Page 1

Page 2

WARNING

Disregarding any of the safety precautions and instructions contained in

this Operator's Guide and on-product labels could cause injury including

the possibility of death!

WARNING

This vehicle may exceed the performance of other vehicles you may have

ridden in the past. Take time to familiarize yourself with your new vehicle.

OPERATOR’S MANUAL 2012

Rave RSTM600

Lynx products are manufactured by BRP.

The following are trademarks of Bombardier Recreational Products Inc. or its subsidiaries.

HPG™

RAVE™

ROTAX

®

TRA™

RS

®

Lynx

®

XPS™

The KYB Pro series is a registered mark of KYB America LLC.

fmo2012enTM

®™ and the BRP logo are trademarks of Bombardier Recreational Products Inc. or its affiliates.

©2011 Bombardier Recreational Products Inc. and BRP US Inc. All rights reserved.

Page 3

FOREWORD

Congratulations on your purchase of

anewLynx

®

snowmobile. Whatever

model you have chosen, it is backed by

the Bombardier Recreational Products

Inc. (BRP) warranty and a network of

authorized Lynx snowmobile dealers

ready to provide the parts, service or

accessories you may require.

At delivery, you were informed of the

warranty coverage and signed the

PREDELIVERY CHECK LIST

to ensure

your new vehicle was prepared to y our

entire satisfaction.

Your dealer is committed to your satisfaction. If you need more information,

please ask your dealer.

Know Before you Go

To learn how to reduce the risk for you

or bystanders being hurt or killed, read

the following sections before you operate the vehicle:

–

SAFETY INFORMATION

–

VEHICLE INFORMATION

.

Also read all safety labels on your

snowmobile.

This vehicle is designed for special purposes and may exceed provincial/state

width limitations for trail riding. Riders

must get all relevant information on local width limitations.

We highly recommend that you take

a safety riding course. Please check

with your dealer or local authorities for

availability in your area.

Failure to follo w the warnings contained in this Operator's Guide can

result in SERIO US INJURY or DEATH.

Safety Messages

The types of safety messages, what

they look like and how they are used in

this guide are explained as follows:

WARNING

Indicates a potential hazard, if not

avoided, could result in serious injury or death.

CAUTION Indicates a hazard

situation which, if not avoided,

could result in minor or moderate

injury.

NOTICE

Indicates an instruction

which, if not followed, could severely damage vehicle components

or other property.

About this Operator's

Guide

This Operator's G uide has been prepared to acquaint the owner and the

operator with this snowmobile and its

various controls, safe riding and maintenance instructions.

The following terminology in regards to

operator, passenger and vehicle configuration is used as follows throughout this guide:

– Operator: refers to the person be-

ing behind the controls and driving

the snowmobile.

– Passenger: refers to a person sit-

ting behind the operator.

– 1-UP: refers to a model designed for

an operator only.

– 2-UP: refers to a model designed to

accommodate one passenger.

Keep this Operator's Guide in the vehicle as you can refer to it for things such

as maintenance, troubleshooting and

instructing others.

Note tha t this guide is availab le in several languages. In the event of any discrepancy, the English version shall prevail.

If you want to view and/or print an extra

copy of your Operator's Guide, sim p ly

visit the following website

www.brpusersclub.com.

_______________

1

Page 4

FOREWORD

The inform atio ns contained in this document are correct at the time of publication. BRP, however, maintains a policy of continuous improvement of its

products without imposing upon itself

any obligation to install th em on products previously manufactured. Due

to late changes, some differenc es between the m a nufactured product an d

the descriptions and/or specifications

in this guide may occur. BRP reserves

the right at any time to discontinue or

change specifications, designs, features, models or equipment without

incurring any obligation upon itself.

This Operator's Guide should remain

with the vehicle when it's sold.

2

_______________

Page 5

TABLE OF CONTENTS

FOREWORD .......................................................................... 1

Know Before you Go............................................................. 1

Safety Messages................................................................. 1

About this Operator's Guide .................................................... 1

SAFETY INFORMATION

GENERAL PRECAUTIONS.......................................................... 8

Avoid Carbon Monoxide Poisoning ............................................. 8

Avoid Gasoline Fires and Other Hazards ....................................... 8

Avoid Burns from Hot Parts ..................................................... 8

Accessories and Modifications ................................................. 8

SPECIAL SAFETY MESSAGES .................................................... 9

RIDING THE VEHICLE .............................................................. 12

Pre-Ride Inspection............................................................. 12

How to Ride ..................................................................... 14

Rider Position (Reverse Operation)............................................ 15

Carrying a Passenger ........................................................... 15

Terrain/Riding Variations ........................................................ 15

Environment..................................................................... 19

IMPORTANT ON-PRODUCT LABELS ............................................ 22

Premix Fuel/Oil Ratio ........................................................... 22

VEHICLE IN FOR MATION

CONTROLS, INSTRUMENTS AND EQUIPMENT .............................. 24

1) Handlebar ..................................................................... 25

2) Throttle Lever................................................................. 25

3) Brake Lever ................................................................... 25

4) Parking Brake Lever.......................................................... 25

5) Engine Cut-off Switch........................................................ 26

6) Emergency Engine Stop Switch ............................................ 26

7) Primer Button................................................................. 27

8) Rewind Starter Handle....................................................... 27

9) Pre-Heat Switch .............................................................. 27

10) High Beam/Low Beam Switch............................................. 27

11) Heated Grips/Heated Throttle Lever Switch.............................. 27

12) Multifunction Analog/Digital Gauge ....................................... 28

13) Front and Rear Bumpers ................................................... 41

14) Drive Belt Guard............................................................. 41

15) Spare Drive BeltHolder..................................................... 42

16) Hood ......................................................................... 43

17) Side Panels .................................................................. 43

FUEL AND OIL....................................................................... 45

Recommended Fuel ............................................................ 45

_______________

3

Page 6

TABLE OF CONTENTS

FUEL AND OIL (cont’d)

Recommended Oil .............................................................. 46

Premix Fuel/Oil Ratio ........................................................... 46

BREAK-IN PERIOD.................................................................. 47

Operation During Break-In...................................................... 47

BASIC PROCEDURES .............................................................. 48

Engine Starting Procedure ..................................................... 48

Vehicle Warm-Up................................................................ 48

Shutting Off the Engine......................................................... 48

RIDING CONDITIONS AND YOUR SNOWMOBILE ............................ 49

Altitude........................................................................... 49

Temperature ..................................................................... 49

Hard Packed Snow.............................................................. 49

SPECIAL PROCEDURES ........................................................... 50

Towing Another Snowmobile .................................................. 50

Emergency Starting Procedure ................................................ 50

TUNE YOUR RIDE .................................................................. 52

Rear Suspension Adjustments................................................. 52

Front Suspension Adjustments................................................ 57

Adjustment Tips According toVehicle Behavior .............................. 59

VEHICLE TRANSPORTATION..................................................... 60

MAINTENANCE INFORMATION

BREAK-IN INSPECTION ........................................................... 62

PERIODIC MAINTENANCE CHART .............................................. 63

MAINTENANCE SCHEDULE (2-STROKE)....................................... 64

PRESEASON PREPARATION...................................................... 66

STORAGE............................................................................ 67

MAINTENANCE PROCEDURES .................................................. 68

Throttle Position Sensor (TPS) ................................................. 68

Air Filter .......................................................................... 68

Engine Coolant .................................................................. 69

Exhaust System................................................................. 69

Spark Plugs ...................................................................... 69

Engine Stopper.................................................................. 70

Brake Fluid ....................................................................... 70

Chaincase Oil .................................................................... 71

Drive Belt ........................................................................ 72

Drive Pulley ...................................................................... 74

Track.............................................................................. 76

Suspension ...................................................................... 79

Skis............................................................................... 80

Fuse .............................................................................. 80

4

_______________

Page 7

TABLE OF CONTENTS

MAINTENANCE PROCEDURES (cont’d)

Lights............................................................................. 80

VEHICLE CARE...................................................................... 83

Post-Operation Care ............................................................ 83

Vehicle Cleaning and Protection ............................................... 83

STORAGE AND PRESEASON PREPARATION .................................. 84

Storage........................................................................... 84

Preseason Preparation ......................................................... 84

TECHNICAL INFORMATION

VEHICLE IDENTIFICATION ........................................................ 86

Vehicle DescriptionDecal ...................................................... 86

Identification Numbers ......................................................... 86

EC DECLARATION OF CONFORMITY............................................ 87

SPECIFICATIONS ................................................................... 88

TROUBLESHOOTING

TECHNICAL GUIDELINES ......................................................... 92

MONITORING SYSTEM ........................................................... 94

Pilot Lamps, Messages and Beeper Codes................................... 94

Fault Codes ...................................................................... 95

WARRANTY

LIMITED WARRANTY VALIDATION.............................................. 98

BRP FINLAND OY INTERNATIONAL LIMITED WARRANTY: 2012 LYNX

®

SNOWMOBILES .................................................................... 99

CUSTOMER INFORMATION

PRIVACY INFORMATION ........................................................ 104

CHANGE OF ADDRESS/OWNERSHIP......................................... 105

_______________

5

Page 8

TABLE OF CONTENTS

6

_______________

Page 9

SAFETY

INFORMATION

________

SAFETY INFORM ATION

________

7

Page 10

GENERAL PRECAUTIONS

Avoid Carbon Monoxide

Poisoning

All engine exhaust contains carbon

monoxide, a deadly gas. Breathing carbon monoxide can cause headaches,

dizziness, d rowsiness, nausea, confusion and eventually death.

Carbon monoxide is a colorless, odorless, tasteless gas that may be present

evenifyoudonotseeorsmellanyengine exhaust. Deadly levels of carbon

monoxide can collect rapidly, and you

can quickly be overcome and unable

to save y ourself. Also, deadly levels of

carbon monoxide can linger for hours

or days in enclosed or poorly ventilated

areas. If you experience any symptoms of carbon monoxide poisoning,

leave the area immediately, get fresh

air and seek medical treatment.

To prevent serious injury or death from

carbon monoxide:

– Never run the vehicle in p oorly ven-

tilated or partially enclosed areas

such as garages, carports or barns.

Even if you try to ventilate engine

exhaust with fans or open windows

and doors, carbon monoxide can

rapidly reach dangerous levels.

– N ev er run the vehicle outdoors

where engine exhaustcanbedrawn

into a building through openings

such as windows and doors.

Avoid Gasoline Fires and

Other Hazards

Gasoline is extremely flammable and

highly explosive. Fuel vapors can

spread and be ignited by a spark or

flame many feet away from the engine. Toreduce the risk of fire or explosion, follow these instructions:

– U se only an approved gasoline con-

tainer to store fuel.

– Stric tly adhere to instructions in

FU-

ELING PROCEDURE

.

– N ever start or operate the engine if

the fuel cap is not properly installed.

Gasoline is poisonous and can cause

injury or death.

– Never siphon gasoline by mouth.

– If you swallow gasoline, get any in

your eye or inhale gasoline vapor,

see your doctor immediately.

If gasoline spills on you, wash with

soap and water and change your

clothes.

Avoid Burns from Hot Parts

The exhaust system and en gine become hot during operation. Avoid contact during and shortly after operation

to avoid burns.

Accessories and

Modifications

Do not make unauthorized modifications, or use attachments or accessories that are not approved by BRP.

Since these changes have not been

tested by BRP, they may increase the

risk of crashes or injuries, and they can

make the vehicle illegal.

