1.2 Add a “Velocity” channel type - I/O card (Frequency) 38

21.1.3 Add a “Depth” channel type - I/O card (4-20mA) 39

21.1.4 Add a “Depth” channel type - I/O card (Shaft encoder) 40

21.1.5 Add a “Flowrate (Velocity)” channel type - I/O card 41

21.1.6 Add a “Flowrate (Weir)” channel type 42

21.1.7 Add a “Total ow” channel type 44

21.1.8 Add a “Event - pulse” channel type 45

21.1.9 Add a “Event-status change” channel type 46

21.1.10 Add a “Input pulse total” channel type 47

21.1.11 Add a “Binary” channel type - I/O card 48

21.1.12 Add a “User dened” channel type - I/O card (Voltage) 49

RetuRn to toC

MaCe HydR oMaCe 3000 PROD UCT MANUA L 1

Section A:

Hardware Manual

Mace HydroMace 3000

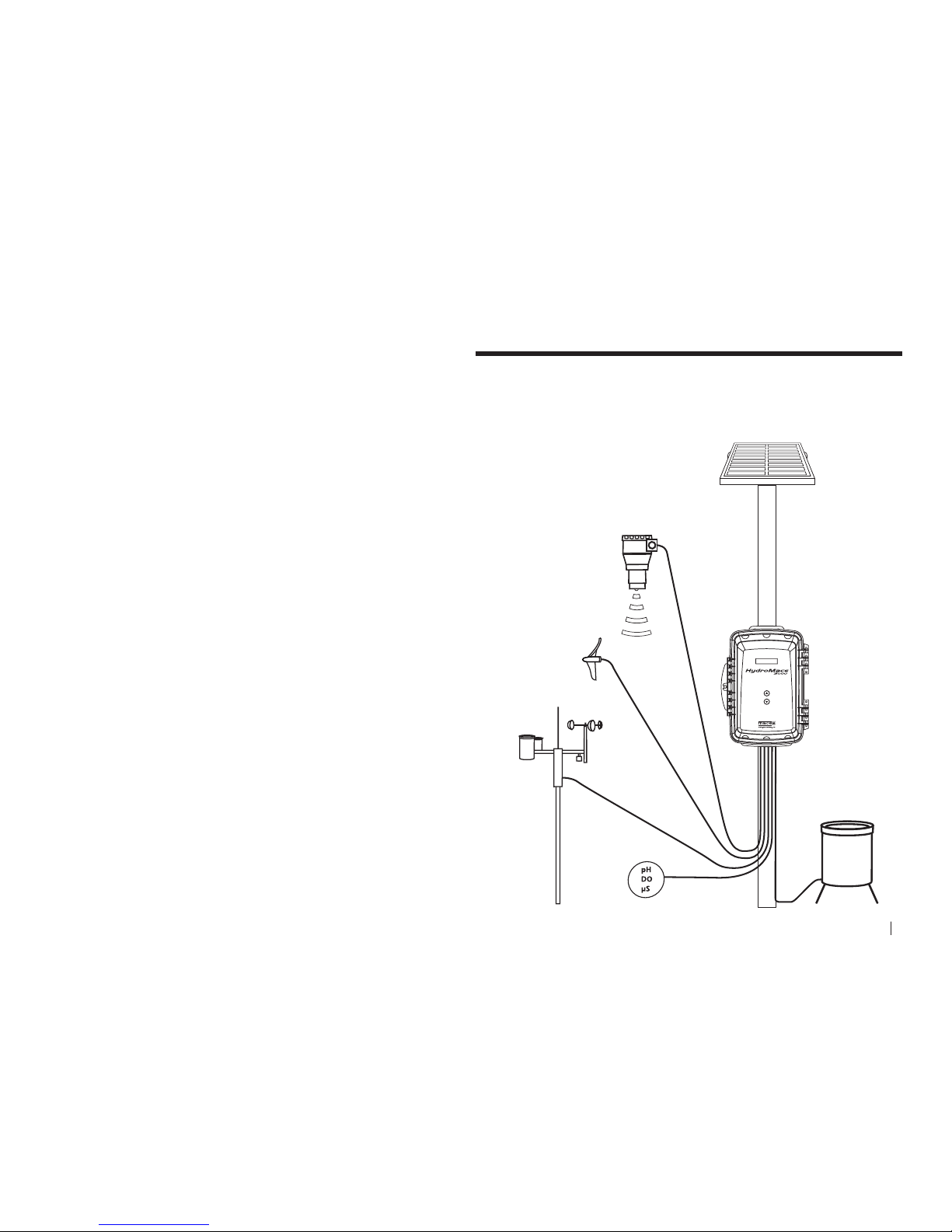

1.0 Introduction to HydroMace 3000

This manual describes the installation, use and maintenance of the HydroMace

3000. The HydroMace 3000 typically consists of four main components:

• Theelectronicsmodule.

• Thesensor(s).

• Thesolarpanel(orpowersupply).

• Flocom+ software enabling you to congure

and download your HydroMace 3000.

Rainfall

Gauge

Ultrasonic

Depth

Sensor

Electronics

Module

Solar Panel

Weather

Station

Multiple

Water

Quality

Sensors

Multiple

Flow Sensors

2 SeCtion a HARDWARE MANUAL

RetuRn to toC

RetuRn to toC

MaCe HydR oMaCe 3000 PROD UCT MANUA L 3

2.0 Warnings

2.1 Intrinsic Safety

The HydroMace 3000 is NOT an intrinsically safe instrument and should not be

installed in hazardous (explosive) environments. Should an intrinsically safe

instrument be required, MACE can oer other instruments with this approval

level.

2.2 Floods

MACE recommends that the HydroMace 3000 electronics module be

mounted above known ood peak levels. MACE will not be liable for damage

caused by ooding. (The unit is weatherproof, but NOT waterproof and

should NOT be submerged).

2.3 Sunlight

MACE recommends that the HydroMace 3000 electronics module be

mounted so that the LCD faces in a direction away from direct sunlight (ie

South in the Southern Hemisphere and North in the Northern Hemisphere).

2.4 Cable damage

MACE recommends that all cables be appropriately routed through electrical

conduit or other similar mechanism. MACE will not be liable for damage to

cables, especially if it is caused by vehicles, digging implements, animals or

debris in the pipe or channel.

2.5 Insects and moisture

After the HydroMace 3000 system has been installed and fully tested, MACE

recommends the use of expanding “space ller” foam down the rst 5 to 10cm

(2 to 4 “) of the conduit or mounting pole to prevent insect/moisture ingress.

