Lyrec TR532, TR532-8, TR532-16, TR532-24 Series Manual

1. CONTENTS

2. SPECIFICATIONS

2.1 Technical Specifications

2.2 Dimensions

2.3 Accessories

3. GENERAL DESCRIPTION

3.1 Service Manual

3.2 Tape Deck

3.3 Record/playback Amplifiers AM77

3.4 VU-meter Panel

3.5 Console

3.6 Remote Control Unit

4. INSTALLATION

4.1 Unpacking

4.2 Interconnection

4.3 Connector Table

4.4 Connector Drawings

4.5 Transportation

5. OPERATION

5.1 Switching On

5.2 Loading

5.3 Play Mode

5.4 Record Mode

5.5 Fast Wind Mode

5.6 Edit Mode

5.7 Stop Mode

5.8 Tape Deck Logic

5.9 Ready

5.10 Drop In/Out

5.11 Safe

5.12 Line/Sync/Repro

5.13 Solo/Defeat

5.14 Tape Timer

5.15 Search Function

5.16 Varispeed

5.17 Sync Output

5.18 Special Features

5.19 Tape Position Controller TPC

1977-05-01 TR532 CONTENTS

6. OPTIONS

6.1 Remote Timer Display

6.2 XLR-panel

6.3 VU-meter Panel

6.4 Mounting Facilities for External Equipment

6.5 External Motor Control

6.6 Free Space on 8 and 16 Track Model

6.7 Transport Frame

6.8 Tape Position Controller

6.9 Tape Speed 7 1/2 - 15 ips

6.10 NAB - CCIR Switchable

7. ADJUSTMENTS

7.1 Reel Platform Height

7.2 Supply Tension Arm Pressure

7.3 Take-up Tension Arm Pressure

7.4 Capstan Pinch Roller Pressure

7.5 Guide Roller Pressure

7.6 Roller Perpendicularity

7.7 Upper Capstan Bearing Point

7.8 Mechanical Brakes

7.9 Tape End Microswitch

7.10 Tension Arm Potentiometer

7.11 Edit Mechanism Microswitch

7.12 Pinch Roller Solenoid Microswitch

7.13 Tension Arm, Guide Roller and Pinch Roller Air Cylinder

7.14 Power Supply

7.15 Lamp and Phototransistor Positioning

7.16 Capstan Speed

7.17 Maximum Capstan Speed

7.18 Maximum Varispeed

7.19 Hall Generator Balance Potentiometer

7.20 Tension Arm Servo System

7.21 Wind Speed Limit

7.22 Start Power

7.23 Start Power Time

7.24 Tape Motion Sensor

7.25 Relay 5

7.26 Search Logic

7.27 Coarse Head

7.28 Fine Azimuth

7.29 AM77 Adjustment Procedure

7.30 Playback/Sync

7.31 Bias

7.32 Record Level

7.33 Erase

7.34 VU-meter Panel

7.35 Bias Filter and DC-current

1977-05-01 TR532 CONTENTS

8. SERVICE

8.1 Capstan Motor System

8.2 Capstan Speed Preamplifier

8.3 Frequency Detector

8.4 Motor Control Commutator

8.5 Reel Motor Servo System

8.6 Wind Speed Limit Circuit

8.7 Dynamic Brake System

8.8 Capstan and Guide Roller Solenoids

8.9 Remote Control Unit Muting System

8.10 Demagnetization

8.11 Ventilation

8.12 Lubrication

8.13 Removing Head Block

8.14 Tension Arm Potentiometer Replacement

8.15 Performance Check

9. SPARE PARTS

9.1 Special Tools

9.2 Spare Parts

10. APPLICATION NOTES

11. SERVICE BULLETINS

12. DIAGRAMS

1977-05-01 TR532 CONTENTS

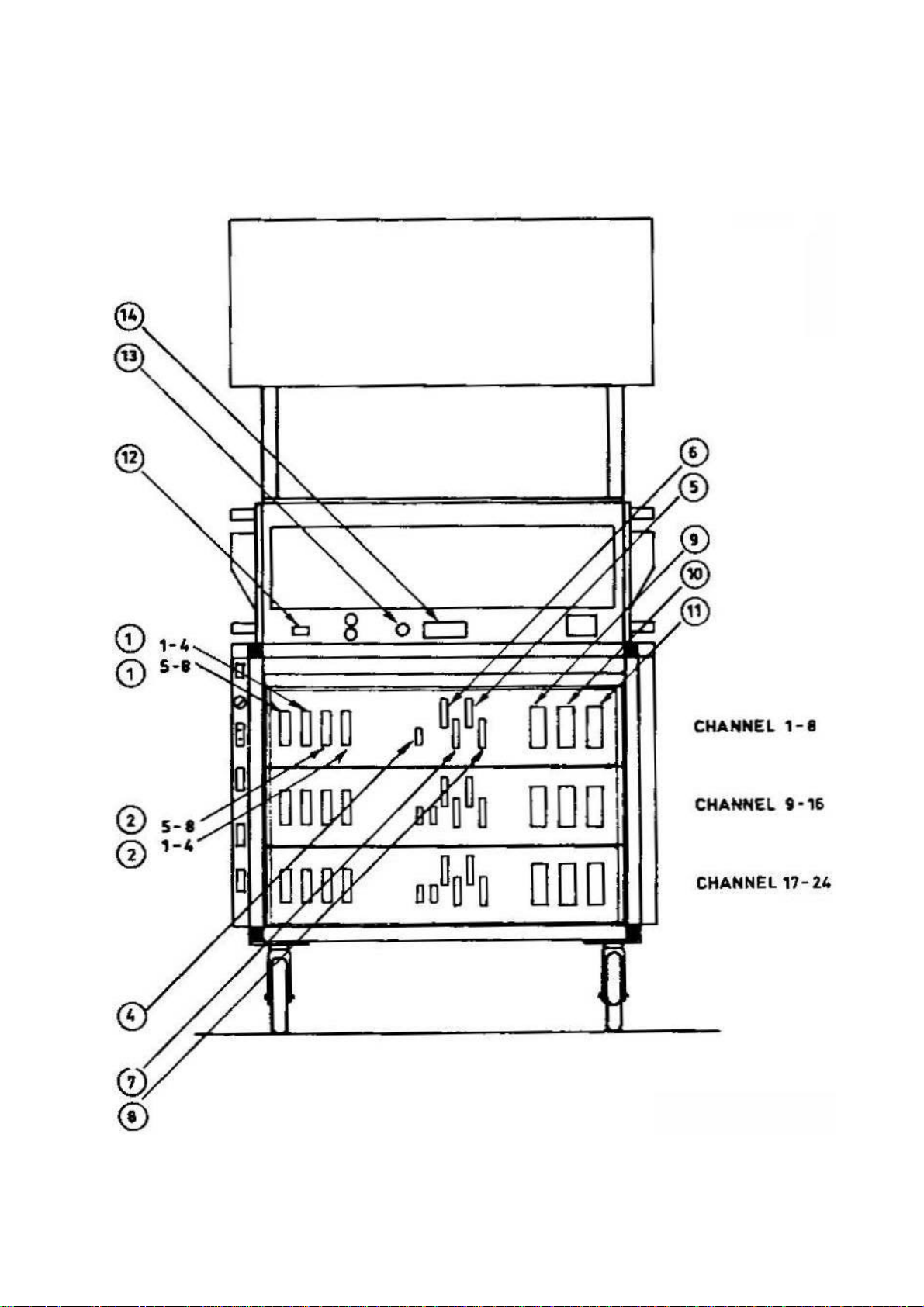

MULTITRACK RECORDER 16 AND 24 TRACKS - TR532-16 AND TR532-24

2.1 SPECIFICATION

Tape speed: 15 and 30 ips. Varispeed 7½ to 60 ips.

(Optional: 7½ and 15 ips. Varispeed 3 3/4

to 30 ips.)

