Page 1

DRYER

PSXH47EFWW

07-MAN-DR-02

Page 2

2

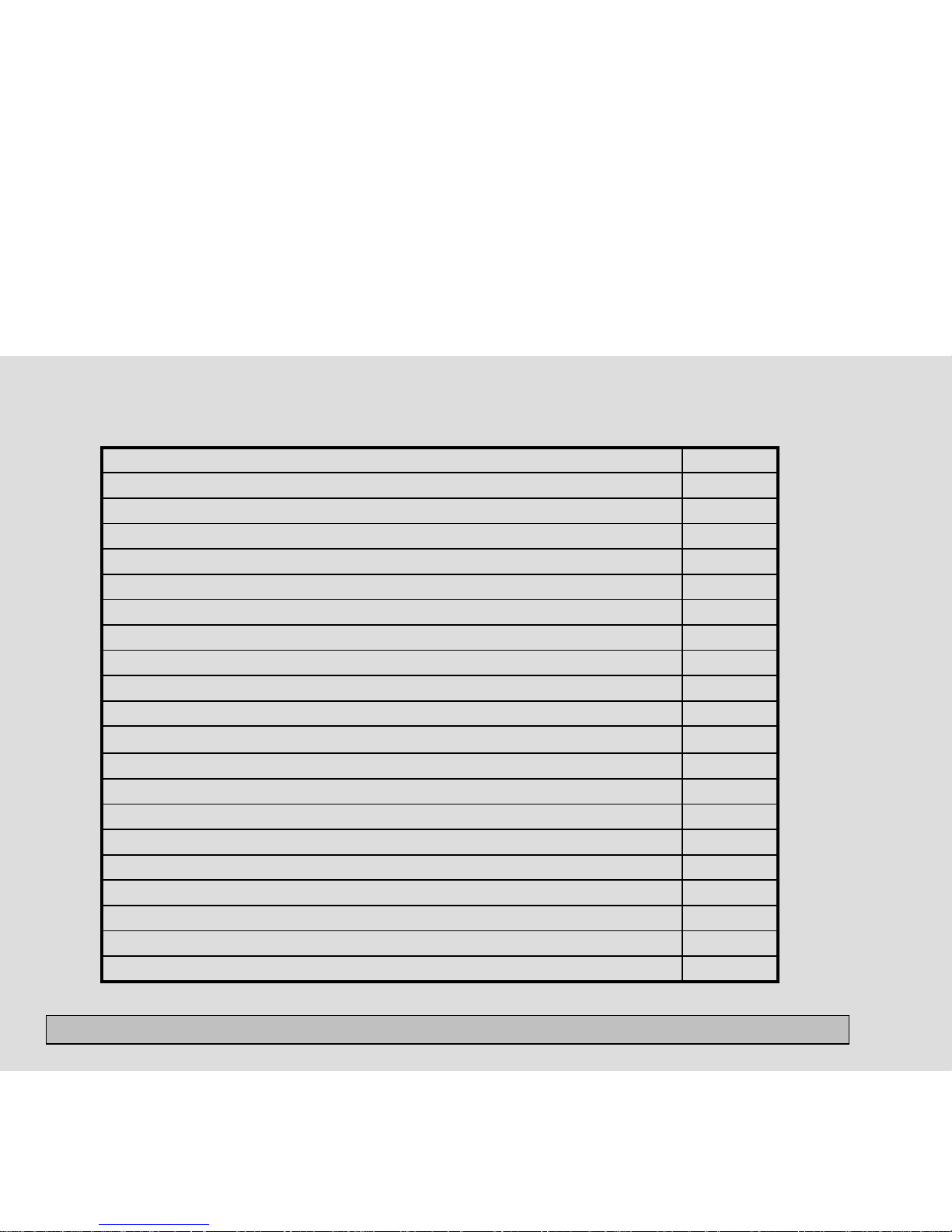

TABLE OF CONTENTS

Important Safety Notice

3

Specification

4, 5

Component Resistances

6

FunctionTest Sequence

7, 8, 9

Electronic Control Board Circuits

10

Drive Motor Circuit

11, 12

Temperature Sensing Circuit

13

Heating Circuit

14

Drying Time

15

Troubleshooting

16, 17, 18

Error Code Chart

19, 20

Troubleshooting Flow Charts

21, 22, 23, 24

Wiring Diagram

25

mabe CONFIDENTIAL AND PROPRIETARY INFORMATION-NOT FOR PUBLIC DISCLOSURE. JANUARY 2007

Page 3

3

IMPORTANT SAFETY NOTICE

The information in this presentation is intended for use by individuals

possessing adequate backgrounds of electrical, electronic, and

mechanical experience. Any attempt to repair a major appliance may

result in personal injury and property damage. The manufacturer or

seller cannot be responsible for the interpretation of this information,

nor can it assume any liability in connection with its use.

