Page 1

e

Reference Manual

R FR 5010 / R FR 5011

Series 5000 Rack Frame

Ver 2.0

© LYNX Technik AG

CardModul

Series 5000

www.lynx-technik.com

Brunnenweg 3

64331 Weiterstadt

Germany

Page 2

Reference Manual R FR 5010 Version1.4

Information in this document is subject to change without

notice. No part of this document may be reproduced or

transmitted in any form or by any means, electronic or

mechanical for any purpose, without express written permission

of LYNX Technik AG.

LYNX Technik AG may have patents, patent applications,

trademarks, copyrights or other intellectual property rights

covering the subject matter in this document. Except as

expressly written by LYNX Technik AG, the furnishing of this

document does not give you any license to patents,

trademarks, copyrights or other intellectual property of LYNX

Technik AG or any of its affiliates.

© LYNX Technik AG 2002-2005 all rights reserved

Page 2

Page 3

Reference Manual R FR 5010 Version1.4

WARNING

Electrical supplies in excess of 50 (fifty) volts peak value

are potentially hazardous or lethal. AC supplies between

100 and 250 peak volts exist within the rack frame chassis

when connected to AC power.

Only qualified personnel should service the rack frame

assembly.

Removal of technical earth may render the equipment

dangerous and intentional removal is prohibited.

This unit has to be separated from mains by disconnecting

the power supply cords.

This unit may have two power supplies and two power

supply cords. Disconnect all power supply cords before

servicing to avoid electric shock.

DOUBLE POLE / NEUTRALE FUSING

After operation of the fuse, parts of equipment that remain

energized might represent a hazard during servicing.

For continued protection against risk of fire, replace only

with same type and rating of fuse.

F1 .. F4: T2AH250V

Replacement AC fuses must be of the specified type and

rating: F1 .. F4: T2AH250V

The use of repaired fuses or shorting links is to be avoided.

WARNING! CAUTION!

Page 3

Page 4

Reference Manual R FR 5010 Version1.4

WARNUNG!

Wenn das Gerät an das Wechselstromnetz angeschlossen

ist, treten innerhalb des Gerätes Wechselspannungen

zwischen 100 und 250 V auf, die potentiell gefährlich oder

tödlich sein können. Deshalb darf Reparatur und

Instandhaltung nur von qualifiziertem Personal

durchgeführt werden.

Das Entfernen des Schutzleiters kann das Gerät in einen

gefährlichen Zustand bringen, vorsätzliches Entfernen des

Schutzleiters ist verboten.

Das Gerät ist durch Abziehen der Netzstecker vom Netz zu

trennen.

Das Gerät kann 2 Netzgeräte mit 2 Netzkabeln haben. Vor

Servicearbeiten müssen alle Netzkabel abgezogen werden,

um elektrischen Schlag zu vermeiden.

Die Netzzuführung ist 2-polig abgesichert. Nach Ausfall

einer Sicherung können Teile der Schaltung weiter unter

Spannung bleiben und bei Servicearbeiten zu Gefahren

führen.

Vor Servicearbeiten Stromversorgung unterbrechen und

Teile vor Berührung prüfen.

Um Schutz gegen Feuer aufrechtzuerhalten, sind bei

Sicherungswechsel nur Sicherungen des gleichen Typs mit

gleichen Daten zulässig.

F1 .. F4: T2AH250V

Page 4

Page 5

Reference Manual R FR 5010 Version1.4

This Page is intentionally left blank

Page 5

Page 6

Reference Manual R FR 5010 Version1.4

Warranty

LYNX Technik AG warrants that the product will be free from

defects in materials and workmanship for a period of two (2)

years from the date of shipment. If this product proves defective

during the warranty period, LYNX Technik AG at its option will

either repair the defective product without charge for parts and

labor, or will provide a replacement in exchange for the

defective product.

