mabe PTAN9150MWW, PTAN9250MWS, PTAN9350MWS, PTAN9450MWS, PTAN9455MGG Technical Service Manual

Page 1

Technical Service Guide

New Top Load Washer

Model Number:

PTAN9150MWW, PTAN9250MWS, PTAN9350MWS, PTAN9450MWS, PTAN9455MGG

Mabe Canada

Robert Gauthier

Training & Technical Support

Pub #10-MAN-AW-02

DATE: May 2011

1

Page 2

IMPORTANT SAFETY NOTICE

The information in this service guide is intended for use

by individuals possessing adequate backgrounds of

electrical, electronic, and mechanical experience.

Any attempt to repair a major appliance may result in

personal injury and property damage. the manufacturer

or seller cannot be responsible for the interpretation of

this information, nor can it assume any liability in

connection with its use.

WARNING

To avoid personal injury, disconnect power before

servicing this product . If electrical power is required for

diagnosis or test purposes, disconnect the power

immediately after performing the necessary checks.

RECONNECT ALL GROUNDING DEVICES

If grounding wires, screws, straps, clips, nuts, or

washers used to complete a path to ground are removed

for service, they must be returned to their original

position and properly fastened.

mabe Canada

2

Page 3

Table of Contents

Nomenclature……………………………………………………………………….. ……...…………………………....4

Introduction………………………………………………………………………….. …………………………………...5

About the control panel…………………………………………………………… ……………………………….6,7,8

Installation…………………………………………………………………………… …………………………………...9

Washer Warranty…………………………………………………………………… ………………………………….10

Drawer dispenser…………………………………………………………………... ………………………………….11

Loading the Washer……………………………………………………………….. ………………………………….12

Water consumption and cycle times……………………………………………. ………………………………….13

TM

HydroSoft

Infusor

Understand the consumer’s issue first……………………………………… … …………………………15, 16, 17

Wash Cycle Progression………………………………………………………….. ………………..18, 19, 20, 21, 22

Shower Rinse Progression ………………………………………………………. ………………………………….23

Deep Rinse Progression…………………………………………………………... ………………………………….24

Final Spin…………………………………………………………………………….. ………………………………….25

TM

Washer Tips…………………………………………….. ………………………………….14

Operating Cycles…………………………………………………………………… ………………………………….26

Component Locator Views……………………………………………………….. ……………………………..27, 28

How to remove the control panel, top, control board ………………………. ………… …………………..29, 30

Infusor Removal, transmission removal……………………………………….. …………………….31, 32, 33, 34

ATC Thermistor………………………………………………………… ………….. ………………………………….35

Water valves, Drain Pump, Wax Motor, Motor Sensor……………………… ……………………………...36, 37

Testing the Motor…………….…………………………………………………….. ………………………………….38

Shifter System………………………………………………………………………. ………………………………….39

Motor Sensor………………………………………………………………………... ………………………………….40

Lid Lock………………………………………………………………………………. …………………….41, 42, 43, 44

How to check the Programs Switch…………………………………………….. ………………………………….45

How to check the Selector Switch……………………………………………… ………………………………….46

Wiring Diagram……………………………………………………………………... ………………………………….47

How to Enter or Exit to Service Mode………………………………………….. ………………………………….48

Component testing (knob position)…………………………………………….. ………………………………….49

Error and Fault Code………………………………………………………………. ………………………………….50

………………………………….51

Pressure Sensor……………………………………………………………………. ………………………………….52

Circuit Board Connections……………………………………………………….. ……………………………..53, 54

3

Page 4

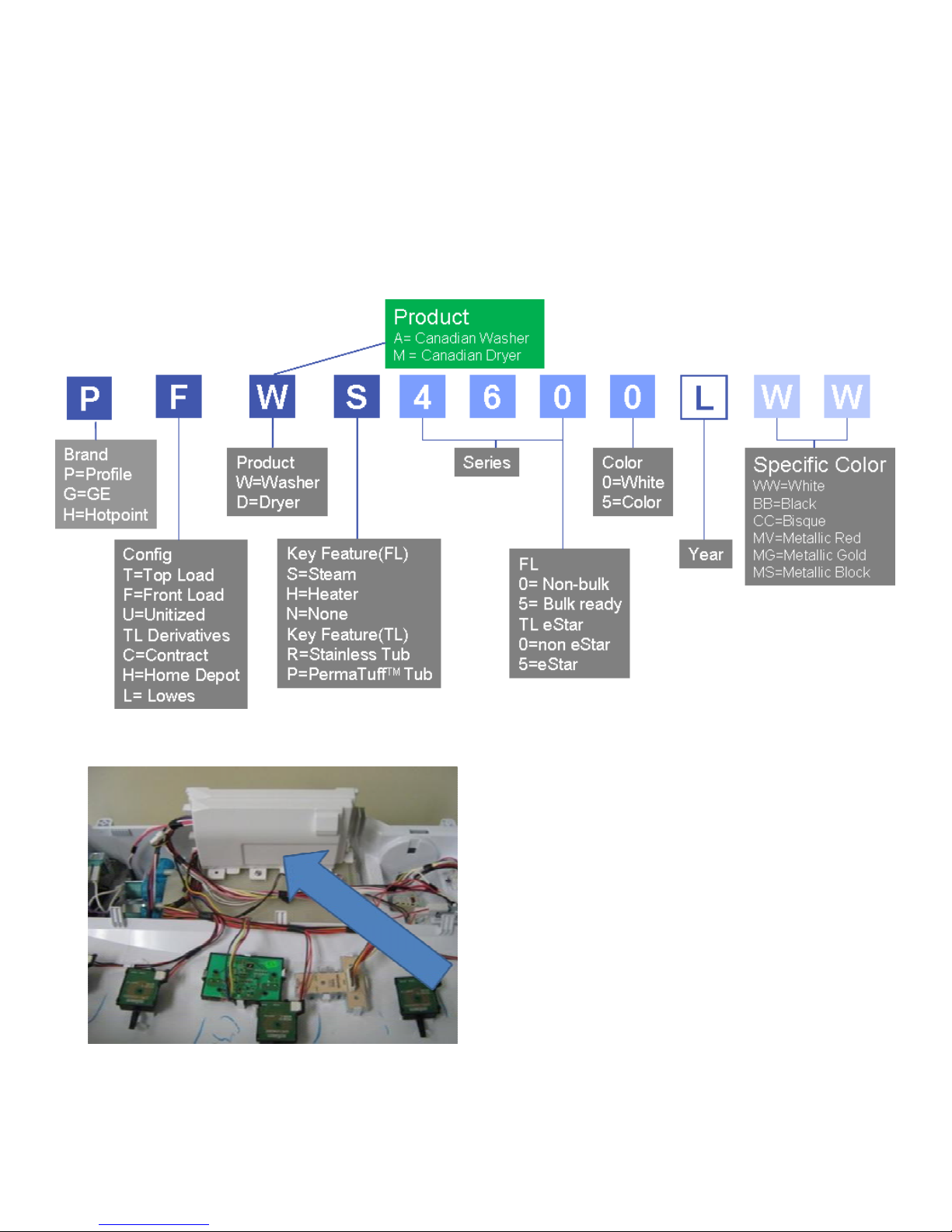

2010 Clothes Care Nomenclature Washer

Location of mini-manual

4

Page 5

Introduction

Feature Current models New models

Wash action Agitator Impeller

Washer cover Plastic Plastic or glass

Wash temperatures 3 settings 3 to 5 settings + ATC

Rinse system Normal Shower + Deep rinse

Drive system

Transmission with solenoid

Safety

Lid lock w/mech switch (2

minutes to open)

