Page 1

- 1 -

Service Manual

June-2016

Top Load Washer Kraken 27”

HTW200BMKWW GTW460BMKWW

MTW200BMKWW GTW485BMKWS

GTW220BMKWW GTW680BMKWS

GTW330BMKWW GTW680BMKDG

GTW465BMKWS

Ingeniería de Servicio

Page 2

- 2 -

IMPORTANT SAFETY NOTICE

IMPORTANT SAFETY NOTICE

The information in this presentation is intended for use by individuals

possessing adequate backgrounds of electrical, electronic, & mechanical

experience. Any attempt to repair a major appliance may result in personal

injury & property damage. The manufacturer or seller cannot be

responsible for the interpretation of this information, nor can it assume any

liability in connection with its use.

WARNING

To avoid personal injury, disconnect power before servicing this

product. If electrical power is required for diagnosis or test purposes,

disconnect the power immediately after performing the necessary

checks.

RECONNECT ALL GROUNDING DEVICES

If grounding wires, screws, straps, clips, nuts or washers used to complete

a path to ground are removed for service, they must be returned to their

original position & properly fastened.

Mabe authorized Service Technicians are required to use the Personal

Protection Equipment (PPE) listed below, for your own protection.

Ingeniería de Servicio

Page 3

- 3 -

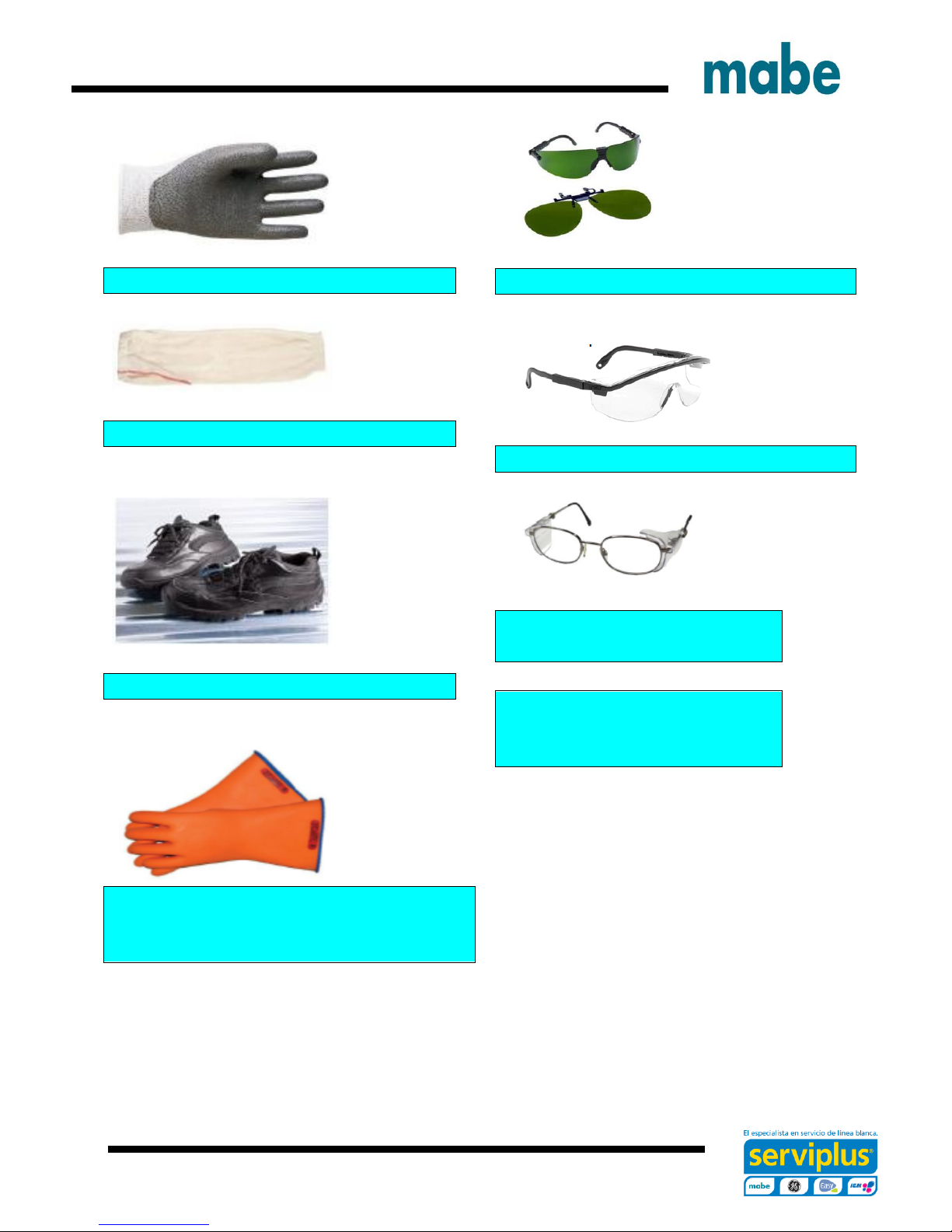

Dyneema® Cut Resistant Glove

Cut Resistant Sleeve(s)

Steel Toe Work Boot

Brazing Glasses

Plano Type Safety Glasses

Prescription Safety

Glasses

Safety Glasses must be

ANSI Z87.1-2003

compliant

Electrically Rated Glove and

Dyneema® Cut Resistant Glove

Keeper

Ingeniería de Servicio

Page 4

- 4 -

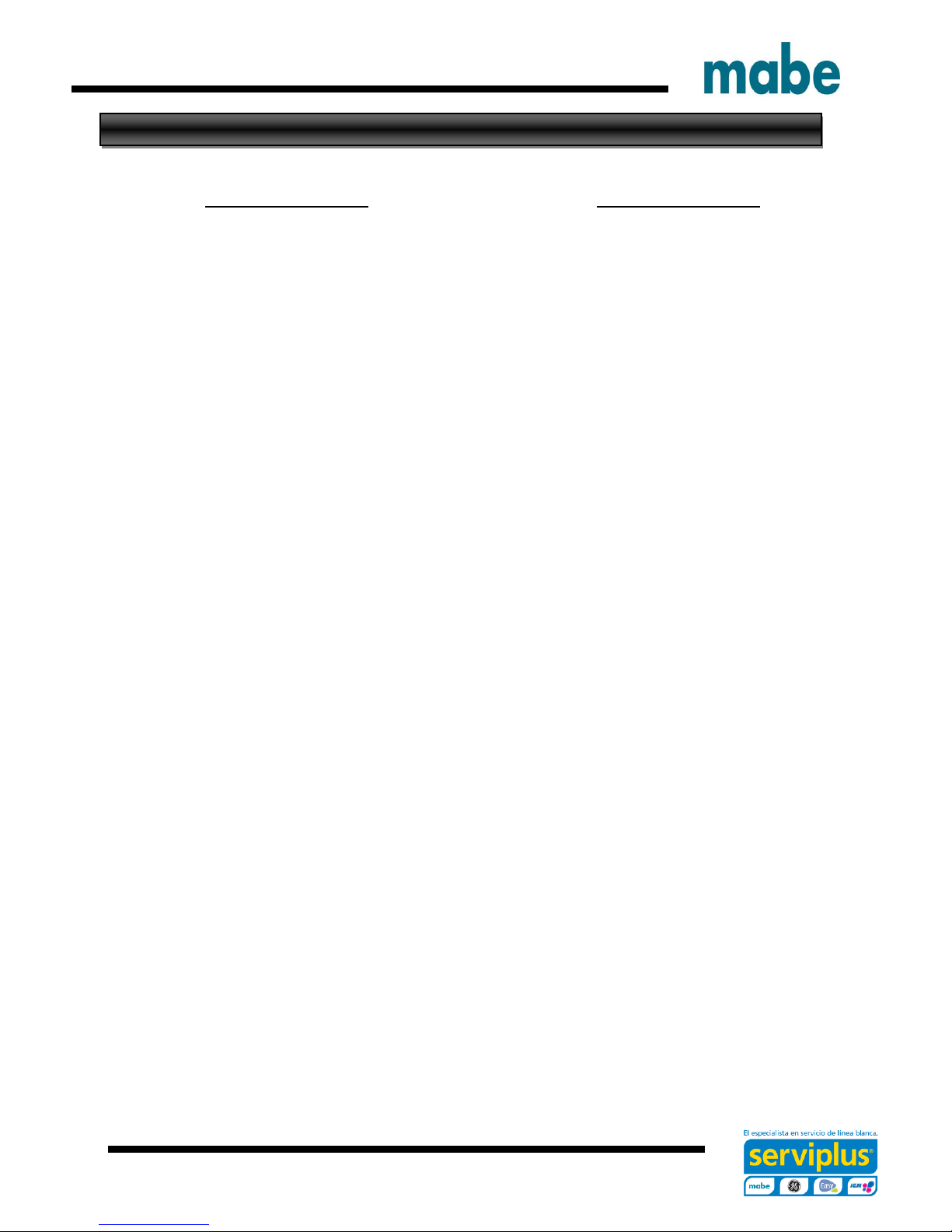

CAUTION

Prior to disassembly of the Washer to access components,

Mabe authorized Service Technicians are REQUIRED to

follow the Lockout / Tagout (LOTO) 6 Step Process

Step 1

Plan and Prepare

Step 4

Apply LOTO device & Lock

Step 2

Shut down the appliance

Step 5

Control (discharge) stored

energy

Step 3

Isolate the appliance

Step 6

“Try It” Verify that the

appliance is locked out

Ingeniería de Servicio

Page 5

- 5 -

Some Features & Benefits

GTW460 Models

Deep Fill: Adds more water for larger

loads.

Dual-Action Agitator: Provide gentle,

dual-wash action.

Deep Rinse: Removes any leftover

soap residue.

Auto Soak: Loosens stains by soaking

up to 2 hours.

Speed Wash: Delivers ready-to-go

results within minutes.

Load Size: Automatically measures

load size, and adjusts settings and

water levels accordingly. Settings are

customizable, so you always get the

wash you want.

GTW680 Models

Sanitize with Oxi: Remove 99.9% of

bacteria with a dedicated cycle that

uses an Oxi additive to boost your

detergents cleaning power while

keeping fabric looking their best.

Stain Removal Guide: Assist removing

tough stains with preprogrammed

settings that modify your cycle to treat

the four most common stains.

Warm Rinse: Just what the consumer

ordered. The option to select between

a warm or cold rinse.

Deep Fill: Adds more water for larger

loads.

Deep Rinse: Removes any leftover

soap residue.

Auto Soak: Loosens stains by soaking

up to 2 hours.

Ingeniería de Servicio

Page 6

- 6 -

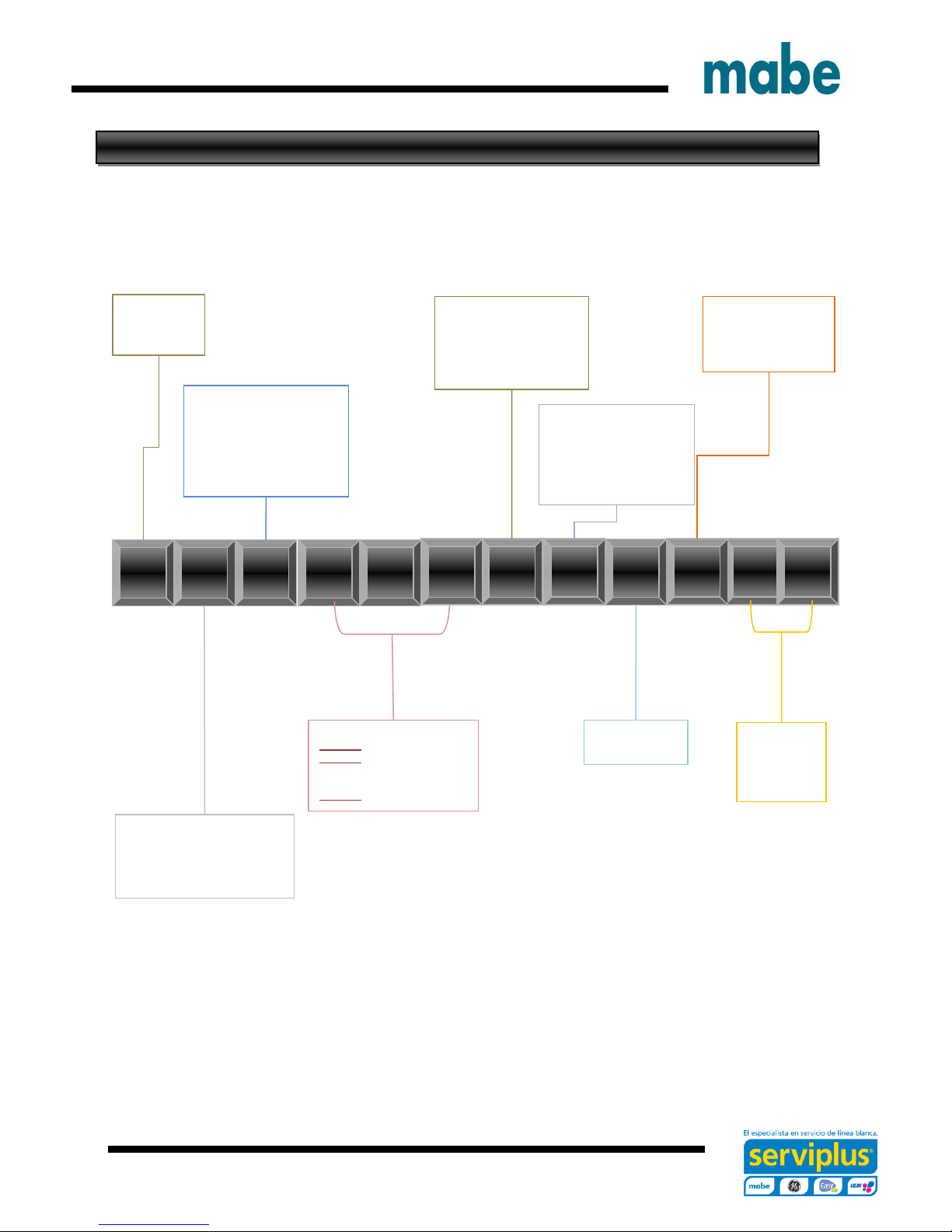

T

W

6

8

B

M

K

W

Brand

G = GE

H = Hot Point

M = Moffatt

Configuration:

F = Front Load

T = Top Load – Rear Control

N = Top Load – Front Control

U = Unitized

Platform:

W = Washer

D = Vented Dryer – Std

V = Vented Dryer – Long

C = Condenser Dryer

H = Heat Pump

Z = Flat Back Dryer – Long

X = Flat Back Dryer - Std

Series 1, 2, 3:

Series 1 = 1-9

Series 2 = 1-9

4 = 24” unitized

7 = 27” unitized

Series 3 = 1-9 Washer only

Partner Type

P = Premium Cost (color)

H = Home Depot

L = Lowes

S = Standard

C = Contract (Hoses)

M = Mabe

Year:

K = 2016

Engineering Number

0

1

2

Color:

W

S

0

0

G

S

Product Type

R = Riser

A = 2” Cover Top Load

B = 4” Cover Top Load

S = Standard / Stationary

P = Portable

Nomenclature

The nomenclature breaks down and explains what the letters and numbers mean in the model

number

Seguridad Advertencias y

Ingeniería de Servicio

Page 7

- 7 -

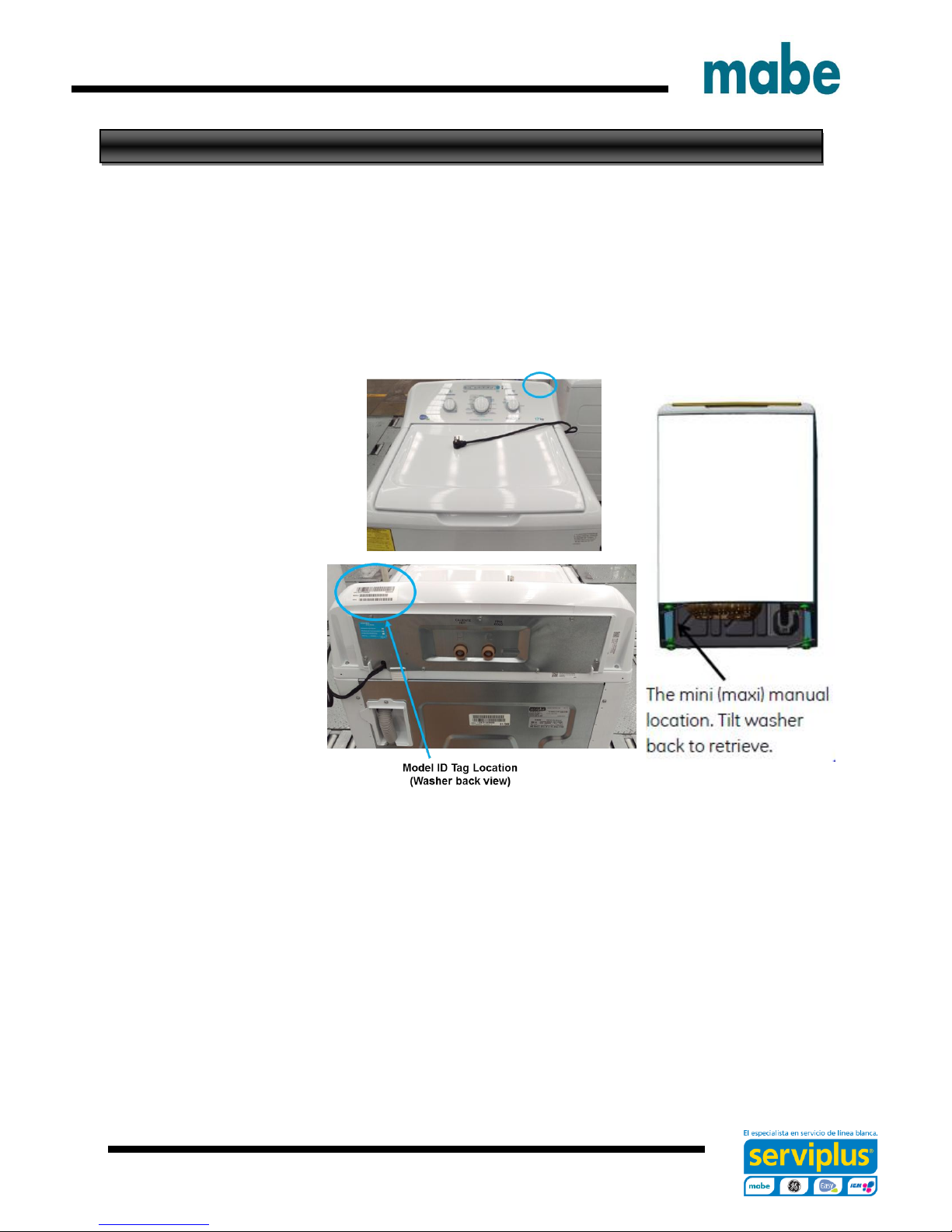

Serial Number and Mini Manual Location

Serial Number

The Serial Number breaks down and explains what the letters and numbers mean in its

structure:

Example of Serial Number: LG312345C

The first two characters of the serial number identify the month and year of manufacture: LG =

June, 2016

A = JAN A = 2013

D = FEB D = 2014

F = MAR F = 2015

G = APR G = 2016

H = MAY H = 2017

L = JUN L = 2018

M = JUL M = 2019

R = AUG R = 2020

S = SEP S = 2021

T = OCT T = 2022

V = NOV V = 2023

Z = DEC Z = 2024

The letter designating the year repeats every 12 years

The third character denotes the product being produced: 3 = Washer (Saltillo, Mexico)

Character 4 thru 8 will denote the number of units built for a given product and will start with

00001 at the beginning of each fiscal month and progress sequentially until 99,999 is

reached or the fiscal month has changed.

Character 9 will denote the Brand and Manufacturing site of final assembly: (Saltillo, Mexico:

C = GE, M = Signature, H = HPT)

The Model Serial ID Tag is located on the right top edge of the backsplash (left top edge from

back view).

The Mini Manual is in a storage bag inside the cabinet at bottom left side.

Ingeniería de Servicio

Page 8

- 8 -

Water Levels

Approximate Minimum Water Levels

Impeller – 7 Gallons or 3 in. depth from

the bottom of the basket.

Agitator – 9 Gallons or 3-3/4 in. depth

from the bottom of the basket.

Test are completed with an empty basket.

Approximate Maximum Water Levels

Impeller – 26 Gallons or 13-1/2 in.

depth from the bottom of the basket.

Press and hold for 3 seconds “Deep

Fill” to achieve.

Impeller “Bulky” setting water level is

25 gallons or 12-3/4 in. depth from the

bottom of the basket.

Agitator – 26 Gallons or 12-1/2 in.

depth from the bottom of the basket.

Set to super.

Ingeniería de Servicio

Page 9

- 9 -

Model Graphics

Ingeniería de Servicio

Page 10

- 10 -

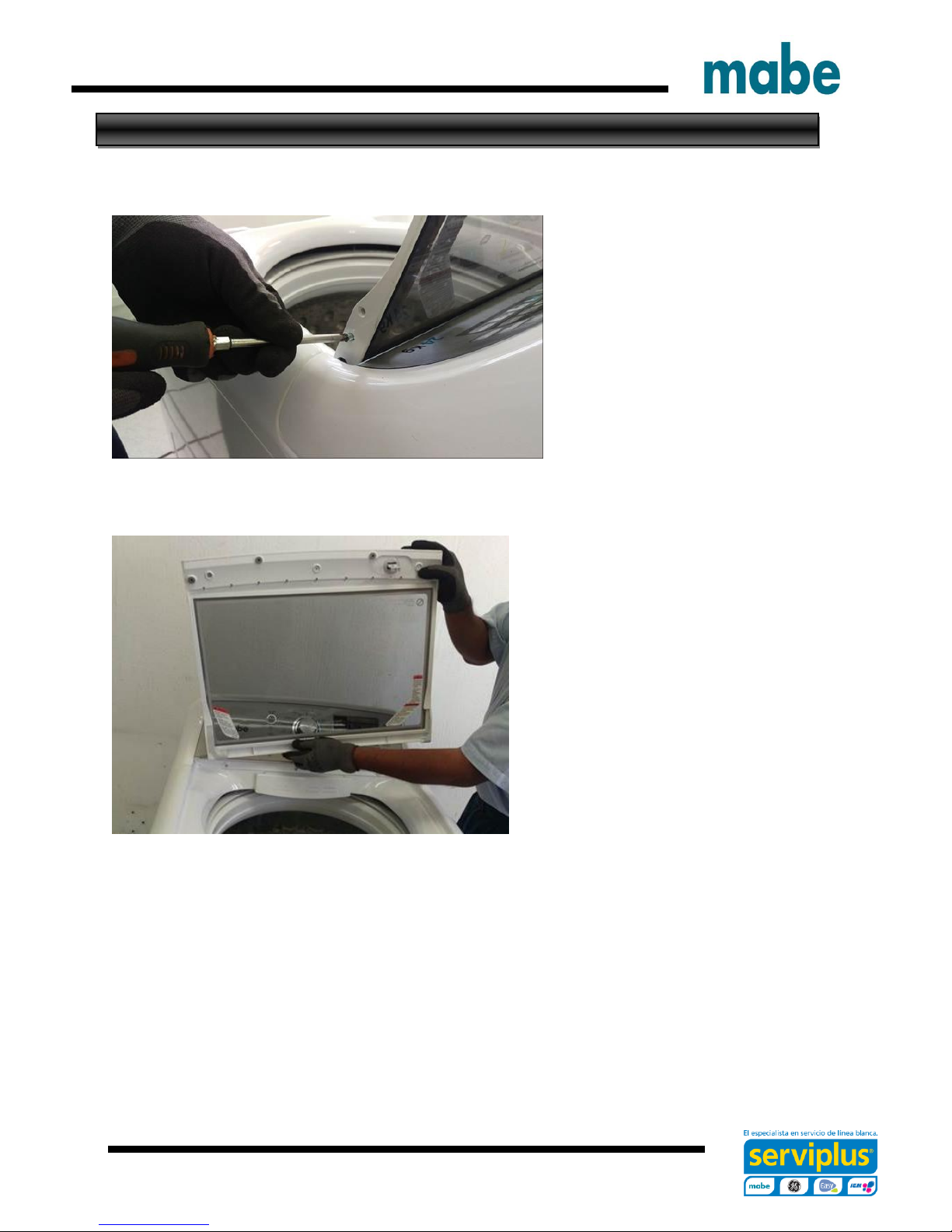

Lid Assembly Removal

Remove the two Philips head

screws of one Hinge (Right or Left

side).

Slide the lid toward the Hinge

Removed and lift it up to remove

Ingeniería de Servicio

Page 11

- 11 -

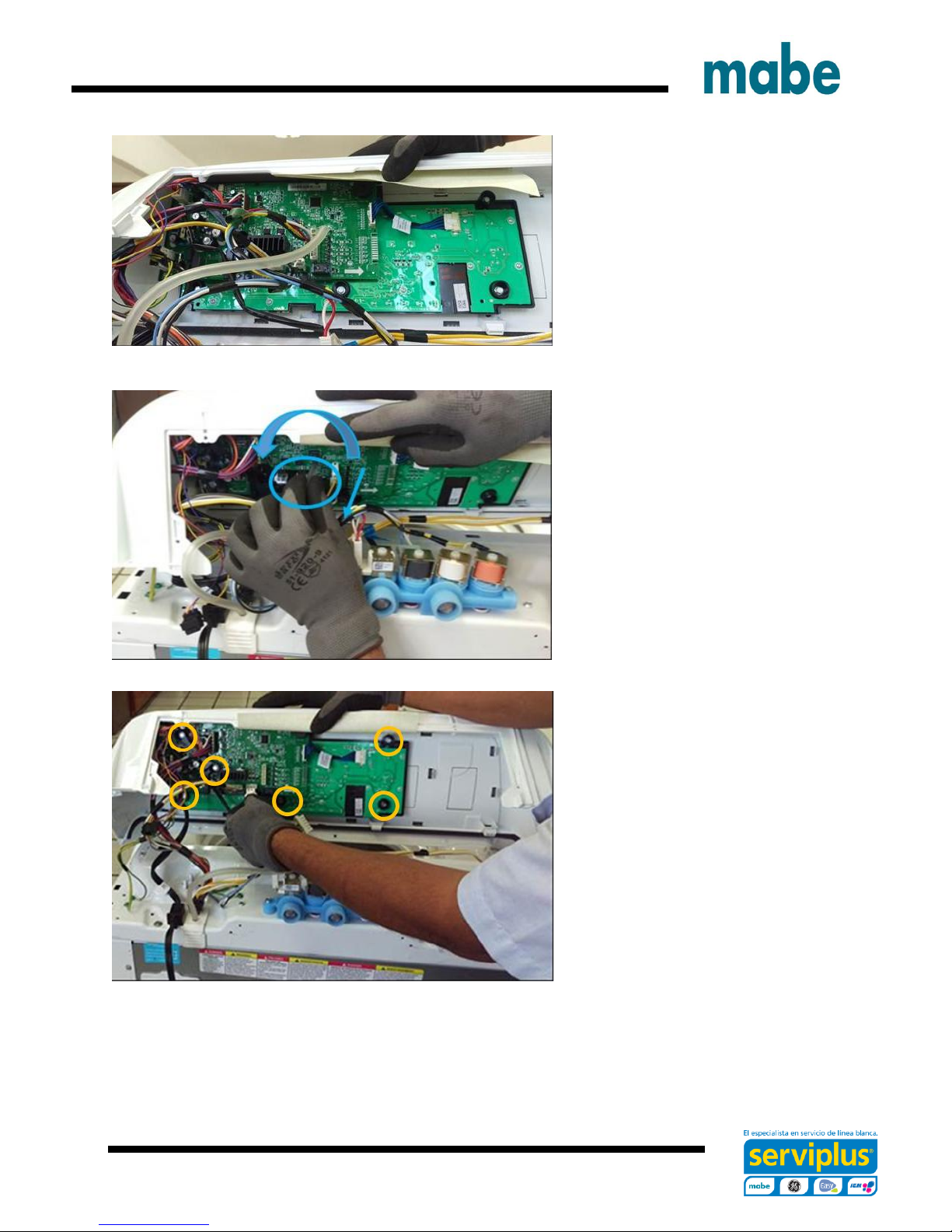

Control Panel Assembly Removal

To remove the control panel assembly, first remove the lid assembly.