Reel type: Up to 10.5" NAB hub

Long term speed

stability: Better than 0.1%

Wow and flutter: Peak weighted: Max 0.04%

Peak unweighted: Max 0.09%

Measured with EMT 420 according to DIN 45.507

Rewind time: Adjustable. Standard 180 sec for 730 m tape

(2400 ft)

Start time: 15 ips approx 0.6 sec

30 ips approx 1.2 sec

Timer accuracy: +/- 0.1 %

Signal inputs: Balanced and floating

Input impedance 10 kOhms

-6 dBm to +24 dBm input level (adjustable)

to produce 510 nWb/m tape flux

Signal outputs: Balanced and floating

Output impedance 40 ohms max

510 nWb/m tape flux causes output level

0 to +8 dBm (adjustable)

Max unclipped output level +24 dBm into 200 ohms

Sync output: Level: +O, -3 dB. Non-floating. Min load 10 kOhms

Equalization: 15 ips NAB or CCIR, 30 ips 17.5 µ sec (AES)

Bias frequency: 100 kHz

1977-05-01 TR532 2.1

Signal to noise 15 ips: Peak weighted RMS unweighted

ratio: 16 track, rec-repro 58 dB 62 dB

16 track, rec-sync 58 dB 60 dB

24 track, rec-repro 56 dB 61 dB

24 track, rec-sync 56 dB 58 dB

30 ips:

16 track, rec-repro 58 dB 62 dB

16 track, rec-sync 58 dB 60 dB

24 track, rec-repro 56 dB 61 dB

24 track, rec-sync 56 dB 58 dB

All values refer to 510 nWb/m tape flux. Peak

weighted values measured with weighting curve

according to DIN 45.505. RMS unweighted values

measured with bandpass filter 30 Hz - 15 KHz.

Frequency response: 15 ips 30 ips

Rec-repro 60 - 16000 Hz ±1 dB 60 - 18000 Hz ±1 dB

30 – 20000 Hz +1/-3 dB 50 – 20000 Hz +1/-3 dB

Rec-sync 30 – 18000 Hz +1/-3 dB 50 - 18000 Hz +1/-3 dB

Crosstalk: 16 track - less than 50 dB/1 kHz

24 track - less than 46 dB/I kHz

Erase efficiency: 75 dB minimum at 1 kHz

Power requirements: Standard 210-240 V ±10 %/50 Hz/600 VA max

Optional 110 V - 120 V - 240 V/50-60 Hz

Working conditions: Ambient temperature range: +10 - +40°C

Humidity range: 30 – 90 %

Dimensions: 73 cm wide x 56 cm deep x 91 cm high

Inc. Vu-meter console: 16 track - 127 cm high

24 track - 137 cm high

Lyrec Manufacturing A/S reserves the right to introduce modifications

and improvements from time to time without prior notice. Small

differences in component values or circuitry may be found between

diagrams and actual electronics. If these changes are of major

importance for performance, revised diagrams will be forwarded when

printed.

Only figures with tolerances or limit can be considered guaranteed

data. Figures without tolerances are informative data, without

guarantee. (IEC 278, section 5.4 note.)

No part of this manual may be reproduced without written consent.

1977-05-01 TR532 2.1 cont.