Accessory passenger seats approved

by BRP and conforming to SSCC standards may be available for certain models. If such a seat is used, you must

follow the guidelines and recommendations in regards to a passenger in

this guide.

WARNING

Passenger seat must have a strap

or handholdsandmustmeetSSCC

standards.

See your authorized Lynx dealer for

available accessories for your vehicle.

8

________

SAFETY INFORM ATION

________

Page 11

SPECIAL SAFETY MESSAGES

SEVERE INJURY OR DEATH can result if you do not follow these instructions:

– Always make a pre-ride inspection BEFORE you start the engine.

– Throttle mechanism should be checkedforfreemovementandreturn to idlepo-

sition before starting engine.

– A lwa ys attach te th e r cord eye let to clothing before starting the engine.

– Never operate the engine without drive belt guard and brake disk guard securely

installed or, with hood or side panels opened or removed. Never run the engine

without drive belt installed. Running an unloaded engine such as without drive

belt or with track raised, can be dangerous.

– Always engage parking brake before starting the engine.

– Everyone is a beginner the first time he sits behind the controls of a snowmobile

regardless of previous experie nce in driving any other type of vehicle. The safe

use of your snowmobile depends on many conditions such as visibility, speed ,

weather, environment, traffic, vehicle condition and the condition of the opera-

tor.

– Basic training is required for the safe operation of any snowmobile. Study your

Operator's Guide paying particular attention to cautions and w arnings. Join

your local snowmobile club: its social activities and trail systems are planned

for both fun and safety. Obtain basic instructions from your snowmobile dealer,

friend, fellow club member or enroll in your state or provincial safety training

program.

– Any new operator must read and u nderstand all safety labels on the snowmo -

bile, the Operator's Guide before operating the snowmobile. Only allow a new

operator to op erate the snowmobile in a restricted flat a re a, a t least until he is

completely familiar with its op eration . If snowmobile operator's tra inin g course

is offered in your area, have him enroll.

– The performance of some snowmobiles may significantly exceed that of other

snowmobiles you have operated. Therefore, use by novice or inexperienced

operators is not recommended.

– Snowmobiles are used in many areas and in many snow conditions. Not all

models perform the same in similar conditions. Always consult your snowmo-

bile dealer when selecting the snowmobile model for your particular needs and

uses.

– Injury or death may result to the snowmobile operator or bystander if the snow-

mobile is used in risky conditions which are beyond the operators's or snowmo-

bile's capabilities or intended use.

– BRP recommends the operator has at least 16 years old of age.

– It is very important to inform any operator, regardless of his experience, of the

handling characteristics of this snowmobile. The snowm obile configuration,

such as ski stance, ski type, suspension type, track length, width and type vary

from a model to another. The snowmobile handling is greatly influenced by

these characteristics.

– The novice operator should become fa miliar with th e snowmobile through prac-

tice on a level area at slow speeds before venturing far afield.

________

SAFETY INFORM ATION

________

9

Page 12

SPECIAL SAFETY MESSAGES

– Know your local laws. Federal, state, provincial and local government agencies

have enacted laws and regulations pertaining to the safe use and operation of

snowmobiles. It is your responsibility as a snowmobiler to learn and obey these

laws and regulations. Respect and ob se rv ance will result in safer sno wmobiling

for a ll. Be a w a re of the liability property damages and insurance laws regardin g

your equipment.

– Speeding can be fatal. In many cases, you cannot react or respond quickly

enough to the unexpected. Always ride at a speed which is suitable to the trail,

weather conditions and your own ability. Know your lo cal rules. Spe ed limit

maybeineffectandmeanttobeobserved.

– Always keep right hand side of the trail.

– Always keep a safe distance from other snowmobiles and bystanders.

– Remember, promotional material may show risky maneuvers performed by

professional riders under ideal and/or controlled conditions. You should never

attempt any such risky maneuvers if they are beyond your le vel of riding ability.

– Never ride this vehicle under influence of alcohol or drugs. They slow reaction

time and impair judgement.

– Yoursnowmobileisnotdesigned to be operatedonpublicstreets,roadsorhigh-

ways.

– Avoid road traveling. If you must do so, and it is permitted, reduce speed. The

snowmobileisnotdesignedtooperate or turn on paving. When crossing a road,

make a full stop, then look carefully in both directions before crossing at a 90°

angle. Be wary of parked vehicles.

– Snowmobiling at night can be a delightful experien ce but because of reduce d

visibility, be extra cautious. Avoid unfam iliar terrain and be sure your lights are

working. Always carry a flashlight and spare light bulbs.

– Never remove any original equipment from your snowmobile. Each vehicle

has many built in safety features. Such features include various guards an d

consoles, plus reflective materials and safety labels.

– Nature is w onderful but don't let it distract your attention from driving. If you

want to truly appreciate winter's scenery, stop your snowmobile on the side of

the trail so that you don't become a hazard to others.

– Fences represent a very serious threat for both you and your snowmobile. Give

a wide berth to telephone poles or posts.

– Hidden wires unseen from a distance can cause serious accidents.

– Always wear an approved safety helmet, eye protection and a face shield.

– Be aware of inherent risks associated with riding off trails, such as avalanche

and other natural or m an made hazards or obstacles.

– Tailgating another snowmobile should b e avoided. If the snowmobile in front of

you slows for any reason, its operator and passenger could be harmed through

your neglect. M aintain a safe stopping distance between you and the snowmo-

bile in front of you. Depending on the terrain condition, stopping may require a

littlemorespacethanyouthink. Play it safe. Be prepared to use evasive driving.

– Venturing out alone with your snowmobile could also be hazardous. You could

run outoffuel,haveanaccident, or damageyoursnowmobile. Remember, your

snowmobile is capable of traveling further in half an hour than you may be able

to walk in a day. Use the “buddy system”. Always ride with a friend o r member

of your snowmobile club. Even then, tell someone where you are going and the

approximate time you plan to return.

10

_______

SAFETY INFORMATION

________

Page 13

SPECIAL SAFETY MESSAGES

– Mea dow s sometimes have low areas where water accumulate and freezes

over in winter. This ice is usually glare ice. Attempting to turn or brake on

this surface could caus e your vehicle to spin out of control. Never brake or

attempt speeding or turning on glare ice. If you do happen to travel over such a

condition, reduce speed by carefully releasing the throttle.

– Never “jump” with your snowmobile.

– When riding in group, do not “gun” the throttle. Snow and ice can be thrown

back into the path of a following snowmobile. In addition, when “gunning” the

throttle, the vehicle digs into and leaves an irregular snow surface for others.

– Riding in group is fun and enjoyable but don't show off or overtake others in the

group. A less experienced operator might try to do the sam e as you and fail.

When riding with others, limit your abilities to the experience of others .

– In case of an emergency, press down on the engine emergency stop switch,

then apply brake .

– A lways engage parking brake when veh icle is n ot in use.

– Never run the engine in a non-ventilatedarea and/or if vehicle is left unattended.

– Ensure the path behind is clear of obstacles or bystanders before proceeding in

reverse.

– Always remove the tether cord cap from engine cut-off switch when vehicle is

not in operation in order to prevent accidental engine starting, to avoid unautho-

rized use by children or others or theft.

– NEVER stand behind or near a rotating track. Debris could be projected causing

severe injuries. Toremovepackedsnow or ice, stop engine, tilt and hold vehicle

on its side and use screwdriver.

– Do not stud the track unless it has been approvedforstuds. At speed, a studded

track that has not been approved for studs could tear and separate from vehicle.

See an authorized Lynx dealer for current specific studding availability and appli-

cations.

– You may stud the track on this vehicle model. However,you MUST only use the

BRPapprovedtypestudforuseonLynxsnowmobiles. DONOTEVERusecon-

ventional studs because the track thickness is thinner then our standard tracks.

The stud could tear off of track and separate from vehicle.

– Always wear an approved helmet and follow the same dressing guidelines as

those recommended for the operator and described in this guide.

– M ake sure that you are able to achieve a stable stance, both feet resting posi-

tively on the footboards of footrests with good grip, and that you are able to hold

on firmly to the handholds.

– Do not forget, with 2-UP models, theoperatorisresponsible for the safetyofthe

passenger. A lw ays remember that the snowm ob ile handling, s tability and brak-

ing distance may be affected when riding with a passenger.

– B efore riding the vehic le, ask your passenger to inform you to slow d own or

stop immediately if he feels uncomfortable or insecure during the ride. Keep a

watchful eye on your passenger while riding.

________

SAFETY INFORMATION

________

11

Page 14

RIDING THE VEHICLE

Each op erator has a responsibility to

ensure the safety of other recre ation ists or bystanders.

You are responsible for proper operation of your vehicle as well as training

thosewhomyouallowtorideordrive.

There may be noticeable handling and

performance differences from one

snowmobile to the ot her.

A snowmobile is relatively simple to

operate b ut like any other ve h icle or

mechanical equipment, it ca n be hazardous if you are reckless, thoughtless

or inattentive. We encourage you to

have an Annual Safety Inspection of

your snowmobile. Please contact an

authorized Lynx dealer for further details. Fin ally, we urge you to v isit an

authorized Lynx dealer pe riod ically for

regular and safety maintenance, as

well as snowmobile accessories you

may require.

Before venturing on the trails, operate

the sn owmobile in a restricted flat area

until you are complete ly familiar with

its operation and feel comfortable that

you can safely tackle a more demanding task. Have an enjoyable and safe

ride.

Pre-Ride Inspection

WARNING

The pre-operation check is very

important prior to operating the

vehicle. Always check the proper

operation of critical controls,

safety features and mechanical

components before starting.

Before Starting the Engine

1. Remove snow and ice from body including lights, seat, footrests, controls and instruments.

2. Verifythatairsilencer prefilterisfree

of snow.

3. Verify that skis and steering operate

freely. Check corresponding action

of skis versus handlebar.

4. Check fuel level. Replenish if necessary.

5. Check coolant and brake fluid levels.

In case of a low level, contact an authorized Lynx dealer.

6. All storage compartments must be

properly latched and they must not

contain any heavy or breakable objects. Hood and side panels must

be also properly latched.

7. Check track condition. Remove

snow or ice if necessary.

8. Check rear suspension slider shoes

condition.

9. Activate the throttle control le ver

several times to check that it operates easily and smoothly. It must return to idle position when released.

10. Activat e the brake lever and make

sure the brake fully applies be f ore

the brake control lever touches the

handlebar grip. It must return to

the rest position when released.

11. Apply parking brake and check if it

operates properly. Leave parking

brake applied.

12

_______

SAFETY INFORMATION

________

Page 15

RIDING THE VEHICLE

After Engine is Started

For proper engine starting procedure,

refer to the

ENGINE STARTING PRO-

CEDURE

section.

1. Check headlights high beam and

low beam, taillight, stop light and

pilot lamps operation.

NOTE: You may need to detach tether

cord from your clothes to check lights.

In such a case, attac h cord as soon

as you get back at the controls of the

snowmobile.

2. Check the engine cut-off switch (by

pulling teth er cord cap) and emergency engine stop switch operation.

3. Release parking brake.

4. Refer to the

VEHICLE WARM UP

section and follow instructions.

Pre-Ride Check List

ITEM OPERATION

✔

Body including seat, footrests,

lights, controls and instruments

Check condition and remove snow or ice.

Air silencer prefilter

Check condition and remove snow or ice.