Remove the three Philips head

screws that secure the control

panel assembly to the top cover

at front.

Remove the seven ¼ in. hex head

screws from the back panel and

remove it.

Remove the two ¼ in. hex head screws

from the rear corners on the control panel

IMPORTANT.- Do not move the control panel until disengaging the pressure tube from

the control board, otherwise the pressure sensor could be damaged.

Ingeniería de Servicio

Page 12

- 12 -

Grasp the control panel and

push it a little toward the front of

the washer in order to see the

pressure tube.

To disengage the pressure tube

from the control board, grasp the

tube where it connects to the

pressure sensor on the board.

Twist the tube while pulling it off

the sensor

IMPORTANT.- Pressure tube

should not be handled vertically

or horizontally as there is a risk

of damage to the pressure

switch, only must disengage as

indicated above.

Disconnect connectors from the

control board and remove six ¼

in. hex screws securing the

control board bracket to the

control panel assembly and

remove.

IMPORTANT.- When reinstalling the control panel assembly, ensure that all ground

wires are reconnected and tested for proper continuity to the ground terminal on the

power cord.

Ingeniería de Servicio

Page 13

- 13 -

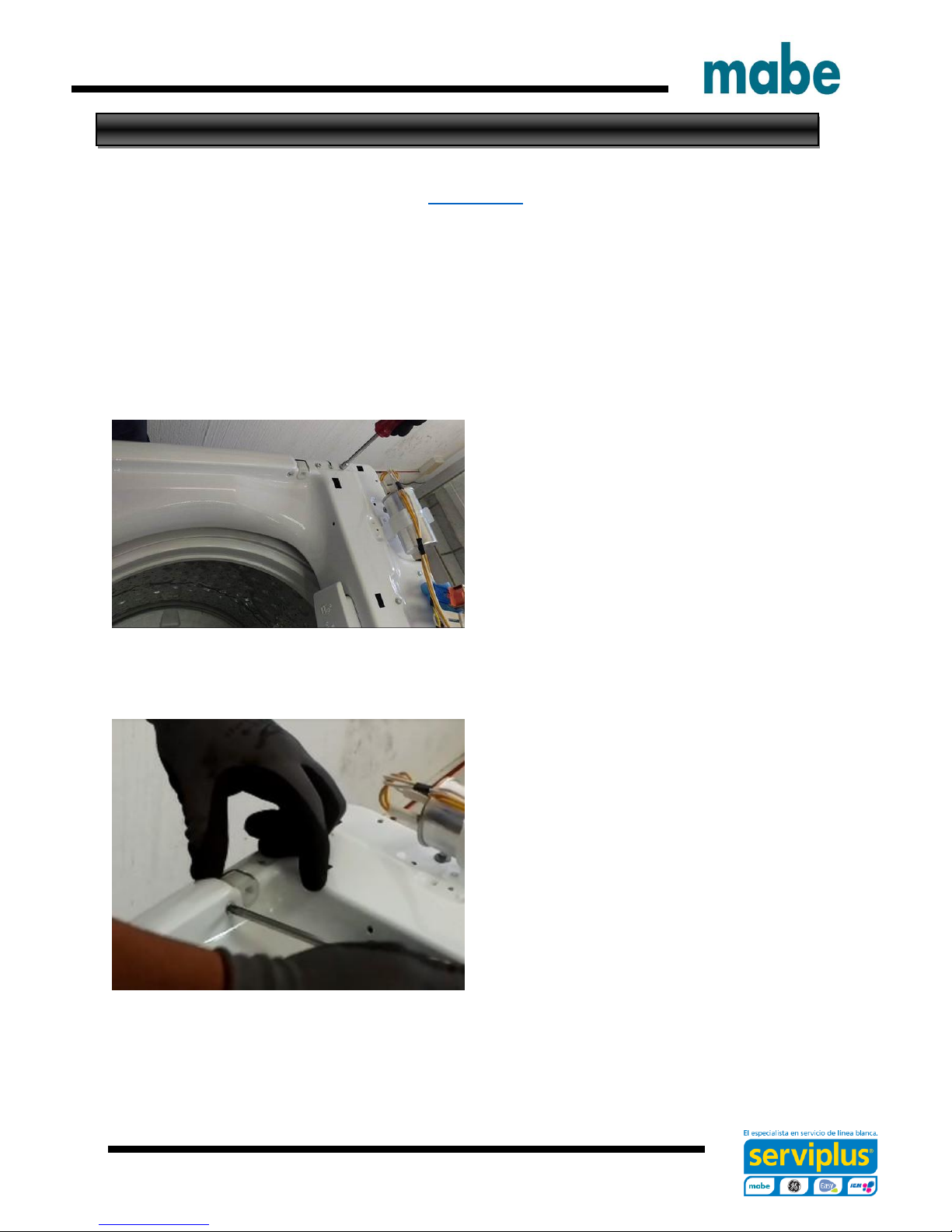

Lid Hinge

Video Link

Hinge removal can be achieved without removing the top cover or disconnecting the

control panel assembly completely.

Remove the lid assembly.

Disengage the control panel from the top cover and slide toward the rear to expose the

hinge mounting screws.

Remove the two ¼ in. hex head hinge

mounting assembly screws

Remove the Philips head screw from the

top cover.

Ingeniería de Servicio

Page 14

- 14 -

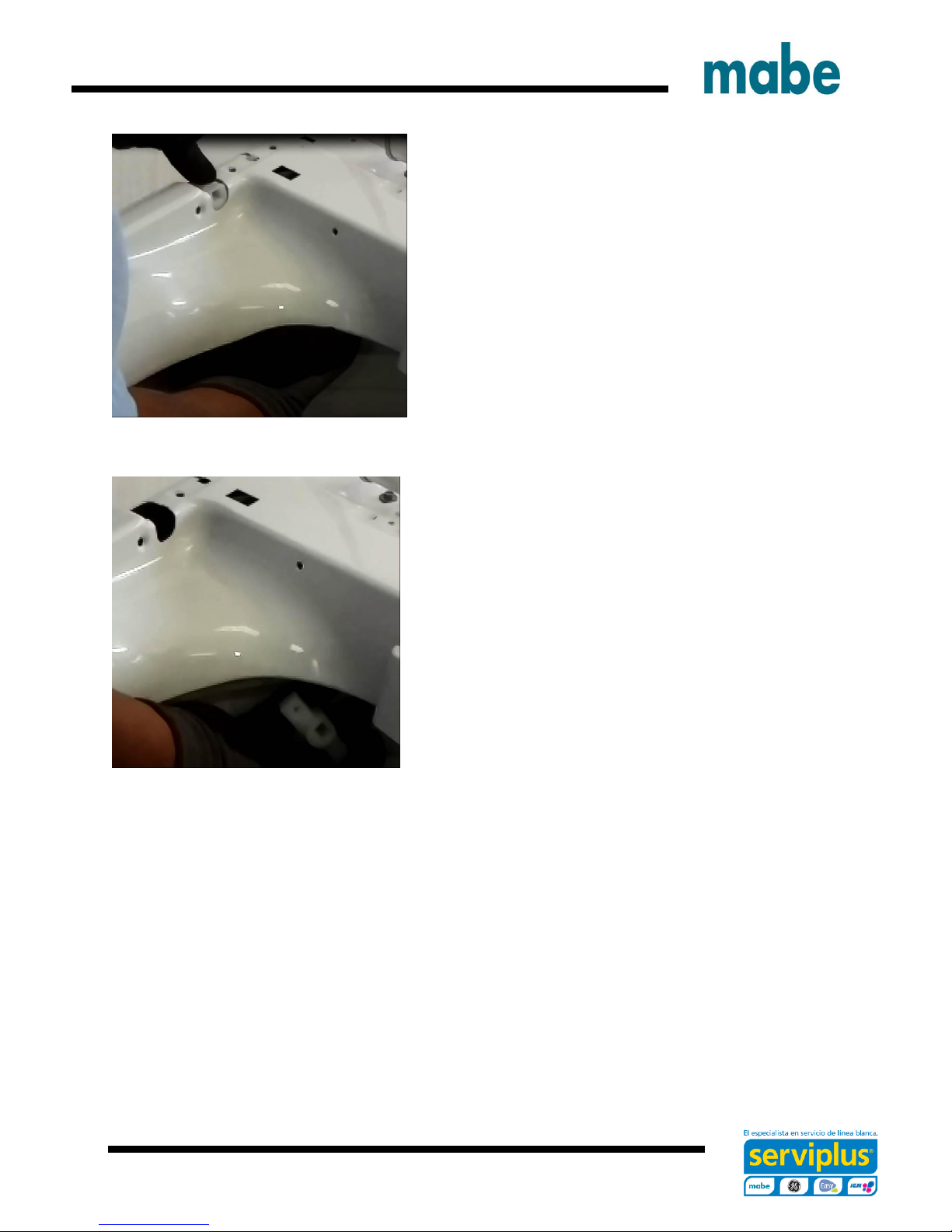

Slide a hand between the tub cover and the top

cover.

Grasp the hinge assembly and remove it from

under the top cover.

Ingeniería de Servicio

Page 15

- 15 -

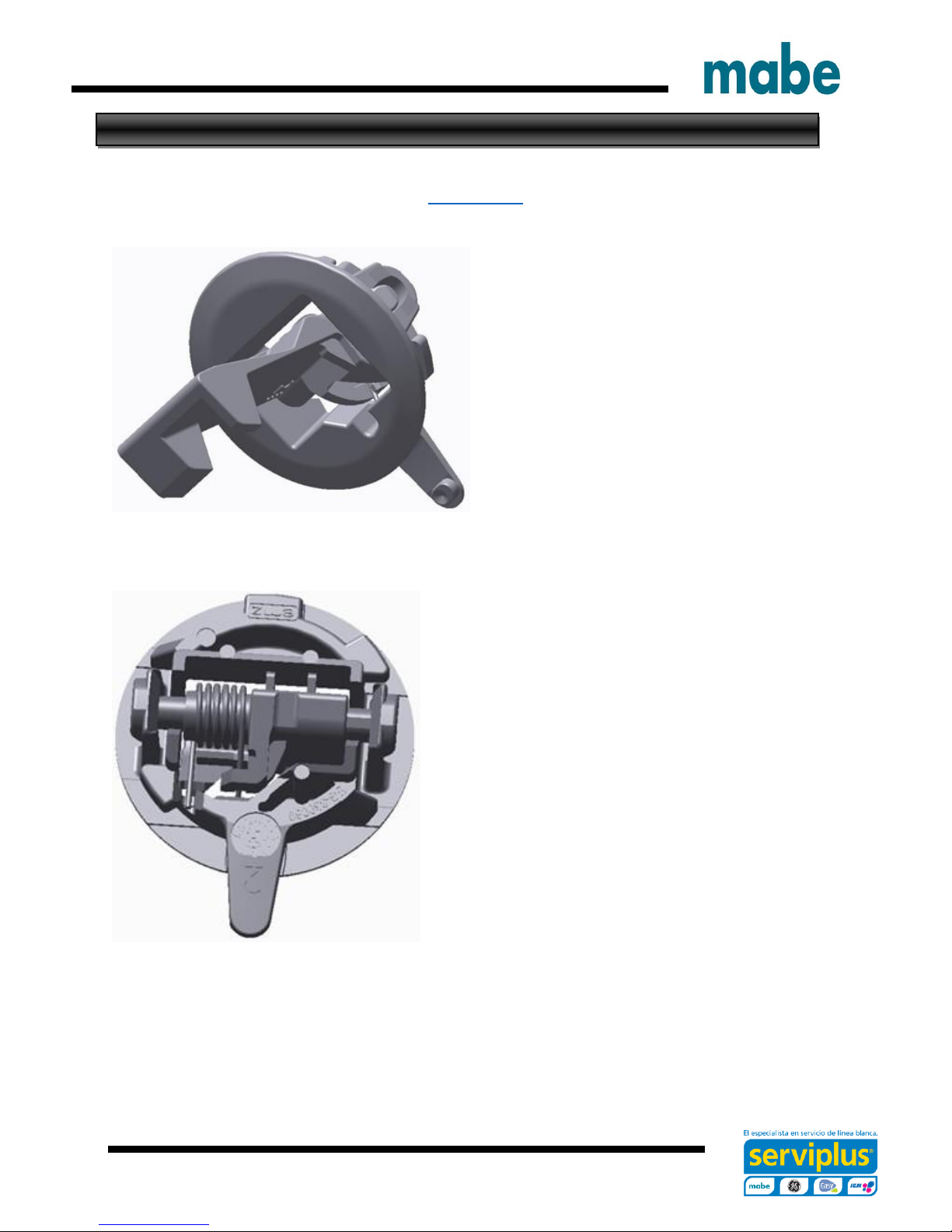

Lid Lock Striker

Video Link

The lid lock striker slides into the lid

lock/switch assembly. When a cycle is

started the lock assembly engages with

the striker preventing the lid from opening

during the cycle.