2.6 Battery life

Care must be taken when a mains power supply is used to charge the internal

battery instead of a solar panel. If the mains power remains disconnected

for an extended period of time, the internal battery may be permanently

damaged.

2.7 Electromagnetic compatibility (EMC)

This is a Class A product. In a domestic environment this product may cause

radio interference in which case the user may be required to take adequate

measures.

3.0 Installing HM 3000 power options

3.1 Solar panel installation on a 2” pole

The solar panel is used to charge the internal battery of the HydroMace 3000

where mains power is unavailable.

Users are advised to ascertain the suitability of solar panels for

their application by checking relevant solar radiation maps for

their region (for example those found at http://rredc.nrel.gov/

solar/old_data/nsrdb/redbook/atlas/ ). As a guideline, for an

HM 3000 with three I/O cards and measuring every ve minutes,

at least three hours sunlight is required per day

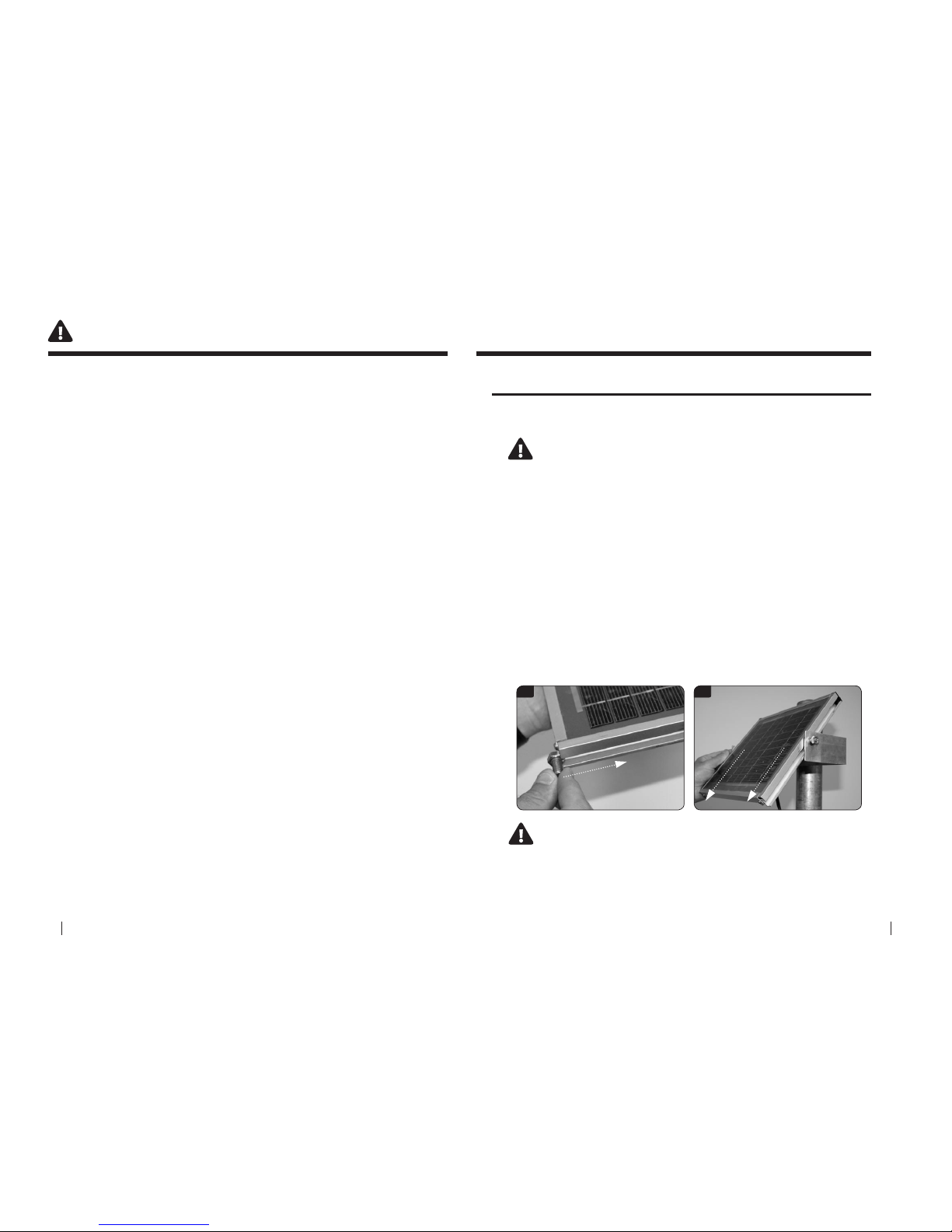

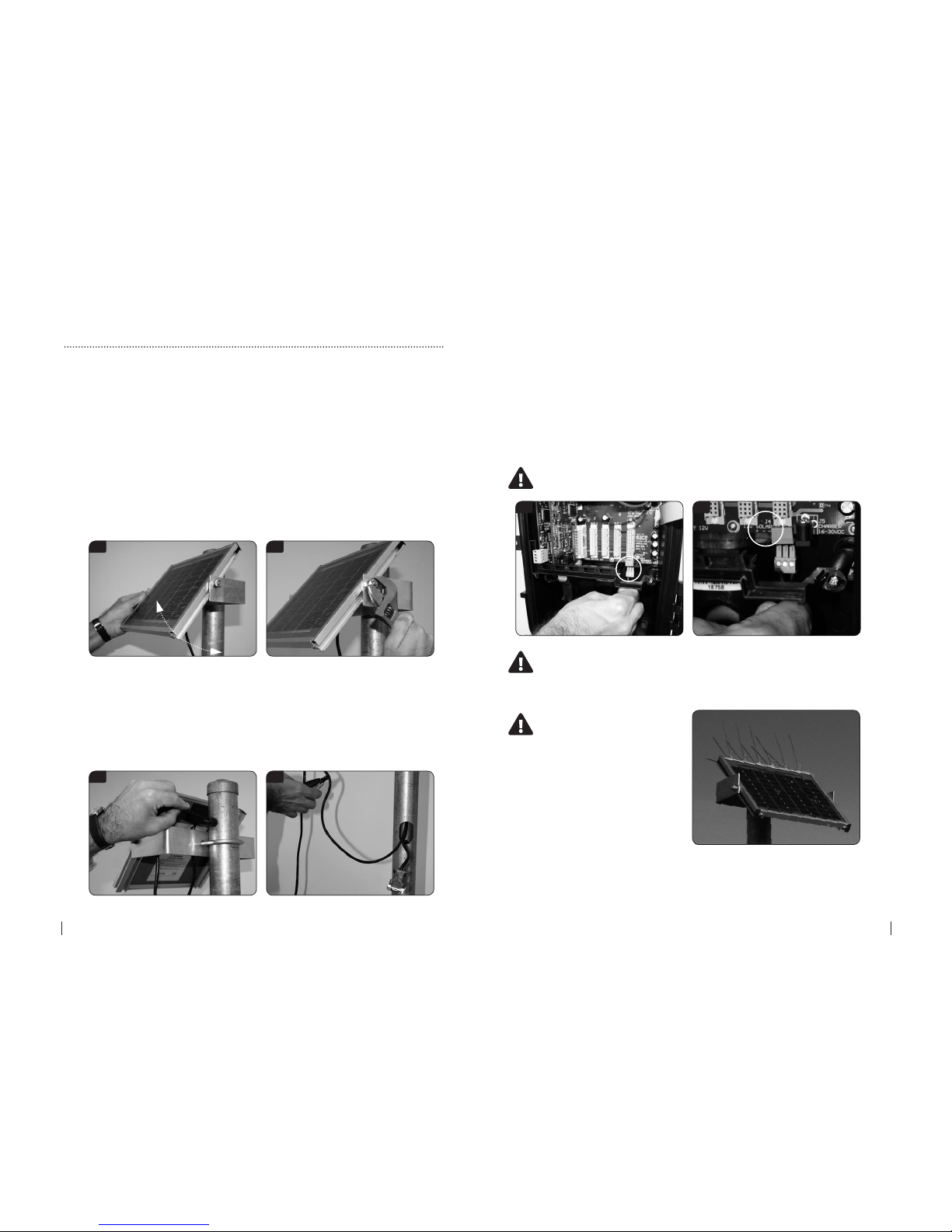

1. Place an M8 bolt with M8 at washer through the hole in left arm of the

mounting bracket. Ensure that the head of the bolt is on the INSIDE and the

thread faces outward.

2. On the OUTSIDE of the bracket, place an M8 spring washer then an M8 nut.

DO NOT TIGHTEN THE NUT.

3. Repeat these two steps on the right hand side of the bracket.

4. Holding the solar panel carefully, hold it above the two arms of the

mounting bracket.

5. Slide the solar panel down so that the head of each of the M8 bolts ts in

the channel on either side of the solar panel.

Ensure that the gutter of the solar panel is positioned between

the at washer and the head of the M8 Bolt

7. Place the u-bolt provided in the solar panel mounting kit around the pole.

5 5

4 SeCtion a HARDWARE MANUAL

RetuRn to toC

RetuRn to toC

MaCe HydR oMaCe 3000 PROD UCT MANUA L 5

8. Place the solar panel mounting bracket onto the u-bolt. Ensure that the

arms of the bracket face out from the pole and that the mounting hole on

each arm is towards the top of each arm.

9. Slide the bracket to the desired position on the pole, taking care to place it

at the desired height and so that the open face of the bracket faces towards

the sun.

10. Place the 3/8” at and spring washers on to the U-bolt and tighten the two

nuts so that the bracket is secured on the pole.

11. Tilt the solar panel so that the active side faces towards the sun (North in

Southern hemisphere, South in Northern hemisphere) at an angle specied

in the data sheet provided. (your latitude + 15°).

11 12

