Lytron LCS20 Series User Manual

© Lytron Inc., 2010

Model: LCS20 Series

USER MANUAL

www.Lytron.com

Telephone: +1-781-933-7300, Fax: +1-781-935-4529

55 DRAGON COURT

WOBURN, MA 01801

Lytron Liquid Cooling System

Manual# 820-0166, Rev. J, 03/06/19

Liquid Cooling System LCS20 Series Technical Manual

{THIS PAGE IS LEFT BLANK INTENTIONALY}

Manual# 820-0166, Rev. J, 03/06/19 2 of 32

Liquid Cooling System LCS20 Series Technical Manual

TABLE OF CONTENTS

TABLE OF CONTENTS ..................................................................................................................................................... 3

REVISION HISTORY.......................................................................................................................................................... 4

INTRODUCTION ................................................................................................................................................................ 5

SAFETY PRECAUTIONS .................................................................................................................................................. 6

LABEL AND SILKSCREEN MARKINGS (LOCATED IN THE BACK OF UNIT) ............................................................. 7

PART NUMBER DESCRIPTION ....................................................................................................................................... 9

INSTALLATION REQUIREMENTS ................................................................................................................................. 10

INSTALLATION PROCEDURE ....................................................................................................................................... 12

CONTROLLER ................................................................................................................................................................. 13

CHANGING TEMPERATURE UNITS .............................................................................................................................. 21

STARTUP PROCEDURE & SYSTEM OPERATION ....................................................................................................... 22

SYSTEM MAINTENANCE AND SERVICE ..................................................................................................................... 23

TROUBLE SHOOTING GUIDE ........................................................................................................................................ 25

SPARE PARTS LIST ....................................................................................................................................................... 26

ELECTRICAL SCHEMATIC ............................................................................................................................................ 28

PLUMBING SCHEMATIC ................................................................................................................................................ 29

WARRANTY ..................................................................................................................................................................... 30

DECLARATION OF CONFORMITY ................................................................................................................................ 32