The latch has spring tension on it to keep it

engaged with the switch/lock assembly

Ingeniería de Servicio

Page 16

- 16 -

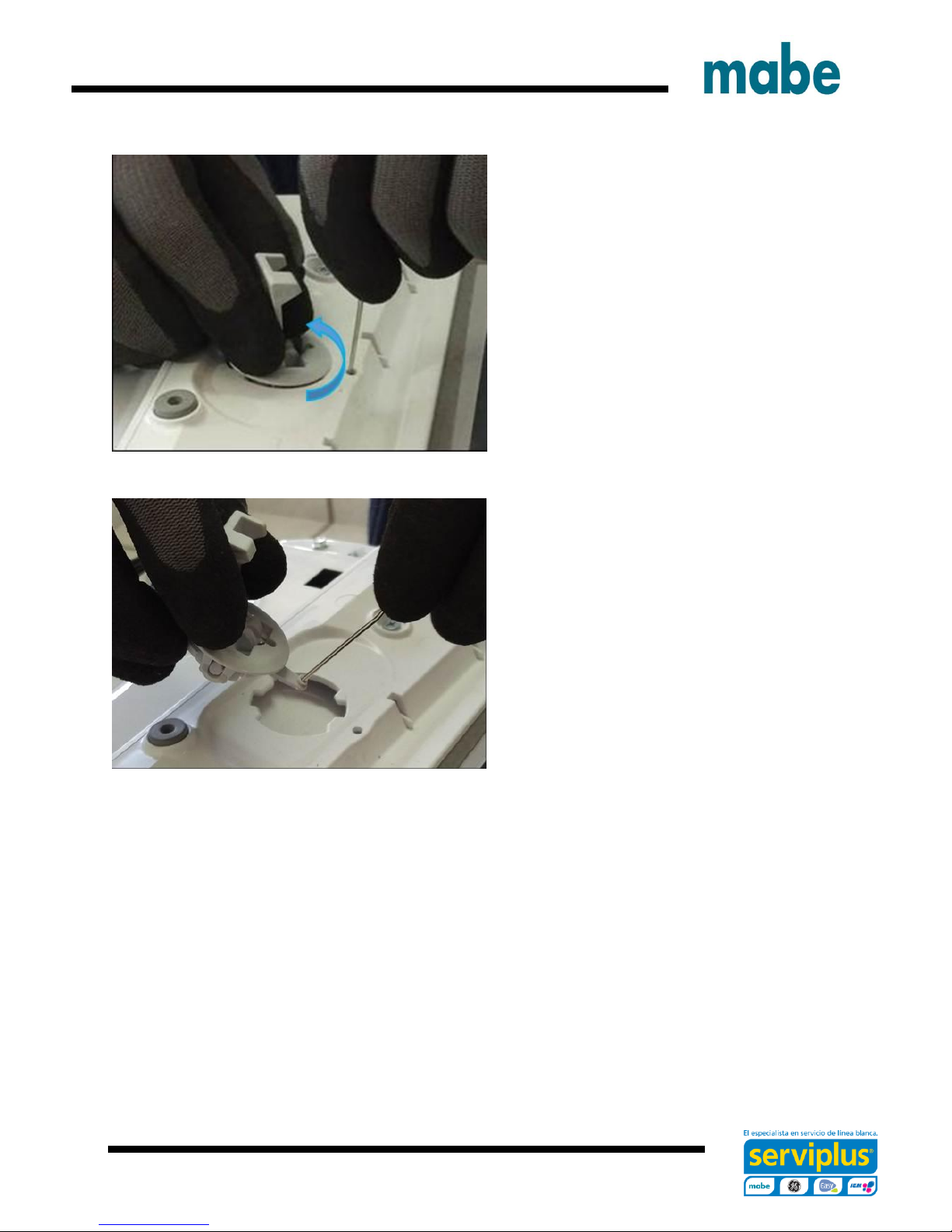

To remove the striker from the lid:

Open the lid.

Using a small screwdriver, insert it into

the small hole below the striker.

Push inward gently on the locking tab

and turn the striker to the left

Pull the striker from the lid

Ingeniería de Servicio

Page 17

- 17 -

Lid Switch/Lock Assembly

Video Link

The lid lock and switch are together in

one part. It requires 120 VAC to activate

the lock.

The approximate resistance of the lock

coil is 70 ohm from Blue – Black from

J513 board connector (at Lid Lock closed

position)

Checking between Black and White wires

at the same board connector will show the

continuity of the lid switch.

To remove the lid switch/lock assembly:

Ingeniería de Servicio

Page 18

- 18 -

Remove the bezel from the top cover by

reaching under the top cover toward the

lock assembly and feel for the bezel tabs

to extend through the lock body.

Push the tabs out from the side of the

lock body and then push up to

remove the bezel from the top cover

Ingeniería de Servicio

Page 19

- 19 -

Using a small screwdriver, push down

gently on the tab that prevents the lock

assembly from sliding.

Slide the lock assembly to the left first to

disengage the right tab, then slide to the

right allowing the lock assembly

disengage from the top cover.

Pull the lock assembly from under the

top cover and disconnect the harness

connector.

Ingeniería de Servicio

Page 20

- 20 -

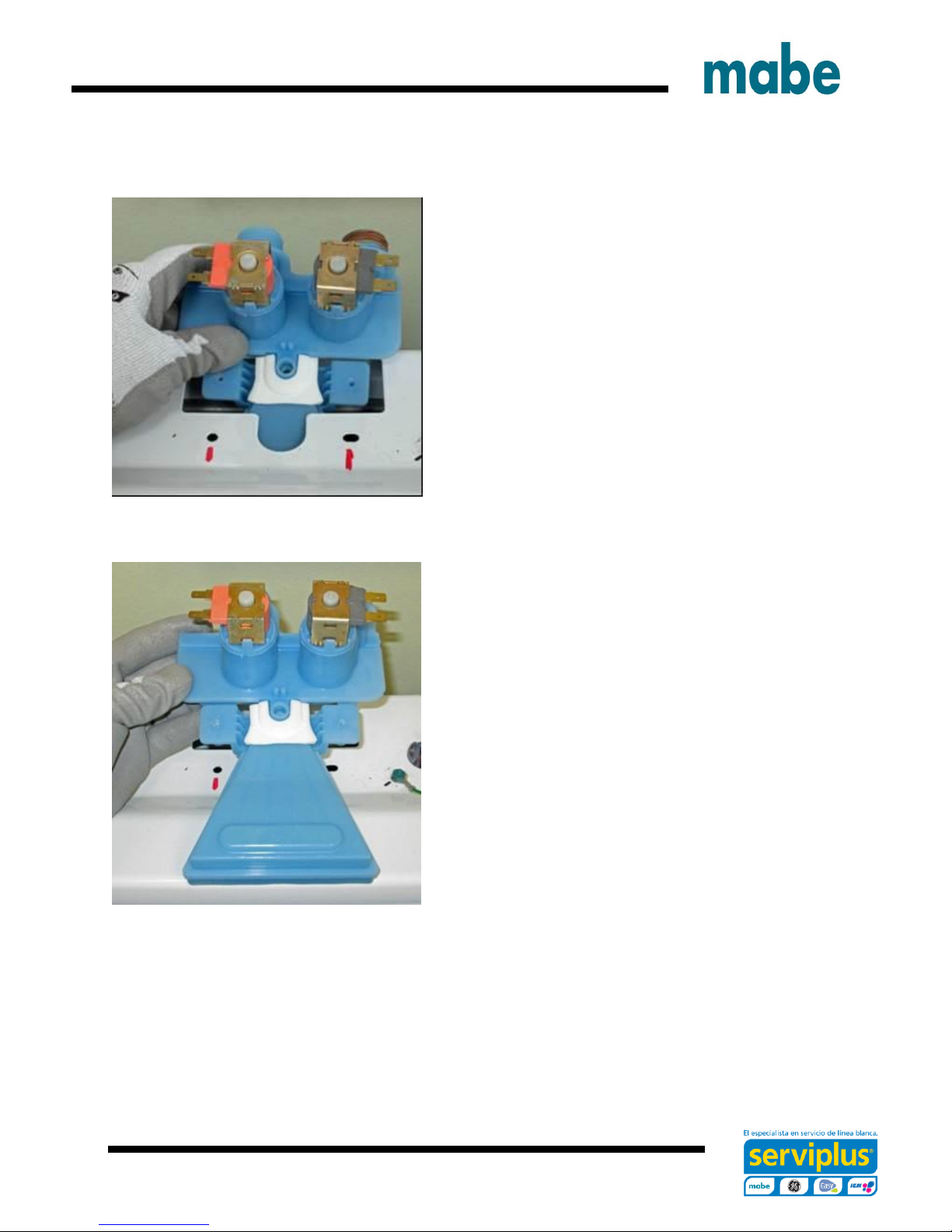

Two Coil Water Valve

Turn water supply off to valve. Hoses do

not need to be disconnected at this time.

Remove two Phillips head screws that go

through the thermistor mounting bracket

into the body of the valve.

Remove thermistor by pulling up on lip of

thermistor. Ensure o-ring is removed with

thermistor.

Ingeniería de Servicio

Page 21

- 21 -

Tilt back of valve up and slide out of top cover.

Once valve is out and held over the basket,

disconnect hoses.

Valve, funnel and Gasket are one part.

