Mäktig 601625 Instruction Manual

INSTRUCTION MANUAL

Electric

Drum Pump

Electric drum pump designed for

pumping fuels, water based media, light

oils, DEF & select chemicals from metal

drums of 55 gallon (205 litre or 275-330

gallon (1000-1250 litre) IBC’s

Compact & lightweight construction

Convenient ON/OFF Switch with LED

Indicator

Built-in fuse for overload protection

Silenced motor makes almost no noise

Stainless steel filter built into the suction

tube inlet prevents contaminants from

getting in & causing damage

Built-in 2" bung adaptor fits directly onto

metal drums of 55 gallon (205 litre). Bung

adapter can be adjusted by 0.6” (15 mm)

to adjust to drums with varying heights.

Includes an additional bung thread

converter for converting 2” standard bung

threads to 2.5" X 5 mm buttress for using

pump with IBC’s

Lift Handle

18.5V, 1.3Ah Li-Ion

Battery

Thread Converter

(with 2.5" X 5 mm

Buttress Threads)

On/O Switch

Pump outlet

with swivel

connection

Flexible

Corrugated Hose

2m (6.6’) long

601625

3/4” (19mm)

SS Spout

Manual

Dispensing

Nozzle

Telescopic suction tube extends from 331/2" (850 mm) to 49" (1245 mm) for use

with 55 gallon (205 litre) drums or 275330 gallon (1000-1250 litre) IBC’s

Supplied complete with 2m (6.6’) hose &

manual dispensing nozzle with 3/4" (19

mm) OD Stainless Steel Spout

Duty Cycle: 15 minutes On /

15 Minutes O

WETTED COMPONENTS

Viton, Acetal (POM), Stainless Steel (SS),

Polyethaline (PE), Polypropylene (PP),

Nitrile Butadiene Rubber (NBR)

RECOMMENDED USE

Diesel, Kerosene, Bio Diesel, DEF/

Adblue, Water based media, Antifreeze,

Detergents, Pesticides Herbicides, Urea,

Light oils with viscosity upto 100 cst

! WARNING:

Failure to follow all safety information can result in death, personal injury and/or property damage.

• Do Not Use With: Gasoline, Corrosive chemicals, Lacquer thinners, or any material that is not

FEATURES

DELIVERS

UPTO

28 LPM

(7.4 GPM)

• Keep all sources of fire away from the pump.

• Wear safety glasses at all times when working with this pump.

• Wear a face shield, proper apparel and suitable respiratory equipment when pumping hazardous

• In case of accident, immediately seek medical attention. Do not try to treat the injury yourself.

• Keep work area clean, uncluttered and properly lighted.

• Use only genuine factory parts for repair.

FLUIDS

DIESEL

KEROSENE

BIO DIESEL

Telescopic

Suction Tube

SS Strainer

compatible with the pump construction.

chemicals.

DEF / ADBLUE

WATE R ANTIFREEZE

DETERGENTS

PESTICIDES

HERBICIDES

UREA

Nozzle

Holster

LIGHT OIL

6

SPECIFICATION

MOTOR TYPE DC Brush Motor (5 Pole)

TEMPERATURE 5° to 40°C (41° to 104°F)

MAX. VISCOSITY OF MEDIA 100 cst

POWER SOURCE

POWER SOURCE RECHARGEABLE (Li-Ion)

Power Cord Rechargeable 1.3 Ah Li Ion Battery with

1 hour Quick Charger

Voltage 18.5V Battery & AC charger

(110V or 220V)

Max. Discharge 28 LPM (7.4 GPM)