Manual# 820-0166, Rev. J, 03/06/19 3 of 32

Liquid Cooling System LCS20 Series Technical Manual

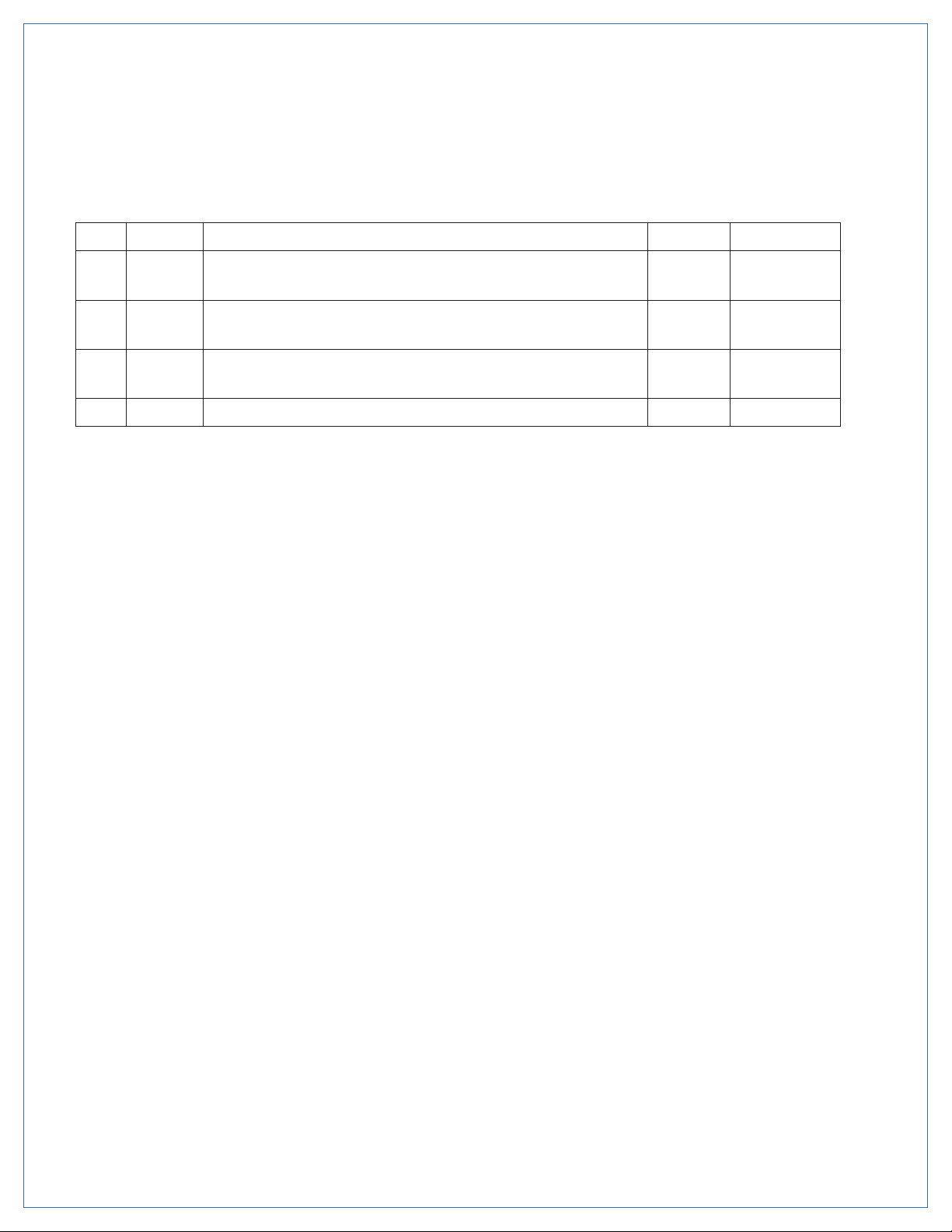

REV

ECN

REASON FOR CHANGE

DATE

ORIGINATOR

F

17284

UPDATED DECLARATION OF CONFORMITY, SAFETY SYMBOLS,

AND NEW CONTROLLER INFORMATION.

07/08/10

G

18011

CHANGE REFERENCE FORM# ON BOTTOM OF SERVICE

POLICY AND ADD TO LYTRON WARRANTY.

01/10/12

NG

H

1023210

ADDED ENVIRONMENTAL SPECIFICATIONS AS PART OF 61010-1

3RD ADDITION CERTIFICATION. UPDATED DEC OF CONF.

01/11/16

AJL

J

201269

UPDATED DES

03/06/19

PDB

REVISION HISTORY

Manual# 820-0166, Rev. J, 03/06/19 4 of 32

Liquid Cooling System LCS20 Series Technical Manual

INTRODUCTION

Receiving Your Liquid Cooling System

Inspect your LCS (liquid cooling system) immediately upon receiving it. If the unit shows shipping

damage, contact the transportation company and file a freight damage claim. Retain all cartons and

packing material until the unit is operated and found to be in good condition. Your LCS has been

fully tested at the Lytron factory with clean water. Although the system has been drained, some

residual fluid may remain. This will not hinder the performance of the chiller.

About The Warranty

Refer to the end of manual for the LCS standard warranty. All units returned for warranty claims must

have an RMA (Return Material Authorization) number on the outside of the container. Call Lytron

Customer Service at +1-781- 933-7300 for an RMA number. Units should be drained of all fluids and

packaged in its original packaging.

Customer Service Support

Lytron is committed to servicing the customer, both during and after the sale. If you have any

questions concerning the operation of your unit, contact our Application Engineering Department at

+1-781- 933-7300. To facilitate your call, please have the model number and serial number of the

unit (located on the rear of the LCS) for the Lytron Applications Engineer. For a detailed description

of Lytron’s LCS service policy, refer to the back of this manual.

