mabe Kraken, HTW200BMKWW, MTW200BMKWW, GTW485BMKWS, GTW220BMKWW Service Manual

...

- 1 -

Service Manual

June-2016

Top Load Washer Kraken 27”

HTW200BMKWW GTW460BMKWW

MTW200BMKWW GTW485BMKWS

GTW220BMKWW GTW680BMKWS

GTW330BMKWW GTW680BMKDG

GTW465BMKWS

Ingeniería de Servicio

- 2 -

IMPORTANT SAFETY NOTICE

IMPORTANT SAFETY NOTICE

The information in this presentation is intended for use by individuals

possessing adequate backgrounds of electrical, electronic, & mechanical

experience. Any attempt to repair a major appliance may result in personal

injury & property damage. The manufacturer or seller cannot be

responsible for the interpretation of this information, nor can it assume any

liability in connection with its use.

WARNING

To avoid personal injury, disconnect power before servicing this

product. If electrical power is required for diagnosis or test purposes,

disconnect the power immediately after performing the necessary

checks.

RECONNECT ALL GROUNDING DEVICES

If grounding wires, screws, straps, clips, nuts or washers used to complete

a path to ground are removed for service, they must be returned to their

original position & properly fastened.

Mabe authorized Service Technicians are required to use the Personal

Protection Equipment (PPE) listed below, for your own protection.

Ingeniería de Servicio

- 3 -

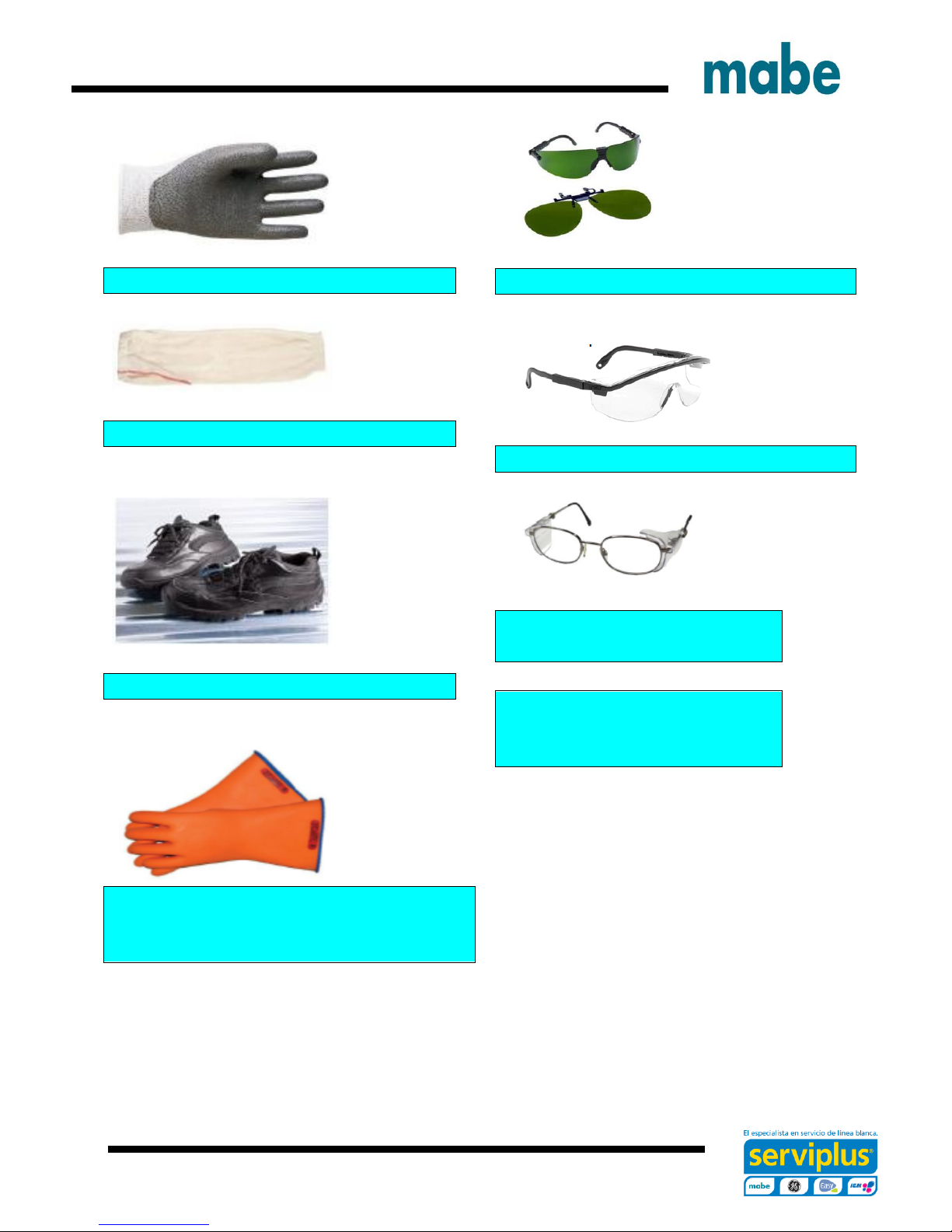

Dyneema® Cut Resistant Glove

Cut Resistant Sleeve(s)

Steel Toe Work Boot

Brazing Glasses

Plano Type Safety Glasses

Prescription Safety

Glasses

Safety Glasses must be

ANSI Z87.1-2003

compliant

Electrically Rated Glove and

Dyneema® Cut Resistant Glove

Keeper

Ingeniería de Servicio

- 4 -

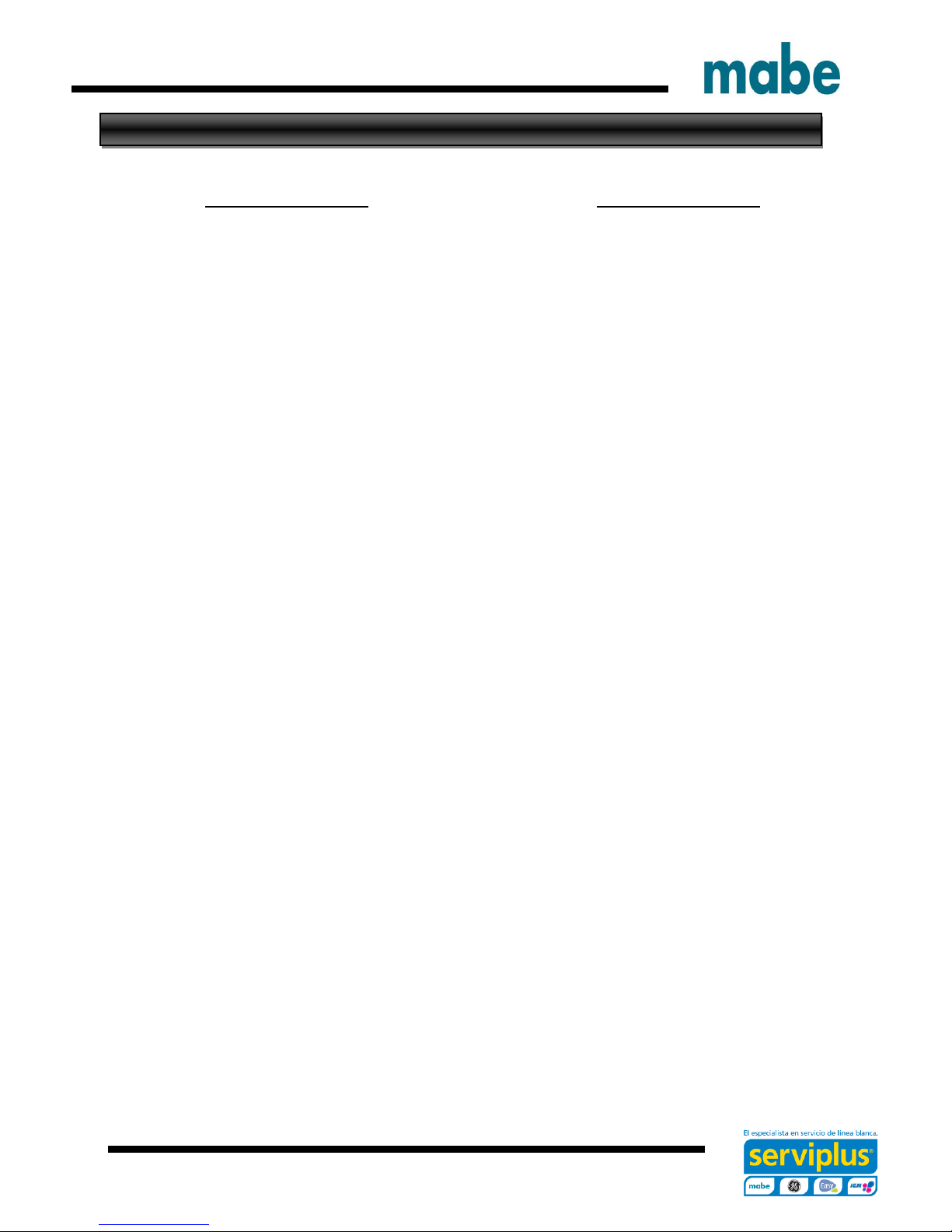

CAUTION

Prior to disassembly of the Washer to access components,

Mabe authorized Service Technicians are REQUIRED to

follow the Lockout / Tagout (LOTO) 6 Step Process

Step 1

Plan and Prepare

Step 4

Apply LOTO device & Lock

Step 2

Shut down the appliance

Step 5

Control (discharge) stored

energy

Step 3

Isolate the appliance

Step 6

“Try It” Verify that the

appliance is locked out

Ingeniería de Servicio

- 5 -

Some Features & Benefits

GTW460 Models

Deep Fill: Adds more water for larger

loads.