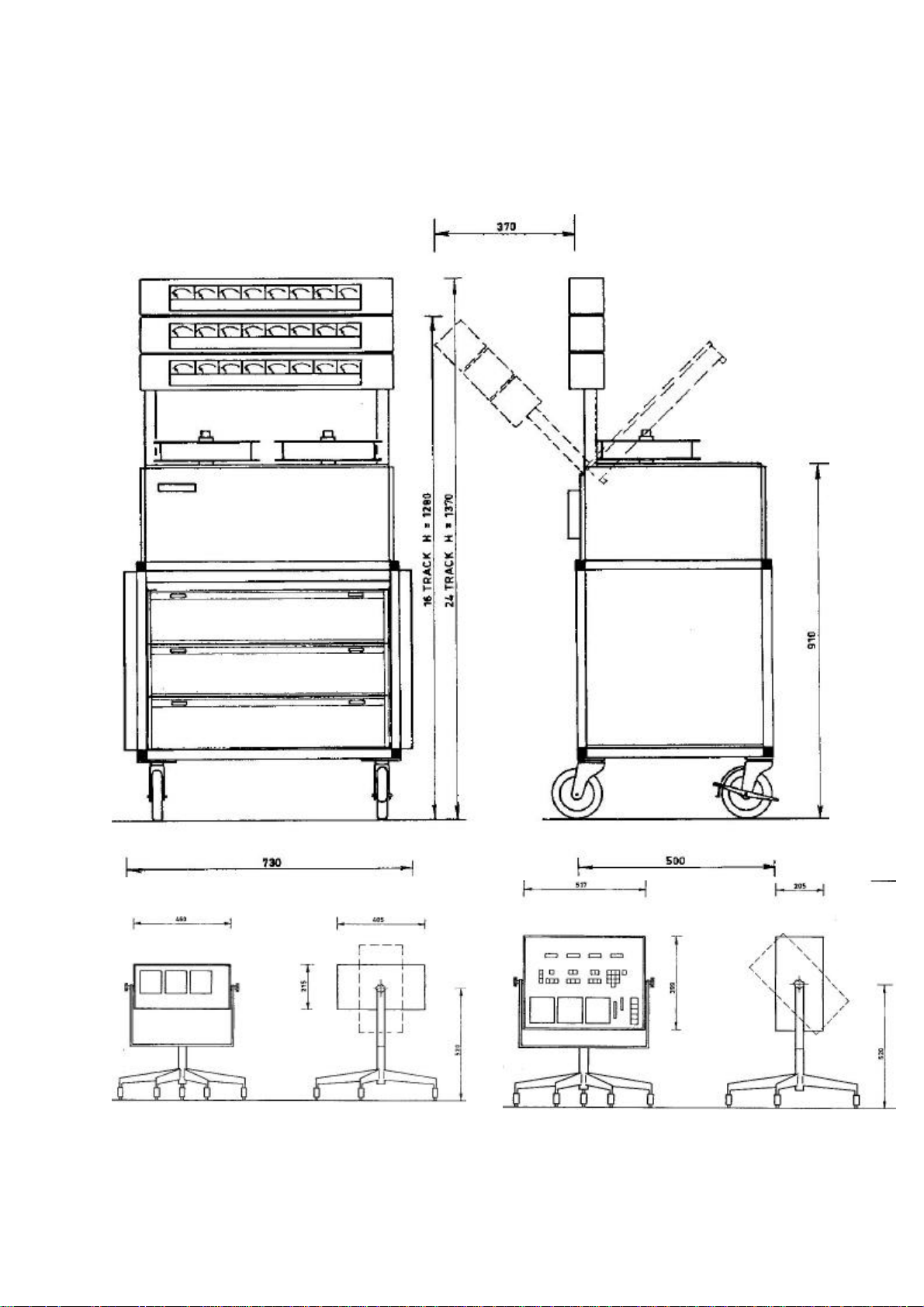

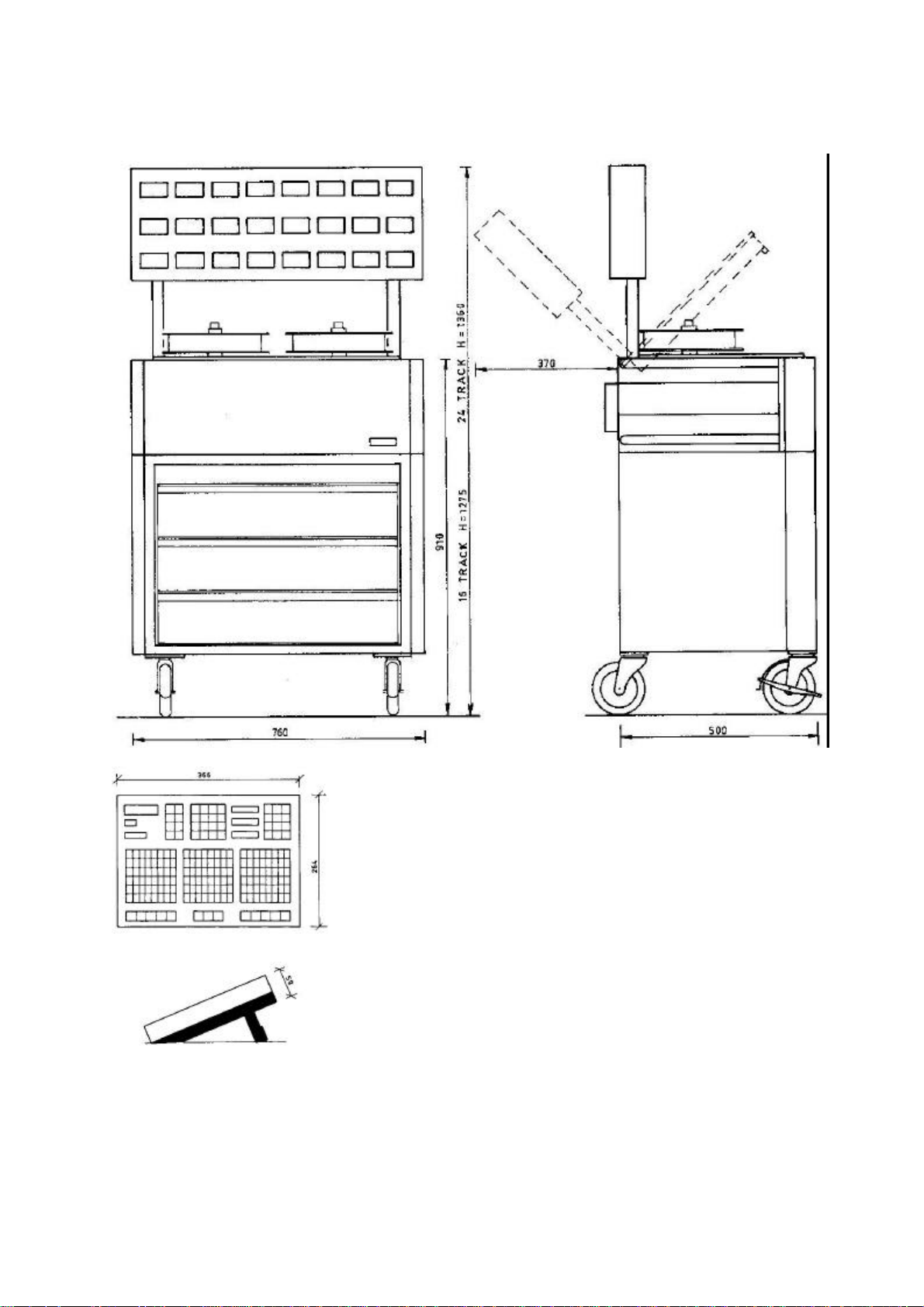

2.2 DIMENSIONS

Remote control type RCU Remote control type TPC

1977-05-01 TR532

1977-05-02 2.2

Remote Control type ATC

1984-05-17 TR532 2.2

2.3 LIST OF ACCESSORIES

1 Tool case, plastic

1 Set of Allen keys 1.5, 2, 2.5, 3 mm

1 Allen key 3 mm x 90 mm

1 Allen key 2 mm x 90 mm

1 Screwdriver 80 mm x 2 mm, Belzer

1 Oilcan, mini Belzer, with Esso NUTO HP 32

1 Bottle of cleaning fluid

1 Bag of Q-tips

2 Double air filter

5 Telephone lamp 36 V, 50 mA

1 Minilamp 28 V, 40 mA

4 Fuse 2 A slow

2 Fuse 4 A slow

2 Mains cable, 3 m

1 Test cable 1.5 m coax with jack and banana plug

1 Manual

1 Dust cover

1 Remote control unit extension card

For each 8-track unit;

4 12 pole connector Siemens C42334-A41-A3

4 Connector housing Siemens C42334-A228-A842

2 9 pole connector Cannon DE-9P

2 Connector housing Cannon DE51218-1

1977-05-01 TR532

2.3 LIST OF ACCESSORIES

969002 1 Tool case, plastic

969011 1 Set of Allen keys 1.5, 2, 2.5, 3 mm

969016 1 Allen key 3 mm x 90 mm

969017 1 Allen key 2 mm x 90 mm

969020 1 Screwdriver 80 mm x 2 mm, Belzer

969036 1 Oilcan with Esso NUTO HP 32

501009 2 Double air filter

961701 5 Telephone lamp 36V, 5OmA

922134 2 Lamp EAO 11.903.0 for ATC

961711 1 Minilamp 28V, 4OmA

961920 4 Fuse 2A slow

961941 2 Fuse 4A slow

961910 2 Fuse 1A slow

999999 1 Mains cable 3 m

501027 1 Test cable 1.5 coax with jack and banana plug

969044 1 Manual

969046 1 Manual for ATC

501028 1 Extender print for AM77

953701 1 25 pole connector Cannon DB25P - male

953702 1 Connector housing Cannon DB115339-2

999999 4 Allen screw M3 x 8 ULS

999999 4 Allen screw M4 x 10 ULS

999999 24 Screw M3 x 10

869583 1 Brake band

For each 8 track unit;

954409 4 12 pole connector Siemens C42334-A41-A3

954408 4 Connector housing Siemens C42334-A228-A842

953743 1 9 pole connector Cannon DE-9P

953746 1 Connector housing Cannon DE51218-1

1984-06-12 TR532 2.3

GENERAL DESCRIPTION

3.1 SERVICE MANUAL

This manual covers the description, installation, operation and

service instructions for the Lyrec TR532-series of 2" and 1"

professional tape recorders. The available configurations are the

following

- TR532-8. 1" 8 track recorder

- TR532-16, 2" 16 track recorder

- TR532-24, 2" 24 track-recorder

It is possible to change these configurations in the field by means of

interchangeable head blocks and rollers.

3.2 TAPE DECK

The TAPE DECK has a very compact and clean layout. The head screen is

easily removable without any tools. Tape path is simple and tape is

easy to thread.

The nominal tape speeds are controlled by a DC-motor which may be set

internally to two fixed nominal speeds or varied over a wide range.

It may also be controlled from an external source enabling two or more

machines to be syncronized together via external equipment (i.e.

MagLink, Minimag or similar).

Tape tension on either side of the capstan is maintained within

working limits by servo controlling the wind motors by way of their

respective tape tension sensing arm assemblies.

The tape transport function controls are situated along the front of

the TAPE DECK towards the left. Normal functions include START, STOP

and RECORD buttons, all illuminated, as also the WIND button which

activates the WIND SPEED CONTROL placed in the middle of this group.

This control allows for infinitely variable speed increments in the

wind mode in either direction.

Near the pinch roller is the EDIT CONTROL. This prevents the pinch

roller to press the tape against the capstan but allows all other

functions. In this way spot erase of single channels may be effected

by hand.

At the extreme right of the front edge of the tape deck is the

illuminated MAINS on/off button, which also carries a safety feature.

It will not disconnect the machine until the STOP MODE has been

reached. In this way tape spills and accidental recording

interruptions are avoided.

1977-05-01 TR532 3.2

Close to the MAINS button are the two speed selection buttons, 15 and

30 ips. When power has been switched off the tape recorder will always

come back to the previously selected speed.

The power supplies for the machine are housed below the tape deck,

together with the servo electronics.

3.3 RECORD/PLAYBACK AMPLIFIERS AM 77

The RECORD/PLAYBACK AMPLIFIERS are housed in 8-track units below the

mechanical section of the machine. One complete RECORD/PLAYBACK

AMPLIFIER AM 77 is contained on a single printed board. All necessary

adjustments are made from the front and each amplifier is an easily

replaceable plug-in unit.

Equalization amplifiers, level control and bias level control are

contained on plug-in boards on the AM 77. This allows easy changing

from standard version to any other version by plugging in the correct

equalization boards.

Furthermore there is a possibility of letting the tape speed

pushbuttons control the amplifiers only. In this way a 15 ips CCIR 15 ips NAB recorder is obtained.

For purposes where it is necessary to change bias level on a few

tracks on a prerecorded tape, a switch is installed on each amplifier.

An arbitrary bias value may then be set without disturbing the two

normal bias settings.

3.4 VU-METER PANEL

The VU-METER PANEL is mounted at the rear top of the TAPE DECK. It may

be mounted at any remote location if the user so desires. Each VUMETER may be calibrated over a wide range of levels to suit individual

studio requirements.

3.5 CONSOLE

The TAPE DECK, RECORD/PLAYBACK AMPLIFIERS and VU-METER PANEL are

mounted in a solid framework on large casters which aid moving the

machine around. The three sections are electrically interconnected

with cable harnesses which are long enough to allow good service but

which are placed at the rear of the machine where they are out of the

way in normal use.

1977-05-01 TR532 3.5

All heat producing elements are located at the rear of the machine so

that the sides may be placed in direct contact with other equipment,

thereby taking up a minimum of control room space.

Low-noise fans further enhance the temperature safety margin.

3.6 REMOTE CONTROL UNIT

A normal feature of the machine is a very complete REMOTE CONTROL

UNIT; facilities include the possibility of switching the output

signal of each channel between the LINE input, the SYNC output and the

PLAYBACK output. It is possible to drop in or out of record on any

individual channel. A SOLO button is also provided for each channel.

The switching logic for these functions is so designed as to simplify

the operators requirements in so far as routing systems and working

requirements are concerned. This allows the use of simpler desks or

less tiring work routines.

Further features of the REMOTE CONTROL UNIT include VARISPEED

continuously covering the range 7.5 to 60 ips. Actual tape speed can

be monitored by the TAPE TIMER DISPLAY enabling any VARISPEED setting

to be repeated accurately. A SEARCH FUNCTION is provided whereby the

machine can rewind to any pre-selected position of the tape, with no

overshoot.

The normal tape transport functions START, STOP, RECORD and FAST WIND

modes are also present in the REMOTE CONTROL UNIT. There is a socket

on the rear of the box enabling a REMOTE TIMER DISPLAY to be installed

up to 10 meters away from the box, in any convenient control room

location.