Steering system Check for free movement and proper action.

Skis and runners Check condition.

Fuel

Check level and replenish if necessary.

Coolant

Check level. If low, contact an authorized Lynx

dealer.

Brake fluid

Check level. A low fluid level indicates a leak or

worn brake pads. Contact an authorized Lynx

dealer.

Storage compartment

Check for proper latching an d no heavy or

breakable objects.

Throttle lever

Check for proper action.

Track

Check condition and remove snow or ice.

Rear suspension slider shoes

Check condition.

Brake lever

Check for proper operation.

Parking device

Check for proper operation.

Emergency engine stop switch

and e ngine cut-off switch

Check for proper action. Tether cord must be

attached to operator clothing eyelet.

Lights

Check for proper operation.

________

SAFETY INFORMATION

________

13

Page 16

RIDING THE VEHICLE

How to Ride

Riding Gear

Proper snowmobile clothing should

be worn. It should be comfortable

andnottootight. Alwayscheckthe

weather forecast before going on a

ride. Dress for the coldest weather

expected. Thermal underwear next to

theskinalsoprovidesagoodinsulation.

Wear an approved helmet at all times

for safety and comfort. They provide both warmth and reduce injury.

A stocking type cap, balaclava and

face mask should always be carried

or worn. Goggles or a face shield that

attach to the helmet are indispensable.

Carry colored lens if your helmet is not

equipped so.

Hands should be protected by a pair

of snowmobile gloves or mitts which

have sufficient insula tio n and allow use

of thumbs and fingers for operation of

controls.

Rubber bottom boots with either a nylon or a leather top, with removable felt

liners are best suited for snowmobiling.

You should keep yourself as dry a s possible when snowmobiling. When you

come indoors, take your snow mobile

suit and boots off and make c ertain

they dry properly.

Do not wear long scarfs and loose apparels that could get caught in moving

parts.

What to Bring

First aid kit Mobile phone

Knife

Spare spark plugs

Flashlight Friction tape

Trail map

Spare drive belt

Snack

Toolkit

Rider Position (Forward Operation)

Your riding pos ition and b alance are

the two basic principles of making you r

snowmobile go where you want it to.

When turning on the side of a hill, you

must be ready to shift body weight to

help it turn in the desired direction. You

must never attempt this maneuvering

by placing feet outside of the vehicle. Experience will teach you how

much lean to put into turns at differ en t

speeds and how much you will have

to lean into a slope to maintain proper

balance.

Generally, the riding position for best

balance and control is sitting. However, the posting, kneeling or standing

positions are also used under certain

conditions.

WARNING

Do not attempt any maneuvers if

they are beyond your abilities.

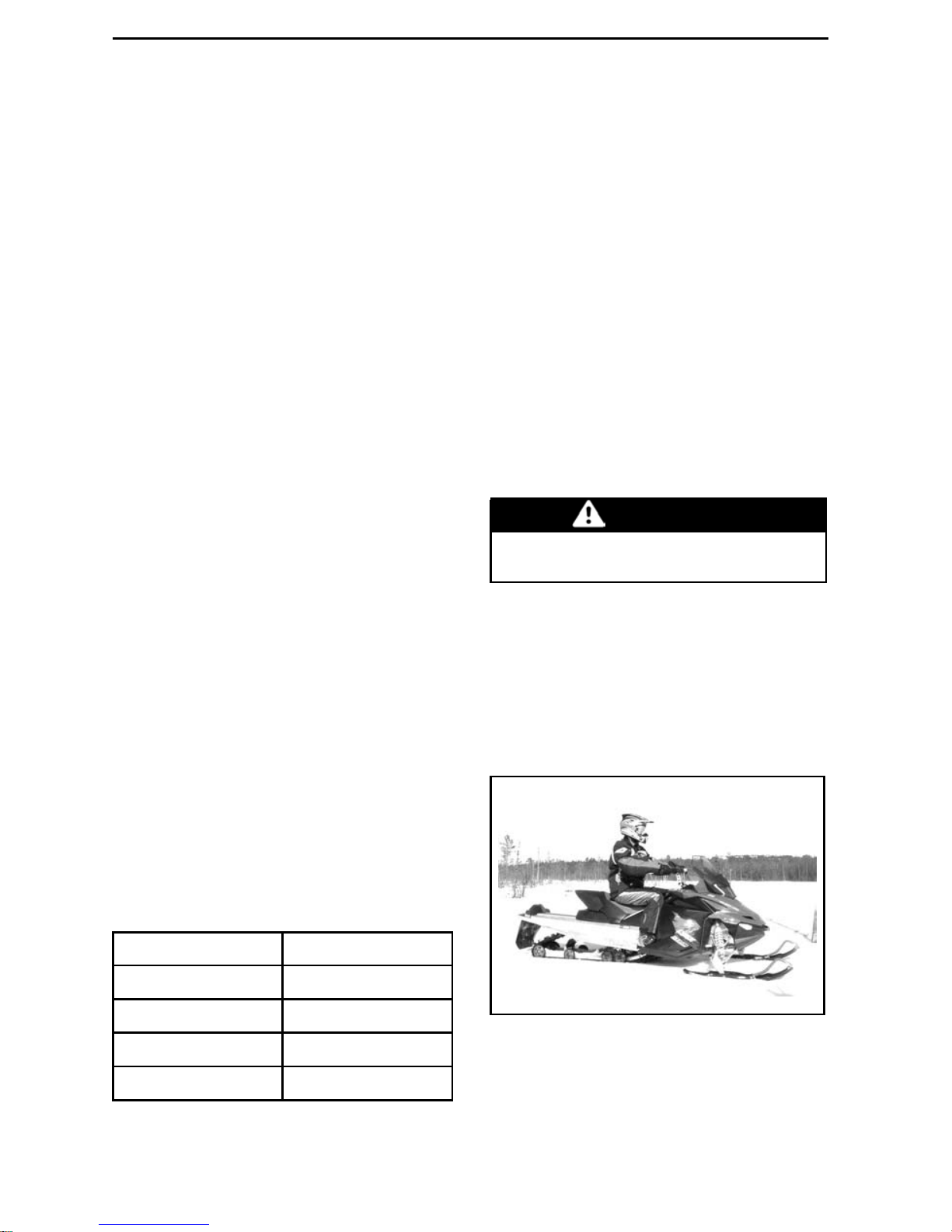

Sitting

Feet on the running boards, body midway back on seat is an ideal position

when operating the snowmobile over

familiar, smooth terrain. Knees and

hips should remain flexible to absorb

shocks.

fmo2008-003-001

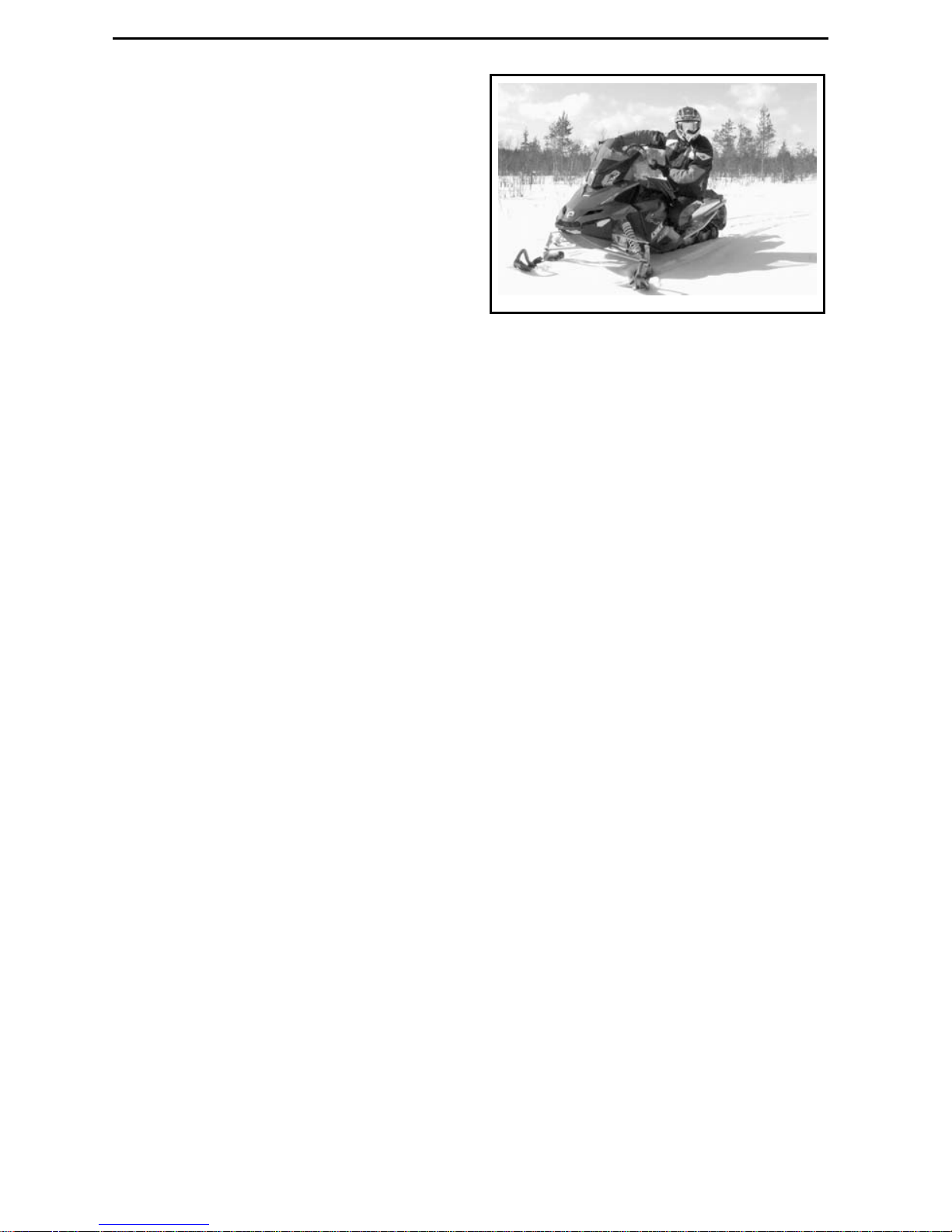

Posting

A semi-sitting position with the body

off the seat and thefeetunderthebody

in a sort of squatting posture, thus al-

14

_______

SAFETY INFORMATION

________

Page 17

RIDING THE VEHICLE

lowing the legs to absorb the shocks

when traveling over uneven terrain.

Avoid abrupt stops.

fmo2008-003-002

Kneeling

This position is achieve d by placing

one foot firmly on the running board

and the opposite knee on the seat.

Avoid abrupt stops.

fmo2008-003-003

Standing

Place both feet on the running boards.

Knees should be flexed to absorb the

shock from surface bumps. This is an

effective position to see better and

to shift weight as conditions dictate.

Avoid abrupt stop.

fmo2008-003-004

Rider Position (Reverse

Operation)

We recommend sitting on your snowmobile when operating in reverse.

Avoid standing up. Your weight could

shift forward against throttle lever

while o perating in reverse, causing

an unexpected acceleration.

WARNING

Unexpected acceleration when

snowmobile operates in reverse

can cause a loss of control.

Carrying a Passenger

Certain snowmobiles are designed for

an operator only (1-UP), and others can

allow one passenger only (2-UP). Make

sure to identify and respect the warnings according to your specific models.