mabe CONFIDENTIAL AND PROPRIETARY INFORMATION-NOT FOR PUBLIC DISCLOSURE. JANUARY 2007

Page 4

4

SPECIFICATIONS

SPECIFICATIONS ELECTRIC MODELS

GAS MODELS

Electrical

Volts 120/208 or 120/240

Amps (circuit)

Motor wattage

Heat input (watts @ 208/240 VAC)

Heat input (BTU/Hr.)

Auto. Elec. Ignition

120/208 or 120/240

30

160-350 watts

3200/4500

---

---

120

15

160-350 watts

--20,000

Yes

Drum

Size (Cu. Ft.)

R.P.M.

5.7

48 - 54

5.7

48 - 54

Airflow CFM

200 200

DRUM TEMPERATURES (Max.

opening on 1st cycle)

High

Medium

Medium/Low

Low

138° - 190°

134° - 180°

130° - 170°

120° - 165°

145° - 190°

140° - 180°

130° - 170°

120° - 165°

mabe CONFIDENTIAL AND PROPRIETARY INFORMATION-NOT FOR PUBLIC DISCLOSURE. January 2007

Page 5

5

SPECIFICATIONS (cont.)

SPECIFICATIONS ELECTRIC MODELS

GAS MODELS

Dimensions (Inches)

Height (Stack Models)

Width

Depth

36”

27”

28.5”

36”

27”

28.5”

Vent Capability** 4-Way 3-Way

Port Opening (Sq. In.) 235 235

** Electric dryers can be vented four ways: through back, bottom, right or left side.

** Gas dryers can be vented three ways: through back, bottom or right side.

mabe CONFIDENTIAL AND PROPRIETARY INFORMATION-NOT FOR PUBLIC DISCLOSURE. January 2007

Page 6

6

COMPONENT RESISTANCES*

Component Resistances* Electric Models Gas Models

Drive motor (120 volts, 60 Hz, 1/4 h.p. 1725 rpm)

Motor Start Winding

Motor Run Winding

4.5 Ohms

3.8 Ohms

4.5 Ohms

3.8 Ohms

Heating Element 12.8 Ohms

Control Thermistor 50,000 Ohms 50,000 Ohms

Burner Assembly

Ignitor

Secondary Coil

Booster Coil

---

---

---

50 - 400 Ohms

1200 Ohms

1320 Ohms

* +/-10% @ 77°F

mabe CONFIDENTIAL AND PROPRIETARY INFORMATION-NOT FOR PUBLIC DISCLOSURE. January 2007

Page 7

7

FUNCTION TEST SEQUENCE

This is a functional test for the dryer. To activate this mode, perform the following steps:

1. Turn the cycle selector knob to the 12 o’clock position.

2. Press and hold the SELECT and PAUSE CANCEL buttons simultaneously for 6 seconds.

3. Immediately after, press and hold the PAUSE CANCEL and START buttons for 4 seconds.

The control will enter the test mode, the buzzer will sound 3 times and all LEDs will rapidly

flash.

After entering the test mode, the selector can now be rotated to select the following tests:

1 Turn Drive motor runs; heat source is on. DRYING LED is lit. Control thermistor

reading is displayed. **

2 Turns Drive motor runs; heat source is off. COOL DOWN LED is lit.

3 Turns Drive motor runs; heat source is off. DRYING and COOL DOWN LEDs are lit.

The MORE DRY LED should be ON. Opening the door (press in on door switch plunger) and

placing a finger on both moisture sensor bars at the same time will make the DAMP LED

come on.

mabe CONFIDENTIAL AND PROPRIETARY INFORMATION-NOT FOR PUBLIC DISCLOSURE. January 2007

Page 8

8

FUNCTION TEST SEQUENCE (cont.)

4 Turns Drive motor runs; heat source is off.

a. When the TEMPERATURE selector is rotated, there should be a key beep with each setting.

b. When the DRYNESS key is pressed, all the dryness level LEDs should light.

c. When the OPTIONS or SELECT key is pressed, all the options LEDs should light.

d. When the START key is pressed, all the cycle status LEDs should light.

e. When the PAUSE CANCEL key is pressed, all the cycle status LEDs should light.