Service Hotline

Lytron has a 24-hour per day, 7 day per week service hotline to help you with questions on the

startup and operation of your LCS. (We recommend you review the troubleshooting guide

before calling our service hotline.) Lytron service can be reached by dialing +1-781- 933-7300. To

facilitate your call please have the model number and serial number (located on rear of the LCS) of

the unit for the Lytron Service Technician. For a detailed description of Lytron’s LCS service policy,

refer to the back of this manual.

Manual# 820-0166, Rev. J, 03/06/19 5 of 32

Liquid Cooling System LCS20 Series Technical Manual

SAFETY PRECAUTIONS

This system is designed to provide fluid cooling only as specified in this manual. If you use this system in a

manner other than as specified, the safety protection of the system may be impaired.

Warnings are posted throughout the manual. Read and follow these important instructions. Failure to

observe these instructions or use the LCS other than as specified may impair safety protection, void the

warranty, and can result in permanent damage to the unit, significant property damage, personal injury

and/or death.

Make sure you read, understand, and follow all instructions and safety precautions listed in this manual

before operating your unit. If you have any questions concerning the operation of your unit or the

information in this manual, please contact our Applications Engineering Department at +1-781-933-7300.

x DO NOT USE AUTOMOTIVE ANTI-FREEZE IN THE LCS. The rust inhibitors in the automotive

type may cause premature failure of the pump seals. Use of automotive anti-freeze in a

Lytron LCS will void the warranty.

x Never place the unit in a location where excessive heat, moisture, or corrosive materials are

present.

x The unit must be plugged into a properly grounded power source.

x Do not connect the SUPPLY or RETURN fitting to your building water supply or any

pressurized source.

x DO NOT USE OR MAINTAIN THE LCS OUTDOORS. These units were not designed to

withstand outdoor weather conditions.

x Performance of installation, operation or maintenance procedures other than those described

in this manual may result in a hazardous situation and may void the Lytron warranty.

x Transport the unit with care. Sudden jolts or drops can damage the unit.

x Drain the unit of all water when transporting, shipping, or leaving unused for long periods of

time. This will prevent freezing and algae build up while idle.

x Observe all warning labels. Never remove warning labels.

x Do not operate damaged or leaking equipment.

x Do not operate the unit without fluid in the reservoir.

x Always turn the unit "OFF" and disconnect the power cord from the power source before

performing any service, maintenance procedures or before moving the unit.

x Do not operate equipment with damaged power cords.

x A qualified technician should perform Service and repairs.

