MacAllister MTC500 User Manual

500W Tile Cutter

EN

Original Instructions_MNL_MTC500_GB_V01_180102

WARNING! Read the instructions before using the product!

MTC500

EAN: 3663602797906

EN

MTC500 by MacAllister

Let’s

These instructions are for your safety. Please read through them thoroughly

before use and retain them for future reference.

get started…

02

Getting started...

Your product

Technical and legal information

Before you start

In more detail...

Product functions

Care and maintenance

Trouble shooting

Recycling and disposal

Guarantee

EC declaration of conformity

02

03

05

12

22

23

27

33

34

35

36

MTC500 by MacAllister

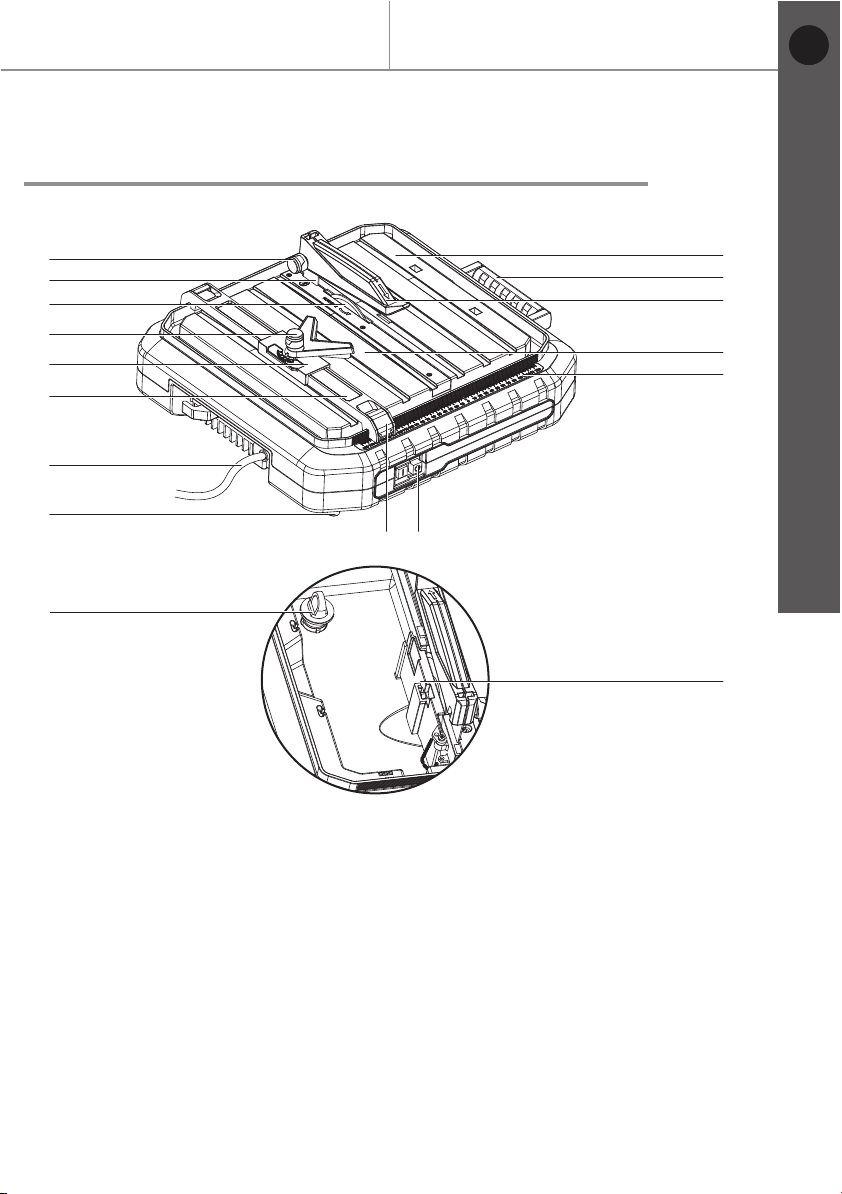

Your product

Your product

EN

17

16

15

14

13

12

11

10

9

1. 45° Vertical fence

2. Transportation handle

3. Upper protective guard

4. Working table

5. Scale

6. Lower protective guard

7. On/Off switch

8. Locking knob

(for parallel cutting guide)

9. Water reservoir plug

1

2

3

4

5

78

Getting started...

