Page 1

Training services to Mabe Consumer home

Service Manual

MODEL SERIES:

PSS and GSS

21, 23, 25, 27 and 29 cubic feet

PUB # 31-9072-SP 01/0

Page 2

IMPORTANT SECURITY NOTICE

The information in this service guide is intended to be used by

persons having adequate background with electrical, electronic and

mechanical experience. Any attempt to repair a large device can

result in personal injury and damage to the property. Manufacturer

or seller cannot be responsible for the interpretation of this

information, nor can take any duty in relationship with its use.

CARE

To prevent personal injury, disconnect power before servicing

this product. If electric power for purposes of diagnosis or test is

required, disconnect power immediately after making the

necessary check-ups.

RECONNECT ALL DEVICES TO LAND

If you wire them, screws, belts, fasteners, or nuts, the grounding,

used to complete a pass to earth are removed for service, should

be returned to his position original and adjusted properly.

Entrenamiento de Servicios a Domicilio del Consumidor de GE

Guía Técnica de Servicio

Copyright © 2001

Todos los derechos reservados. Esta guía de servicio no puede ser reproducida total o

parcialmente en ninguna forma, sin el permiso escrito de la General Electric Company.

!

Page 3

- 1 -

INDEX

Introduction

Installation

Specifications

Nomenclature

Operation characteristics

General views of localization

Mechanical disassembly

Diagnostics

Views of localization of components

and connector

Diagrams

Catalogs illustrated parts

. . . . . . . . . . . . . . . . . . . . . . .

2

. . . . . . . . . . . . . . . . . . . . . . .

3

. . . . . . . . . . . . . . . . . . . . . . .

4

. . . . . . . . . . . . . . . . . . . . . . .

5

. . . . . . . . . . . . . . . . . . . . . . .

6

. . . . . . . . . . . . . . . . . . . . . . .

13

. . . . . . . . . . . . . . . . . . . . . . .

15

. . . . . . . . . . . . . . . . . . . . . . .

29

. . . . . . . . . . . . . . . . . . . . . . .

52

. . . . . . . . . . . . . . . . . . . . . . .

59

. . . . . . . . . . . . . . . . . . . . . . .

60

Page 4

- 2 -

Introduction

2001 SxS Energy models are being introduced in response to

the requirements of more energy-efficient refrigerators by mid2001, along with improvements in features and operation. The

primary differences in this cooling system are the defrosting

adaptable system (watch Pub # 31-9062), control board,

software, and systems control that operate regardless in the

sections of the cooler and freezer. The new high-efficiency

control system has the ability of cycling components and

adjusting the fan speeds as required, to maintain the

temperature adjustment ranges in the cooler and freezer

sections. The feedback systems are digital inputs and relay

outputs. The sensors (thermistors) are used to measure the

temperature with communication to the main board, which

controls the components of the unity.

The refrigerator has key controls to give inputs to the

microprocessor. The cooler and freezer controls are of the

temperature control point type and have settings of 0-9 with 9

being the coldest possible temperature. The new NONCLEAN condenser is repairable from the back and is designed

to prevent the customer from having to

clean the condenser in conditional normal use.

The sealed operation system and the compressor are working

in the same way as the previous models, with some minor

changes.

The collateral models Profile Performance and Arctica are

the affected models. These models are available with cold

water through the door and ice dispenser, and a water filter

detail that can be filled. In models that require an ice

machine, the new electronic ice machine model (see Pub. #

31.09063) has been or can be installed.

The freezer has built-in grills, a spill-proof grill that pulls out,

an Easy Space grill, deep door grills, based on the model. The

chiller section has a Baking Soda holder, a fruit and vegetable

drawer, drawer dividers, and a moisture-adjustable drawer

and a convertible meat drawer.

The new high-efficiency refrigerator is a combination of the

most efficient refrigeration systems and the most desirable

customer details available.

Page 5

- 3 -

METODO

PREFERIDO

ASEGURESE QUE EXISTE

ADECUADA PUESTA A

TIERRA ANTES DE USAR

ETODO TEMPORAL

(En Canadá no se permiten

daptadores de enchufe)

ASEGURE ADECUADA

PUESTA A TIERRA Y

CONEXION FIRME

ANTES DE USAR

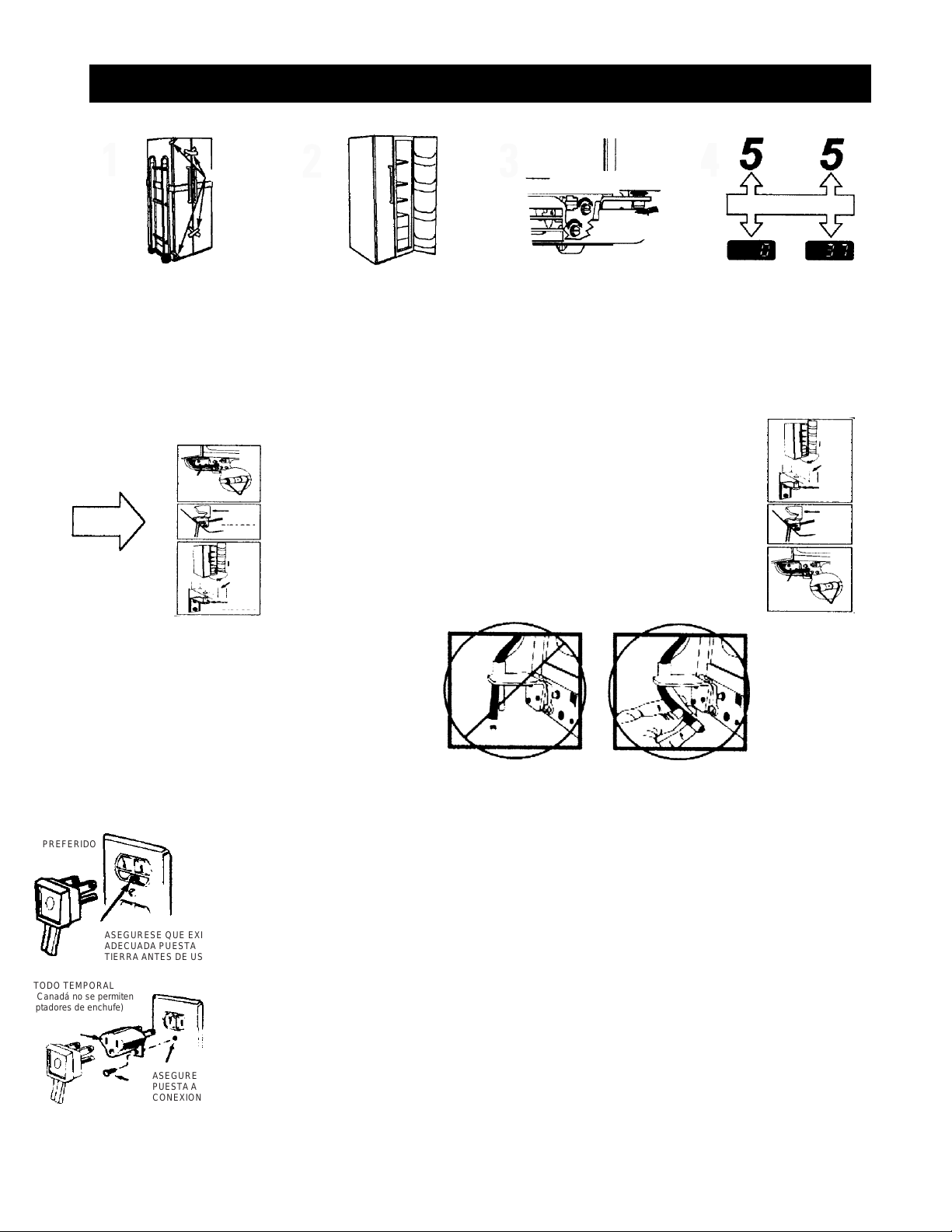

Installation

Tape

Use a cushioned hand truck to protect the

finished refrigerator. LEAVE

THE TAPE IN THE DOORS until it is in its

final location. LOAD ONLY FROM THE

SIDE. Avoid tighten the belt a lot to avoid

damage of the doors

REMOVE ALL THE PROTECTOR

TAPE FROM THE SURFACE, then

move the unit to its position. If the inlet

is less than 38" wide, remove the doors

before installation and reinstall them

according to the pro- bottom down.

Connect the water lines and the electric

cord. ADJUST THE FRONT ROLLS so

that the refrigerator is firm on the floor

and the doors close easily. MAKE SURE

THE DOORS ARE COUPLES ABOVE.

TEMPERATURE CONTROLS ARE

PRESCRIBED IN THE FACTORY

FOR RE-COMBUSED ADJUSTMENT

REMOVING THE DOORS

The doors must be in closed position.

Near the bottom hinge on the freezer side, tighten

the collar on the water line and pull the tubing from

the coupling. Also, disconnect the wiring from the

wire. Pull the water line and wiring through the

bottom rail.

Remove the covers of the upper hinges to access

the hinges. Remove the hinges using a Torx T-20.

Carefully turn the door by 90 °. Guiding the water

line and wiring the fence, lift the door straight up.

Avoid loading the lower hinges sideways. Place the

doors on a protected surface. Avoid piercing the

water pipe and wiring the wiring in the bottom of the

door.

With the doors open at 90 °, place them on the lower

hinge. Carefully turn the doors to the closed position.

Avoid loading the lower hinges sideways.

Reinstall the upper hinges and tighten the screws

firmly. Reinstall the hinge cover. If the doors are not

level, adjust the lower right hinges with a 7/16 open

end wrench.

Insert the water pipe back into the coupler. It is fully

connected when the mark on the pipe is no longer

visible. Reconnect the wiring of the wiring. Open the

water supply.

CABLEADO

ALAMB.

PUERTA

SUJET.

BISAGRA

CUBIERTA

BISAGRA

REBORD

CABL.

REBORDES

CUBIERTA

PUERTA

SUJT.

AJUSTE ALTURA

RODILLO

AJUSTE ALTURA PUERTA

CONTROLS ADJUSTMENTS

REINSTALLING THE DOORS

• HEET WAX IS RECOMMENDED TO REMOVE TAPE WASTE AND HAND FINGER FROM THE REFRIGERATOR OUTSIDE.

• REMOVE ALL TAPE AND PACKAGING MATERIAL FROM INSIDE REFRIGERATOR. DO NOT REMOVE THE SERIAL PLATE.

• REMOVE THE PROTECTIVE FILM ON THE TEMPERATURE CONTROL PANEL.

IMPORTANT: PLEASE READ CAREFULLY

FOR PERSONAL SAFETY, THIS APPLIANCE MUST BE ADEQUATELY GROUNDED

The power cord of this appliance is equipped with a three-prong (grounded) connector that fits a three-pronged (grounded)

standard receiver to minimize the risk of an electrical hazard to this appliance. The customer should check the wall receiver and

the circuit by a qualified electrician to make sure that the appliance is properly grounded.

Where a standard two-pronged wall receiver is located, it is the customer's responsibility and personal obligation to exchange it

for a properly grounded three-prong wall receptacle.

NDER NO CIRCUMSTANCES, CUT OR REMOVE THE THIRD POINT OF THE (EARTH) CONNECTOR FROM THE ENERGY

CORD. SITUATIONS OF USE IN WHICH THE ELECTRICAL CORD OF THE APPLIANCE WILL BE DISCONNECTED

INFRECTIVELY

Due to potential safety hazards under certain conditions, we strongly recommend against the use of an adapter plug. Without

em However, if you always choose to use an adapter where local codes permit, a TEMPORARY CONNECTION can be made to a

properly grounded two-prong wall receptacle approved by the UL adapter list which is available in most of the hardware stores.

The largest hole in the adapter must be aligned to give an appropriate polarity in the power cord connection.

to CAUTION: Connecting the terminal of the grounding adapter to the screw cover of the wall receiver does not ground

the device, unless the cover of the screw is made of metal, and is not insulated and the receiver of the wall is grounded through

the wiring of the house. The customer must check the circuit by a qualified electrician to make sure the receiver is properly

grounded. When disconnecting the power cord from the adapter, always hold the adapter with one hand. If you do not do this,

the terminal of the ground adapter is very safe to break with repeated use. If this happens, DO NOT use the appliance until a

ground connection has beenestablished

SITUATIONS OF USE IN WHICH THE ELECTRICAL CORD OF THE APPLIANCE WILL BE DISCONNECTED FREQUENTLY

Do not use an adapter plug in these situations because frequently disconnecting the power cord places undue stress on the

adapter and leads to eventual failure of the adapter terminal to ground. The customer must change the two-pronged receiver

on the wall for a receiver

Three-prong (grounded) by a qualified electrician before using the appliance.

Page 6

ELECTRIC SPECIFICATIONS

Temperature control………………………

Relay……………………………..…….....

Overload .................................................

Capacitor Func. (12 uF) .........................

Thermostat Overtemperature ................... Wiring

Wiring & Thermostat heat defrost .....

Heater Discong. & Clamp ..........

Fan Motor Condenser .....................

Fan Evaporator Engine ........................

Main Board ..................... ...................

Dispenser Board ..................................

Thermistor (EV) ............................................

Thermistor (FZ) ............................................

Thermistor (FF) ............................................

Thermistor (FF) ............................................

Fans Fan Motor ........................................

Shock absorber……………………………

wr55x10023

wr07x10031

wr08x10025

wr62x10079

wr50x10015

wr23x10142

wr51x10030

wr60x10042

wr60x10043

wr55x10024

wr55x10029

wr55x10025

wr55x10026

wr55x10027

wr55x10028

wr60x10051

Specifications

DISCONNECT THE POWER CORD BEFORE

SERVICING. -IMPORTANT- CONNECT ALL

EARTHED APPLIANCES AGAIN

All parts of this device capable of conducting electrical

current are grounded. If the wires, bolts, fasteners,

fasteners, nuts and ground washers used to complete a

grounding are removed for service, they must be returned

to their original position and be properly tightened.

IMPORTANT SAFETY NOTICE

This information is intended to be used by people

who have an adequate background in electrical,

electronic and mechanical experience. Any

attempt to repair an appliance can result in

personal injury or property damage. The

manufacturer or seller cannot be responsible for

the interpretation of this information, nor can it

assume any responsibility in relation to its use.