1977-05-01 TR532 3.6

4. INSTALLATION

4.1 UNPACKING

The machine has been packed in a container specially designed for air

freight. Inspect it visually and if any damage is observed notify your

carrying agent immediately. If all is normal unpack the machine

carefully and retain the packing material for possible future use.

Remove the front and side covers of TAPE DECK and inspect the SERVO

CONTROL print boards; they should be firmly seated in their positions,

and all connectors should be likewise.

Inspect the TAPE DECK and check that none of the metal parts that come

in contact with the tape are damaged in any way.

Check the HEAD BLOCK and particularly the front of the head stacks.

Rubber rollers should be smooth and all metal rollers should move

freely; tension arms should feel slightly hard because of the damping

cylinders but movement should be smooth, with no indication of

friction or roughness.

Check the seating of the individual RECORD/PLAYBACK AMPLIFIERS

modules.

Refer to the CONNECTOR TABLE below and check that all factory wired

plugs and connectors are properly in place.

Proceed likewise with the REMOTE CONTROL UNIT and the VU-METER PANEL.

Place the VU-METER PANEL in position and secure it with the four

screws provided.

4.2 INTERCONNECTION

After checking the above refer to the CONNECTOR TABLE again and the

CONNECTOR DIAGRAMS and wire up the mains connectors. BE SURE YOUR

LOCAL MAINS VOLTAGE IS COMPATIBLE WITH THE MACHINE. BE SURE THAT YOU

COMPLY WITH YOUR LOCAL REGULATIONS AND PAY PARTICULAR ATTENTION TO THE

EARTHING CONNECTIONS. Then wire up all the LINE IN and LINE OUT

connectors the RECORD INDICATION connectors, where applicable, and the

SYNC OUTPUT connectors.

Connect the REMOTE CONTROL UNIT umbilical to the connector on the rear

of the tape deck.

CAUTION: THIS CONNECTION SHOULD NOT BE MADE OR BROKEN WITH EITHER

MACHINE OR THE REMOTE CONTROL UNIT OR BOTH SWITCHED ON.

DAMAGE TO THE DIGITAL CIRCUITRY WILL ENSUE.

This completes the installation procedure.

1977-05-01 TR532 4.2

Mating connector

NO Designation Connector

1 LINE IN 1-4

(5-8)(9-12)(13-

16) (17-20)(21-

24)

2 LINE OUT 1-4

(5-8)(9-12)(13-

16) (17-20)(21-

24)