In order to obtain service under this warranty, customer must

notify LYNX Technik of the defect before expiration of the

warranty period and make suitable arrangements for the

performance of service. Customer shall be responsible for

packaging and shipping the defective product to the service

center designated by LYNX Technik, with shipping charges

prepaid. LYNX Technik shall pay for the return of the product to

the customer if the shipment is within the country which the LYNX

Technik service center is located. Customer shall be responsible

for payment of all shipping charges, duties, taxes and any other

charges for products returned to any other locations.

This warranty shall not apply to any defect, failure, or damage

caused by improper use or improper or inadequate

maintenance and care. LYNX Technik shall not be obligated to

furnish service under this warranty a) to repair damage resulting

from attempts by personnel other than LYNX Technik

representatives to install, repair or service the product; b) to

repair damage resulting from improper use or connection to

incompatible equipment; c) to repair any damage or

malfunction caused by the use of non LYNX Technik supplies; or

d) to service a product which has been modified or integrated

with other products when the effect of such modification or

integration increases the time or difficulty servicing the product.

THIS WARRANTY IS GIVEN BY LYNX TECHNIK WITH RESPECT TO THIS

PRODUCT IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR

IMPLIED. LYNX TECHNIK AND ITS VENDORS DISCLAIM ANY IMPLIED

WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE. LYNX TECHNIK`S RESPONISIBILITY TO REPAIR AND

REPLACE DEFECTIVE PRODUCTS IS THE SOLE AND EXCLUSIVE

REMEDY PROVIDED TO THE CUSTOMER FOR BREACH OF THIS

WARRANTY. LYNX TECHNIK AND ITS VENDORS WILL NOT BE LIABLE

FOR ANY INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTAL

DAMAGES IRRESPECTIVE OF WHETHER LYNX TECHNIK OR THE

VENDOR HAS ADVANCE NOTICE OF THE POSSIBILITY OF SUCH

DAMAGES.

Page 6

Page 7

Reference Manual R FR 5010 Version1.4

Regulatory information

Europe

Declaration of Conformity

We LYNX Technik AG

Brunnenweg 3

D-64331 Weiterstadt

Germany

Declare under our sole responsibility that the product

TYPE: R FR 5010 / R FR 5011

To which this declaration relates is in conformity with the following

standards (Environments E1-E3):

EN 55103-1 /1996

EN 55103-2 /1996

EN 60950 /2001

following the provisions of 89/336/EEC and 73/23/EEC directives.

USA

Winfried Deckelmann

Weiterstadt, January 2004

Place and date of issue Legal Signature

FCC 47 Part 15

This device complies with part 15 of the FCC Rules. Operation is

subject to the following two conditions: (1) This device may not

cause harmful interference, and (2) this device must accept any

interference received, including interference that may cause

undesired operation.

Note: This equipment has been tested and found to comply with the

limits for a Class A digital device, pursuant to the part 15 of the FCC

Rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses, and can

radiate radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment in

a residential area is likely to cause harmful interference in which case

the user will be required to correct the interference at his own

expense

Page 7

Page 8

Reference Manual R FR 5010 Version1.4

Contents

Warranty................................................................................... 6

Regulatory information ........................................................... 7

Europe .............................................................................................. 7

Declaration of Conformity........................................................... 7

USA.................................................................................................. 7

FCC 47 Part 15 ............................................................................ 7

Contents................................................................................... 8

Getting Started ...................................................................... 10

Packaging ....................................................................................... 10

Product Description........................................................................ 10

Rack Layout ................................................................................... 12

Power Supply ......................................................................... 14

Rear Termination Panel ......................................................... 16

Rack Connections........................................................................... 16

Power Connection ..................................................................... 16

Alarm Connection ..................................................................... 17

Alarm Function.......................................................................... 18

Extend Connection .................................................................... 19

Control Connection ................................................................... 20

LAN Connection ....................................................................... 21

External Sync Connection ......................................................... 21

Alarm/LED Status Indicators ................................................. 22

Power Supply LED Indicators ................................................... 23

Fan Alarm LED (R FR 5011 only) ............................................ 23

Rack Configuration ............................................................... 24

Assembly........................................................................................ 24

Rack Layout Considerations...................................................... 24

Rear Connection Plates.............................................................. 24

Redundant Power Supply .......................................................... 25

