M2 Antenna Systems 6M7 User Manual

SPECIFICATIONS

Model .....................................6M7

Frequency .............................49.5-50.5 MHz

Gain ........................................10.5 dBd

Front to back ..........................23 dB

Beamwidth E - Plane ...........E=42o / H=50o

Stacking Distance ..................24' Wide, 22' High

Feed Impedance / Conn. .......50 Ohms / “N” fem.

VSWR ....................................1.2:1 @ 50.1 MHz

Power Handling ......................1.5 KW

Match Type ............................‘T’ Match

Balun ......................................4:1 Coaxial

Lightening Protection .............All Elements Grounded

Boom Length / Dia .................26’ 9” / 2" O.D.

Element Type .........................1/4" Rod with 3/8” Sleeve

Mast Size ...............................2"

Wind Area / Survival ..............3 sq ft / 100 MPH

Weight / Ship Wt. ...................17 Lbs / 19 Lbs UPS

FEATURES

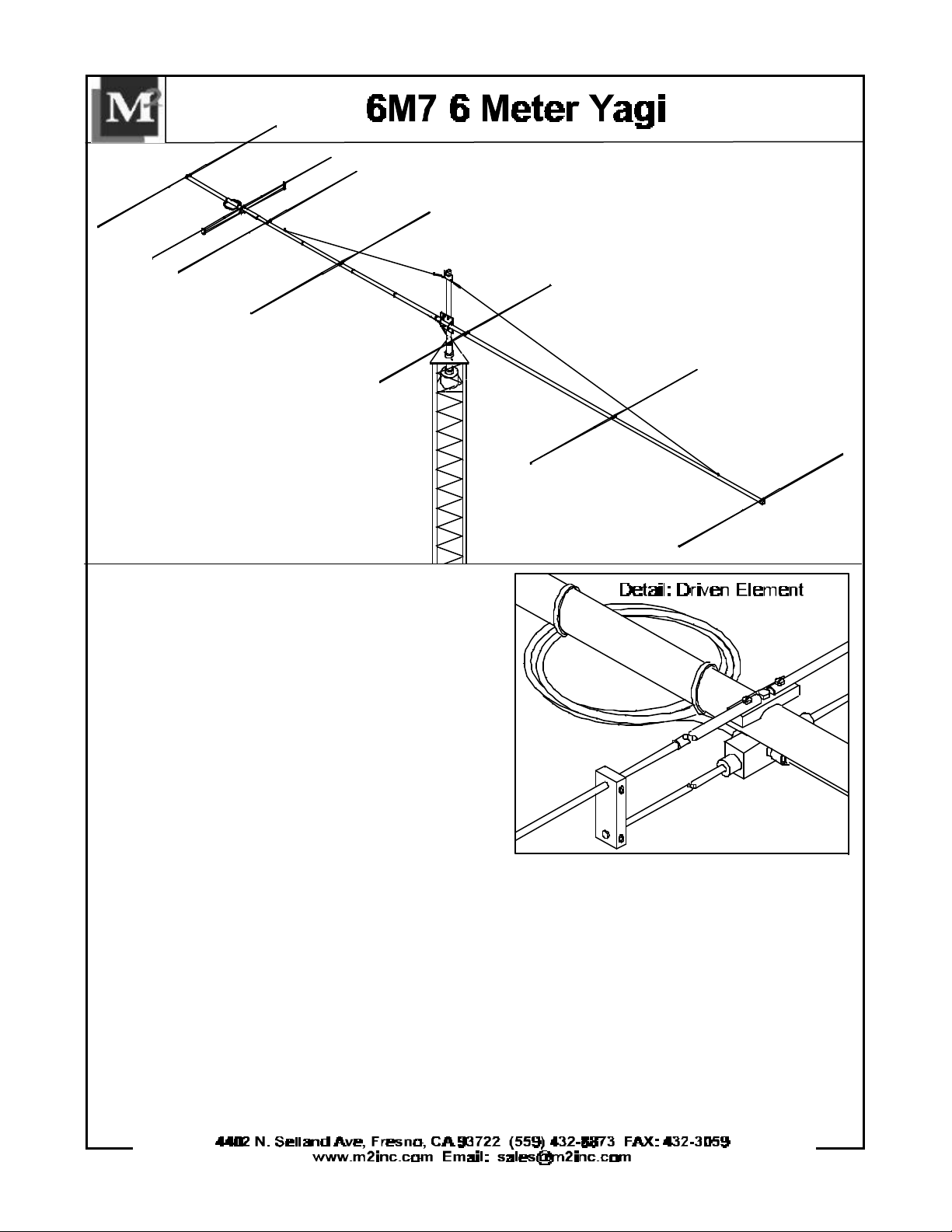

The 6M7 is a mid-sized 7 element antenna designed with the aid of computer technology to

produce maximum gain for its boom length. Features include machined aluminum element

mounting blocks, O-ring sealed connectors and balun, silicone-gel sealed “T” match block, and

stainless steel hardware. Elements are 1/4” aluminum rod with 3/8” tube center sleeves, and all

are DC grounded. An overhead guy system is provided for additional boom support.

TOOLS REQUIRED: Screwdriver, 11/32 wrench, socket or spintite, a 7/16" and 1/2" wrench or

socket, tape measure.