5 Turns Drive motor runs; heat source is off. COOL DOWN LED is lit. Control

thermistor reading is displayed. **

mabe CONFIDENTIAL AND PROPRIETARY INFORMATION-NOT FOR PUBLIC DISCLOSURE. January 2007

Page 9

9

FUNCTION TEST SEQUENCE (cont.)

6 Turns Drive motor runs; heat source is on.

DRYING LED is lit. Control thermistor reading is displayed. **

To exit test mode, press and hold the SELECT and PAUSE CANCEL buttons

simultaneously for six seconds or disconnect power from dryer. Dryer will be reset for

regular operation.

**The dryness LEDs are used to determine the control thermistor reading. The number of

flashes of the bottom three LEDs will determine the value of the temperature as follows:

NORMAL = HUNDRED’S

LESS DRY = TEN’S

DAMP = ONE’S

Example: NORMAL flashes 1 time.

LESS DRY flashes 2 times.

DAMP flashes 6 times.

Temperature = 126 degrees.

mabe CONFIDENTIAL AND PROPRIETARY INFORMATION-NOT FOR PUBLIC DISCLOSURE. January 2007

Page 10

10

ELECTRONIC CONTROL BOARD CIRCUITS

Line L1 is applied to the control board at pin 1 of the eight pin plug and neutral on pin 2 of the

eight pin plug.

The control board receives inputs from:

• the selector switch, the temperature switch and the push buttons which program the control;

• the contact sensors which sense the amount of moisture in the clothes;

• the control thermistor which senses the temperature in the dryer.

The control board uses these inputs to control the drive motor circuit by opening and closing

the contacts of relay RL1 and the heater circuit by opening and closing the contacts of relay

RL2.

mabe CONFIDENTIAL AND PROPRIETARY INFORMATION-NOT FOR PUBLIC DISCLOSURE. January 2007

Page 11

11

DRIVE MOTOR CIRCUIT

When power is connected to the dryer, line L1 is applied through the thermal limiter (a

non-resettable fuse mounted on the rear wall of the dryer ) to the COM terminal of the door

switch.

When the door is closed the COM terminal is connected to

terminal NO of the door switch. From terminal NO power is

applied to terminal J4-2 of the motor relay RL1 on the

control board. When the control board closes relay RL1

power is applied through terminal J4-1 to terminal M4 of

the drive motor.

Terminal M4 is connected inside the motor to one side of the thermal overload. (The thermal

overload protects the motor from being damaged by overheating.) The other side of the

thermal overload is connected to one end of both the run winding and the start winding of the

drive motor. When the motor is not turning, the other end of the start winding is connected

internally to terminal M5 of the motor through the NC contact of the motor centrifugal switch.

The other end of the run winding is also connected internally to terminal M5, which is

connected to neutral.

mabe CONFIDENTIAL AND PROPRIETARY INFORMATION-NOT FOR PUBLIC DISCLOSURE. January 2007

Page 12

12

DRIVE MOTOR CIRCUIT (cont.)

When the motor is not turning, the start winding and the run winding are connected in

parallel. When the contacts of relay RL1 are closed, with the dryer door closed, line L1

and neutral voltage is applied across both the start and run windings of the drive

motor. With power applied to both the start and run windings, the motor starts to turn.

When the speed of the motor reaches about 80% of it’s normal run speed, the contacts

of the centrifugal switch remove power from the start winding thus removing the start

winding from the circuit.

The drive motor performs two tasks in the dryer. A pulley attached to one end of the

motor shaft uses a belt to drive the dryer drum. The blower wheel is attached to the

other end of the motor shaft to pull the air through the clothes and force it out the

exhaust vent.

mabe CONFIDENTIAL AND PROPRIETARY INFORMATION-NOT FOR PUBLIC DISCLOSURE. January 2007

Page 13

13

TEMPERATURE SENSING CIRCUIT

The temperature in the dryer is

controlled by the control thermistor and

the electronic control board. The

control thermistor, mounted in the

blower fan housing, is a negative

coefficient thermistor that decreases in

resistance as the temperature

increases.