Controls Electronic w/knobs

Service

Only 1 error code, no service mode

Transmission with wax

switch

Lid lock w/instantaneous

switch

Electronic w/knobs and 3

digit display

Multiple error codes, full

service and demo mode

5

Page 6

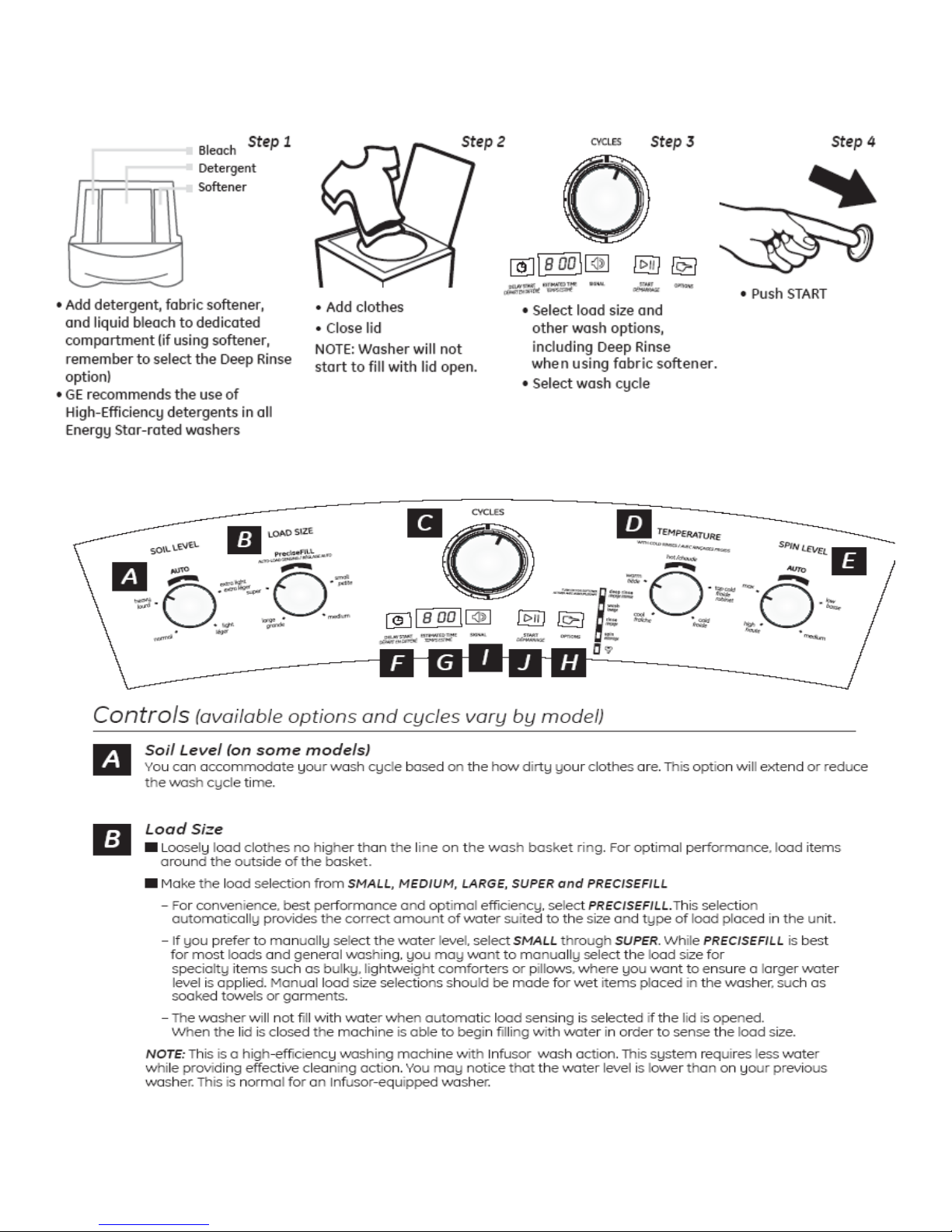

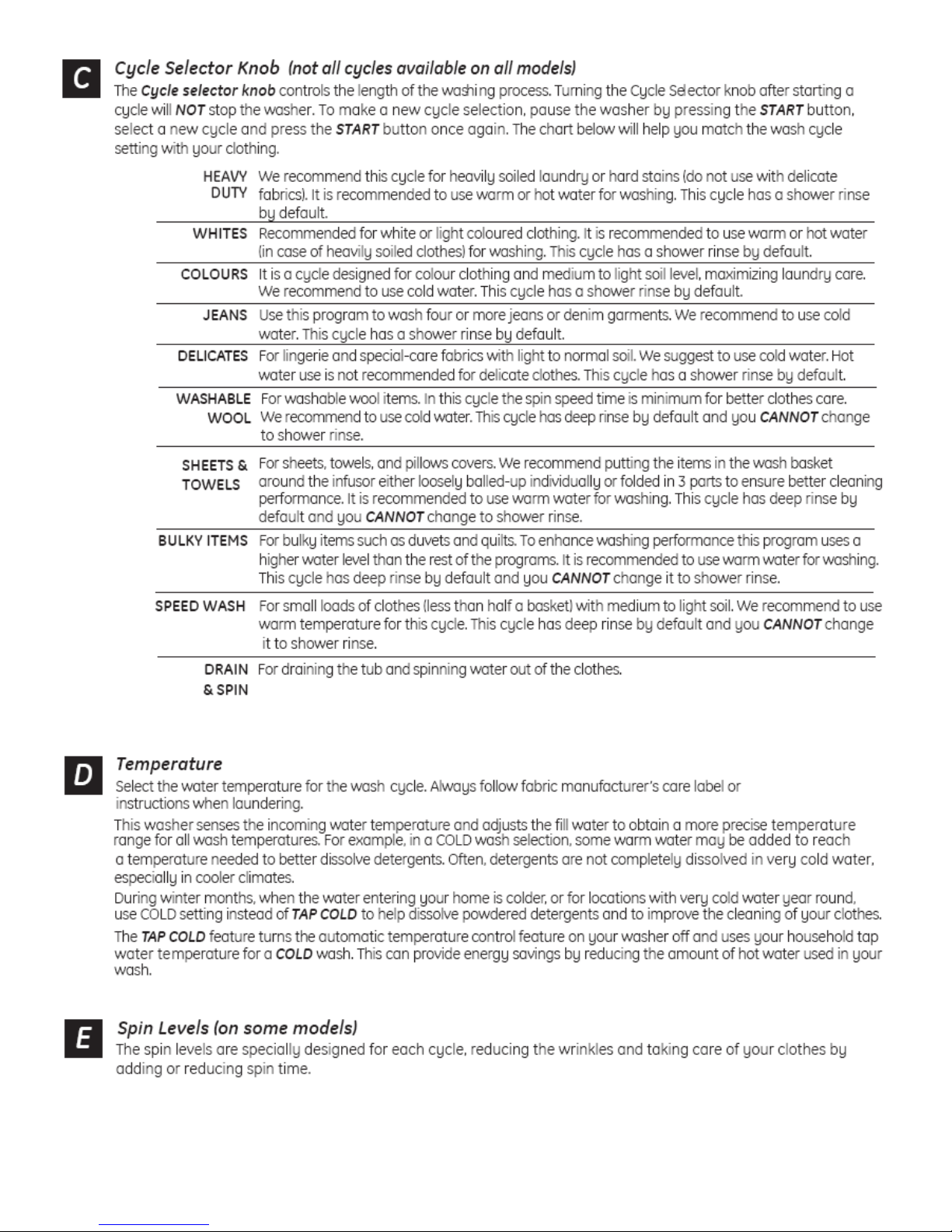

Quick Start Guide

About the control panel.