12. Now tighten the M8 nuts on each side of the mounting bracket to secure.

13. The cables from the solar panel/charger to the electronics unit must be

enclosed to minimise exposure to the elements. The cable should be either

routed through conduit or through the solar panel mounting pole. You will

need a hole drilled in the mounting pole at the top near the solar panel as

well as a cut away where the electronics unit is to be mounted. Refer to the

pictures below.

13 13

3.1 Solar panel installation on a 2” pole - Continued

14. Ensure that the cable from the solar panel is terminated using the threepin connector provided in the electronics box and that the polarity is correct.

The photo below shows the location of the three-pin connector inside the

HM 3000.

15. The polarity is labelled on the circuit board near the connector in the

photo below.

NOTE: When wiring the solar panel either of the ground (-ve)

terminals may be used

14 15

NOTE: The electronics module should be installed before

connecting the solar panel. Refer to the next chapter on the

electronics module for more detail

MACE highly reccomends

the use of Tri-spikes on the

top of the solar panel to

reduce accumulation of bird

droppings on the front face

of the solar panel

6 SeCtion a HARDWARE MANUAL

RetuRn to toC

RetuRn to toC

MaCe HydR oMaCe 3000 PROD UCT MANUA L 7

1

1

1

1

3.2 Installing a MACE mains powered trickle charger

In certain applications or where the use of a solar panel is impractical or

undesirable, the HM 3000 can be powered from any DC source of 16-30 Volts

(2Amps).

When the ambient temperature is less than -10°C (14F), the battery

should be removed to avoid permanent damage to the battery. The

HM 3000 should be powered by an external power source

1. The charger available from MACE (Part No. 850-323) comes complete with

a circular barrel connector that plugs directly into the electronics module.

The barrel connector for the 16-30VDC charger input is centre positive

2. Alternatively, if a DC source other than a MACE charger is used, this

is terminated using the same three-pin connector as for the solar panel

described above.

3.3 Powering the HM 3000 with an external battery

In certain applications, it may be desirable to power the HM 3000 with an

external battery.

1. The HM 3000 can be powered by an external 12V battery through the

dedicated “External Battery 12V” terminal. See photos below.

2. If a solar panel is connected to the HM 3000 as in Chapter 3.1, the internal

charging circuit of the HM 3000 will also charge the external battery. The

charging circuitry of the HM 3000 has a 20 Watt capacity.

