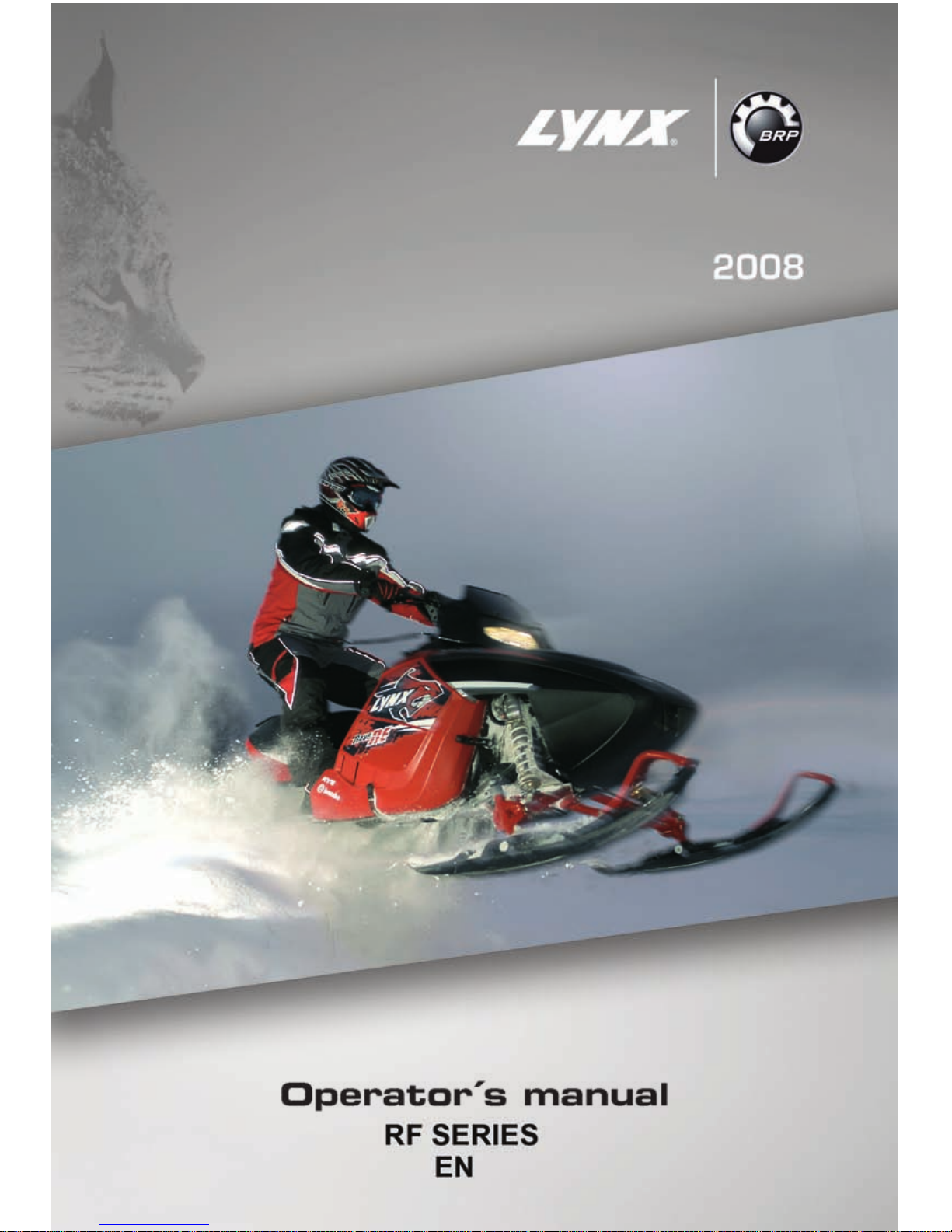

Page 1

Page 2

OPERATOR’S MANUAL LYNX 2008

Adventure V-800

Ranger V-800

Ranger 550

SAFETY WARNING

Disregarding any of the safety precautions and instructions contained in this

Operator’s Guide, or on-product warnings may result in injury, including the

possibility of death.

This Operator’s Guide should remain with the unit at time o f resale.

LYNX products are manufactured by BRP.

Bombardier* Lite

* Trademark of Bomb ardier Inc. used under license.

The following a re trademarks of Bombardier Rec re ational Products Inc. or its

subsidiaries.

LYN X

®

RER

TM

RF™

SC™

ROTAX

TM

Pilot™ TRA™

DESS™

Printed in Canada. (mmo2008-RF HT)

®™ and the BRP logo are trademarks of Bombardier Recreational Products Inc. or its affiliates.

©2007 Bombardier Recreational Products Inc. and BRP US Inc. All rights reserved.

* Trademark of Bombardier Inc. used under license.

Page 3

FOREWORD

Congratulations on your purchase of

a new LYNX snowmobile. Whatever

model you have chosen, it is backed

by the Bombardier Recreational Products. (BRP) warranty and a netw ork of

authorized LYNX snowmobile dealers

ready to provide the parts, s ervice or

accessories you may require.

The Operator's Guide has been prepared to acquaint the owner/operator

and passenger with this new snowmobile and its various controls, maintenance and safe riding instructions.

This guide is indispensable for the

proper use of the product and should

be kept with this snowmobile at all

times.

Make sure you read and understand

the content of this Operator's Guide.

After reading, please keep this Operator's Guide with the snowmobile. If

the snowmobile is resold, please give

the guide to the new owner for his

awareness.

Also note that the guide is available in

several languages.

If you have any question regarding any

topic wh ether or not it is covered in

this Operator's Guide, please contact

your Dealer.

This guide uses the following safety

alert symbol in conjunction with signal

words to indicate a potential personal

injury hazard.

WARNING

Indicates a potentially hazardous

situation which, if not avoided,

could result in death or serious

injury.

CAUTION

Indicates a potentially hazardous

situation which, if not avoided,

may result in minor or moderate

injury. When used without the

safety alert symbol ,potential

hazard exists for property damage

only.

NOTE: Indicates supplementary infor-

mation needed to fully complete an instruction.

WARNING

2-UP vs 1-UP models:

Throughout this Operator's Guide,

the term “1-UP” refers to vehicles

designed to carry the operator only while the term “2-UP” refers to

vehicles designed to carry also a

passenger.

Make sure to identify and follow

the warnings and instructions that

are applicable to your specific

model.

Although the mere reading of such information does not eliminate the hazard, the understanding and application

of the information will promote the

correct use of the vehicle.

Your dealer is committed to your satisfaction. He has taken training to perform the initial set-u p and in s pection

of your snowmobile as w ell as completed the final adjustment required

to suit your specific weight and riding

environment before you took possession. At delivery, your dealer would

have explained the snowmobile controls and provided you with a brief

explanation of the various suspension

adjustments. We trust you have taken full advantage of this!

______________________

1

Page 4

At delive ry, you were also informed

of th e warranty coverage and have

completed the Warranty Registration

process.

The information and components/

system descriptions contained in this

guide are correct at time of publication. BRP, however maintains a

policy of continuous improvement of

its products without imposing upon

itself any obligation to install them on

products previously manufactured.

Because of its ongoing commitment

to product quality and innovation, BRP

reserves the right at any time to discontinue or change specifications, designs, features, models or equipment

without incurring oblig atio n.

The illustrations in this document

show the typical construction of the

different assemblies and, in all cases,

may not reproduce the full detail or

exact s hape of the parts shown, however, they represent parts which have

the same or a similar function.

It is understood that this guide may

be translated into another language.

In the event of any discrepancy, the

English version shall prevail.

Specifications are given in the SI metric system. Where precis e accuracy

is not required, some conversions are

rounded off for easier use.

Most components of this snowmobile

are built with parts dimensioned in the

metric system. Most fasteners are

metric and must not be replaced by

customary fasteners or vice versa.

We recommend genuine BRP products for replacement parts and accessories. They've been specially

designed for your vehicle and manufactured to meet BRP's demanding

standards.

For any questions pertaining to the

warranty and its application, consult

the WARRANTY section in this guide,

and/or an authorized LYNX dealer.

2

_______________________

Page 5

TABLE OF CONTENTS

SAFETY INFORMATION

INTRODUCTION ..................................................................... 8

IMPORTANT BASIC SAFETY MEASURES....................................... 9

LAWS AND REGULATIONS....................................................... 13

RIDING THE VEHICLE.............................................................. 14

Principle of Operation .......................................................... 14

How to Ride ..................................................................... 14

Carrying a Passenger ........................................................... 16

Terrain/Riding Variations........................................................ 18

Transporting and Towing ....................................................... 22

TRACTION ENHANCING PRODUCTS........................................... 23

SAFETY LABELING................................................................. 27

ENVIRONMENT INFORMATION

GENERAL ............................................................................ 34

JUST WHAT IS LIGHT TREADING? ............................................. 35

WHY IS LIGHT TREADING SMART.............................................. 36

VEHICLE INFORMATION

HOW TO IDENTIFY YOUR SNOWMOBILE ..................................... 38

CONTROLS/INSTRUMENTS/EQUIPMENT .................................... 40

1) Speedometer................................................................. 41

2) Tachometer ................................................................... 43

3) Pilot Lamps ................................................................... 43

4) Throttle Lever ................................................................ 43

5) Brake Lever................................................................... 43

6) Parking Brake Lever ......................................................... 43

7) Multi-Function Switch ....................................................... 44

8) Handlebar ..................................................................... 45

9) Ignition Switch ............................................................... 45

10) Tether Cut-Out Switch ..................................................... 46

11) Engine Cut-Out Switch .................................................... 47

12) Rewind Starter Handle..................................................... 47

13) Choke Lever ................................................................ 47

14) Fuel Tank Cap/Gauge....................................................... 48

15) Windshield .................................................................. 48

16) Hood and Side Panel Latches............................................. 48

17) Fuses ........................................................................ 49

18) Front Grab Handle/Front Bumper ......................................... 51

______________________

3

Page 6

19) Storage Compartment ..................................................... 52

20) Rear Rack ................................................................... 52

21) Tool Kit....................................................................... 52

22) Spark Plug Holder .......................................................... 52

23) Spare Drive Belt Compartment ........................................... 53

24) Hitch ......................................................................... 53

25) Shields and Guards......................................................... 53

26) Track ......................................................................... 53

27) Holding Strap ............................................................... 53

28) Rear Grab Handles ......................................................... 54

29) Adjustable Mirrors.......................................................... 54

30) Backrest ..................................................................... 54

31) Gear Shift Lever ............................................................ 54

32) Seat Strap ................................................................... 54

RECOMMENDED FUEL AND OIL ................................................ 55

BREAK-IN PERIOD.................................................................. 57

OPERATING INSTRUCTIONS..................................................... 58

Pre-Operation Check ........................................................... 58