6

Page 7

7

Page 8

8

Page 9

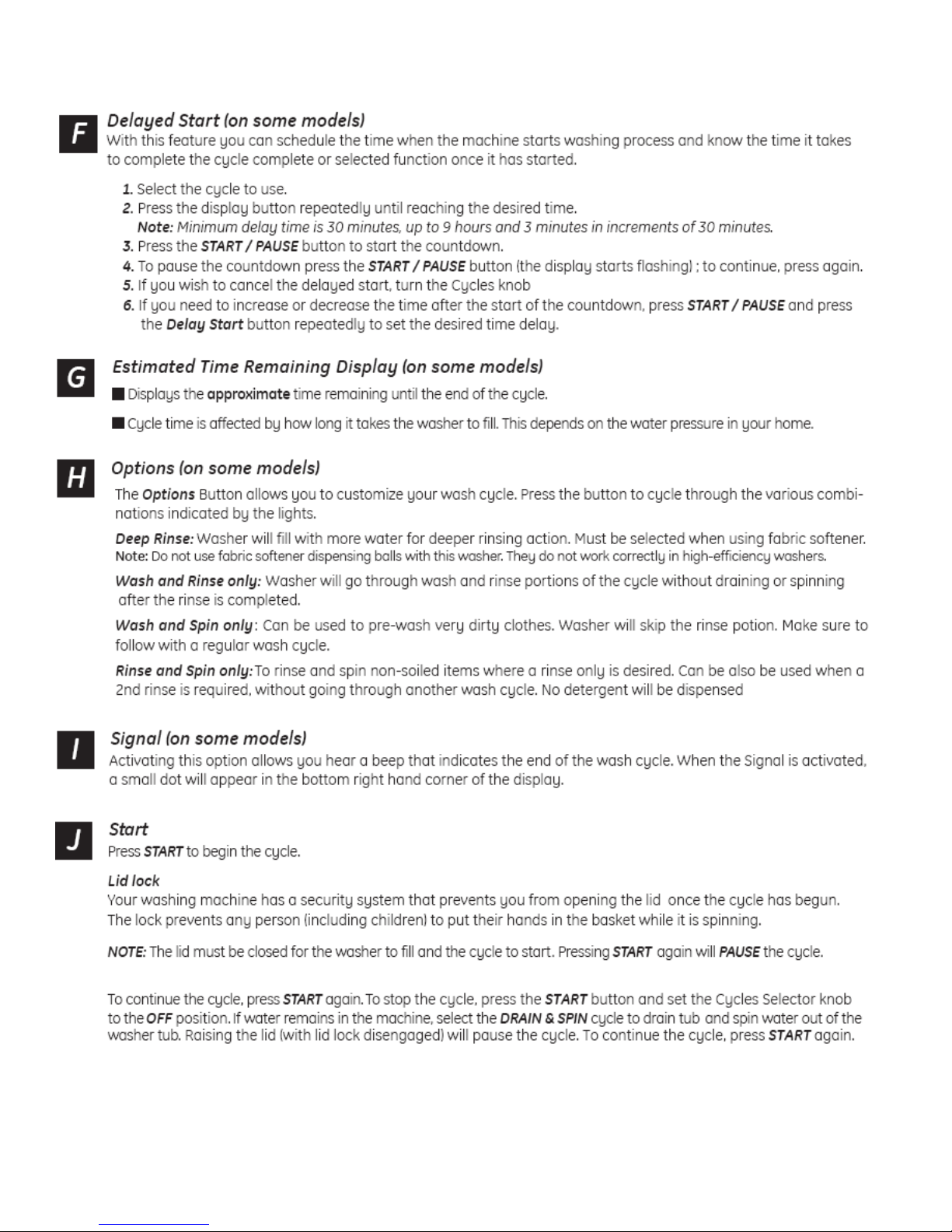

Installation

INSTALLATION REQUIREMENTS

DRAINAGE

A vertical standpipe with an internal diameter of 1-1/2”

(3.8 cm) is required. The standpipe height above the

floor must be:

Minimum height: 36” (91,4 cm)

Maximum height: 96” (243,8 cm)

Insert the drain hose into the standpipe and secure it

with the cable tie located inside the accessories bag.

The standpipe must be open to the atmosphere (there

must be an air gap around the drain hose).

If you need to extend the lenght of the drain hose to

reach

your standpipe, please contact your local parts store to

purchase the recommended drain hose extension for

your washer.

Cable tie

WATER SUPPLY REQUIREMENTS

Hot and cold water faucets MUST be installed within 42”(107 cm) of your washer’s water inlet. The

faucets MUST be 3/4” (1.9 cm) garden hose-type so inlet hoses can be connected.

Water pressure MUST be between 10 and 100 pounds per square inch.

Your water department can advise you of your water pressure.

The hot water temperature should be set to deliver water at 120° to 140°F (48° to 60°C).

