M2 Antenna Systems RC2800PX-AZ Service manual

TABLE OF CONTENTS

4-23-03 REV 7-22-03

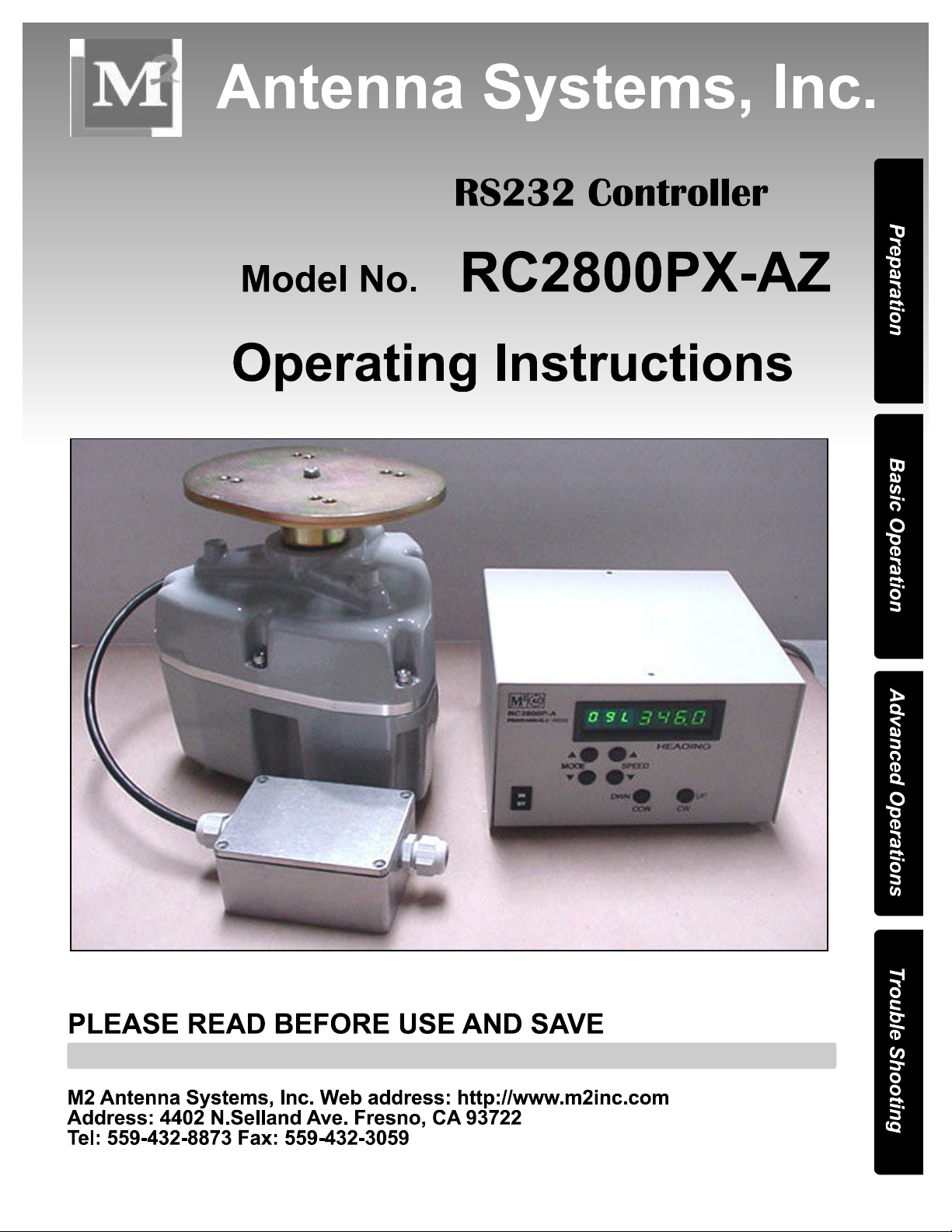

COVER PAGE

TABLE OF CONTENTS 2

FEATURES 3

GETTING STARTED 4

FRONT PANEL CONTROLS 5

RUN MODES 6

PROGRAMMING MODES & CALIBRATION 7,8

PROGRAMMING PRESETS 9

REAR PANEL AND INSTALLATION HINTS 10

OPERATION BY COMPUTER 11

AZ AND EL OPERATION BY COMPUTER 12

WRITING CONTROL SOFTWARE 13,14

TROUBLE SHOOTING 15,16

SIMPLIFIED THEORY OF OPERATION 17

WIRING AND PARTIAL PCB SCHEMATIC 18

WARRANTY 19

4-23-03

FEATURES

Our ALL NEW, GREEN LED, PIC rotator controller is packed with new features including