Remote Controller ..................................................................... 25

Hot Swapping ........................................................................ 27

Power Supplies............................................................................... 27

Power Supply Failure ................................................................ 27

CardModules ................................................................ 27

Rack Installation .................................................................... 28

Location..................................................................................... 28

Ventilation................................................................................. 28

Mechanical Installation ............................................................. 29

Front Panel Removal R FR 5010............................................... 29

Front Panel Removal R FR 5011............................................... 29

Page 8

Page 9

Reference Manual R FR 5010 Version1.4

Electrical Installation. ............................................................31

Installation Instructions..........................................................32

Installations-Anweisung ........................................................ 33

Settings and Control ..............................................................34

Specifications (R FR 5010 / R FR 5011).................................. 35

Available Options..................................................................36

Parts List ..................................................................................37

Service....................................................................................37

Contact Information ..............................................................38

Page 9

Page 10

Reference Manual R FR 5010 Version1.4

Getting Started

Packaging

The shipping carton and packaging materials

provide protection for the module during transit.

Please retain the shipping cartons in case

subsequent shipping of the product becomes

necessary.

Product Description

The R FR 5010 / R FR 5011 is a high quality 2 RU high

19 inch rack frame enclosure for the LYNX Series

5000 CardModules, designed primarily for

broadcast and professional applications.

The rack frame can accept up to 10 Series 5000

CardModules plus an optional controller card. All

modules are installed from the front. Module

connection plates are supplied with each

CardModule and are mounted on the rear of the

rack to align CardModule installed. All

CardModules and power supplies are hot

swappable.

The R FR 5010 / R FR 5011 features connections for

remote alarming, serial control and a local

extension port. A LAN connection is also provided

for use with the optional R CT 5030 Master

Controller.

Optional redundant power capability can be

installed and two separate AC power connections

are provided for maximum isolation. The power

supplies have sophisticated power filtering with

microprocessor control for power monitoring and

communication with the control system. An on

Page 10

Page 11

Reference Manual R FR 5010 Version1.4

board multifunction LED has various states to

indicate different alarm conditions and a separate

GPO alarm output is provided for connection to an

external monitoring system.

The system is convection cooled plus forced aircooling (low noise fans) so it can be used in areas

where noise level is critical. Power supplies have a

small temperature controlled DC micro fan, which

is only used when needed and is also low-noise

when operating.

The R FR 5011 rack frame has a front cover with

integrated fans for applications, where no external

forced cooling is available or if modules with high

power dissipation are used in this rack frame.

All electrical contacts inside the R FR 5010 / R FR

5011, the CardModules and power supplies are

gold plated ensuring maximum reliability and

protection from corrosion.

The R FR 5010 is the primary building block in the

LYNX Series 5000 CardModule system that provides

high quality, modularity and flexibility in a very small

form factor.