Engine Starting Procedure (2-Stroke) ......................................... 59

Engine Starting Procedure (4-Stroke) ......................................... 60

Vehicle Warm-Up ............................................................... 61

Shutting Off the Engine ........................................................ 61

Post-Operation Care ............................................................ 61

Suspension Adjustments ...................................................... 61

SPECIAL OPERATING INSTRUCTIONS ......................................... 67

Riding at High Altitudes or Sea Level......................................... 67

Riding in Cold Weather......................................................... 67

Emergency Starting............................................................. 67

Towing an Accessory........................................................... 68

Towing Another Snowmobile.................................................. 68

Transporting the Vehicle........................................................ 68

TROUBLESHOOTING .............................................................. 70

SPECIFICATIONS ................................................................... 73

MAINTENANCE INFORMATION

PERIODIC MAINTENANCE CHART .............................................. 80

2-STROKE............................................................................ 81

4-STROKE............................................................................ 84

ENGINE SYSTEM................................................................... 87

Air Filter Cleaning ............................................................... 87

Coolant Level.................................................................... 87

Exhaust System................................................................. 88

Injection Oil Level............................................................... 88

Engine Oil Level................................................................. 89

Engine Oil/Oil Filter Change ................................................... 89

4

_______________________

Page 7

DRIVE SYSTEM..................................................................... 91

Belt Guard Removal and Installation.......................................... 91

Brake Fluid Level................................................................ 92

Brake Condition ................................................................. 93

Brake Adjustment............................................................... 93

Chaincase Oil Level............................................................. 93

Chaincase Oil Change .......................................................... 94

Drive Chain Tension ............................................................ 94

Drive Belt Condition ............................................................ 94

Drive Belt Removal/Installation................................................ 94

Drive Belt Height Adjustment ................................................. 96

Drive Pulley Adjustment ....................................................... 98

Track Condition.................................................................. 99

Track Tension and Alignment ................................................ 100

ELECTRICAL SYSTEM ........................................................... 103

Battery Electrolyte ............................................................ 103

REAR SUSPENSION ............................................................. 104

STEERING AND FRONT SUSPENSION....................................... 105

BODY/FRAME..................................................................... 106

Vehicle Cleaning and Protection............................................. 106

Bulb Replacement ............................................................ 106

Headlamp Beam Aiming ..................................................... 107

STORAGE AND PRESEASON PREPARATION ............................... 108

WARRANTY

BRP FINLAND OY INTERNATIONAL LIMITED WARRANTY: 2008 LYNX

®

SNOWMOBILES .................................................................. 110

PRIVACY OBLIGATIONS/DISCLAIMER ....................................... 113

CHANGE OF ADDRESS/OWNERSHIP ........................................ 114

______________________

5

Page 8

6

_______________________

Page 9

SAFETY

INFORMATION

____________

SAFETY INFORMATION

____________

7

Page 10

INTRODUCTION

Everyone is a beg in ner the first time

he sits behind the controls of a snowmobile regardless of previou s experience in driving an automobile, a

motorcycle or a motorboat. The safe

use of your snowmobile is dependent

on many condition s such as visibility,

speed, weather, environment, traffic,

vehicle condition and the condition of

the driver.

Each operator has a resp onsibility to

ensure the safety of his/her passenger, if any, and of other recreationists

or bystanders.

You are responsible for proper operation of your vehicle as well as training

thosewhomyouallowtorideordrive.

There may be noticeable handling and

performance differences from one

snowmobile to the other.

A snowmobile is relatively simple to

operate but like any other vehicle

or mechanical equipment, it can be

hazardous if you or a passenger are

reckless, thoughtless or inattentive.

We encourage you to have an Annual

Safety Inspection of yo ur snowmobile. Please contact an authorized

LYNX dealer for further details. Finally, we urge you to visit an authorized

LYNX dealer periodically for regular

and safety maintenance, as well as

snowmobile accessories you may require.

8

____________

SAFETY INFORMATION

___________

Page 11

IMPORTANT BASIC SAFETY MEASURES

Training

Basic training is required for the

safe operation of any snowmobile.

Study your Operator's Guid e paying

particular attention to cautions and

warnings. Join your local snowmobile club: its social activities

and trail systems are planned for

both fun and safety. Obtain basic

instructions from your snowmobile

dealer, friend, fello w club member

or enroll in your state or provincial

safety training program.

Always show a new operator how

to s ta rt and stop the vehicle. Indicate the correct riding positions

and, above all else, only allow him

to operate the snowmobile in a restricted flat area — at least until he

is co m pletely fa miliar with its o p eration. If there is a local snowmobile

operator's training course existing,

have him enroll.

Performance

The performance of some snow-

mobiles may significantly exceed

that of other snowmobiles you have

operated. Therefore, use by novice

or inexperienced operators is not

recommended.

Snowmobiles are used in many

areas and in m any snow conditions. Not all models perform the

same in similar conditions. Always

consult your snowmobile dealer

when selecting the snowmobile

model for your particular needs and

uses.

Injury or death may result to the

snowmobile operator, passenger

or bystander if the snowmobile is

used in risky conditions which are

beyond the driver's, passenger's

or snowm o b ile's capabilities or intended use.

Age

BRP recommends the operator has

at least 16 years old of age. NOTE!

Follow your local regulation !

Speed

Speeding can be fatal. In many

cases, you cannot react or respond

quickly enough to the unexpected.

Always ride at a speed which is

suitable to the trail, weather conditions and your own ability. Know

your local rules. Speed limit may

be in effect and meant to be observed.

Riding

Always keep right hand side of the

trail.

Always keep a safe dista nc e

from other snowmobiles and bystanders.

Remember, promotional material

may show risky maneuvers performed by professional riders under

ideal and/or c ontrolled conditions.

You should never attempt any such

risky maneuvers if they are beyond

your level of riding ability.

Never ride after consuming drugs or

alcohol or if you feel tired o r ill. Operate your snowmobile prudently.

Your snowmobile is not designed to

be operated on public streets, roads

or highways.

Snowmobiling at night can be a de-

lightful experience but because o f

reduced visibility, be extra cautious.

Avoid unfamiliar terrain and be sure

your lights are working. Always carry a flashlight and spare light bulbs.

____________

SAFETY INFORMATION

___________

9

Page 12

Nature is wonderful but don't let it

distract your attention from driving.

If you want to truly appreciate winter's scenery, stop your snowmobile on the side of the trail so t h at

you don't become a hazard to others.

Fences represent a very serious

threat for both you and your snowmobile. Give a wide berth to telephone poles or posts.

Hidden wires unseen from a dis-

tance can cause serious accidents.

Always wear an approved safety

helmet, eye protection and a face

shield. This also applies to your

passenger.

Be aware of inherent risks associ-

ated with riding off trails, such as

avalanche and other natural or man

made hazards or obstacles.

Avoid road traveling. If you must

do so, and it is permitted, reduce

speed. The snowmobile is not designed to operate or turn on paving.

When crossing a road, make a full

stop, then look carefully in both directions before crossing at a 90° angle. Be wary of parked vehicles.

Tailgating another sn owmobile

should be avoided. If the snowmobile in front of you slows for any

reason, its driver and passenger

could be harmed through your neglect. Maintain a safe stopping

distance between you and the

snowmobile in front of you. Depending on the terrain condition,

stopping may require a little more

space than you think. Play it safe.

Be prepared to use evasive driving.

Venturing out alone with your snow-

mobilecouldalsobehazardous.

You could run out of fuel, have an

accident, or damage your snowmobile. Remember, your snowmobile

is capable of traveling further in half

an hour than you may be able to

walk in a day. Use the “buddy system”. Alway s ride with a friend or

member of your snowmobile club.

Even then, tell someone where you

are going and the approximate time

you plan to return.

Meadows sometimes have low ar-

eas where water accumulate and

freezes over in winter. This ice is

usually glare ice. Attempting to

turn or brake on this surface could

cause your vehicle to spin out of

control. Never brake or attempt

speeding or turning on glare ice. If

youdohappentotraveloversuch

a condition, reduce speed by carefully releasing the throttle.

Never “jump” with your snowmo-

bile. This should be left to professional stunt men. Don't show off.

Be responsible.

While on safari, do not “gun” the

throttle. Snow and ice can be

thrown back into the path of a

following snowmobile. In addition,

when “gunning” the throttle, the

vehicle digs into and leaves an irregular sn o w surface for others.

Safaris are both fun and enjoyable

but don't show off or overtake

others in the group. A less experienced operator might try to do the

same as you and fail. When riding

with others, limit your abilities to

the experience of others.

10

___________

SAFETY INFORMATION

___________

Page 13

Operation

Always make a pre-start inspection

BEFORE you turn on the ignition.

In an emergency, the snowmobile

engine can be stopped by activating

the engine cut-out s w itch, pulling

the tether cord cap or turning off the

key.

Throttle mechanism should be

checked for free movement and

return to idle position before starting engine.

Always engage parking brake when

vehicle is not in use.

Never run the engine in a non-

ventilated area and/or if vehicle is

left unattended.

Never operate the engine without

belt guard securely installed or,

with hood or access/side panels

open or removed. Never run the

engine without drive belt installed.

Running an unloaded engine such

as without drive belt or with track

raised, can be dangerous.

Electric start models only: Never

charge or boost a battery while installed on snowmobile.

Ensure the path behind is clear of

obstacles or bystanders before proceeding in reverse.

Do not leave your keys in the ig-

nition switch, it is a n invitation to

thieves and a danger to young children.

Raising the rear of your snowmobile

while the engine is running could

cause snow, ice or debris to be

thrown back at an observer. Never raise the rear of th e vehic le while

the engine is running. To clear or inspect the track, stop the engine, tilt

thevehicleonitssideandremove

blockage with a piece of wood or

branch. Never allow anyone near a

rotating snowmobile track.

Maintenance

Know your snowmobile and treat

it with the respect and care due of

any power driven machine. Common sense, proper handling and

routine maintenance will result in

safer and enjoyable use.

Only perform procedures as de-

tailed in this guide. Unless otherwise specified, engine should be

turned OFF and cold for all lubrication, adjustment and maintenance

procedures.

Never have the engine running

whilethehoodisopen. Evenat

idle, a snowmob ile engine is turning around 1,800 revolutions per

minute. Always turn off the ignition before opening the hood for

any reason.

Never remove any original equip-

ment from your snowmobile. Each

vehicle has many built in safety features. Such features include various guards and console s, plus reflective materials and warning labels.

A poorly maintained snowmobile

itself can b e a potential haza rd. Excessively worn components could

render the vehicle completely inoperative. Keep the snowmob ile

in good working condition at all

times. Follow your pre-operation

check, weekly, monthly and annually routine maintenance and

lubrication procedures as detailed

in this guide. Consu lt a snowmo bile dealer or acquire a shop manual

and proper tools and equipment if

other repairs or service is required.