Dual-Action Agitator: Provide gentle,

dual-wash action.

Deep Rinse: Removes any leftover

soap residue.

Auto Soak: Loosens stains by soaking

up to 2 hours.

Speed Wash: Delivers ready-to-go

results within minutes.

Load Size: Automatically measures

load size, and adjusts settings and

water levels accordingly. Settings are

customizable, so you always get the

wash you want.

GTW680 Models

Sanitize with Oxi: Remove 99.9% of

bacteria with a dedicated cycle that

uses an Oxi additive to boost your

detergents cleaning power while

keeping fabric looking their best.

Stain Removal Guide: Assist removing

tough stains with preprogrammed

settings that modify your cycle to treat

the four most common stains.

Warm Rinse: Just what the consumer

ordered. The option to select between

a warm or cold rinse.

Deep Fill: Adds more water for larger

loads.

Deep Rinse: Removes any leftover

soap residue.

Auto Soak: Loosens stains by soaking

up to 2 hours.

Ingeniería de Servicio

- 6 -

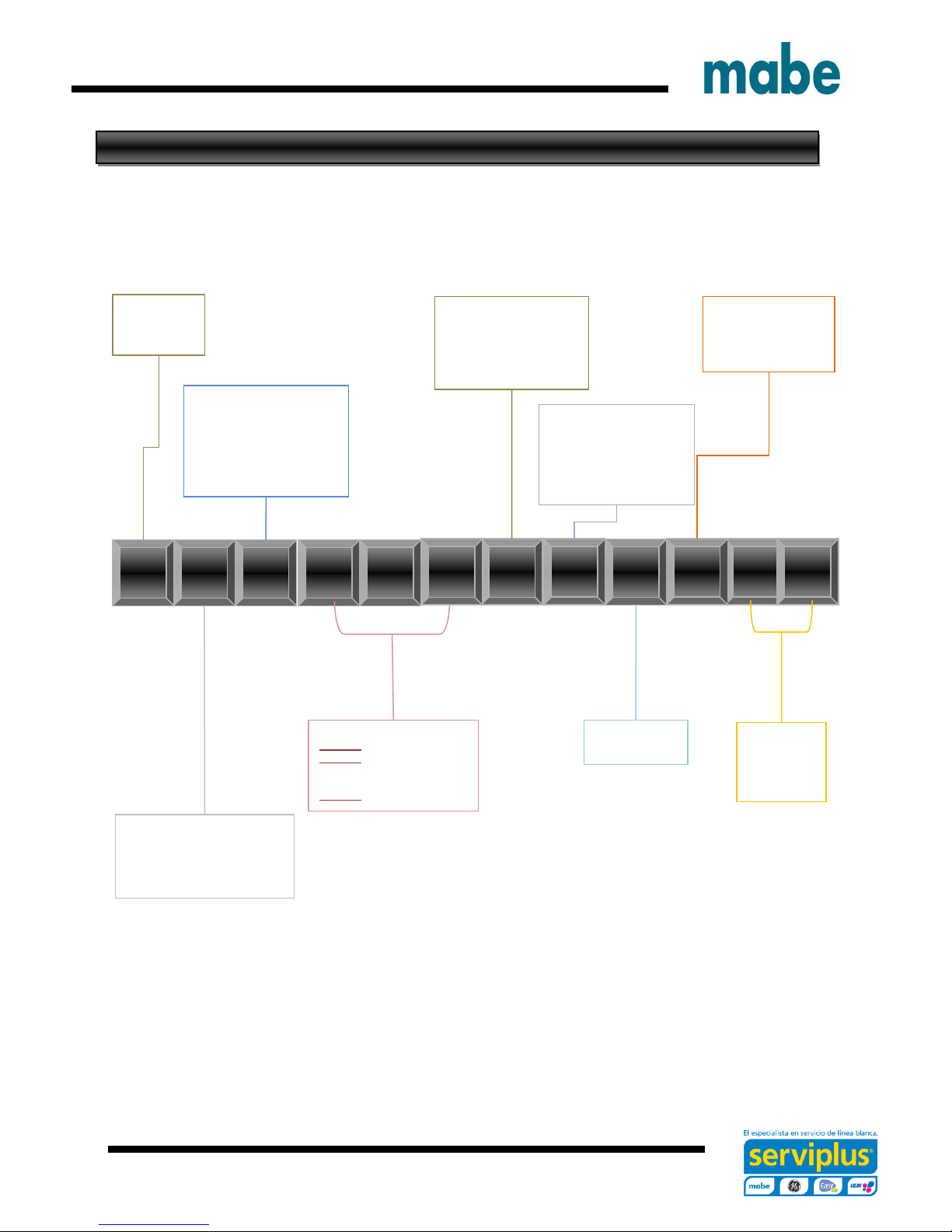

T

W

6

8

B

M

K

W

Brand

G = GE

H = Hot Point

M = Moffatt

Configuration:

F = Front Load

T = Top Load – Rear Control

N = Top Load – Front Control

U = Unitized

Platform:

W = Washer

D = Vented Dryer – Std

V = Vented Dryer – Long

C = Condenser Dryer

H = Heat Pump

Z = Flat Back Dryer – Long

X = Flat Back Dryer - Std

Series 1, 2, 3:

Series 1 = 1-9

Series 2 = 1-9

4 = 24” unitized

7 = 27” unitized

Series 3 = 1-9 Washer only

Partner Type

P = Premium Cost (color)

H = Home Depot

L = Lowes

S = Standard

C = Contract (Hoses)

M = Mabe

Year:

K = 2016

Engineering Number

0

1

2

Color:

W

S

0

0

G

S

Product Type

R = Riser

A = 2” Cover Top Load

B = 4” Cover Top Load

S = Standard / Stationary

P = Portable

Nomenclature

The nomenclature breaks down and explains what the letters and numbers mean in the model