6

10. Base foot

11. Plug cable

12. Parallel cutting guide

13. Mitre cutting guide

14. Locking knob

(for mitre cutting guide)

15. Cutting disc

16. Metal bracket

17. Locking knob

(for upper protective guard)

03

EN

MTC500 by MacAllister

Safety devices

Metal bracket

The metal bracket (16) prevents a workpiece being caught by the cutting disc (15)

and being hurled at the operator.

The metal bracket must always be mounted during operation.

Upper protective guard

The upper protective guard (3) prevents accidental contact with the cutting disc (15)

and stops workpiece parts and cooling water from being flung out.

The upper protective guard must always be mounted during the operation and can

be lowered to the workpiece.

Lower protective guard

The lower protective guard (6) prevents accidental contact with the cutting disc

(15) and stops workpiece parts and cooling water from being flung out.

The lower cutting disc cover must always be mounted during operation.

Getting started...

Your product

04

MTC500 by MacAllister

Technical specifications

General

> Input Voltage

> Power Input

> No Load Speed

> Insulation Class

> Diamond Disc Size

> Table Size

> Table Tilt Range

> Maximum Cutting Depth

> Net Weight

Technical and legal

information

:

220-240V~50Hz

:

500W

:

5200min

:

Class I

:

ø115mmx2.1mmxø22.2mm

:

330x360mm

:

0°/45°

:

20mm

:

5.9kg

-1

EN

NOISE

A weighted sound pressure LpA................................................................98dB(A)

A weighted sound pressure LWA..........................................................105.2dB(A)

Uncertainty................................................................................................3dB(A)

The sound intensity level for the operator may exceed 85dB(A) and sound

protection measures are necessary.

Important note

Remove the mains plug from socket before carrying out any adjustment or

servicing.

Ensure your mains supply voltage is the same as your tool rating plate voltage.

The following information applies to professional users only but is

good practice for all users:

ADDITIONAL SAFETY WARNING FOR CONSTRUCTION DUST

The updated Control of Substances Hazardous to Health Regulations 1st October

2012 now also targets to reduce the risks associated with silica, wood and gypsum

dusts.

Construction workers are one of the at-risk groups within this because of the dust

that they breathe: silica dust is not just a nuisance; it is a real risk to your lungs!

Silica is a natural mineral present in large amounts in things like sand, sandstone

and granite. It is also commonly found in many construction materials such as

concrete and mortar. The silica is broken into very fine dust (also known

Getting started...

05

EN

MTC500 by MacAllister

as Respirable Crystalline Silica or RCS) during many common tasks such as cutting,

drilling and grinding Breathing in very fine particles of crystalline silica can lead to

the development of:

Lung cancer Silicosis Chronic Obstructive Pulmonary Disorder (Chronic obstructive

pulmonary disease (COPD) And breathing in fine particles of wood dust can lead

to the development of Asthma The risk of lung disease is linked to people who

regularly breathe construction dust over a period of time, not on the odd occasion.

To protect the lung, the COSHH Regulations sets a limit on the amount of these

dusts that you can breathe (called a Workplace Exposure Limit or WEL)

when averaged over a normal working day. These limits are not a large amount of

dust: when compared to a penny it is tiny – like a small pinch of salt:

This limit is the legal maximum; the most you can breathe after the right controls

have been used.

How to reduce the amount of dust?

1. Reduce the amount of cutting by using the best sizes of building products.

2. Use a less powerful tool e.g. a block cutter instead of angle grinder.

3. Using a different method of work altogether – e.g. using a nail gun to direct fasten

cable trays instead of drilling holes first.

Please always work with approved safety equipment, such as those dust masks

Getting started...

that specially designed to filter out microscopic particles and use the dust extraction

facility at all time.

For more information please see the HSE website:

http://www.hse.gov.uk/construction or http://www.hse.gov.uk/pubns/cis69.pdf

Warning: Some dust particles created by power sanding, sawing,

grinding, drill and other construction jobs contain chemicals known to

cause cancer, birth defects or other reproductive harm. Some examples

of these chemicals are:

• Lead from lead-based paints.

• Crystalline silica from bricks and cement and other masonry products.

• Arsenic and chromium from chemically treated timber.

Your risk from these exposures varies, depending upon how often you do this type

of work. To reduce your exposure to these chemicals:

• Work in a well-ventilated area.

• Work with approved safety equipment, such as those dust masks that are specially

designed to filter microscopic particles.