The electronic control board reads the resistance of the thermistor and

converts it to temperature. It compares the reading from the thermistor to the

temperature setting for the cycle.

mabe CONFIDENTIAL AND PROPRIETARY INFORMATION-NOT FOR PUBLIC DISCLOSURE. January 2007

Page 14

14

HEATING CIRCUIT

The electronic control board applies power to the heating circuit through the contacts

of heater relay RL2. When the electronic control senses the temperature in the drum

is below the programmed temperature, it closes the contact of RL2. This applies line

L1 power to the high limit thermostat mounted on the heating element assembly.

The high limit thermostat is a safety device that prevents

the dryer from overheating if the contacts of the RL2 fail

closed. The contacts of the high limit thermostat, normally

closed, are set to open at a temperature above the preset

temperature specifications of the electronic control board.

From the output terminal of the high limit thermostat, line

L1 is connected to one side of the element and to pin 3 of

the eight pin plug. The other side of the heating element is connected to line L2

through the contacts of the second centrifugal switch in the drive motor. This switch

prevents power from being applied to the element if the motor is not running.

The connection to pin 3 allows the control to monitor the contacts of the high limit

thermostat and show an error code if the contacts open above a preset number of

times in a cycle.

mabe CONFIDENTIAL AND PROPRIETARY INFORMATION-NOT FOR PUBLIC DISCLOSURE. January 2007

Page 15

15

DRYING TIME

The amount of drying time is determined in one of two ways. A fixed amount of drying

time is determined by turning the SELECTOR knob to one of the fixed drying times.

The AUTO DRY cycles a variable amount of time determined by the size of the load,

the amount of moisture in the clothes, and the dryness setting selected. In the AUTO

DRY cycle, the electronic control reads the capacitance between the two sensor bars

located in the vent cover.

When wet clothes are placed in the dryer, the clothes

touch the sensor bars and the moisture lowers the

capacitance between the bars. As the dryer runs, moisture

is removed from the clothes and the capacitance between

the bars increases.

When the increase in capacitance satisfies the electronic control, the cycle status

changes from AUTO DRY to COOL DOWN and the load is tumbled without heat.

At the end of cycle, the electronic control will turn the dryer off and the end-of-cycle

signal sounds.

mabe CONFIDENTIAL AND PROPRIETARY INFORMATION-NOT FOR PUBLIC DISCLOSURE. January 2007

Page 16

16

TROUBLESHOOTING

Service Error Codes

The electronic controls of the dryer have self diagnostics codes built in that cover

most product failures. When a failure occurs, the dryer stops or pauses.

The control will beep and flash the STATUS lights to tell the customer that a failure

has occurred. To stop the flashing and beeping, touch the PAUSE CANCEL button.

The error code remains stored in the control.

To view the error codes:

1. Rotate the cycle selector knob to the 3 o’clock position.

2. Press and hold the SELECT and PAUSE CANCEL buttons simultaneously for 6

seconds.

3. Immediately after, press and hold the START and Pause Cancel buttons

simultaneously for 4 seconds.

4. Rotate the cycle selector knob to the 2 o’clock position.

mabe CONFIDENTIAL AND PROPRIETARY INFORMATION-NOT FOR PUBLIC DISCLOSURE. January 2007

Page 17

17

TROUBLESHOOTING (cont.)

The four indicator lights of DRYING, COOL DOWN, EXTRA CARE and CLEAN LINT

FILTER will flash the number of times for the first digit of the code after the E, and the

START

indicator light will flash the number of times fo r the second digit after the E. The code is

obtained by counting the number of times the lights flash. Example E24: the four

indicator lights would flash twice indicating the 2 and the START indicator light will flash

four times indicating the 4. The four indicator lights and the START indicator light will

start flashing at the same time. The control will then pause for 2 seconds, then repeat

the code.

Troubleshoot the problem by using the chart on the next pages.

The error codes remain in memory until cleared from the control.

To move to the next code, press the OPTIONS button.

To clear the code, press the SELECT button.

To exit this mode, simultaneously press and hold the SELECT and PAUSE CANCEL

buttons for 6 seconds.

mabe CONFIDENTIAL AND PROPRIETARY INFORMATION-NOT FOR PUBLIC DISCLOSURE. January 2007

Page 18

18

TROUBLESHOOTING (cont.)

Note: A letter appearing in the code stands for a number higher than nine.