3 Record

Indication

4 SYNC OUT B To external

5 POWER C Power supply in

6 VU-METERS D To VU meter

7 REMOTE CONTROL

A

8 REMOTE CONTROL

B

9 ERASE HEAD E To erase head FACTORY

10 RECORD HEAD E To record head FACTORY

11 PLAYBACK HEAD E To playback head FACTORY

12 220 V 50 Hz G From mains

13 Ext. motor

control

14 Remote control

Tape deck

15 220 V 50 Hz G From mains

16 Slave display J To slave display

1977-05-01 TR532

CONNECTOR TABLE

type

from/to

A From external

signal source

A To external

equipment

B To noise

reduction

equipment

equipment

tape deck

panel

D To remote

control unit

C To remote

control unit

supply

H From external

speed control

equipment

I From remote

control unit

supply

Mating

connector

wired by

User

USER

USER

USER

FACTORY

FACTORY

FACTORY

FACTORY

FACTORY

USER

FACTORY

FACTORY

USER/FACTORY

Electronics

Tape Deck

Remote

control

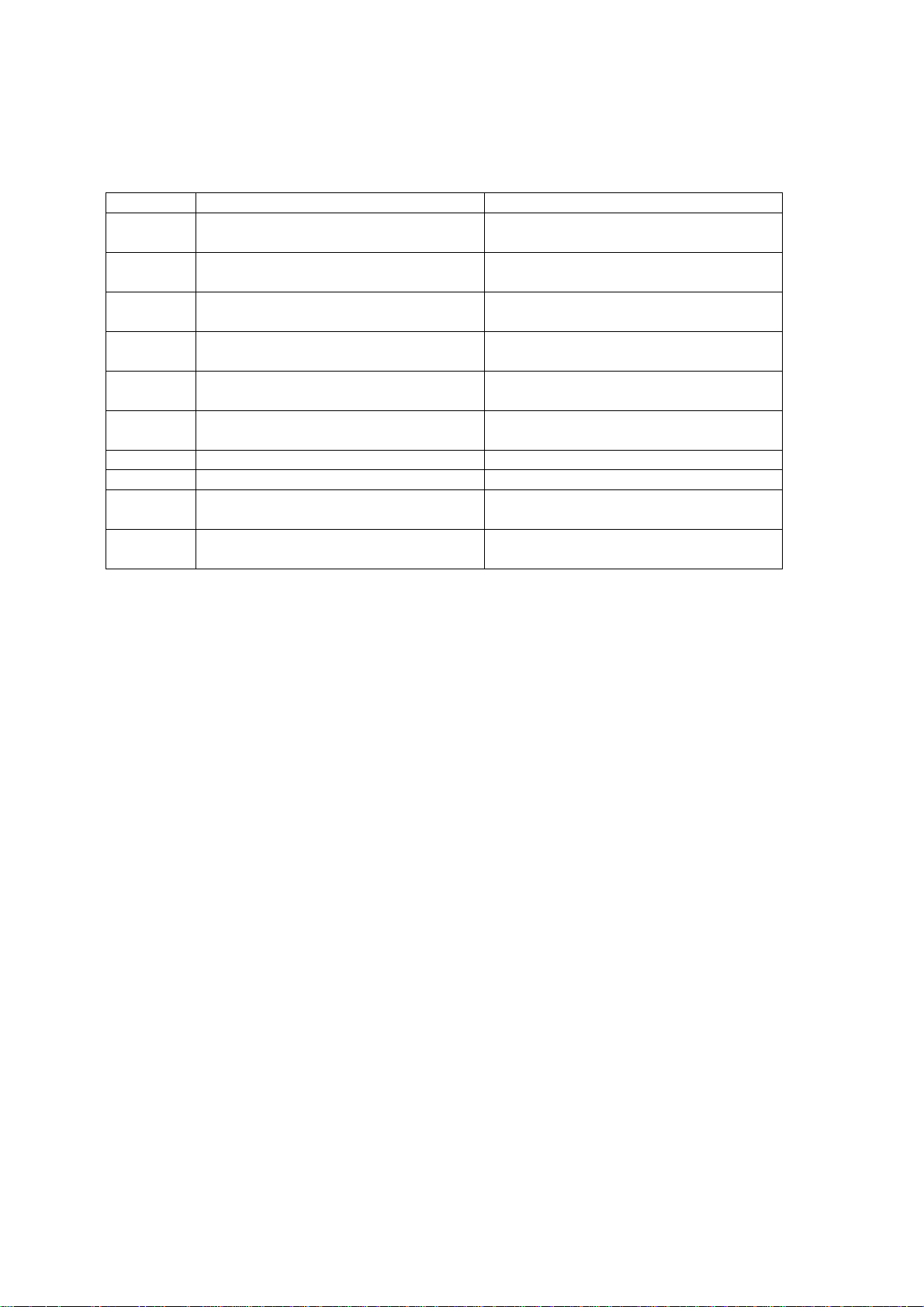

CONNECTOR TYPES

Type Chassis Connector Mating Connector

A Siemens C42334-A41-A4 with

tray C42334-A228-C92

Siemens C42334-A41-A3

with shell C42334-A228-A842

B Cannon DE-9S Cannon DE-9P

with Shell Cannon DE51218-1

C Cannon DB-25P Cannon DB25S with shell

DB115339-2

D Cannon DB25S Cannon DB25P with shell

DBI15339-2

E Siemens A42334-A44-A4

with tray A42334-A228-C95

F Siemens A42334-A44-A3

with tray A42334-A228-C95

Siemens A42334-A44-A3

with shell A42334-A228-A845

Siemens A42334-A44-A4

with shell A42334-A228-A845

G Otto Heil 6061-1 Otto Heil 4010

H Amphenol-Tuchel T3262 Amphenol-Tuchel T3261/1

I Amphenol-Tuchel 2071-030

with tray 1136-002

J Amphenol-Tuchel 2009-012

with tray 1148-002

Amphenol-Tuchel 2070-030

with shell 1124-001

Amphenol-Tuchel 2008-012

with shell 1122-001

1977-05-01 TR532

Rear view, connector numbers shown without cables

1977-05-01 TR532

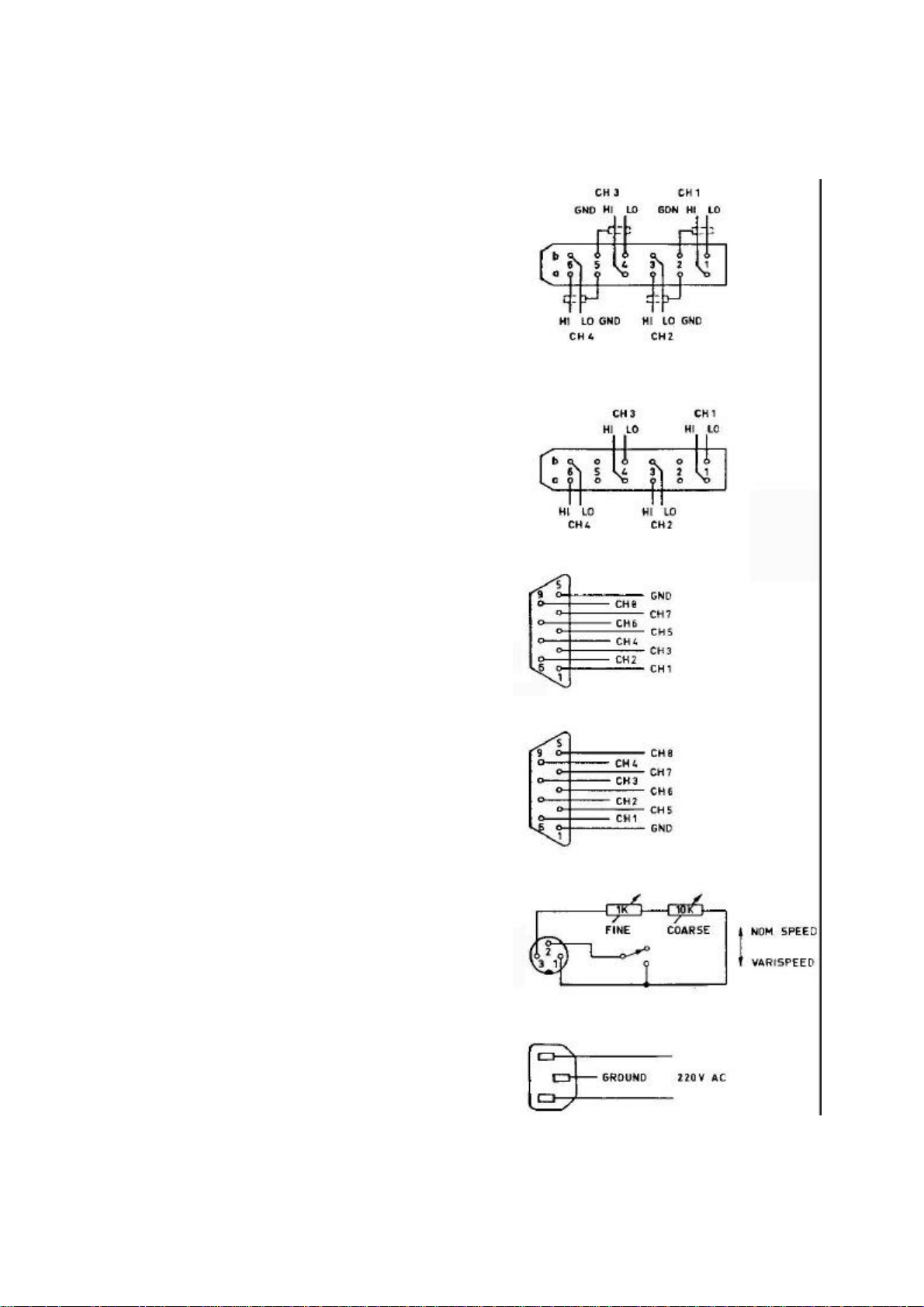

CONNECTOR DRAWINGS

No. I LINE IN 1-4

(5-8, 9-12, 13-16, 17-20,

21-24)

(all grounds internally

connected)

No. 2 LINE OUT 1-4

(5-8, 9-12, 13-16, 17-20,

21-24)

(pins 2a, 2b, 5a, 5b not

connected)

No. 3 RECORD INDICATION 1-8

(9-16)(17-24)

When a channel is in RECORD,

output will be +24 V, other

wise a high impedance to ground.

Ext. load min 3 Kohms.

No. 4 SYNC OUT 1-8

(9-16, 17-24)

Ext. load min 10 kOhms

No. 13 Ext. Motor Control

Note: Do not use this circuit

simultaneously with Varispeed

from Remote Control Unit.

No. 12, 15

All connectors are cablepart seen from solderside.

1977-05-01 TR532

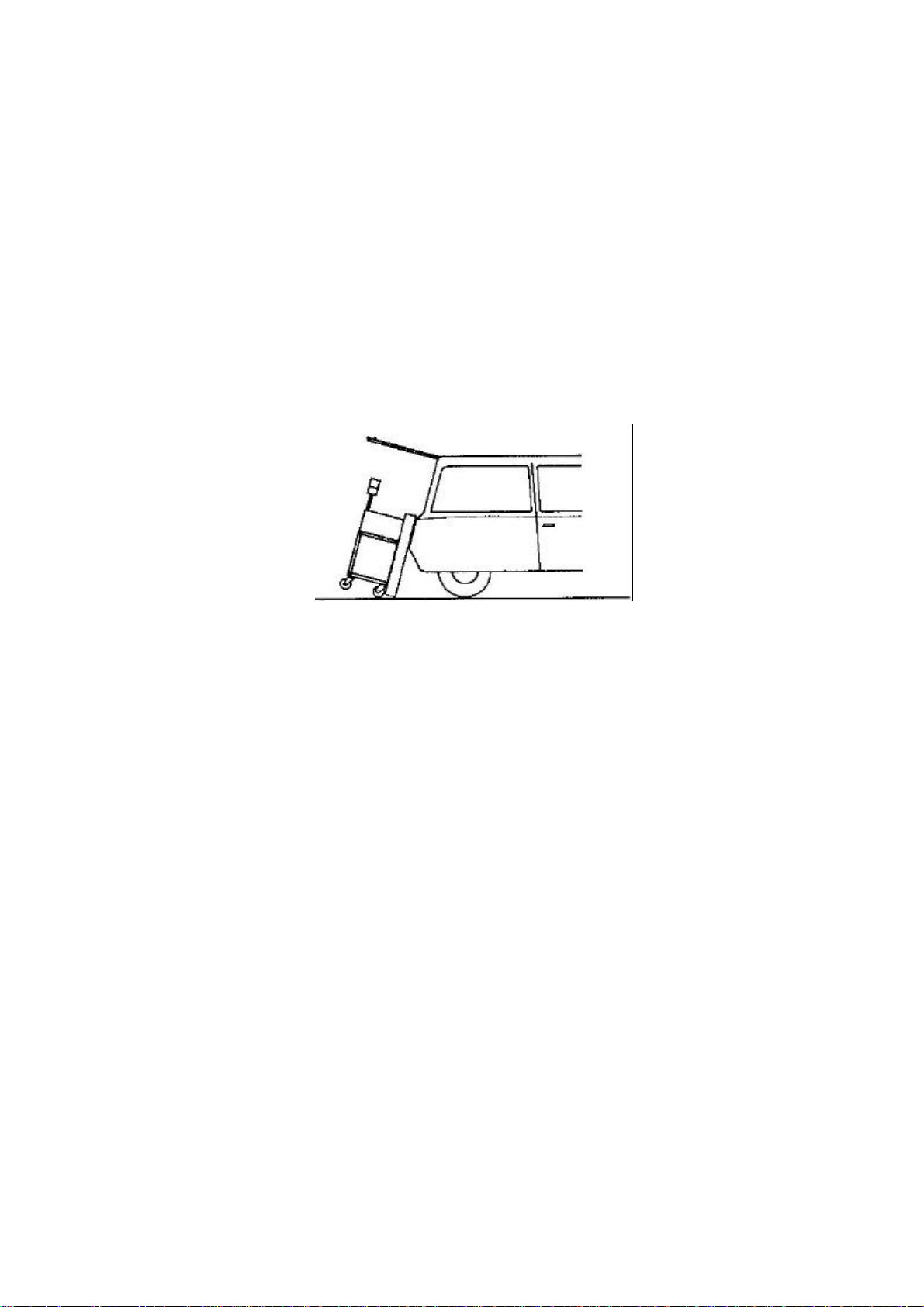

4.5 TRANSPORTATION

The Lyrec TR532 can be transported in a car or van. During transport

it can either stand up or be laid down on it's front. For this purpose

the factory has developed a special transport frame that fits the

front of the recorder (see section 6.7).