AUTO-CALIBRATE, AUTO SLOW DOWN as limits are approached, ONE STEP PROGRAMMING saving all changes by exiting the program mode. SOFTWARE UPDATES directly from our “m2inc.com” website Also included is increased circuitry and reed switch

protection. Of course computer control has also been improved. The new RC-2800PX

now accepts fractional inputs like 138.7 degrees and the Auto-calibrate command from a

computer or remote site. What we did not change is front and back panel layout so it

doesn’t require re-learning the controls and the actual operation is almost identical to the

old units. Everything is just a bit smoother and easier. The new PIC microprocessor lends

itself to easier custom programming for special rotator control functions. This custom program can be downloaded directly through the RS-232 port on your RC-2800PX from our

site on the WEB. Of course this new controller works with any of our older OR-2800DC rotators. It can also be easily modified to work with MOST of our older AC (OR-2800AC)

units as well. By ordering an RC-2800PPX controller this design can control a Prop Pitch

Rotator with all the same features. If you have a very custom rotator system using a large

AC or DC motor of almost any voltage or phase (like 3 phase 240 AC) the RC-2800PX

design can control your rotator system. This same controller also controls our line of Elevation rotators (Positioners) like the MT-1000, MT-3000, MT-4000 and the largest, MT-

5000. The Elevation controller can be linked to the AZ controller and both then can be

controlled by computer through a single RS-232 line. We also have a Dual controller (RC2800PRKX) in one rack mount case to control an AZ-EL system. The new RC-2800PX

controller it can handle any gear ratio from 1000 to over 50,000:1

Our OR-2800DC rotator is now supplied with a 60” PIGTAIL and a WATER TIGHT

HOUSING for a terminal strip. This creates an easy access, trouble free control cable

connection. Your control cable can have as few as 2 motor wires (see the “size VS distance” information later in manual) and a small single shielded lead for the position feedback.

4402 N. Selland Ave, Fresno CA 93722 (559) 432-8873 FAX 432-3059

www.m2inc.com Email: sales@m2inc.com

3

GETTING STARTED (with an OR2800 azimuth rotator)

We highly recommend that upon receiving the rotator and controller, you hook it up in the shack

and get used to the operation.

Here is what you do.

1. Connect the black lead in the rotator pigtail to terminal #1 on the back of the control box.

2. Connect the White wire to terminal #2. (AND ON AC UNITS, connect the RED wire to #3).

3. Connect the Orange wire to terminal #5.

4. Connect the Blue wire to terminal #6.

5. Unwrap the AC power cord and plug in the RC-2800PX controller.

6. Turn on the controller. The NEW green display should come up and read “0” “9” XXX .X

7. Push and hold in the UPPER mode button. “P20 0.0” should come up.

8. Bump the LOWER mode button SEVEN (7) times until you see “P0 CAL”

9. Push in the LOWER mode button and you will see the SEGMENTS of the digit to the left of

the “C” start to rotate counterclockwise at the same time the rotator is moving Counterclockwise

(CCW). Release the LOWER mode button and the rotator will continue going CCW by itself at

half speed. Soon the rotator will stop and the display will change to read “0 9 L346”. The rotator

and the control box are now in sync and CALIBRATED. THIS PROCEDURE CAN BE REPEATED ANYTIME IF YOUR CALIBRATION IS LOST, CHANGED OR SUSPECT. It can also be

done remotely from a computer. Normally, the only thing that can keep your RC-2800PX from

displaying the correct heading is IF your mast or antenna has slipped.

10. Now push the CW button and rotate the OR-2800 until the display reads 0.00 or close.

This represents TRUE NORTH, not MAGNETIC NORTH. The “antenna system” if one were

clamped to the top plate, should be pointed at TRUE NORTH and the mast clamps tightened.

YOU ARE NOW CALIBRATED. You should use the above procedure for your final setup too.