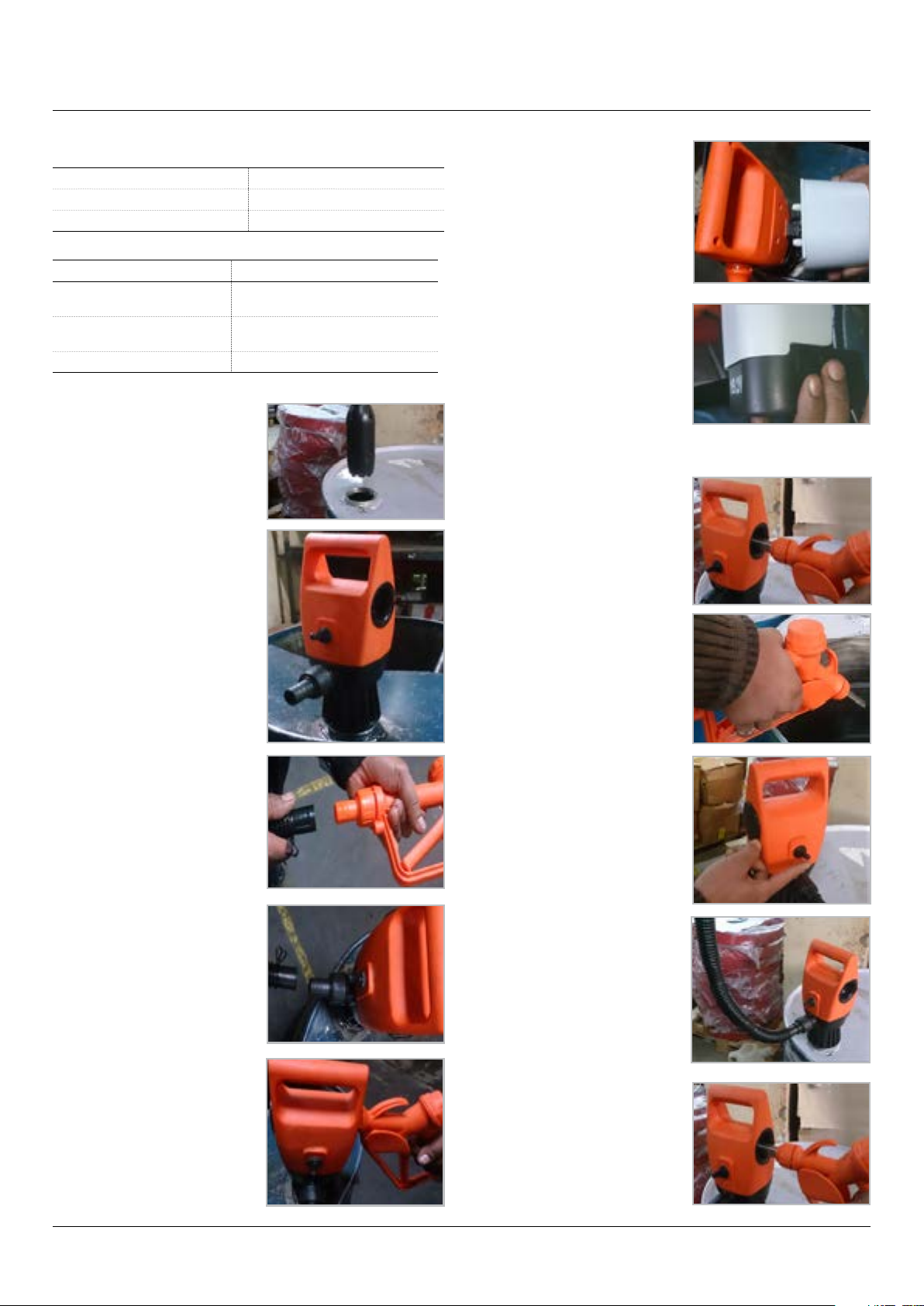

INSTALLATION

1. Insert the Pump into the

Drum through the Drum

Hole.

2. Screw the Bung adaptor

with the Drum hole.

Note: Buttress thread

adaptor can be used with

2.5" x 5mm thread IBC’s.

BATTERY CONNECTION

1. Connect the Battery

holder plug with the

pump socket and mount

the Battery holder on to

the pump by screwing

the holder into the pump

body. (Refer to Exploded

View point 50 & 51)

2. Push a fully charged

battery into the Battery

holder.

Note: Press the side

buttons on the battery

while removing it or else it

will not come out.

3. Turn the toggle switch to ‘ON’ position to start the pump.

OPERATION

1. Pull out the Nozzle from

the Nozzle Holster

2. Place the Nozzle into the

receiving container to

transfer the liquid.

3. Clamp the hose with the

nozzle using the Hose

clamp.

4. Clamp the other end of

the Hose with the outlet

Hose barb on the pump

outlet.

5. Place the Nozzle inside

the Nozzle Holster

provided on the side of

the pump.

3. Switch On the Toggle

switch (Up) and pull the

Nozzle Trigger.

4. After Dispensing Switch

O the Toggle switch

(Down) and lift the

Nozzle upward allowing

all the liquid in the line to

flow back into the Drum.

5. Place the Nozzle back

into the Holster to

prevent any damage

to the Hose or to the

Nozzle.

7

Loading...

Loading...