If the external battery is charged via its own solar panel and NOT

through the HM 3000 charging circuit, the internal HM 3000

battery will discharge completely

8 SeCtion a HARDWARE MANUAL

RetuRn to toC

RetuRn to toC

MaCe HydR oMaCe 3000 PROD UCT MANUA L 9

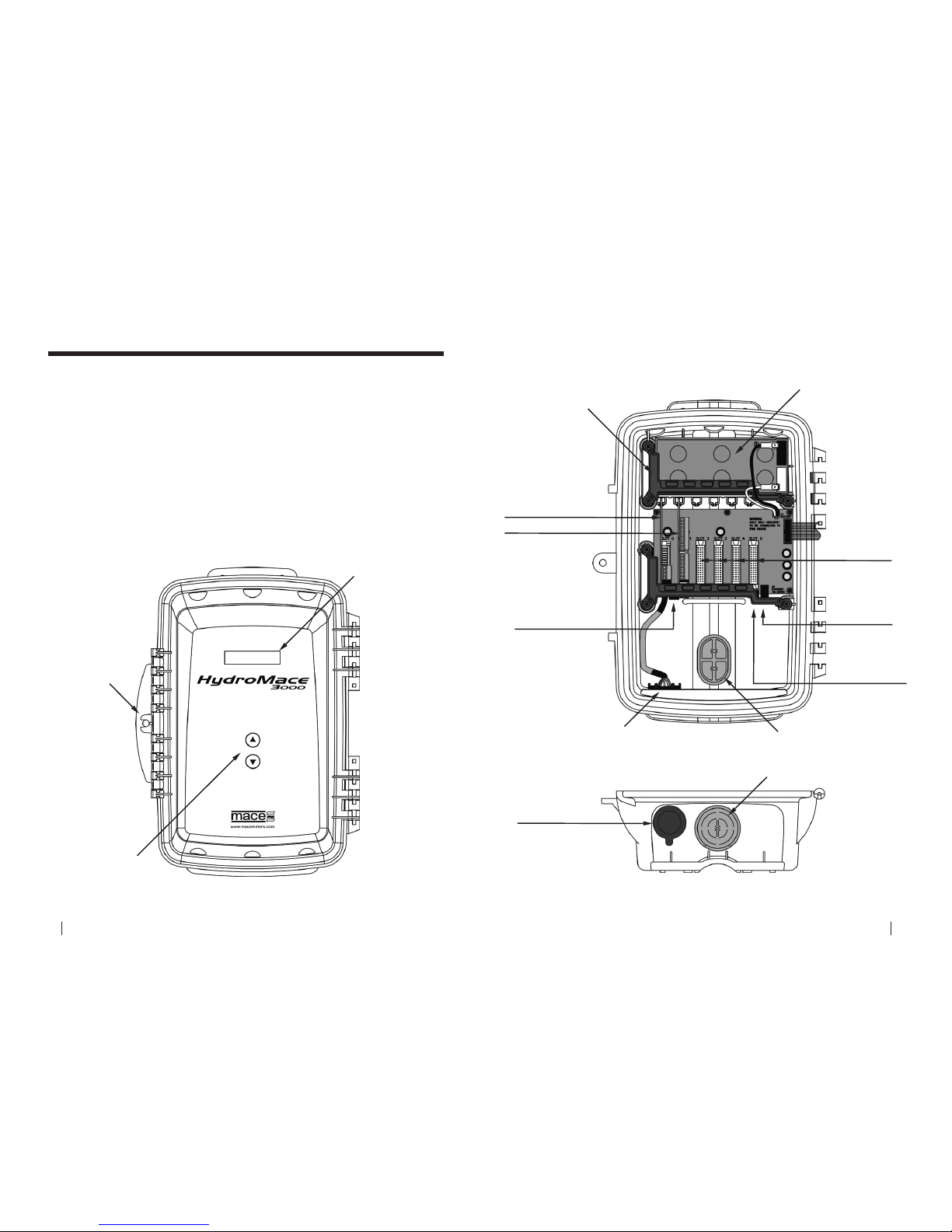

4.0 Electronics module

The electronics module is the central processing unit of the HydroMace 3000.

It includes the enclosure, battery and circuit boards that control the device.

On the front of the HydroMace 3000, a backlit liquid crystal display (LCD)

allows the user an on-site readout of parameter values and status messages.

Pressing either membrane switch will turn on the LCD.

The membrane switches can be used to scroll the display between the

various parameters being measured.

A serial communications port is located on the bottom face of the main

enclosure. Using the MACE serial data cable (Part No. 891-300) between this

port and a PC, users can congure, troubleshoot and download the device.

LCD Display

Secure Latch

with Padlock

Hole

Membrane Switches

(scrolls the display up & down)

ELECTRONICS MODULE - FRONT

NOTE: Door not shown

Conduit Cable Entry Point

Pole Cable Entry Point

12v Battery

Bracket

Charger Input

16-30VDC

(Centre of jack

is positive)

External Battery Input

12VDC

(Charged by Series3 Device)

Solar Panel/Charger

Input 16-30VDC

(Use with Solar Panel

or Mains Plug Pack)

Serial Communications Port

ELECTRONICS MODULE - INSIDE

ELECTRONICS MODULE - UNDERSIDE

Module Slots 2-5

Input/Output Module (slot 1)

Serial Communications Port

Controller Module (slot 0)