Ingeniería de Servicio

Page 22

- 22 -

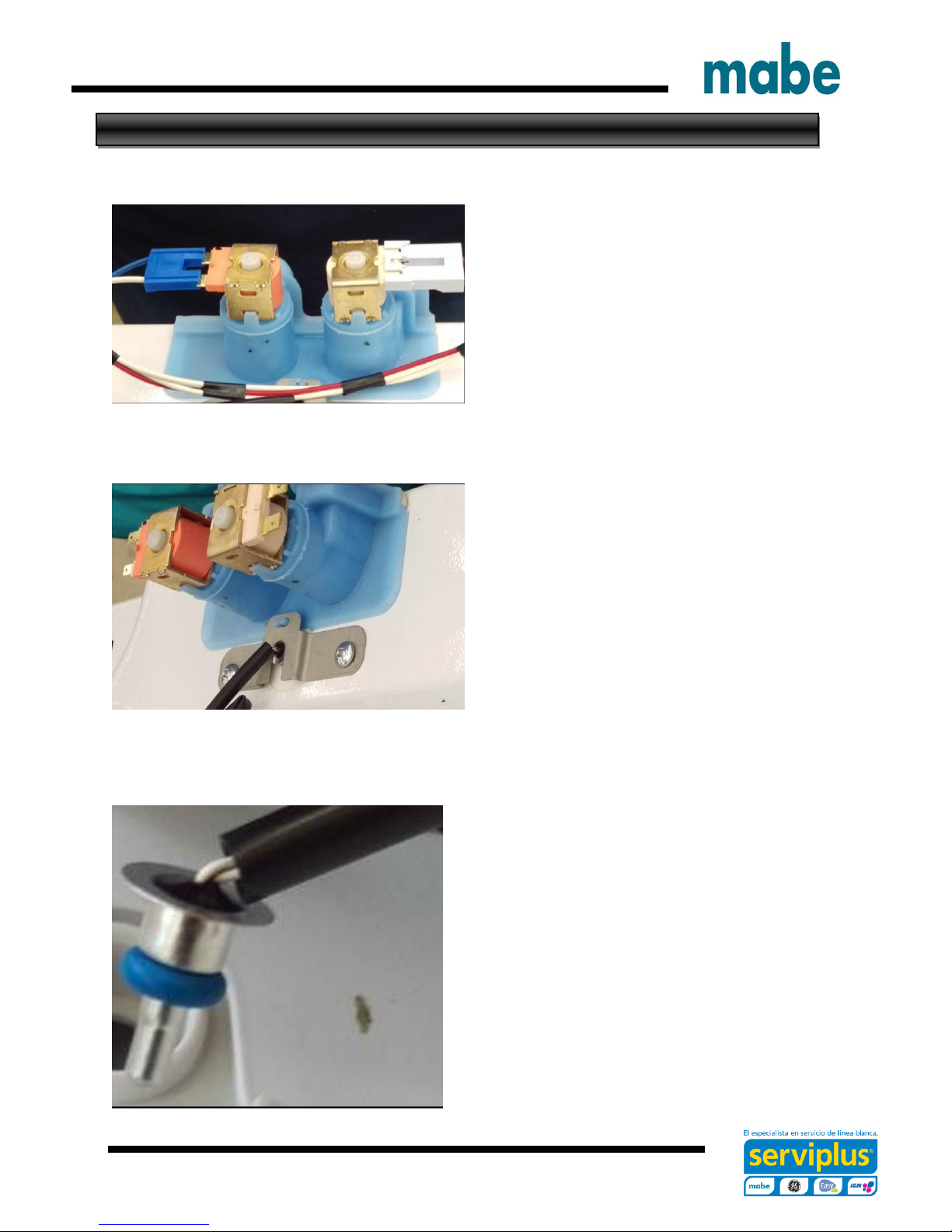

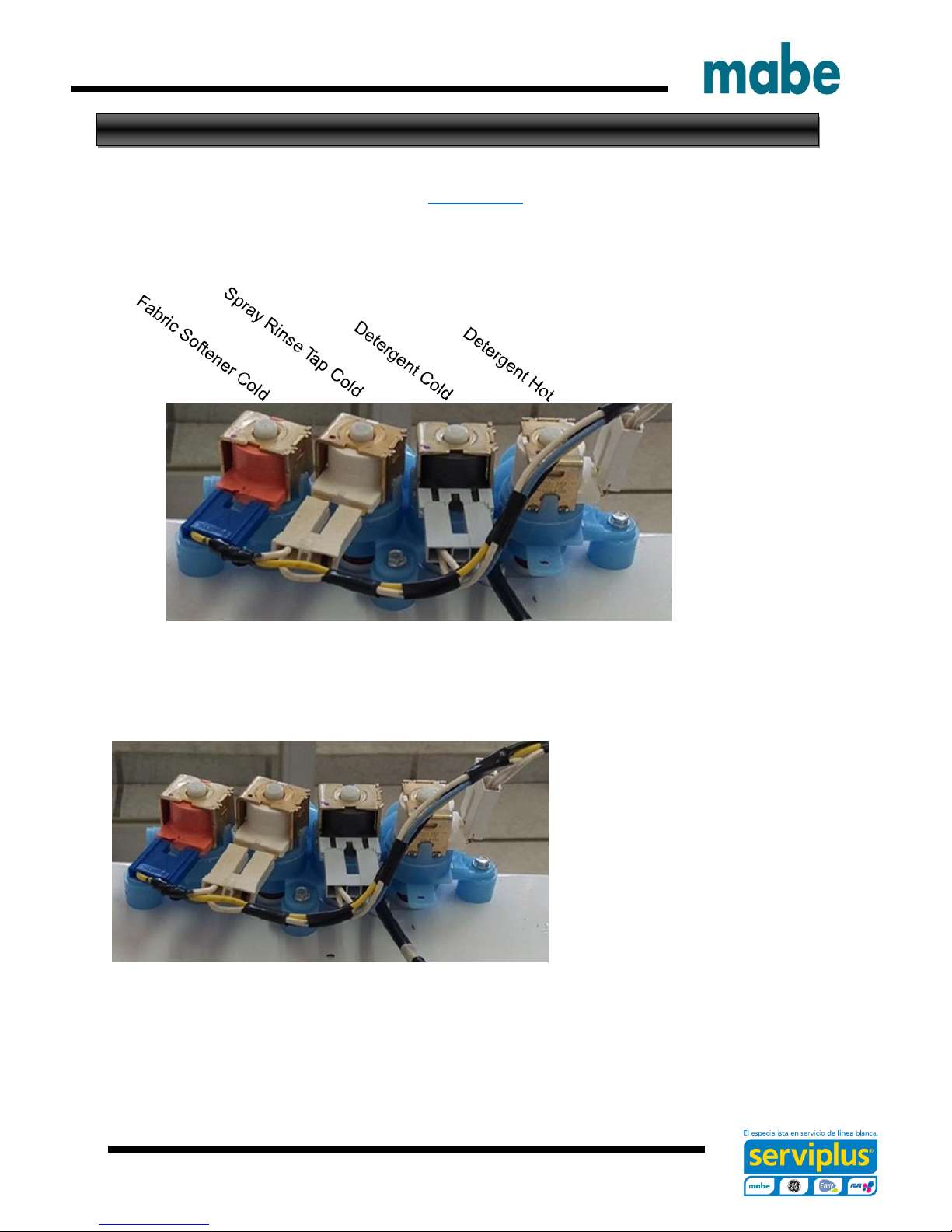

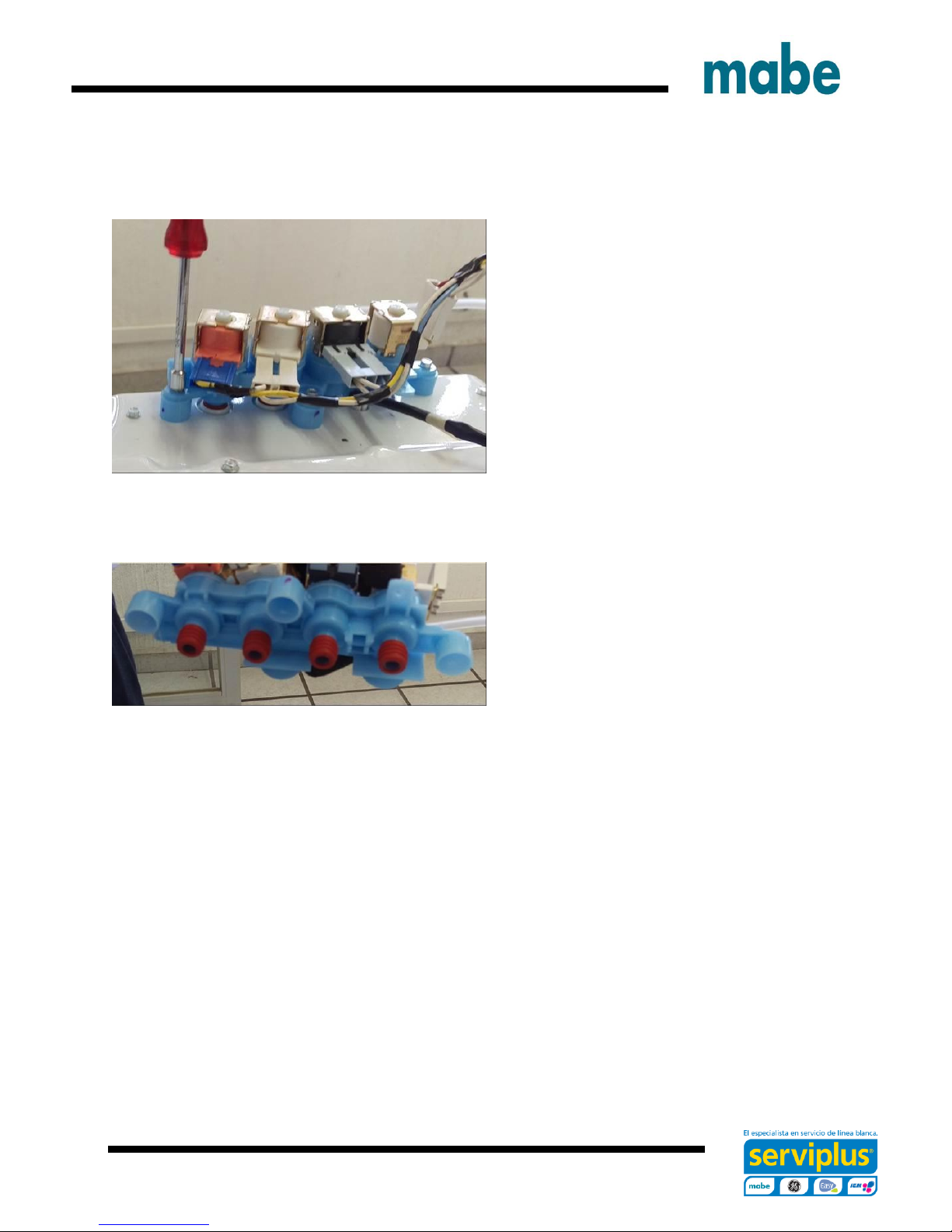

Four Coil Water Valve On GTW680 Model

Video Link

To remove the water valve:

Shut off the water supply to the

washer. Hoses do not need to be

disconnected at this time.

Lean the control panel assembly

back. It does not have to be

completely removed.

Disconnect the harness from the

water valve.

Ingeniería de Servicio

Page 23

- 23 -

Remove three ¼ in. hex head screws

securing the valve to the top cover and

pull the valve up.

Hold valve over the basket and

disconnect the supply hoses from the

valve.

Quad Valve and the four rubber seals

are together in the same part number

Ingeniería de Servicio

Page 24

- 24 -

Thermistor Removal

After the water valve is removed, the

thermistor can be accessed and

remove.

It is pushed into the dispenser box

and held in place by the water valve

and is sealed with an O-ring.

Remove thermistor by pulling up on

lip of thermistor. Ensure O-ring is

removed with the thermistor.

Ingeniería de Servicio

Page 25

- 25 -

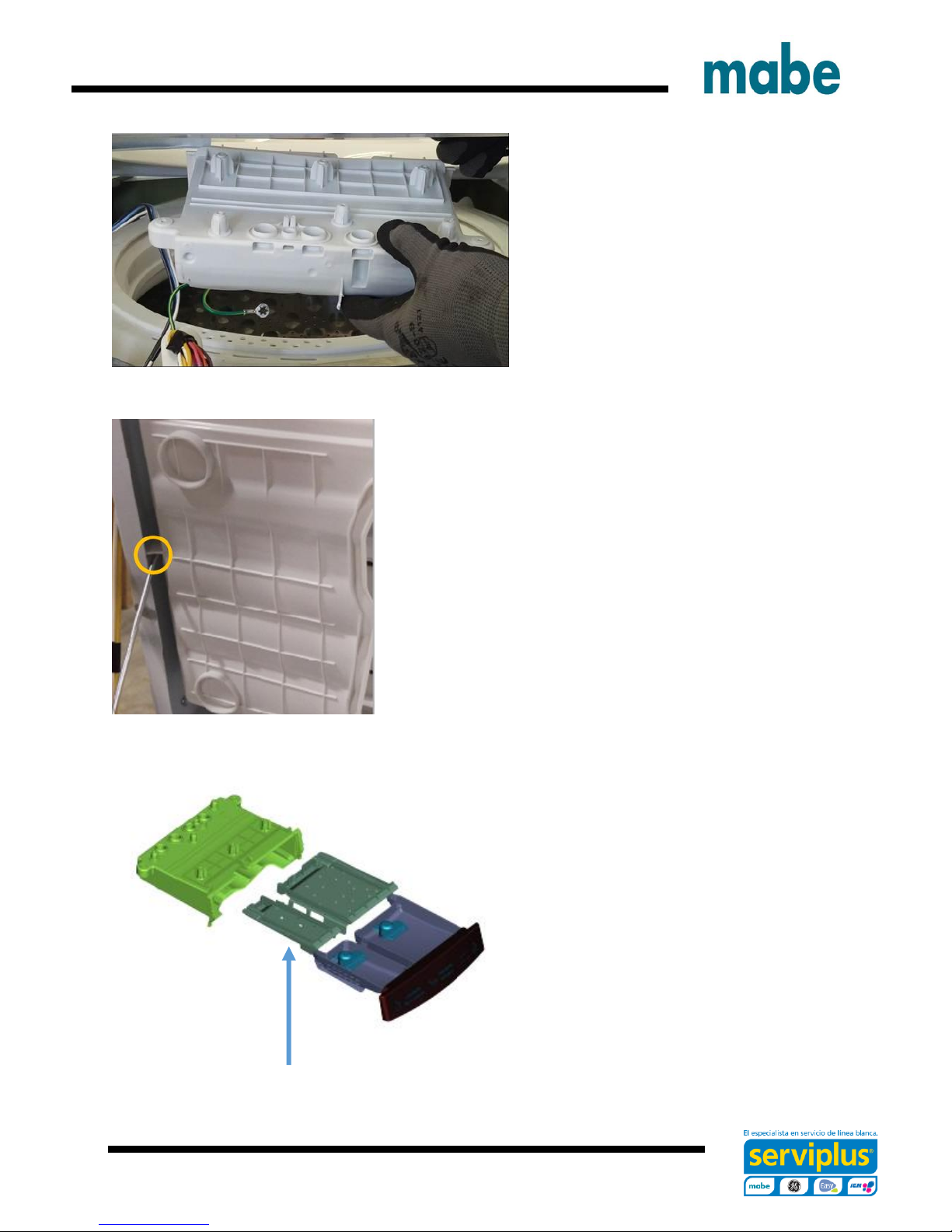

Dispenser Removal

The dispenser hold detergent and

fabric softener and delivers it at

precise times for the cycle selected.

Water is added to the dispenser from

the water valve to fill and flush the

cups. After the valve turns off the

remaining water in the cup siphons

out.

Video Link

When bleach is added to the bleach

cup it is funneled through to the tub

cover and into the tub.

Remove the backsplash assembly,

water valve and top cover.

Remove the dispenser tray from the

dispenser body.

Remove four ¼ in. hex head screws

from the top cover securing the

dispenser body to the top cover

Ingeniería de Servicio

Page 26

- 26 -

Dispenser Shower Insert

Remove the dispenser body from the

top cover by pushing back slightly on

the dispenser body and pull away

from top cover.

Take care of the back tap of the dispenser body in

order to not damage it.

The dispenser shower insert can be

removed at this time for cleaning if

necessary.