ELECTRIC SPECIFICATIONS

Temperature Control (Position 5) ................

Defrosting Control ........................... …….

Thermostat Overtemperature ...................

Defrosting Thermistor………....................

Electric Capacity: 115V, AC 60 Hz .........

Maximum Current Leak .................. ……

Maximum Resistance to Earth ................

Energy consumption……………………..

OPERATION WITHOUT LOAD

MID / MID Control Position

and Environment of:

Refrigerator, ° F .................................

Freezer, ° F ................................. ….

Func. Time,% ....................................

REFRIGERATION SYSTEM

Refrigerant charge (R134a) ..................

Compressor……………………………...

Minimum Compressor Capacity ............

Minimum Equalized Pressure

@ 70 ° F .................................... ………

@ 90 ° F .................................................

7-(-11)°F

60 hrs @ 35 min

without door openings

140-110°F

65°F

11.6 Amp

0.50 mA.

0.14 Ohms

KWH/month

70°F 90°F

34-40 34-40

(-3) 3 (-3) 3

<45% <70%

4.75 onzas

690 BTU/hr

22 pulgadas

48 PSIG

60 PSIG

Page 7

VOLUME

23/25/27/29

NOMENCLATURE

Profile Models 2001

P S S 2 5 I E M A F W W

Location of

the sheet

with

technical

information

(Remove the grid assembly

stuck under the cabinet)

- 5 -

INTERIOR/GRILL

D = Wire Deluxe I =

Vidrio Deluxe

J = Glass of first class

K = Glass against overflow

M = Glass against overflow/

Slides to the outside

Q = Derivative Exposure S =

Stainless Steel Doors U = ABV

Derivative V = Derivative

SEARS W = Derivative HPS

(Contract) X = Derivative

REGIONAL

PROF/ENERGY

S = ESTANDARD

T = TROPICAL

G = GLOBAL

BRAND/PRODUCT

G = GE

H = HOTPOINT

P = PROFILE (GE)

E = ETERNA (GE)

R = RCA

S = SELECT (GE)

ICE MACHINE / EXTERIOR

B = Not ready for dispenser / ice maker

D = Ice cubes / Water

E = Ice cubes and chopped / Water

F = Filter / ice cubes and chopped 6

months G = Filter / ice cubes and

chopped 1 year

i = Filter / Indicator & C / CW online

EXTERIOR COLOR

WW = White / White

AA = Almond / Almond

BB = Black / Black CC

= Bisque / Bisque WH

= White / Black BS =

Black / Stainless Steel

TYPE OF DOOR

F = Plane door (Line-

G) (ESPACIO = Door

Plane (S- & Línea-T)

K = Door of adjustment

YEAR MODEL

M = 2001

CONFIGURATION

S = Ref Door Col

DESIGN OF

NOMENCLATURE

A = INITIAL DESIGN

B = 1ST REVIEW.

Page 8

Operation characteristics

INDEX

Independent Operation of the Cooler / Freezer

............................................... 7

Normal Operation Characteristics, but Different

of Previous Models ........................................................................................................ 7

Features Abnormal Operation (Incorrect Operation) ..................................................... 7

Adaptive Defrosting ....................................................................................................... 7

Cooling Operation (Adaptive Defrosting) ....................................................................... 8

Pre-Cooling Operation (Adaptive Defrosting)

Operation Heater Defrosting (Adaptive Disconnect)

............................... 8

.............................. 8

Rest Period (Adaptive Defrosting) ................................................................................. 8

Post Rest (Adaptive Defrosting) .................................................................................... 8

Liner Protection Mode ................................................................................................... 8

Electronic Ice Machine .................................................................................................. 9

Dispenser functions ....................................................................................................... 9

Fast Ice ....................................................................................................................... 9

Door Alarm

Dispenser Light

............................................................................................... 9

.............................................................................................. 9

Closing the Dispenser .................................................................................................. 9

Filters ............................................................................................................................. 10

Hinge and Door Closing System ................................................................................... 10

Air Flow (Cabinet Interior) ............................................................................................. 10

Condenser "JELLY ROLL"

Main Control Board

.................................................................................. 11

.................................................................................. 12

Page 9

Independent Operation of the Refrigerator / Freezer

In previous models, the chiller and freezer compartment

components worked at the same time. When the cooler

compartment asked for cold air, the components of the

freezer compartment worked with the components of the

cooler compartment. This is called operation

no Independent.

In this model, the components of the compartment of

the cooler they can operate without the operation

of the components of the freezer compartment. This is called

independent operation.

Normal Operating Characteristics that may

Occur, but Different from Previous Models

• The ice machine's drill rotates in the direction of the

hands of the clock.

• The evaporator fan operates without the compressor or

condenser fan. Refrigerator fan is switched on.

• Post Rest (adaptive defrost), compressor fan and condenser

on with the evaporator fan off after the defrost cycle.

• Lining Protection Mode, fans come on when doors open

for 3 minutes.

• When the doors open, the fans turn off.

• There is no air flow to the cooler compartment when the

evaporator fan is on.

• The evaporator and compressor fan can operate

continuously for 8 hours.

• The fans change speeds, different levels of sound can be

noticed when this happens.

• Quick Ice Mode, the evaporator fan works for 48 hours

without stopping.

• Response time for drastic temperature changes is 2 to 10

minutes. The main control board will only respond to 8

degrees of temperature change per minute as determined by

the change of resistance of thesensor.

- 7 -

Abnormal Operation Characteristics (Incorrect

Operation)

• Cooler fan on and evaporator fan off.

• Evaporator fan on, cooler fan and compressor off,

and damper closed.

• Quick changes in fan speed, the fan takes at least 1

minute to change speeds.

• The compressor running without the condenser

fan. The compressor and condenser

fan forever must of functional to the same weather.

• The condenser fan running without the

compressor. The compressor and condenser fan

should always work at the same time.

Adaptive Defrosting

Adaptive defrosting can be described as a defrosting system

that adapts to the environment around the refrigerator and the

use of the home.

Unlike traditional defrosting systems that use

electromechanical timers with a

Fixed defrost cycle time, adaptive defrost uses intelligent

electronic control to determine when the defrosting cycle is

necessary. In order to achieve the correct defrosting time

cycle, the main control board monitors the following cooler

operations:

• Length of time when the refrigerator doors were

opened since the last defrost cycle.

• Length of time that the compressor has operated

since the last defrost cycle.

• Amount of time that the defrost heaters were on since

the last cycle of defrosting.

• Adaptive defrosting is divided into separate

cycles. These operations are:

• Cooling operation Pre-cooling

operation

• Defrosting Heater Operation Rest Period

• Post Break

See Pub # 31-9062 for more information on

Defrosting Adaptable

Page 10

Cooling Operation (Defrosting Adaptable)

During the cooling operation, the main control board

monitors door openings (cooler and freezer doors) and

operating time of the compressor. The length of time

between consecutive defrosts is reduced by each open

door. If the doors are not opened, the compressor will

work up to 60 hours between defrosting. If the doors open

frequently and / or for long periods, the operating time of

the compressor between defrosting will be reduced to as

little as 8 hours

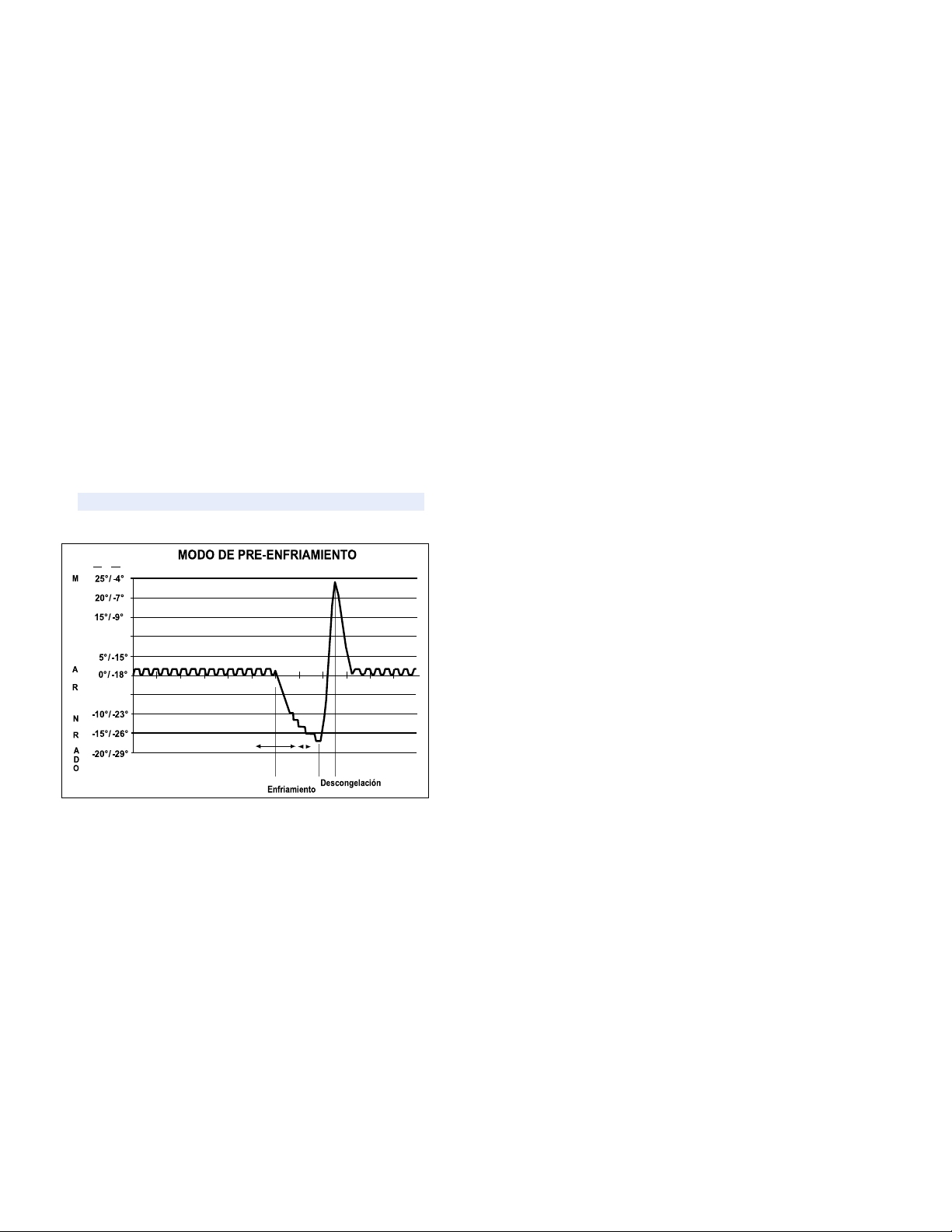

Pre-Cooling Operation (Defrosting

Adaptable)

When the main control board determines that the

defrosting is necessary, the main control board will force

the refrigerator to a continuous mode cooling (precooling). During pre-cooling, the freezer temperature can

be carried down the set point temperature of the control

panel screen. However, the temperature of the cooler will

be regulated by the shock absorber Pre-cooling and will

last 2 hours if it is not interrupted by some open door. If

after 8 hours, the unit could not complete a pre-cooling

without interrupting, the defrost cycle will continue.

Operation of the defrost heater

After 2 hours of pre-cooling operation or 8 hours of

interrupted pre-cooling attempts, the main control board turns

off the compressor, condenser fan and the evaporator

fan. The main control board then energizes the defrost relay,

which completes the Defrost Cycle.

A thermostat-defrosting (switch) protects the defrosting

system. The thermostat opens when the evaporator

temperature rises to 140 ° Fahrenheit and closes when the

evaporator temperature drops to 110 degrees Fahrenheit.

Rest Period (Adaptive Defrosting)

After the main control board has completed the operation of the

defrosting heater, there is a resting period of 5 minutes. During

this period, the compressor, condenser fan and evaporator fan

they stay off. Frost melting that remains of the evaporator will

continue to fall and drain to that the evaporator to be completely

clean of any humidity before the cooling operation. After 5

minutes of resting period, the unit enters a post break.

Post Rest (Adaptive Defrosting)

The post-rest period is designed to cool the evaporator before

circulating the air inside the refrigerator. This prevents any

residual heat in the evaporator from being distributed in the

freezer. During this period, the compressor and the condenser

fan are on, but all the interior fans are off and the shock

absorber is turned off. Post-rest times vary with the different

Models. However, there is a maximum of 5-minutes

of resting time.

Liner Protection Mode

The liner protection mode will be activated if any of the doors

have been opened for 3 minutes. This mode will start the fans

and will close the damper. This mode is controlled by 2

timers. Timer # 1 monitors door open time. A 3-minute open

count. The door will start when the door is opened. If it passes

3 minutes before the door is closed, the protection mode of

lining will be activated. Once the door is closed, timer # 1 is

reset and the liner protection mode passes to reserve. In

reserve, normal fan and damper operations begin and timer #

2 begins a count of 3 closed door minutes. If you spend 3

minutes without opening the door, the liner protection mode will

be completely deactivated. If a door is opened within the timer

#2 coun 2 closed door, the remaining time in door counting

closed the count of timer # 1 of open door will be deducted.

During the defrosting operation, the main control board monitors

the evaporator temperature using inputs to the evaporator

thermistor. The thermistor will usually end the operation of the

thermistor heater in less than 20 minutes. The typical thawing

time is 20-30 minutes.

- 8 -

Pre-

-5° / -21°

08:00 09:00 10:00 11:00 12:00 13:00 14:00 15:00 16:00 17:00 18:00

10° / -12°

F° / C°

T

E

P

E

R

A

T

U

R

A

S

I

E

E

F

I

R

Page 11

Electronic Ice Machine

This refrigerator is equipped with an Ice Machine

Electronics. For more information, see Pub # 31-

9063.

Dispenser functions

The main control board controls the functions of

water, crushed ice and cubed ice. To select a

function, press the appropriate key on the

dispenser. The led will light to identify the selection.

To dispense the chosen option, press the dispenser

holder located at the entrance of the dispenser. The

set of selenoid and link will open the ice firing gate

to dispense the ice. If cube ice is selected, the

solenoid deviation of crushed ice will allow cube ice

to be deviate from the ice crusher. The ice trigger

door must stay open for 5 seconds after it has

stopped the dispensation. After a delay of 5

seconds, the set of selenoid and link will close the

ice trigger door.