10 SeCtion a HARDWARE MANUAL

RetuRn to toC

RetuRn to toC

MaCe HydR oMaCe 3000 PROD UCT MANUA L 11

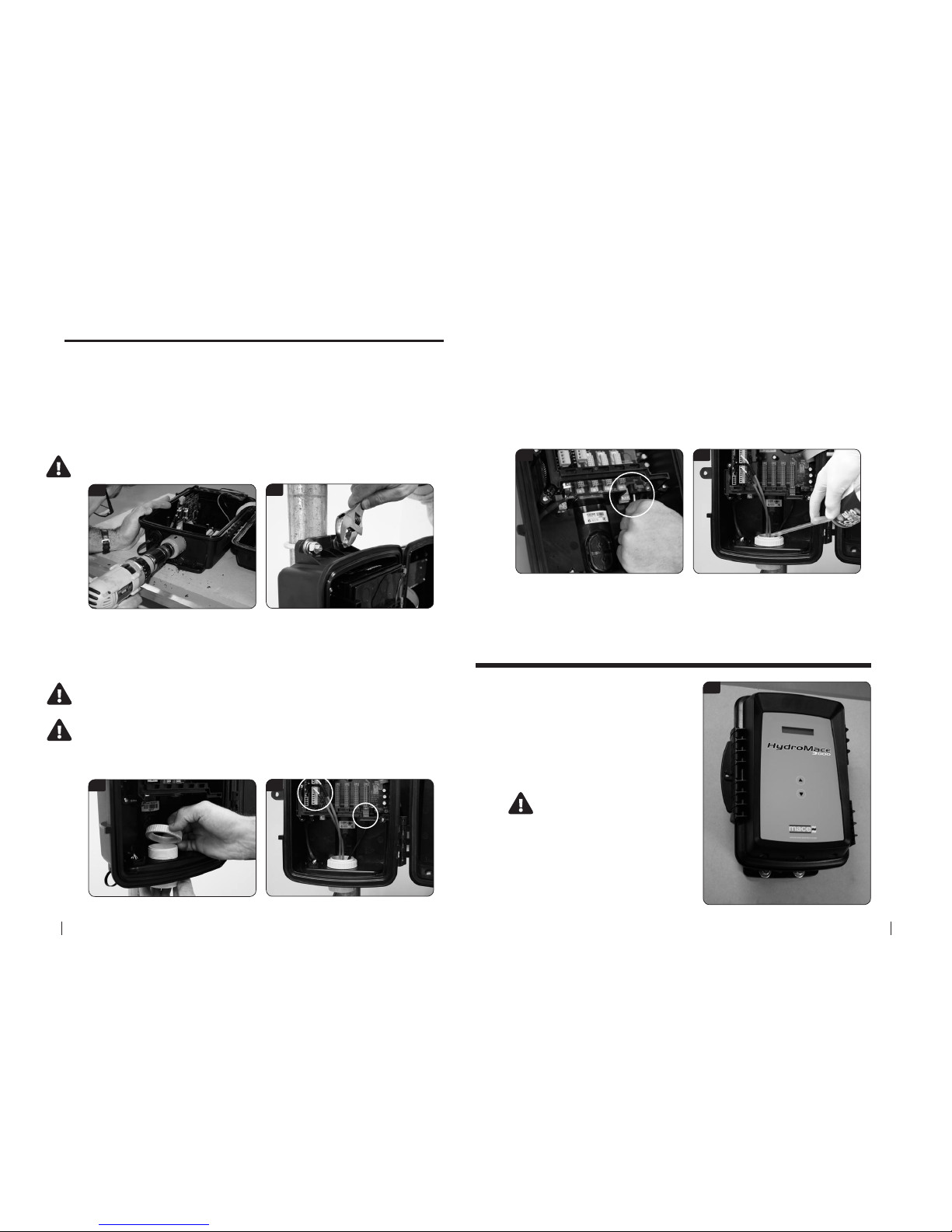

5.0 Installing the HM3000 on a 2” pole

The sensor and power cables can be routed either directly through the inside

of the 2” mounting pole or through electrical conduit. Installation directions

for both are provided below.

MACE recommends that the HM3000 electronics module be mounted so

that the LCD faces in a direction away from direct sunlight.

5.1 Sensor and power cables routed inside the pole

1. Place the electronics module on a work bench and using a hammer and

screwdriver carefully knock out the plastic cable entry point from the rear

of the enclosure. It is only thin plastic and is designed to break away at the

edges so work your way around the edge of the oval shape until the cover is

completely broken free of the unit.

2. File away any rough edges from the plastic cable entry point

1 2

3

4 5

6 7

3. Hold the electronics module up against the pole so that the oval cut-away

on the pole matches the cable entry point. Route the sensor and power

cables through the cable entry point as shown.

IMPORTANT: Apply NON-ACIDIC cure silicon sealant to the back of the

electronics module in the channel around the cable entry point. This will

stop water owing down the pole and into the electronics module

4. Use the two “U” bolts, 3/8” nuts and 3/8” washers provided to secure the

electronics module to the pole.

Do not overtighten the pole mounting bolts as permanent

damage may occur to the electronics enclosure

5. Plug in both the sensor cable and solar panel cable into the sockets as

shown in the picture below.

Sensor cables should be looped prior to connecting to act as a

form of strain relief.

Ensure that the cable from the solar panel/charger is terminated

using the three-pin connector provided in the electronics box and

that the polarity is correct. The polarity is labelled on the circuit

board near the connector

6. If using a 16-30VDC mains charger then plug this into the socket shown

in the picture below. Alternatively, the charger may be wired into the solar

panel screw terminal block (to the left of the socket).

7. Once all the cables are connected the system should be fully tested.

Assuming everything is connected and fully functional the cable entry point

should be lled with expanding “space ller” foam. This is to prevent insects

and/or moisture damaging the system.

12 SeCtion a HARDWARE MANUAL

RetuRn to toC

RetuRn to toC

MaCe HydR oMaCe 3000 PROD UCT MANUA L 13

5.2 Sensor and power cables routed through conduit

1. Place the electronics module on a work bench. Using a power drill and 2”

holesaw, carefully drill out the round plastic cable entry point at the base

of the unit as shown below. It is only thin plastic and is designed to break

away. Alternatively, the round cable entry point may be removed using the

“hammer and screwdriver” method described in Chapter 5.1.

2. Use the two “U” bolts, 3/8” nuts and 3/8” washers provided to secure the

electronics module to the pole.

Do not overtighten the pole mounting bolts as permanent damage may

occur to the electronics enclosure

1

2

3

4

5 6

3. Carefully attach an electrical conduit adaptor (Clipsal 50mm or Carlon 1 1/2”)

to the electronics module.

4. Plug in both the sensor cable and solar panel cable into the sockets as

shown in the picture below.

Sensor cables should be looped prior to connecting to act as a form of

strain relief

Ensure that the cable from the solar panel/charger is terminated using

the three-pin connector provided in the electronics box and that the

polarity is correct. The polarity is labelled on the circuit board near the

connector

5. If using a 16-30VDC mains charger then plug this into the socket shown

in the picture below. Alternatively, the charger may be wired into the solar

panel screw terminal block (to the left of the socket).

6. Once all your cables are plugged in you need to fully test the system.

When you are happy that everything is connected and working properly you

need to ll the cable entry point with expanding “space ller” foam. Fill down

the rst 5 to 10cm (2” to 4”) of the conduit. This is to prevent insects and/or

moisture damaging the system.

6.0 Installing the HM3000 on a wall

2

1. Follow instructions on the previous

page to drill out the cable entry point

for routing cables through conduit.

2. Use four M8 screws, bolts or coach

screws to secure the box to the wall.

(Use at washers between the screw

head and the box).

Do not overtighten the wall

mounting bolts as permanent

damage may occur to the

electronics enclosure

3. Follow instructions 3-6 on the

previous page for routing the cables

through conduit.