number

Seguridad Advertencias y

Ingeniería de Servicio

- 7 -

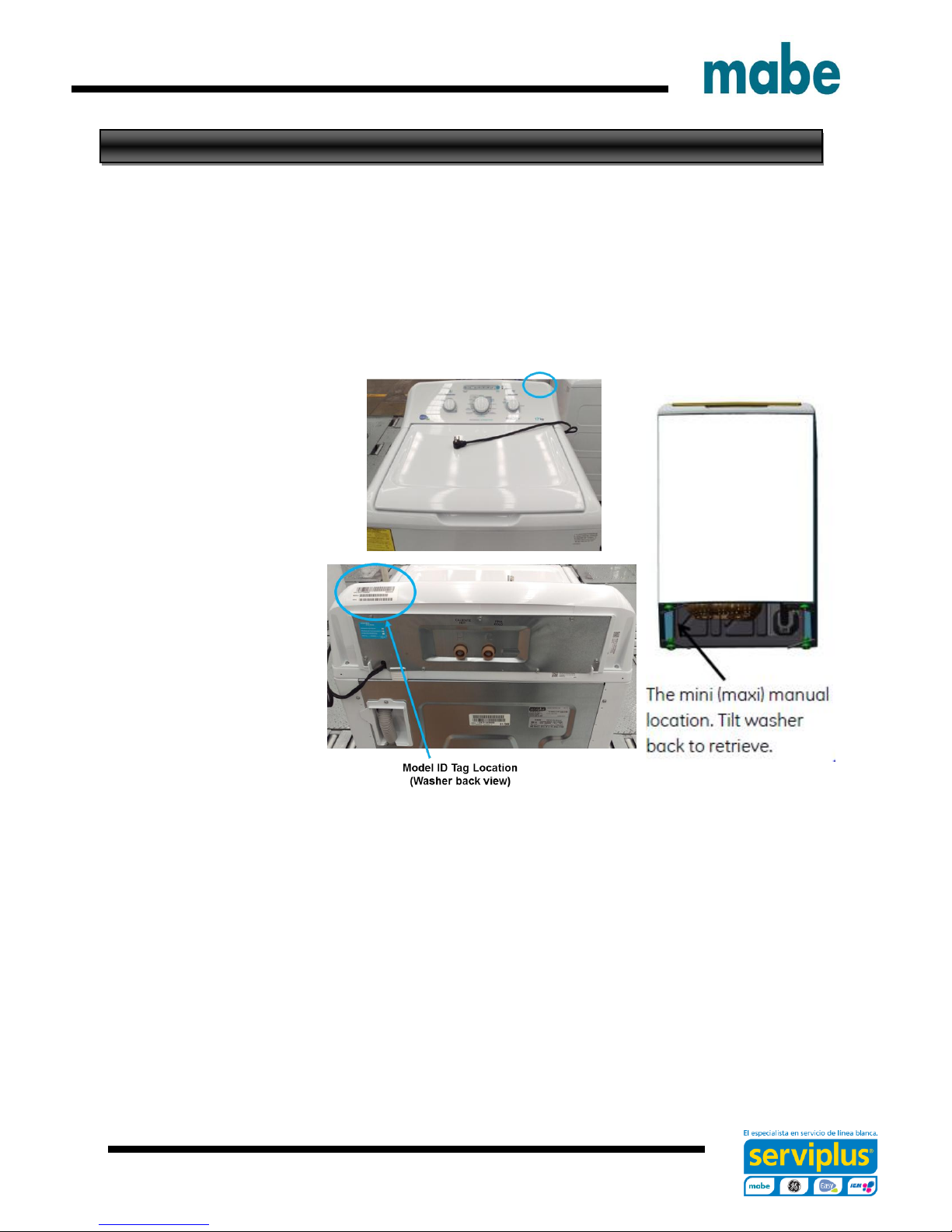

Serial Number and Mini Manual Location

Serial Number

The Serial Number breaks down and explains what the letters and numbers mean in its

structure:

Example of Serial Number: LG312345C

The first two characters of the serial number identify the month and year of manufacture: LG =

June, 2016

A = JAN A = 2013

D = FEB D = 2014

F = MAR F = 2015

G = APR G = 2016

H = MAY H = 2017

L = JUN L = 2018

M = JUL M = 2019

R = AUG R = 2020

S = SEP S = 2021

T = OCT T = 2022

V = NOV V = 2023

Z = DEC Z = 2024

The letter designating the year repeats every 12 years

The third character denotes the product being produced: 3 = Washer (Saltillo, Mexico)

Character 4 thru 8 will denote the number of units built for a given product and will start with

00001 at the beginning of each fiscal month and progress sequentially until 99,999 is

reached or the fiscal month has changed.

Character 9 will denote the Brand and Manufacturing site of final assembly: (Saltillo, Mexico:

C = GE, M = Signature, H = HPT)

The Model Serial ID Tag is located on the right top edge of the backsplash (left top edge from

back view).

The Mini Manual is in a storage bag inside the cabinet at bottom left side.

Ingeniería de Servicio

- 8 -

Water Levels

Approximate Minimum Water Levels

Impeller – 7 Gallons or 3 in. depth from

the bottom of the basket.

Agitator – 9 Gallons or 3-3/4 in. depth

from the bottom of the basket.

Test are completed with an empty basket.

Approximate Maximum Water Levels

Impeller – 26 Gallons or 13-1/2 in.

depth from the bottom of the basket.

Press and hold for 3 seconds “Deep

Fill” to achieve.

Impeller “Bulky” setting water level is

25 gallons or 12-3/4 in. depth from the

bottom of the basket.

Agitator – 26 Gallons or 12-1/2 in.

depth from the bottom of the basket.

Set to super.