A = 10

B = 11

C = 12

D = 13

E = 14

F = 15

Example Code E4A: the first digit would be 4 and the second digit would be 10. If this

code would appear on a dryer, the four indicator lights would blink four times and the

START indicator light would blink ten times.

mabe CONFIDENTIAL AND PROPRIETARY INFORMATION-NOT FOR PUBLIC DISCLOSURE. January 2007

Page 19

19

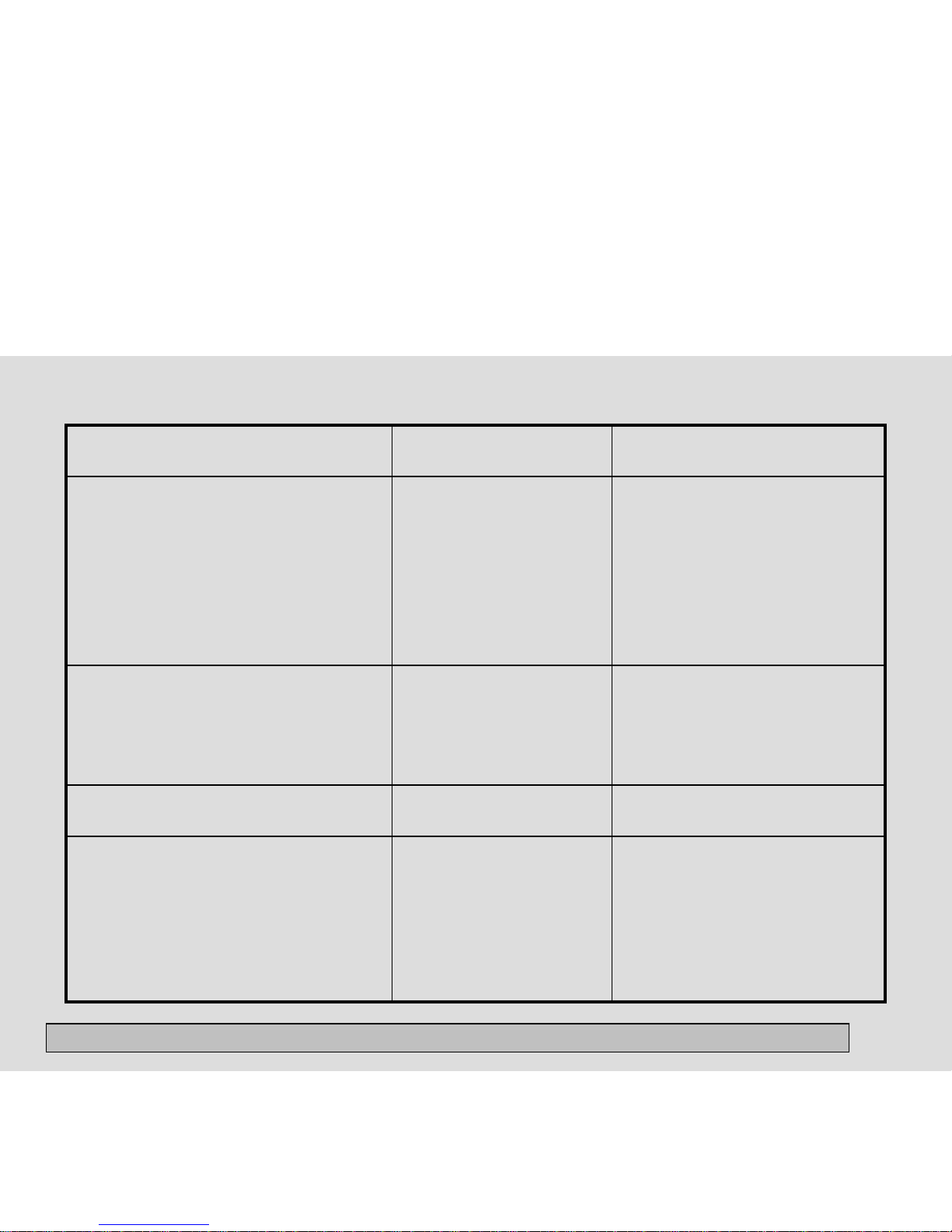

ERROR CODE CHART

Error code Fault condition Action

E 10

E 11

E 12

E 24

E 25

Communication failure – EEPROM

Communication failure - Problem with

communication or memory did not check,

one has become corrupted

Communication failure - Memory

Shorted control thermistor

Open control thermistor

Clear code, exit mode and start dryer. If

the error persists, replace the control board.

Clear code, exit mode and start dryer. If

the error persists, replace the control board.

Clear code, exit mode and start dryer. If

the error persists, replace the control board.

Remove wires from the control thermistor.