Page 11

Page 12

Reference Manual R FR 5010 Version1.4

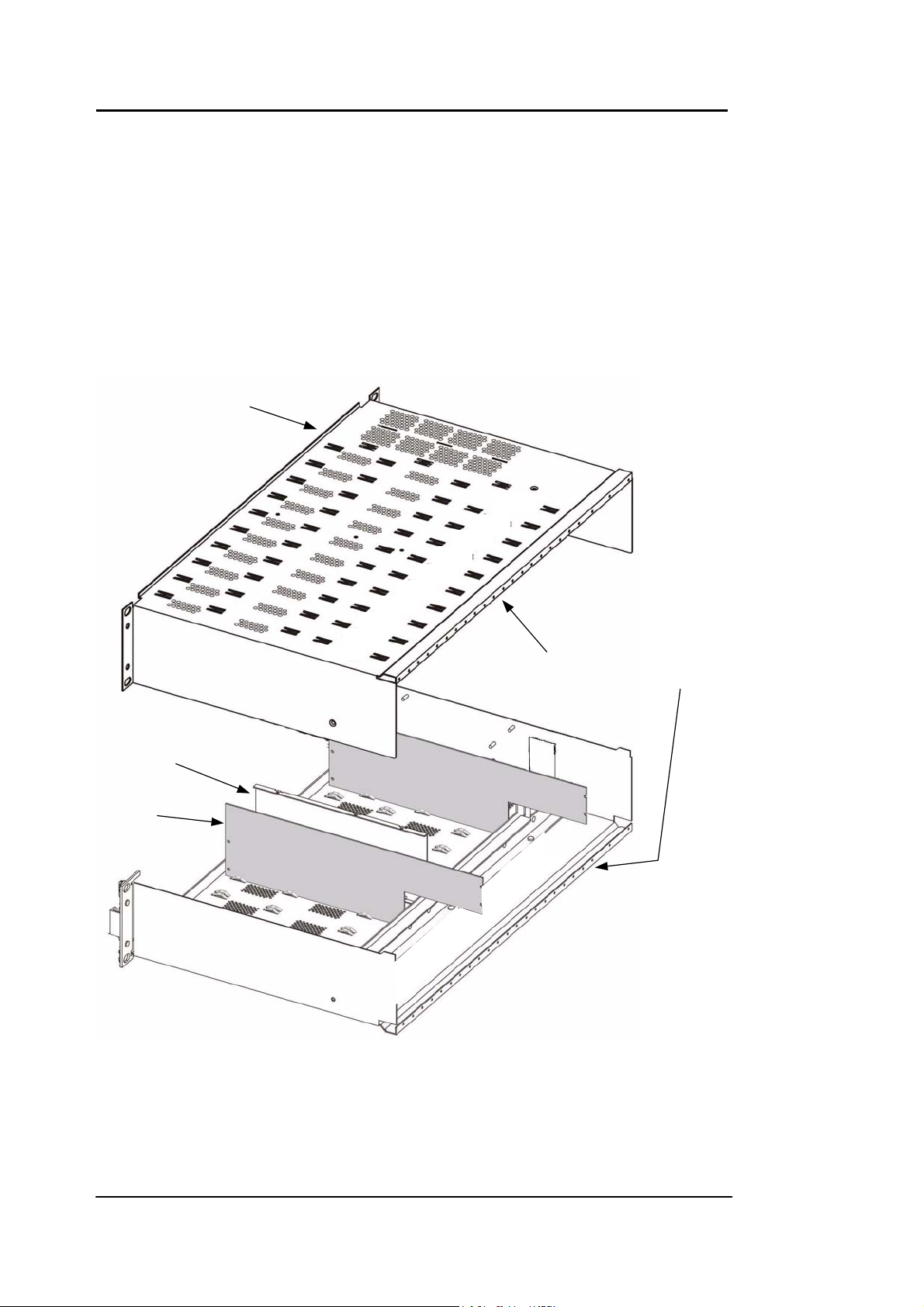

Rack Layout

Figure 2 and 3 shows exploded views of the R FR

5010 / R FR 5011. The Front cover is removed and

not shown.

Caution :

holes on top and bottom sides of rack.

Refer to mounting instructions for more

Mid Rack Vertical

Do not obstruct ventialtion

Support

details.

Mounting rails on rear of

rack for connection panels

CardModule

Page 12

Figure 2. Exploded rack view

Page 13

Reference Manual R FR 5010 Version1.4

Caution :

holes on top and bottom sides of rack.

Refer to mounting instructions for more

Do not obstruct ventilation

details.

Controller

Mid Rack Vertical

Support

CardModule

Rack mounting Screws

For clarity (to show rack construction) power

supplies, rear termination panel and connection

Note

. Exploded views are shown for reference only

It is not necessary to disassemble the rack as shown

Figure 3 – Exploded rack view

panels for the modules have been omitted.

Page 13

Page 14

Reference Manual R FR 5010 Version1.4

Power Supply

The R FR 5010 / R FR 5011 includes the primary

power supply. A second identical power supply

can be added for redundancy. The Power supply is

a sophisticated design designed for critical

applications and includes power filtering and

integral microprocessor. This monitors the supply

operation and reports into the control system.

Should a fault develop, the errors are alarmed in

the following ways:

• Via the LED located on the front of the supply

(Figure 4).