Move the recorder close to the back of the vehicle and place the

transport frame on the front of the machine. Tilt the recorder into

place and slide it in. This operation can easily be made by two

people.

1977-05-01 TR532 4.5

5. OPERATION

5.1 SWITCHING ON

Connect both line cords to the appropriate voltage and press the MAINS

button on the tape deck. Select the desired tape speed. The MAINS, the

STOP and one of the speed buttons on the TAPE DECK and the STOP button

on the REMOTE CONTROL UNIT should light up. The ventilation fans

should start running and the VU-meters should light up (if of

illuminated type).

Switch on the REMOTE CONTROL UNIT; the power switch is on the rear

panel. All channels should illuminate their SAFE and SYNC LED'S. The

TAPE TIMER should indicate 00.00 and the speed should be set at

nominal speed, whichever has been selected.

TAPE DECK

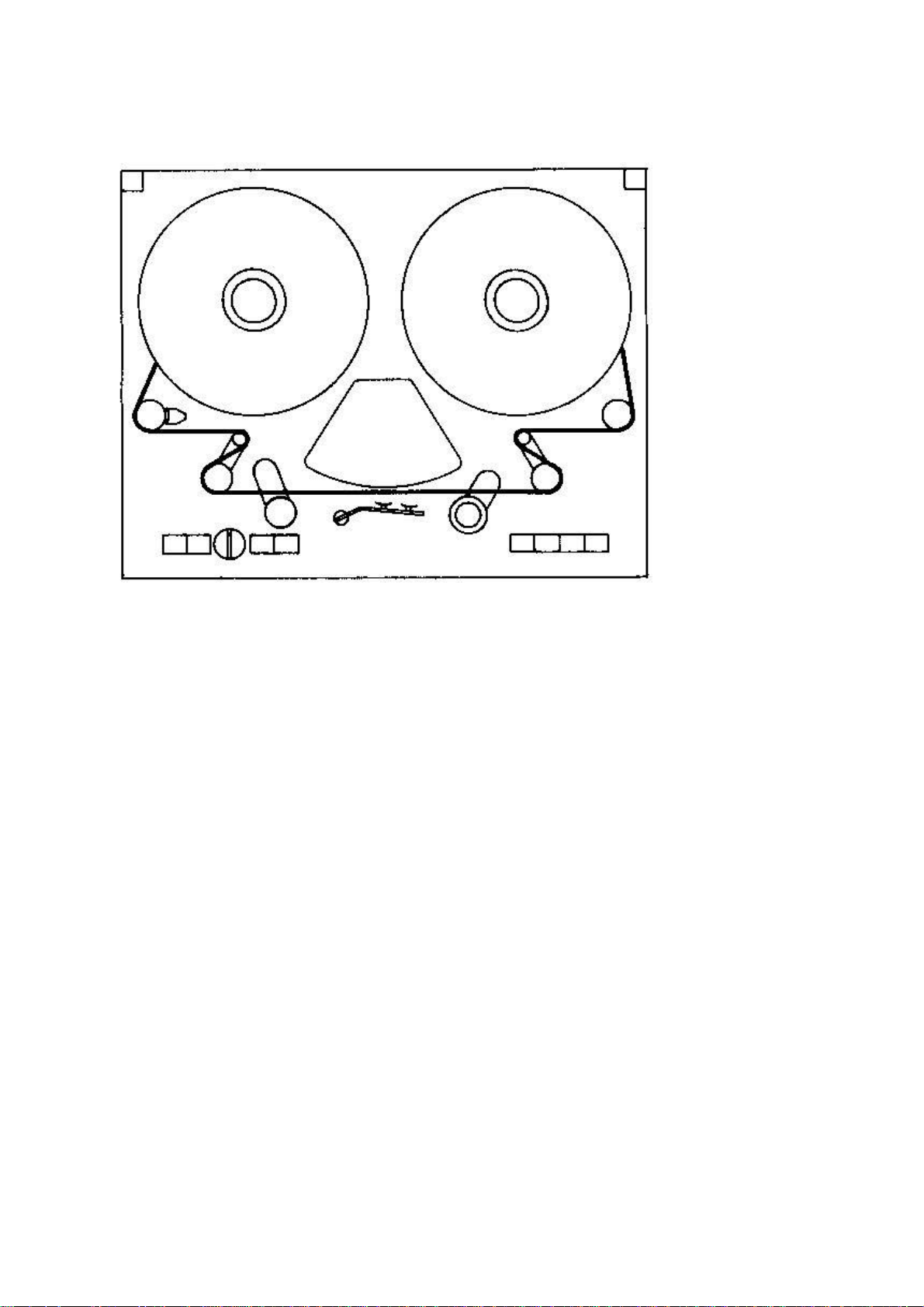

5.2 LOADING

Place an empty reel and a full reel on the appropriate hubs. The

knurled knob on the top of the hub should be turned clockwise to lock

the reels in place. Refer to drawing No. 5.02 and thread the tape

through the tape path. Check the height of the tape, and if necessary

adjust it. See section 7.1 for this adjustment.

5.3 PLAY MODE

Press START button on the TAPE DECK or on the REMOTE CONTROL UNIT.

Both buttons should illuminate; the PINCH ROLLER and GUIDE ROLLER

should pull in, placing the tape in contact with the heads and the

capstan, which will cause the tape to move forward at its nominal

speed.

On the REMOTE CONTROL UNIT the timer will begin to show seconds and

then minutes of elapsed time. Select REPRO on the REMOTE CONTROL UNIT

on those channels from which the tape playback signal is to be

monitored.

5.4 RECORD MODE

Select the channels to be recorded on the REMOTE CONTROL UNIT by

pressing the READY buttons on the appropriate channels; the red LED's

will immediately begin flashing to indicate that these channels are

ready to record. On the same channels the green SAFE LED will go off.

Press RECORD and START buttons simultaneously either on the TAPE DECK

or on the REMOTE CONTROL UNIT; the same mechanical functions as in the

play mode will occur. On the REMOTE CONTROL UNIT the red flashing

LED's will illuminate steadily indicating RECORD MODE on those

channels.

1977-05-01 TR532 5.4

Drawing No. 5.02, Tape path

1977-05-01 TR532

5.5 FAST WIND MODE

A. From the TAPE DECK

Press the WIND button and select the direction and speed of wind by

setting the WIND SPEED CONTROL.

B. From REMOTE CONTROL UNIT

Press the appropriate button to select wind direction and alternate

with the other to control speed.

5.6 EDIT MODE

Turn the EDIT CONTROL in anti-clockwise direction, thereby causing the

tape to come into contact with the PLAYBACK head but not with the

capstan. The SERVO TENSION ARMS are locked and the tape path is now

rigid. For convenience the head shields may be removed by simply

pulling up, when commencing the operation.

Any of the previous modes may be used simultaneously with the EDIT

MODE allowing editing in the PLAY MODE, searching in the WIND MODE or

hand controlled spot-erasing in the RECORD MODE. It is also possible

to enter the EDIT MODE from any of the previous modes.

5.7 STOP MODE

Pressing the STOP button immediately interrupts the PLAY or RECORD

modes. In both cases the tape motion is immediately halted and the

tape is lifted from the heads. Coming from the RECORD MODE the

electronics are also switched to a stand-by condition, see below.

When coming from the FAST WIND mode dynamic brakes are first applied

to slow the reels and when the tape motion sensor indicates that the

tape is halted then mechanical brakes are applied, simply to hold the

reels in place.

5.8 TAPE DECK LOGIC

The TAPE DECK SERVOSYSTEM and LOGIC is so designed as to avoid

throwing tape loops or causing spills, jerks or other situations

dangerous to the tape. It is possible to go from any mechanical mode

to any other with no problems. For description of the circuits, see

section 8.

REMOTE CONTROL UNIT

Channel function selectors.

5.9 READY

As previously indicated these buttons select a given channel and place

it in READY MODE so that when the START and RECORD buttons are pressed

the channel goes into RECORD MODE. In the READY MODE

1977-05-01 TR532 5.9

the red LED flashes continuously; when the machine is placed in the

RECORD MODE the flashing stops and the LED glows steadily. If a READY

button is pressed when the machine is already in the RECORD MODE this

channel will not drop into RECORD MODE although the LED will start

flashing. It will stay in the READY MODE until the START and RECORD

buttons are again pressed simultaneously. Doing this has no effect on

the tape motion; it simply drops the new READY channels into the

RECORD MODE. (As a special option it is possible to add a switch to

the REMOTE CONTROL UNIT which will allow the READY button to drop a

channel directly into RECORD MODE when either RECORD button has been

selected and the machine is already in motion.)