Ingeniería de Servicio

Page 27

- 27 -

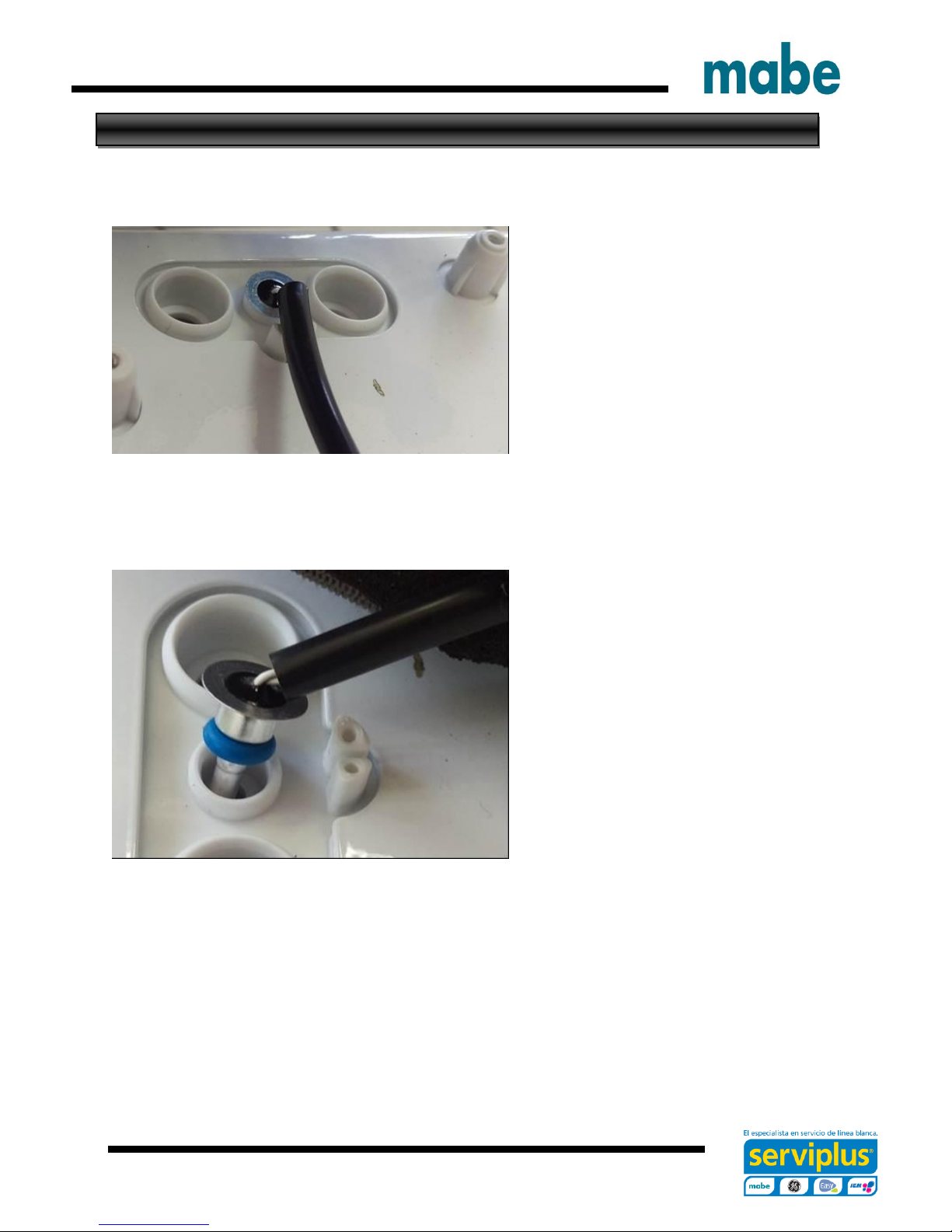

Top Cover Removal

Remove the lid assembly and control panel assembly.

.

Disengage the power cord from the top

cover by pulling up on the front of the

power cord grommet.

Slide the power cord grommet forward

Ingeniería de Servicio

Page 28

- 28 -

Pull up off of the top cover.

Remove ground screws.

Slide the harness grommet out toward

the rear of the washer

Ingeniería de Servicio

Page 29

- 29 -

The harness grommet for the lid lock

does not need to be removed unless

replacing the top cover.

If replacing the top cover, squeeze

the two clips on the grommet and

push it through the opening. Transfer

to the new cover

Remove lid assembly and the control panel

assembly.

Remove two ¼ in. hex head screws (one on

each side) at the rear corners of the top

cover.

Slide the harness grommet out toward the

rear of the washer.

Disengage the power cord from the top

cover by lifting up on the front of the cord

grommet, slide forward and up off of the top

cover.

Raise the rear of the top cover up, then pull

forward slightly to disengage from the front

clips that secures the front of the top cover

to the cabinet.

Ingeniería de Servicio

Page 30

- 30 -

Impeller

Dual Action

Agitator

Single Action

Agitator

Impeller and Agitators

Ingeniería de Servicio

Page 31

- 31 -

Impeller

To remove the impeller, pop the

center cap off with a small flat

screwdriver to access the 7/16th in.

hex bolt.

The splined coupler is part of the

impeller and agitators.

Note.- Impeller bolt should be

replaced any time it is removed for

service and torqued to 100 in.lbs.

If it is necessary, use a couple of nose pliers in order

to disassemble the impeller.

Ingeniería de Servicio

Page 32

- 32 -

Dual Stage Agitator

To remove the dual action agitator, the cup section needs to be removed to access the

7/16th in. hex bolt. The bolt is located inside the agitator at the bottom. A long socket

extension (at least 17 in. long) will be needed to remove it.

Note.- Agitator bolts should be replaced any time it is removed for service and torqued

to 100 +/- 5 in-lbs.

Ingeniería de Servicio

Page 33

- 33 -

Single Stage Agitator

Remove the single action agitator by taking the agitator cap off to access the 7/16th in.

hex bolt. The bolt is located inside the agitator at the bottom. A long socket extension

(at least 17 in. long) will be needed to remove it.

Note.- Agitator bolts should be replaced any time it is removed for service and torqued

to 100 +/- 5 in-lbs.

Ingeniería de Servicio

Page 34

- 34 -

Basket Removal

Remove the lid, control panel assembly and top cover.

Remove the tub cover by unclipping eight

clips around the edge and lift it off.

Ingeniería de Servicio

Page 35

- 35 -

Basket Removal

Remove the 1-5/16th in. hub nut by

turning the nut clock-wise to loosen

(reverse threads).

A new hub nut should be used when

reinstalling the basket assembly.

Torque to 100 +/- 10 ft.lbs.

Remove the hub washer

Right position Wrong position

Be care of position when reinstalling the hub washer.

Ingeniería de Servicio

Page 36

- 36 -

Lift the basket out of the tub.

Remove the tub washer.

Ingeniería de Servicio

Page 37

- 37 -

Tub and Cabinet Removal/Replacement

Remove the lid, control panel assembly and top cover.

Remove one Philip screw from the hose

cover.

Remove hose cover.

Ingeniería de Servicio

Page 38

- 38 -

Disengage the rod and spring suspension

from the tub assembly.

Ingeniería de Servicio

Page 39

- 39 -

Tub and Cabinet Removal/Replacement

Once the suspension is disengage, remove the

prop blocks letting the tub assembly rest on the

belt protector.

Raise the cabinet up and over the tub assembly

and set aside.

Note.- Be careful of the tub assembly balance

while removing cabinet.

Ingeniería de Servicio

Page 40

- 40 -

Harness Removal/Replacement

The cabinet needs to be removed to replace the

harness assembly.

Once the cabinet is removed there are two ¼ in. hex

head screws that secure the harness to the side of the

tub that need to be removed.

There is one ¼ in. hex head screw on the bottom.

Ingeniería de Servicio

Page 41

- 41 -

Bottom Component View

Ingeniería de Servicio

Page 42

- 42 -

Drain And Recirculation Pump

Recirculation pump

The GTW680 model has a recirculation pump

located at the front of the bottom of the tub. It

mounts to the tub the same as the drain pump.

Video Link

Drain Pump

The drain pump is located on the right side of the

bottom of the tub. It is mounted directly to the tub

secured by three (3) 3/8th in. hex head bolts.

Video Link

Both pumps are 120 VAC.

The approximate resistances of the pumps checked

from J512 board connector are:

Drain pump – 13.2 ohms

Recirculation pump – 31.7 ohms

Ingeniería de Servicio

Page 43

- 43 -

Drain And Recirculation Pump

Once the bolts are removed, the pump can be pulled from the tub.

Have something to catch excess water. The seal is integrated to the pump as one Part

Number.

Ingeniería de Servicio

Page 44

- 44 -

Drive Belt

The drive belt has five ribs and

can be removed easily turning

the pulley to walk the belt off.

To reinstall the belt, put it on the

motor pulley first.

Stretch the belt around the

transmission pulley as far as it can go.

Then rotate the pulley until the belt is

in place. Be sure all the ribs of the

belt.

Ingeniería de Servicio

Page 45

- 45 -

Drive Motor

Video Link

There are two different horsepower

motors. One third and one half

horsepower motors. They are both

120 VAC reversible motors.

Resistances are ½ hp.- White –

Brown and White – Yellow approx.

3.1 ohm.

1/3rd hp. approx. 3.8 ohm from J511

board connector.

To remove the motor:

Remove the belt and fan pulley. The pulley is held on by a 9/16 in. lock nut.

Use a new nut when reinstalling the pulley and torque to 110 in-lbs.

Disconnect the motor harness connector.

Ingeniería de Servicio

Page 46

- 46 -

Drive Motor

Unclip the hall/speed sensor from the

motor.

Remove two ½ in. bolt mounting the

motor to the tub letting the motor

come loose from the platform.

When reinstalling the motor mounting

bolts torque to 110 in-lbs

Note.- If the hall/speed sensor is wire tied to the motor when replacing the motor, order

both, the motor and hall/speed sensor.

Ingeniería de Servicio

Page 47

- 47 -

Mode Shifter Assembly

The mode shifter either engages or

disengages the clutch with the

transmission pulley depending on

whether the cycle is in spin or

agitate.

The clutch home position is

engaged with the pulley or ready for

spin.

It has a 120 VAC motor.

Resistance of the mode shift motor

from Red – Blue is 5700 +/- 10 %

ohm from J512 board connector.

To remove the mode shifter:

Remove the transmission pulley and nut. The pulley is held on by a 9/16 in. lock nut.

Use a new nut when reinstalling the pulley and torque to 110 in-lbs.

Ingeniería de Servicio

Page 48

- 48 -

Mode Shifter Assembly

Disconnect the mode shifter motor

harness connector.

Remove two 3/8th in. hex head

mounting bolts. This will allow the

complete mode shifter assembly to be

removed with the clutch.

The clutch spring and spring washer

will come off as well. When

reinstalling be sure to install the

spring washer before the clutch

spring.

Ingeniería de Servicio

Page 49

- 49 -

Platform Transmission Assembly

The platform transmission

assembly is one complete part with

the exception of two harness

connector brackets and one motor

splash guard. These will need to be

transferred to the new platform

assembly when replacing the

platform transmission assembly.

The platform assembly is secured

to the tub by nine 3/8th in. hex head

bolts circled. One of these bolts

also holds one of the harness

brackets to the platform.

To remove the platform assembly

after all other components have been

removed, remove the nine 3/8th in.

hex head bolts and pull the platform

away from the tub.

Note.- The bottom of the tub can be

used to pry the platform transmission

assembly off of the tub.

The tub seal is pressed on to the

platform transmission assembly. If

there is a leak from the seal, the

complete transmission will need to be

replaced.

Ingeniería de Servicio

Page 50

- 50 -

Platform Transmission Assembly

To reinstall the platform assembly

to the tub, slide the shaft of the

transmission into the opening of the

tub.

Press the tub seal into the tub

opening.

Note.- Line the guide post with the

opening in the platform.

Tighten the nine hex head bolts in

a crisscross pattern so that the seal

is pulled into the tub evenly and

securely

This is done by tightening each bolt about ¼ of the way in at a time.

Torque to 70 in-lbs.

Ingeniería de Servicio

Page 51

- 51 -

Schematic

Ingeniería de Servicio

Page 52

- 52 -

Control Board User Interface

Ingeniería de Servicio

Page 53

- 53 -

Consumer Error Mode Entry

Entry into Consumer Error Mode

From an idle state only (all LEDs off), press and hold Start button for 10 seconds.

After holding Start for 10 seconds, all LEDs will turn on, signifying the user may

release the Start button.

Behaviors While In Consumer Error Mode

The Pause and Lid Locked LEDs should be constantly blinking while in CEM.

The first fault, if present, will show on the display.

Pressing Start will display the next fault code.

o Models without 7-segment display: Fault code will blink in binary – the

consumer will report which LEDs are blinking and which are not. See Binary

Display Fault Chart.

o Models with 7-segment display: Fault code will blink on the 7-segment display.

At the end of the fault list or if no faults present.

o Models without 7-segment display: All status LEDs will blink.

o Models with 7-segment display: 7-segment display will blink “-“.

Exiting Consumer Error Mode

Pressing any button (other than Start) or turning any knob will exit Consumer Error

Mode.

Consumer Error Mode will time out after 10 minutes.

Ingeniería de Servicio

Page 54

- 54 -

Your washer is equipped with Consumer Help Indicator (CHI) is our way to

communicate a simple remedy for some situations that you perform without the need to

call for service. The chart below describes the helpful messages you may notice

scrolling on your display when you return to start another load. These messages will

provide simple remedies you can quickly perform.