Even when a passenger is allowed,

this person must b e physically fit for

snowmobiling.

Terrain/Riding Variations

Groomed Trail

On a maintained trail, sitting is the

most preferred riding position. Do not

race and, above all, keep to the right

hand side of the trail. Be prepared

for the unexpected. Observe all trail

signs. Do not zigzag from one side of

the trail to the other.

________

SAFETY INFORMATION

________

15

Page 18

RIDING THE VEHICLE

Ungroomed Trail

Unless there has been a fresh snowfall you can expect “washboard” and

snowdrift conditions. Taken at excessive speeds, such conditions can be

physically harmful. Slow down. Hold

on the handlebar and assume a posting position. Feet should be under the

body assuming a crouched position to

absorb any jarring effect. On longer

stretches of “washboard” trails, the

kneeling position of one knee on the

seat can be adopted. This provides a

certain amount of comfort, while at the

same time keeps the body loose and

capable of vehicle control. Beware of

hidden rocks or tree stumps partially

hidden by a recent snowfall.

Deep Snow

In deep “powder” snow, your vehicle

could begin to “bog” down. If this occurs,turninaswideanarcaspossible

and look for a firmer base. If you do get

“bogged”, and it happens to everyone,

do not spin your track as this makes the

vehicle sink deeper. Instead, turn the

engine off, get off and move the back

of the vehicle onto new snow. Then

tramp a clear path ahead of the vehicle. A few feet will generally suffice.

Restart the engine. Assume the standing position and rock the vehicle gently

as you steadily and slowly apply th e

throttle. Depending on whether the

front or rear end of the vehicle is sinking, your feet should be placed on the

opposing end of the running boards.

Never place foreign material beneath

the track for support. Do not allow anyone to stand in front of, or to the rear

of, the snowmobile with the engine

running. Stay away from the track.

Personal injury will result if co ntact is

made with the revolving track.

Frozen Water

Traveling frozen lakes and riv ers can be

fatal. Avoid waterways. If you are in

an unfamiliar area, ask the local authorities or residents about the ice condi-

tion, inlets, outlets, springs, fast moving currents or other hazards. Never

attempt to operate your snowmobile

on ice that may be too weak to support you and the vehicle. Operating

a snow m obile on ice or icy surfaces

can be very dangerous if you do not

observe certain precautions. The very

nature of ice is foreign to good control of a snowmobile or any vehicle.

Traction for starting, turning or sto pping is much less than that on snow.

Thus, these distances can be multiplied manyfold. Steering is minimal,

and u ncontrolled spins are an ever

present danger. When operating on

ice, drive slowly with caution. Allow

yourself plenty of room for stopping

and turning. This is especially true at

night.

Hard Packed Snow

Don't underestimate hard packed

snow. It can be difficult to negotiate

as both skis and track do not have as

much traction. Best advice is to slow

down and avoid rapid acceleration,

turning or braking.

Uphill

There are two types of hills you can en counter — the open hill on which there

are few trees, cliffs or other obstacles,

and a hill that can only be climbed directly. On an op en hill, the approach is

to climb it by side hilling or slaloming.

Approachatanangle. Adopt a kneeling

position. Keep your weight on the uphill side at all times. Maintain a steady,

safe speed. Continue as far as you can

in this directio n, then switch to a n opposite hill angle and riding position.

A direct climb could present problems.

Choose the standing position, a ccelerate before you start the climb and then

reduce throttle pressure to prevent

track slippage.

In either case, vehicle speed should be

as fast as the incline demands. Always

slow down as you reach the crest. If

you cannot proceed further, don't spin

16

_______

SAFETY INFORMATION

________

Page 19

RIDING THE VEHICLE

your track. Turn the engine off, free the

skis by pulling them out and downhill,

place the rear of the snowmobile uphill

restart the engine and ease it out with

slow even throttle pressure. Positio n

yourself to avoid tipping over, then descend.

Downhill

Downhill driving requires that you have

full control of your vehicle at all tim es.

On steeper hills, keep your center of

gravity low and both hands on the handlebar. Maintain slight throttle pressure and allow the machine to run

downhill with the engine operating.

If a higher than safe speed is reached,

slow down by braking but apply the

brake with frequent light pressure.

Never jam the brake and lock the track.

Side Hill

When crossing a side hill or traversing up o r downhill, certain procedures

must be followed. All riders should

lean towards the slope as required for

stability. The pre ferre d operating positions are the kneeling position, with

thekneeofthedownhilllegonthe

seat and the foot of the uphill leg on

the running board, or the posting position. Be prepared to shift your weight

quickly as need ed. Side hills and steep

slopes are not recommended for a beginner or a novice snowmobiler.

Slush

Slush should be avoided at all times.

Always check for slush before starting

across any lake or river. If dark spots

appearinyourtracks,getofftheice

immediately. Ice and water can be

thrown rearward into the path of a following snowmobile. Getting a vehicle

out of a slush area is strenuous and in

some cases, impossible.

Fog or Whiteout Conditions

On land or water, fog or visibility-limiting snow can form. If you have to

proceed into the fog or heavy snow, do

so slowly with your lights on and watch

intently for hazards. If you are not sure

of your way, do not proceed. Keep a

safe distance behind other snowmobilers to improve visibility and reaction

time.

Unfamiliar Territory

Whenever you enter an area that is

new to you, drive with extreme caution. Go slow enough to recognize

potential hazards such as fences or

fence posts, brooks crossing your

path, rocks, sudden dips, guy wires

and cou ntless other obstacles which

could result in a termination of your

snowmobile ride. Even when following existing tracks, be cautious.

Travel at a speed so you can see what

is around the next bend or over the top

of the hill.

Bright Sunshine

Bright sunny days can considerably

reduce your vision. The glare from

sun and snow may blind you to the extent that you cannot eas ily distinguish

ravines, ditches or other obstacles.

Goggles with colored lenses should always be worn under these conditions.

Unseen Obstruction

There may be obstructions hidden

beneath the s now. Driving off established trails and in the woods requires reduced speed and increased

vigilance. Driving too fast in an area

can make even minor obstacles very

hazardous. Even hitting a small rock

or stump could throw your snowmobile out of control and cause injury to

its riders. Stay on established trails

to reduce your exposure to hazards.

Be safe, slow down and enjo y the

scenery.

Hidden Wires

Always be on the lookout for hidden

wires, especially in areas that may

have been farmed at one time or another. Too many accidents have been

________

SAFETY INFORMATION

________

17

Page 20

RIDING THE VEHICLE

caused by running into wires in the

fields, guy wires next to poles and

roads, and into chains and wires used

as road closures. Slow speeds are a

must.

Obstacles a nd Jumping

Unplanned jumps of snowdrifts, snowplow ridges, culverts or indistinguishable objects can be dangerous. You

can avoid them by wea rin g the proper

color lenses or face shields and by operating at a lower speed.

Jumping a snowmobile is an unsafe

and dangerous practice. However, if

the trail does suddenly drop away from

you, crouch (stand) towards the rear

ofthevehicleandkeeptheskisup

and straight ahead. Apply pa rtial throttle and brace yourself for the impact.

Knees must be flexed to act as shock

absorbers.

Tur ning

Depending on terrain conditions, there

are two preferred ways to turn or corner a snowmobile. For most snow

surfaces, “body english” is the key to

turning. Leaning towards the inside of

the turn and positioning body weight

on the inside foot will create a “banking” condition ben eath the track. By

adopting this position and positioning

yourself as far forwa rd as possible,

weight will be transferred to the inside

ski.

On occasion, you will find that the only

way to turn the vehicle about in deep

snow is to pull the snowmobile around.

Do not over-exert yourself. Get ass istance. Remember to always lift u sing

your legs as opposed to your back.

fmo2008-003-005

Road Crossing

In some cases, you will be approaching the road from a ditch or snowbank.

Choose a place where you know you

can climb without difficu lty. Use the

standing position and proceed with

only as much speed needed to crest

the bank. Stop completely at the top

of the bank and wait for all traffic to

clear. Judgethedroptotheroadway.

Cross the road at a 90° angle. If you encounter another snowbank on the opposite side, position your feet near the

rear of the vehicle. Remember, your

snowmobile is not designed to operate on bare pavement and steering on

this type of surface is more difficult.

Railroad Crossing

Never rid e on railroad tracks. It is illegal. Railroad trac ks and railroad

rights-of-way are private property. A

snowmobile is no match for a train.

Before crossing a railroad track, stop,

look and listen.

Night Rides

The amount of natural and artificial

light at a given time can affect your

ability to se e or to be seen. Nig httime

snowmobiling is delightful. It can be

a unique experie nce if you ackn owledge your reduced visibility. Before

you start, make certain your lights

are clean and work properly. Drive

at speeds that will allow you to stop

in time when you see an unknown or

dangerous object ahead. Stay on established trails and never operate in

18

_______

SAFETY INFORMATION

________

Page 21

RIDING THE VEHICLE

unfamiliar territory. Avoid rivers and

lakes. Guy wires, barbed wire fences,

cabled road entrances and other objects such as tree limbs are difficult

to see at night. Never drive alone. Always carry a flashlight. Keep away

from residential areas and respect the

right of others to sleep.

Group Riding

Before starting out, designate a “trail

boss” to lead the party and another person to follow-up at the end of the party.

Ensure that all members of the party

are aware of the proposed route and

destination. Make certain that you are

carrying all necessary tools and equipment and that you have sufficient fuel

to complete the trip. Never overtake

the trail boss or, for that matter, any

other snowmobile. Use down-the-line

hand signals to indicate hazards or intent of direction change. Assist others

whenever necessary.

ItisalwaysIMPORTANTtokeepa

safe distance between each snowmobile. Always maintain a safe interval

and allow sufficient stopping distance.

Don't be a tailgater. Know the position

of the machine ahead.

Signals

Ifyouintendtostop,raiseeitherhand

straight above your head. A left turn is

indicated by extending your left hand

straight out in the proper direction. For

right turns, extend the left arm and

raise the hand to a vertical position so it

forms a rig ht angle at the elbow. Every

snowmobiler should relay any signal to

the ones behind.

Trail Stops

Whenever possible, pull off the trail

when you stop. This will reduce the

hazard to other snowmobilers using

the trail.

Trails and Signs

Trail signs are used to control, direct or

regulate the use of snowmobiles on

trails. Become familiar with all signs

used in the area where you are snowmobiling.

Environment

Wildlife compliments yo ur snowmobiling day. Snowmobile tracks p rovide

firm ground o ver which animals can

travel from area to area. Do not violate

this privilege by chasing or harassing

wildlife. Fatigue and exhaustion can

lead to animal's death. Avoid areas

posted for the protection or feeding of

wildlife.

If you happen to be fortunate enough

to see an animal, stop your snowmobile and observe quietly.

The guidelines that we support are not

designed to limit your sno wmobiling

fun, but to preserve the beautiful freedom that you can experience only on

a snowmobile! These guidelines will

keep snowmobilershealthy,happyand

able to introduce others to what they

know and enjoy about their favorite

winter pastime. So, the next time you

hit the trails on a cool, crisp and clear

winter day, we ask you to remember

that you are paving the way for the future of our sport. Help us lead it down

the right path ! From all of us at BRP,

thank y ou for doing your share.

There is nothing more exhilarating than

snowmobiling. Venturing onto snowmobile trails that criss-cross wild areas

is an exciting and healthy winter sport.