The dispenser light will turn on automatically when

the dispenser holder is depressed and will gradually

disappear 5 seconds after it was released. The

dispenser selection is recorded on the main control

board. In the case of a power failure, the last

selected function will be restored.

Fast Ice

The quick ice detail is available on some models.

This detail causes the evaporator fan to operate

without stopping for 48 hours (the fan can operate at

high or low speed). This allows a maximum output

of the ice machine.

The QUICK ICE key starts the quick ice mode in the

refrigerator. By pressing the QUICK ICE key the

LED is unlimited and adjusts the evaporator fan

operating at medium speed (unless the main control

board selects high speed) for a period of 48

hours. The evaporator fan is finished during

thawing, rest, post rest and doors opening.

The selection of quick ice is stored in the principal

control panel. The function will be restored in the

case of lack of energy.

Door alarm

The DOOR ALARM key is used to turn on and off the alarm

detail of the door. If the detail is on, the DOOR ALARM LED

will flash when the door is opened. If the door opens for

more than 2 minutes, the door alarm will sound. The alarm

can be stopped by pressing the DOOR ALARM key or

closing the door. If the DOOR ALARM key is pushed while

the door is open, the alarm will stop but the led will continue

to flash until the door is closed. When the door is closed, the

audible alarm will be restored. This detail will be retained in

the event of a power failure

.

Dispenser Light

The LIGHT key turns the dispenser light on and off. When the light

is off, it will gradually disappear. The dispenser light will turn on

automatically when the dispenser holder is depressed and will

disappear gradually 5 seconds after it was released. The LIGHT

key will not turn off the light while dispensing.

Closing the Dispenser

When the dispenser system is closed, no dispensing commands will

be accepted. This includes dispenser support and will prevent

accidental waivers that may be caused by children or pets. If you

press a key with the system closed, it will be recognized with three

presses of the LOCK LED accompanied by an audible tone.

To close or open communication between the dispenser and the

main control board, press the LOCK key and hold it for 3 seconds.

The LOCK LED will flash while the LOCK key is pressed. When the

communication is closed, the LOCK LED will light up.

The status of other functions, selected before the start of the closing

detail, will be displayed on the screen. If the latch is engaged while

a mode is activated, the LED will stay on until the mode ends.

If the latch is engaged when the filtering time ends, the LED will light

but cannot be reset until the latch is turned off.

The closing detail will be retained during a power cut.

Page 12

- 10 -

Filters

The FreshSaver filter is located in the fresh food drawer and

will last for 1 year. Some models are equipped with a

FreshSaver FILTER LED. After a 1-year refrigerator

operation time the FreshSaver filter LED will illuminate as a

reminder for the owner to change the filter. The LED can be

readjusted by pressing and holding the HOLD 3 SECS key for

3 seconds. The LED will flash while the key is pressed, it will

remain illuminated for 3 seconds after the key has been

released and turned off.

Some models are equipped with a water filter that is located

in the upper corner of the right side of the cooler

compartment. The filters are designed to be used for up to 18

hours of valve open time or 1 year of clock time.

When 90% of the filter time has passed (valve open time or

clock time, whichever comes first) the main control board will

illuminate the filter reminder LED (amber). When 100% of the

filter time has passed, the main control board will illuminate

the filter reminder LED (Red).

Hinge and Door Closing System

The hinge clamps are not adjustable in the cabinet. The

cooler door can be adjusted up and down using the hinge

adjustment pin (located on the bottom hinge of the cooler

door).

This refrigerator is equipped with an open / close door detail.

This detail consists of a loaded spring arm located in the

lower part of the cabinet for each door. The arm stops the

door when it is partially open and automatically closes the

door when it is almost closed

.

IMPORTANT:

The refrigerator rollers must be properly adjusted

for proper door closure. When the wheels are adjusted correctly,

the door should close easily when it opens approximately 45

degrees (half way).

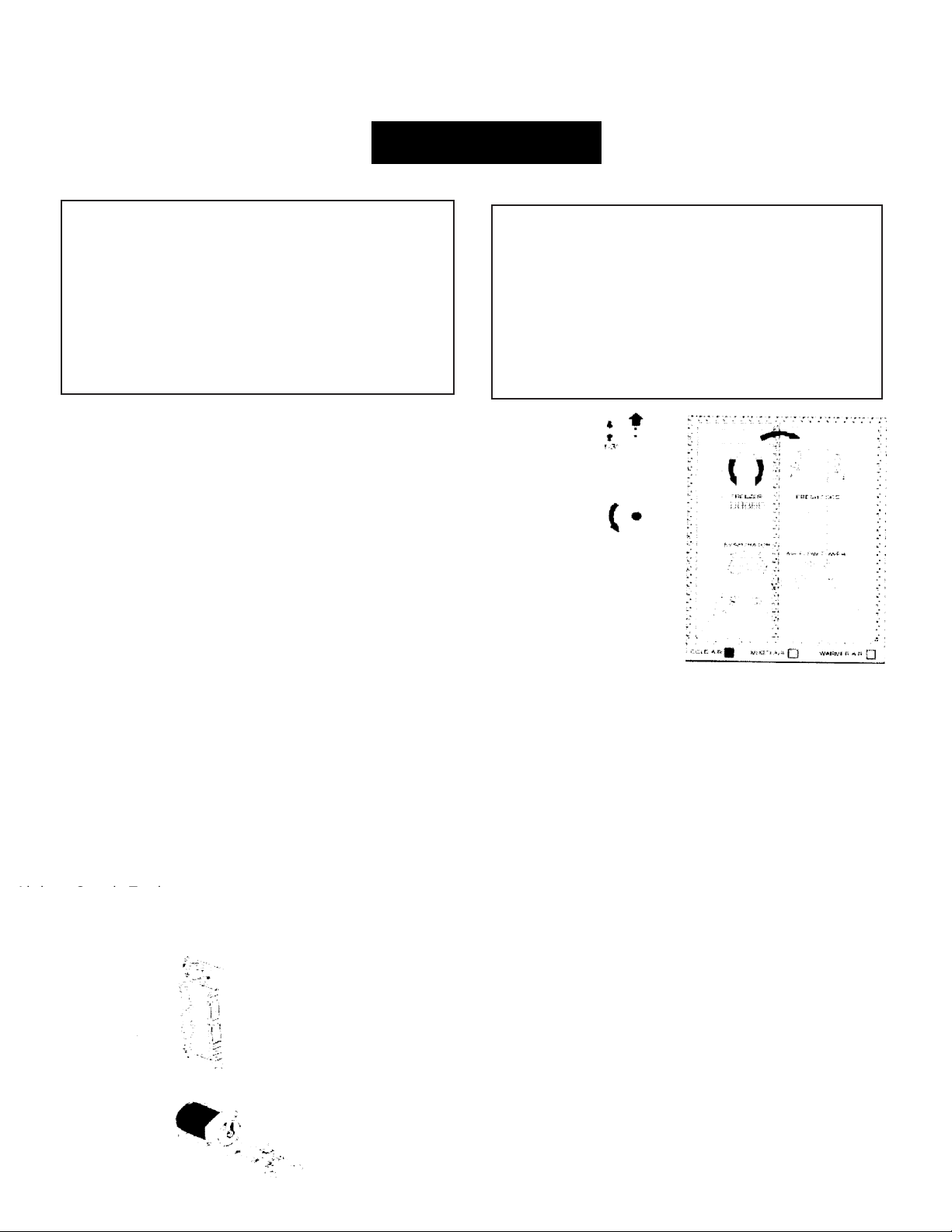

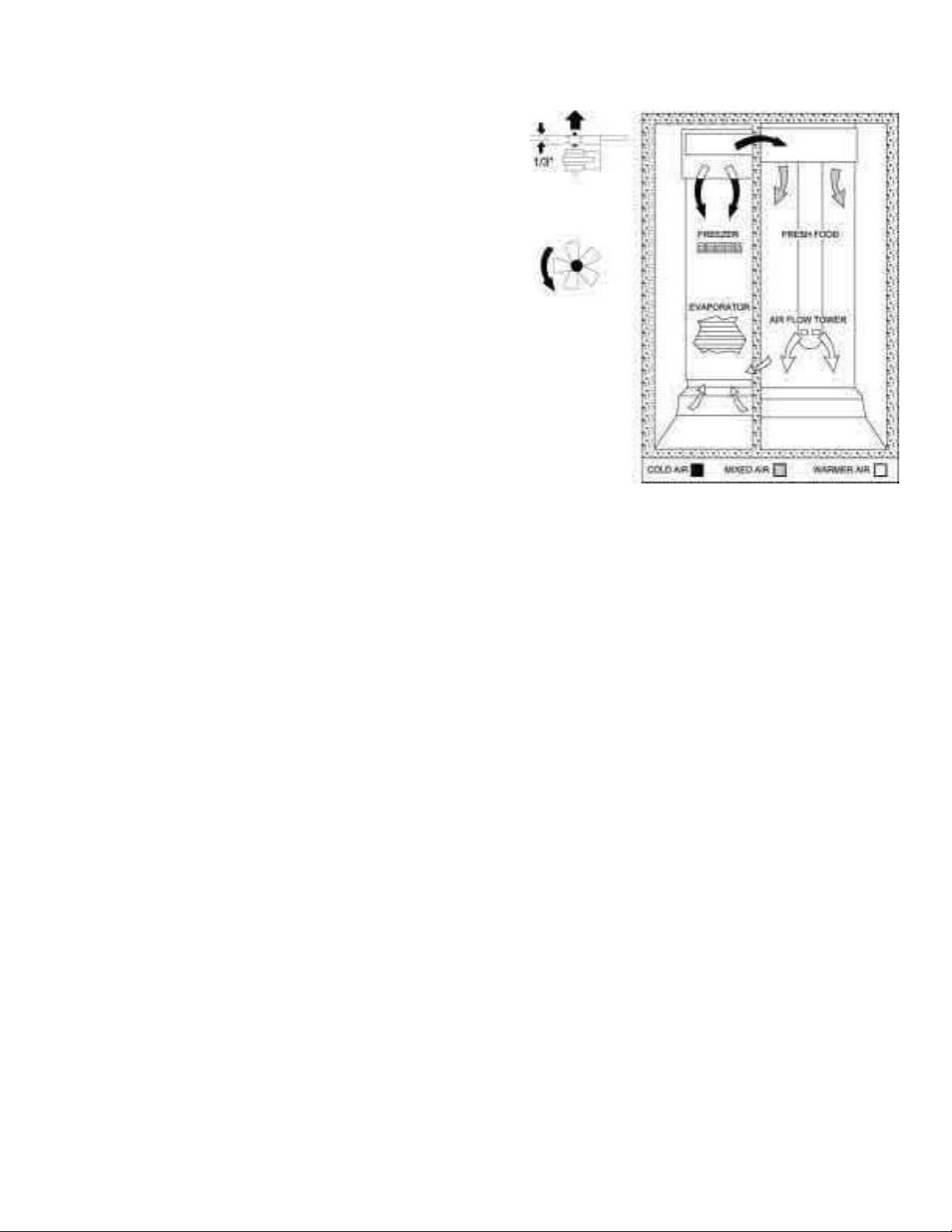

Air Flow (Cabinet Interior)

AIR FLOW

The freezer cabinet is designed so that air is carried inside the lower part

of the air tunnel and through the evaporator when the evaporator fan is

operating. The cold air is then pushed out towards the top of the freezer.

The cooler compartment receives cool air through an electronic shock

absorber that is located in the upper rear of the cooler between the freezer

cabinet and the cooler cabinet. The cushion is controlled by the main

control board and when it is opened, it allows the cold air from the freezer

air tunnel to move inside the cooler's air tower. The cold air tower of the

cooler contains a cooling fan that draws cold air from the freezer (through

the damper) into the air tower. The air tower directs cool air through the

top of the cooler cabinet to two exits. The air tower also directs cool air

down the back of the wall of the cooler cabinet. The cold air draws the air

out of the tower through fans in the tower.

The air returns from the cooler cabinet to the freezer cabinet through an

upright located on the left side of the fresh food drawer.