Do not stud the track unless it as

been approved for studs. At speed,

a s tudded track that as not been

approved for studs could tear and

separate from vehicle posing a risk

of severe injury or death.

____________

SAFETY INFORMATION

___________

11

Page 14

Fuel

Always stop the engine before

refueling. Fuel is flammable and

explosive under certain conditions.

Always work in a we ll-ve ntilated

area. Do not smoke or allow open

flames or sparks in the vic inity.

Open cap slowly. If a differential pressure condition is noticed

(whistling sound heard when loosening fuel tank cap) have vehicle

inspected and/or repaired before

further operation. Do not overfill

or top off the fuel tank before placingthevehicleinawarmarea.

As temperature increases, fuel expands and might overflow. Always

wipe off any fuel spillage from the

vehicle. Periodically verify fuel system.

Basics for Passenger

Never ride as a passenger unless

the snowmobile is equipped with a

passenger seat, and sit only on the

designated passenger seat.

A lwa ys wear a DOT approved hel-

met and follow the same dressing

guidelines as those recommended

for the operator and described in

this guide.

M ake sure that you are able to

achieve a stable stance, both feet

resting positively on the footboards

of footrests with good grip, and

that you are able to hold on firmly

to the handholds.

Once underway, if you feel uncom-

fortable or insecure for any reason,

don‘t wait, tell the driver to slow

down or stop.

12

___________

SAFETY INFORMATION

___________

Page 15

LAWS AND REGULATIONS

Know your local laws.

Federal, state, provincial and local gov-

ernment agencies have enacted laws

and regulations pertaining to the safe

use and operation of snowmobiles. It

is your responsibility as a snowmobiler

to learn and obey these laws and regulations. Respect and observance will

result in safer snowmobiling for all.

Be aware of the liability property damages and insurance laws regarding

your equipment.

____________

SAFETY INFORMATION

___________

13

Page 16

RIDING THE VEHICLE

Before venturing on the trails, operate

the snowmobile in a restricted flat area

until you are completely familiar with

its operation and feel comfortable that

you can safely tackle a more demanding task. Have an enjoyable and safe

ride.

Principle of Operation

Propulsion

Depressing throttle lever increases

engine RPM causing th e drive pulley

to engage. Depending on models engine RPM must be between 2500 and

4200 before drive pulley engagement

will occur.

Outer sheave of drive pulley moves

toward inner sheave, forcing the drive

belt to move upward on the drive

pulley and simultaneously forcing the

sheaves apart on the driven pulley.

The driven pulley senses the load on

the track and limits the belt movement. The result is an optimized

speed ratio between engine RPM and

the speed of the vehicle at any time.

WARNING

Never operate engine without belt

guard securely installed or, with

hood or access/side panels open

or removed.

Power is transferred to the track

through the chaincase or gearbox

and drive axle.

WARNING

Always use a wide-base snowmobile mechanical stand to properly

support vehicle during any track

verification. Slowly accelerate

engine in order to rotate track at

very low speed when it is not on

ground.

Tur nin g

Handlebar controls the steering of the

vehicle. As the handlebar is rotated to

right or left, the skis are turned right or

left to steer the snowmobile.

Stopping

Before riding your snowmobile, you

should understand how to stop it.

This is done by releasing the throttle

and gradually depressing the brake

lever on the left side of the handlebar.

In an emergency, you may stop your

vehicle by pressing the engine cut-out

switch located near the throttle control

and applying the brake. Remember, a

snowmobile cannot “stop on a dime”.

Braking characteristics vary with deep

snow, packed snow or ice. If the track

is locked during hard braking, skidding

may result.

How to Ride

How to Dress

Proper snowmobile clothing should

be worn. It should be comfortable

and not too tight. Always check the

weather forecast before going on a

ride. Dress for the coldest weather

expected. Thermal underwear next

to the skin also provides a good insulation.

DOT approved helmets are recommended at a ll times. They provide

both warmth a nd reduce injury. A

stocking type cap, balaclava and face

mask should always be carried or

worn. Goggles or a face shield that

attach to the helmet are indispensable.

Hands should be p rotected by a pair

of snowmobile gloves or mitts which

have sufficient in su latio n and allow

use of thumbs and fingers for operation of controls.

14

___________

SAFETY INFORMATION

___________

Page 17

Rubber bottom boots with either a nylon or a leather top, with removable

felt liners are best suited for snowmobiling.

You should keep yourself as dry as

possible when snow m obiling. When

you come indoors, take your snowmobile suit and boots off and make certain they dry properly.

Do not wear long scarfs and loose apparels that could get caught in moving

parts.

What to Bring

Every snowmobiler should carry at

least the follow ing basic parts and

tools that can help him and others in

an emergency:

• this Operator's Guide

• spare spark plugs and wrench

•frictiontape

• spare drive belt

• spare starter rope

• spare light bulbs

• tool kit (including at least p liers,

screwdriver, adjustable wrench)

•knife

• flashlight.

Include other items depending on the

length and time of your ride.

Riding Position

Your riding position and balance are

the two basic principles of making

your snowmobile go where you want

it to. When turning on the side of a

hill, you and your passenger must be

ready to shift body weight to help it

turn in the desired direction. Driver

and passenger(s) must never attempt

this maneuvering by placing feet outside of the vehicle. Experience will

teach you how much lean to put into turns at different speeds and how

much you will have to lean into a slope

to maintain proper balance.

Generally, the riding position for best

balance and control is sitting. However, the posting, kneeling or standing

positions are also used under certain

conditions.

The novice driver should become familiar with the snowmobile throu g h

practice on a level area at slow speeds

before venturing afield.

WARNING

Do not attempt any maneuvers if

they are beyond your abilities.

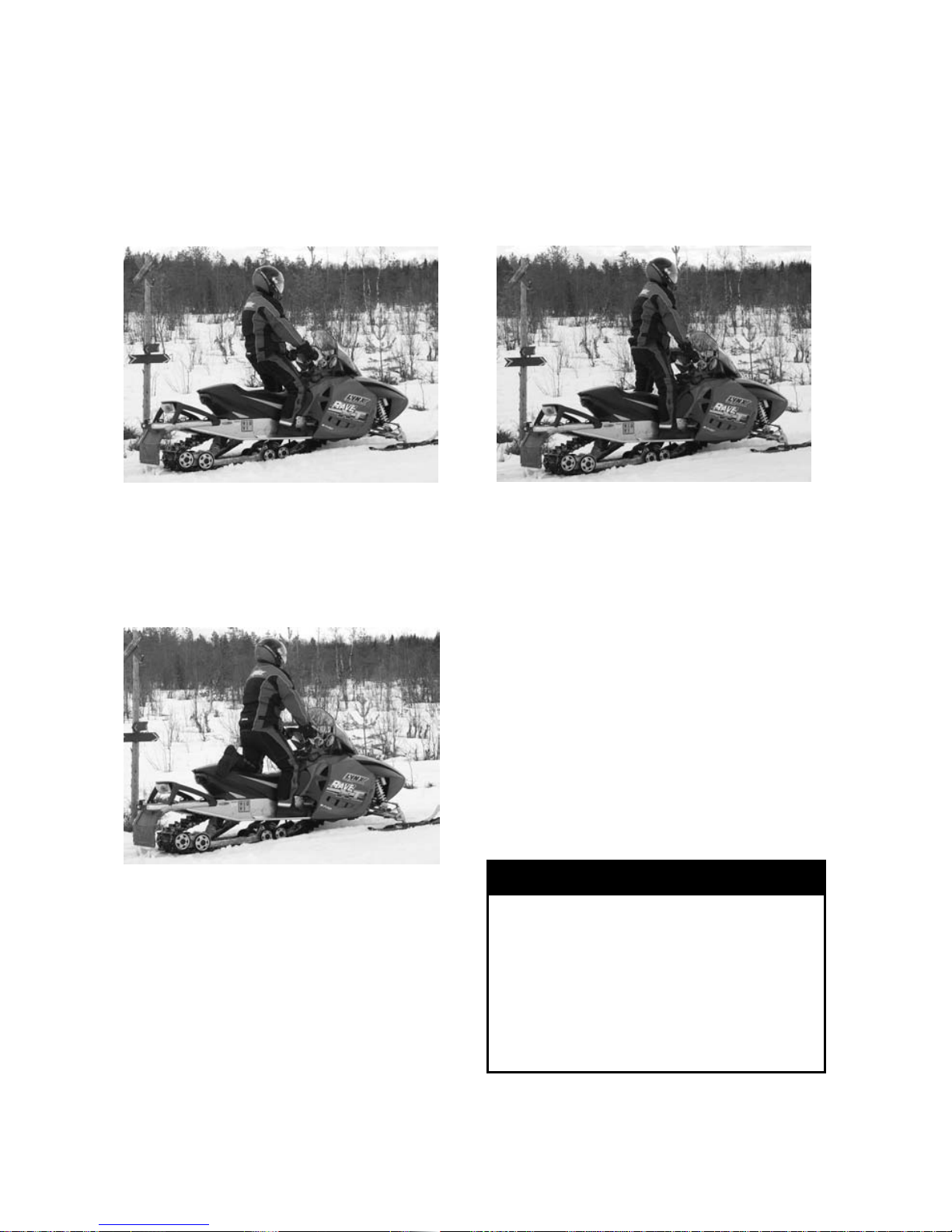

Sitting

Feet on the running boards, body midway back on seat is an ideal position

when operating the snowmobile over

familiar, smooth terrain. Knees and

hips should remain flexible to absorb

shocks.

____________

SAFETY INFORMATION

___________

15

Page 18

Posting

A semi-sitting position with the body

off the seat and the feet under the

body in a sort of squatting posture,

thus allowing the legs to absorb the

shocks when traveling over uneven

terrain. Avoid abru pt stops.

Kneeling

This position is achieved by placing

one foot firmly on the running board

and the opposite knee on the seat.

Avoid abrupt stops.

Standing

Place both feet o n the running boards.

Knees should be flexed to absorb the

shock from surface bumps. This is

an effective position to see better and

to shift weight as conditions dictate.

Avoid abrupt stop.

Carrying a Passenger

Certain snowmobiles are designed for

an operator only, others can allow one

passenger only, and others can allow

up to two passengers. Refer to the

indications on the vehicles to know if

any particular snowmobile can accommodate passengers or not, and if so,

how many. Always respect those indications. Overloading is dangerous because snowmobiles are not designed

for it.

Even when passengers are allowed,

you must make sure that the persons

who would like to become passengers

are p hysically fit for snowmobiling.