5.10 DROP IN/OUT CAPABILITY

If it is necessary to pre-select a certain track or group of tracks,

to drop in and out of them continuously, the following procedure is

used:

Select the tracks by means of the READY buttons. Then press the START

button; to drop in press both START and RECORD buttons. To drop out

keep START pressed and momentarily press the STOP button; the tracks

will stop recording but tape motion will not be interrupted and the

READY pre-selection will be maintained.

5.11 SAFE

When pressed the individual channel SAFE buttons illuminate a steady

green LED. In this condition a channel cannot go into the RECORD MODE

even though the RECORD MODE may be selected by pressing the START and

RECORD buttons. As a further feature there is a master SAFE button

which throws all the channels of the machine into SAFE MODE. The SAFE

MODE may be used also as a "drop-out" from the RECORD MODE and may be

activated during RECORD MODE without interrupting the tape motion.

To review these functions:

A channel will only go to RECORD at the moment where RECORD and START

are pressed simultaneously, and only if it before that moment was in

READY.

To get channels out of RECORD several ways exist:

1. STOP. The tape will stop. Channels in RECORD will go to READY.

Channels in READY will stay in READY.

2. Master SAFE. The tape will continue. Channels in RECORD and READY

will go to SAFE.

3. Individual SAFE. The tape will continue. That particular channel

will go to SAFE. No other channels will change state.

4. START and momentarily STOP. The tape will continue. All channels in

RECORD will go to READY. No other channels will change state.

1977-05-01 TR532 5.11

5.12 LINE/SYNC/REPRO

The LINE OUT signal from each PLAYBACK AMPLIFIER may be selected by

one of the three following controls: LINE, SYNC and REPRO. This does

not affect the recording on this track.

Pressing the LINE button selects the LINE INPUT signal of that channel

and routes it to the output.

Pressing the SYNC button selects the signal from the record head of

that channel, used as a playback head.

Pressing the REPRO button for that channel selects the signal from the

normal playback head.

There are also three master buttons for LINE, SYNC and REPRO which

will throw all the channels to that particular function.

The only exception to these selections occurs when a given channel is

selected to SYNC and it is also placed in the RECORD MODE. In this

situation the channel is automatically switched to LINE, returning to

SYNC when the RECORD MODE is cancelled.

5.13 SOLO/DEFEAT

When the SOLO button of a channel is pressed it causes all the other

channels to switch to LINE. (This can be changed on special order so

that the other channels mute instead of switching to LINE.) Any amount

of channels may be soloed simultaneously. In order to return them to

their normal situation the DEFEAT button is pressed.

5.14 TAPE TIMER

The TAPE TIMER receives information from the tape motion sensor on the

tape deck, and shows elapsed time in minutes and seconds relative to

15 ips. By means of the RESET button on the left, it may be reset to

00.00 at any point desired by the operator. In order to avoid

accidental resets this button has a protective cover.

5.15 SEARCH FUNCTION

The SEARCH FUNCTION comprises two controls, an illuminated SEARCH

button and a PRESET DIAL. When the SEARCH button is pressed the TAPE

DECK goes into the WIND MODE and automatically winds the tape in such

a way as to make the timer display equal to the display on the PRESET

DIAL. A built-in feature of this function ensures that the tape will

not overshoot since the wind speed is progressively lowered as soon as

the difference between the two displays drops below a preset amount.

1977-05-01 TR532 5.15

5.16 NOMINAL/VARISPEED

When the NOMINAL button is pressed the LED lights up and the machine

will transport the tape at fixed nominal speed of 15 or 30 ips,

whichever has been selected. When the VARISPEED button is pressed the

LED flashes continuously to warn of a non-normal condition; the speed

of the tape now depends on the setting of the two potentiometers below

the VARISPEED button. As indicated they allow COURSE and FINE

adjustments of the tape speed from slightly below 7 1/2 ips to

slightly above 60 ips. A further feature of both buttons, in

combination with the TAPE TIMER display allows for checking the actual

tape speed. This is operated as follows: Select either the NOMINAL

speed or VARISPEED. Do not release the selector button but hold it

down. In this position the TAPE TIMER display will change over to 4

digits which express the actual tape speed according to the following

formula:

1000

speed ips = 15 x

2.000 - DISPLAY

Table 1 and 2 shows the full range of the displays with their

equivalents in speed deviation in ips, in percentage or in musical

values. This speed checking function may be used to reset any

VARISPEED setting at any time within close tolerances.

An important feature of this function is that it does not disturb the

TAPE TIMER counting. When the button is released the timer will go

back to its normal timing function without having lost count in the

interval.

Note: No reading will result if the tape is not in motion,

since the information is taken from the TAPE MOTION SENSOR,

therefore reflecting the actual tape motion, not the capstan

motor speed.

1977-05-01 TR532 5.16

TABLE 1; nominal speed 15 ips. Applicable for standard REMOTE

CONTROL UNIT, RCU

Display Speed (ips) Deviation %

0000 7.50 - 50.00

0100 7.89 - 47.37

0200 8.33 - 44.44

0300 8.82 - 41.18

0400 9.38 - 37.50

0500 10.00 - 33.33

0550 10.34 - 31.03

0600 10.71 - 28.57

0650 11.11 - 25.93

0700 11.54 - 23.08

0750 12.00 - 20.00

0800 12.50 - 16.67

0850 13.04 - 13.04

0865 13.22 - 11.89 - 1 tone

0900 13.64 - 9.09

0902 13.66 - 8.93 - 3/4 tone

0920 13.89 - 7.41

0937 14.11 - 5.93 - 1/2 tone

0940 14.15 - 5.66

0953 14.33 - 4.49

0960 14.42 - 3.85

0969 14.55 - 3.01 - 1/4 tone

0980 14.71 - 1.96

0985 14.78 - 1.48

1000 15.00 0

1015 15.23 1.52

1020 15.31 2.04

1029 15.45 2.99 + 1/4 tone

1040 15.63 4.17

1043 15.67 4.49

1056 15.89 5.93 + 1/2 tone

1060 15.96 6.38

1080 16.30 8.70

1082 16.34 8.93 + 3/4 tone

1100 16.67 11.11

1106 16.78 11.86 + 1 tone

1150 17.65 17.65

1200 18.75 25.00

1250 20.00 33.33

1300 21.43 42.86

1350 23.08 53.85

1400 25.00 66.67

1450 27.27 81.82

1500 30.00 100.00

1977-05-01 TR532 5.16 cont.

TABLE 2; nominal speed 30 ips. Applicable for standard REMOTE

REMOTE CONTROL UNIT, RCU

Display Speed (ips) Deviation %

1000 15.00 - 50.00

1050 15.79 - 47.37

1100 16.67 - 44.44

1150 17.65 - 41.18

1200 18.75 - 37.50

1250 20.00 - 33.33

1275 20.69 - 31.03

1300 21.43 - 28.57

1325 22.22 - 25.93

1350 23.08 - 23.08

1375 24.00 - 20.00

1400 25.00 - 16.67

1425 26.09 - 13.04

1432 26.43 - 11.89 - 1 tone

1450 27.27 - 9.09

1451 27.32 - 8.93 - ¾ tone

1460 27.78 - 7.41

1468 28.22 - 5.93 - ½ tone

1470 28.30 - 5.66

1476 28.65 - 4.49

1480 28.85 - 3.85

1484 29.10 - 3.01 - ¼ tone

1490 29.41 - 1.96

1492 29.56 - 1.48

1500 30.00 0

1507 30.46 1.52

1510 30.61 2.04

1514 30.90 2.99 + ¼ tone

1520 31.25 4.17

1521 31.35 4.49

1528 31.78 5.93 + ½ tone

1530 31.91 6.38

1540 32.61 8.70

1541 32.68 8.93 + ¾ tone

1550 33.33 11.11

1553 33.56 11.86 + 1 tone

1575 35.29 17.65

1600 37.50 25.00

1625 40.00 33.33

1650 42.86 42.86

1675 46.15 53.85

1700 50.00 66.67

1725 54.55 81.82

1750 60.00 100.00

1977-05-01 TR532 5.16 cont.

RECORD/PLAYBACK AMPLIFIERS

5.17 SYNC OUTPUT

Apart from the normal sync signal which is routed to the LINE OUTPUT

each AM 77 RECORD/PLAYBACK AMPLIFIER incorporates a separate sync

amplifier. The signal from this extra sync output is available

independently for each channel at a separate plug. This output is

unbalanced and should not be terminated with less than 10 kOhms.

The SYNC OUTPUT does not in any way affect or interfere with the

ordinary sync signals available at the line output, nor can it be

controlled by the SYNC button on the REMOTE CONTROL UNIT.