• Via a GPO alarm via the alarm connector on

the termination panel (figure 5), if a controller

option is fitted

• Via the control system (if installed)

If the redundant power supply is installed, the

system will switch supplies automatically in the

event of primary supply failure, with no interruption

to the normal operation of the rack.

The supply has a noiseless integral DC fan for

cooling.

The supply is installed and removed from the front

of the rack. Removing the rack front cover plate

provides access. The supply is secured firmly in

place with a screw located at the bottom front of

the unit (figure 4).

Page 14

Page 15

Handle for removal

LED Alarm indicator

Reference Manual R FR 5010 Version1.4

Integral Fan

Securing Screw

Power Supply seen

from Front

Figure 4: Power Supply

Page 15

Page 16

Reference Manual R FR 5010 Version1.4

Rear Termination Panel

The R FR 5010/ R FR 5011 has an integral termination

panel on the rear of the rack for the connection of

power and various other connections for expansion

and interfacing. Figure 5

Figure 5 Rear Panel Connections

Rack Connections

Power Connection

There are two power connections provided for the

rack. One is for primary power and the other for the

optional redundant power supply. Input power

range is 100 to 240VAC 50 to 60Hz. Connection is

made using an IEC power cable. For systems

without redundant power connection is made to

AC1 in only. The power fuse is in the connector

assembly (Figure 5) and removal of this small

module will enable fuse exchange. Please ensure

you use the correct fuse rating. (2A).

Page 16

Page 17

Reference Manual R FR 5010 Version1.4

A stud is provided on the termination panel for the

connection of an external ground. (Figure 5)

Note: the chassis is permanently grounded via the

AC connections.

Caution

Service to be performed by qualified

personnel only

!

Caution

Please remove power before attempting to

exchange a power fuse. Only replace the

fuse with a correctly rated replacement. For

safety DO NOT physically disconnect or

!

isolate the rack from earth for any reason.

Alarm Connection

An external alarm connection is available from the

rack. This is a 9 pin SubD male connector. Function

and connection information is described below.

Pin

Number

1 GND Shield 6 N/C

2 Alarm Major 7 GPI in A

3 Alarm Minor 8 GPI in B

4 Alarm Common 9 GND Shield

5 GND

Connection

1

Pin

Number

5

Connection

9 6

Figure 6. Alarm Connector

Page 17

Page 18

Reference Manual R FR 5010 Version1.4

Alarm Function

This function requires the controller option. The user

can assign triggers for the preferred Major / Minor

and No Alarm conditions using the controller and

supplied software.

The alarm connector provides GPO contacts for 2

alarm levels and a GPI input for future use. This

allows for the connection of an external monitoring

system. Alarm conditions are triggered by the

optional control system and will vary depending on

the configuration of the system and user

preferences.

For critical failures in the rack a contact can be

closed between Alarm Minor and Alarm Common.

Some examples of “critical” type failures are listed

below*:

• Over temperature

• Redundant Power Supply Failure

For major failures in the rack a contact can be

closed between Alarm Major and Alarm Common.

Some examples of “major” failures in the rack are:

• Loss of Power

Page 18

Page 19

Reference Manual R FR 5010 Version1.4

Extend Connection

Bus Extension. This connection is used to interface

racks together when using the optional LYNX

control system. This is a simple (and inexpensive)

way to extend the reach of the host RCT 5020

controller into several more racks fitted with RCT

5010 bus expanders. It uses a proprietary LYNX

control interface and this connection is physically

daisy chained between all connected racks.

Connection details can be seen in the table below.

The connection is a 9 pin SubD female connector.

Function and connection information is described

below.

Connector wiring detail when used for the Bus

Extension

Pin

Number

1 Prop CLK A 6 Prop CLK B

2 Prop TX A 7 Prop TX B

3 Prop RX B 8 Prop RX A

4 GND 9 Prop SEL 2

5 Prop SEL 1

Connection

Pin

Number

Connection

Note the “prop” term refers to proprietary for the

LYNX interface.