However, as the number of people using these recreational parks increases,

so does the potential for damage to the

environment. Abuse of land, facilities

and resources inevitably leads to restrictions and closures of both private

and public land.

________

SAFETY INFORMATION

________

19

Page 22

RIDING THE VEHICLE

In es sence, the greatest threat to our

sport, is all around us. Which leaves

us with one logical choice. When we

snowmobile, we must always ride responsibly.

The vast majority respect the law and

the environment. Each of us must set

an example for those who are new to

the sport, young and old alike.

It is in every one's best inte re st to tread

lightly into our recreational areas. Because, in the long run, to protect the

sport we must preserve the environment.

Recognizing the importance of this issueandtheneedforsnowmobilersto

do their share in preserving areas that

make it possible to enjoy our sport,

BRP has developed the “Light Treading Is Smart Sledding” campaign for

snowmobilers.

Light Treading refers to more than the

thread of our trac ks. It's a statement

of concern, respect and willingness

to take the lead and take action. I t applies to the environment in general, its

proper care and maintenance, its natural inhabitants and all enthusiasts and

the public at large who enjoy the great

outdoors. With this theme, we invite

all snowmobilers to remember that respecting the environment is not only

critical to the future of our industry but

to future generations.

Light Treading in no way suggests you

should curb your appetite for snowmobiling fun! It simply me an s tread with

respect!

The fundamental ob je ctive of Light

Treading is one of respect for where

and how you ride a snowmobile.

You're a light treader when you follow

the principles below.

Become informed. Obtain maps, regulations and other information from

the Forest Service or from other public land agencies. Learn the rules and

follow them and that goes for spee d

limits, too!

Avoid running over young trees,

shrubs, and grasses and don't cut

wood. On flatlands or areas where trail

riding is popular, it's important to ride

only where authorized. Remember,

there is a link between protecting your

environment and your own safety.

Respect wild life and be particularly

sensitive o f animals that are rearing

young or suffering from food shortage.

Stress can sap scarce energy res erves.

Refrainfromridinginareaswhereonly

animals are intended to tread!

Obey gate closures and regulatory

signs and remember, light treaders

don't litter!

Stay out of wilderness areas. They're

closed to all vehicles. Know where the

boundaries are.

Obtain permission to travel across

private land. Respect the rights of

landowners and other people's privacy. Remember, snowmobile technology has lowered the noise factor

considerably, but you still shouldn't rev

your engines where quiet “is the order

of the day”.

Snowmobilers know all too well the efforts that have been made throughout

the sport's history to enjoy access to

areas where people can snowmobile

safely and responsibly. This effort continues today, as strong as ever.

Respectingtheareaswhereweride...

wherever they may be... is the only

way to ensure their future enjoyment.

That's one major reason why we know

you'll agree that Light Treadingissmart

sledding! And ther e are m ore.

Enjoying the opportunity to see winter

and all its natural majestic wonders,

is an experience cherished by snowmobilers. Light Treading will preserve

this opportunity and w ill make it possible for us to expose others to the

beauty of winter and the unique thrill of

our sport! Light Treading will help our

sport to grow!

20

_______

SAFETY INFORMATION

________

Page 23

RIDING THE VEHICLE

Finally, Light Treading is the sign of a

smart snowmobiler. You don't have

to leave big tracks or careen through a

virgin forest to show you can ride. So

whether you're driving a high performanceLynx, a sporty RAVE

®

snowmobile or any other make or model, show

you know what you're doing. Show

you know how to send snow flying and

make tracks with a light touch!

________

SAFETY INFORMATION

________

21

Page 24

IMPORTANT ON-PRODUCT LABELS

Premix Fuel/Oil Ratio

NOTICE

Warning label on the vehicle

NOTICE

Fuel / oil label on the vehi-

cle

22

_______

SAFETY INFORMATION

________

Page 25

VEHICLE

INFORMATION

_______________

23

Page 26

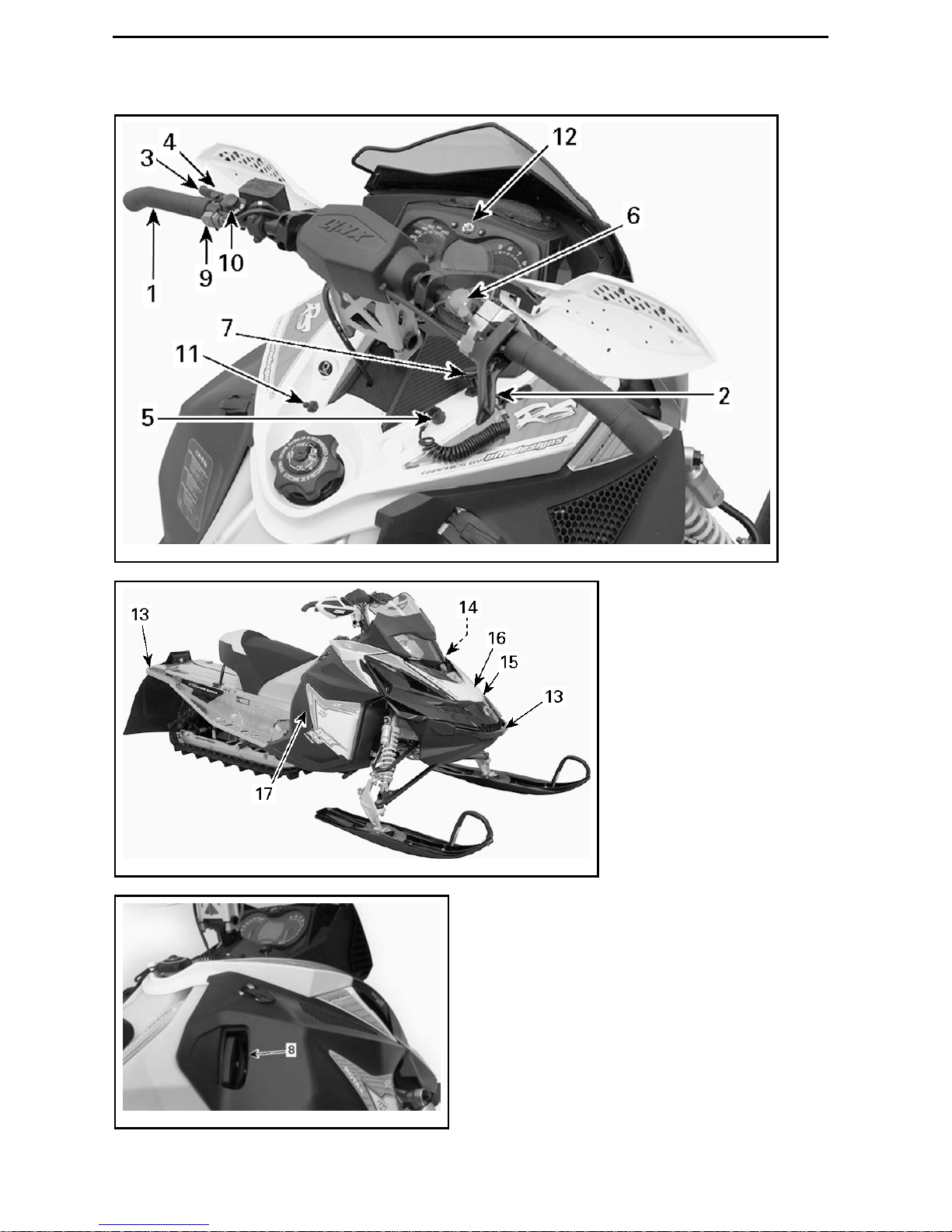

CONTROLS, INSTRUMENTS AND EQUIPMENT

fmo2011-007-007_c

fmo2011-007-010_d

fmo2011-007-011_a

24

______________

Page 27

CONTROLS, INSTRUMENTS AND EQUIPMENT

1) Handlebar

The handlebar controls the steering

of the snowmobile. As the handlebar

is rotated to right or left, the skis are

turned right or left to steer the snowmobile.

2) Throttle Lever

Throttle lever is located on the RH side

of handlebar.

Designed to be thumb activated.

When squeezed, it increases the engine speed and engages the transmission. When released, engine speed

returns automatically to idle.

WARNING

Test the throttle lever operation

each time before starting the engine. The lever must return to its

original position once released.

Otherwise, do not start engine.

3) Brake Lever

Brake lever is located on the LH side of

handlebar.

When squeezed, brake is applied.

When released, it autom atically returns to its original position. Braking

effect is proportional to the pressure

appliedontheleverandtothetypeof

terrain and its snow coverage.

4) Parking Brake Lever

Parking brake is located on the LH side

of handlebar.

Parking brake should be used whenever snowmobile is parked.

WARNING

Make sure parking brake is fully

disengaged before operating the

snowmobile. When you ride the

vehicle, brake pads that are caused

to drag by a continuous pressure

on the lever may cause damage to

the brake system and cause loss of

braking capacity and/or fire.

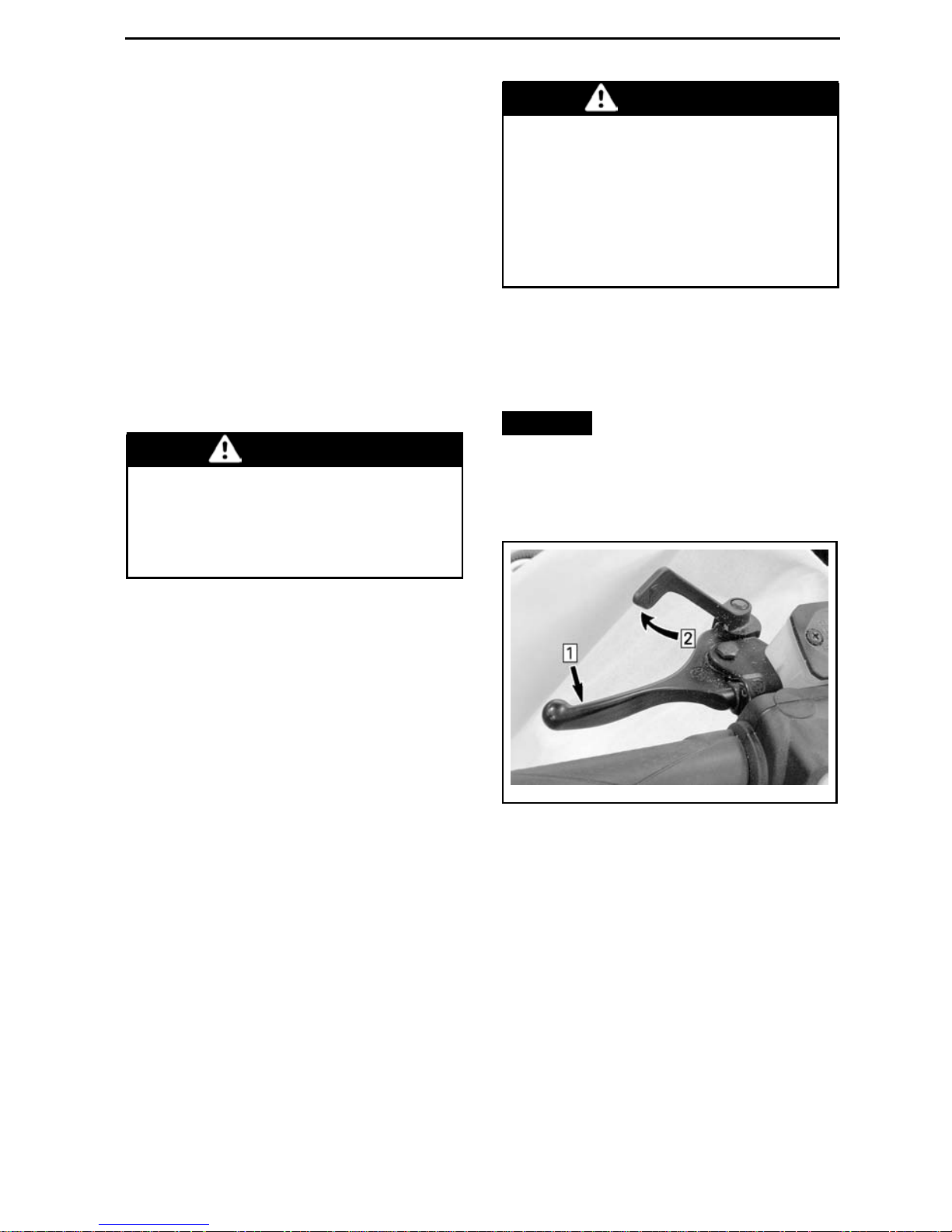

To Engage Parking Brake

Apply and hold brake, then lock brake

lever using the p arking brake lever as

shown.