Page 10

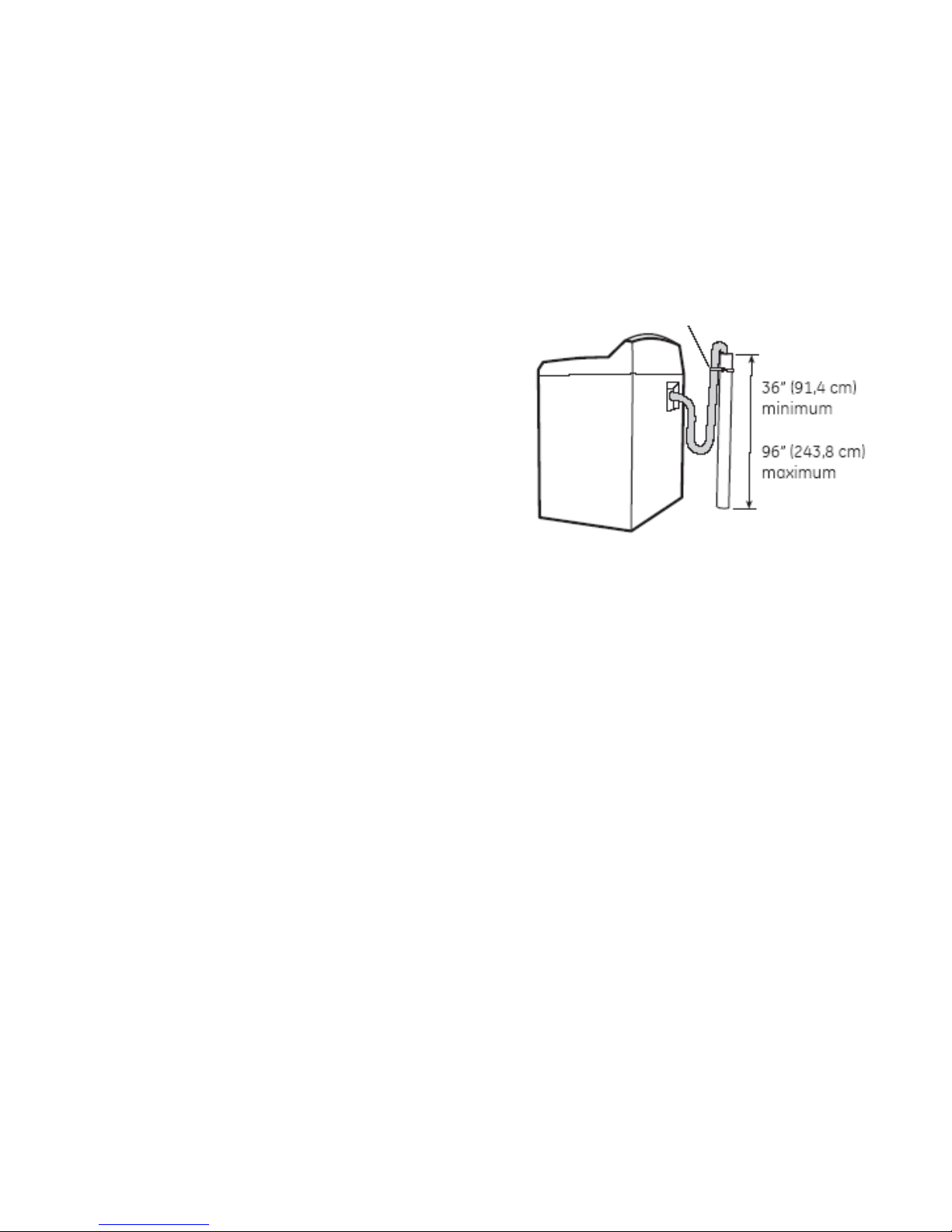

Washer Warranty

Page 11

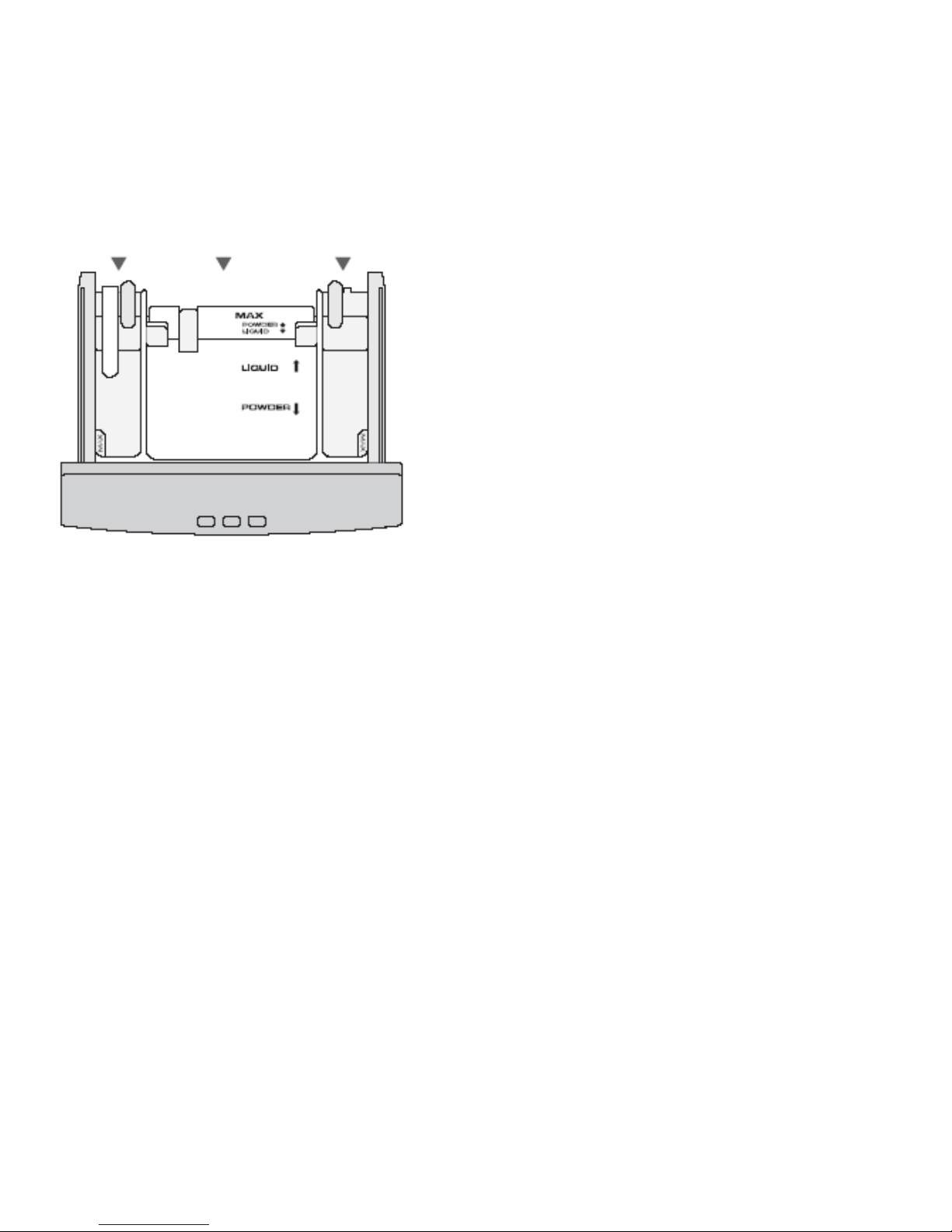

Flow Logic automatic drawer dispenser.

Your washer is equipped with an automatic dispensing system, comprised of a drawer with 3

compartments:

Bleach Detergent Softener

Liquid bleach

Pour liquid bleach into the designated compartment without filling beyond the mark.

Check clothing care labels for special instructions. Use

less for smaller loads.

Do not dilute bleach. Bleach will be added automatically

diluted to avoid direct contact with the clothes. Use only

this compartment, do not add bleach directly onto clothes.

IMPORTANT:

To avoid any potential leftover bleach mixture being dispensed in a subsequent cycle, it is strongly recommended

to verify that the bleach compartment of the dispenser is

free of any leftover bleach and water mixture. If there is

some leftover bleach mixture, please empty the contents

to avoid any damage to clothes that cannot tolerate

bleach

.

Detergent

Add the amount of powder or liquid low suds detergent in the compartment, as recommended by the manufacturer and according to the size of the

load. You should not put the detergent directly on the clothes in the washer.

· For powder detergent: Install the divider in the front position. Put the detergent selection blue wall, that is located at the end of the dispenser, in

the front position

· For liquid detergent: Install the divider in the back position. Put the detergent selection blue wall , that is located at the end of the dispenser, at

the back position.

Place the amount of liquid detergent without exceeding the maximum level indicated.

Fabric Softener

Pour fabric softener into the designated compartment without filling beyond the mark.

Note: in order for the fabric softener to be dispensed you must select the DEEP RINSE option. Please refer to the Options

section of this manual.