14 SeCtion a HARDWARE MANUAL

RetuRn to toC

RetuRn to toC

MaCe HydR oMaCe 3000 PROD UCT MANUA L 15

INPUTSOUTPUTS

TERMINALS

I/O CARD DIAGRAM

48 PIN CONNECTOR

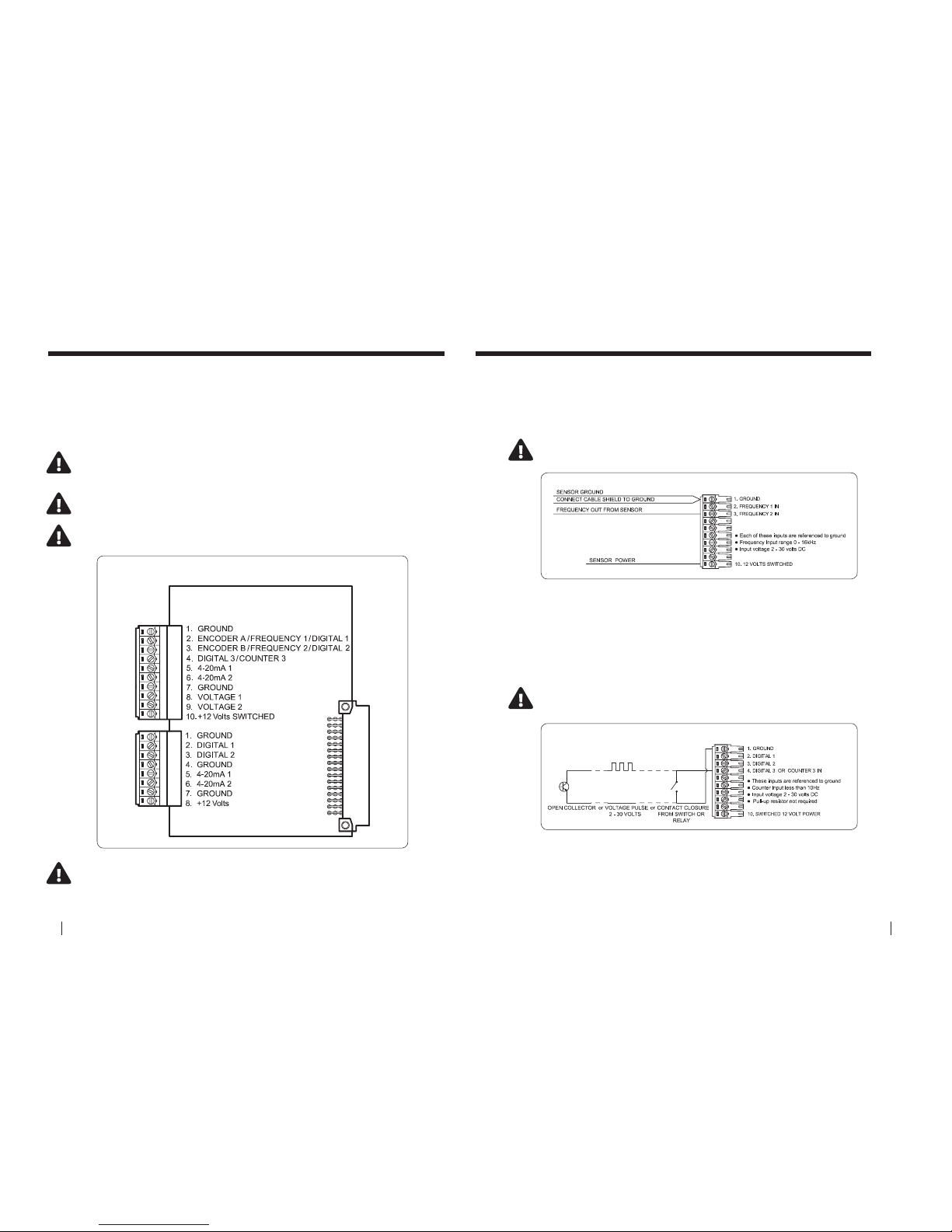

7.0 The I/O (Input/Output) card

The I/O card (module) supplied in the HydroMace 3000 provides the

inputs for connecting environmental monitoring sensors and outputs for

connection to ancillary devices.

The input and output terminals available on each I/O card are shown in the

diagram below.

MACE recommends the user studies the relevant documentation

supplied with each third party sensor prior to connection

Should insucient I/O be available on a single I/O card another card

(Part No. 850-329) should be purchased. HydroMace 3000 supports a

maximum of ve I/O cards

WARNING: The maximum system current available for powering sensors

attached to ALL I/O cards is 1.25 Amps at 12VDC

WARNING: The maximum input voltage on any terminal is 30VDC

FREQUENCY INPUT DIAGRAM

FREQUENCY INPUT DIAGRAM

DIGITAL OR COUNTER INPUT DIAGRAM

8.0 Wiring digital inputs

8.1 Frequency Input

Each I/O card provides up to two frequency inputs for connecting devices

such as ultrasonic depth sensors and/or ow meters. The frequency input

terminals available on each I/O card are shown in the diagram below.

8.2 Digital or Counter Input

Each I/O card provides up to three digital inputs or one counter input

for connecting devices such as rainfall gauges, hours run meters and/or

counting pulses. The digital/counter input terminals available on each I/O

card are shown in the diagram below.