Page 13

- 11 -

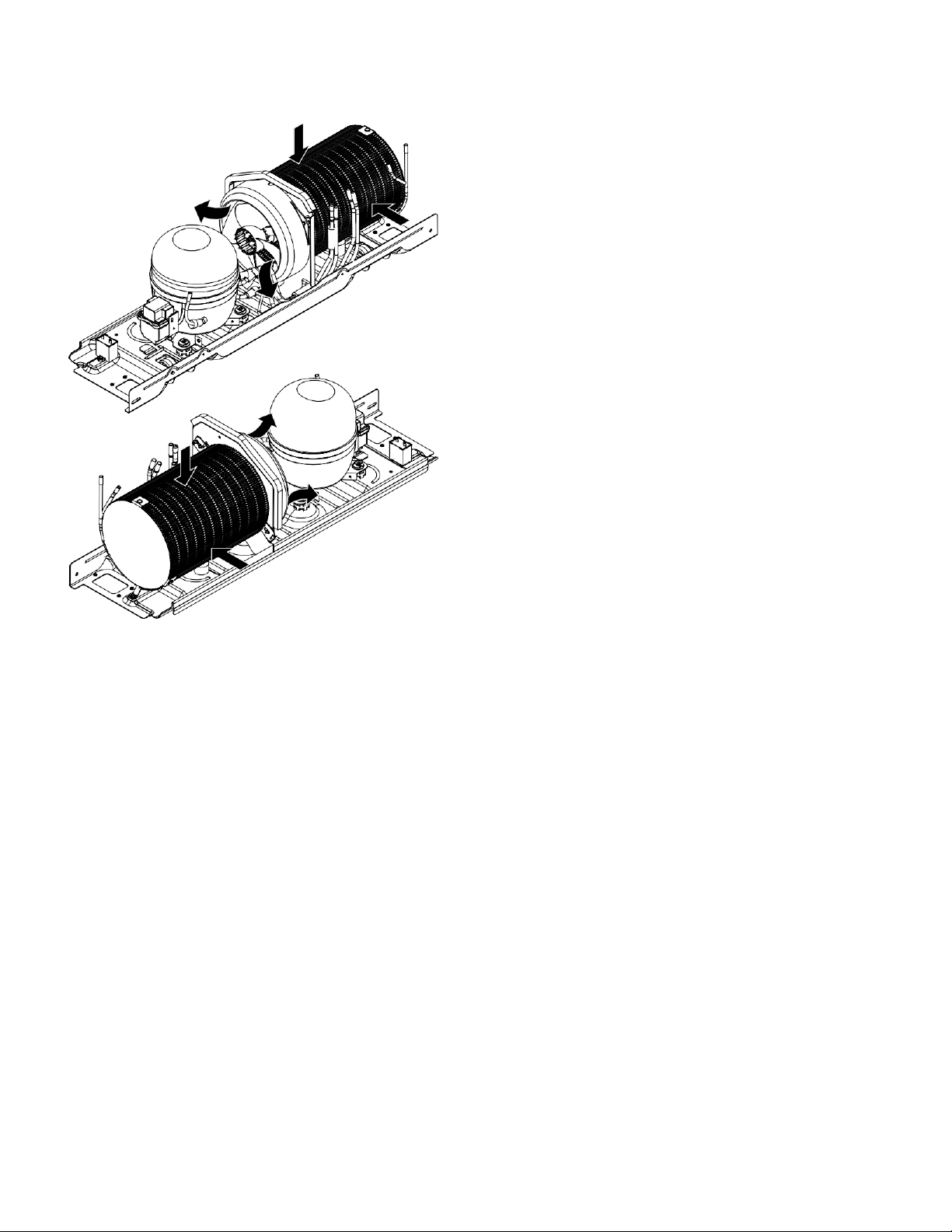

Condenser "Jelly Roll"

The "jelly roll" capacitor is a new type of capacitor. The

condenser fan is located at one end of the "jelly roll" condenser

and a solid plate is located at the other end. Air is drawn

through the outside diameter of the condenser and pulled out

by the condenser fan. The condenser is located in the

compartment of the machine that can be accessed through the

back of the unit in the background

.

GEA00911

Page 14

- 12 -

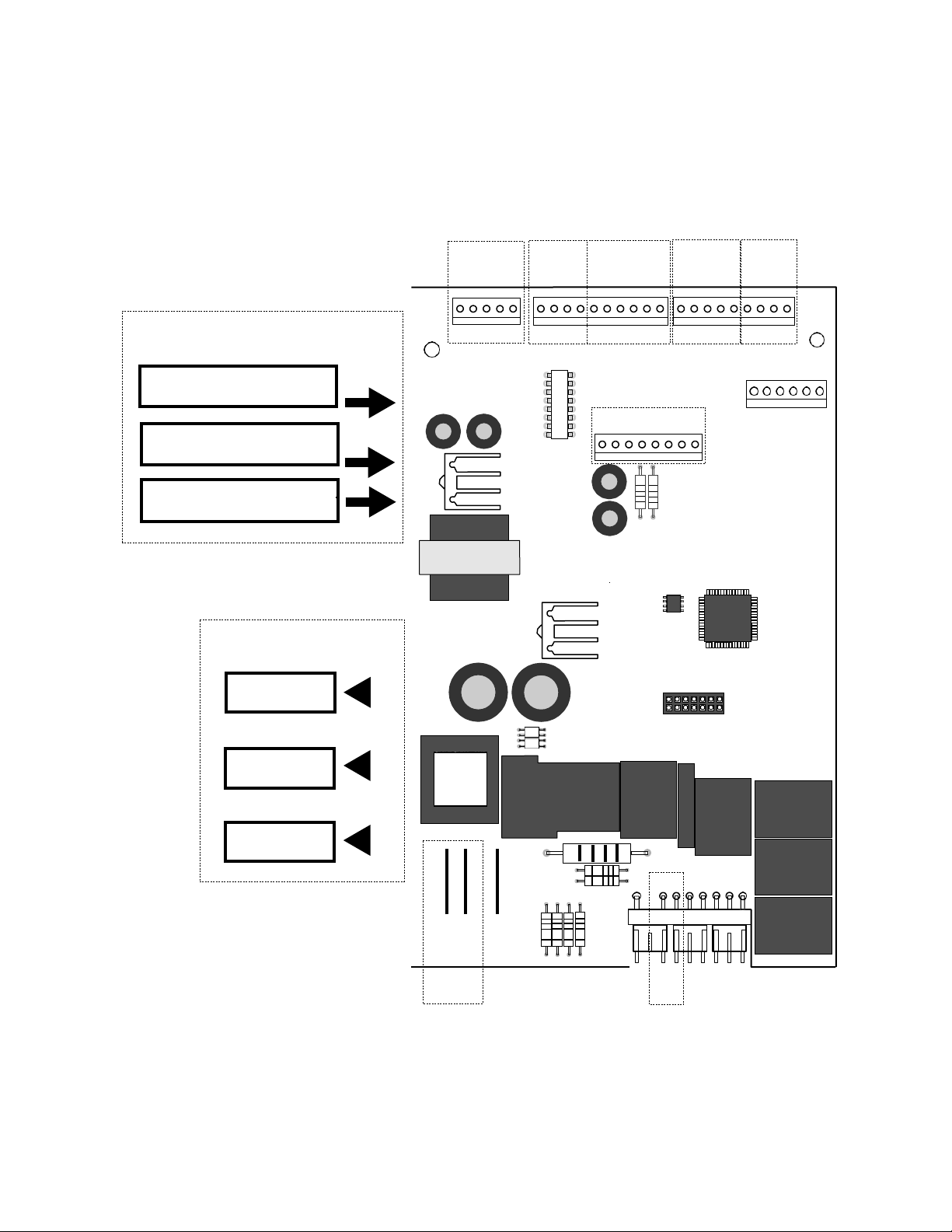

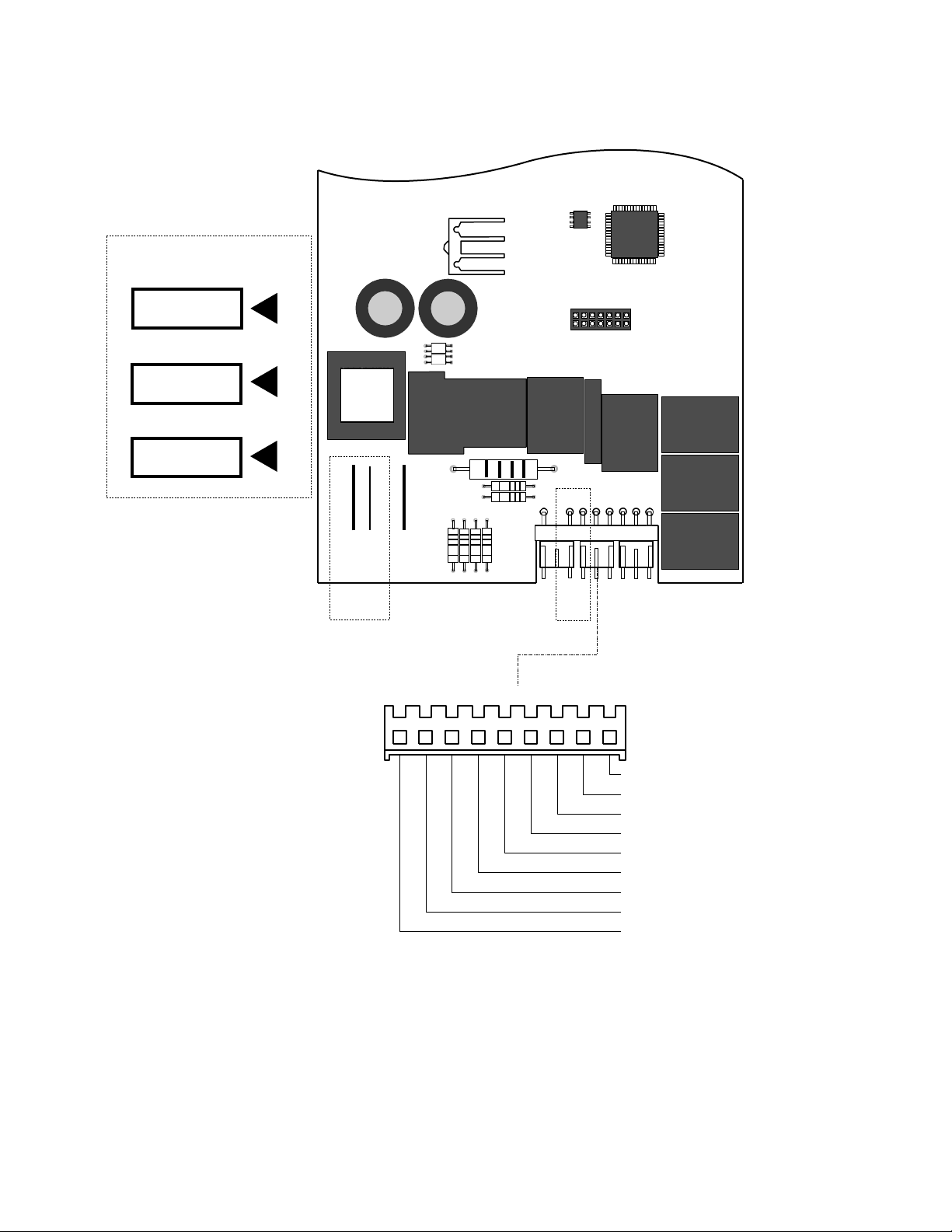

Main Control Board

ENTERS

IGNITION TIME OF THE DESCONG

HEATER. (MINUTES)

COMPRESSOR OPERATING

TIME (MINUTES)

OPEN DOORS ACCUMULATED

ENF AND CONG (MINUTES)

UNIT

PROCESSING

ENTRADAS

SWITCH

PUERTA

COMPRESOR

Y

DESCONGEL.

SALIDAS

SELECC.

MODELO

ENTRADAS

THERMISTO

R

ENTRADAS

CODIFICADOR

SERPENTINES

AMORT.

COMMUNICACION

ENTRADA/SALIDA

SALIDAS VENTILADOR

DEPARTURES

DEFROST.

PRE-COOLI

COOLING

1 COMM

2 +12V

3 -COM

4 DI

5 DO

L1

COMP

DESCONG

1

J4

LINEA

5 1

K4

COMP

J3

1

PAILA_CALT

N

K3

DESCONG. J6

10

DFZ

DFF

OCH

COMUN

AGUA

TRITR

TALADRO

2 1

J2

1

K5

QC

J7

8

K7

PAILA/CALT J1

1

K1

AUGER

K2

C/CR

K6

AGUA J5

9 6

Page 15

- 13 -

General views of the Locator

Temperature

Controls

Light

Freezer

Switch

Evaporator

Fan

Evaporator

Thermistor

Evaporator

Freez

er

Thermistor

Shock absorber

Coolant Thermistor

Switch Light Cooler

Page 16

- 14 -

GEA00977

Control

panel

Water

Solenoids

Fan

condenser

Jelly Roll

condenser

Overload and relay

(low cover)

Dryer

Page 17

- 15 -

Disarmed Mechanic

Content

Door Handle

Door packing

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

17

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

17

Quick Access to the Door of the Cooler Compartment . . . . . . . . . . . . . . . . . .

17

Switch Light Cooler Door. . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

18

Door Shelves of the Cooler Compartment . . . . . . . . . .

... . . . . . . . . . . . . . . . . . . . . . 18

Cooler Compartment Shelves ....................................................................................... 18

Cooler Compartment Drawers. . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Lights of the Cooler Compartment

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

18

Water filter

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

19

Fan Cushion and Chiller Study. . . . . . . . . . . . . . . . . .

. . . . . .

19

Shock absorber

DELIFRESH

. . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

20

Chiller Thermistors ......................................................................................................... 20

Temperature Control Panel. . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

21

Freezer Door Drawers. . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

21

Doors and Door Hinges

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

21

Adjustment of the Cooler

Door

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

22

Rollers

. . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . .

22

Roller Adjustment

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

23

Freezer Compartment Shelves and Drawers .................................................................. 23

Switch Freezer Door Light .............................................................................................. 23

Ice Dispenser

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

23

Drill and Solenoid Drive of Ice Dispenser Cubes

. . . . . . . . .

24

Ice Machine ................................................................................................................... 24

Page 18

- 16 -

Freezer Light .............................................................................................................. 27

Evaporator Fan

Evaporator thermistor

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

27

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

28

Defrosting Thermostat

De-icer heater

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

28

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

28

Paila Evaporator Collector ......................................................................................... 29

Evaporator ................................................................................................................. 29

Freezer Thermistor .................................................................................................... 29

Condenser Fan .......................................................................................................... 30

Main Processor Card ................................................................................................. 30

Water solenoids ......................................................................................................... 30

Page 19

- 17 -

Door Handle

The door handles allow access to the cooler and freezer

compartments. They are mounted in front with 1 Torx head

screw.

1. Using a small flat-bladed screwdriver, slide the trim of the

handle down and pull it out.

2. Remove the lower Torx head screw.

3. Lift the handle with a movement of the inside and up until

the locking ears disengage. Pull the handle out to remove it.

Door packing

The door gasket is a packing set molded

inside a channel located in the door shell.

Door of Easy Access to the Comparison

of the Cooler

The cooler compartment allows access without

opening the cooler door.

1. Open the easily accessible door and remove the Torx head

screws on the hinge (2), located on each side of the door.

2. With a small flat-blade screwdriver, remove the door

frame and door frame assembly.

3. Remove the packing and slide the door out of the frame.

4. The easily accessible door also has an interlock switch

located on the upper right side of the interior frame. Remove

the Phillips screw and slide the switch assembly down and

out.

5. Disconnect the switch wires and remove them.

1.

Open the door.