11

Page 12

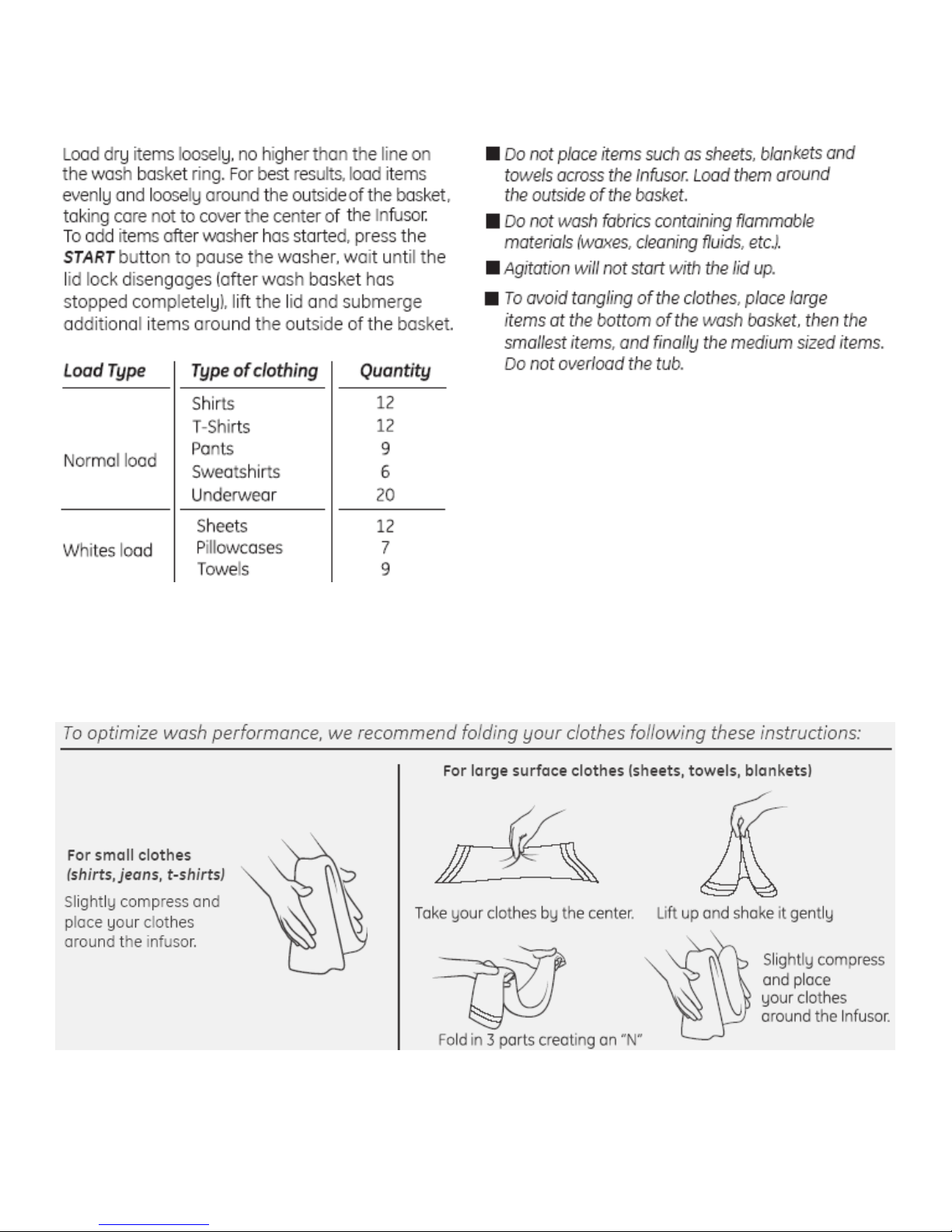

Loading the Washer

12

Page 13

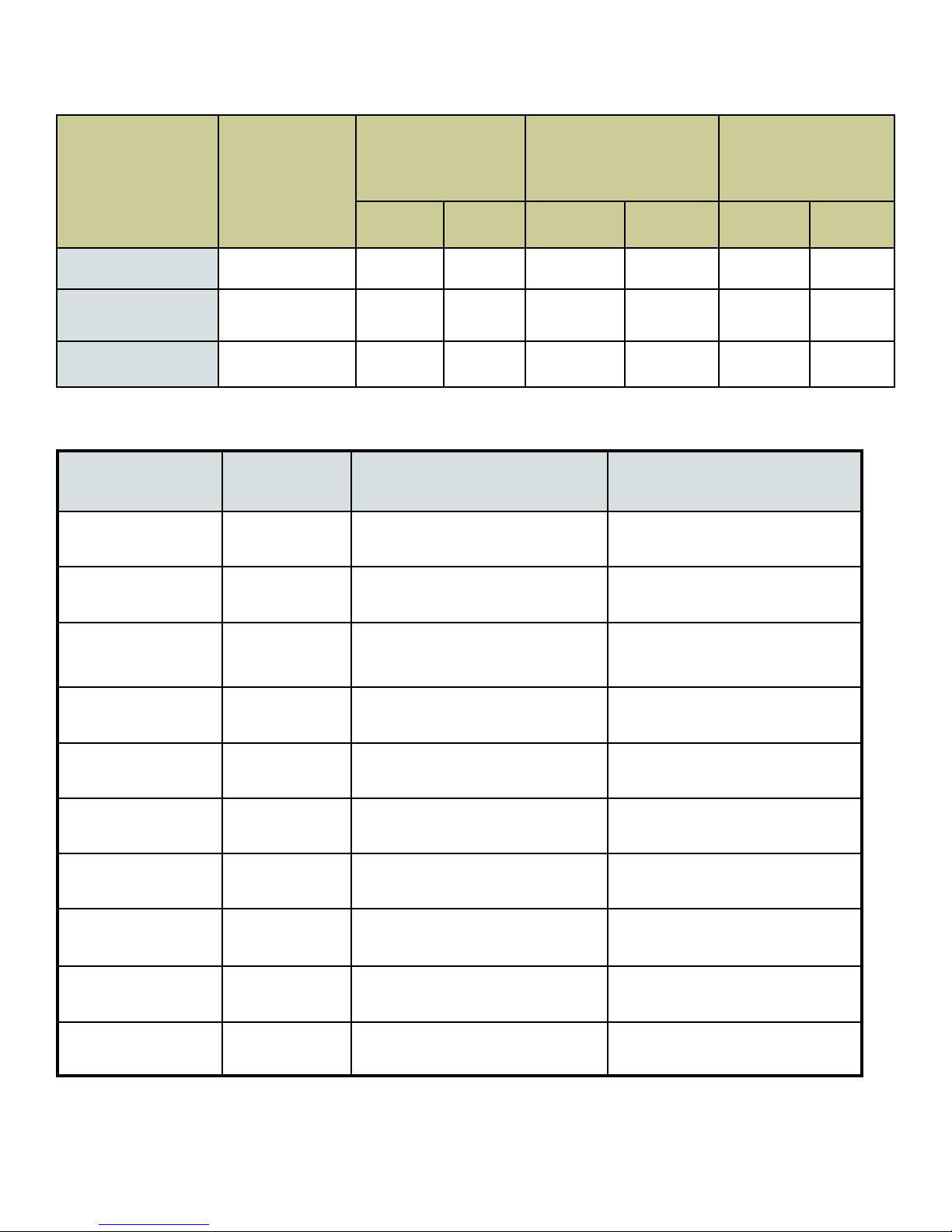

Water Level

Water consumption

Approx

Wash Rinse Total

Load Size

Gal. Lt. Gal. Lt. Gal. Lt.

Max Level

High Level

Medium Level

12 — 16 lb 13.74 52 8.98 34 22.72 86

9 — 11 lb 12.15 46 8.98 34 21.14 80

6 — 8 lb 10.30 39 6.08 23 16.38 62

Cycle times

Programs Wash Final Spin

Heavy Soil

Whites

colors

Jeans

18 min. 10 min.

18 min. 16 min.

14 min. 2 min.

13 min. 5 min.

Total

1:17

1:21

1:12

1:09

Delicates

Wool

Towels / Linen

Bulky items

Quick Wash

Wash & Spin

6 min. 2 min.

8 min.

13 min. 5 min.

11 min. 5 min.

3min. 3 min.

N/A 6 min.

Only 3 spin ramps

13

:59

:38

1:09

1:02

:53

:10

Page 14

TM

HydroSoft

INTRODUCTION

TM

HydroSoft

technology provides excellent cleaning. Infusor models are ENERGY STAR® qualified

using only 23 gallons of water per (super) load compared to 48 gallons for a similar

load with a standard machine .

High efficiency (HE) detergent is required with Infusor models. Liquid HE detergents

dissolve faster in water. For best performance, load the machine by adding liquid HE

detergent first. Add the dirtiest clothes around, but not covering, the center of the

Infusor, then add the remaining clothes. Do not load clothes higher than the line

indicated on the balance ring at the top of the wash basket. Insert items as per the

Use and Care. Select proper load size, water temperatures, and rinse options. Use a

fabric softener for better performance

model washers use an InfusorTM, not a traditional agitator. Infusor wash

Infusor

.

TM

Washer Tips

Infusor models turn the washer basket at slow speed during fill to allow the fill funnel

to evenly coat the wash load with water and push clothes to the bottom. The lid will be

locked during the fill to evenly wet the clothes. If you wish to add or remove an item,

press the Start/Pause button to pause the washer. The lid will unlock once the basket

has come to a complete stop. This is for your safety.

Infusor models spin at up to 700 RPM. This extracts more water during the spin cycle,

compared to a standard machine, and minimizes drying time. If wrinkling is a concern,

use a lower spin level to shorten the spin duration.

Given that Infusor washers operate differently from standard top-load machines,

consumers may comment on lint, lower water levels, washing differently than

expected, spots on clothing, wrinkling, water temperature, vibrating/shaking, too-wet

clothes, unusual sounds, or loose tub/basket.

Take the time to listen carefully and fully understand the consumer’s specific issue

before proceeding. Address the appropriate issue today to avoid a return service call.

14

Page 15

UNDERSTAND THE CONSUMER’S ISSUE FIRST

1. Lint

Do not overload the washer. Use the Deep Rinse option, adding more water, to

reduce lint.