WARNING

Anypassengermustbeableto

firmly lay his feet on the footrests

andkeephishandsonthegrab

handles or seat strap at all times

when seated. Respecting those

physical criteria is important to

ensure that the passenger is stable

and to reduce the risks of ejection.

16

___________

SAFETY INFORMATION

___________

Page 19

On snowmobiles allowing two passengers, if you have an adult and a

child for passenger, BRP recommends

that the child sits in the center location. This a llows an adult sitting in the

rear seat to keep a visual contact with

the child and h old him if necessary.

In addition, the child is best protected

against the wind and cold temperature

if seated in the center lo catio n.

Each op e ra tor has a responsibility to

ensure the safety of his passengers

and should inform them of snowmobiling basics.

WARNING

– Passengers must only sit on

designated passenger seats.

Never allow anyone to sit between the handlebar and the

operator.

– Each passenger seat must have

a strap or grab handles and

meet SSCC standards.

– Passengers and operators must

always wear DO T approved helmets and warm clothing appropriate for snowmobiling. Make

sure that no skin is exposed.

– O nce underway, if a passenger

feels uncomfortable or insecure

for any reason, he must not

wait, and tell the driver to slowdown or stop.

Riding with passen gers on board is

different than riding alone. The operator has the benefit of knowing what

will be the next maneuver and is able

to prepare himself accordingly. The

operator also benefits from the support of his grip on the handlebar. In

contrast, the passengers have to rely on the operator’s carefu l and safe

operation of the vehicle. In addition,

“body english” is limited with passengers, and the operator can sometimes

see more of the trail ahead than the

passengers. Therefore, smooth starting and stopping are required with

passengers, and the operator must

slow down. The operator must also

warn passengers of side hills, bumps,

branches, etc. An unforeseen bump

can leave you passenger-less . Remind your passe n ge r s to lean into

the turn with you, without causing

the vehicle to topple. Be extremely

careful, go more slowly and check the

passengers frequently.

WARNING

When riding with a passenger:

– Braking ability and steering

control are reduced. Decrease

speed and allow extra space to

maneuver.

– Adjust suspension according to

weight.

For c omplete information on how

to adjust the suspension, please refer to the section of this Operator’s

Guide entitled SUSPENSION ADJUST-

MENTS under OPERATING INSTRUCTIONS and to the relevant label on the

belt guard.

Use extra caution and go even more

slowly with young passengers. Check

frequently to make certain the child

has a firm grip and is properly positioned with his feet on the running

boards.

____________

SAFETY INFORMATION

___________

17

Page 20

Terrain/Riding Variations

Groomed Trail

On a maintained trail, sitting is the

most preferred riding position. Do not

race and, above all, keep to the right

hand side of the trail. Be prepared

for the unexpected. Observe all trail

signs. Do not zigzag from one side of

the trail to the other.

Ungroomed Trail

Unless there has been a fresh snowfall you can expect “washboard” and

snowdrift conditions. Taken at excessive speeds, such conditions can be

physically harmful. Slow down. Hold

on the handlebar and assume a posting position. Feet should be under the

body assuming a crouched position to

absorb any jarring effect. On longer

stretches of “washboard” trails, the

kneeling position of one knee on the

seat can be adopte d. This provides

a certain amount of comfort, while at

thesametimekeepsthebodyloose

and capable of vehicle control. Beware of hidden rocks or tree stumps

partially hidden by a recent snowfall.

Deep Snow

In deep “powder” snow, your vehicle

could begin to “bog” down. If this occurs,turninaswideanarcaspossible and look for a firmer base. If you

do get “bogged”, and it happens to

everyone, do not spin your track as

this makes the vehicle sink deeper. Instead, turn the engine off, get off and

move the back of the vehicle onto new

snow. Then tramp a clear path ahead

of the vehicle. A few feet will generally suffice. Restart the engine. Assume the standing position and rock

the vehicle gently as you steadily an d

slowly apply the throttle. Depending

on whether the front or rear end of

the vehicle is sinking, your feet should

be placed on the opposing end of the

running boards. Never place foreign

material beneath the track for support.

Do not allow anyone to stand in front

of, or to the rear of, the snowmobile

with the engine running. Stay away

from the track. Personal injury will result if conta c t is made with th e revolving track.

18

___________

SAFETY INFORMATION

___________

Page 21

Frozen Water

Traveling frozen lakes and rivers can

be fatal. Avoid w aterwa ys. If you

are in an un fam iliar are a, ask the local authorities or residents about the

ice condition, inlets, outlets, springs,

fast moving currents or other hazards. Never attempt to operate your

snowmobile on ice that may be too

weak to support you and the vehicle.

Operating a snowmobile on ice or icy

surfaces can be very dangerous if you

do not observe certain precautions.

The very nature of ice is foreign to

good control of a snowmobile or any

vehicle. Traction for starting, turning

or stopping is much less than that

on snow. Thus, these distances can

be multiplied manyfold. Steering is

minimal, and uncontrolled spins are

an ever pre s e nt dange r. When op erating on ice, drive slow ly with caution.

Allow yourself plenty of room for

stopping and turning. This is especially true at night.

Hard Packed Snow

Don't underestimate hard packed

snow. It can be difficult to negotiate

as both skis and track do not have as

much traction. Best advice is to slow

down and avoid rapid acceleration,

turning or braking.

Uphill

There are two types of hills you can encounter — the open hill on which there

are few trees, cliffs or other obstacles,

and a hill that can only be climbed directly. On an open hill, the approac h

is to climb it by side hilling or slaloming. Approach at an angle. Adopt a

kneeling position. Keep your weight

on the uphill side at all times. Maintain a steady, safe speed. Continue

as far as you can in this direction, then

switch to an opposite hill angle and riding position.

A direct climb could present problems.

Choose the standing position, accelerate before you start the climb and

then reduce throttle pressure to prevent track slippage.

In either case, vehicle speed should

be as fast as the incline demands.

Always slow down as you reach the

crest. If you cannot proceed further,

don't spin your track. Turn the engine off, free the skis by pulling them

out and downhill, place the rear of the

snowmobile uphill restart the engine

and ease it out with slow even throttle

pressure. Position yourself to avoid

tipping over, then descend.

Downhill

Downhill driving requires that you

have full control of your vehicle at all

times. On s te e pe r hills, keep your

center of gravity low and both hands

on the handlebar. Maintain slight

throttle pressure and allow the machine to run downhill with the engine

operating. If a higher than safe speed

is reached, slow down by braking but

apply the brake w ith frequent light

pressure. Never jam the brake and

lock the track.

Side Hill

When crossing a side hill or traversing up or downhill, certain procedures

must be followed. All riders should

lean towards the slope as required

for stability. The preferred operating

positions are the kneeling position,

with the knee of the down hill leg

on the seat and the foot of the uphill leg on the running board, or the

posting position. Be prepared to shift

your weight quickly as needed. Side

hills and steep slopes are not recommended for a beginner or a novice

snowmobiler.

____________

SAFETY INFORMATION

___________

19

Page 22

Slush

Slush should be avoided at all times.

Always check for slush before starting across any lake or river. If dark

spots appear in your tracks, get off the

ice immediately. Ice and water can be

thrown rearward into the path of a following snowmobile. Getting a vehicle

out of a slush area is strenuous and in

some cases, impossible.

Fog or Whiteouts

On land or water, fog or visibilitylimiting snow can form. If you have

to proceed into the fog or heavy snow,

do so slowly with your lights on and

watch intently for hazards. If you are

not sure of your way, do not proceed.

Keep a safe distance behind other

snowmobilers to impr ove visibility

and reaction time.

Unfamiliar Territory

Whenever you enter an area that is

new to you, drive with extreme caution. Go slow enough to recognize

potential h azards such as fences or

fence posts, brooks crossing your

path, rocks, sudden dips, guy wires

and countless other obstacles whic h

could result in a termination of your

snowmobile ride. Even when following existing tracks, be cautious.

Travel at a speed so you can see what

is around the next bend or over the

top of the hill.

Bright Sunshine

Bright sunny days c an considerably reduce your vision. The glare from sun

and snow may blind you to the extent that you cannot easily distinguish

ravines, ditches or other obstacles.

Goggles with colored lenses should

always be worn under these conditions.

Unseen Obstruction

There may be obstructions hidden

beneath the snow. Driving off established trails and in the woods requires

reducedspeedandincreasedvigilance. Driving too fast in an area can

make even minor obstacles very hazardous. Even hitting a small rock or

stump could throw your snowmobile out of control and cause injury to

its riders. Stay on established trails

to reduce your exposure to hazards.

Be safe, slow down and enjoy the

scenery.

Hidden W ires

Always be on the lookout for hidden

wires, especially in areas that may

have been farmed at one time or another. Too many accidents have been

caused by running into wires in the

fields, guy wires next to poles and

roads, and into chains and wires used

as road closures. Slow speeds are a

must.

Obstacles and Jumping

Unplanned jumps of snowdrifts,

snowplow ridges, culverts or indistinguishable objects can be dangerous.

You can avoid them by wearing the

proper color lenses or face shields and

by operating at a lower speed.

Jumping a sno wmobile is an unsafe

and dangerous practice. However, if

the trail does suddenly drop away from

you, crouch (stand) towards the rear

ofthevehicleandkeeptheskisup

and straight ahead. Apply partial throttle and brace yourself for the impact.

Knees must be flexed to act as shock

absorbers.

20

___________

SAFETY INFORMATION

___________

Page 23

Tur nin g

Depending on terrain conditions, there

are two preferred ways to turn or corner a snowmobile. For most snow

surfaces, “body english” is the key to

turning. Leaning towards the inside of

the turn and positioning body weight

on the inside foot will create a “banking” condition beneath the track. By

adopting this position and positioning

yourself as far forward as poss ible,

weight will be transferred to the inside

ski.

On oc cas ion, you will find that the only way to turn the vehicle about in

deep snow is to pull the snowmobile

around. Do not over-exert yourself.

Get assistance. Remember to a lways

lift using your legs as opposed to your

back.

Road Crossing

In some cases, you will be approaching the road from a ditch or snowbank.

Choose a place where you know you

can climb without diffic ulty. Use the

standing position and proceed with only as much speed needed to crest the

bank. Stop completely at the top of

the bank and wait for all traffic to clear.

Judge the drop to the roadway. Cross

the road at a 90° angle. If you encounter another snowbank on the opposite side, position your feet near the

rear of the v eh icle. Remember, your

snowmobile is not designed to operate on bare pavement and steering on

this type of surface is more difficult.

Railroad Crossing

Never ride on railroad tra cks. It is illegal. Railroad tracks and railroad rightsof-way are private property. A snowmobile is no match for a train. When

crossing a railroad track, stop, look and

listen.