Measure resistance of the thermistor. If the

reading is not 50K (+/-10%), replace

thermistor. If the reading is within 50K

(+/-10%) check wiring between thermistor

and electronic control. If good, replace

electronic control.

Remove wires from the control thermistor.

Measure resistance of the th ermistor. If

the reading is not 50K (+/-10%), replace

thermistor. If the reading is within 50K

(+/-10%) check wiring between thermistor

and electronic control. If good, replace

electronic control.

mabe CONFIDENTIAL AND PROPRIETARY INFORMATION-NOT FOR PUBLIC DISCLOSURE. January 2007

Page 20

20

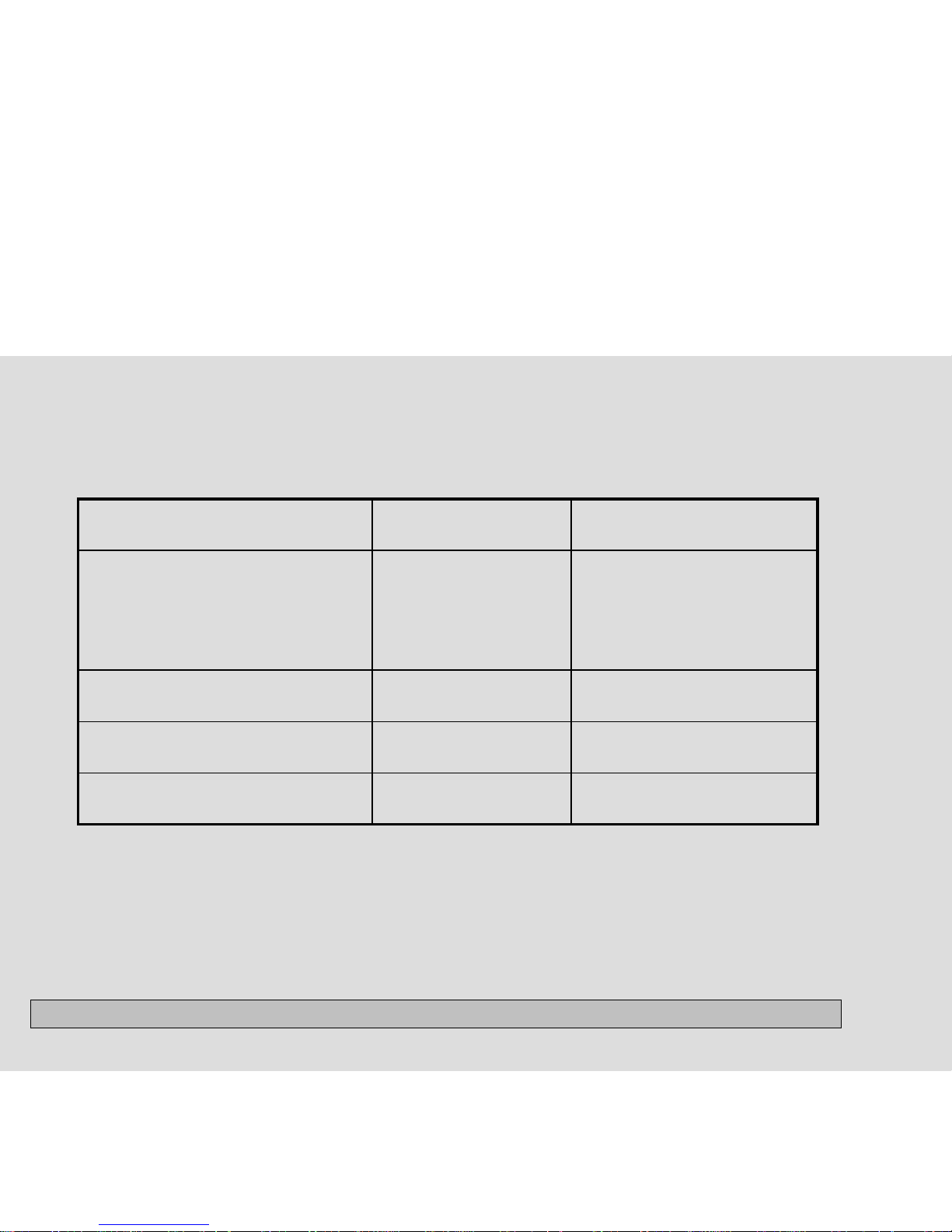

ERROR CODE CHART (cont.)