2. Grasp the gasket and pull it outward until the molded

gasket separates from the door shell

Page 20

- 18 -

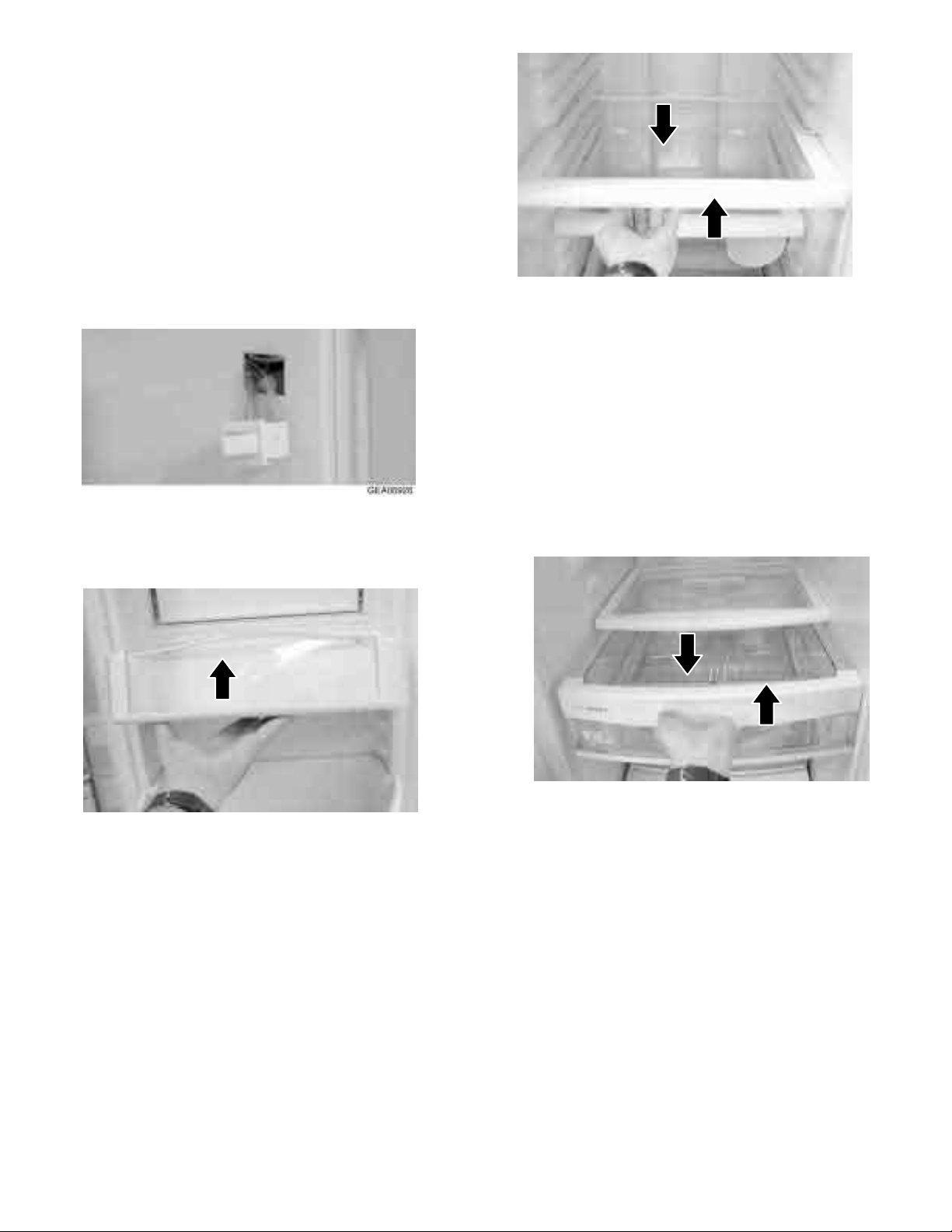

Switch of the Cooler Door Light

In addition to the easy access door light switch, cooler

compartment has a door light switch located on the

corner-right next to the compartment.

1.Use a small flat blade screwdriver to open the

locking lugs and pull the switch out until the

connector wire is visible.

2. Disconnect the connector and remove the

switch.

Door Shelves of the Cooler Compartment

The door shelves allow you to store perishable items

GEA00928

Cooler Compartment Drawers

The cooler compartment drawers are designed

to store fruits, vegetables and DELI items. The

drawers are located in the lower part of the

cooler compartment.

1. Pull the drawer out until the Rhodes are the

mechanical stop.

2. Tilt the drawer upwards and pull out until it is

withdrawn.

1.

Tilt the shelf up and slide it out.

GEA00929

GEA00927

Cooler Compartment Shelves

These shelves allow storage of larger items and

pull them for easy access.

1.

Pull the shelf until the stop tab on the shelf

meets the compartment stop.

2.

Push the stop tab of the shelf down and

pull the shelf out until it is removed.

Lights of the Cooler Compartment

The chiller compartment lights are located on

top and bottom of the chiller compartment.

1.

To access the top lights, remove the opaque

cover by opening the lugs and pulling the cover

down.

Page 21

- 19 -

GEA00930

2. To access the lower lights, pull out the DELI FRESH

shock absorber knob.

3. Lift the opaque cover of the lugs.

GEA00931

Cooler fan and shock absorber

The cooler compartment fan is located below the top

working duct in the cooler compartment. This fan

distributes the cold air of the freezer through the

cushion mount. The shock absorber post is located

in the same assembly as the fan. Both are controlled

by the processor.

1. Remove the DELI FRESH adjustment knob and

the light cover.

2. Open the top and bottom parts by locking lugs for

the center work duct and remove it. The work duct is

also fastened with a double-sided adhesive tape on

the upper and lower parts

Water filter

The water filter is located on the upper right side of the

cooler compartment. The water filter filters the water

for the ice machine and the water dispenser. An LED

on the temperature control panel will light up when the

filter needs to be changed.

1. Turn the water filter 1/2 turn counterclockwise and pull it

down.

2. To install the filter, push it in while turning 1/2 turn

clockwise. Do not force the filter.

Page 22

- 20 -

1. Remove the upper cover of the water filter.

2. Open the lugs of the opaque top light cover and

remove the cover.

3. Open the upper lugs of the work duct and remove

it

GEA00934

4. Remove the screws (8) Phillips head for the

plastic clamp assembly of the upper light.

9. Place the fan and shock absorber assembly

against the compartment and open the rear cover.

10. Disconnect the wire connections and remove the

damper or fan.

Shock absorber DELI FRESH

The DELI FRESH damper is located below the cold air duct.

Allows the cold air flow to be adjusted to the DELI FRESH

drawer.

1. Remove the DELI FRESH damper by adjusting

the knob and lower light cover.

2. Remove the center duct by opening the top and

bottom lugs. Double-side adhesive tape is

applied to the upper and lower areas.

3. Remove the screws (3) Phillips head mount the

shock absorber and remove the shock

absorber.

GEA00935

7. Pull down the stainless steel light clamp until the wires are

exposed and disconnected.

8. Remove the screws (2) Phillips head from the cooler fan

and from the shock absorber cover and remove the cover.

ChillerThermistors

GEA00938

The cooler thermistors are located in the upper

and lower parts of the cooler compartment. They send

temperature signals to the processor.

GEA00936

Page 23

- 21 -

1. Using a small flat-bladed screwdriver, open the

lugs and remove the assembly.

2. Remove the thermistor from the cover and

disconnect the wire connector..

Freezer Door Drawers

The freezer door drawers are located on the inside of

the freezer door and are tilted outward to allow easy

access to frozen items.

1.

Tilt the drawer and slide out the door.

Panel de Control de Temperatura

The temperature control panel is located in the cooler

compartment and mounted on the upper front part. This

panel allows temperature control for the cooler and

freezer compartments. Each compartment has a reading

LED of the temperature setting

Puertas y Bisagras de la Puerta

GEA009

In addition, the panel has a reading LED for the change of

the water filter.

1. Remove the Phillips head mounting screws (3) from

the control panel.

2. Pull the panel down until the connections are

exposed.

IMPORTANT: The freezer door is not adjustable. The

cooler door can be adjusted up and down to match

the height of the freezer door. Adjust the cooler door

up or down using the adjustment hinge (located on

the lower hinge of the cooler door).

IMPORTANT: The rollers of the refrigerator must be

adjusted correctly to ensure an adequate closing of the

door. For more information see the Roller Adjustment

section in this chapter.

4. Disconnect the wire connector from the panel.

5. Disconnect the ribbon from the circuit board.

GEA00940

1.

Remove the grid from the base.

2.

With the door in the closed position, disconnect the

wire wiring connector.

3.

Disconnect the water tubing

6. Open the closing lugs of the cards located on the left

and right bottom corners of the card.

7. Remove the card.

To disconnect the tubing, push the white flange on

the quick connector inward and pull the tubing out.

GEA00943

Tornillos

Page 24

- 22 -

4. With a small flat-blade screwdriver, unhook the locking

lugs from the cover of the upper hinge and remove it.

5. Remove the screws (2) Torx head from the hinge and

lift the upper hinge of the unit

CAUTION: Do not load the hinges aside.

CAUTION: Only the freezer door - Do not allow the connector

to make contact with the floor. A hard contact can damage the

connector.

NOTE: Guide the water line and wire harness through the

hinge while lifting the hinge door.

1. Open the door 90 ° and lift it straight up and out of

the lower hinge

Manguito

Pasador Bisagra

Tornillo Torx

GEA00908

4.

Remove the screws (3) Torx and the

lower hinge of the cabinet

Manguito

Bisagra

Ajuste Pasador

Bisagra

Tornillo Torx

Lower Hinge, Side of the Cooler

Cooler door adjustment

IMPORTANT:

The freezer door is not adjustable. The

cooler door can be adjusted to match the height of the

freezer door.

IMPORTANT:

The refrigerator rollers must be correctly

adjusted to ensure an adequate closing of the door. For

more information see the Roller Adjustment section in

this chapter.

1. Remove the grid from the base.

2. Turn the hinge adjustment pin (located on the bottom

hinge of the cooler) clockwise to raise the door level and

counter- clockwise to lower the door.

Rollers

The unit has 4 rollers for easy movement of the

refrigerator. There are 2 rollers located on the front and

2 rollers located on the back of the unit.

IMPORTANT: The rollers of the refrigerator must be

adjusted correctly to ensure an adequate closing of the

door. See Roller Adjustment.

1. To remove the front rollers, reverse the level

adjustment screw completely.

2. Remove the 1/4 "roller mounting bolts and remove the

mold.

GEA00945

3. To remove the rear screws, remove the 1/4 "mounting

screws (2).

4. Tilt the roller down and slide it out.

Tornillos

Page 25

- 23 -

Adjustment of the roller

The front rollers (2) are adjustable. Adjust them so

that the refrigerator is solid and the doors close

easily:

1. Remove the grid from the base.

2. Using a flat-blade screwdriver, turn the adjusting

screw clockwise to raise the roller and counterclockwise to lower the roller.

Freezer Compartment Shelves and Drawers

Shelves and drawers slide out for easy access to

frozen items.

Ice dispenser

Ice dispenser

The ice dispenser is located in the upper part of the

freezer compartment. The set stores the ice made by

the ice machine and removes it as required by the

surface switch of the door dispenser.

1. Remove the upper tray from the ice tray.

2. Slide out the ice dispenser assembly.

.

1.

Slide the shelf / drawer out until it reaches a stop

2.

Tilt the shelf / drawer up and slide it out of the

compartment.

GEA009

47

Light Switch Freezer Door

The switch is located on the right side of

the freezer compartment and sends

signals to the processor.

3. Remove the ice cube selenoid Phillips head

screw union and slide the union backwards.

4.

Remove the Phillips head screws (2) from the

ice crusher cover and remove it.

5.

With a pair of pliers, bend the tabs

of the backing plate on each side of the disposer.

1. With a small flat blade screwdriver, open the

locking tabs and pull the switch until the connector

wire is visible.

2. Disconnect the wire connector and remove the

switch.

Page 26

- 24 -

6.

Using two small flat blade screwdrivers, open the ice

crusher locking lugs located on each side of the ice

crusher.

7.

Lift the ice crusher out of the bucket

.

8.

Remove the back cover of the ice crusher.

9.

Remove the closing ring from the disposer drill of

ice.

10.

Remove the plastic nut with a pair of pliers by

turning it clockwise.

11.

Remove the spacers and blades. The blades are

listed for reassembly.

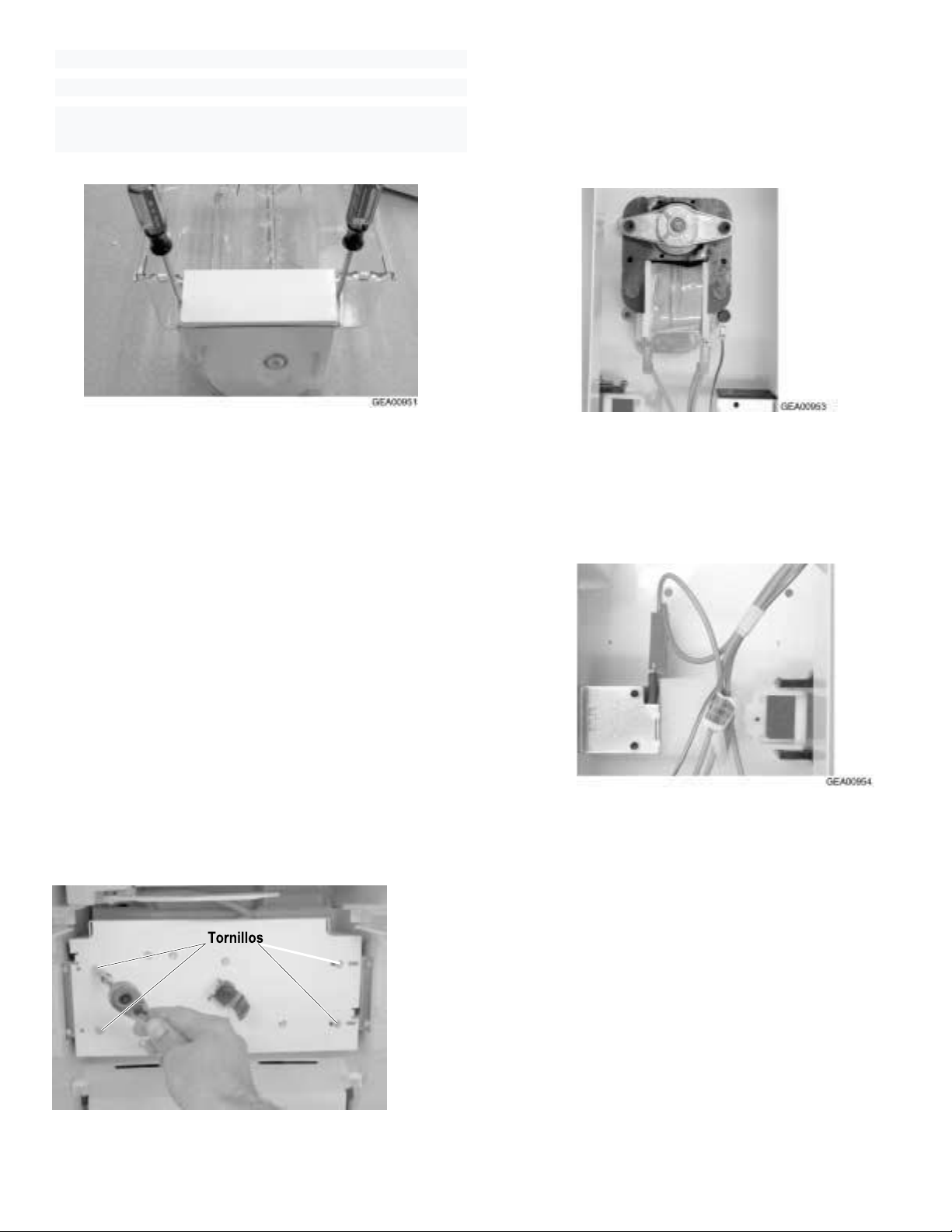

Cube Slew and Ice Dispenser Drill Driver

The drive motor of the ice dispenser and the cube

solenoid are located in the upper rear part of the

freezer compartment. The drive motor moves the drill

by means of a fork located in the drive motor. The cube

solenoid allows the cube or crushed cube to exit when

requested.