NOTE: If a frequency input is wired a shaft encoder input is not

available

NOTE: If a shaft encoder input is wired only a single

digital/counter input is available

16 SeCtion a HARDWARE MANUAL

RetuRn to toC

RetuRn to toC

MaCe HydR oMaCe 3000 PROD UCT MANUA L 17

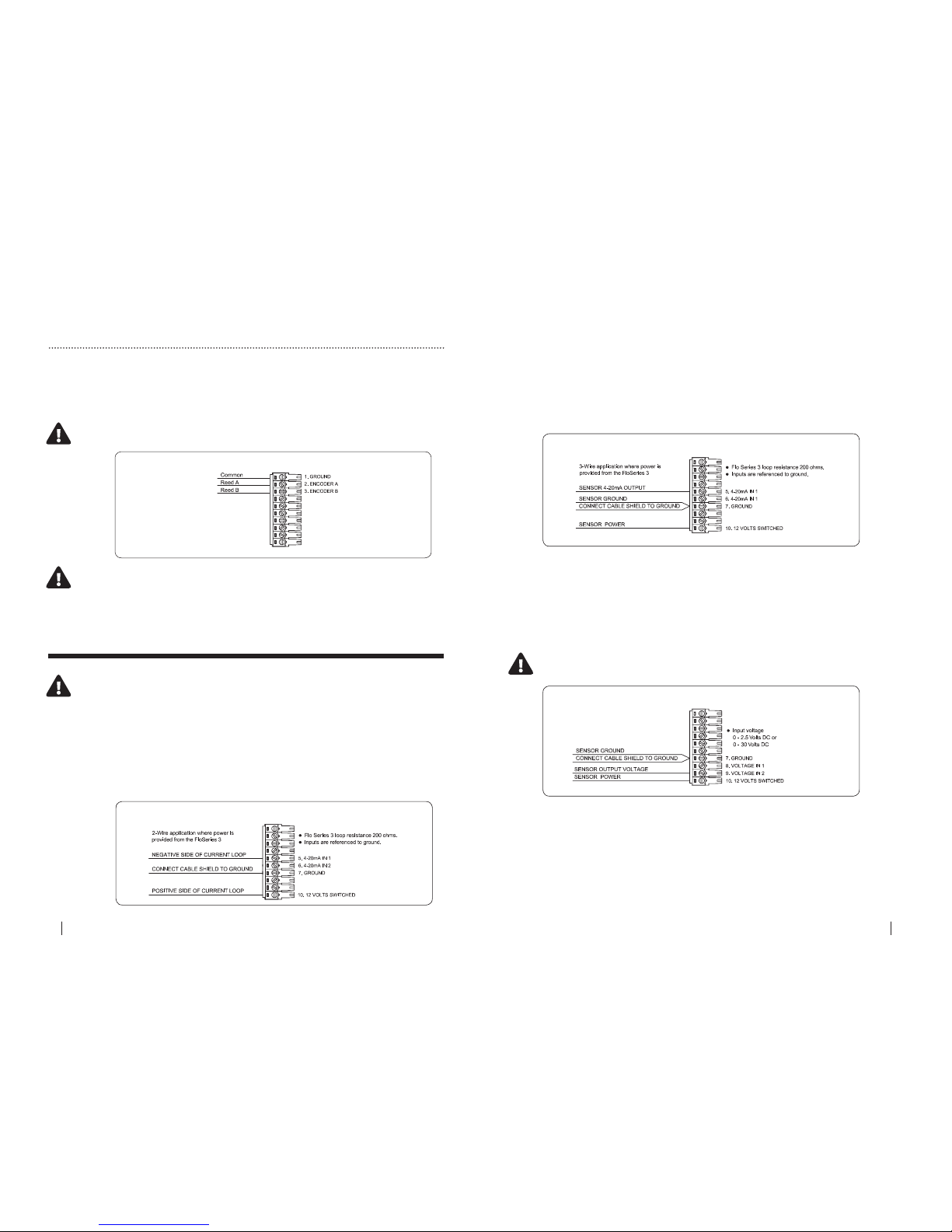

8.3 Shaft Encoder Input

Each I/O card provides one input for connecting a shaft encoder. The shaft

encoder input terminals available on each I/O card are shown in the diagram.

NOTE: If a shaft encoder input is wired only a single

digital/counter input is available. NO frequency input is available

Should the eld application require a shaft encoder and a frequency

input another I/O card (Part No. 850-329) should be purchased

8.0 Wiring digital inputs - Continued

FREQUENCY INPUT DIAGRAM

DIGITAL OR COUNTER INPUT DIAGRAM

SHAFT ENCODER INPUT DIAGRAM

2 - WIRE 4-20mA INPUT DIAGRAM

2 - WIRE 4-20mA INPUT DIAGRAM

3 - WIRE 4-20mA INPUT DIAGRAM

2 - WIRE 4-20mA INPUT DIAGRAM

3 - WIRE 4-20mA INPUT DIAGRAM

VOLTAGE INPUT DIAGRAM

9.0 Wiring analogue inputs

9.1 Two - Wire 4-20mA Input

Each I/O card provides up to two 4-20mA inputs for connecting devices such

as ultrasonic depth sensors and/or ow meters. The 4-20mA input terminals

available on each I/O card are shown in the diagram below.

9.2 Three - Wire 4-20mA Input

Each I/O card provides up to two 4-20mA inputs for connecting devices such

as ultrasonic depth sensors and/or ow meters. The 4-20mA input terminals

available on each I/O card are shown in the diagram below.

9.3 Voltage Input

Each I/O card provides up to two voltage inputs for connecting devices such

as ultrasonic depth sensors, conductivity probes and/or temperature sensors.

The voltage input terminals available on each I/O card are shown in the

diagram below.

NOTE: The input voltage range can be either 0 - 2.5 VDC or

0 - 30 VDC

NOTE: 12 VDC sensor power is available on terminal 10 of the input

terminal strip. This is a switched power supply and the warm up time

for sensors that require power is congurable using FloCom+ software.

FloCom+ is available for download from www.macemeters.com

18 SeCtion a HARDWARE MANUAL

RetuRn to toC

RetuRn to toC

MaCe HydR oMaCe 3000 PROD UCT MANUA L 19

DIGITAL OUTPUT DIAGRAM

DIGITAL OUTPUT DIAGRAM

4-20mA OUTPUT DIAGRAM

10.0 Wiring digital outputs

11.0 Wiring analogue outputs

Digital Output

Each I/O card provides up to two digital outputs for sending pulses to

devices such as water samplers and/or data loggers. The digital output

terminals available on each I/O card are shown in the diagram below.

4-20mA Output:

Each I/O card provides up to two 4-20mA outputs for sending signals to

devices such as SCADA systems and/or PLC’s. The 4-20mA output terminals

available on each I/O card are shown in the diagram below.