VIBRATION

The European Physical Agents (Vibration) Directive has been brought in to help

reduce hand arm vibration syndrome injuries to power tool users. The directive

requires power tool manufacturers and suppliers to provide indicative vibration

test results to enable users to make informed decisions as to the period of time

Technical and legal

information

06

MTC500 by MacAllister

Technical and legal

information

a power tool can be used safely on a daily basis and the choice of tool.

SEE TECHNICAL SPECIFICATIONS IN THE INSTRUCTION MANUAL FOR

THE VIBRATION LEVELS OF YOUR TOOL.

The declared vibration emission value should be used as a minimum level and

should be used with the current guidance on vibration.

Calculating the actual period of the actual period off use can be difficult and the

HSE website has further information.

The declared vibration emission been measured in accordance with a standardised

test stated above and may be used to compare one tool with another tool.

The declared vibration emission value may also be used in a preliminary

assessment of exposure.

Warning: The vibration emission value during actual use of the power tool

can differ from the declared value depending on the ways in which the tool

is used dependant on the following examples and other variations on how the

tool is used:

How the tool is used and the materials being cut or drilled.

The tool being in good condition and well maintained.

The use the correct accessory for the tool and ensuring it is sharp and in good

condition.

The tightness of the grip on the handles.

And the tool is being used as intended by its design and these instructions.

While working with this power tool, hand/arm vibrations occur. Adopt the

correct working practices in order to reduce the exposure to vibration. This

tool may cause hand-arm vibration syndrome if its use is not adequately

managed.

Warning: Identify safety measures to protect the operator that are based

on an estimation of exposure in the actual conditions of use (taking account

of all parts of the operating cycle such as the times when the tool is switched off

and when it is running idle in addition to the trigger time). Note The use of other

tools will reduce the users’ total working period on this tool.

Helping to minimise your vibration exposure risk. ALWAYS use sharp chisels,

drills and blades.

Maintain this tool in accordance with these instructions and keep well lubricated

(where appropriate).

Avoid using tools in temperatures of 10ºC or less. Plan your work schedule to

spread any high vibration tool use across a number of days.

EN

Getting started...

Health surveillance

All employees should be part of an employer’s health surveillance scheme to

help identity any vibration related diseases at an early stage, prevent disease

progression and help employees stay in work.

07

EN

MTC500 by MacAllister

Technical and legal

information

Symbols

On the product, the rating label and within these instructions you will find among

others the following symbols and abbreviations.

Familiarise yourself with them to reduce hazards like personal injuries and damage

to property.

V~

W

min-1

yyWxx

Volt

Input power

Per minute

Manufacturing date code; year of manufacturing (20yy) and week of

manufacturing (Wxx);

Caution / Warning.

Hz

kg

dB(A)

Wear hearing protection.

Hertz

Kilogram

Decibel (A-rated)

Read the instruction

manual.

Wear gloves.

Wear eye protection.

Wear respiratory protection.

Getting started...

Caution, risk of cutting.

Switch the product off and disconnect it from the power supply before

assembly, cleaning, adjustments, maintenance, storage and transportation.

The product complies with the applicable European directives and an

evaluation method of conformity for these directives was done.

WEEE symbol. Waste electrical products should not be disposed of with

household waste. Please recycle where facilities exist.

Check with your Local Authority or local store for recycling advice.

MTC500 Designation of the tool (M - MacAllister, TC - Tile cutter, 500 - 500W)

Safety warnings

GENERAL SAFETY INSTRUCTIONS

WARNING! To ensure safe operation when using your Tile Cutter,

make sure you follow basic safety principles to reduce risk of

personal injury, electric shock and fire. Please read the following

instructions prior to operating this product and keep for future use.

Use only non fragmented discs.

08

MTC500 by MacAllister

Technical and legal

information

SAVE THESE INSTRUCTIONS

1. Keep the work area clean.

> Cluttered and dark areas invite accidents.

2. Consider work area environment.

> Do not expose power tools to rain. Do not use power tools in damp or wet

locations. Keep the work area well lit. Do not use tools in the presence

of flammable liquids or gases.

3. Guard against electric shock.

> Avoid body contact with earthed or grounded surfaces (e.g. pipes, radiators,

ranges, refrigerators).

4. Keep children away.

> Do not let persons, especially children, not involved in the work touch the tool

or the extension cord and keep them away from the work area.