NOTICE

Parking brake position

can vary depending on brake pads

wear. Ensure when the parking

brake is applied that the vehicle

stays securely in place.

mmo2009-005-006_a

TYPICAL — ENGAGE MECHANISM

Step 1: Apply and hold brake

Step 2: Lock brake lever using parking brake

lever

To Release Parking Brake

Squeeze brake lever. Locking lever will

automatically re turn to its original position. Always release parking brake before riding.

_______________

25

Page 28

CONTROLS, INSTRUMENTS AND EQUIPMENT

mmo2008-007-011_b

TYPICAL — RELEASE MECHANISM

Step 1: Squeeze brake lever

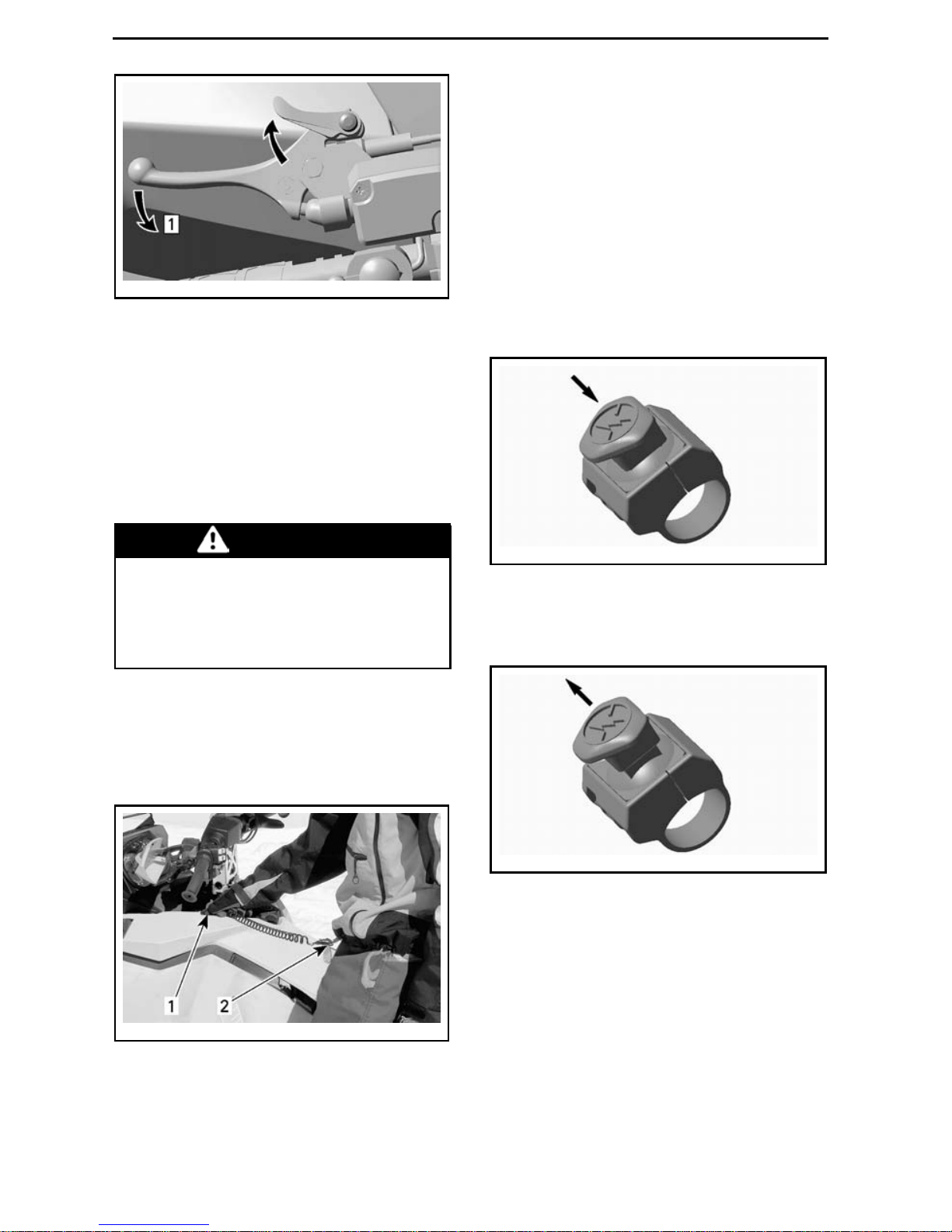

5) Engine Cut-off Switch

General

When the tether cord cap is removed,

it shuts the engine off preventing

snowmobile to runaway if the operator falls off the vehicle accidently.

WARNING

Always remove the tether cord cap

when vehicle is not in operation in

order to prevent accidental engine

starting, to avoid unauthorized use

bychildrenorothersortheft.

Operation

Attach tether cord eyelet to clothing,

then snap cap over post before starting

engine.

mmo2008-003-012_a

TYPICAL

1. Snap over post

2. Attach to clothing

If emergency engine shut off is required, pull tether cord cap from post

completely.

6) E m ergen cy Engine

Stop Switch

The emergency engine stop switch is

located on the RH side of handlebar.

To stop the engine in an emergency,

select OFF position (down) and simultaneously apply the brake.

mmo2007-009-038_a

OFF POSITION

To allow eng ine starting , the switch

must be in the ON position (UP).

mmo2007-009-038_b

ON POSITION

All operators of the snowmobile

should familiarize themselves with the

function of this device by using it several times on first outing and whenever

stopping the engine thereafter. This

engine shut off procedure will become

a reflex and will prepare operators for

emergency situations requiringits use.

26

______________

Page 29

CONTROLS, INSTRUMENTS AND EQUIPMENT

WARNING

If the switch has been used in an

emergency caused by a suspected

malfunction, the source of the malfunction should be determined

and corrected before restarting

engine. See an authorized Lynx

dealer for servicing.

7) Primer Button

Pull and push button. It is not necessary when engine is warm.

To prime, activate button until a pumping resistance is felt. From this point,

pump 2 or 3 times to in je ct fue l in intake manifold. After priming, ensure

that primer button is pushed back.

NOTE: In very cold temperature, it is

recommended to rotate primer button

3 - 4 turns prio r to pulling it. Th is will

eliminate the possibility of sticking.

8) Rewind Starter Handle

Auto-rewind type located on right hand

side of snowmobile. To engage mechanism, pull handle slowly until a resistance is felt then pull vigorously.

Slowly release handle.

9) Pre-Heat Switch

Racing Application Only

NOTE: This switch must be removed

on vehicles modified for warranty validation.

1

A33E0SA

2

1. Button depressed: Pre-heat timing curve

2. Button released: Normal tim ing curve

After starting the engine, push and

hold the pre-heat switch button in order to pre-heat the tuned pipe.

Release pre-heat switch button once

the tuned is pre-heated.

10) High Beam/Low B eam

Switch

Allows selection of headlamp high

beam or low beam.

1

2

mmo2006-007-002_a

1. Low beam

2. High beam

11) Heated Grips/Heated

Throttle Lever Switch

Select the desired position to keep

your hands and thumb at a comfortable temperature.