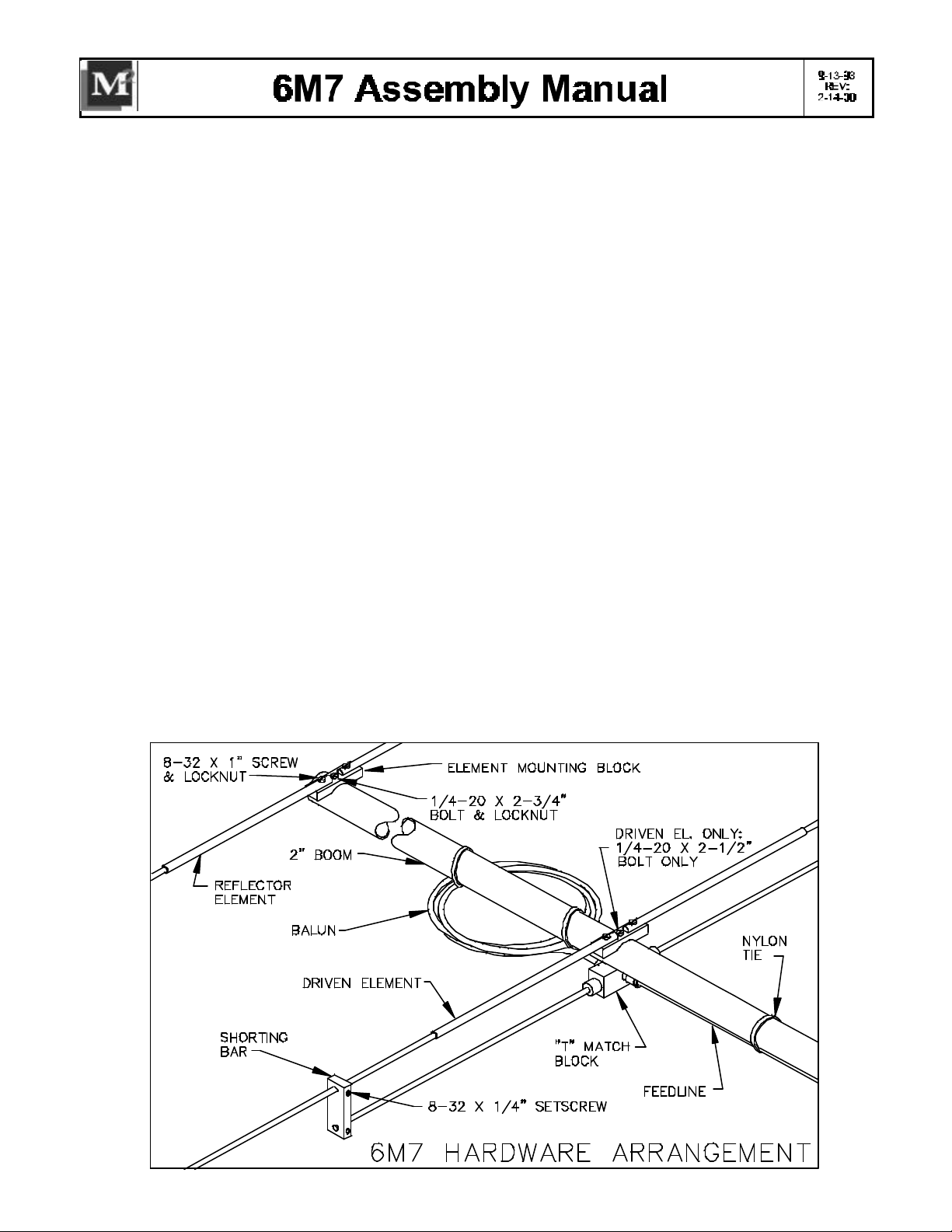

1. Layout the boom sections as shown on Dimension Sheet and assemble with 1/4-20 x 2-1/2” bolts

and locknuts. Note: the REAR boom section, #1, has the most holes. Section #2 has one element

mounting hole 36-1/2” from the swaged (necked down) end. Section #3 has one at 39-3/4” from the

swaged end. Section #4 is unswaged. Tighten the nuts securely.

2. Use the Dimension Sheet as reference for ins talling the ELEMENT HALVES on to the ELEMENT

MOUNTING BLOCKS. U se the 8-32 x 1" screws and locknuts. Install screws from bottom of blocks.

3. Mount the longest element (REFLECTOR - 60-1/8” element halves) to the hole at the rear end of the

boom using a 1/4-20 x 2-3/4” bolt and locknut. Tighten securely.

4. Mount the DRIVEN ELEMENT next with a 2-1/2” bolt, threading it into the 'T' MATCH BLOCK held

to the underside of the boom. Orient the match block with the “N” feed connector pointed to the front.

Mount the DIRECTOR ELEMENTS using 1/4-20 x 2-3/4” bolts and locknuts.

5. Thread the gold SEAL NUTS all the way onto the two small connectors on the 'T' match block,

black neoprene side out. Then connect the balun connectors and tighten them GENTLY with a

7/16" end wrench. Now back out the seal nuts until they are up against the face of the balun

connectors and tighten them about 1/2 turn with a 1/2" end wrench. Secure coiled balun to boom with

two nylon ties.

6. Install two 8-32 x 1/4” Setscrews into each SHORTING BAR. Then slide a SHORTING BAR onto

each DRIVEN ELEMENT HALF and onto the 1/4” “T” match rods. Position so there is 17-3/8” between

the outer edge of the match block and the inner edge of the shorting bar (also see Dimension Sheet).

Align rods and element halves parallel and tighten the set screws with the 5/64" Allen wrench provided.

7. Install the feedline, mating and tightening the Male 'N' connector carefully. Route the cable forward to

Loading...

Loading...