5. Store idle tools.

> When not in use, tools should be stored in a dry, high or locked up place, out

of reach of children.

6. Do not force the tool.

> It will do the job better and safer at the rate for which it was intended.

7. Use the right tool.

> Do not force small tools to do the job of a heavy-duty tool. Do not use tools

for purposes not intended, for example, do not use circular saws to cut tree

limbs or logs.

8. Dress properly.

> Do not wear loose clothing or jewellery, they can be caught in moving parts.

Non-skid footwear are recommended when working outdoors. Wear protective

hair covering to contain long hair.

9. Use protective equipment.

> Use safety glasses. Use face or dust mask if working operations create dust.

10. Connect dust extraction equipment.

> If the tool is provided for the connection of dust extraction and collecting

equipment, ensure these are connected and properly used.

11. Do not abuse the cord.

> Never yank the tool to disconnect it from the socket. Keep the cord away from

heat, oil and sharp edges.

12. Secure work.

> Where possible use clamps or a vice to hold the work. It is safer than using

your hand.

13. Do not overreach.

> Keep proper footing and balance at all times.

EN

Getting started...

09

EN

MTC500 by MacAllister

14. Maintain tool with care.

> Keep cutting tools sharp and clean for better and safer performance. Follow

instructions for lubrication and changing accessories. Inspect tool cord

periodically and if damaged have them replaced by an authorised service

facility. Inspect extension cords periodically and replace if damaged. Keep

handles dry, clean and free of oil or grease.

15. Disconnect tools.

> When not in use, before servicing and when changing accessories such

as blades, bits and cutters, disconnect tools from the power supply.

16. Remove adjusting keys and wrenches.

> From the habit of checking to see that keys and adjusting wrenches are removed

from the tool before turning it on.

17. Avoid unintentional starting.

> Ensure switch is in the “off” when plugging in.

18. Use outdoor extension leads.

> When tool is used outdoors, use only extension cords intended for outdoor use

and so marked.

19. Stay alert.

Getting started...

> Watch what you are doing. Use common sense. Do not operate tool when you

are tired.

20. Check damaged parts.

> Before further use of the tool, it should be carefully checked to determine that

it will operate properly and perform its intended function. Check for alignment

of moving parts, binding of moving parts, breakage of parts, mounting and any

other conditions that may affect its operation. A guard or other part that

is damaged should be properly repaired or replaced by an authorised service

centre unless otherwise indicated in this instruction manual. Have defective

switches replaced by an authorised service facility. Do not use the tool if the

switch dose not turn it on and off.

21. Warning.

> The using of any accessory or attachment other than those recommended in

this instruction manual may present a risk of personal injury.

22. Have your tools repaired by qualified person.

> This electrical tool complies with the relevant safety requirements. Repairs

should only be carried out by qualified persons using original spare parts,

otherwise this may result in considerable danger to the user.

Technical and legal

information

10

HEALTH ADVICE

Warning! When drilling, sanding, sawing or grinding, dust particles will be

produced. In some instances, depending on the materials you are working

MTC500 by MacAllister

Technical and legal

information

with, this dust can be particularly harmful to you (e.g. lead from old gloss paint).

You are advised to consider the risks associated with the materials you are working

with and to reduce the risk of exposure. You should:

- Work in a well-ventilated area.

- Work with approved safety equipment, such as those dust masks that are

specially designed to filter microscopic particles.

ADDITIONAL SAFETY INSTRUCTIONS FOR YOUR TOOLS

> Do not use diamond discs which are damaged or deformed.

> Replace table insert when worn.

> Use only diamond discs recommended by the manufacturer.

> Take care that the selection of the diamond discs is suitable for the material

to be cut.

> Wear suitable personal protective equipment when necessary, this could

include hearing protection to reduce the risk of induced hearing loss, respiratory

protection to reduce the risk of inhalation of harmful dust, wear gloves when

handling diamond discs and rough material.

> Never use blades on this machine.

> Use only diamond discs for which the maximum possible speed is not less

than the maximum spindle speed of the tool and the material to be cut.

> Faults in the machine, including guards or diamond discs, should be reported

as soon as they are discovered. Never use the machine without the guard in

position.

> Maximum size of working piece should be 1m².

> This tile cutter should be used with limitations on ambient conditions (between

15°C and 30°C).

> The machine must be supplied through a residual current device (RCD).