15

Figure 7. Extend Connector

6 9

Note. When using this interface all connected racks

must be mounted close together, (preferably with

no space in-between racks), as the distance of this

interface is restricted. Please refer to the R CT 5010

Rack Bus Expander reference manual for more

details on this interface and the cables required.

Page 19

Page 20

Reference Manual R FR 5010 Version1.4

Control Connection

An external Control Interface is provided on the

rear termination panel. When an R CT 5020 Rack

Controller (or R CT 5030 Master Controller) is fitted

to the rack this port can be used for two primary

functions:

1. When configured as a RS 232 serial port this can

be connected directly to a PC running the LYNX

control software.

2. When configured for RS 422 operation this port is

used to daisy chain other racks fitted with R CT

5020 Rack controllers (up to 15 additional racks)

Note. Please refer to the R CT 5020 Reference

Manual for details on how to re-configure the port

and more detail on the use of this control interface.

The connection is a 9 pin SubD female connector.

Function and connection information is described

below.

Connections for RS 422

Pin

Number

1 GND Shield 6 GND

2 TX A 422 7 TX B 422

3 RX B 422 8 RX A 422

4 GND 9 GND Shield

5 GND

Connection

Pin

Number

Connection

Connections for RS 232

Page 20

Pin

Number

1 GND Shield 6 GND

2 TX 232 7

3 RX 232 8

4 GND 9 GND Shield

5 GND

Connection

Pin

Number

Connection

Page 21

Reference Manual R FR 5010 Version1.4

15

Figure 8. Control Connector

6 9

LAN Connection

This is a standard RJ48 connection and is used to

provide standard TCP/IP network control

connectivity into a control system. To be

operational this port requires the R CT 5030 Master

Controller is fitted to the rack. Please see the

reference manual for the R CT 5030 for more details

on the use of this connection

External Sync Connection

An external sync reference (loop through

connection) can be connected for the rack. This

provides a common genlock reference for the

modules installed in the chassis. Sync signal can be

black or composite analog sync NTSC or PAL. This is

to provide a common reference to all modules

installed in the rack and can simplify the distribution

of the reference signal in some system applications.

Page 21

Page 22

Reference Manual R FR 5010 Version1.4

Alarm/LED Status Indicators

There are a number of status / alarm indicators

visible through the front panel of the R FR 5010 Rack

frame. Figure 9.

Figure 9. LEDs and indicator locations and function

Page 22

Page 23

Reference Manual R FR 5010 Version1.4

Power Supply LED Indicators

The Table below shows the error conditions for the

LED on the power supply units. These are visible

through the ventilation holes on the left side of the

front of the rack (figure 9)

LED Color Condition

Green Normal Operation

Yellow Warning: High Temperature

Red Flashing Warning: Over Temperature

Red Continuous Warning: Voltage out of range

Off Failure: Exchange Supply

Fan Alarm LED (R FR 5011 only)

The Table below shows the error conditions for the

LED on the fan front cover of the R FR 5011. This is

visible on the right side of the front of the rack

(figure 9)

LED Color Condition

Green Normal Operation, all fans working

Yellow 1 or 2 fans failed

Red Continuous all fans failed

Page 23

Page 24

Reference Manual R FR 5010 Version1.4

Rack Configuration

Assembly

If starting with an empty R FR 5010 / R FR 5011 rack

frame please follow the following steps for correct

installation of the Series 5000 Card Modules

Rack Layout Considerations

If you have a variety of module types it’s a good

idea to plan the order in which you install the

various CardModules. While a module can occupy

any of the 10 available slots provided,

consideration can be given to the position of the

modules in the rack to facilitate external wiring.

Figure 10 shows a layout example.

Rear Connection Plates

The series 5000 CardModule is supplied with a

connection plate and two screws. This is fitted to

the rear of the rack frame behind the module.

Position the connection pate on the rear mounting

rails (figure 2) and secure with the two screws

provided. Do not fully tighten the screws initially.

Test fit the module into the rack and make sure the

edge connector from the CardModule is aligned

correctly with the connection plate. When

alignment is correct, tighten the two screws.