To ensure that you see the message, the washer will scroll the message continually

until you interact in some way with the controls.

“Ob” (Out of balance)

After the wash cycle, the clothing wasn´t evenly distributed

enough to spin out the water. Redistribute the clothes more

evenly in the washer and then run a Drain & Spin cycle

“Po” (Water took too long

to Pump Out)

Resume cycle or enter Drain & Spin. If water pumps out,

then the clog has likely cleared. If water remains in the

washer, check for clogged or pinched drain hose. This

situation could be more likely to appear, over time, if the

external drain hose has been extended or restricted

“H2O Supply” (Water not

entering washer)

Check your house water supply. Did you forget to turn on

one or both supply valves after installation or coming back

from vacation? As soon as the message starts to scroll, the

washer will initiate a 3 minute lock-out period. The washer

controls won´t respond/change during this time. After the 3

minutes, you can begin your cycle again. If you try to bypass

the lock-out period by unplugging the washer, the 3 minute

timer will start over again.

“”CAnCELEd”

If your machine has stopped itself before the cycle

completed, CAnCELEd will scroll in the display. On models

without a display, the two furthest right LED lights will flash.

This indicates that an error has occurred. Try to run a Drain

& Spin cycle to see if it will clear. If it does not clear, call

800GECARES (800.432.2737), in Canada, call

1.800.561.3344 for service.

Consumer Help Indicator

Ingeniería de Servicio

Page 55

- 55 -

Service Mode Entry

Field Service Mode Entry

From an idle state only (all LEDs off), press and hold Start button while rotating the

cycle selection knob 180 degrees (7 clicks) and then release the Start button.

Once service mode is entered all LEDs will be flashing.

o On 7-segment display models: (0) will be displayed for test (0).

o On models without a 7-segments display: All of the status LEDs above the

cycle knob will be lit.

The cycle selection knob is now used to control the test selection menu.

o Rotating the knob clockwise will increment the test numbers in the display.

o Rotating the knob counter clockwise will decrement the test number in the

display.

o Models without 7-segment display: Will display test using the status lights

above the cycle knob in a binary format. (See Binary Chart).

o Turning the knob to go to a different test will terminate any current active

state.

Once the test number is selected, pressing Start will begin the selected test.

Exit Field Service Mode

Field service mode will time out after 30 minutes if there is no user activity.

Models without 7-segment display: Press and hold the Start button for 3 seconds.

Models with a 7-segment display: Press Power button.

Once the washer is in Service Mode, the following service features are available via the

cycle knob (on some models):

Ingeniería de Servicio

Page 56

- 56 -

Fault/Test #

displayed on

7-segment display

When entered into service mode

Service Mode Test

0 All LEDs on

1 Fault Codes

2 Personality ID

3 UI Software Version (Critical)

4 UI Software Version (Non-Critical)

5 XML Version (Non-critical)

6 Hot Water Valve

7 Cold Water Valve

8 Fabric Softener Dispenser

9 Spray Rinse Valve

10 Preasure Sensor

11 Recirculate Pump

12 Drain Pump

13 Lid Switch

14 Spin

15 Agitate

16 Clear all F Codes

17 Change Personality

18 Analog knob

Filled circles indicate

light on

Fault/Test # displayed in

binary format using

cycle status ligths

Binary Display Fault Chart

Display Test and Fault Chart

Ingeniería de Servicio

Page 57

- 57 -

Knob Index / Test

number (Displayed

on SSD, 7-segment

display, if present)

(Without SSD will

be displayed in

binary format. (See

Binary Chart)

Test Name

Description of test

If tests call for numbers to be shown it will:

(Display on SSD, 7-segment display, if present)

(Without SSD will be displayed in binary format.

(See Binary Chart) Turning the cycle knob will

index to the next or prior test.

0

All LEDs on

All LEDs on the display will be blink including “88”

on the (7-segment display) SSD at a rate of 1 Hz.

1

Fault Codes

Models without 7-segment display:

Faults will be shown:

- On Start button press, blink first fault code in

binary. (See Binary Chart)

- On next Start button press, blink next fault

code.

- At end of list OR if no fault codes are present,

blink all LEDs.

- Pressing Start at the end of the fault list will

wrap back around.

- Use the fault sequence.

7-segment display models:

On Start button press, blink first fault code

Display fault code in SSD

At end of list OR if no fault codes are present,

washer will flash “- -“.

2

Personality

ID

Pressing Start will start the test.

Flash the set personality after pressing Start.

Models without SSD use binary to show

personality.

Model with SSD will display personality.

(See Personality ID Chart for the correct ID for

the model being checked).

Service Mode Tests

Ingeniería de Servicio

Page 58

- 58 -

Knob Index / Test

number (Displayed

on SSD, 7-segment

display, if present)

(Without SSD will

be displayed in

binary format. (See

Binary Chart)

Test Name

Description of test

If tests call for numbers to be shown it will:

(Display on SSD, 7-segment display, if present)

(Without SSD will be displayed in binary format.

(See Binary Chart) Turning the cycle knob will

index to the next or prior test.

3

UI Software

Version

(Critical)

After entering this test, press the Start button to

toggle through the software version number as

follows:

Example: v01.23

High end UI

1st press – “01” on 7SD

2nd press – “23” on 7SD

Low end UI (See Version Diagram below)

Major version (Pause LED ON)

3rd press – Display 2 in binary

4th press – Display 3 in binary

4

UI Software

Version (Noncritical)

After entering this test, press the Start button to

toggle through the software version number as

follows:

Example: v01.23

High end UI

1st press – “01” on SSD

2nd press – “23” on SSD

Low end UI (See Version Diagram below)

Major version (Pause LED ON)

1st press – Display 0 in binary (all LEDs off)

2nd press – Display 1 in binary

Minor version (Lid Locked LED ON)

3rd press – Display 2 in binary

4th press – Display 3 in binary

Service Mode Tests

Ingeniería de Servicio

Page 59

- 59 -

Knob Index / Test

number (Displayed

on SSD, 7-segment

display, if present)

(Without SSD will

be displayed in

binary format. (See

Binary Chart)

Test Name

Description of test

If tests call for numbers to be shown it will:

(Display on SSD, 7-segment display, if present)

(Without SSD will be displayed in binary format.

(See Binary Chart) Turning the cycle knob will

index to the next or prior test.

5

XML Version

(Non-Critical)

Example: v01.23

High end UI

1st press – “01” on SSD

2nd press – “23” on SSD

Low end UI (See Version Diagram below)

Major version (Pause LED ON)

1st press – Display 0 in binary (all LEDs off)

2nd press – Display 1 in binary

Minor version (Lid Locked LED ON)

3rd press – Display 2 in binary

4th press – Display 3 in binary

NOTE: We only show the non-critical version

number because the critical XML version number

must match the application non-critical version

number for the control to boot. If you get to

service mode, then the XML critical version is

correct. If not, update software.

6

Hot Water

Valve

Pressing Start will toggle the hot water valve on

and off. Test will have a timeout for how long

valve will be on (1 minute). The valve will turn off

when the test is exited.

7

Cold Water

Valve

Pressing Start will toggle the cold water valve on

and off. Test will have a timeout for how long

valve will be on (1 minute). The valve will turn off

when the test is exited.

Service Mode Tests

Ingeniería de Servicio

Page 60

- 60 -

Knob Index / Test

number (Displayed

on SSD, 7-segment

display, if present)

(Without SSD will

be displayed in

binary format. (See

Binary Chart)

Test Name

Description of test

If tests call for numbers to be shown it will:

(Display on SSD, 7-segment display, if present)

(Without SSD will be displayed in binary format.

(See Binary Chart) Turning the cycle knob will

index to the next or prior test.

8

Fabric

Softener

Dispenser

Pressing Start will toggle the fabric softener valve

on and off.

Test will have a timeout for how long valve will be

on (1 minute). The valve will turn off when the

test is exited.

9

Spray Rinse

Valve Check

Pressing Start will toggle the spray rinse valve on

and off.

Test will have a timeout for how long valve will be

on (1 minute). The valve will turn off when the

test is exited.

10

Pressure

Sensor

Pressing Start will start the test.

Pressure sensor test will have a time out.

All valves will turn on.

All LEDs will blink at start of test.

Stop blinking LEDs as approximate water levels

are crossed.

The levels are:

2”

3”

4”

5”

6”

7” Water valves shut off at this level.

11

Recirculate

Pump

Pressing Start will toggle the recirculation pump

on and off.

Test will have a timeout (1 minute) for how long

recirculation pump will be on.

The recirculation pump will turn off when the test

is exited.

Service Mode Tests

Ingeniería de Servicio

Page 61

- 61 -

Knob Index / Test

number (Displayed

on SSD, 7-segment

display, if present)

(Without SSD will

be displayed in

binary format. (See

Binary Chart)

Test Name

Description of test

If tests call for numbers to be shown it will:

(Display on SSD, 7-segment display, if present)

(Without SSD will be displayed in binary format.

(See Binary Chart) Turning the cycle knob will

index to the next or prior test.

12

Drain Pump

Pressing Start will toggle the drain pump on and

off.

Test will have a timeout (4 minute) for how long

drain pump will be on.

The drain pump will turn off when the test is

exited.

14

Spin

Pressing Start will start the test. Spin test will

perform child safety algorithm before it starts to

spin. (Two (2) sprays of water before locking the

lid). The lid must be closed to start the test. If lid

is opened the Locked LED will blink.

When started, the mode shift to spin will occur if

required and the lid will be locked.

When mode shift is complete, the washer will

begin spinning to max spin speed for the model

being tested.

Spin test will have a timeout (4 minute).

Be sure to only run this test with an empty basket

as there is no OOB detection during this test.

The spin will stop when the test is exited.

The lid will unlock once the speed reaches 0 after

the test is exited.

Service Mode Tests

Ingeniería de Servicio

Page 62

- 62 -

Knob Index / Test

number (Displayed

on SSD, 7-segment

display, if present)

(Without SSD will

be displayed in

binary format. (See

Binary Chart)

Test Name

Description of test

If tests call for numbers to be shown it will:

(Display on SSD, 7-segment display, if present)

(Without SSD will be displayed in binary format.

(See Binary Chart) Turning the cycle knob will

index to the next or prior test.

15

Agitate

Pressing Start will start the test. Agitate test will

perform child safety algorithm before it starts to

agitate. The lid must be closed to start the test. If

lid is opened the Locked LED will blink.

When started, the mode shift to agitate will occur

if required.

When mode shift is complete, the washer will

begin agitating.

The test will pause if the lid is opened after

starting. The test will resume on lid close if it was

running when opened.

The test will stop when the test is exited.

16

Clear all Fault

Codes

Pressing Start will clear all fault codes.

17

Change

Personality

Pressing Start will start the test.

Press Start button again and the next valid

personality should be displayed.

Press and hold the Start button to select the

correct personality.

18

Analog Knob

Pressing Start will start the test.

Each options knob is represented by a specific

corresponding status LED (for left options knob to

the far left status LED).

When knob position changes, the LED for the

specific knob blinks.

With each click to the right, the LED for the

specific knob blinks faster.

With each click to the left, the LED for the specific

knob blinks slower.

Service Mode Tests

Ingeniería de Servicio

Page 63

- 63 -

Fault

Code

(Hex)

Name

Description

Repair Action

1

Lock

Monitor

Lid lock didn’t occur

or lid lock signal not

seen by control due

to lack of connection.

Check the resistance of the lid lock assembly.

Check the harness for open wires and or

connectors from the board to the lock

assembly.

If lock assembly and harness prove good at

the time of service, replace the lid lock

assembly.

2

Lid

Monitor

Control did not get lid

closed signal from

switch while motor

was moving. Could

mean the switch

didn’t close or control

didn’t get the signal

because of lack of

connection.

Replace control if this fault happens

repeatedly.

3

Locked

Rotor

Monitor

For 5 straight

seconds control not

seeing signal

changes indicating

the motor is turning

while trying to spin.

Could mean the

motor isn’t rotating or

Control didn’t get the

signal because of

lack of connection

Physically check the washer for anything

preventing motor movement.

Check harness and harness connections from

the control to the motor.

Verify hall sensor is connected to the main

harness. Put washer in Service Mode and run

Test 13. Spin Test. If hall sensor is bad or

disconnected, the basket will start to spin

normally and then stop spinning after

approximately 5 seconds. Ensure hall sensor

is properly connected and positioned on the

motor. If basket spins for approximately 15

seconds, the hall sensor is most likely NOT the

cause.

TCO should reset in approximately 45 minute.

If TCO is tripped, make sure motor moves

freely and that nothing is jamming it. Replace

motor if it does not.

Fault Codes

Ingeniería de Servicio

Page 64

- 64 -

Fault

Code

(Hex)

Name

Description

Repair Action

4

Reset

Monito

r

Control is resetting

the software by itself

due to criteria it

believes could

resolve itself upon

reset.

Check for loose connections at the control.

Reconnect if any.

Check for recommended house line voltage

to the washer.

5

Mode

Shifter

Control didn’t see the

transition from Agitate

ti Spin or vice-versa

in the time required.

Could mean the shift

didn’t occur or

Control didn’t get the

signal because of

lack of connection

Check mode shifter coupler for damage and

the ability to slide in and out freely.

Using an Ohm meter, check to ensure mode

shifter switch is in the open position.

Check resistance of mode shifter motor

(approximately 5,700 ohms)

Check for 120 VAC to the mode shifter motor

at the control J512 connector.