1. Remove the screws (4) 1/4 "mounting from the box

located in the four corners of the box.

2. Slide the box forward until the connector is visible,

disconnect the connector, and remove the unit from

the box.

Note: The drive fork has inverse threads, turn them

counterclockwise to remove them.

3. Remove the fork of the drive motor by turning

it clockwise.

4. Disconnect the motor connectors and remove

the ground wire.

5.

Remove the 1/4 "mounting screws (3) and remove

the motor.

6. Disconnect the wires from the cube solenoid.

7. Remove the mounting screws (2) from the 1/4

"socket solenoid and remove the cube solenoid.

Ice machine

The ice machine is located in the upper back part of

the freezer compartment and supplies ice to the

dispenser bowl.

1. Disconnect the cable connector from the

icemaker.

2. Remove the 1/4 "mounting screws from the ice

machine and slide the ice machine out.

This refrigerator is equipped with an Electronic Ice

Machine. For more information see Pub # 31-9063..

GEA00952

Page 27

2

.

Remove the ¼” screws (2) de 1/4" from the mounting

clamp of the ice dispenser and remove the clamps

Freezer Light

GEA00955

The freezer light is located on the back of the freezer

compartment. The light is covered with an opaque cover.

1. Open the locking lugs and remove the cover.

2. Change the light of the appliance.

GEA00958

3.

Remove the 1/4 "screws (2) from the upper duct of the

evaporator fan.

4. Open the lugs and remove the lower duct from the evaporator

fan.

5. Remove the 1/4 "screws (4) from the evaporator cover and

remove the cover.

Evaporator fan

The evaporator fan is located in the upper rear part of the freezer

compartment. This fan supplies cold air to the freezer and cooler

compartments. The evaporator thermistor must be replaced when

changing the fan.

1. Remove the 1/4 "mounting screws (4) from the ice machine

clamp on the four corners of the clamp.

GEA00959

6

. Remove the two 1/4 "upper duct screws from the evaporator

fan located on the bottom of the duct.

7. Using a small flat-bladed screwdriver, open the lugs for the

ice machine and dispenser cables.

8. Slide out the upper fan duct.

9. Disconnect the wiring from the evaporator fan wiring.

GEA00957

- 25 -

Page 28

- 26 -

Thermostat Defrosting

The defrost thermostat is pressed to the top of the

evaporator. The thermostat sends temperature

information to the processor. The defrosting heater must

be replaced when you change the thermostat.

1. Remove the lower fan duct from the evaporator cover.

2. Remove the 1/4 "screws from the evaporator cover

and remove the evaporator cover.

3. Remove the thermostat defrosting

.

Evaporator Thermistor

The evaporator thermistor is pressed in the upper part

of the evaporator. The thermistor sends temperature

signals from the evaporator to the processor. The

thermistor must be replaced when changing the

evaporator fan.

1. Complete the evaporator fan procedure.

2. Release the evaporator thermistor and remove it.

GEA00961

GEA00963

Thermist

Tornillos

7. Remove the 1/4 "screw of ground wire from the

evaporator fan.

8. Remove the 1/4 "screws (2) from the

evaporator fan mounting bracket located on each

side of the clamp

9. Remove it

Defrosting Heater

The defrosting heater is located in the lower part of

the evaporator. The defrost heater heats the

evaporator in the defrost operation mode. The

thermostat must be replaced when changing the

defrost heater.

1. Complete the defrosting thermostat procedure.

2. Remove the screws (2) Phillips head mounting

defrosting heater.

3. Remove the defrosting heater.

Page 29

- 27 -

Evaporator Collector Shovel

The collecting pan of the evaporator is located

below the evaporator. This blade collects the

condensation of the evaporator that is

generated during the defrosting operation

mode.

1. Remove screws (2) of 1/4 "mounting

bracket.

2. Remove the pick-up pan.

Evaporator

G

E

A

0

0

9

6

4

.

Air is conducted through the evaporator coils to produce

cool air for the freezer and cooler compartments.

1.

Remove the lower duct from the evaporator fan.

2.

Remove the 1/4 "screws (4) from the evaporator cover

and remove the evaporator cover.

3.

Remove the defrosting thermostat and the evaporator

thermistor.

4.

Remove the screws (2) Phillips head of the defrosting

heater and remove the heater.

5.

Remove the 1/4 "mounting screws (4) from the

evaporator located in the four corners of the

evaporator.

Freezer Thermistor

The freezer thermistor is located in the center of the right wall of

the freezer compartment. It sends temperature signals to the

processor.

1. Using a small flat-blade screwdriver, open the lugs

and remove the assembly

2. Remove the thermistor from the cover and

disconnect the wire connector.

Warning: To avoid damage to the capillary

tube, the capillary tube must be remove weld

first.

6. Unsolder the capillary tube of the evaporator.

7. Remove weld of the suction line. Use a pair

of tongs to hold the evaporator.

8. Remove the evaporator.

9. With a file, tear the capillary tube just below

the ex welded section. Break the dis-welded

section of the capillary tube. This helps prevent

the soldering iron from plugging into the tube

during assembly.

10. Place the new evaporator inside the freezer

and insert the suction and capillary tube inside

the evaporator.

11. Solder the suction and capillary tube to the

evaporator using a silver soldering iron.

12. Install a replacement for the evaporator

13. Recharge the system using the actual

acceptable procedures

Page 30

- 28 -

Condenser fan

The condenser fan is located on the back of the unit.

Gives FORCED-DRAFT cooling for the condenser

coil.

1. Remove the 1/4 "screws (5) from the rear access

panel and remove the rear panel.

Water selenoids

GEA0096

When the selenoids receive a signal from the

processor, they send water to the filter, cooler and ice

machine.

1. Remove the 1/4 "screws (10) from the rear panel

and remove it.

2. Remove the 1/4 "screw from the clamp.

3. Slide the solenoid assembly outward.

4. Disconnect the cable assembly.

5. Disconnect the water pipe. To disconnect the quick

connection, push the black lip in and pull the tube out.

6. Remove the solenoid

2. Remove the 1/4 "mounting screw from the

condenser fan and slide the fan until the wire is

exposed.

3. Disconnect the supply wire connector.

Main Processor Card

The main processor card is located on the back of

the unit. This card controls the operation of the unit.

If a cut on a fan has occurred, replace the fan

before the card and the card will be destroyed.

1. Secure the power to the unit.

2. Remove the 1/4 "screws (10) from the

processing board panel and remove the panel.

3. Disconnect the processor connector cables.

4. Remove the card by opening the plastic lugs

located at the corners of the card.

Page 31

Diagnostic

Content

Efficient use of the Diagnostic……………………………………………………………………………………….29

Causes of failure (Table 1). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Automatic diagnostics……………………………………………………………………………………………………… 30

Diagnostic Tests (Table 2). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . …………. . . . 32

Communication Tests (0 2, 03 or 0 4) ……………………………………………………………………………………32

Self-Test Temperature Control Panel (0 6). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ………………… . . . . . 32

Dispenser Board ……………………………………………………………………………………………………………33

Self-Test of the Control and Sensor System (0 7)………………………………………………………………………. 33

Main Control Board (Low Voltage Side)…………………………………………………………………………………… 34

Main Control Board (Side 120-VAC). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ………….. . . . . . . . . . . . . . . . . . . . 35

Table Locator Board of C.o.n.tr.o.l.P.r.in.c.ip. to. l (.L.a.d.o. D. E.B.a.jo.V.o.l.ta.je.) ………………………………….36

Table Locator Main Control Board (Side 120-VAC) ………………………………………………………………………38

Dead Unit, No Sound and No Cool (diagnostic chart)……………………………………………………………………. 39

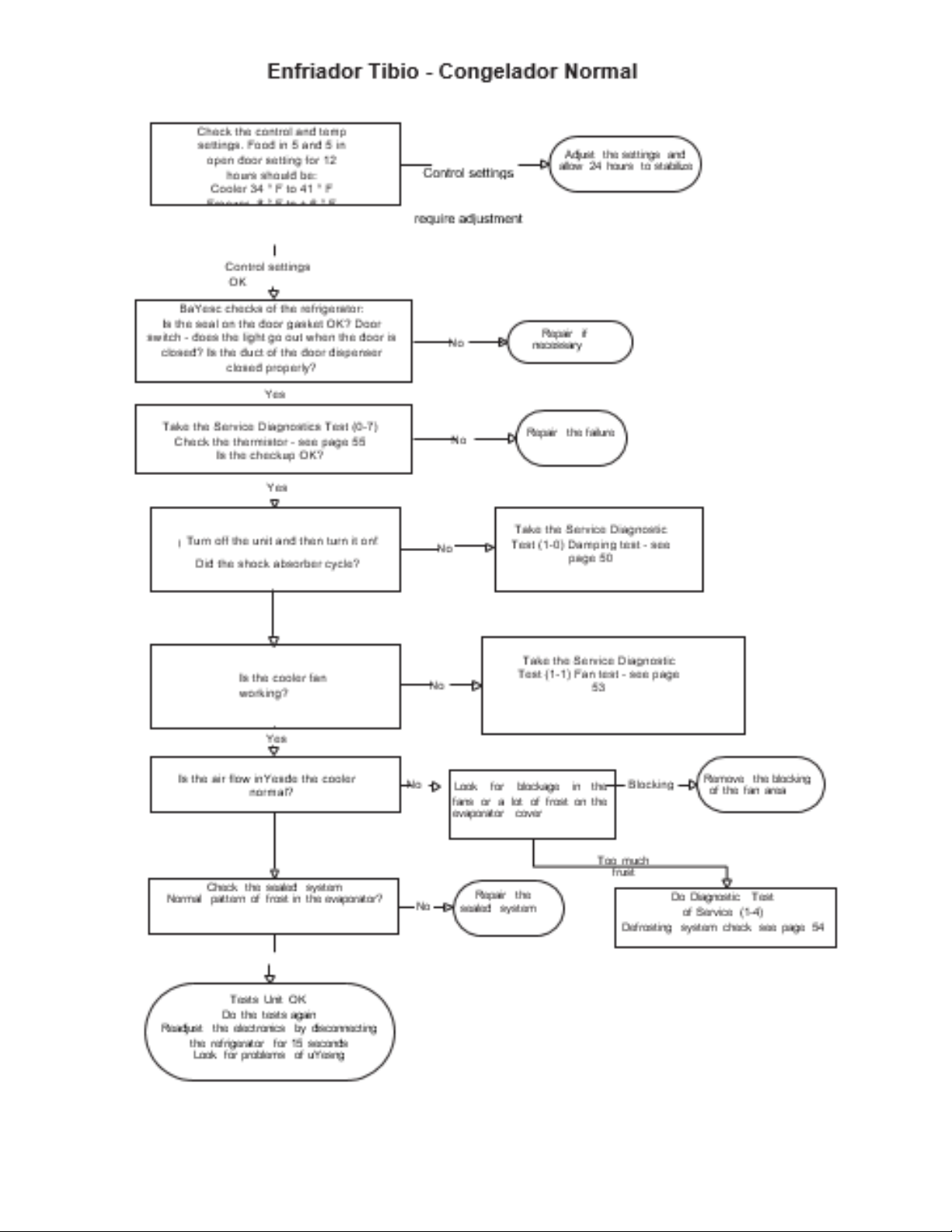

Warming Cooler - Warm Freezer (diagnostic board)……………………………………………………………………… 40

Warming Cooler - Normal Freezer (diagnostic table) ……….. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Very Cold Cooler - Normal Freezer (diagnostic table)…………………………………………………………………….. 42

Warm Freezer - Normal Cooler (diagnostic table)…………………………………………………………………………. 43

Compressor Does Not Work (diagnostic chart). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ……… . . . . . . . . . . . 44

Shock Absorber Door Does Not Open or Close (diagnostic chart) ………………………………………………………..45

Condenser Fan Does Not Work (Diagnosis Box) …………………………………………………………………………… 46

Evaporator Fan Does Not Work (Diagnosis Box) …………………………………………………………………………….47

Cooler Fan Does Not Work (Diagnosis Box) ………………………………………………………………………………… 48

A lot of Frost in the Evaporator (diagnostic table) …………………………………………………………………………….49

Thermistor test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ……………………………………… . . . . . . . . . 50

Thermistor values (table 3)

Efficient Use of the Diagnostic. . . . . . . . . . . . …………. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Page 32

Table 1. Causes of

Failure

Freezer bin

Cooler bin

Above

15°

Fanrenheit

High resistance thermistor freezer

Low resistance thermistor

evaporator Failure condenser fan

Failure evaporator fan

Heater defrosting locked

Fail in door switch

Main control board failing

Faulting wiring

Open dispenser lid

Leaking in door packaging

Half-closed door

Fail sealed system

Above

50 °

Fahrenheit

High-resistance in the thermistor of

the cooler compartment

Closed cushion

Failure cooling fan

Evaporator fan failure

Failure door switch

Main control board failing

Failed wiring

Leak in the door package

Half-closed door

Normal Cycle

(entre 14° y -14°

Fahrenheit)

Normal Cycle

(entre 49° y 33°

Fahrenheit)

Below 15°

Fahrenheit

Closed damper closed

Low-resistance in the circuit of the

thermistor of the freezer

Main control board failing

Below

32°

Fahrenheit

Open locked shock absorber

Low-resistance in the sensor

circuit of the cooler compartment

Main control board failing

Enviroment temperature below 60 °

Shock absorber failing

Auto-Diagnostics

To enter the Auto-Diagnostic mode, both screens of the temperature control panels should be illuminated. A screen can

be illuminated by pressing an attached temperature adjustment button. When both screens are illuminated, adjust the

cooler and freezer temperature settings to 5. Simultaneously press and hold all 4 temperature adjustment buttons for

approximately 3 seconds. A 0 flashing on the refrigerator and freezer display will indicate that the refrigerator is in the

Auto-Diagnostic mode.