Remove and insert the CardModule a few times to

check installation. If the CardModule sticks, or

installation is in anyway difficult loosen the

connection pate screws and check alignment.

Repeat this process for each CardModule.

Note. It is important to note the order of the

CardModules on the front of the rack.

Page 24

Page 25

Reference Manual R FR 5010 Version1.4

Redundant Power Supply

The basic RFR 5010 / R FR 5011 is supplied with the

primary power supply installed. The redundant

supply (option) is installed next to the primary

supply.

Remote Controller

Depending on your system design you may have

one of the LYNX controller options available (RCT

5010, R CT 5020 or R CT 5030). Install the controller

into the first module slot next to the power supply(s).

Please refer to documentation supplied with the

controller CardModule on the configuration and

use of the LYNX controller options.

Page 25

Page 26

Reference Manual R FR 5010 Version1.4

connecting power

instructions before

!

CAUTION: See Instal lation

CONTROL

EXTEND

ALARM

DUAL ANALOG AUDIO

DISTRIBUTION AMP

D AA3320 D

8 BIT SDI TO ANALOG CONVERTER

nc

C DA 3000

SDI IN

DUAL AUDIO ANALOG DIST AMP

D AA3320 W

IN L IN R

DUAL AES AUDIO DEMULTIPLEXER

FUSE

FUSE

1.8A

AC

90-250V 47-63Hz

FUSE

FUSE

AC 2 in AC 1 in

LAN

SDI out 2

SDI out 1

OUT L1 OUT R1

REF IN

INOUT

Y (S-vid)out

B / U out

LYNX Technik AG

C out

R / V out

OUT R4

OUT L4

CVBS out

G / Y out

OUT R3

OUT L2 OUT R2

OUT L3

OUT 2.1

SDI IN 2

SDI IN

D VD3320

P DX 3212

SDI IN 1

8 BIT SDI TO ANALOG CONVERTER

nc

C DA 3000

SDI IN

8 BIT SDI TO ANALOG CONVERTER

nc

C DA 3000

SDI IN

DUAL SDI DISTRIBUT ION AMP

SDI loop 1

SDI out 2

SDI out 1

SDI out 2

SDI out 1

OUT 2.2

OUT 2.3

SDI loop 3

OUT 1.3

LYNX Technik AG

Y (S-vid)out

B / U out

LYNX Technik AG

Y (S-vid)out

B / U out

LYNX Technik AG

OUT 2.4

SDI loop 4

OUT 1.4

C out

R / V out

C out

R / V out

SDI loop 2

OUT 1.1

OUT 1.2

CVBS out

G / Y out

CVBS out

G / Y out

on rack frame - 10 max

OUT 2.1

SDI IN 2

D VD 3320

SDI IN 1

Rear connection panels mounted to match

bottom secure connection plate to chassis

D VD 3320

installed module cards. Two mounting screws one in the top and one in the

D VD 3320

D VD 3320

DUAL SDI DISTRIBUT ION AMP

SDI IN 2

SDI IN 1

DUAL SDI DISTRIBUT ION AMP

SDI IN 2

SDI IN 1

DUAL SDI DISTRIBUT ION AMP

SDI IN 2

SDI IN 1

OUT 2.2

OUT 2.3

OUT 2.4

OUT 1.1

OUT 1.2

OUT 1.3

OUT 1.4

(selection shown is just an example)

Module rear connection panels mounted

OUT 2.1

OUT 2.2

OUT 2.3

OUT 2.4

OUT 1.1

OUT 1.2

OUT 1.3

OUT 1.4

OUT 2.1

OUT 2.2

OUT 2.3

OUT 2.4

OUT 1.1

OUT 1.2

OUT 1.3

OUT 1.4

OUT 2.1

OUT 2.2

OUT 2.3

OUT 1.1

OUT 1.2

OUT 1.3

Figure 10 Rear Rack with

OUT 2.4

connector plates

OUT 1.4

Page 26

Page 27

Reference Manual R FR 5010 Version1.4

Hot Swapping

Power Supplies

The Series 5000 CardModules and Power Supplies

are fully hot swappable in the event of a fault or

failure.