Ingeniería de Servicio

- 9 -

Model Graphics

Ingeniería de Servicio

- 10 -

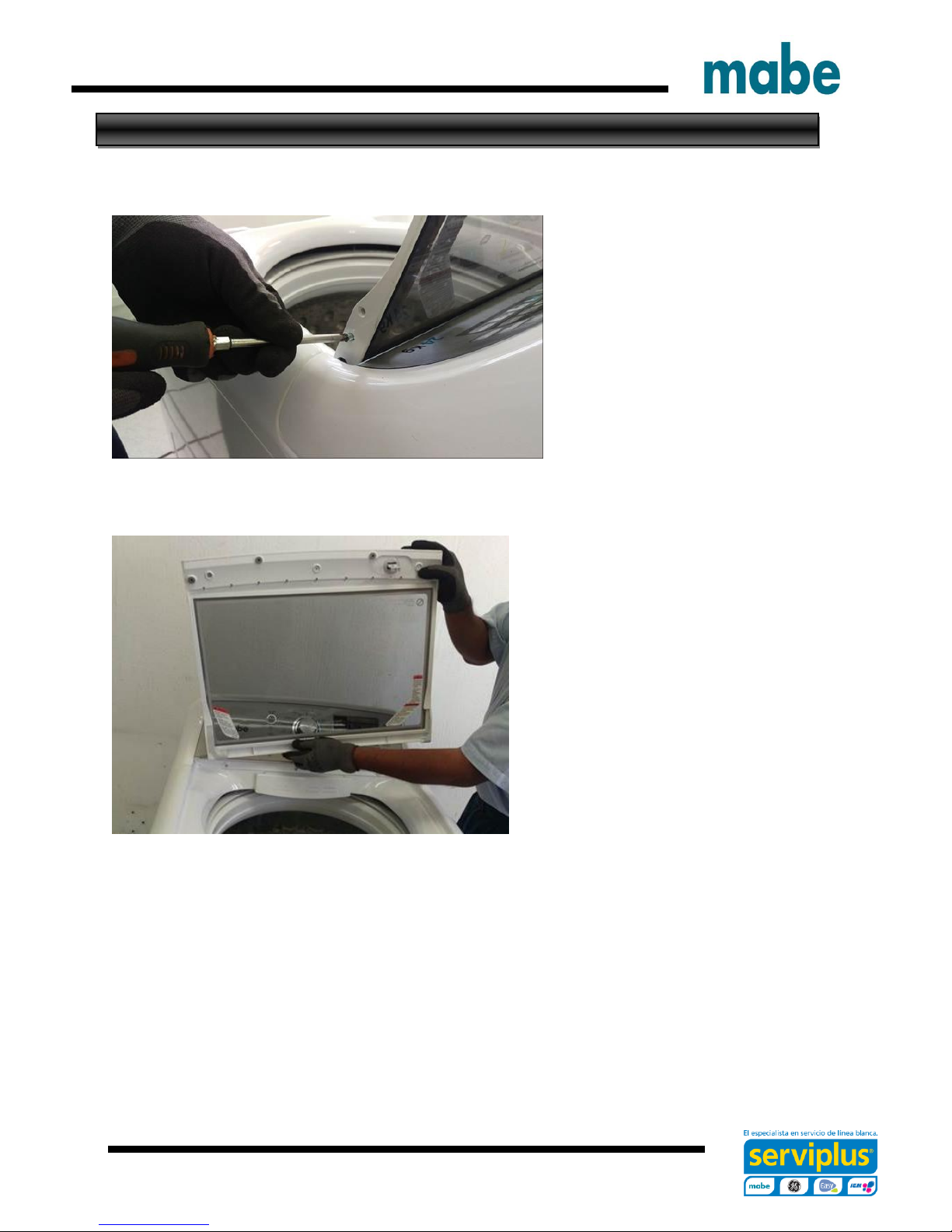

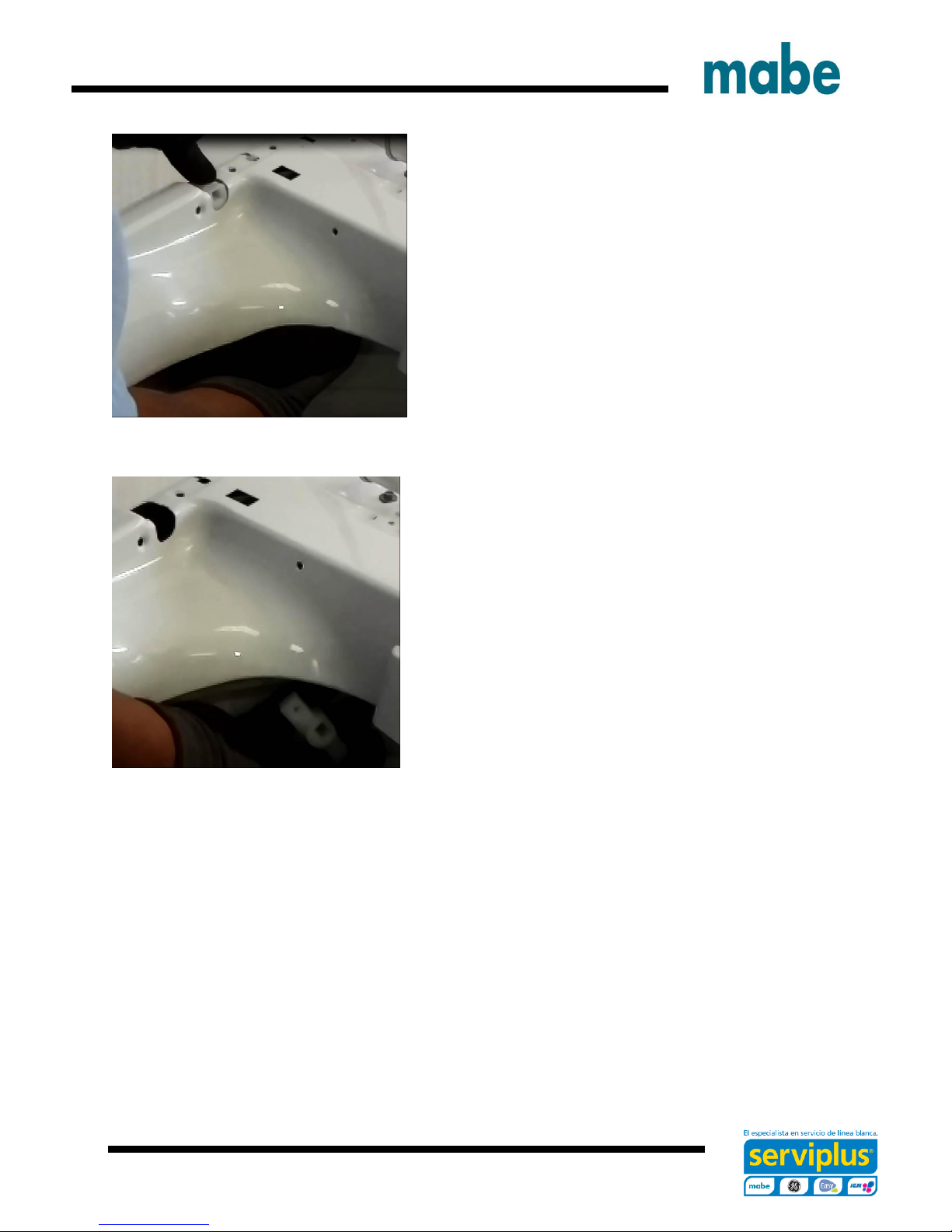

Lid Assembly Removal

Remove the two Philips head

screws of one Hinge (Right or Left

side).

Slide the lid toward the Hinge

Removed and lift it up to remove

Ingeniería de Servicio

- 11 -

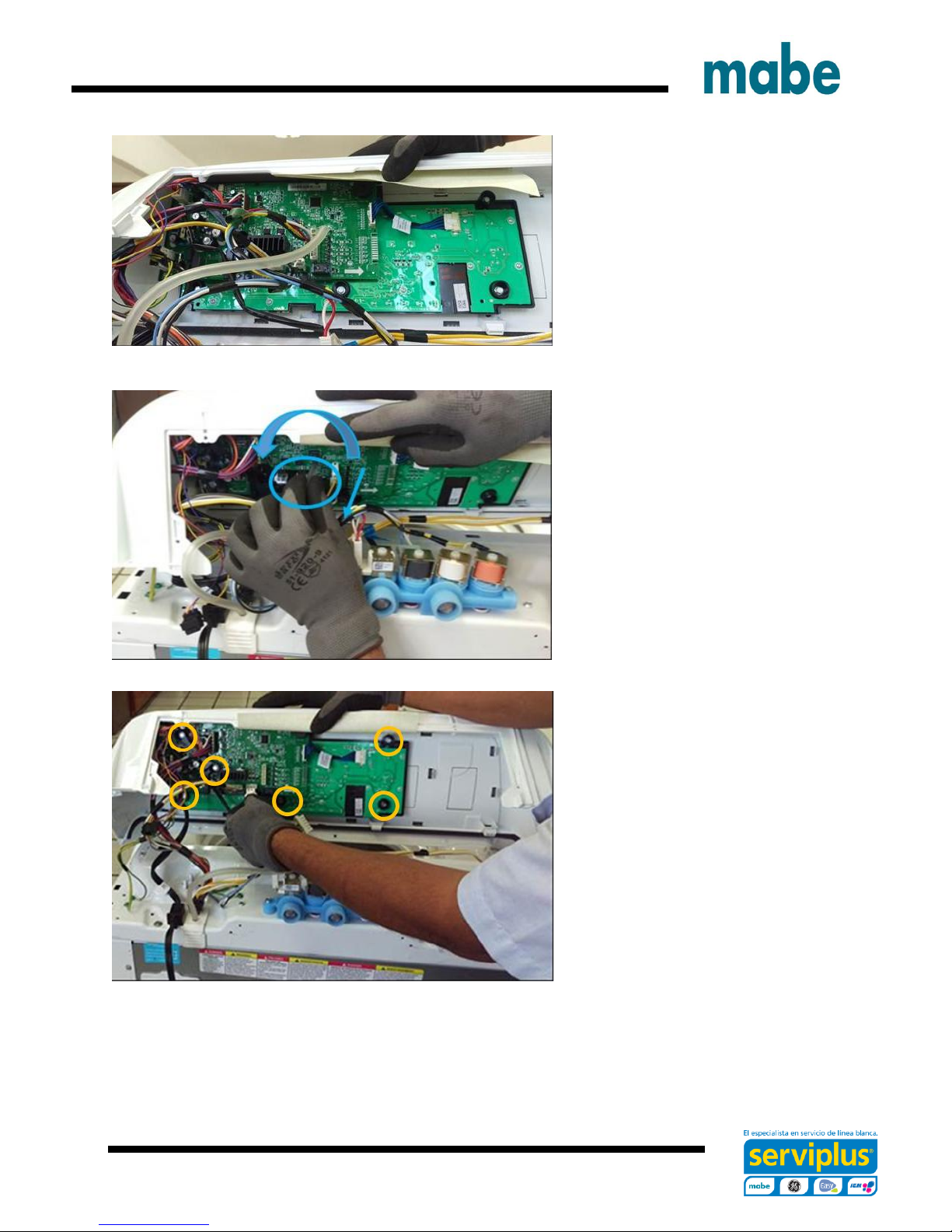

Control Panel Assembly Removal

To remove the control panel assembly, first remove the lid assembly.

Remove the three Philips head

screws that secure the control

panel assembly to the top cover

at front.

Remove the seven ¼ in. hex head

screws from the back panel and

remove it.

Remove the two ¼ in. hex head screws

from the rear corners on the control panel

IMPORTANT.- Do not move the control panel until disengaging the pressure tube from

the control board, otherwise the pressure sensor could be damaged.

Ingeniería de Servicio

- 12 -

Grasp the control panel and

push it a little toward the front of

the washer in order to see the

pressure tube.

To disengage the pressure tube

from the control board, grasp the

tube where it connects to the

pressure sensor on the board.

Twist the tube while pulling it off

the sensor

IMPORTANT.- Pressure tube

should not be handled vertically

or horizontally as there is a risk

of damage to the pressure

switch, only must disengage as

indicated above.

Disconnect connectors from the

control board and remove six ¼

in. hex screws securing the

control board bracket to the

control panel assembly and

remove.

IMPORTANT.- When reinstalling the control panel assembly, ensure that all ground

wires are reconnected and tested for proper continuity to the ground terminal on the

power cord.