Manual# 820-0166, Rev. J, 03/06/19 6 of 32

Liquid Cooling System LCS20 Series Technical Manual

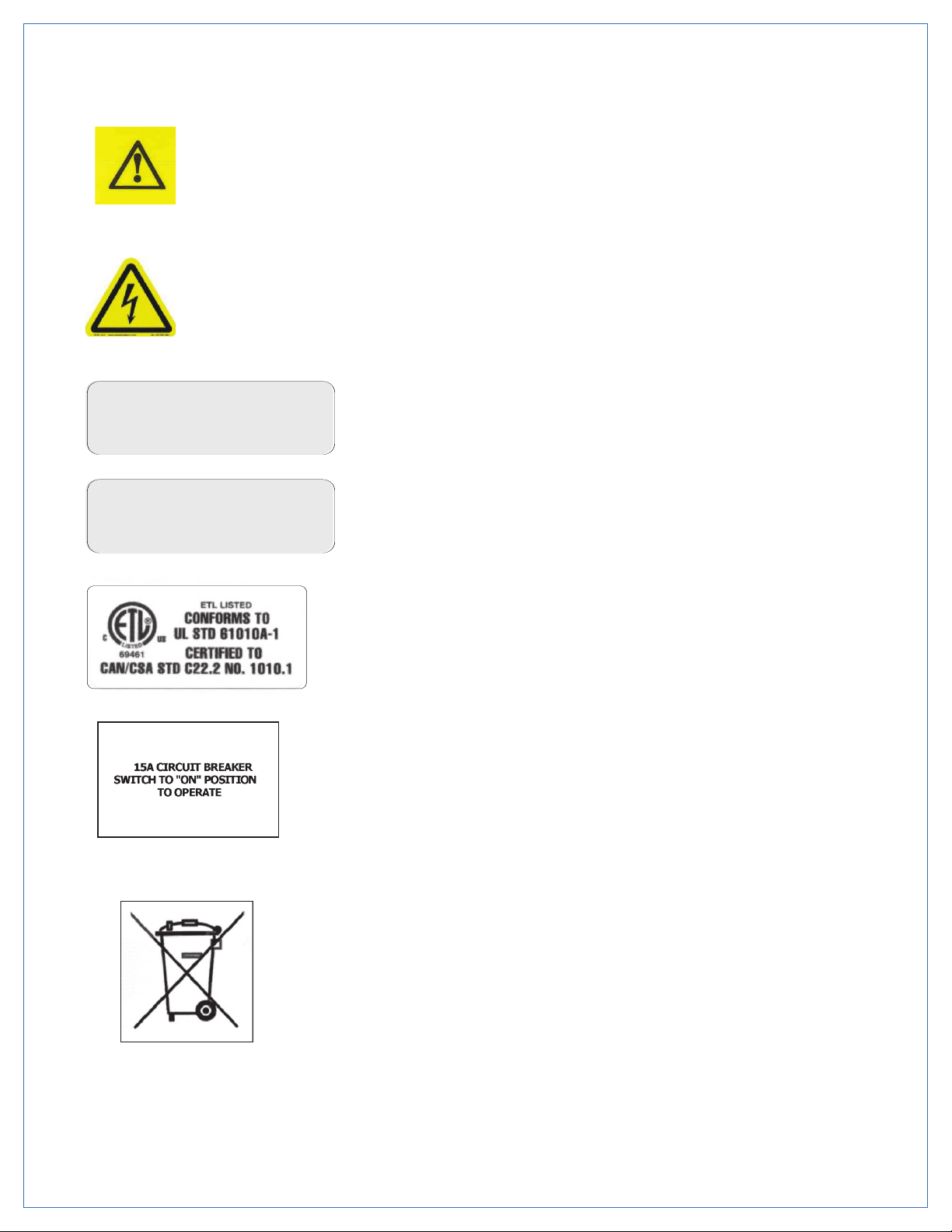

SUPPLY LABEL: This label identifies the connection where

chilled fluid is supplied to the user’s machine.

RETURN LABEL: This label identifies the connection where

heated fluid is

supplied from the user’s machine.

FUNCTIONAL/EARTH LABEL: (ground) Terminal.

LABEL AND SILKSCREEN MARKINGS (Located in the back of unit)

RETURN

SUPPLY

CAUTION LABEL: The triangle symbol tells maintenance personnel

and users to consult the Technical Manual for more information. In this

example, the symbol calls attention to the High Voltage Warning in the

Control Box.

GROUND LABEL: This symbol appears on the unit next to a protective

earth ground terminal

CE LABEL: This symbol certifies that the Liquid Cooling System

conforms to the EMC Directive and all applicable directives at the time

of marking.

PRODUCT ID LABEL: Identifies the model number, serial number,

electrical information, and pump type

.

Manual# 820-0166, Rev. J, 03/06/19 7 of 32

Liquid Cooling System LCS20 Series Technical Manual

ATTENTION / WARNING

LABEL

VOLTAGE LABEL

: This symbol is to alert you of the presence

of dangerous voltage within the unit’s enclosure. The voltage

is of sufficient magnitude to constitute a risk of electrical

shock.

FACILITY WATER OUT L

ABEL: Discharge facility water

from LCS unit.

F

ACILITY WATER IN LABEL: Supply LCS unit with facility water

from LCS unit.