NOTE: The pulse output consists of a 50 millisecond pulse with a 50

millisecond space between pulses

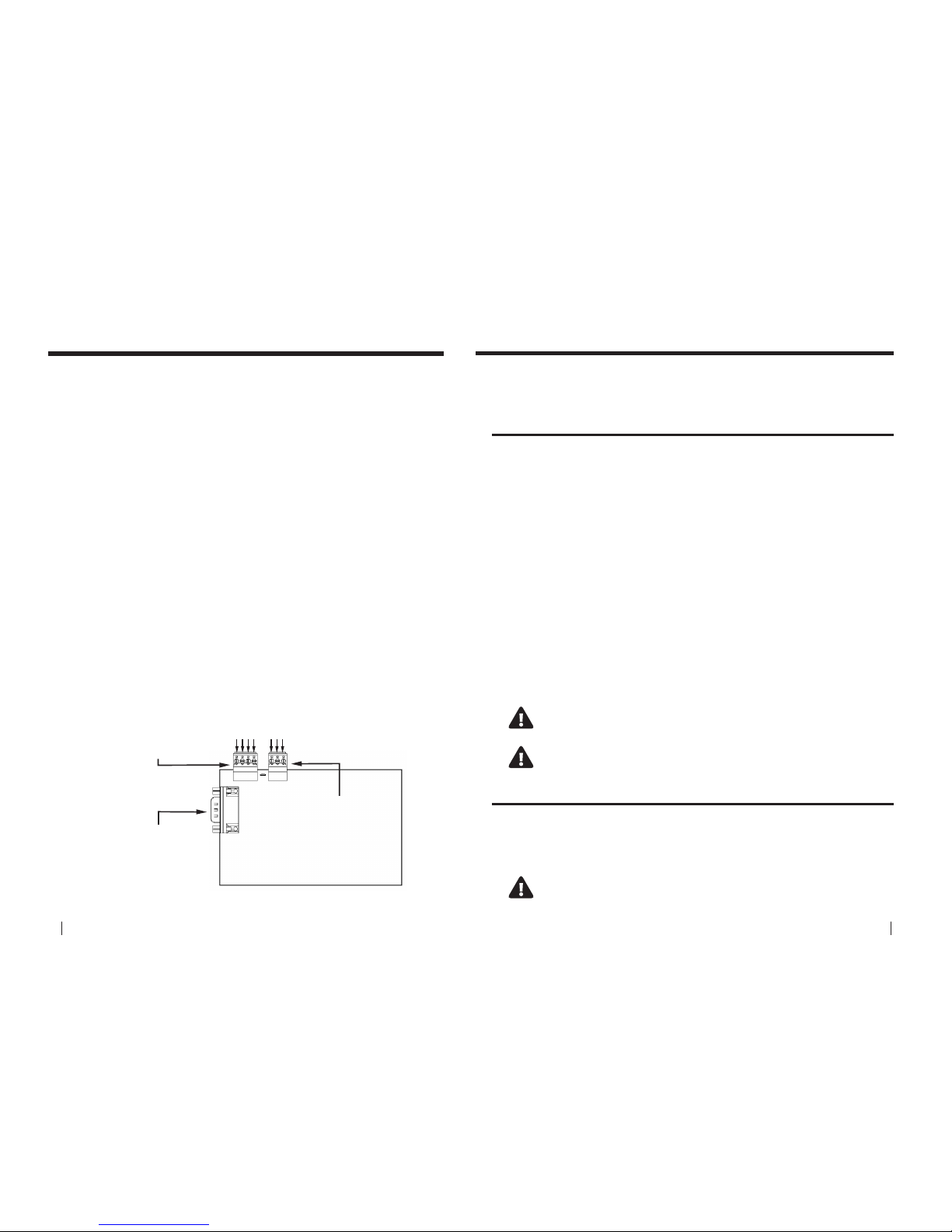

12.0 Installing additional cards

Users are advised to download data and stop the HM 3000 prior

to installing additional cards

1. Open the Series3 enclosure and remove the three screws (using a #2

Phillips screwdriver) fastening the PCB clamping bracket. Take care not to drop

screws in the box as damage may occur to the circuitry.

IMPORTANT: Before removing card from packaging you MUST earth

yourself by touching one of the screws on the display module

1

3

3. Remove the MACE Series3 card from its packaging. Position the new card

in your hand such that the large cream 48-pin connector is facing down and

aligned with the mating connector on the backplane PCB.

4. Earth yourself again. Your nger must remain earthed on the screw

whilst carefully inserting the card into any spare slot. Take care to align the

pins of the two connectors together. There is a slot at the top of the card

area that helps the alignment process. Ensure that the card is contained

within this slot and press down rmly to ensure that it is seated fully.

5. Replace the PCB clamping bracket ensuring that the slots in the underside

of the bracket are aligned with the tops of all the cards. Fix the bracket into

place with the 3 screws. DO NOT over tighten the screws.

6. Connect to the instrument with a PC and congure the card using FloCom+

as detailed in the software section of this manual.

4

20 SeCtion a HARDWARE MANUAL

RetuRn to toC

RetuRn to toC

MaCe HydR oMaCe 3000 PROD UCT MANUA L 21

13.0 Installing a Series3 FloSI card

The Flo Series Serial Interface (FloSI) is an optional upgrade module for

Flo Series3 devices. The FloSI provides unconditional polling access to the

most recent user congured measurement results of Flo Series3 devices.

The FloSI requires no routine maintenance and has no user serviceable

components.

Conguration of the FloSI requires MACE Flocom+ software and successful

PC communications with a MACE Flo Series3 device. The FloSI conguration

settings are available from the settings menu of Flocom+ as described in the

software section of this Manual.

Installing the FloSI Card

Install the FloSI card as per the procedure outlined in the previous chapter

12.0 Installing additional cards.

Wiring the FloSI

After installing the card, connect it to the remote device using either:

1. The 9-pin d-connector (RS232, ASCII or RS232 ModBUS) for RS232;

2. The 4-way terminal block for RS485 ModBUS mode;

3. The 3-way terminal block for SDI-12 mode.

Pin out details for the various connectors are printed on the back of the FloSI

card and below:

RS232

Pin 2 – Transmit Data (TxD)

Pin 3 – Receive Data (RxD)

Pin 5 – Ground (GND)

Pin 7 – Ready to Send (RTS)

Pin 8 – Clear to Send (CTS)

FloSI Card - Diagram

RS485

Pin 1 – Ground

Pin 2 - D1

Pin 3 - D0

Pin 4 - (+12V Out)

SDI-12

Pin 1 – Ground

Pin 2 - Data

Pin 3 - (+12V Out)

1234

123

14.0 Maintenance

Depending on the physical location and the type of sensors being monitored,

the HydroMace 3000 may require regular maintenance. Should the instrument

require servicing, it must be returned to your vendor.

14.1 Battery maintenance

The HydroMace 3000 internal battery, if kept fully charged should last many years.

However, if the battery remains at for an extended time, it may be damaged and

should be replaced. Contact your vendor for a replacement battery.

14.1.1 Removing the damaged/at battery

1. Disconnect the battery cable assembly from the backplane board.

2. Carefully hold the battery in position.

3. Use a #2 Phillips head screwdriver to remove the three screws which fasten the

battery bracket to the main enclosure.

4. Carefully remove the battery from the main enclosure.

5. Disconnect the battery cable from the battery terminals.

14.1.2 Installing the new battery

1. Connect the battery cable to the new battery, with the red lead to the positive

terminal of the battery and the black lead to the negative terminal.

2. Place the battery in the main enclosure and hold it in place.

3. Secure the new battery in place using the battery bracket and three screws.

4. Tighten all three screws.

5. Reconnect the battery cable assembly to the backplane board.

Damage to the HydroMace 3000 caused by incorrect battery

replacement will void the warranty

Using a battery that is not approved MAY damage the

HydroMace 3000 and void the warranty

14.2 Solar panel maintenance

The solar panel should be checked regularly for build up of solids such as dust

and bird droppings. These type of build-ups can aect the performance of the

solar panel and result in a decrease of the charge that is received by the internal

battery. The solar panel should be cleaned with a wet brush or rag.

Do not use steel bristle brushes that may cause damage to the glass of

the solar panel

Loading...

Loading...