Night Rides

The amount of natural and artificial

light at a given time can effect your

ability to see or to be seen. Nighttime

snowmobiling is d elig htful. It can be

a unique experience if you acknowledge you r reduced visibility. Before

you start, m ake certain your lights

are clean and work properly. Drive

at speeds that will allow you to stop

in time when you see an unknown

or dangerous object ahead. Stay on

established trails and never operate in

unfamiliar territory. Avoid rivers and

lakes. Guy wires, barbed wire fences,

cabled road entrances and other objects such as tree limbs are difficult

to see at night. Neve r drive alo ne .

Always carry a flashlight. Keep away

from residential areas and respect the

right of others to sleep.

Safari Riding

Before starting out, designate a “trail

boss” to lead the party and a nother

person to follow-up at the end of the

party. Ensure that all members of the

party are aware of the proposed route

and destination. Make certain that

you are carrying all necessary tools

and equipment and that you have

sufficient fuel to complete the trip.

Never overtake the trail boss or, for

that matter, any other snowmobile.

Use down-th e-line hand signals to indicate hazards or intent of direc tio n

change. Assist others whenever necessary.

____________

SAFETY INFORMATION

___________

21

Page 24

ItisalwaysIMPORTANTtokeepa

safe distance between each snowmobile. Always maintain a safe interval

and allow sufficient stopping distance.

Don't be a tailgater. Know the position

of the machine ahead.

Signals

If you intend to stop, raise either hand

straight above your head. A left turn is

indicated by extending your left hand

straight out in the proper direction.

For right turns, extend the left arm and

raise the hand to a vertical position so

it forms a right angle at the elbow. Every snowmobiler should relay any signal to the ones behind.

Trail Stops

Whenever possible, pull off the trail

when you stop. This will reduce the

hazard to other snowmobilers using

the trail.

Trails and Signs

Trail signs are used to control, direct

or regulate the use of snowmobiles on

trails. Become familiar with all signs

used in the area where you are snowmobiling.

Transporting and Towing

Follow transporting and towing instructions explained further in this

guide.

22

___________

SAFETY INFORMATION

___________

Page 25

TRACTION ENHANCING PRODUCTS

NOTE: This section is applicable to

snowmobiles equipped with a factory

installed pre-studded Ice Series track

or a track that as been approved by

BRP for studs installation.

Using more positive carbide ski r unners and traction enhancing products

(Ice Series tracks or approved studded tracks) on your snowmobile will

change its behavior, particu larly in

terms of manoeuvrability, acceleration, and braking.

Using traction enhancing products

gives a better grip on packed snow

and ice, but has no noticeable effect on soft snow. For this reason,

driving a snowmobile equipped with

traction enhancing products (Ice Series tra cks , approved studded tracks,

carbide ski runners) requires a certain

adaptation period. If your snowmobile

is equipped with traction enhancing

products, be sure to take plenty of

time to get used to the way it h an dle s

when turning, accelerating, and braking.

Also, always check local regulations

concerning the use of traction enhancing products on snowmobiles.

Always drive your snowmobile in a

responsible manner, respecting the

environment and other people’s property.

Manoeuvrability

Using traction enhancing products

makes the snowmobile grip the

ground better at the rear. The use

of carbide runners is therefore required to give the skis a better grip, so

that the front and rear of the snowmobile are in balance. While off-the-shelf

carbide s ki runners are adequate,

they don’t necessarily give you optimal control, since that depends on

your personal preferences, your riding

style, and how your suspension is set.

WARNING

If the front and rear of the snowmobile are out of balance due to an

incorrect combination o f trac tio n

enhancing products and runners,

the snowmobile may tend to oversteer or understeer, which could

lead to a loss of control.

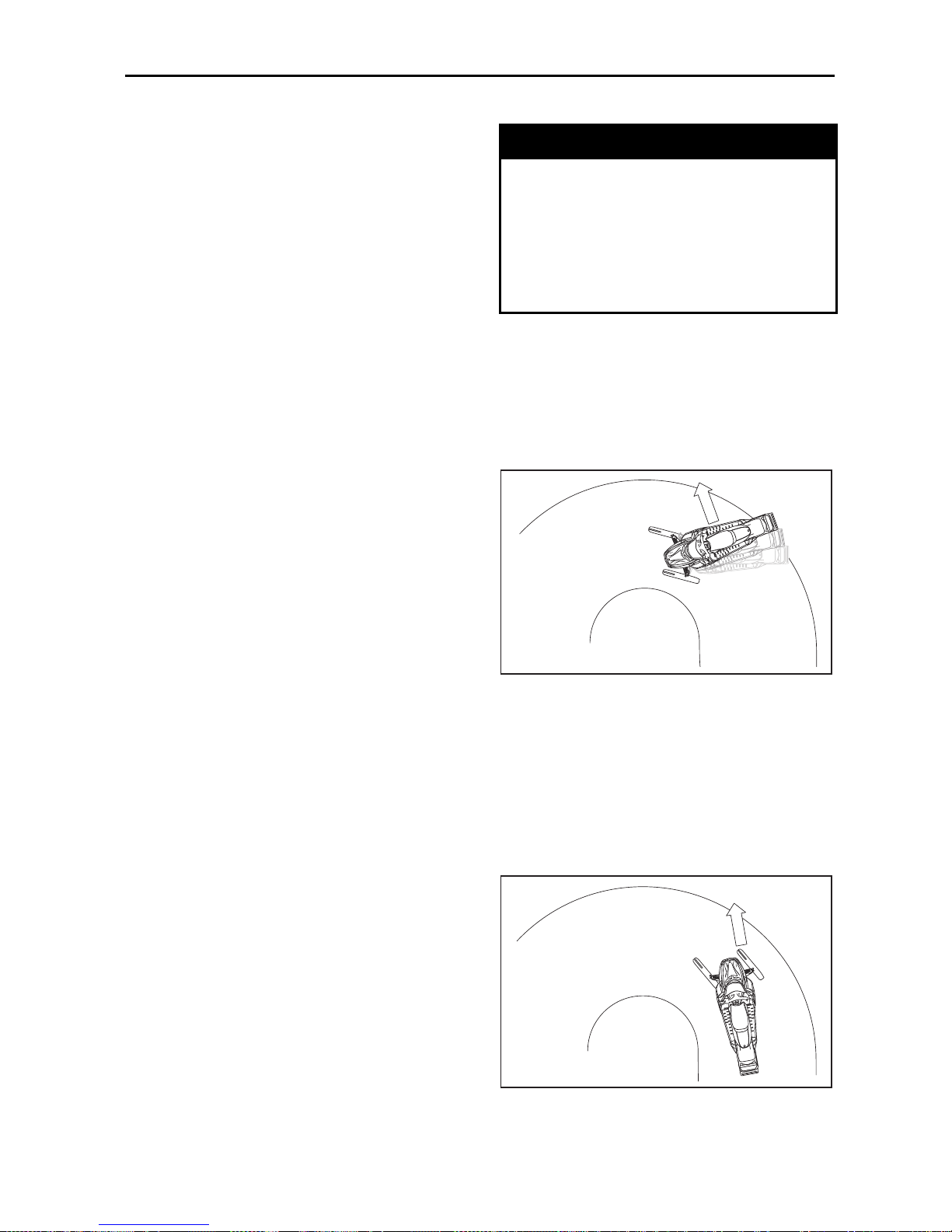

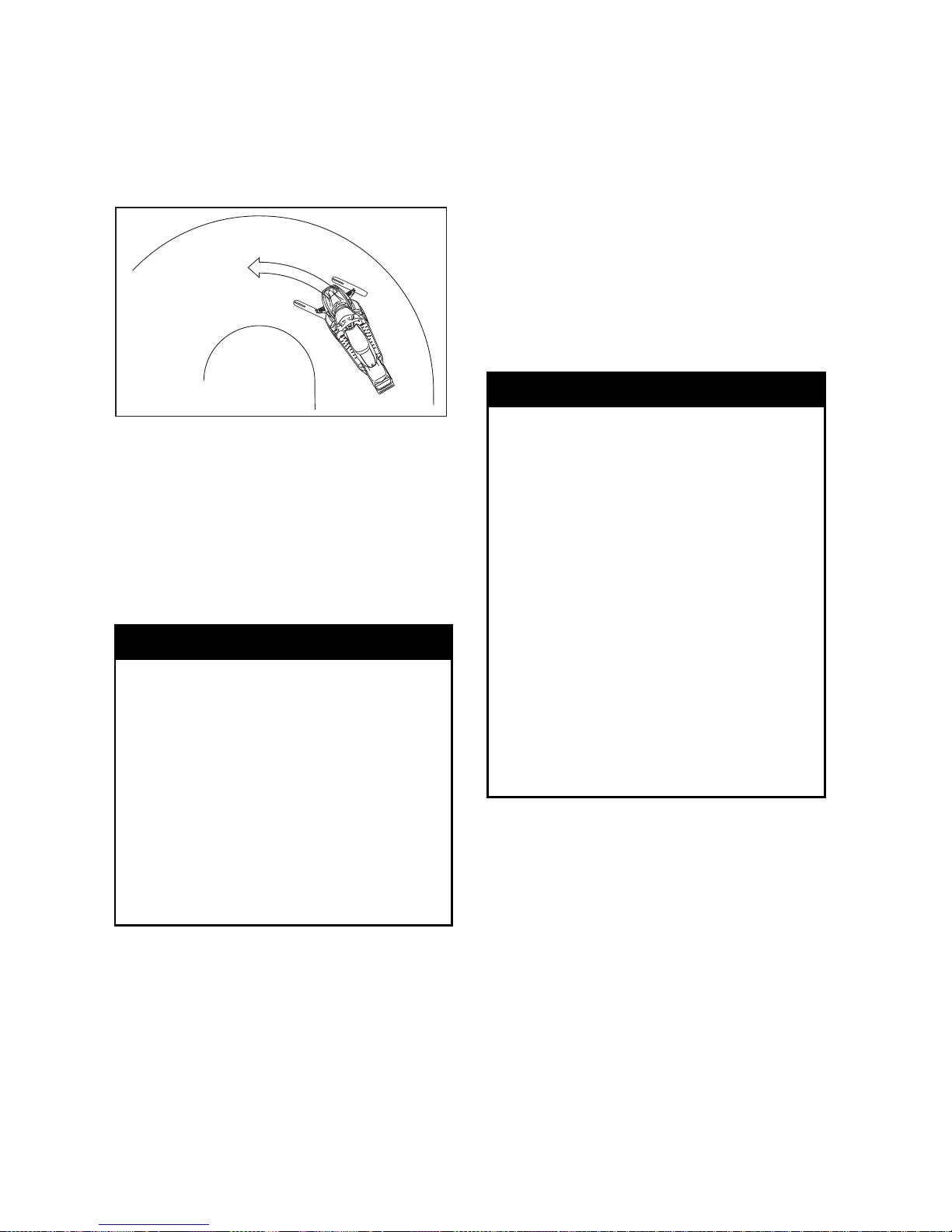

Oversteering

In certain conditions, using more positive carbide ski runners without traction enhancing products could make

the snowmobile prone to oversteering, see illustration.