2. Not filling or low water level

Infusor models are designed to use less water and are ENERGY STAR® qualified.

During the wash cycle, water may not entirely cover the top of clothes. If Super size

load is selected, the water level will be just at the top of the Infusor.

Check for water supply hoses pushed up tightly against a wall. This condition can

affect the position of the fill funnel so that the water spray isn’t correct during fill. Pull

the washer away from the wall a little to correct.

Water pressure and water flow are critical to washer fill. The washer will not fill to the

proper level with a water pressure less than 20 PSI or with a blocked valve inlet

screen or other flow restriction.

The fill volume on the Small setting is 9 gallons. The water level will measure

approximately 5 inches above the bottom of the basket

..

Note: Measured water levels are approximate and can vary plus or minus 1 inch.

On the Super setting, the fill volume is 14 gallons. The water level will measure

approximately 8 inches above the bottom of the basket. With Super setting, the water

will come up to the top of the Infusor.

15

Page 16

All models have the PreciseFill Automatic Load Sensing feature. When PreciseFill is

selected, the machine determines fill time by sensing the load size. The Precise Fill

pressure switch minimum level setpoint. The lower level setpoint is attained at

approximately 1 inch of water depth, at which point the washer will start sensing the

load size and determine the optimal amount of water required and corresponding

water level.

Use the Deep Rinse option to add more water during rinse.

3. Washing differently than expected

Load the basket with similar weight items around the sides of the basket.

Overloading the washer can lead to poor cleaning performance.

Check for water supply hoses pushed up tightly against a wall. This can affect the

position of the fill funnel so that water spray isn’t correct during fill. Pull the washer

away from the wall a little to correct.

4. Spots on clothing

Usually caused by too much HE detergent; use less. Use less HE detergent with

softer water. Clothing is cleaned when soapy water bonds to the dirt and is rinsed

away. Too much detergent can generate soapy foam that is difficult to rinse away.

To correct, run a couple of cycles empty with no soap to rinse the machine, and then

run a load with less HE detergent. Use the Deep Rinse option to add more water

during rinse. Check for possible siphoning condition.

5. Wrinkling

Do not overload the washer. Overloading can lead to poor cleaning performance and

increase wrinkling. Infusor models spin faster than standard top-load machines to

extract more water for faster drying and can cause more wrinkling. If wrinkling is a

concern, use the Deep Rinse option to add more water during rinse, and select a

lower spin level for less spin time.

16

Page 17

6. Water temperature

Energy-star requirements dictate that even on a hot setting, the washer will mix in

some cold water. If the home water supply pipes have a long run, are imbedded in a

concrete slab, and/or the washer is used during the winter months, it may take

longer for the first hot water to reach the washer. Run the hot water at a nearby

faucet to check water supply temperature.

7. Vibrating/shaking

Check for proper levelling. If only an occasional complaint, check for out-of-balance

load.

8. Too-wet clothes

If the final spin leaves clothes too wet, re-arrange the clothes to balance the load,

then run another drain and spin cycle.

9. Loose wash tub/basket

A loose basket is normal when the washer is idle. Infusor models do not use a

mechanical brake to prevent the basket from turning. The basket slows down on its

own and will normally come to a full stop in less than 2 minutes if spinning at full

speed.

17

Page 18

Wash Cycle Progression

Level detection/

Overload sensing

Clothes

arrangement

Fill to Minimum Wa-

ter Level

(Sensing Level)

Washer starts by sensing if basket is over loaded.

Washer executes pattern to set the

clothes previous to agitation in order to improve wash performance.

Water and detergent are admitted in

this stage between tub and basket; at

the same time water circulates intermittently 6 seconds each 45 seconds

detergent dilution.

Final Spin

Rinse

Rinse Fill

Load

Sensing

Fill to selected

level

Agitation

Intensive agitation pattern if

or 14.5 min.

Washer agitates to determine water

level matches clothes load and type of

clothes.

After sensing load washer fills if

more water is required.

Untangling

Soft agitation pattern for 3.5 min. in

order to detangle and balance

clothes previous to spin.

Intermediate Spin Pattern

consist of a series of

speed ramps until maximum speed is reached.

Intermediate

Spin

Drain

Drain the wash

liquid.

18

Page 19

Wash Cycle Progression (cont.)

Level

detection/

Takes 2 spins, measures time to reach a certain angle.

Estimates if load is greater than 17 lbs or not.

Overload

sensing

Clothes

arrangement

If load is greater than 17lbs, it bypasses the "load arrangement" phase and goes straight to the pre-fill portion.

Washer executes pattern to distribute the clothes previous to

agitation in order to improve wash performance.

Load spins 2 times (CCW-CW), each time injecting cold water for 8

seconds.

• During each spin portion, the motor is successively activated (for

600 ms) and deactivated (for 2 seconds), intermittently spinning the

basket for a total of approx 10 seconds.

• Once the 10 seconds are over, unit goes into a full spin (at 700

RPM) and drain pump is activated for 10 seconds.

•After this, unit slows down to 100RPM.

Fill to Minimum

Water Level

(Sensing Level)

Water and detergent are admitted in this stage

directly into the basket.

• Water fill starts until the minimum water level is

reached.

• Water is at temp selected by consumer, regulated

by ATC thermistor.

19

Page 20

Wash Cycle Progression (cont.)

Washer agitates to determine if water level (as selected by con-

Load

Sensing

Fill to

selected

level

sumer) is appropriate for actual load size and type of clothes.

•After minimum water level is attained, washer senses if load is

greater than 17lbs (impeller only goes back and forth).

• Basket is spin intermittently by pulses (3 times CCW, then 3 times

CW) and water is injected via the dispenser, dispensing soap.

•If load is less than 17lbs, agitation can start after fill is complete to

desired level.

After load sensing, washer fills to desired level

• Washer fills to level selected by consumer or greater level if load

sensing determines selected load size is not sufficient.

Agitation

Washer agitates according to settings chosen by consumer,

between 14 and 18 minutes.

20

Page 21

Untangling

Wash Cycle Progression (cont.)

Soft agitation pattern for 3.5 min. in order to detangle and

balance clothes previous to spin.

• Washer agitates at different rate than main wash to set the

clothes in place for spin, for 3.5 minutes.

Drain

Intermedi-

ate Spin

Drain the wash water, until the minimum water level

setting is reached (no agitation).

Intermediate Spin pattern consist of a series of speed

ramps until maximum speed is reached.

• 30 seconds after "minimum"** water level is reached,

washer starts spinning basket doing 5 preliminary ramp ups

to ensure load is properly distributed and safe to bring up to

next spin level.

• The 6th spin level is the last of the Intermediate spin portion. If it's able to reach 600 rpm in the predetermined

amount of time, it keeps that speed for a total of 1.5 minutes.

** the "minimum" water level is actually lower than the

Minimum water level setting. It's approx. 1" of water in

the tub.

21

Page 22

Wash Cycle Progression (cont.)

Shower rinse is the normal rinse cycle. However, in some

instances the washer will go to a Deep Rinse instead:

•when fabric softener is used and customer has selected the

Deep Rinse option.

•on certain cycles such as Bulky Items.

•if the washer recognizes that a higher water level than the one

selected by the consumer is required to ensure proper operation of the washer.

The shower rinse is a timed fill, with water quantity dependant

Rinse Fill

on the water pressure regulated by water valve.

The number of Shower Rinses is determined by the water level

selected by the consumer and the actual water level as determined by the washer.

• If water level is Maximum or higher, washer does 3 rinse

blocks.

• If water level is High or lower, washer does 2 rinse blocks.

22

Page 23

Shower Rinse Progression

Fills with water up to level selected for

main wash (or adjusted by the washer if

insufficient)

Admits directly in the wash basket a predetermined water amount (approx. 3 gal @ 20

psi). Water amount is determined by time

(approx 40 seconds per block).