Error code Fault condition Action

E4A

E 5B

E 68

E 8C

E AF

The drying time has exceeded program

time for that cycle.

No heat.

One of the keys (buttons)is stuck closed (active).

High limit t hermostat has tripped too many

times in a certain amount of time.

Microcontroller has been reset

by internal Watchdog timer.

Press PAUSE CANCEL and SELECT buttons for

6 seconds to exit test mode. Position cycle

selector to NORMAL, temperature selector to HIGH

HEAT, and touch START. Check for anything that

would extend dry times, such as no heat, restricted

vent, blower fan blade broken or loose, dryer installed

in closet with solid door, or bad connection in moisture

sensor bar circuit or dirty bars. If dryer operates

normally but code returns, replace electronic control.

Refer to flow chart “Drive motor runs but dryer does

not heat.”

Enter function test mode and perform key

(button) test to determine which button is at

fault. Carefully free the key and perform the test

again. If button is free but the key stuck code

still exists, replace electronic control.

Check for blocked lint filter, blocked

exhaust, air leaks around air duct, broken

blower fan blades, worn or loose drum seals,

dryer installed in closet with solid doors or

door seal not correctly seated.

Clear code, exit mode and start dryer. If

problem persists, replace electronic control.

mabe CONFIDENTIAL AND PROPRIETARY INFORMATION-NOT FOR PUBLIC DISCLOSURE. January 2007

Page 21

21

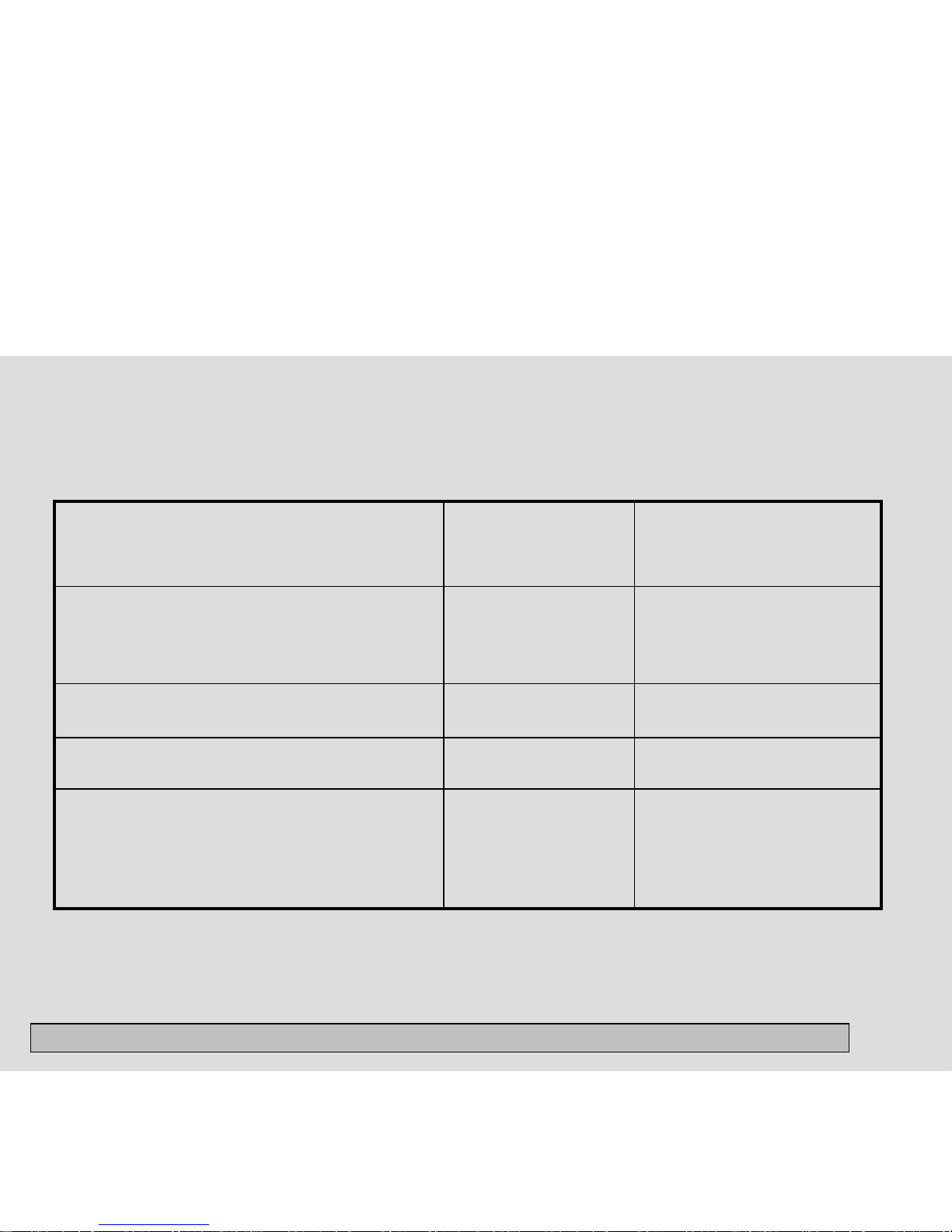

TROUBLESHOOTING FLOW CHARTS

Electric dryer completely inoperative. Note: Always check wiring to the components.

Note: If a fault code is displayed, the dryer will not operate.

Defective door

switch.

Defective thermal limiter.

NO

YES

YES

Refer to error

code chart.

Does the control beep or

the LED flash when the

START button is pushed?

Dryer completely

inoperative.

Measure the voltage drop

between the red wire on the

thermal limiter and neutral.

Measure the voltage drop

between pins 1 & 2 of J-4.

0

120VAC

0

0

Measure the voltage drop

between the orange wire

on the thermal limiter and

neutral.

NO

Is an error code displayed?

Defective household

power supply or

broken wire between

dryer terminal block

and thermal limiter.

120VAC

Defective

control board.

Measure the voltage drop

between pins 1 & 2 of the eight

pin plug of the wire harness to

the control board.

Defective control

board.

120VAC

0

Broken wire between

thermal limiter and the

control board.

120VAC