NOTE: Any known direction can be chosen for use in aligning the antenna to but you must run

the rotator to THAT heading PRIOR TO clamping the antenna in that direction. THAT’S IT. All

that is left to do is mount the rotator in the tower and connect up the control cable at both ends.

Clamp the antenna at the chosen heading as viewed on your RC-2800PX display and you are up

and running. More details on programming, presets, “South stop”, RS-232 interface, cable size

and possible shielding requirements and much more are on subsequent pages of this manual.

4

. 4-23-03

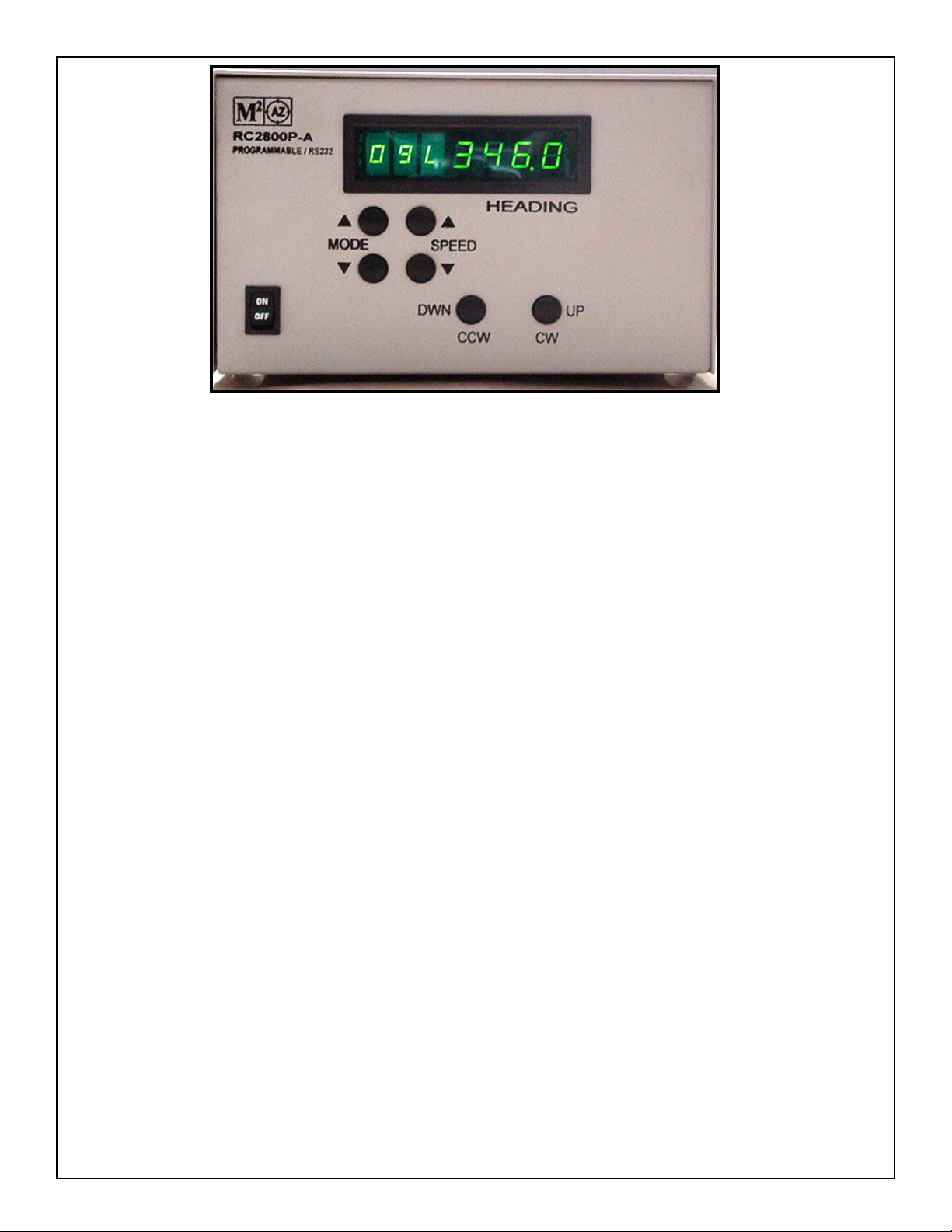

FRONT PANEL CONTROLS

“PWR” ROCKER SWITCH

Located in the lower left hand corner of

the front panel, this button controls AC

power to the unit.