EN

Getting started...

Wear goggles

Wear ear defenders

Wear a breathing mask

11

EN

MTC500 by MacAllister

Before you start

Unpack

> Unpack all parts and lay them on a flat, stable surface.

> Remove all packing materials and shipping devices if applicable.

> Make sure the delivery contents are complete and free of any damage. If you

find that parts are missing or show damage do not use the product but contact

your dealer. Using an incomplete or damaged product represents a hazard to

people and property.

> Ensure that you have all the accessories and tools needed for assembly and

operation. This also includes suitable personal protective equipment.

You will need

(items not supplied)

> Phillips screwdriver

Getting started...

Getting started...

WARNING: Risk of injury!

Always pull out the mains plug (disconnect the product from its

power supply) before commencing work on the product.

(items supplied)

> Straight disc spanner (1 pc)

> Angle disc spanner (1 pc)

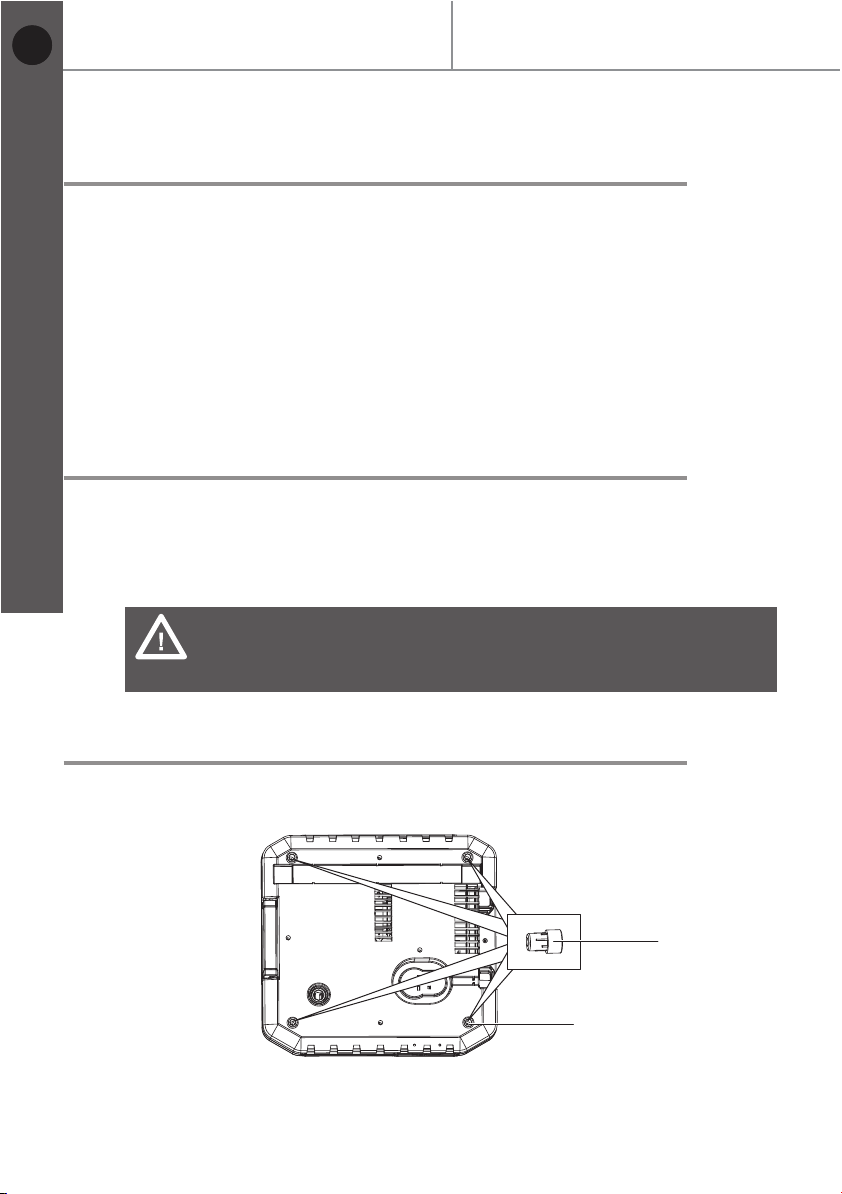

Fitting the base foot

> Insert the four base feet (10) into the openings (18) on the underside of the product.

10

18

Fig. 1

12

Loading...

Loading...