Ingeniería de Servicio

- 13 -

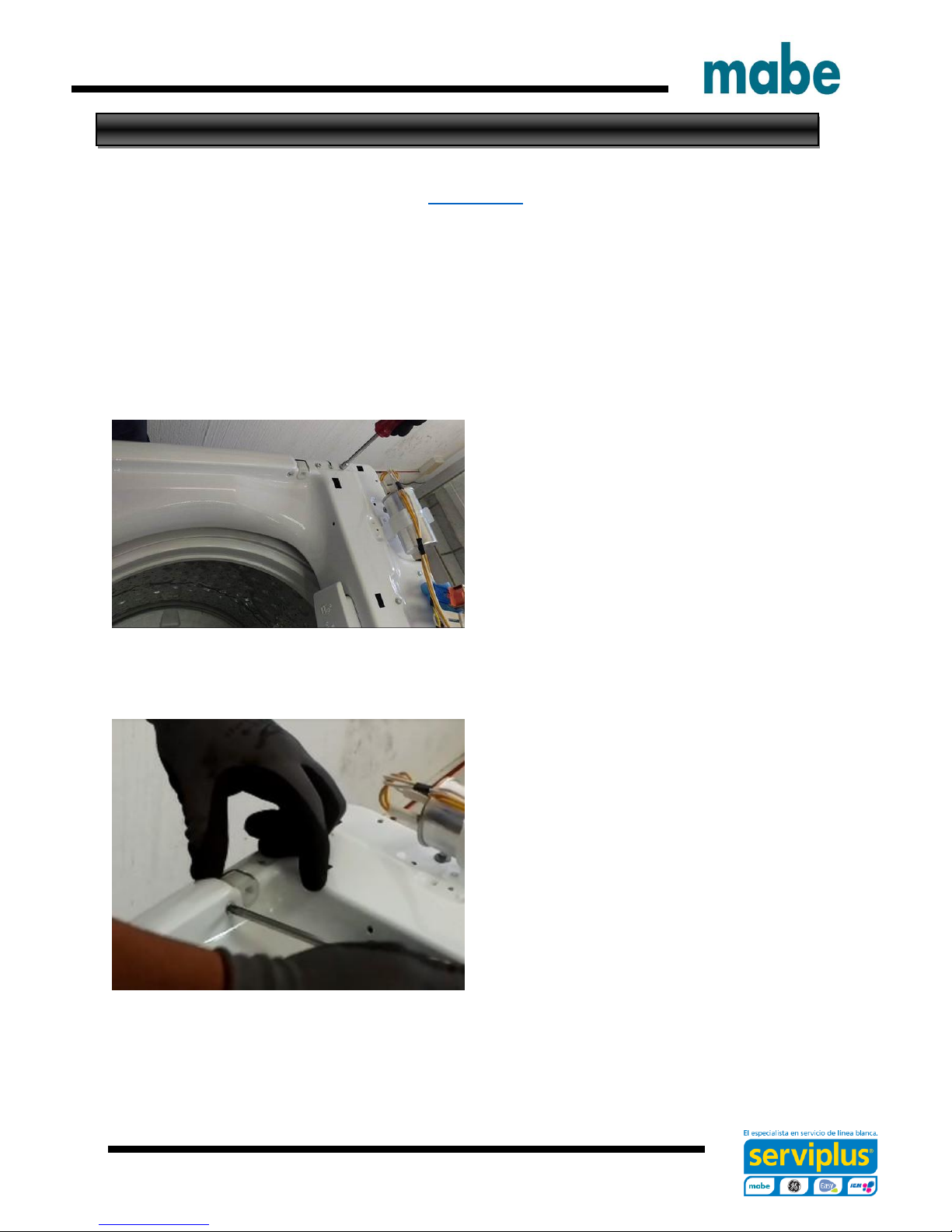

Lid Hinge

Video Link

Hinge removal can be achieved without removing the top cover or disconnecting the

control panel assembly completely.

Remove the lid assembly.

Disengage the control panel from the top cover and slide toward the rear to expose the

hinge mounting screws.

Remove the two ¼ in. hex head hinge

mounting assembly screws

Remove the Philips head screw from the

top cover.

Ingeniería de Servicio

- 14 -

Slide a hand between the tub cover and the top

cover.

Grasp the hinge assembly and remove it from

under the top cover.

Ingeniería de Servicio

- 15 -

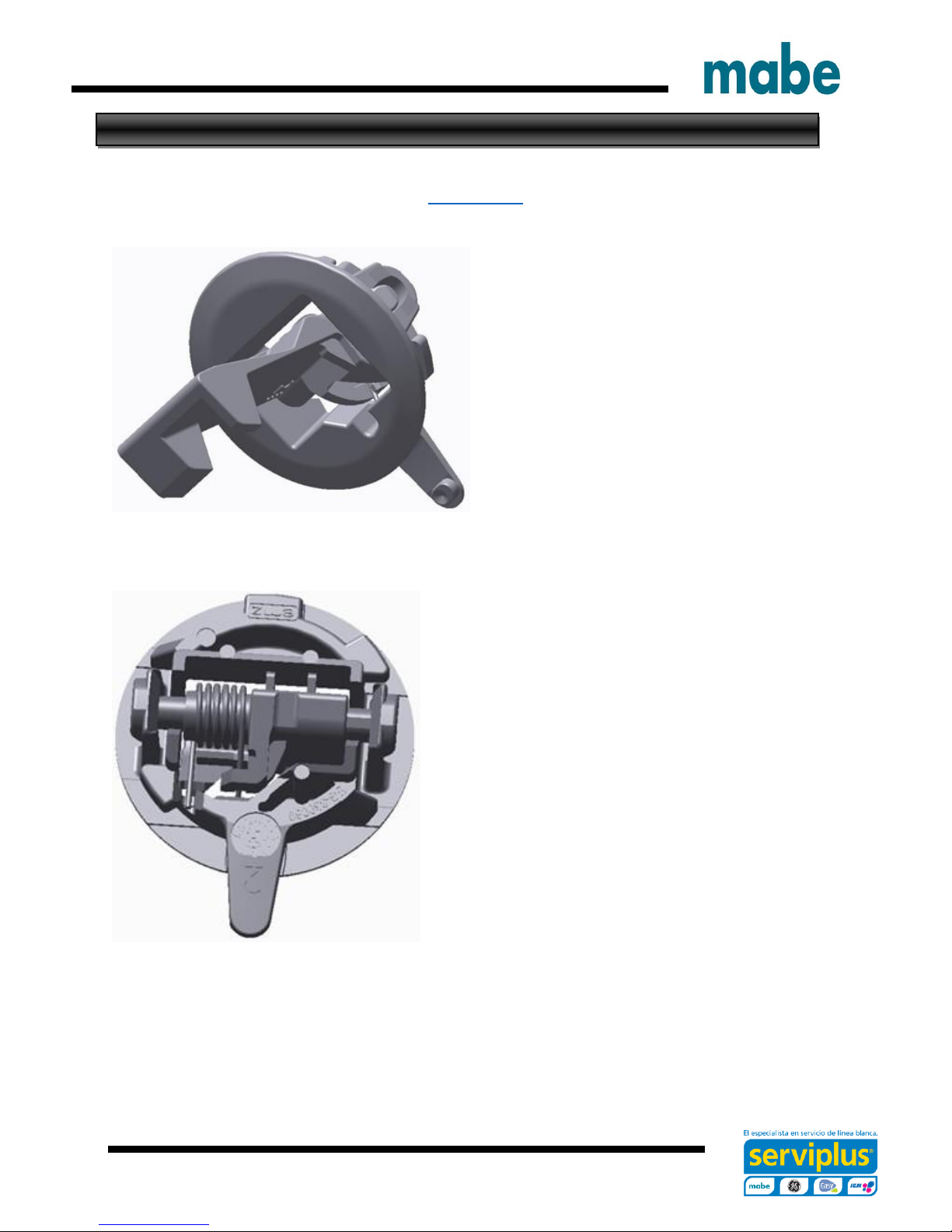

Lid Lock Striker

Video Link

The lid lock striker slides into the lid

lock/switch assembly. When a cycle is

started the lock assembly engages with

the striker preventing the lid from opening

during the cycle.

The latch has spring tension on it to keep it

engaged with the switch/lock assembly

Ingeniería de Servicio

- 16 -

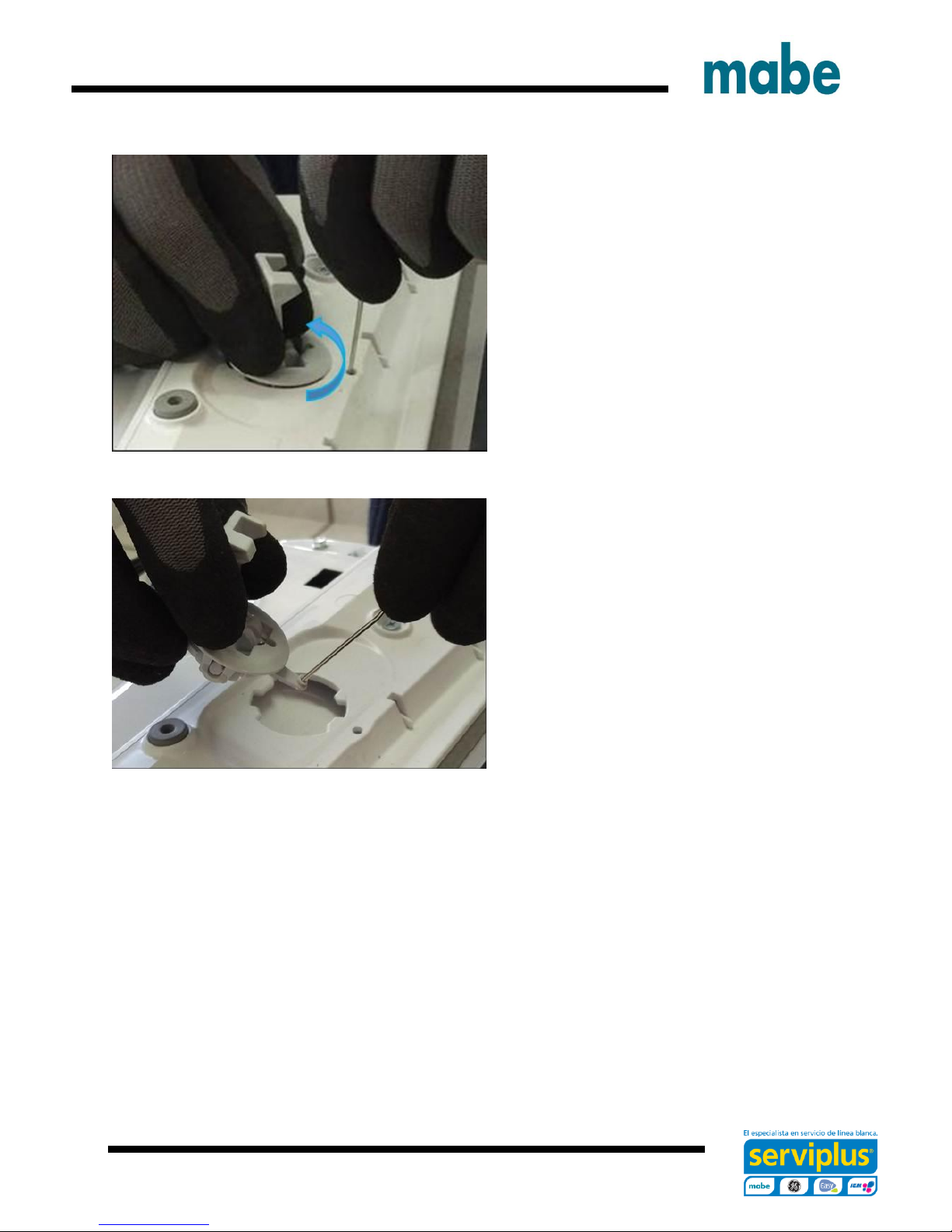

To remove the striker from the lid:

Open the lid.