_______________

27

Page 30

CONTROLS, INSTRUMENTS AND EQUIPMENT

1

2

3

A25H05A

1. Hot

2. Warm

3. Off

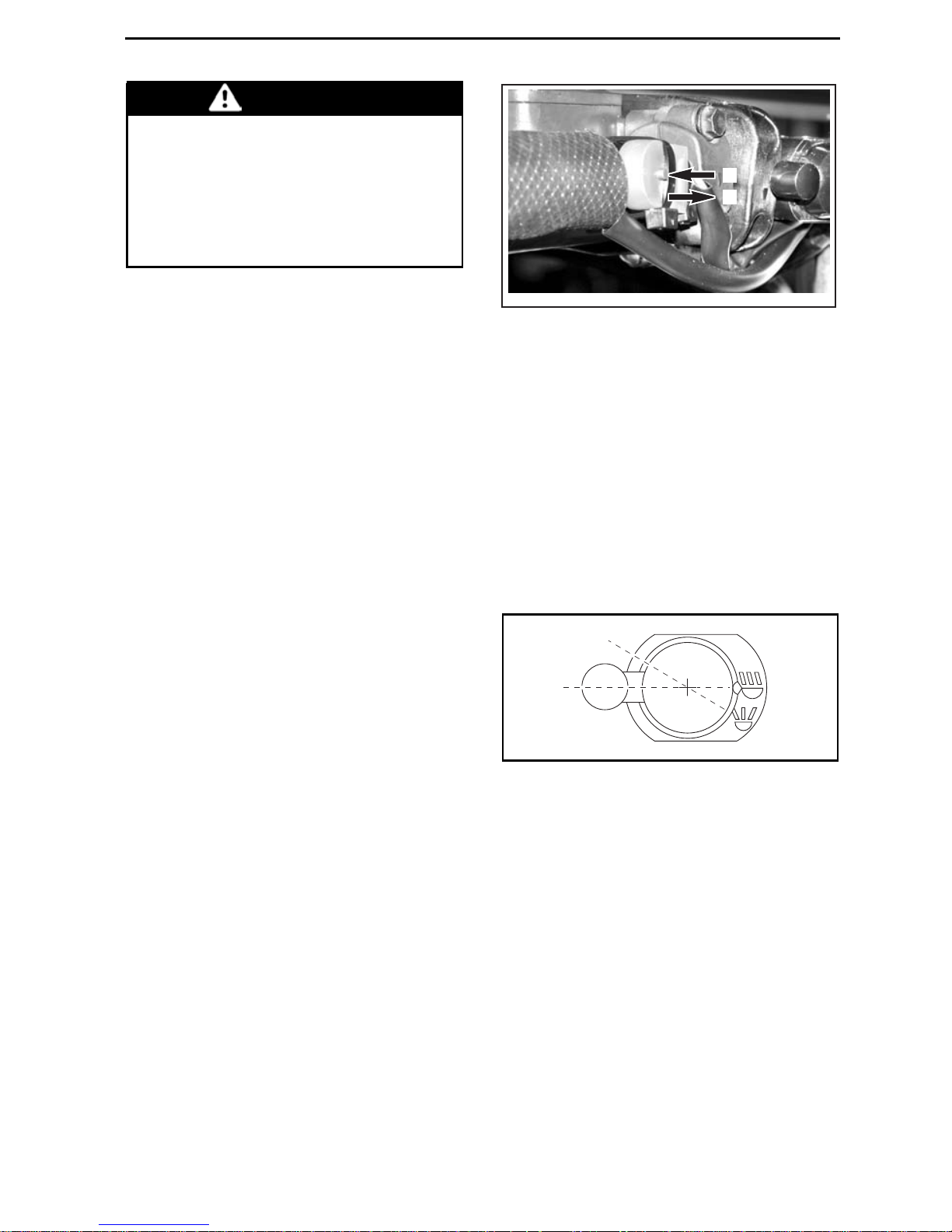

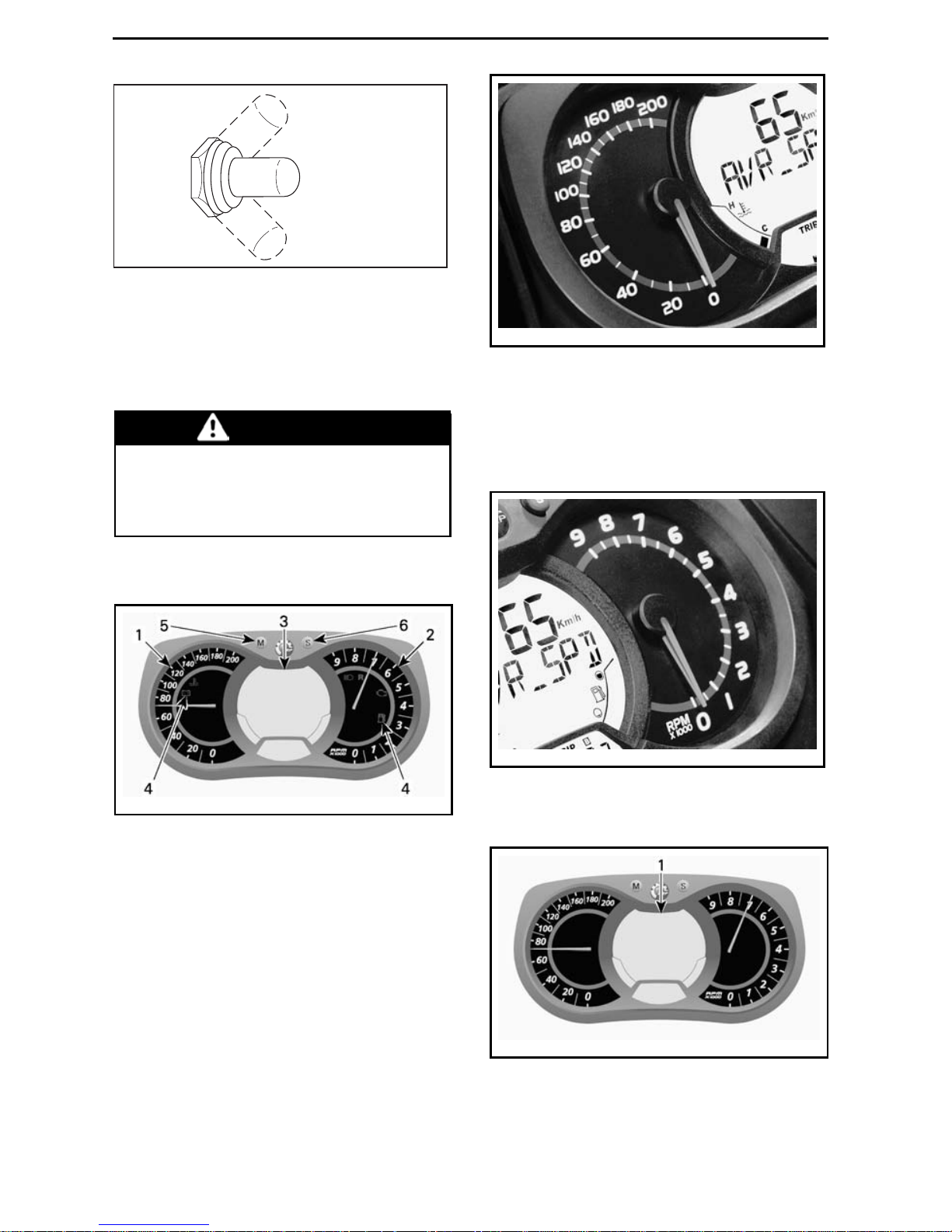

12) Multifunction

Analog/Digital Gauge

WARNING

Reading the gauge digital display

can distract from the operation of

the veh icle, particularly from constantly scanning the environment.

Gauge Description

mmo2007-009-066_x

MULTIFUNCTION ANALOG/DIGITAL GA UG E

1. Speedometer

2. Tachometer

3. Multifunction digital display

4. Pilot lamps

5. Mode button

6. Set button

NOTE: The gauge is factory preset in

metric units but it is possible to change

it to Imperial units, contact an authorized Lynx dealer for unit settings.

1) Speedometer

Measures vehicle speed.

mmo2008-007-017

LH PORTION OF GAUGE

2) Tachometer (RPM)

Measures engine revolution per

minute (RPM). M ultiply b y 1000 to obtain the actual revolutions.

mmo2008-007-018

RH PORTION OF GAUGE

3) Multifunction Digital Display

mmo2007-009-066_u

MULTIFUNCTION ANALOG/DIGITAL GAUGE

1. Multifunction display

28

______________

Page 31

CONTROLS, INSTRUMENTS AND EQUIPMENT

The multifunction display is used to:

– Display the WELCOME mess age

on power up

– Display the KEY recognition mes-

sage

– Provide various indications as se-

lected by the operator

– Activating or changing various func-

tions or modes of operation

– D isplay scrolling messages of func-

tion activation or system faults

– Display fault codes.

When the information center is first

powered up, the numerical display defaults to the last selected indication.

WARNING

Never adjust or set functions on

the multifunction gauge while riding the vehicle.

4) Pilot Lamps and Messages

mmo2008-003-024_a

TYPICAL — PILOT LAMPS

See table below for usual pilot lamps

information. Refer to

MONITORING

SYSTEM

for details on malfunction pi-

lot lamps.

_______________

29

Page 32

CONTROLS, INSTRUMENTS AND EQUIPMENT

PILOT

LAMP(S)

ON

BEEPER

MESSAGE

DISPLAY

DESCRIPTION

Two stroke engine: Injection oil level is low.

Stop vehicle in a safe place then, replenish

injection oil reservoir.

4short

beeps every

5minutes

LOW OIL

Four stroke engines: Low engine oil pressure.

Stop vehicle in a safe place then, check oil

level. Fill to proper level. If oil level was

correct, discontinue use and contact an

authorized Lynx dealer.

——

Low fuel level. One (1) bar left in fuel level

display. Replenish fuel tank as soon as

possible.

Long beeps

repeating

slowly

REVERSE

Reverse is selected.

3short

beeps

REV. FAIL Reverse d id not engage, try again.

——

High beam headlights are selected.

——

WARM UP

Engine and/or injection oil need to warm-up

before normal operation. The engine's RPM

is limite d until desired temperature is reached

(up to 10 minutes when driving). Warm-up

period may occur after a restart in very cold

weather.

5) MODE (M) Button

Buttonusetonavigateingaugemultifunction display.

NOTE: MODE(M)buttononthemultiswitch housing has the sam e functions

and can also be used.

6) SET (S) Button

Button used to navigate, adjust or reset gauge multifunction display.

In order to memorize settings, engine

must be running.

NOTE: SET(S)buttononthemultifunction switch has the same functions and can also be used.

30

______________

Page 33

CONTROLS, INSTRUMENTS AND EQUIPMENT

Gauge Features

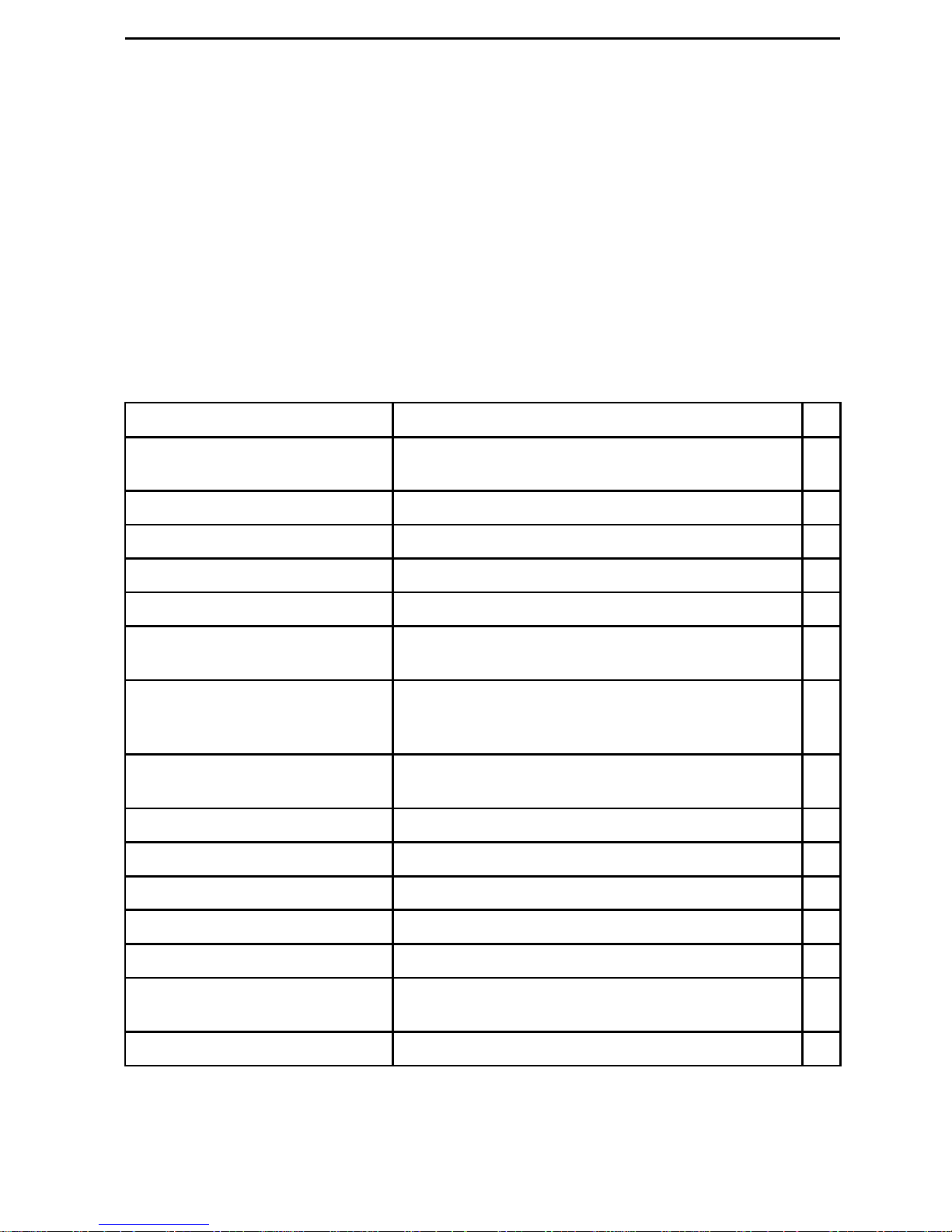

GAUGE FEATURES

FUNCTIONS 600 RS

A) Speedometer

Indication by default

B) Tachometer RPM X

C) Odometer

X

D) Trip meter “A” or “B” X

E) Trip hour meter X

F) Top speed X

G) Average speed

X

H) Instant fuel consumption X

I) Total fuel consumption X

J) Message display X

K) Top RPM X

L) Lap record mode X

M) Exhaust gas temperature X

N) Throttle position display X

X = An X indicates a standard feature

A) Speedometer

In addition of the analog type

speedometer, vehicle speed can

also be displayed via the multifunction

display.