ETL LABEL: The marking on this label certifies that the

equipment has been certified to the UL standard 61010A-1 and

CAN/CSA

STD C22.2 No. 1010.1 standards.

CIRCUIT BREAKER LABEL: Located on the backside of chiller.

This label signifies that the 15A Circuit Breaker Switch must be in

the “ON” position to operate.

WEEE LABEL: The crossed out wheeled bin label requires that

the product be disposed of or recycled with the requirements

of local law.

FACILITY

WATER OUT

FACILITY

WATER IN

Manual# 820-0166, Rev. J, 03/06/19 8 of 32

Liquid Cooling System LCS20 Series Technical Manual

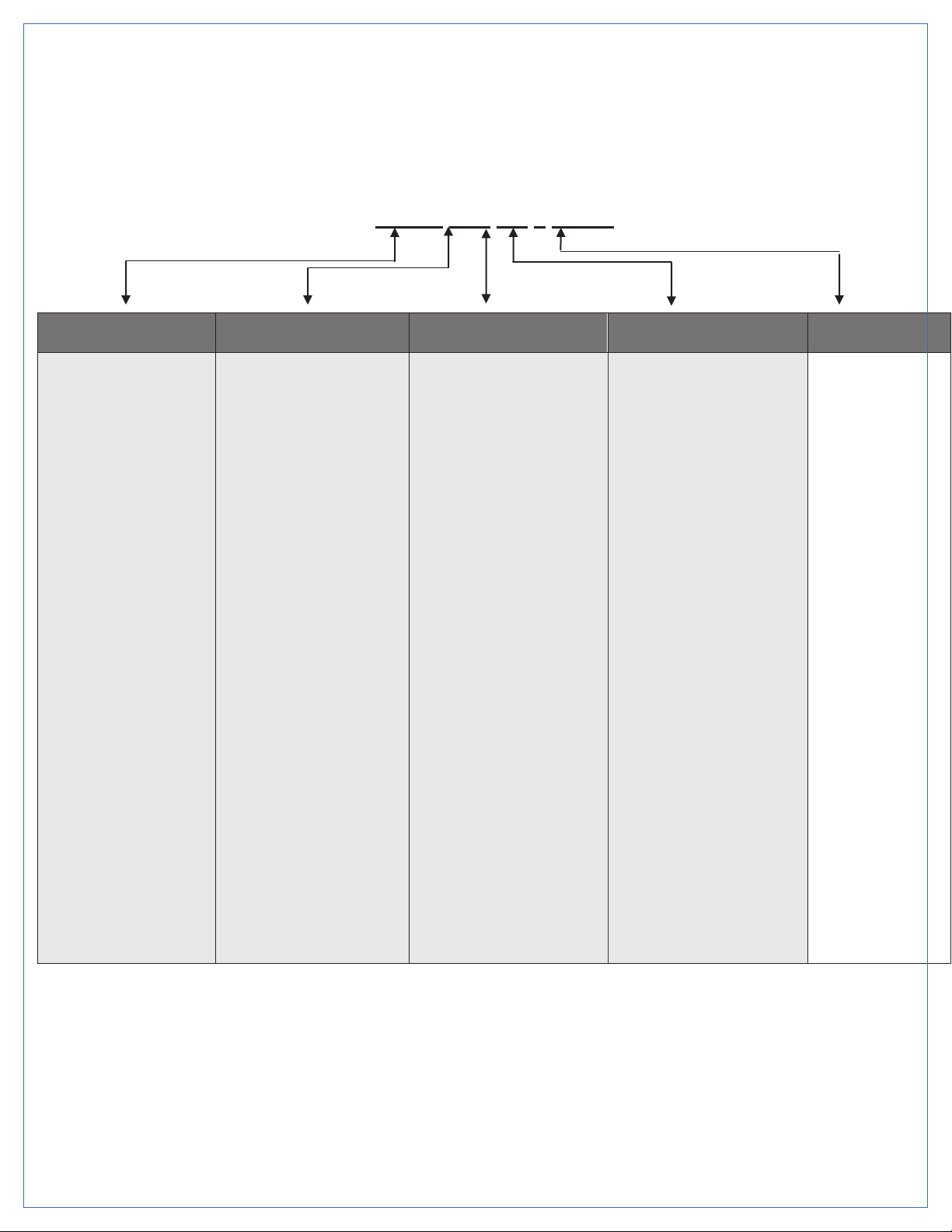

Basic Model No.