Using a small screwdriver, insert it into

the small hole below the striker.

Push inward gently on the locking tab

and turn the striker to the left

Pull the striker from the lid

Ingeniería de Servicio

- 17 -

Lid Switch/Lock Assembly

Video Link

The lid lock and switch are together in

one part. It requires 120 VAC to activate

the lock.

The approximate resistance of the lock

coil is 70 ohm from Blue – Black from

J513 board connector (at Lid Lock closed

position)

Checking between Black and White wires

at the same board connector will show the

continuity of the lid switch.

To remove the lid switch/lock assembly:

Ingeniería de Servicio

- 18 -

Remove the bezel from the top cover by

reaching under the top cover toward the

lock assembly and feel for the bezel tabs

to extend through the lock body.

Push the tabs out from the side of the

lock body and then push up to

remove the bezel from the top cover

Ingeniería de Servicio

- 19 -

Using a small screwdriver, push down

gently on the tab that prevents the lock

assembly from sliding.

Slide the lock assembly to the left first to

disengage the right tab, then slide to the

right allowing the lock assembly

disengage from the top cover.

Pull the lock assembly from under the

top cover and disconnect the harness

connector.

Ingeniería de Servicio

- 20 -

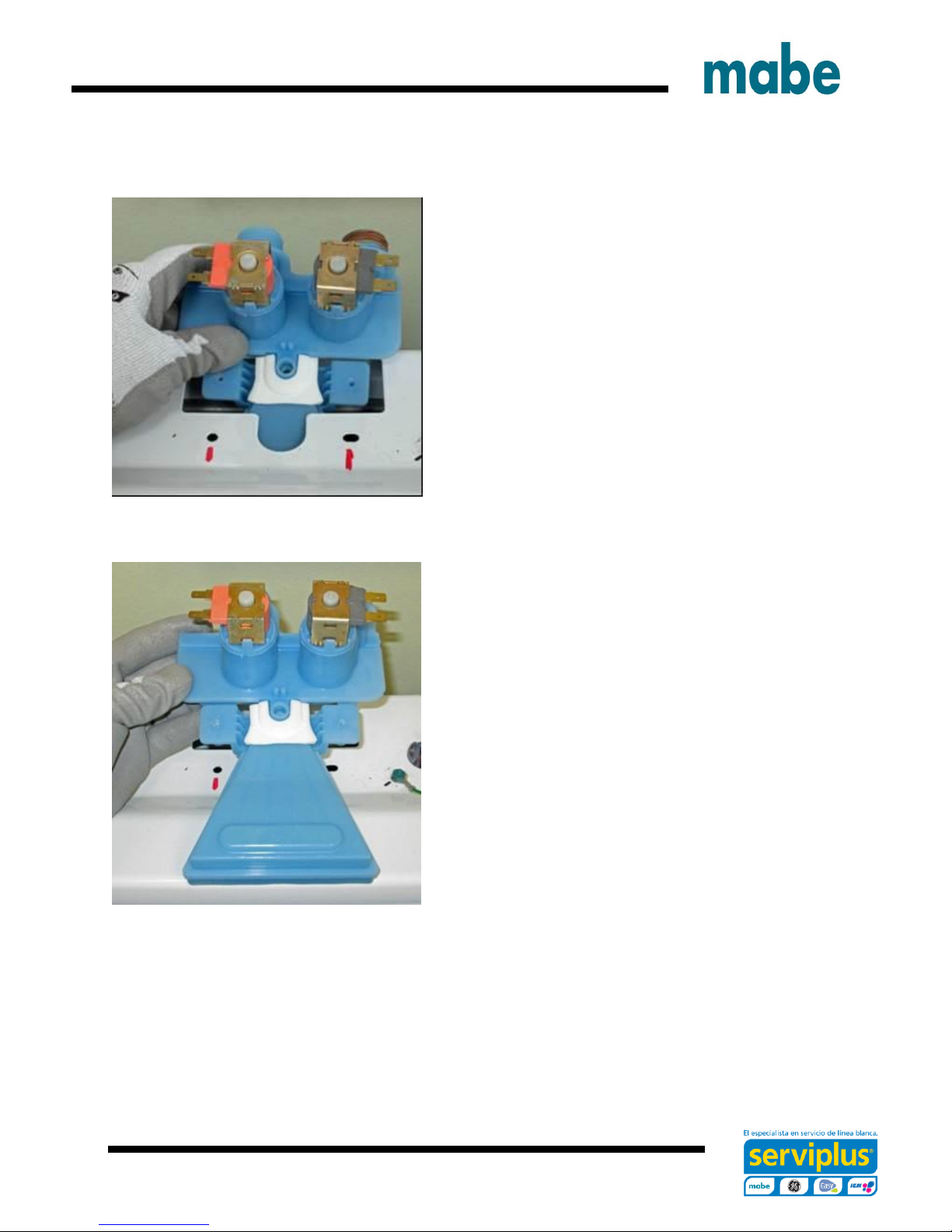

Two Coil Water Valve

Turn water supply off to valve. Hoses do

not need to be disconnected at this time.

Remove two Phillips head screws that go

through the thermistor mounting bracket

into the body of the valve.

Remove thermistor by pulling up on lip of

thermistor. Ensure o-ring is removed with

thermistor.

Ingeniería de Servicio

- 21 -

Tilt back of valve up and slide out of top cover.

Once valve is out and held over the basket,

disconnect hoses.

Valve, funnel and Gasket are one part.