A33A31A

OVERSTEERING

Understeering

In certain conditions, the use of traction enhancing products could make

the snowmobile prone to understeering if the skis are not equipped with

more positive carbide runners, see illustration.

A33A33A

UNDERSTEERING

____________

SAFETY INFORMATION

___________

23

Page 26

Controlled Driving

A balanced combination of carbide ski

runners and traction enh an cing products ensures adequate control and

better handling, see illustration.

A33A34A

CONTROLLED DRIVING

Acceleration

Using traction enhancing products will

allow your sled to accelerate better on

packed snow and ice but will have no

noticeable effect on soft snow. This

can cause sudden variations in traction

under certain conditions.

WARNING

To prevent surprises that could

lead to a loss of control of the

snowmobile, possibly resulting in

serious injury or death:

– Always go easy on the throttle.

– NEVER try to spin the track to

make the rear of the snowmo-

bile skid.

This could cause debris or ice to be

thrown violently backwards, possibly injuring others nearby or on

snowmobiles behind you.

Braking

As in the case of acceleration, using

traction enhancing products will give

you better braking capacity on packed

snow or ice but will have no noticeable effect on soft snow. Braking may

thus vary suddenly under certain conditions. Be sure to use restraint in

braking to keep from blocking the track

in order to avoid surprises that could

lead to a loss of control.

Important Safety R ules

WARNING

To prevent serious injury to individuals near the snowmobile:

– N EVER stand behind or near a

moving track.

– Always use a wide-base snow-

mobile stand with a rear deflector panel.

– W hen the track is raised off the

ground, only run it at the lowest

possible speed.

Centrifugal force could cause debris, damaged or loose studs,

pieces of torn track, or an entire severed track to be violently

thrown backwards out of the tunnel with tremendous force, possibly resulting in the loss of a leg or

other serious injury.

24

___________

SAFETY INFORMATION

___________

Page 27

Effects of Traction

Enhancing Products

ontheLifeofthe

Snowmobile

The use of traction enhancing products can increase the load and the

stress on certain snowmobile components, as well as the vibration level. This c an cause premature wear on

parts such as belts, brake linings, bearings, chain, chaincase sprocket, and

on approved studded tracks, shorten

track life. Always proceed with a visual inspection of your track before each

use. For more information, refer to

MAINTENANCE/REPLACEMENT section further in this guide.

Traction enhancing products can also

cause serious damage to your snowmobile if it is not equipped with the

tunnel protectors designed for your

particular model. Damage to the electrical wiring or perforation of the heat

exchangers are potential hazards, that

could cause the engine to overheat

and be severely damaged.

WARNING

If tunnel protectors are excessively

worn or not installed, the gas tank

could be punctured, causing a fire.

CAUTION: Ask your dealer for the

appropriate tunnel protectors model and kit number required for your

snowmobile.

NOTE: Consult the BRP limited war-

ranty to find out what w arra nty limitations are related to the use of studs.

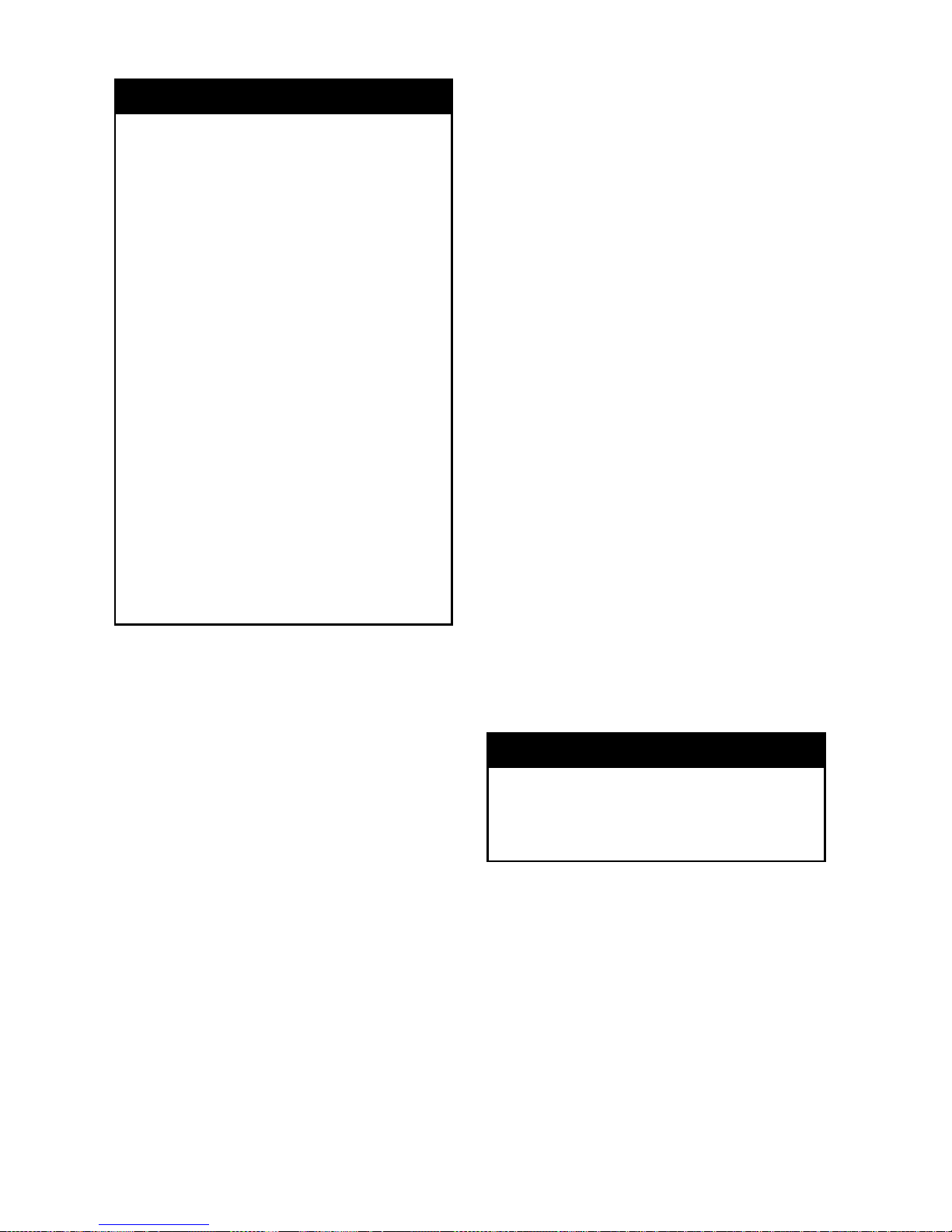

Installation of Studs on

BRP Approved Tracks

WARNING

Never stud a track that has not

been approved for studs. Approved tracks can be identified by

a stud symbol (see illustration)

molded into the track surface. Installing studs on an unapproved

track could increase the risk of the

track tearing or severing, possibly

resulting in serious injury or death.

A33A35A

APPROVED TRACKS CAN BE IDENTIFIED

BY THIS SYMBOL

To ensure safe and proper installation,

BRP recommends to have the studs

installed by your dealer.

– Use only studs, mounting plates,

andnutssoldbyBRP.

– Never use studs that exceed the

height of your snowmobile’s track

profile by more than 9.5 mm (3/8 in).

2

A33A32A

3

1

4

INSTALLATION OF STUDS

1. Stud size

2. Penetration range 6.4 to 9.5 mm

(1/4 to 3/8 in)

3. Track lug height

4. Track belt thickness

____________

SAFETY INFORMATION

___________

25

Page 28

WARNING

– Studs should only be installed in

the locations indicated by molded bulges in the track surface.

– N ever stud a track with a profile

of 35 mm (1.375 in) or more.

– The number of studs installed

must always perfectly match the

pattern of molded bulges in the

track.

– Always consult the traction

product manufacturer’s installation instructions and recommendations before having your

dealer install studs and runners.

It is very important to f ollow

the torque specifications for the

stud bolts.

INSTALLING AN INCORRECT

NUMBER OF STUDS OR AN IMPROPER INSTALLATION CAN INCREASE THE RISK OF THE TRACK

TEARING OR SEVERING, POSSIBLY RESULTING IN SERIOUS

INJURY OR DEATH.

Maintenance/Replacement

PROCEED WITH A VISUAL INSPECTION OF YOUR TRACK BEFORE

EACH USE.

Look for any d efects, such as:

– perforations in the track

– tears in the track (p articularly

around traction holes on studded

tracks)

– lugs that are broken or torn off, ex-

posing portions of rods

– delamination of the rubber

– broken rods

– broken studs (studded tracks)

– bent studs (studded tracks)

– missing studs

– studs that are torn off the track

– missing track guide(s).

On Ice Series pre-studded tracks, broken or missing studs can not be replaced.

On approved studded tracks, replace

broken or damaged studs immediately. If your track shows signs of deterioration, it must be replaced immediately. When in doubt, ask your dealer.

Always proceed with a visual inspection of your track before each use.

WARNING

Riding with a damaged track or

studs could lead to loss of control,

resulting in a risk of serious injury

or death.