If voltage is present, replace the mode shifter.

If voltage is not present at the control, replace

control.

6

Critical

Flood

Level

by

Pressu

re.

Pressu

re level

exceed

s 17.5

inches

above

pressu

re port.

Control received an

extended period of

pressure readings

that is nearing overflow levels. Pressure

17.5”.

Voltage Output must

be present. Could

mean water did get

that high due to

briefly stuck water

valve. Voltage output

of sensor too high for

actual water level

because of sensor or

water in pressure

tube increasing

pressure.

Check pressure tube for pinches where it

goes through top cover grommet.

Check pressure tube for trapped water.

Check for any leaking water valves.

Check the output voltage from the pressure

sensor to ensure it matches the water level in

the basket according to the pressure sensor

chart. If it does not, the control will need to be

replaced as the pressure sensor is mounted

directly to the control.

Fault Codes

Ingeniería de Servicio

Page 65

- 65 -

Fault

Code

(Hex)

Name

Description

Repair Action

7

Flood

Warnin

g Level

by

Pressu

re.

Pressu

re level

exceed

s 16.5

inches

above

pressu

re port.

Main micro received

and extended period

of pressure readings

that is greater than

maximum allowable

fill volume. Pressure

16.5”. Voltage output

must be present.

Could mean water did

get that high due to

briefly stuck water

valve. Voltage output

of sensor too high for

actual water level

because of sensor or

water in pressure

tube increasing

pressure.

This can happen if a large wet load is placed

in the washer.

Check pressure tube for pinches where it

goes through top cover grommet.

Check pressure tube for trapped water.

Check for any leaking water valves.

Check the output voltage from the pressure

sensor to ensure it matches the water level in

the basket according to the pressure sensor

chart. If it does not, the control will need to be

replaced as the pressure sensor is mounted

directly to the control.

Fault Codes

Ingeniería de Servicio

Page 66

- 66 -

Fault

Code

(Hex)

Name

Description

Repair Action

8

Pressure

Sensor Loss

This determines if

there has been a

too great of a

difference in the

pressure sensor

reading and the

expected pressure

sensor reading for

the amount of

water the control

calculated it has

put in. It assumes

there is a pressure

leak, a clog in the

pressure

hose/system

delaying the

increase in

pressure, or a

significant amount

water leaking out.

Check house water supply are turned on.

Check pressure tube for pinches where it

goes through top cover grommet.

Check pressure tube for trapped water.

Check for any leaking water valves.

Check the output voltage from the pressure

sensor to ensure it matches the water level

in the basket according to the pressure

sensor chart. If it does not, the control will

need to be replaced as the pressure sensor

is mounted directly to the control.

9

Lid Switch

Redundancy

Start attempted for

a 4th cycle when

the previous 3

cycles have

completed with

backup micro

seeing lid open.

Could mean the

switches didn’t

occur or backup

processor didn’t

get the signal

because of lack of

connection. See

Fault # 2 as well.

Open and close the lid to clear the error.

Check harness and connectors that go to

the lid switch.

If the error will not clear, replace the lid

switch.

Fault Codes

Ingeniería de Servicio

Page 67

- 67 -

Fault

Code

(Hex)

Name

Description

Repair Action

10

Mode

Shift

Feedb

ack

Monito

r

Signal feedback state

from the mode shifter

(agitate or spin) and

the state requested by

the control are not the

same and the basket

or agitator is rotating

faster than 3-4 RPM.

Agitate mode

feedback signal is no

voltage.

Check mode shifter coupler for damage and

the ability to slide in and out freely.

Use ohm meter to ensure harness shows

continuity to the mode shifter from the

control..

Check resistance of mode shifter motor

(approximately 5.7 K ohms)

Check for 120 VAC to the mode shifter motor

at the control J512 connector.

If voltage is present and no operation,

replace the mode shifter.

If voltage is not present at the control,

replace control.

11

Clock

Monito

r

1. AC power line

frequency is not 60

Hz.

2. Software failure.

Check the frequency of the AC power outlet.

If it is more than a few Hz off of 60 Hz.

If house frequency is good, update software.

12

Redun

dant

Flood

Conditi

on

Backup Processor

received an extended

period of pressure

readings that is

nearing over-flow

levels.

Pressure 18.0”

Voltage Output must

be present. Could

mean water did get

that high due to briefly

stuck water valve.

Voltage output of

Sensor too high for

actual water level

because of Sensor or

water in Pressure tube

increasing pressure.

Check pressure tube for trapped water.

Check each valves Operation… Replace

Water Valve.

Check the output voltage from the pressure

sensor to ensure it matches the water level in

the basket according to the pressure sensor

chart. If it does not, the control will need to be

replaced as the pressure sensor is mounted

directly to the control.

If the pressure tube is intact, replace control.

Fault Codes

Ingeniería de Servicio

Page 68

- 68 -

Fault

Code

(Hex)

Name

Description

Repair Action

13

Redun

dant

Lid

Unlock

ed

In spin mode, the lid

switch feedback has

voltage (lid closed), for

more than 5 seconds

the motor speed

feedback assumes the

basket is spinning > 45 RPM when the lid

lock feedback has no

voltage (Lid

Unlocked). Lid Switch

Feedback has no

Voltage when the

BRPM is > 4-5 RPM.

Check lid switch continuity at J513 on the

control.

Check continuity of lid lock position. Opened

or Closed.

Check for proper operation of lid lock, 120

VAC while activating.

Check lid lock wiring harness from the

control to lock assembly.

If lid lock assembly and harness are OK,

replace control board.

14

Lid

Lock

Failure

Signal received by

control is indicating the

lock will not lock or

unlock when

requested or the lid

switch is indicating

open when the signal

received indicated

locked.

Verify that the lid lock is not blocked by any

external debris.

Check lid switch continuity at J513 on the

control.

Check continuity of lid lock position. Opened

or Closed.

Check for proper operation of lid lock. 120

VAC while activating.

Check lid lock wiring harness from the

control to lock assembly.

If lid lock assembly and harness are OK,

update the software.

15

Water

Temp

Sensor

invalid

1. Thermistor

disconnected/not

present.

2. Failed Thermistor

Check thermistor resistance from connector

J701 on the control board. Validate the

resistance matches the table in mini-manual.

Check wiring harness and connectors.

Replace thermistor

Fault Codes

Ingeniería de Servicio

Page 69

- 69 -

Fault

Code

(Hex)

Name

Description

Repair Action

16

Adapti

ve

Drain/

Slow

Drain

The total number of

times during machine

life the actual amount

of time the pressure

sensor indicated the

wash water had

drained to empty

exceeded the

calculated time by the

software.

This fault is set when adaptive drain cycle

occurs to try to remove the rest of water in

tub.

If the adaptive drain cycle times out. The

control will run a Drain Pump Clearing

algorithm to free the pump impeller of debris.

Then it will finish draining. If drain clearing

algorithm fails look for fault 18.

If fault 16 is 100 and fault 18 never occurs

there is no problem… If fault 16 and fault 18

equal each other in faults, then look for drain

blockages including house standpipe.

17

Dry

Load

Sense

Timeo

ut

Dry load sense times

out and moves to the

next part of the cycle

selected. This occurs

when the washer is

not reaching the target

speed within a defined

time limit for the load

type selected.

1. Check for water in the bottom of the tube. If

so drain and try cycle again.

2. Check the basket for excessive friction.

Basket should spin freely. If not, find source of

friction and remove it.

Fault Codes

Ingeniería de Servicio

Page 70

- 70 -

Fault

Code

(Hex)

Name

Description

Repair Action

18

Drain

Pump

Clearing

algorith

m failed.

While draining the

pressure sensor

value for water level

did not indicate the

washer was empty

before the Max

Continuous Drain

ON time was

reached.

This fault is set and will be seen with fault 16

when Drain Pump Clearing Algorithm failed to

remove the blockage and the rest of water in

tub.

Check the drain pump for blockage.

Check installation instructions for proper

standpipe height.

Check pressure tube for pinches where it

goes through top cover grommet.

Check pressure tube for trapped water.

Check the output voltage from the pressure

sensor to ensure it matches the water level in

the basket according to the pressure sensor

chart. If it does not, the control will need to be

replaced as the pressure sensor is mounted

directly to the control.

Check resistance of the pump (13.2 ohms)

from J512 connector on the control.

If open circuit, check wiring harness to the

pump and pump motor.

Check for 120 VAC to the drain pump.

If voltage is present and pump does not

operate, replace pump.

If voltage is not present, replace IMC

(Interface Machine Control).

19

UI State

Timeout

Washer was paused

for over 12 hours

This is normal operation. This will happen if

the consumer and or control switched cycle to

a paused state.

Fault Codes

Ingeniería de Servicio

Page 71

- 71 -

Fault

Code

(Hex)

Name

Description

Repair Action

20

Critical

Flood

Level by

Gallons

Water volume into

the tub exceeded 41

gallons as calculated

by the control.

1. Pressure tube is

momentarily

pinched, has water in

it, partial blockage if

Flood fault 12

occurs.

2. Low water

pressure/flow or

permanent pressure

system blockage if

NO Flood fault 12

occurs.

Check pressure tube for pinches where it

goes through top cover grommet.

Check pressure tube for trapped water.

Check for any leaking water valves.

Check home water pressure.

Check the output voltage from the pressure

sensor to ensure it matches the water level in

the basket according to the pressure sensor

chart, if it does not, the control will need to be

replaced as the pressure sensor is mounted

directly to the control.

21

Flood

Warning

Level by

Gallons

Water volume into

the tub exceeded

36.3 gallons as

calculated by the

control. Stops filling.

1. Pressure tube is

momentarily pinched

or has water in it,

partial blockage if

Flood fault 6, 7, or 12

occurs.

2. Low water

pressure/flow or

permanent pressure

system blockage if

NO Flood fault 6, 7,

or 12 occurs.

Check pressure tube for pinches where it

goes through top cover grommet.

Check pressure tube for trapped water.

Check for any leaking water valves.

Check home water pressure.

Check the output voltage from the pressure

sensor to ensure it matches the water level in

the basket according to the pressure sensor

chart, if it does not, the control will need to be

replaced as the pressure sensor is mounted

directly to the control.

Fault Codes

Ingeniería de Servicio

Page 72

- 72 -

Fault

Code

(Hex)

Name

Description

Repair Action

22

Out of

Balance

(OOB)

during

Dry Load

Sense.

Large wet/OOB

load being washed.

This is set if OOB

condition is

detected during dry

load sense

algorithm. Dry load

sense will be

abandoned and wet

load sense will be

started.

1. Check for excessively OOB load. Customer

Education on how to distribute load.

2. Check the basket for excessive friction or

for being excessively out of round. Basket

should spin freely and without wobble. If

friction is found, remove it. If basket is bad

replace it.

23

Critical

Lid Lock

1. Lock blockage.

2. Lid Lock failure.

Will not lock or

unlock or is locked

while lid is opened.

Verify that the lid lock is not blocked by any

external debris.

Check lid switch continuity at J513 on the

control.

Check continuity of lid lock position. Opened

or Closed.

Check for proper operation of lid lock. 120

VAC while activating.

Check lid lock wiring harness from the

control to lock assembly.

If lid lock assembly and harness are OK,

replace control board.

24

Lid Logic

Failure

Lid switch failure.

This fault is sent if

the system

perceives the lid to

be both OPEN and

LOCKED for 5

consecutive

seconds.

1. Check harness and connections from the

control to the lid lock assembly for damage

and continuity.

2. Run a spin cycle. Pull up on the lid during

spin for more than 5 seconds and see if this

fault occurs. Replace lid lock assemble.

3. If above does not correct the fault, replace

the control.

Fault Codes

Ingeniería de Servicio

Page 73

- 73 -

Fault

Code

(Hex)

Name

Description

Repair Action

25

Pressure

Sensor

Dropout

1. Disconnected

pressure hose.

2. Pressure tube is

pinched or has

water in it.

3. Pressure sensor

failure.

Check pressure tube for pinches where it

goes through top cover grommet.

Check pressure tube for trapped water.

Check for any leaking water valves.

Check home water pressure.

Check the output voltage from the pressure

sensor to ensure it matches the water level in

the basket according to the pressure sensor

chart. If it does not, the control will need to be

replaced as the pressure sensor is mounted

directly to the control.

Ingeniería de Servicio

Fault Codes

Page 74

- 74 -

Cycle Overview

Ingeniería de Servicio

Page 75

- 75 -

Cycle Overview

Ingeniería de Servicio

Page 76

- 76 -

Cycle Overview

Ingeniería de Servicio

Page 77

- 77 -

Cycle Overview

Ingeniería de Servicio

Page 78

- 78 -

Cycle Overview

Ingeniería de Servicio

Page 79

- 79 -

Cycle Overview

Ingeniería de Servicio

Page 80

- 80 -

Cycle Overview

Ingeniería de Servicio

Page 81

- 81 -

Cycle Overview

Ingeniería de Servicio

Page 82

- 82 -

Cycle Overview

Ingeniería de Servicio

Page 83

- 83 -

Cycle Overview

Ingeniería de Servicio

Page 84

- 84 -

Cycle Overview

Ingeniería de Servicio

Page 85

- 85 -

Cycle Overview

Ingeniería de Servicio

Page 86

- 86 -

Cycle Overview

Ingeniería de Servicio

Page 87

- 87 -

Cycle Overview

Ingeniería de Servicio

Page 88

- 88 -

Warranty

Ingeniería de Servicio

Loading...

Loading...