To do the self-diagnostic test, locate the test in Table 2, Diagnostic Tests.

For temperature control panels with single-digit displays, the COLD temperature setting knob will increment the numbers

upward and the ENVIROMENT temperature setting knob will increment the numbers downward. Use the freezer

temperature adjustment buttons to enter the test code number on the freezer screen. Use the refrigerator temperature

adjustment buttons to enter the test code number on the refrigerator screen. When a test code has been entered, the

screens will flash to confirm the test. Press the HOLD button for 3 seconds to start the test.

For 3-digit temperature control panels, the COLD temperature button will increase the numbers down and the enviroment

temperature button will increase the numbers upwards. Use the freezer temperature adjustment buttons to enter the

code number of the freezer screen. Use the refrigerator temperature adjustment buttons to enter the refrigerator's screen

code number.

After entering a test code, the screen will flash to confirm the test code. Press any button other than the temperature

adjustment button to begin the test.

Page 33

When the test has been completed, do one of the following:

• Enter the code 1 5 to completely reset the system

• Enter the code 1 6 to exit diagnostic mode. The temperature control panel is automatically reset.

• Unplug the refrigerator for at least 10 seconds. The test mode will end when the refrigerator is reconnected.

The test mode will automatically end after 15 minutes of inactivity.

Temperature Control Panel (One Digit Display)

- 31 -

9 ES MAS FRIO

9 ES MAS FRIO

TIBIO

MAS FRIO

TIBIO

MAS FRIO

AJUSTE TEMP REFRIGERADOR

AJUSTE TEMP CONGELADOR

Page 34

- 32 -

Communication Tests (0 2, 0 3 or 0 4)

A communication test will display the test code while checking the communication. When the test is finished,

the freezer display will show a P (pass) or an F (fault) for 2 seconds. After 2 seconds, the screens will show

the test code. At this time, you can enter a new test code.

Self-Test Temperature Control Panel (0 6)

This test applies only to the temperature control board inside the cooler compartment. When the Temperature

Control Panel Self-Test starts, all the LEDs and numerical segments on the screen will light up. When the

SAFE THAW button is pushed, all 3 LEDs for safe defrosting should be turned off. When the QUICK CHILL

button is pressed, all 3 LEDs for quick cooling should be turned off. Continue this procedure for each pair of

LED / button on the screen. The coldest key is to turn off seven-segment LEDs.

The warmer key is to turn off the Adjustment LED for both the freezer and cooler compartments.

To exit the Temperature Control Panel Auto-Test, both refrigerator temperature and adjustment keys must

be pressed simultaneously for 3 seconds. This can be done at any time to exit the test.

Table 2. Diagnostic Tests

Freezer

screen

Fridge

screen

Mo

de

Comment

0

2

Communication of the control

panel of temperature to the main

control panel

P on the CG screen if it is OK

F on the CG screen if it is not OK

0

3

Communication of the

temperature control panel to the

board disp.

P on the CG screen if it is OK

F on the CG screen if it is not OK

0

4

Communication of the board

disp. main control board

P on the CG screen if it is OK

F on the CG screen if it is not OK

0

6

Self-test temperature control

panel

See Self-Test Temperature Control Panel on page 32.

0

7

Self-test of the control system

and sensor

See Self-Test Control and Sensor on page 33.

1 0

Open shock absorber

Shock absorber will open, brief pause and then close.

1 1

Speed fan test

Each fan works for 10 secs. then for

1

2

100% running time

This mode operates the sealed system 100% of the time

for 1 hour.

1

3

Between pre-cooling

This places the freezer in the pre-cooling mode.

1

4

Defrost entity

This will put the refrigerator in the defrost mode. If the

cabinet is not cold when it is run, this mode can do it

extremely quickly. The cooler will return to normal

operation by itself.

1

5

Reset fridge

It causes a readjustment of the system.

1

6

Out of Test Mode

It causes the system to exit the test mode and readjust

the temperature control panel.

1

7

C/F Degrees

Refrigerator temperature adjustment keys can be used to

change the display from F to C or C to F.

Page 35

- 33 -

Dispenser Board

There is no self-diagnostic test for the dispenser board. The operation of the dispenser board is tested by

pressing each button and checking its proper operation.

Self-Test Sensor and Control System (0 7)

This test checks all five thermistors located through the unit. Once the test is started, the test code (0 7) will

stop flashing and the thermistor test results will appear on the freezer screen in the test order listed below.

The sequence number of the thermistor test will not be shown on the screen.

If the unit is not equipped with the Quick Cool option, the third thermistor (rapid cooling) will show 0 and three

audible beeps will sound on the temperature control panel. This is not a fault if the unit is not equipped with

the option of Fast Cooling.

Thermistor test results:

P = Pass

0 = Fail

S = Short to 5 VDC

B = Bad amplifier

The sequence of the thermistor test is:

1. Top cooler thermistor

2. Lower cooler thermistor

3. Quick cooling thermistor (0 displayed if the unit is not equipped with the Quick Cool option)

4. Evaporator thermistor.

5. Freezer thermistor.

Note: The results of the thermistor test will appear in the sequence shown above. The number of the

thermistor test sequence will not be shown on the screen.

Page 36

- 34 -

Main Control Board (Low-Voltage Sid)

1

- Black

2

- Red

3

Blue

4

- Purple

5

- White

1 – Blue/Red

2 - Yellow

3 – Red / White

4 – Blue/ White

5 - Blue

J4 J3 J1

J2

8 - Red

7 – Not used

6 – Black/ White

5 - Yellow

4 – Yellow/Black

3 - White

2 – Blue/White

1 - Blue

GEA00906

PROCESSING

UNIT

SALIDAS VENTILADOR

SELECCION

MODELO

THERMISTO

R

ENTRADAS

CODIFICADOR

ENTRADAS

SERPENTINES

AMORT.

COMUNICACION

ENTRADA/SALIDA

ENTRIES

TIME ON WARMER DEFROST

(MINUTES)

TIME COMPRESSOR

OPERATION (MINUTES)

OPEN DOORS ACCUMULATED

ENF AND CG (MINUTES)

- Yellow

– Red/Black

White-brown

4 – Blue/Yellow

1 COMM

2 +12V

3 -COM

4 DI

5 DO

1

J4

5 1

J3

1

10

J2

1 8

J1

1

J5

9 6

Page 37

- 35 -

Main Control Board (Side 120-VAC)

J7

1

- Beige

2

- Silver

3

- Yellow

4

–Red/White

5

-Blue/White

6

-Purple

7

- Red

8

– Not used

9

- Orange GEA00907

UNIDAD DE

PROCESAMIENTO

SALIDAS

COMPRESOR

Y

DESCONG.

SALIDAS

SWITCH

PUERTA

SALIDAS

ENFRIAMIEN-TO

DESCONGELACION

PRE-ENFRIA-

MIENTO

L1

COMP

DESCONG

J8 J9 LINEA J4

K4

COMP

J12 PAN_HTR

N

K3

DESCONG.

J6

DFZ

DFF

OCH

COMUN

AGUA

TRITUR.

TALADRO

2 1

K5

QC

J7

K7

PAILA/CALT

K1

TALADRO

K2

C/CR

K6

AGUA

Page 38

- 36 -

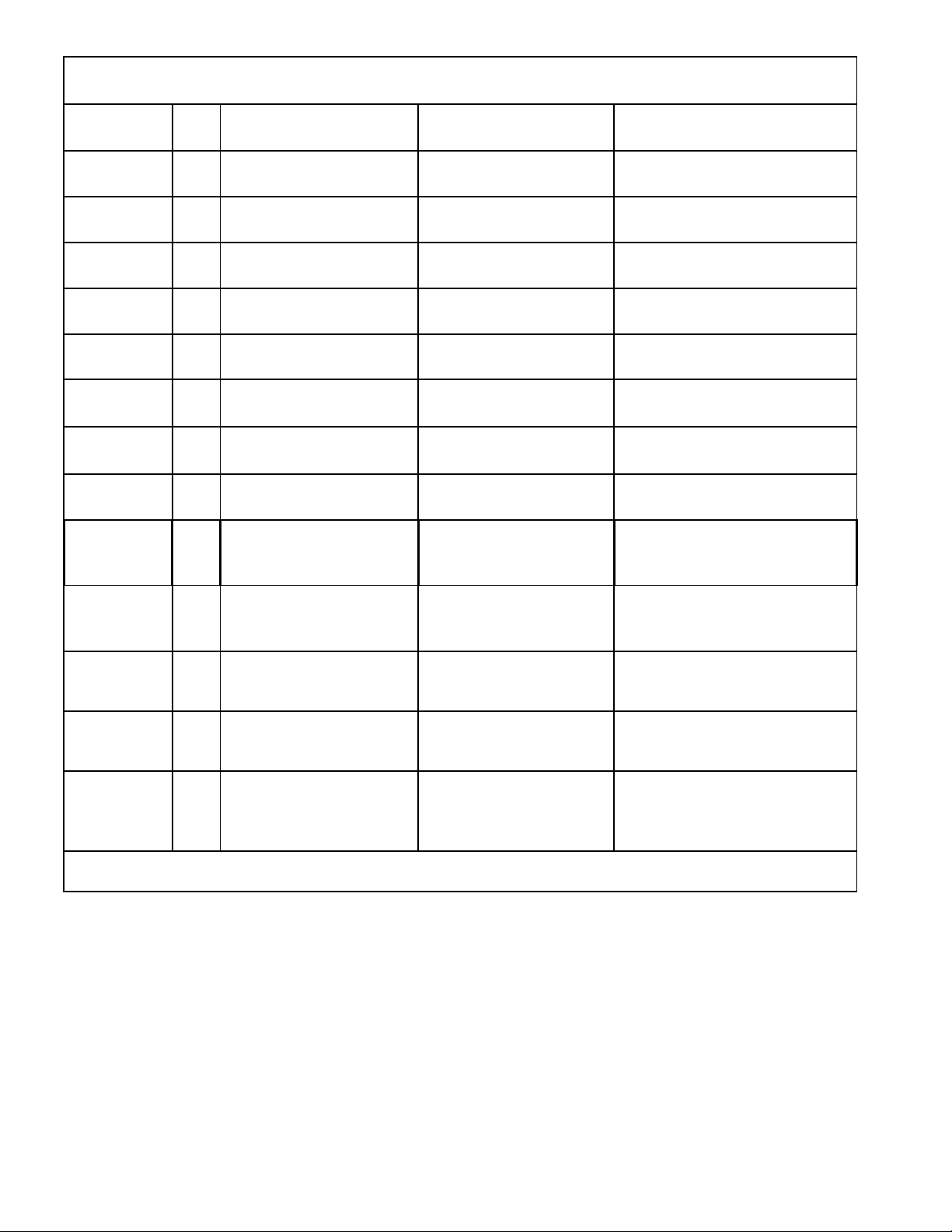

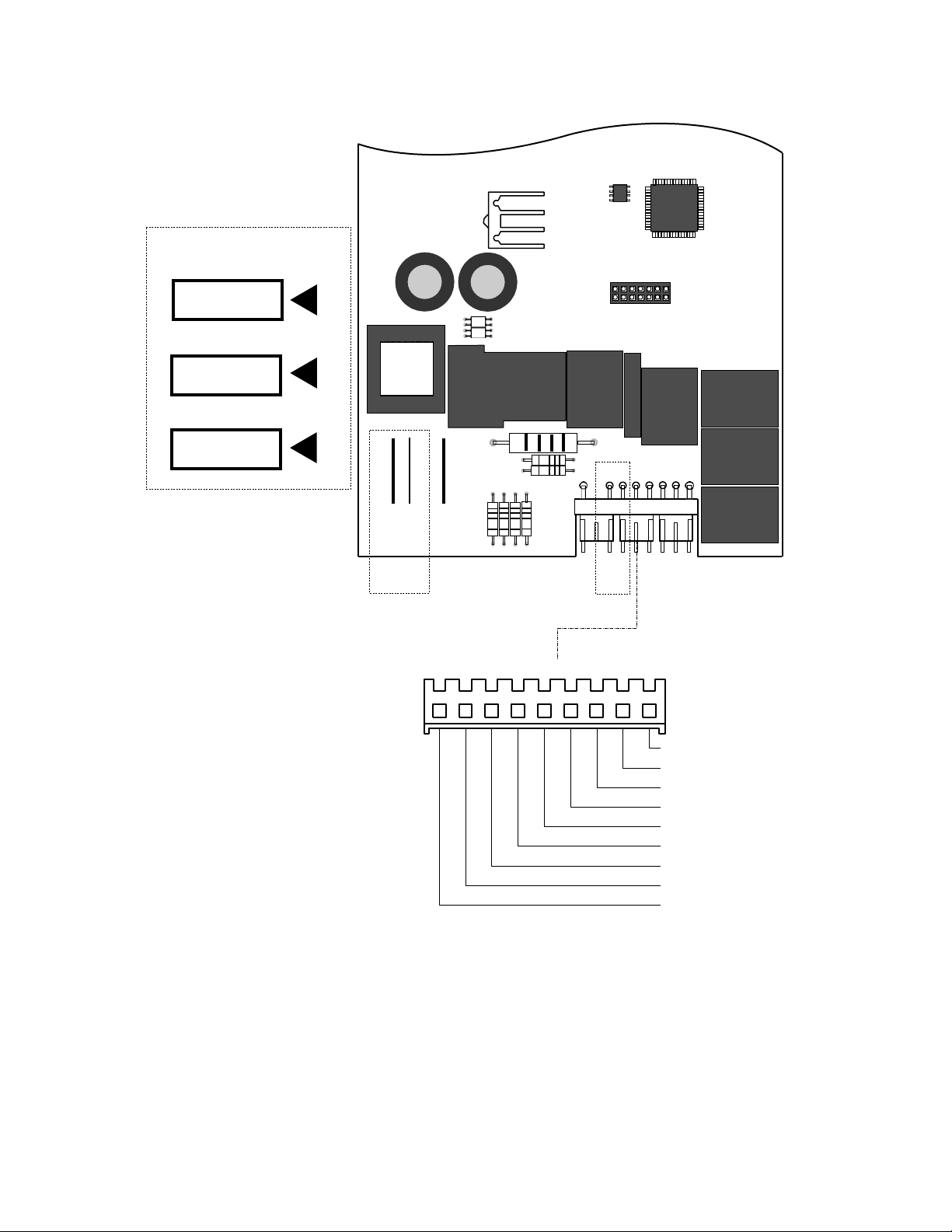

Main Control Board Locator Box (Low-Voltage Side)