mabe CONFIDENTIAL AND PROPRIETARY INFORMATION-NOT FOR PUBLIC DISCLOSURE. January 2007

Page 22

22

Longer than normal drying times. (Possible E 4A)

Longer than normal

drying times.

Are the clothes wetter than normal

when removed from the washer?

Yes

Check washer

spin cycle.

No

Is the vent

restricted?

Yes

Clear vent.

No

Is the blower motor running

at full speed?

No

Replace motor.

Yes

Is the dryer level so the clothes

touch the sensor bars?

Is the dryer heating properly?

Yes

Level dryer.

No Yes

Review proper

programming of

the control with

the customer.

No

Refer to “Drive motor runs but dryer does not heat.”

flow chart.

mabe CONFIDENTIAL AND PROPRIETARY INFORMATION-NOT FOR PUBLIC DISCLOSURE. January 2007

Page 23

23

Clothes not dry in auto cycle.

Tested good.

Failed test.

No

Yes

Checks good. Checks bad.

Clothes not dry in the

auto cycle.

Using the function test, do the 3

o’clock test. (Refer to page 4.)

Check that the dryer is

level or slightly tipped

forward.

Are the sensor bars clean?

Clean bars.

Check the connections at the

bars and the wiring between the

control and the bars.

Replace the

electronic control.

Tighten the connections

or

replace the wire.

mabe CONFIDENTIAL AND PROPRIETARY INFORMATION-NOT FOR PUBLIC DISCLOSURE. January 2007

Page 24

24

Drive motor runs but dryer does not heat.

0

50,000 Ohms +/-10%

Drive motor runs but dryer not heat.

Check the resistance of the control thermistor at

room temperature.

Defective thermistor.

Program the dryer for a NORMAL Cycle with HIGH Temp and

touch START. Measure the voltage drop

between the two terminals of RL2.

Defective electronic

control board.

Measure the voltage drop between the two terminals of the

high limit thermostat.

Defective high

limit thermostat.

Remove power from the dryer and disconnect the black wire

from RL2. Restart the dryer and measure the voltage drop

between red wire on RL2 and neutral.

Open wire from

terminal block.

Remove power from the dryer, reconnect the black wire from RL2

and disconnect the plug from the drive motor. Restart the dryer and

measure the voltage drop between yellow and white wire in the plug.

Defective motor.

Defective

heating element.

More or less than

50,000 Ohms +/-10%.

240 VAC

0

240 VAC

0

120 VAC

120 VAC

0

mabe CONFIDENTIAL AND PROPRIETARY INFORMATION-NOT FOR PUBLIC DISCLOSURE. January 2007

Page 25

25

mabe CONFIDENTIAL AND PROPRIETARY INFORMATION-NOT FOR PUBLIC DISCLOSURE. January 2007

Loading...

Loading...