26

___________

SAFETY INFORMATION

___________

Page 29

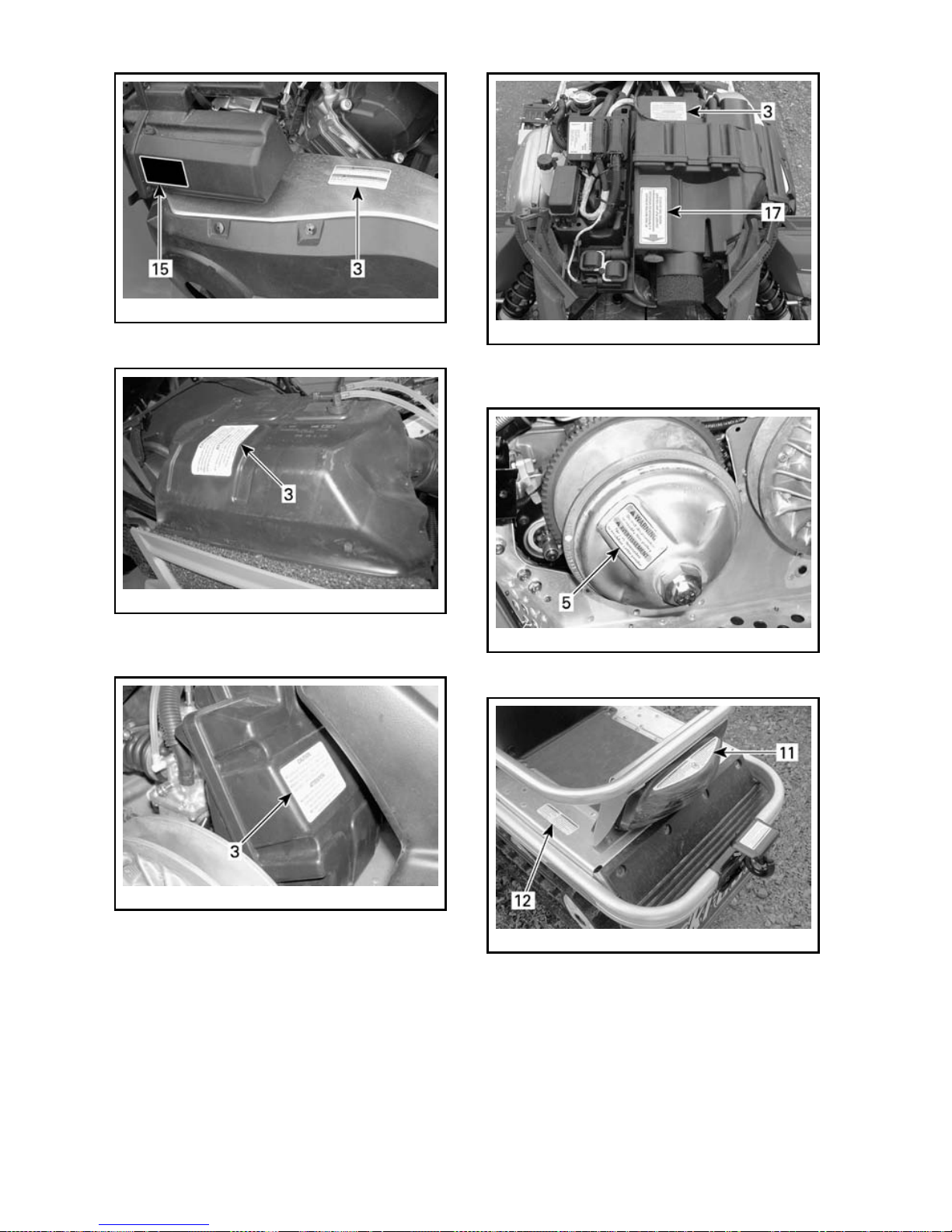

SAFETY LABELING

Safety standards for snowmobiles

have been adopted by the Snowmobile Safety and Certification Committee (SSCC) of which BRP is a proud

participating member. Assurance that

your snowmobile meets these standards is easily checked by locating the

Certification Label on a right vertical

portion of the vehicle.

This label shows that an independent

testing laboratory has verified compliance with the SSCC safety standards.

CE MODÈLE A ÉTÉ ÉVALUÉ

PAR UN LABORATOIRE

D'ESSAIS INDÉPENDANT

ET SATISFAIT TOUTES LES

NORMES DE SÉCURITÉ DU

SSCC EN VIGUEUR À LA

DATE DE FABRICATION.

PARRAINÉ PAR LE COMITÉ DE

SÉCURITÉ DE CERTIFICATION

DE LA MOTONEIGE, INC.

THIS MODEL HAS BEEN

EVALUATED BY AN INDEPENDENT TESTING LABORATORY AND IT MEETS ALL

SSCC SAFETY STANDARDS

IN EFFECT ON THE DATE OF

ITS MANUFACTURE.

SPONSORED BY THE SNOWMOBILE SAFETY AND CERTIFICATION COMMITTEE, INC.

PRINTED IN U.S.A.

CERTIFIED

CERTIFIÉ

A00A1MA

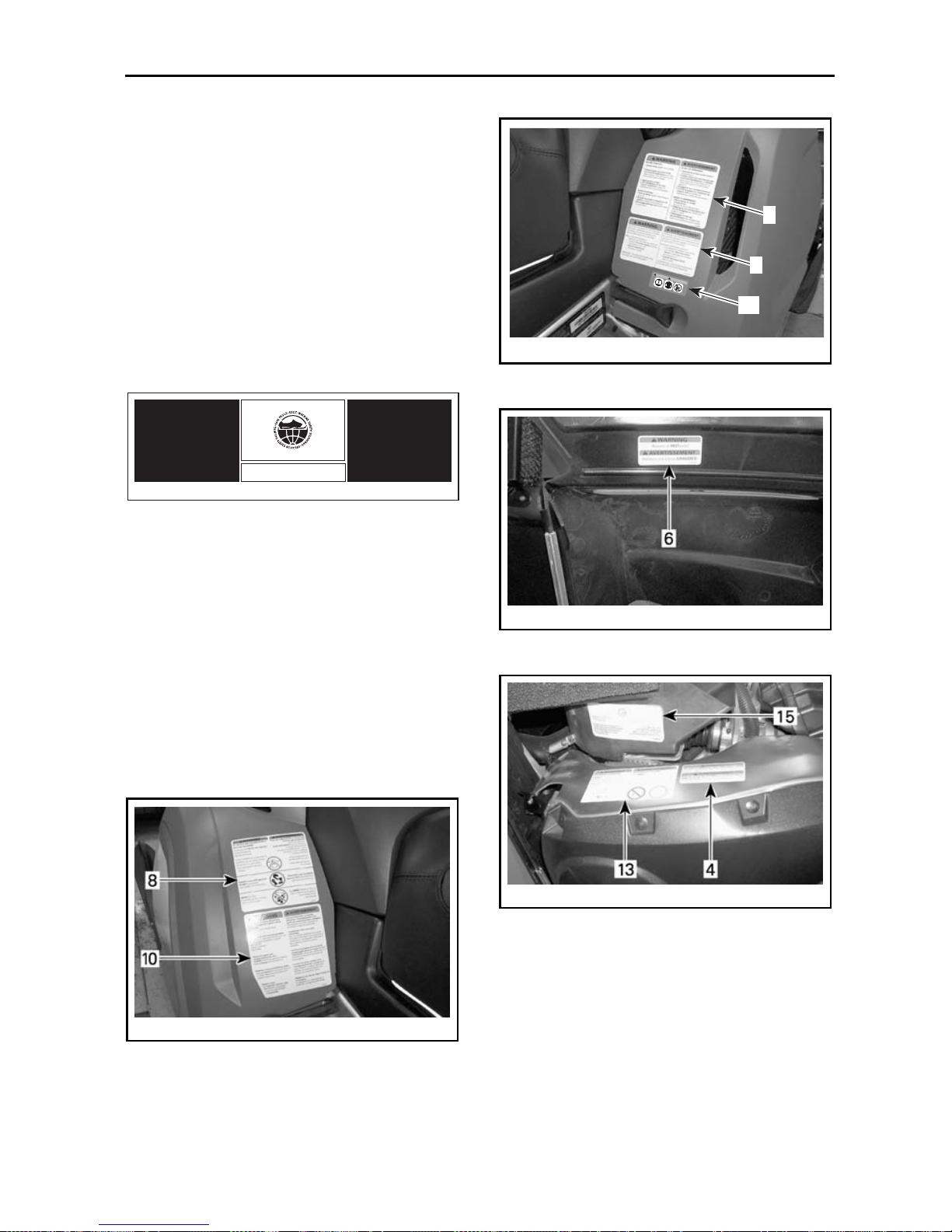

Other important labels on the vehicle

are WARNING or CAUTION labels relating to safety, maintenance and/or

snowmobile operation. Ensure all

such labeling is retained on the vehicle and its content is followed by

vehicle operator and passenger.

If missing or damaged, the decals can

be replaced. See an authorized LYNX

dealer.

Please read the following in stru ction s

carefully before operating this snowmobile.

mmo2006-004-004_a

LH SIDE PANEL

AVERTISSEMENT

WARNING

1

9

14

mmo2006-004-005_a

RH SIDE PANEL

mmo2006-004-022_a

INSIDE RH SIDE PANEL

mmo2006-004-021_a

PULLEY GUARD — FAN-COOLED

____________

SAFETY INFORMATION

___________

27

Page 30

mmo2007-003-031_a

PULLEY GUARD — LIQUID-COOLED

mmo2006-004-025_a

AIR INTAKE SILENCER (BODY SIDE) —

FAN-COO L E D

mmo2006-004-024_a

AIR INTAKE SILENCER (ENGINE SIDE) —

FAN-COO L E D

mmo2007-003-032_a

AIR INTAKE SILENCER (ENGINE SIDE) —

LIQUID-COOLED

mmo2006-004-023_a

DRIVE PULLEY — FAN-COOLED

mmo2007-003-033_a

REAR CARGO AREA — (2-UP)

28

___________

SAFETY INFORMATION

___________

Page 31

2

mmo2006-004-028_a

EUROPEAN MODELS

Instruction 1

A33A2CA

Instruction 2

mmo2007-003-034_aen

ENGLISH LABEL

mmo2007-003-034_afr

FRENCH LABEL

Instruction 3

A01A2EA

Instruction 4

Ce garde-courroie doit TOUJOURS être en place lorsque le

moteur fonctionne. Attention aux pièces en rotation _ elles

peuvent vous blesser ou capter vos vêtements.

This guard must ALWAYS be in place when engine is running.

Beware of rotating parts _ they could cause injuries or

catch your clothing.

WARNING

AVERTISSEMENT

516 002 670

A33A2FA

Instruction 5

mmo2006-003-006_a

Instruction 6

Attention aux pièces CHAUDES!

Beware of HOT parts!

516002664

A33A2GA

____________

SAFETY INFORMATION

___________

29

Page 32

Instruction 8

mmo2006-004-002

Instruction 9

A33A2KA

Instruction 10

mmo2006-004-003

Instruction 11

A33A2NA

Instruction 12

NEVER SIT IN CARGO AREA.

Exceeding maximum cargo load

may affect steering

control and braking ability.

MAXIMUM cargo load :

XX Kg /XX Lbs.

NE JAMAIS S'ASSEOIR À LA PLACE DU CARGO.

Excéder le poids maximal du cargo peut

affecter le contrôle de la

direction et la capacité de freinage.

Charge MAXIMALE cargo :

XX Kg / XX Lbs.

mmo2007-002-002

Instruction 13

A33A2PA

FAN-COO L E D MODELS

Instruction 14

AVERTISSEMENT

WARNING

mmo2006-003-007_A

EUROPEAN MODELS

30

___________

SAFETY INFORMATION

___________

Page 33

Instruction 17

This is not a storage compartment.

Do not use this space for storage purpose.

Objects put in this space can limit steering and

can cause an accident ending in injury or death.