1

Basket stop

to 0 rpm

Waits until the basket

stops completely.

Water

Admission

Directly

no

Basket stop to 0

rpm

The water is sprayed on the

clothes while basket spins inter-

Clothes Saturation

(fresh water)

Drain &

Spin

Spin pattern

“between

rinse blocks”.

Rinse Blocks

Complete?

Number of rinse blocks depends on

selected load size:

2 blocks for Small, Med and Large

3 blocks for Super

Qty of water per block:

11 liters/2.9 gallons

Total Spin Time 16 min

Final Spin

End Cycle

23

Page 24

Deep Rinse Progression

Fills with water up to

level selected for

main wash (or adjusted by the washer.

1

Basket stop

to 0 rpm

Waits until the

The water is injected on the

clothes while basket spins

intermittently.

Water Ad-

mission

Directly

4 minutes of agitation. Agitation pattern same as wash

cycle.

Clothes

Saturation

(fresh water)

Agitation

basket stops

completely.

Drain &

Final Spin

End

Cycle

24

Page 25

Final Spin

• Washer start draining until "minimum" level is reached.

• After level is reached, washer starts spinning basket, ramping up to

400 RPM

• Washer then slows down to 230 RPM, then ramps up to spin speed

selected by consumer

• If washer CANNOT reach desired spin speed, motor shut off until

speed reaches 300 RPM

• After reaching 300 RPM, washer attempts to ramp up to final spin

speed again.

• If successful, spin lasts approx 16 minutes total

• If UNSUCCESSFUL at attaining desired spin speed BUT unit has only

performed 1 Deep Rinse, washer does another Deep Rinse cycle.

• If UNSUCCESSFUL at attaining desired spin speed AND unit has al-

ready performed 2 deep rinses, washer stops and an error code is

logged. (See codes page 55)

25

Page 26

26

Page 27

Component Locator Views

Hot Water

Valves

ATC (temperature control)

Dispenser water

Valves

Electronic Board

Pressure

Sensor

Lid

Switch

Lid Lock With Quick Release Dispenser

27

Page 28

Component Locator Views

Capacitor

Speed Sensor

Wax Motor

Transmission

Drain Pump

Motor

28

Page 29

HOW TO REMOVE THE CONTROL PANEL

1- Remove the two screws behind the control panel.

2– Lift back of console and tilt console towards machine front to free front

3 tabs.

29

Page 30

HOW TO REMOVE TOP

Remove the two screws behind the

washer. Pull the back of the top up

and forward to remove

Disconnect the 2 connectors (1) (2)

and remove the pressure switch hose

to remove the top.

..

(1)

Pressure switch hose

ELECTRONIC CONTROL (PCB)

The electronic control cover is held in place with plastic tabs.

(2)

The electronic control is held in place with two screws.

30

Page 31

INFUSOR REMOVAL

1- Remove the cap 2- Remove the bolt

3- Removing the Infusor

NOTE

Use a 3 ft by 3 ft floor protector under the washer to avoid damaging its components

or the floor when separating the tub assembly from the cabinet.

1- Remove the top (see page 24)

2- Remove the Infusor

TRANSMISSION REMOVAL

31

Page 32

3- Remove the tub cover 4- Remove the tub nut

5- Remove the basket

Use a tub wrench (WX5X1325 ) to remove the left hand thread

tub nut. Same wrench used on a GE washer.

Note

: When re-assembling, use a hammer with the wrench to

tighten the tub nut. Hand tighten with the wrench then ¼ of a

turn using a hammer.

6- Suspension

Before the outer tub is released, unlock the main harness and

the drain hose clips. Release the drain hose from the cabinet

so both components can be separated.

7- The suspension rods are detached by pulling the rods up

and removing the socket.

8-Once the tub is separated from the cabinet, lift the cabinet off

and turn the tub up side down.

32

Page 33

Note: The motor, pump and was motor can be service from the bottom without removing the cabinet.

The next step in removing the transmission (mode shifter), it is to remove the belt and

the motor.

The belt can be forced over the transmission pulley.

9- Remove the belt. (The belt can be

forced over the transmission pulley).

10-Rmove motor

11- Remove the pulley and shifter gear.

(Use lock ring pliers to remove the lock

ring that holds the pulley to the transmission. Using any other tools can damage

the lock ring.)

12- Remove 2 (3/8) bolts to remove the

wax switch base. The base can also be

removed before removing the wax switch

to make the disassembling easier.

13- The capacitor is held in place with a

¼” screw.

33

Page 34

NOTE:

14- Remove the pump to prevent it

from getting damaged, It is held in place with 3 (1\4 “ screws)

15– Remove the wax switch

16- Remove 12 (3/8) bolts holding the

transmission base to the outer tub.

17- Once the base is removed, release

the wire harness plastic retainer.

Transmission removal is now complete

The transmission is a complete sub-assembly

including the base as shown in the picture.

34

Page 35

ATC Thermistor

The ATC controls the water temperature selected by the customer.

If the ATC thermistor fails or harness is broken, the washer will still operate.

The control will open just the cold water valve.

At room temperature ( 20ºC) , the resistance should be approximately ~11KΩ.

Resistance goes down as temperature goes up.

NOTE: The ATC is activated Only during main fill.

35

Page 36

Water valves & Drain Pump

Testing Water valve

• With harness disconnected the resistance

value of any of the 4 water valve coils should

be approximately 1KΏ

• The water valve can also be tested with a

120 Volt test cord.

Testing Drain Pump

• With harness disconnected the resistance value

of the drain pump should be 15Ώ

• The pump can also be tested with a 120 Volt

test cord.

See page 48, 49

36

Page 37

Wax Motor and Motor Sensor

SPIN

Testing Wax Motor

• Wax motor can be tested with a 120 Volt test cord.

• Should take approximately 45 seconds to fully as described above.

See page 48, 49

37

Page 38

Testing Motor

Direction Switch is included in the electronic control board

CCW

J2

CW

White Yellow

MOTOR

Line

Neutral

Black

Motor measurement

White – Yellow = 10.2 Ώ

White - Black = 5.2 Ώ¶

Yellow – Black = 5.2 Ώ¶

38

Page 39

Shifter System

Wax Motor

Shifter

AGITATE SPIN.

Driving pulley

With the wax motor NOT energized,

the washer is ready to Spin.

39

120 VOLTS APPLIED

With the wax motor energized the

washer is ready to agitate.

Page 40

Motor Sensor

The speed sensor in the motor operates on a 10 vdc signal from the control board.

The control board reads the pulses from the motor to determine proper operation.

This signal can not be read with a conventional multi-meter while operating. Besides

diagnostic error code mode – disconnect the sensor harness from the control and

read AC millivolts on the sensor harness while rotating the spin basket CCW.

In wash mode, after the water valve turns off, it is normal for the motor to operate in a

short stroke pattern before the regular agitation cycle begins. The motor will then run

in both clockwise and counter clockwise rotation to provide 180 degrees of agitator

arc.

In the spin/rinse mode, the motor runs only in counter clockwise rotation. At spin

startup it is normal for the motor to pulse a couple of times in each direction – this

assures the shifter gear is set for spin. A clunking noise is normal during this startup

routine. In spin the control will perform two ramp ups in speed to 290 rpm and then

turn the motor off until 0 rpm is reached. The control will then energize the motor for

full spin.

Motor sensor =39 KΏ. (Reverse the polarity from your multimeter you will read infinite.)

40

Page 41

Lid Lock Step 1

Step1:

Currentisapplied(120VOLTSAC)toterminals4and2(neutral)whenanycy

•

selectedbeforepressingstart.

•Thisenergizesthebi‐metalbutdoesnotlockasthecampreventsit

fromdoingso.

• Thelidshouldnotbelockedatthisstage.Ifitdoespressthestart

buttontounlock.

Locking pin does not drop as the cam

prevents it from doing so.