1977-05-01 TR532 5.17

5.18 SPECIAL FEATURES

The machine has been designed for maximum ease of operation. In this

context several facilities have been included which are not normally

found as standard items.

HEADBLOCK

To ease maintenance and format changes the HEADBLOCK uses a plug and

socket interconnection with a precision mechanical seating arrangement

that allows fast changeover operations.

EDITING FACILITIES

As described (5.6) the EDIT CONTROL not only permits splice editing

but also provides for very precise spot erasing with the RECORD MODE

activated and the tape moved by hand. Holding the EDIT CONTROL half

way in during FAST WIND permits listening to the tape without close

contact to the playback head.

SWITCH-OFF SAFE-GUARD

As mentioned (3.2) the MAINS SWITCH will not switch off the machine

unless it is in STOP MODE. This avoids accidental tape spills or

interruptions.

SPEED MEMORY

When mains is switched on and off the taperecorder always comes back

to the same speed. Change between the two nominal speeds can only be

done in STOP MODE.

TRANSIENT PROTECTION

To avoid strong switch-on and switch-off transients in the outputs,

which might damage monitor speakers, a relay has been included which

short-circuits the output of the playback amplifiers for a few seconds

after power is applied, until DC conditions are stabilized, and also

immediately after it has been removed, before DC working conditions

can change.

RECORD INDICATION OUTPUT

A socket is provided on the back of each eight-channel unit, which

delivers +24 V from each individual channel when it goes into the

RECORD MODE, enabling external equipment-functions to be controlled

(i.e. noise reduction). In other modes the RECORD INDICATION OUTPUT

has a high impedance to ground external load: min 3000 ohms.

SEARCH FUNCTION

As described (5.15) the SEARCH FUNCTION is a useful aid in speeding up

working routines; it is built into the machine and requires no extra

hardware or powering.

1977-05-01 TR532 5.18

SOLO buttons

This facility (5.13) is most useful when mixing but it does not affect

any other function of the machine and can be used at any time to check

the contents of any individual track.

SPEED CHECK

Using an internal crystal reference the machine provides an easy check

on its performance and the calibration of the VARISPEED settings

without recourse to outside instrumentation. (See 5.16)

VARISPEED

Again no outside hardware is necessary to provide a facility (5.16)

which, in combination with a speed check, becomes a highly useful

tool.

EXTERNAL SPEED CONTROL

An extension of the previous circuit allows the machine to be

controlled from an external source or synchronized with other machines

or equipment.

SYNC OUTPUT

This facility (5.17) is most useful for effects purposes, for example

phasing, single shot repeats, phrasing corrections, double tracking,

noise gate key control, compressors in parallel, etc. where it is

necessary to have available both the SYNC and the PLAYBACK signals

from the same channel. Some examples are presented in section 10,

Application notes.

MUTING

To protect your speakers there is a muting device on the LINE OUTPUT.

In STOP and WINDING MODES all outputs are muted. This muting can be

cancelled in two ways:

a) By turning the EDIT CONTROL on the tape deck.

b) By pressing the DEFEAT button on the REMOTE CONTROL UNIT.

1977-05-01 TRS32 5.18 cont.

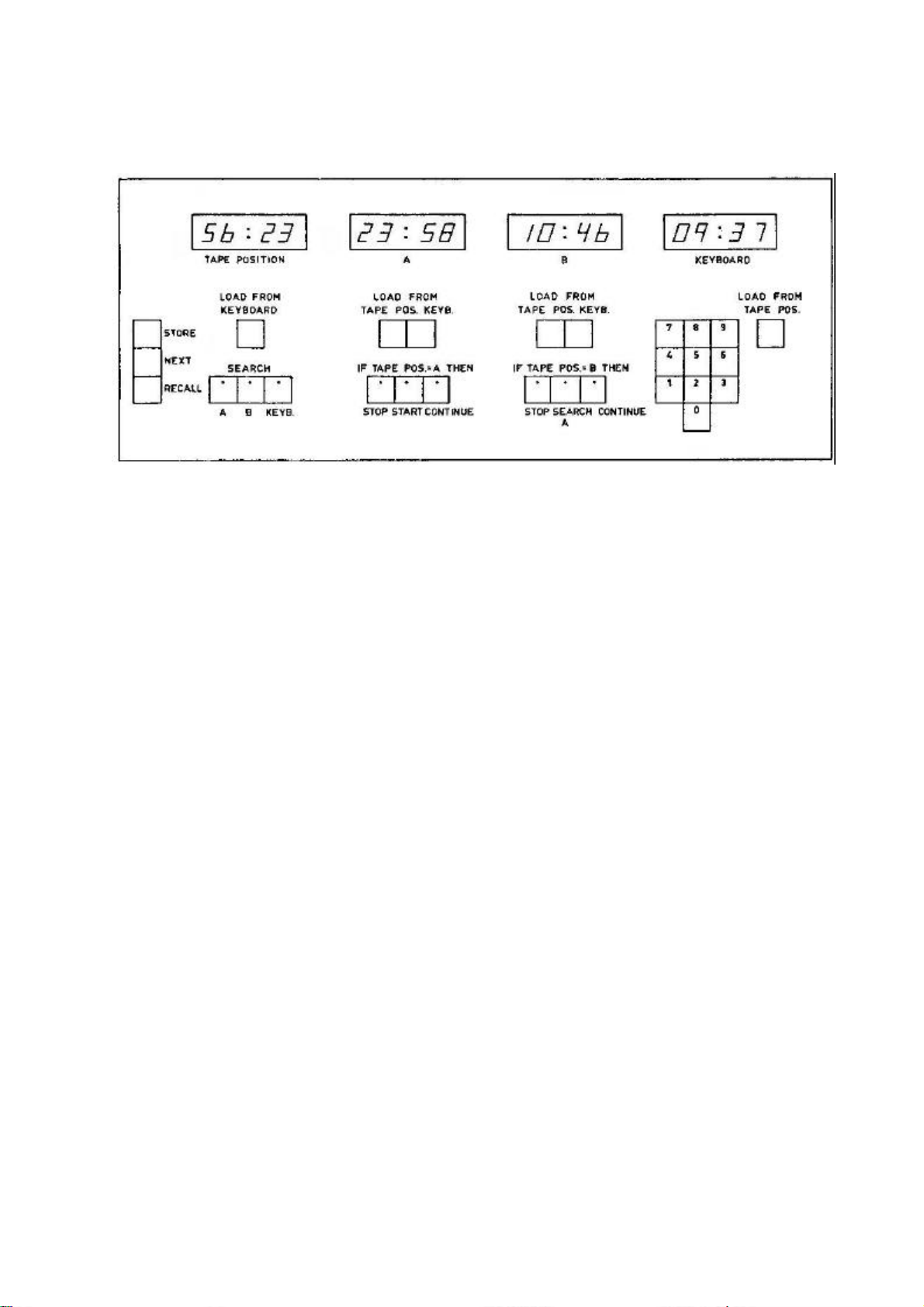

5.19 TAPE POSITION CONTROLLER, TPC (OPTIONAL)

The unit is built up around a four-digit display, TAPE POSITION, which

works as an ordinary tape timer. It counts in minutes and seconds at

the tape speed 15 ips (7 1/2 ips available as option).

Besides the TAPE POSITION-display, there are an A-display, a B-display

and a KEYBOARD-display. The content of the KEYBOARD display is

controlled from the keys 0-9 in the KEYBOARD. When a key is pressed,

the digits in the KEYBOARD-display will roll one position to the left.

The left-most digit will disappear, and the pressed digit will show up

in the right-most position.

Another way of controlling the KEYBOARD-display is through the LOAD

FROM TAPE POSITION-key. When this is activated, the number in TAPE

POSITION will be copied into KEYBOARD. The A and B displays can be

loaded from TAPE POSITION as well as from KEYBOARD, while TAPE

POSITION only can be loaded from KEYBOARD.

If TAPE POSITION is different from A (or B or KEYBOARD), it is

possible to search A (B, KEYBOARD) by activating SEARCH A (B,

KEYBOARD). The unit will cancel the selected machine-function (STOP,

START, RECORD) and through WIND MODE make TAPE POSITION equal to A (B,

KEYBOARD) and end up in STOP (unless something else is selected). This

SEARCH-function can only be cancelled by a STOP-command. During SEARCH

it is not possible to change the contents of the TAPE POSITION-display

and the display which is being searched.

If one of the two keys IF TAPE POSITION = A THEN STOP/START has been

activated, the machine will, when TAPE POSITION displays the same

number as A, carry out the selected function, no matter how the two

numbers have become equal. This will happen every time the two numbers

are equal until the CONTINUE-key is pressed.

1977-05-01 TR532 5.19

Loading...

Loading...