Vehicle speed can be displayed on display 1 or display 2.

mmo2007-009-066_q

MULTIFUNCTION DISPLAY

1. Display 1

2. Display 2

_______________

31

Page 34

CONTROLS, INSTRUMENTS AND EQUIPMENT

Use MODE (M) button to select the desired d isplay, then proceed as follows:

mmo2007-009-066_m

While display is flashing, press the

SET (S) button to select speedometer

mode.

mmo2007-009-066_n

1. Speedometer mode

Press the MODE (M) button to confirm

selection or w ait 5 seconds.

mmo2007-009-066_o

B) Tachometer (RPM)

In addition of the a nalog type tachometer,RPsMcanalsobedisplayedviathe

multifunction display.

Engine RPM can be displayed on display 1 or display 2.

mmo2007-009-066_q

MULTIFUNCTION DISPLAY

1. Display 1

2. Display 2

Use MODE (M) button to select the desired display, then proceed as follows :

mmo2007-009-066_m

While display is flashing, press SET (S)

button to select RPM mode.

mmo2007-009-066_n

1. RPM mode

Press the MODE (M) button to co nfirm

selection or w ait 5 seconds.

32

______________

Page 35

CONTROLS, INSTRUMENTS AND EQUIPMENT

mmo2007-009-066_o

C) Odometer

Records the total distance travelled.

Press the SET (S) button to select

odometer mode.

mmo2007-009-066_p

1. Odometer (km/mi) mode

D) Trip Meter “A” or “B”

Trip meters records distance trave lle d

since it has been reset.

Press the SET (S) button to select trip

meter (TRIP A/TRIP B) mode.

mmo2007-009-066_p

1. Trip meter (TRIP A/TRIP B) mode

Press and hold the SET (S) button to reset.

mmo2007-009-066_k

E) Trip Hour Meter

Records vehicle running time when

the electrical system is activated since

it has been reset.

Press the SET (S) button to select trip

hour meter (HrTRIP) mode.

mmo2007-009-066_p

1. Trip hour meter (HrTRIP) mode

Press and hold the SET (S) button to reset.

mmo2007-009-066_k

F) Top Speed

Records vehicle top speed since it has

been reset.

To display vehicle top speed, proceed

as follows.

_______________

33

Page 36

CONTROLS, INSTRUMENTS AND EQUIPMENT

Press the MODE (M) button to select

display 1.

mmo2007-009-066_m

While display flashes, press the

SET (S) button to select top speed

(TOP_SPD) mode.

mmo2007-009-066_n

1. Top speed (TOP_SPD) mode

Press the MODE (M) button to confirm

selection or w ait 5 seconds.

mmo2007-009-066_o

Toreset, press the MODE (M) to select

mode.

mmo2007-009-066_m

While display flashes, press and hold

the SET (S) button within 5 seconds to

reset.

mmo2007-009-066_w

G) Average Speed

Records vehicle average speed since it

has been reset.

To display vehicle average speed, proceed as follows.

Press the MODE (M) button to select

display 1.

mmo2007-009-066_m

While display flashes, press SET (S)

button to select vehicle average speed

(AVR_SPD) mode.

34

______________

Page 37

CONTROLS, INSTRUMENTS AND EQUIPMENT

mmo2007-009-066_n

1. Vehicle average speed (AVR_SPD) mode

Press the MODE (M) button to co nfirm

selection or w ait 5 seconds.

mmo2007-009-066_o

Toreset, press the MODE (M) to select

mode.

mmo2007-009-066_m

While display flashes, press and hold

the SET (S) button within 5 seconds to

reset.

mmo2007-009-066_w

H) Instant Fuel Consumption

Calculates vehicle average fuel consumption while riding.

To display vehicle average fu el consumption, proceed as follows.

Press the MODE (M) button to select

display 1.

mmo2007-009-066_m

While display flashes, press SET (S)

button to select instant fuel consumption mode.

mmo2007-009-066_n

1. Instant fuel consumption mode

Press the MODE (M) button to co nfirm

selection or w ait 5 seconds.

_______________

35

Page 38

CONTROLS, INSTRUMENTS AND EQUIPMENT

mmo2007-009-066_o

I) Total Fuel Consumption

Records vehicle average fuel consumption since it has been reset.

To display vehicle to tal fuel consumption, proceed as follows.

Press the MODE (M) button to select

display.

mmo2007-009-066_m

While display fla sh es, press the SET

(S) button to select total fuel consumption (TC) mode.

mmo2007-009-066_n

1. Total fuel consumption (TC) mode

TC appears when the mode is selected.

mmo2008-003-021_a

TYPICAL

Press the MODE (M) button to co nfirm

selection or w ait 5 seconds.

mmo2007-009-066_o

To reset, set the t rip meter to TRIP B.

Refer to

TRIP METER “A” OR “B”

for

more details.

mmo2007-009-066_p

1. Trip meter (TRIP B) mode

Press and hold the SET (S) button to reset.

36

______________

Page 39

CONTROLS, INSTRUMENTS AND EQUIPMENT

mmo2007-009-066_w

J) Message Display

mmo2007-009-066_c

1. Message display

Refer to

PILOT LAMPS AND MES-

SAGES

in this section for details on

usual messages.

Refer to

MONITORING SYSTEM

for

details on malfunction.

K) Top RPM

Records engine top revolution per

minute (RPM) since it has been reset.

To display engine top revolution per

minute, proceed as follows:

1. Press the MODE (M) button to select display.

mmo2007-009-066_m

NOTE: Display will flash for approximately 5 seconds, then will return to

the previously selected mode if display

is not changed.

2. W h ile display flashes, press the SET

(S) button to scroll and select top

RPM (TOP_RPM ) mode.

mmo2007-009-066_n

1. Top RPM (TOP_RPM ) mode

3. P r ess the MODE (M) button to confirm selection or wait 5 seconds.

mmo2007-009-066_o

Toreset, press the MODE (M) to select

mode.

mmo2007-009-066_m

Press and hold the SET (S) button

within 5 seconds to reset.

_______________

37

Page 40

CONTROLS, INSTRUMENTS AND EQUIPMENT

mmo2007-009-066_w

L) Lap Record Mo de

With this mode, vehicle speed, engine

revolutions per minute (RPM) and a

preselected function in display 1 can

be recorded at the same time during a

period of time defined by the operator.

Also, a possibility of nine ( 9) different

sessions (laps) can be recorded for a

maximum total of 2-1/2 minutes.

mmo2007-009-066_h

LAP RECORD MODE

1. Lap record mode display

2. Sessions (laps)

3. Vehicle s peed

4. Engine revolution per minute (RPM)

5. Preselected function

To Activate Lap Record Mode:

1. Press the SET (S) button to select

the odometer mode in display 3.

2. Press and hold SET (S) button for 2

seconds to activate mode, REC will

be displayed to indicate that record

mode has been selected.

mmo2009-009-002_a

1. Record mode

2. Odometer

3. Press the SET (S) button to scroll between modes.

Available modes are: STOP, REC

(record) or PLAY.

To Record:

1. Select REC (record) mode.

mmo2008-007-003

RECORD MODE

2. Press the MODE (M) button to start

recording.

3. While recording, press the MODE

(M) button again each time you want

to record a new lap time (from 1 to 9

laps).

Press theSET(S)buttontostoprecording.

38

______________

Page 41

CONTROLS, INSTRUMENTS AND EQUIPMENT

mmo2009-009-003_a

RECORD MODE

1. Recording time

2. Lap/session

3. Selected mode

To record another session, press the

SET (S) button until REC (record) mode

appears in display. Repeat same procedure previously described to record.

To Review Recorded Data:

Select PLAY mode.

mmo2008-007-005_a

PLAY MODE

1. Press the MO DE (M) button to play

recorded data.

All recorded data (speedometer,

tachometer and the preselected mode

in display 1) will be displayed at the

same time.

2. Press the SET (S) button to stop

recorded lap OR press the MODE

(M)buttontoswitchtoanother

recorded lap.

NOTE: Pressing the SET (S) button will

stop time of the lap in progress, then

the display will show the recorded time

length of that lap and will switch automatically to the following recorded lap

after 5 seconds.

At the end of all recorded laps, STOP

will appear in display.

To review recorded data again, press

theSET(S)buttontoreturntoPLAY

mode. Repeat same procedure previously described to review.

To record other laps, press the SET (S)

buttontoswitchtoREC(record)mode.

Repeat same procedure previously described to record.

Press and hold SET (S) button for 5 seconds to exit the lap record mode, the

previously selected mode will be displayed.

M) Exhaust Gas Temperature

Displays real time exhaust gas temperature and records the maximum reading.

To display exhaust g a s temperature,

proceed as follows:

1. Press the MODE (M) button to select display.

mmo2007-009-066_m

NOTE: Display will flash for approximately 5 seconds, then will return to

the previously selected mode if display

is not changed.

2. While display flashes, press the

SET (S) button to scroll and select

exhaust gas temperature (EGTM)

mode.

_______________

39

Page 42

CONTROLS, INSTRUMENTS AND EQUIPMENT

mmo2008-007-006_a

EXHAUST GAS TEMPERATURE (EGTM)

MODE

1. Current temperature

2. Maximum temperature recorded

3. Press the MODE (M) button to confirm selection or wait 5 seconds.

mmo2007-009-066_o

To reset maximum temperature

recorded, press the MODE (M) to select mode.

mmo2007-009-066_m

Press and hold the SET (S) button

within 5 seconds to reset.

mmo2007-009-066_w

N) Throttle Position Display

Displays real time throttle open ing in

percentage from approximately 0 to

100%.

To display throttle position, proceed as

follows:

1. Press the MODE (M) button to select display.

mmo2007-009-066_m

NOTE: Display will flash for approximately 5 seconds, then will return to

the previously selected mode if display

is not changed.

2. W h ile display flashes, press the SET

(S) button to scroll and select throttle position (TPS) mode.

mmo2009-009-005

THROTTLE POSITION MODE

40

______________

Page 43

CONTROLS, INSTRUMENTS AND EQUIPMENT

3. P r ess the MODE (M) button to confirm selection or wait 5 seconds.

mmo2007-009-066_o

13) Front and Rear

Bumpers

To be used whenever snowmobile requires manual lifting.

CAUTION Use proper lifting

techniques, notably using your legs

force. Do not attempt to lift either

end of the vehicle if it is above your

limits. Use appropriate lifting device or have assistance to share lifting stress if possible.

mmo2008-003-016_a

FRONT

1. Front bumper

mmo2009-009-006_a

REAR

1. Rear bumper

NOTICE

Do not use skis to pull or

lift snowmobile.

14) Drive Belt Guard

Drive Belt Guard Removal

WARNING

NEVER operate engine:

– Without shields and belt guard

securely installed.

– With hood and/or side panels

opened or removed.