Electrical

Configurations

Controller Configuration

Std. Modification

LCS20

NOTE:

P

rated at 60Hz. For

50Hz power

capacity is reduced

by 17%.

G01

100

60Hz

J01

200

/60Hz

BB

(CB*) = 1.3 gpm

Positive Displacement

Pump

BC

(CC*) = 1.8 gpm

Positive Displacement

Pump

BE

(CE*) = 2.3 gpm

Positive Displacement

Pump

BG

(CG*)

= 4.3 gpm

Positive Displacement

Pump

DA

† = CP-

25 Centrifugal

Pump

EB

(FB*) = Turbine

Pump

* Indicates high purity

compatible pump.

† Water filter and DI

cartridge not

recommended with

Centrifugal and

Turbine pumps.

1 = Temperature display,

temperature set-point,

over temp alarm light.

2 = Same as “1” above

with the addition of :

x Low-

level alarm

light.

x

Low flow alarm

light.

x Analog

temperature

output (0-5 V)

PART NUMBER DESCRIPTION

LCS20 G01 BB 1 MXXX

Pump Options

– 20 kW

ump flows are

NOTE: Refer to the product ID label on the on the rear of your chiller for the configuration you have purchased.

Manual# 820-0166, Rev. J, 03/06/19 9 of 32

The table above refers to Lytron’s standard product offering for the LCS product line.

=

-120V, 1Ph, 50/

=

-240V, 1Ph, 50

Liquid Cooling System LCS20 Series Technical Manual

INSTALLATION REQUIREMENTS

Coolant Requirements

x Lytron recommends using filtered clean water above 10

o

x If the set point is 10

required. This unit is equipped with a low flow switch. This feature will shut the chiller down during a

low flow situation to prevent freezing.

C/50oF or below, a freezing point depressant, such as ethylene glycol, is

o

C/50oF as coolant.

x

DO NOT USE AUTOMOTIVE ANTI-FREEZE IN THE LCS. The rust inhibitors in

the automotive type may cause premature failure of the pump seals. Use of automotive antifreeze in a Lytron LCS will void the warranty.

x Avoid using water with a high mineral content.

x If the coolant is exposed to sunlight add an algaecide to control organic growth in lines.

Environmental Requirements

Non-operating

x Ambient Temperature: –20º to 50ºC with a maximum positive/negative rate of change of 20ºC/hour.

x Humidity: Between 5% and 100%, non-condensing, with the maximum allowable positive/negative

rate of change of 30% per hour.

x Altitude: 30 m below sea level to 5000 m above sea level.

Operating

x Ambient Temperature: 10º- 35ºC, with a maximum positive/negative rate of change of 10ºC/hour.

x Humidity: Between 30% and 75%, non-condensing, with the maximum allowable positive/negative

rate of change of 5% per hour.

x Altitude: 30 m below sea level to 2500 m above sea level

Electrical Requirements

Refer to the Specification section and to the product ID label on the rear of the LCS for the specific

electrical requirements of your unit. The LCS power module is configured with a standard

international IEC320/C20 inlet. To safely operate the LCS, use an SJT cord set with an IEC 320/C19

receptacle and an inlet plug that is compatible to the local power grid and the power requirements of

the LCS. All Kodiak chillers should use SJT 3 conductor 12 AWG minimum power cord.

Manual# 820-0166, Rev. J, 03/06/19 10 of 32

Loading...

Loading...