Connector

Pin

Wire

color

Component

Termination

Pin-to-Pin Voltage

Reading

J1

1

Blue/Red

Thermistor # 1

Cooler

J1 pin 1 to pin 5 = 2.8

to 3.5 VDC

J1

2

Yellow

Thermistor # 2

Cooler

J1 pin 2 to pin 5 = 2.8

to 3.5 VDC

J1

3

Red White

Freezer thermistor

J1 pin 3 to pin 5 = 2.8

to 3.5 VDC

J1

4

Blue/White

Evaporator

thermistor

J1 pin 4 to pin 5 = 2.8

to 3.5 VDC

J1

5

Blue

Supply voltage

thermistor (5 VDC)

J1 pin 5 to J4 pin 3 =

5 VDC

J2

1

Blue

Tachometer of the

evaporator fan.

J2 pin 1 to pin 3 =

6.3 VDC

J2

2

Blue/White

Fan inlet

J2 pin 2 to pin 3 =

12 VDC

J2

3

White

Common fan

J2 pin 3 to pin 8 =

12 VDC

J2

4

Yellow/Black

Evaporator fan

J2 pin 4 to pin 3 = 12.4

VDC (high speed),

8 VDC (low speed)

J2

5

Yellow

Common fan

J2 pin 5 a pin 3 = 13.4

VDC (ventilador del cond

es de una velocidad)

J2

6

Black/White

Evaporator fan

J2 pin 6 a pin 3 = 0 VDC

(high speed), 3 VDC (low

speed)

J2

7

Not in use

Non applicable

Non applicable

J2

8

Red

Supply of energy to

the fan (12 VDC)

J2 pin 8 to pin 6 =

13.4 VDC (high vel), 9

VDC (low vel) J2 to 8

to J4 pin 3 = 13.4 VDC

Continues in next page.

Page 39

- 37 -

Main Control Board Locator Box (Low-Voltage Side)

Connecto

r

Pin

Wire

color

Component

ending

Pin-to-Pin

Voltage Reading

J3

1

Yellow

Shock absorber

J3 pin 1 to J4 pin 3 =

Stagnating voltage2.3

VDC Voltage running 6.0

VDC

J3

2

Red/Black

Shock absorber

J3 pin 2 to J4 pin 3 =

Stagnating voltage2.3

VDC Voltage running 6.0

VDC

J3

3

White/Brown

Shock absorber

J3 pin 3 to J4 pin 3 =

Stagnating voltage2.3

VDC Voltage running 6.0

VDC

J3

4

Blue/Yellow

Shock absorber

J3 pin 4 to J4 pin 3 =

Stagnating voltage2.3

VDC Voltage running 6.0

VDC

J4

1

Black

Common dispensing

board transmits /

receives

See the scheme

J4

2

Red

Common dispensing

board

12 VDC

See the scheme

J4

3

Blue

Common grounding

board

See the scheme

Continues on next page.

Page 40

- 38 -

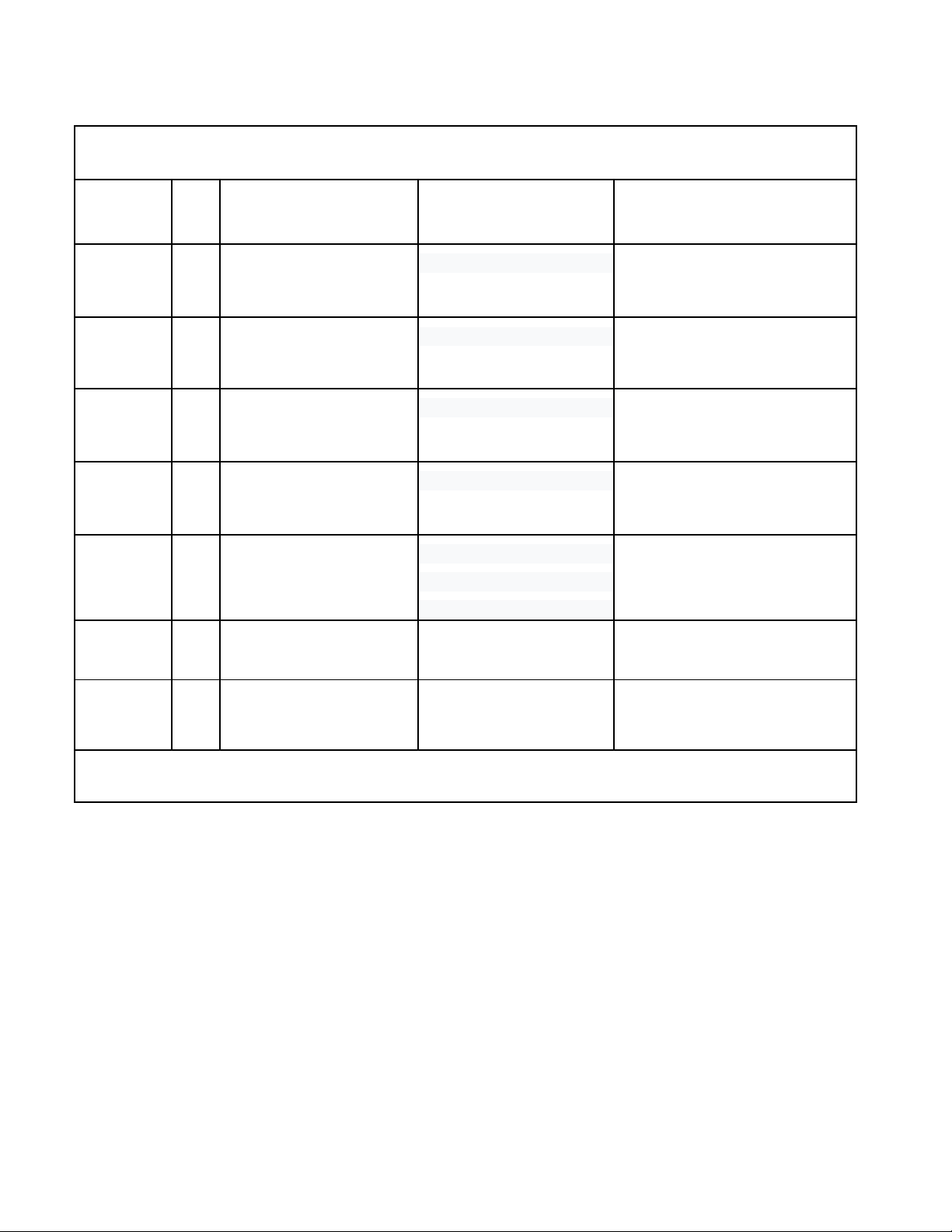

Main Control Board Locator Table

(Side 120-VAC)

Connector

Pin

Wire

Color

Component

ending

Pin-to-Pin Voltage

Reading

J7

1

Beige

Drill motor

J7 pin 1 a J7 pin 9 +

120 VAC

J7

2

Silver

Selenoid cube

J7 pin 2 a J7 pin 9 +

120 VAC

J7

3

Yellow

Water valve

J7 pin 3 a J7 pin 9 +

120 VAC

J7

4

Red/White

Interlock drilling

motor

J7 pin 4 a J7 pin 9 +

120 VAC

J7

5

Blue/White

Quick cooler heater

J7 pin 5 a J7 pin 9 +

120 VAC

J7

6

Purple

Door light cooler

feedback switch

J7 pin 6 a J7 pin 9 +

120 VAC

J7

7

Red

Light freezer door

switch feedback

J7 pin 7 a J7 pin 9 +

120 VAC

J7

8

No se usa

Not used

No se usa

J7

9

Orange

Neutral

Neutral

Page 41

Page 42

Page 43

Page 44

Page 45

Page 46

Page 47

Page 48

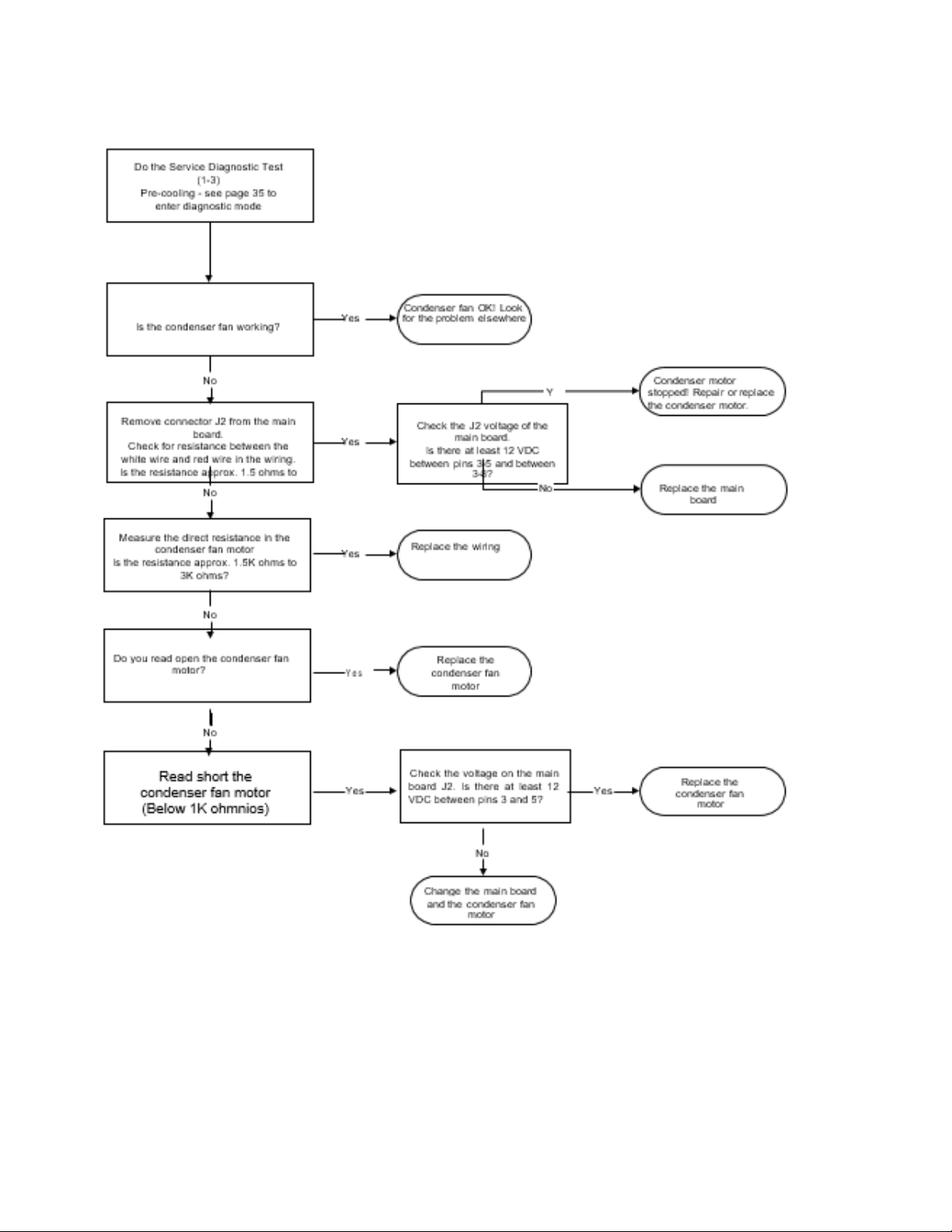

The Condenser Fan Does Not Work

Page 49

Page 50

Page 51

Page 52

Page 53

Table 3. Thermistor values

Temperature

Degrees (C)

Temperature

Degrees (F)

Resistence in

Kilo-Ohmnios

-40

-40

166.8 k

-35

-31

120.5 k

-30

-22

88 k

-25

-13

65 k

-20

-4

48.4 k

-15

5

36.4 k

-10

14

27.6 k

-5

23

21 k

0

32

16.3 k

5

41

12.7 k

10

50

10 k

15

59

7.8 k

20

68

6.2 k

25

77

5 k

30

86

4 k

35

95

3.2 k

40

104

2.6 k

45

113

2.2 k

50

122

1.8 k

55

131

1.5 k

60

140

1.2 k

NOTE: The resistance of the thermistors has a negative coefficient. As the temperature increases, the resistance of

the thermistor decreases.

- 51 -

Page 54

- 52 -

Component Location and Connector Views

Switch

freezer

light

Light

Evaporator

thermistor

Evaporator

Freezer

thermistor

Evaporator

fan

Defrost

thermistor

Heater defrost

Page 55

- 53 -

Shock absorber

Cooler thermistor

Cooler

lights

Cooler

light

switch