Ingeniería de Servicio

- 22 -

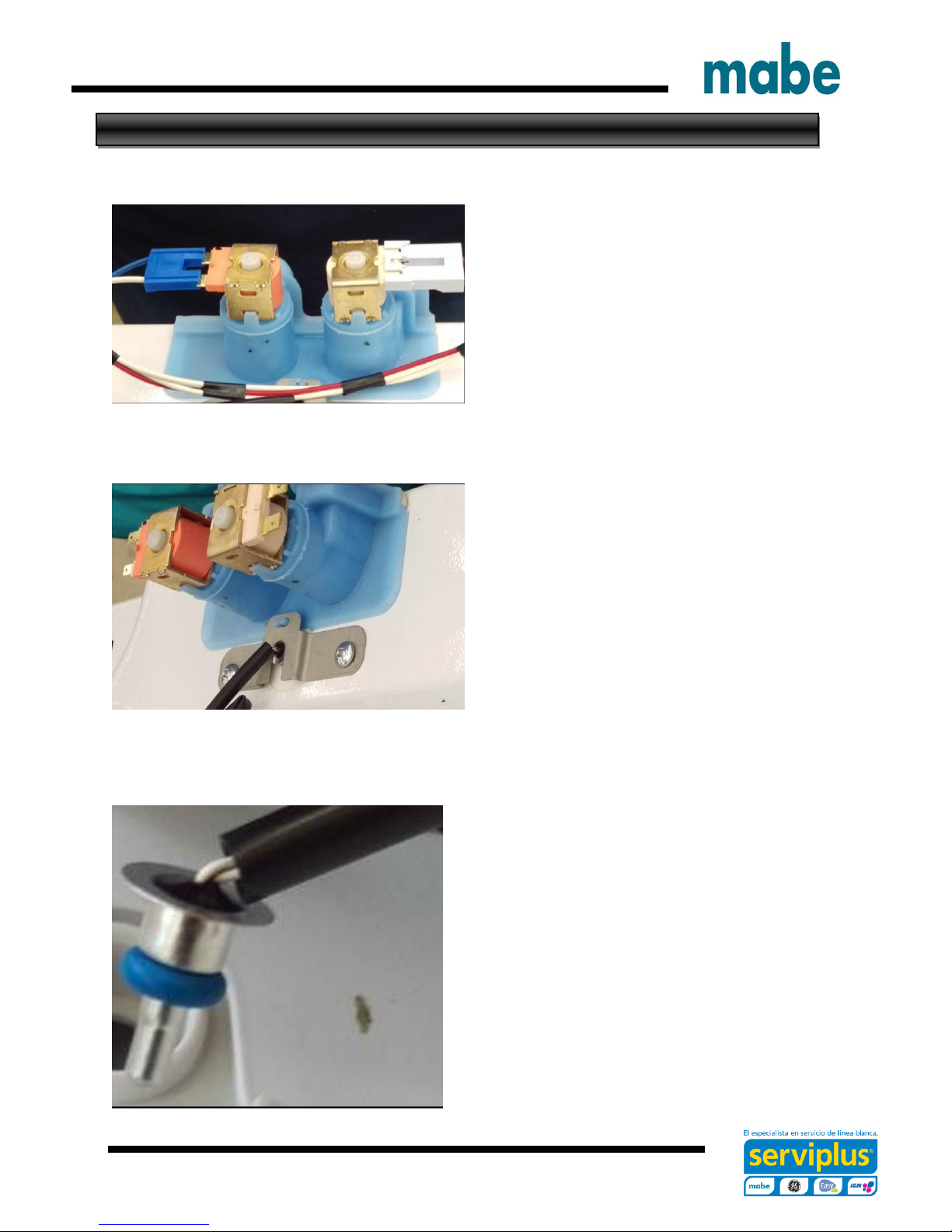

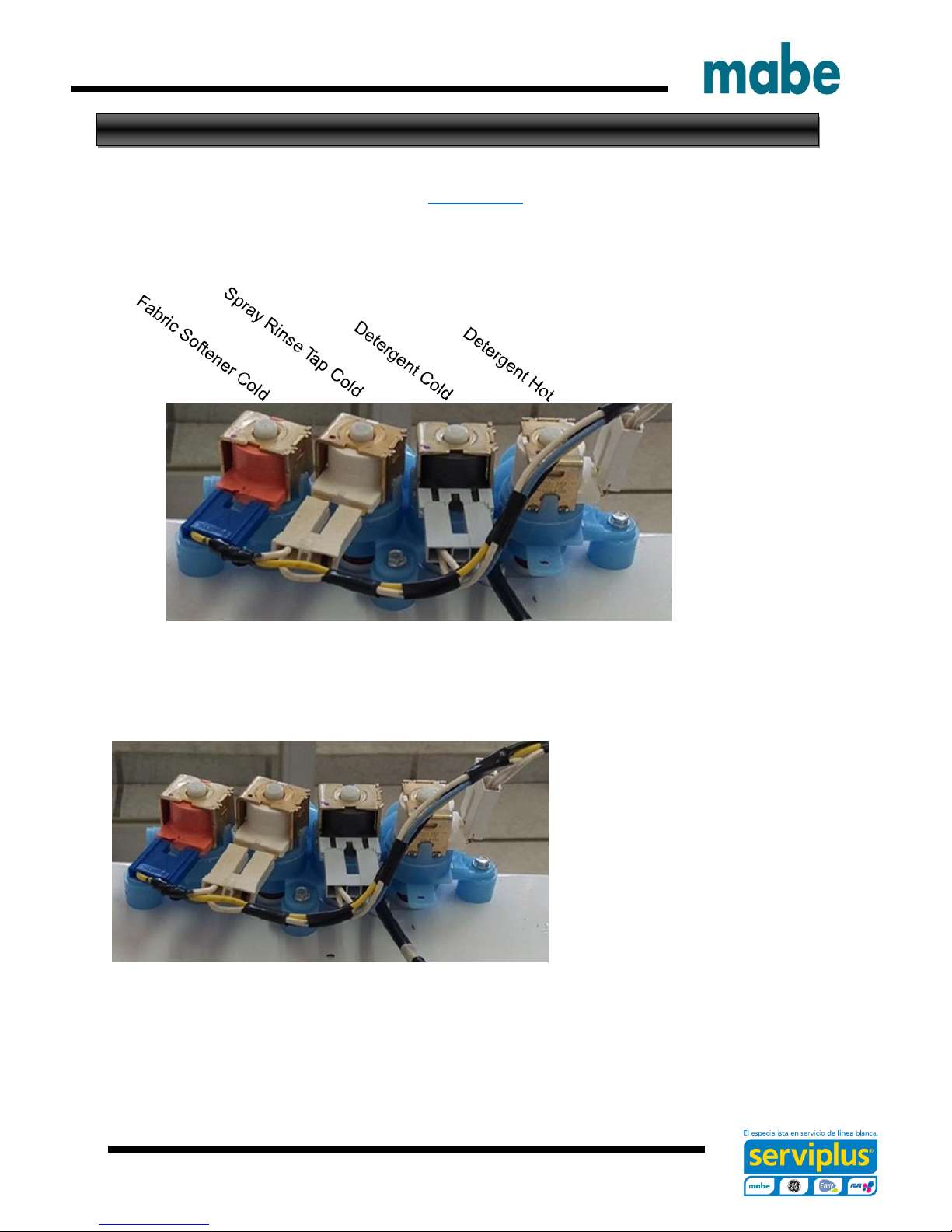

Four Coil Water Valve On GTW680 Model

Video Link

To remove the water valve:

Shut off the water supply to the

washer. Hoses do not need to be

disconnected at this time.

Lean the control panel assembly

back. It does not have to be

completely removed.

Disconnect the harness from the

water valve.

Ingeniería de Servicio

- 23 -

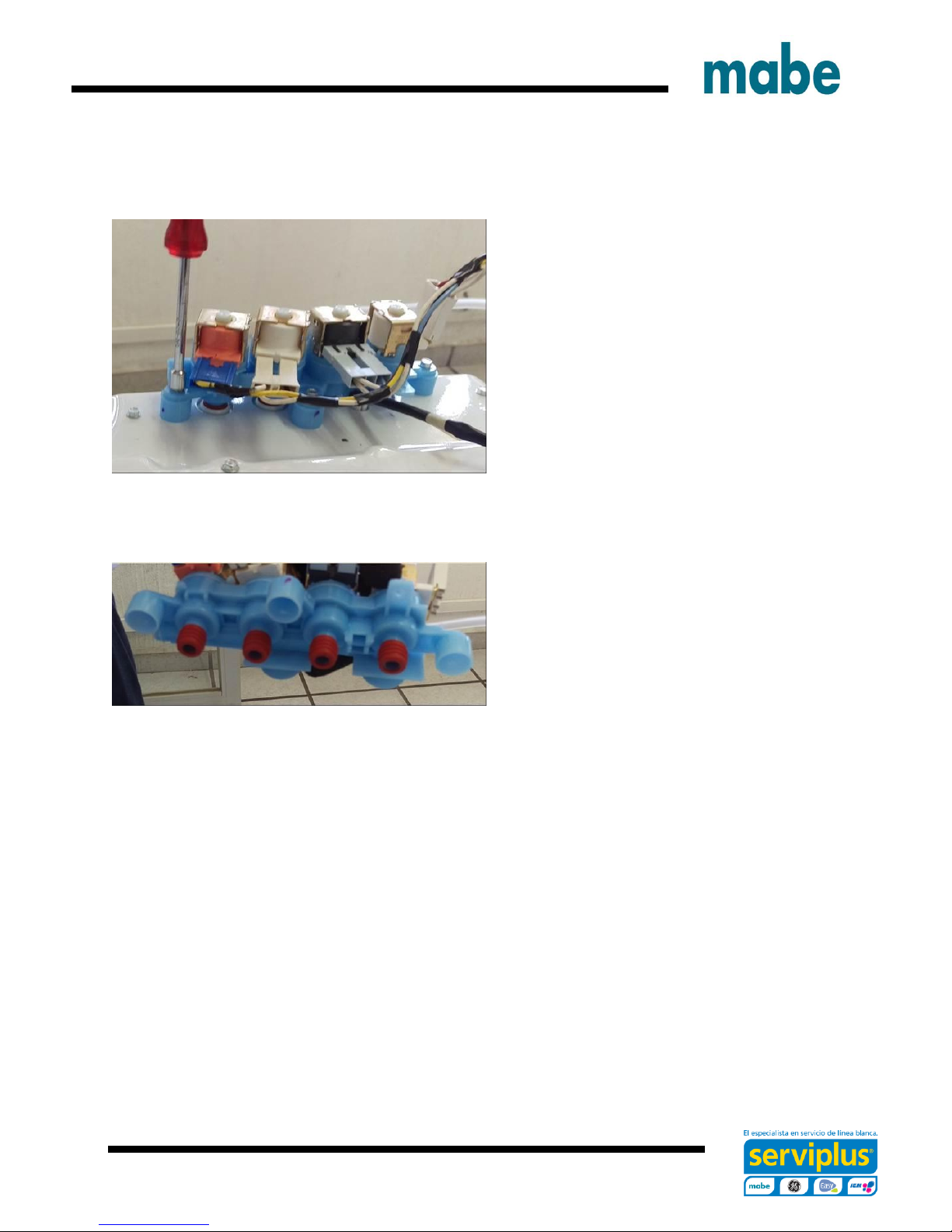

Remove three ¼ in. hex head screws

securing the valve to the top cover and

pull the valve up.

Hold valve over the basket and

disconnect the supply hoses from the

valve.