Ceci n'est pas un espace de rangement.

Ne pas insérer d'objet dans le compartiment

avant du véhicule, car cette action peut

occasionner un blocage de la conduite pouvant

entraîner de graves blessures ou la mort.

mmo2007-003-036

Hang Tag

704901107

vmo2006-005-009_en

____________

SAFETY INFORMATION

___________

31

Page 34

32

___________

SAFETY INFORMATION

___________

Page 35

ENVIRONMENT

INFORMATION

_____________________

33

Page 36

GENERAL

Wildlife compliments your snowmobiling day. Snowmobile tracks provide

firm ground over which animals can

travel from area to area. Do not violate this privilege by chasing or harassing wildlife. Fatigue and exhaustion

can lead to animal's death. Avoid areas posted for the protection or feeding of wildlife.

If you happen to be fortunate enough

to see an animal, stop your snowmobile and observe quietly.

The guidelines that we support are

not designed to limit your snowmobiling f u n, but to preserve the beautiful freedom that you can experience

only on a snowmobile! These guidelines will keep s nowmobilers healthy,

happy and able to introduce others to

what th ey know and enjoy about their

favorite winter pastime. So, the next

time you hit the trails on a cool, crisp

and clear winter day, we ask you to remember that you are paving the way

for the future of our sport. Help us

lead it down the right path! From all

of us at BRP, thank you f or doing your

share.

There is nothing more exhilarating

than snowmobiling. Venturing onto

snowmobile trails th at criss-cross the

wild areas is an e xciting and healthy

winter sport. However, as the number of people using these recreational

parks increases, so does the potential for damage to the environment.

Abuse of land, facilities and resources

inevitably leads to restrictions and clo sures of both private and public land.

In essence, the greatest threat to our

sport, is all around us. Which leaves

us with one logical choice. When we

snowmobile, we must always rid e responsibly.

The vast majority respect the law and

the environment. Each of us must set

an example for those who are new to

the sport, young and old alike.

It is in every one's best interest to

tread ligh tly into our recreational areas.

Because, in the long run, to protect the

sportwemustpreserve the environment.

Recognizing the importance of this issueandtheneedforsnowmobilersto

do their share in preserving areas that

make it possible to enjoy our sport,

BRP has developed the “Light Treading Is Smart Sledding” campaign for

snowmobilers.

Light Treading refers to more than the

thread of our tracks. It's a statement

of concern, respect and willingne ss to

take the lead and take action. It applies to the environment in general, its

proper care and maintenance, its natural inhabitants and all enthusiasts and

the public at large w ho enjoy the great

outdoors. With this theme, we invite

all snowmobilers to remember that respecting the environment is not only

critical to the future of ou r industry but

to future generations.

Light Treading in no way suggests you

should curb your appetite for snowmobiling fun! It simply means tread with

respect!

34

______________________

Page 37

JUST WHAT IS LIGHT TREADING?

The fundamental objective of Light

Treading is one of respect for where

and how you ride a snowmobile.

You're a light treader when you follow

the principles below.

Become informed. Obtain maps,

regulations and other information

from the Forest Service or from other

public land agencies. Learn the rules

and follow them and that goes for

speed limits, too!

Avoid running over young trees,

shrubs, and grasses and don't cut

wood. On flatlands or areas where

trail riding is popular, it's important to

ride only where authorized. Remember, there is a link between protecting

your environment and your own safety.

Respect wildlife andbeparticularly

sensitive of animals that are rearing

young or suffering from food shortage. Stress can sap scarce energy reserves. Refrain from riding in areas

where only animals are intended to

tread!

Obey gate closures and regulatory

signs and remember, light treaders

don't litter!

Stay out of wilderness areas. They're

closed to all v eh icle s. Know where

the boundaries are.

Obtain permission to travel across

private land. Respect the rights of

landowners and other people's privacy. Remember, snowmobile technology has lowered the noise factor

considerably, but you still shouldn't

rev your engines where quiet “is the

order of the day”.

_____________________

35

Page 38

WHY IS LIGHT TREADING SMART

Snowmobilers know all too well the

efforts that have been made throughout the sport's history to enjoy access

to areas where people can snowmobile safely and responsibly. This effort

continues today, as strong as ever.

Respectingtheareaswhereweride...

wherever they may be... is the only way to ensure their future enjoyment. That's one major rea son why

we know you'll a gree that Light Treading Is Smart Sledding! And there are

more.

Enjoying the opportunity to see winter

and all its natural majestic wonders,

is an experience cherished by snowmobilers. Light Treading will preserve

this opportunity and will make it possible for us to expose others to the

beauty of winter and the unique thrill

of our sport! Light Treading will help

our sport to grow!

Finally, Light Treading is the sign of a

smart snowmobiler. You don't have to

leave big tracks or careen through a virgin forest to show you can ride. So

whether you're driving a high performance LYNX snowmobile, show you

know what you're doing. Show you

know how to send snow flying and

make tra cks with a light touch!

36

______________________

Page 39

VEHICLE

INFORMATION

_____________________

37

Page 40

HOW TO IDENTIFY YOUR SNOWMOBILE

Vehicle Description Decal

Vehicle description decal is located on

right hand side of tunnel.

1.

TYPICAL

1. Vehicle description decal

VEHICLE DESCRIPTION DECAL

1. Manufacturer name

2. Manufacturing date

3. Vehicle identification number (VIN)

Serial Numbers

The main components of your snowmobile (engine and frame) are identified by different serial numbers. It

may sometimes become necessary

to locate these numbers for warranty

purposes or to trace your snowmobile

in the event of loss. These numbers

are required by the authorized LYNX

dealer to complete warranty claims

properly. No w arranty will be allowed

by BRP if the engine serial number or

vehicle identification number (VIN) is

removed or mutilated in any way. We

strongly recommend that you take

note of all the serial numbers on your

snowmobile and supply them to your

insurance company.

Vehicle Identification Number

(VIN) Location

VIN is scribed on vehicle description

decal. See above. It is also engraved

on tunnel near vehicle description decal.

Model Number Location

Model number is part of vehicle identification number (VIN).

VIN DESCRIPTION

Engine Serial Number Location

mmo2007-002-008_a

FAN-COOLED — 552 ENGINE TYPE

1. Engine serial number

38

______________________

Page 41

mmo2007-001-001_a

LIQUID-COOLED — V-810 ENGINE TYPE

1. Engine serial number

_____________________

39

Page 42

CONTROLS/INSTRUMENTS/EQUIPMENT

NOTE: Some controls/instruments/equipment do not apply or are optional on

some models. In these cases their reference numbers are deliberately mis sin g

in the illustrations.

TYPICAL — 2-UP MODEL

9

14

10

7

6

1 28 2

11

4

8

13

12-32

23

22

5

mmo2007-003-039_a

TYPICAL — CONSOLE

40

______________________

Page 43

1. Speedometer

2. Tachometer

3. Pilot lamps

4. Throttle lever

5. Brake lever

6. Parking brake lever

7. Multi-function switch

8. Handlebar

9. Ignition switch

10. Tether cut-out switch

11. Engine cut-out switch

12. Rewind starter handle

13. Choke lever

14. Fuel tank cap/gauge

15. Windshield

16. Hood and side panel latches

17. Fuses

18. Front bumper/grab handle

19. Seat latch

20. Storage compartment

21. Rear rack

22. Tool kit

23. Spark plug holder

24. Spare drive belt compartment

25. Hitch

26. Shields and guards

27. Track

28. Holding strap

29. Rear grab handles

30. Adjustable mirrors

31. Backrest

32. Gear shift lever

33. Seat strap

1) Speedometer

If so Equipped

Electronic speedometer that may

show speed in km/h or MPH.

Refer to UNIT SELECTION (MPH VS

KM/H) for changing units.

2

1

4

3

mmo2006-004-046_c

FAN-COO L E D MODELS

1. Reverse (RER) pilot lamp

2. High beam pilot lamp

3. Mode button

4. Multi-function display

1

3

2

6

5

4

mmo2006-004-046_b

LIQUID COOLED MODELS

1. High beam pilot lamp

2. Mode button

3. Multi-function display

4. Engine oil pressure pilot lamp

5. Low battery voltage pilot lamp

6. Engine overheat pilot lamp

Unit Selection (MPH vs km/h)

The speedometer is factory preset in

miles but it is possible to change it to

kilometer reading, refer to the following procedure or contact an authorized

LYN X d eal er.

NOTE: Speedometer, odometer and

trip meter will have their units (kilometer or miles) changed a ll together.

Stop engine.

OpenLHandRHsidepanels.

Unplug hood harness.

Open hood.

Underneath hood, look for:

– 1 circuit male connector housing

with BLACK/GREY wire

_____________________

41

Page 44

– 1 circuit female connector housing

with YELLOW /BLACK wire.

mmo2007-003-030_a

CONNECTOR LOCATION

Plug connectors together to change

units from miles to kilometers.

Unplug to return to miles reading.

Pilot Lamps

Reverse (RER) (fan-cooled)

This pilot lamp w ill light up when reverse is selected.

High Beam

This pilot lamp will light up when headlamp is on HIGH beam.

Liquid Cooled Models Only

Low Battery Voltage

This lamp will light up to indicate a

low battery voltage condition (on so

equipped models). See an autho-

rized LYNX dealer as soon as possible.

Engine Oil Pressure

This pilot lamp will light up when engine oil pressure is too low. Stop vehicle in a safe place then, check oil level

and replenis h as described in ENGINE

OIL LEVEL.

Restartengine,oilpilotlampmustturn

off after few seconds. If oil pilot lamp

still lights up, stop engine and have lubrication system inspected by an authorized LYNX dealer.

Engine Overheat

If this lamp blinks (1 short and 1 long

beep will also be heard), the engine

is overheating, reduce snowmobile

speed and run snowmobile in loose

snow or stop engine immediately and

allow engine to cool. Check cooling

system.

Mode Button

Depress mode button to change multifunction display.

Multi-function Display

NOTE: Each time engine is started,

display shows odometer.

DEPRESS MODE BUTTON TO

CHANGE DISPLAY

ODOMETER

TRIP METER

HOURMETER

Push and hold to

RESET

Return to

Odometer

Odometer

Odometer records the total distance

travelled and displays it either in miles

or kilometers.

Trip M et er (re set able)

Records distance travelled since it has

been reset. D istan ce travelled is displayed either in miles or kilometers.

Hourmeter (resetable)

Records engine running time in hours

and minutes since it has been reset.

Pushandholdmodebuttonfor2seconds to reset the hourmeter.

42

______________________

Page 45

Multi-Function Display Code

If your speedometer shows SCALE

in the multi-function display, it means

that the display selector button is

stuck in the down position or depressed when the electrical system

was activated.