3 5 4 2

Neutral

Power

41

Page 42

Lid Lock Step 2

Press the START button to begin the wash cycle.

Power is sent to terminal 3, activating the solenoid, turning the green cam 30 deg.

Then locking pin falls in place, closing the circuit at terminal 5, sending a signal to the board that

the lid is locked. This terminates power to terminal 3.

The lock signal from terminal 5 to the board now allows the motor to run..

Note: The board looks for this lock signal with a pulse up to 5 times. If it does not receive this

signal it will show F8. The board will repeat this up to 3 times (with a 30 seconds pause between

each try). If the lid still does not lock, an ERROR code Er8 will be shown and unit no longer operate until unplugged and re-plugged or serviced.

42

Page 43

Lid Lock Step 3

• Lid remains locked until the end of the final spin (or until the pause button is pressed) and the

motor has received feedback of 0 rpm from the speed sensor (Hall effect sensor on motor).

• Tounlockthelid,thePCBsendspulses(usually2)throughterminal3toactivatethesolenoid,turnthe

camtodisengagethelockingpin,andopenthecircuittoterminal5.

43

Page 44

Lid Lock Step 3 (cont.)

•IfthePCBstilldetectspowerthroughterminal5afterafewpulses,thePCBwillemitamaximumof5

pulsestodisengagethecontactandcutpowerthroughterminal5.Ifthisfails,thecontrolwillindicatea

FailurecodeF8

•Unitwillthenattemptthesequence,amaxiumof2othertimes(3intotal).Ifthelidstillcan’tbelocked,

anERRORcodeEr8willbeshownandunitnolongeroperateuntilunpluggedandrepluggedorserviced.

44

Page 45

HOW TO CHECK THE PROGRAM SWITCH

Position Function Terminal 1-2 Terminal 2-3

10 Spin only 1100 Ω < 10 Ω

9 Quick Wash 1000 Ω 100 Ω

8 OFF 900 Ω 200 Ω

7 Bulky items 800 Ω 300 Ω

6 Towels / Linen 700 Ω 400 Ω

5 Wool 600 Ω 500 Ω

4 Delicates 500 Ω 600 Ω

3 Jeans 400 Ω 700 Ω

2 Colors 300 Ω 800 Ω

1 Whites 200 Ω 900 Ω

0 Heavy Soil 100 Ω 1000 Ω

You must remove the plug at the selector switch to test.

45

Page 46

HOW TO CHECK THE SELECTOR SWITCH

Position Terminal 1-2 Terminal 3-2

1 720 Ω < 10 Ω

2 < 10 Ω 720 Ω

3 180 Ω 540 Ω

4 360 Ω 360 Ω

5 540 Ω 180 Ω

46

Page 47

Wiring Diagram

47

Page 48

How to Enter or Exit to Service Mode

1. Unplug the washer.

2. Turn the Cycles knob to POSITION 6

3. Re-plug the washer pressing Start/Pause

and Options buttons at the same time for

3 seconds. Display will show “LLL”.

Service mode function

1. Once in the service mode, a technician

can test each component by setting a

knob position and pressing the Options

button.

2. Pressing the Start/Pause button pauses

the component test.

3. A technician can suspend any test by

turning the Cycles knob to any position

(except Heavy Duty) or pushing the

Options button.

How to exit to Service mode

1. Turn the Cycles knob to Heavy Duty and

wait for 3 seconds. Washer is ready to run

any wash cycle.

48

Page 49

Component testing (knob position)

49

Page 50

ERROR AND FAULT CODE

Warning and Error Codes A Warning code appears when a failure has been detec-

ted. After displaying a Warning code for 30 seconds, the washer will attempt to resume the cycle. If the failure persists, the Warning code will be shown once again. If

the washer is able to resume the cycle on its own, Warning code will disappear from

the display and NO SERVICE IS REQUIRED.

After 3 unsuccessful attempts to resume the cycle, should the washer be unable to

continue an ERROR CODE will be shown. At this point, ONCE AN ERROR CODE

APPEARS, SERVICE IS REQUIRED

50

Page 51

HOW TO CHECK SOME COMPONENTS

You can check different components from the plug underneath the top of the washer.

1 2 3

4 5

6 7 8

1- Lift up the top.

2- Unplug the main connection.

3- Do the test.

You can check the wax motor, drain pump, motor and the speed control. The

readings obtained are resistances (Ώ).

1 = White

2 = White / Black

Components Wire location & resistance Colors

Wax Motor

Drain pump

Motor (1 coil)

Motor (1 coil)

Motor (both coils)

Speed sensor

3 = Yellow

4 = Black

Between 2 & 1 =.99KLΏ

Between 8 & 1 =15 Ώ

Between 3 & 8 = 5 Ώ

Between 6 & 8 = 5 Ώ

Between 6 & 3 = 10 Ώ

Between 7 & 5 = 39 KΏ

Reverse the polarity from

your multimeter you will

read infinite

5 = Pink

6 = Blue / White

White/Black&White

Red&White

Yellow&Black

Blue/White&Black

Blue/White&Yellow

Red/White&Pink

7 = Red / White

8 = Red

51

Page 52

Water (level) Pressure Sensor

Water Pressure Sensor

The sensor operates on low voltage DC which can be read from the control board

connector J6.

The voltage will increase from ~ 0 vdc (empty) to ~ 2.1vdc (full) across terminals

1 & 2, (Beige to Purple) .

Terminals 2 & 3, (Purple to Black), will read the inverse voltage, the voltage will

increase on fill.

Test is performed at the control board with the harness attached.

Empty = 0 vdc

Small = 1.3 vdc

Medium = 1.55 vdc

Extra large = 1.85 vdc

Super = 2.10 vdc

Ps. If the water level is changed when testing, allow 30 to 60 seconds before the

motor stop and water valve is energised.

Black Purple Beige

52

Page 53

Circuit Board Connections

1

JP1

J2

4

1

J11

JP1 ( Water Valves)

Position Connect to

1 Softener Valve

2 Detergent Valve

3 Not Used

4 Lid Lock

5 Bleach Valve

6 Hot Valve

7 Not Used

8 Neutral

J2 [Motor, (J2-4,CCW & J2-1, CW)]

Position Connect to

1 CW Motor

2 Not Used

3 Not Used

4 CCW Motor

J4 (Speed Sensor)

Position Connect to

1 12 Vdc

2 Signal

3

5 1

6 2

3

7

8 4

5

1

3 1

1

J3

J6

12

JP2

3

4

1

2

J10

J7

2 9 1

JP2 (Wax Motor, Lid Lock, Drain Pump)

Position Connect to

1 Lid Lock Return

2 Wax Motor

3 Pump

4 Lid Lock

J3 (Lid Switch, ATC)

Position Connect to

1 Lid Lock

2 Not Used

3 Lid Lock

4 ATC

5 ATC (12 Vdc)

J5 (Display)

Position Connect to

1 12 Vdc

2 RX

3 TX

4 Ground

J5

J9

1

3

J4

4

1

1

53

Page 54

Circuit Board Connections (cont.)

J6 (Pressure Sensor)

Position Connect to

1 Ground

2 Signal

3 Vdc

J9 (Start/Pause)

Position Connect to

1 Ground

2 Vdc

3 Select Button

4 Start / Pause Button

5 Lid Lock Led

6 Deep Rinse Led

7 Wash Led

8 Rinse Led

9 Spin Led

J7 (Spin Switch)

Position Connect to

1 Vdc

2 Signal

3 Ground

J10 (Water Level Sensor, Temperature,

Programs, Wash Speed)

Position Connect to

1 Vdc

2 Temperature Control

3 Ground

4 Vdc

5 Washing Speed Control

6 Ground

7 Vdc

8 Water Level Control

9 Ground

10 Vdc

11 Programs Control

12 Ground

J11 (Power, 120 Volts)

Position Connect to

1 Neutral

2 Not Used

3 Line

54

Loading...

Loading...