Quad Valve and the four rubber seals

are together in the same part number

Ingeniería de Servicio

- 24 -

Thermistor Removal

After the water valve is removed, the

thermistor can be accessed and

remove.

It is pushed into the dispenser box

and held in place by the water valve

and is sealed with an O-ring.

Remove thermistor by pulling up on

lip of thermistor. Ensure O-ring is

removed with the thermistor.

Ingeniería de Servicio

- 25 -

Dispenser Removal

The dispenser hold detergent and

fabric softener and delivers it at

precise times for the cycle selected.

Water is added to the dispenser from

the water valve to fill and flush the

cups. After the valve turns off the

remaining water in the cup siphons

out.

Video Link

When bleach is added to the bleach

cup it is funneled through to the tub

cover and into the tub.

Remove the backsplash assembly,

water valve and top cover.

Remove the dispenser tray from the

dispenser body.

Remove four ¼ in. hex head screws

from the top cover securing the

dispenser body to the top cover

Ingeniería de Servicio

- 26 -

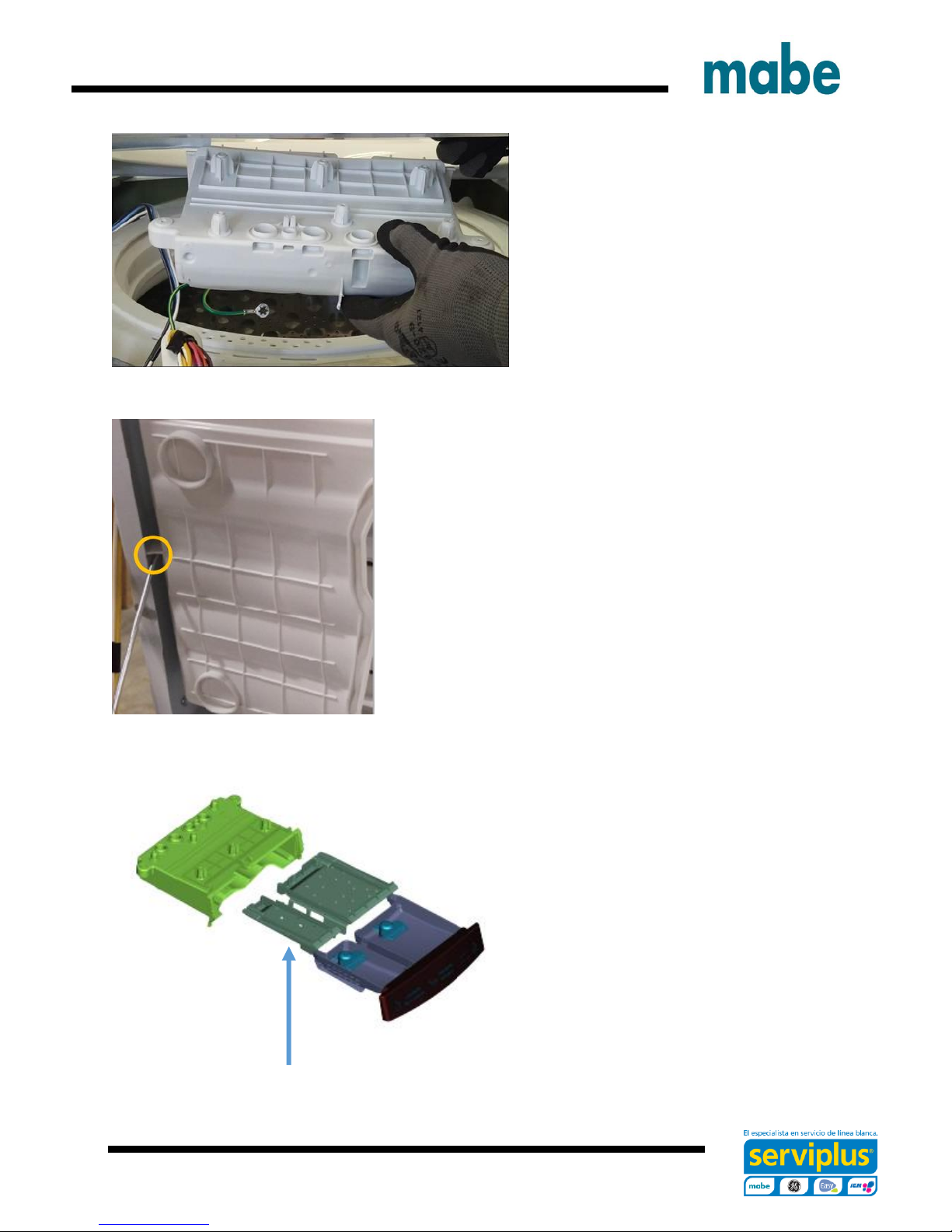

Dispenser Shower Insert

Remove the dispenser body from the

top cover by pushing back slightly on

the dispenser body and pull away

from top cover.

Take care of the back tap of the dispenser body in

order to not damage it.

The dispenser shower insert can be

removed at this time for cleaning if

necessary.

Ingeniería de Servicio

- 27 -

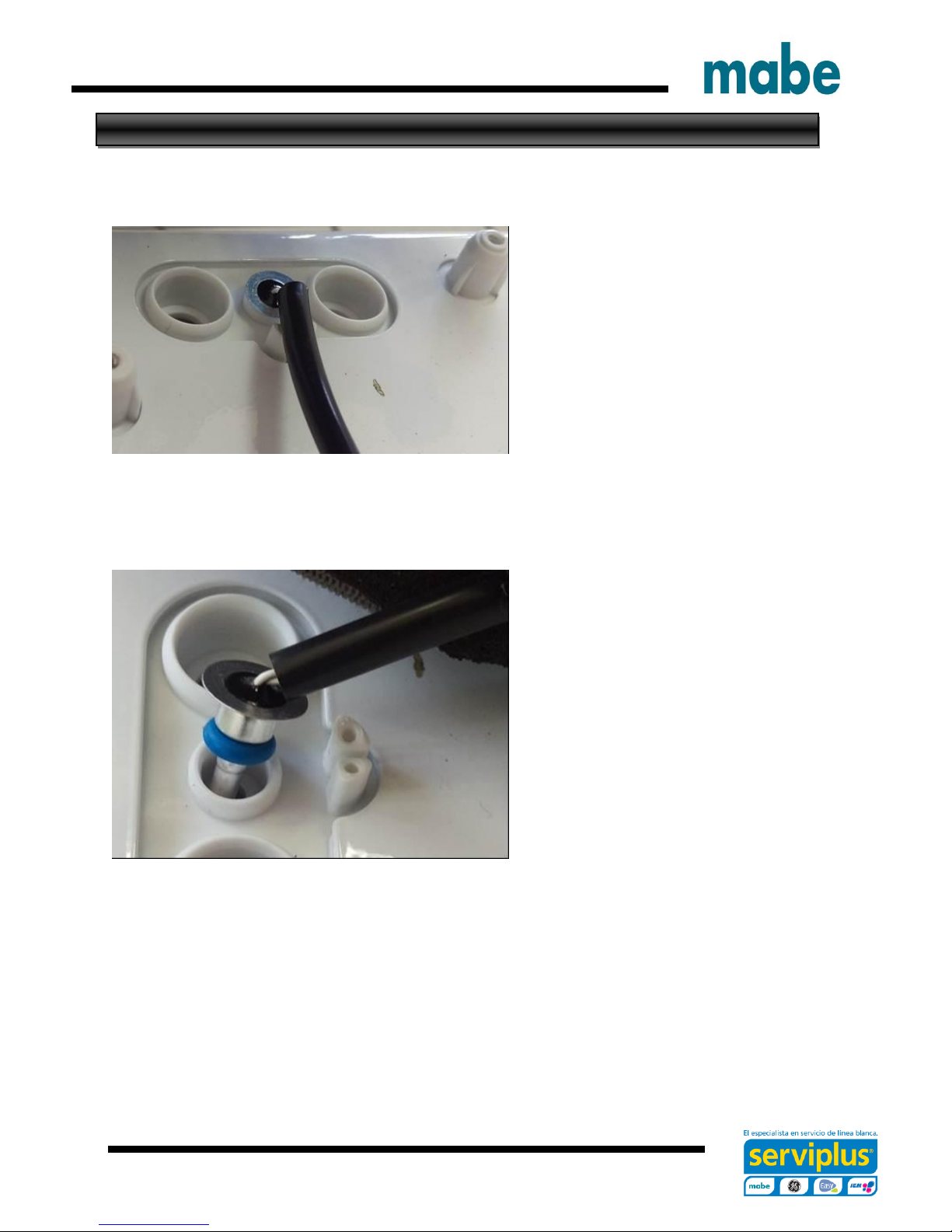

Top Cover Removal

Remove the lid assembly and control panel assembly.

.

Disengage the power cord from the top

cover by pulling up on the front of the

power cord grommet.

Slide the power cord grommet forward

Ingeniería de Servicio

Loading...

Loading...