DIGITAL DISPLAY

The digital display panel shows (from left

to right): MODE, SPEED, and

HEADING / PROGRAMMING data.

Display Digit:

#1: (full left): shows the selected MODE for operation or programming.

#2: Indicates the positioner travel SPEED in relative numbers from 0 to 9.

#3, Indicates, an ”L” for a Limit zone or a digit when programming in a high gear ratio.

#4, 5, 6, 7: Indicates HEADINGS, Azimuth or Elevation, in degrees and programming

data.

MODE BUTTONS

The Mode buttons are used to cycle through and select among 3 operational or "RUN"

modes, and 17 "PROGRAM" mode positions. See RUN MODES and PROGRAM

MODE details following this section.

“SPEED” BUTTONS

The speed buttons control the positioner's rate of speed in relative increments. "1" is

the slowest speed, "9" is the fastest. ‘0’ IS DISPLAYED WHEN THE ROTATOR IS

NOT MOVING. The top button increases the speed, the lower button decreases speed.

Lowest speed available DEFAULTS TO 1 but can be set to any number between 1 and

9 in program mode P5. Speeds can be altered for travel in any of the run modes, but

must be returned to speed 9 for full speed and full ramp functions.

“CW" (“UP”) and "CCW” (“DOWN“) BUTTONS

The "CW" and "CCW" buttons activate the positioner directly in Mode 0, Mode 1 and

Mode 2. These buttons also are used in the PROGRAMMING MODE to make

changes to factory defaults and for selecting preset headings.

NOTE: Throughout this manual you will see different words for the same item. Some

common terms would be: Sometimes we just get tired saying the same old thing.

RC-2800PX = Controller, Control box, box or unit.

DISPLAY = Readout, Heading,

ROTATOR = Positioner, Rotor

5

RUN MODE DESCRIPTIONS AND EXPLANATIONS

RUN MODES: Modes 0, 1, AND 2 are RUN modes that activate the positioner with manual or pre-

set commands. Momentarily push either MODE button to cycle through Modes 0, 1, and 2.

MODE 0: Manual operation mode. Pushing the CCW or DOWN button activates the rotator in the

COUNTER-CLOCKWISE direction and the HEADING count will go down. Pushing the CW or

UP button activates the rotator in the CLOCKWISE or UP direction and the HEADING count

will go up. The positioner runs while "CCW" or "CW" button is depressed, ramping up from

minimum programmed speed to the maximum (9) and stopping, WITHOUT ramp down, when

the button is released. When reversing direction there is a 2-3 second delay before posi-

tioner activation. This delay reduces stress on your antennas, tower and guy system.

NOTE:

Rotation direction, i.e., CW / UP or CCW / DOWN is defined as if you are looking down on

the rotator / antenna from above. There is no automatic speed ramp down when operating

in Mode 0 EXCEPT AS YOU APPROACH A LIMIT. Small movements of positioner may not

allow full speed to be reached.

(Special programming will soon be available at our web site (www.m2inc.com) that can be

downloaded directly into your RC-2800PX to reduce the ’reverse delay’ to .1 sec for special

applications). General updating will be available from the web site as well.

MODE 1: Computer control or Manual preset mode. When computer control is activated, a “1”

automatically appears in the MODE # location on the display. Manually the "CW" / UP and

"CCW" / DOWN buttons can be used to select a heading on the display from the full range of

rotation. AFTER the button is released, there is a short delay before positioner activation, allowing time to adjust or "bump" your selection. As the positioner begins to run, the speed

ramps up from the minimum programmed speed to the maximum. As the target heading is

approached, the speed ramps down to stop. The positioner may then "bump" several times

until within about .5 degrees of preset. To STOP or cancel a preset ANY TIME, TOUCH either mode button.

MODE 2: Programmable preset mode. Press the "CW" / UP and "CCW" / DOWN buttons to cycle

through 10 PRESET headings you program into Modes 20-29. Heading selections are shown on

display. After a short pause, allowing you to confirm you selection, the positioner will proceed to the

displayed heading the same as in MODE #1. Typically, these presets are programmed for frequently

used headings and / or stow positions for parking or extreme weather. TO STOP OR CANCEL A

PRESET IN MID TRAVEL TOUCH EITHER MODE BUTTON.

6