Power Supply Failure

A failure in the Primary power supply will

automatically trigger the use of the redundant

supply (if fitted) and will trigger the following alarm

conditions / indications(requires controller option).

• Reported fault on the monitoring system

• Alarm GPO trigger on the alarm connector (see

Alarm Connections section)

• Front Panel LED (normally green) will go out (See

Alarm / Status indication section)

Once identified, the defective supply can be

removed and replaced with power connected

with no interruption to the operation of the

CardModules.

CardModules

If a CardModule fails the error will be reported over

the monitoring system and via the front side alarm

LED. Alarm function is module dependant so please

refer to the CardModule manual for failure

conditions and indications. The defective

CardModule can be removed and replaced with

an identical replacement without removing power

from the frame.

Page 27

Page 28

Reference Manual R FR 5010 Version1.4

Rack Installation

If you have an empty R FR 5010 rack frame we

recommend you assemble the connection plates

and modules as well as any options such as the

redundant power supply and controller before

mounting the Rack Frame into a 19” inch rack.

(Please refer to assembly section)

Location

The R FR 5010 Rack frame can be located

anywhere there is available 19-inch rack space.

The rack will take up 2 Rack Units (RU) of vertical

rack space.

Ventilation

Depending on the installed modules up to three

R FR 5010 rack frames can be mounted stacked,

with no space in-between. Allowance has been

made in the design providing space between the

racks for adequate air ventilation. Every third rack

there should be 1 RU space provided for additional

airflow.

NOTE: In case of modules with higher power

dissipation, e.g. P VD 5010, appropriate cooling is

required. We recommend in these cases to add 1

RU space in between each rack.

The R FR 5011 with a front cover with integrated fans

should be used for critical applications where

external cooling is not sufficient.

Note. Airflow through the R FR 5010 rack frame is

from bottom to top. Forced (fan) cooling may be

required in case of modules with higher power

dissipation. Please consider other surrounding

equipment when designing rack layout. Placing the

R FR 5010 directly above another piece of

equipment with heat exhaust from the top may

cause the Card Modules to malfunction due to

excessive heat. Like wise, if placed below another

piece of equipment with bottom air intake the R FR

Page 28

Page 29

Reference Manual R FR 5010 Version1.4

5101 rack frame may (due to the small airflow gap)

restrict the flow of air to this piece of equipment.

Also do not place equipment or objects on top of

the R FR 5010 rack frame that could restrict airflow

from the top of the rack. This may cause

malfunction and damage due to excessive heat

buildup.

Mechanical Installation

The R FR 5010 / R FR 5011 is secured into a standard

19-inch rack using 4 standard rack screws. Remove

front cover panel for installation, which allows

access to the rack ears (figure 3 shows location).

Rear support of the rack using rack rails is

recommended but not necessary.

Front Panel Removal R FR 5010

The front panel is removed by simply rotating the

thumbscrews one turn counterclockwise and

pulling the panel outwards.

Front Panel Removal R FR 5011

The front panel is removed by simply rotating the

thumbscrews one turn counterclockwise and

pulling the panel outwards.

If you put back the Fan Front Cover of the R FR 5011

please make sure that the 9 Pin Sub D connector

is connected correctly (see pictures below)

Page 29

Page 30

Reference Manual R FR 5010 Version1.4

Fig.11: Sub D 9 Connector on Front Cover of R FR 5011

Fig.12: Sub D 9 Connector on right side of R FR 5011

Page 30

Page 31

Reference Manual R FR 5010 Version1.4

Electrical Installation.

Electrical power is connected to the R FR 5010 /

R FR 5011 chassis via the two IEC power connectors

located on the termination panel on the rear of the

rack. There is no power switch provided. Two

separate and isolated power connections are

available, one for the primary power and one for

the optional redundant power supply. Primary

power is connected to AC in 1

!

!

Caution

Please remove power before attempting

to exchange a power fuse. Only replace

the fuse with a correctly rated

replacement. For safety DO NOT

physically disconnect or isolate the rack

from earth for any reason.

Caution

Service to be performed by qualified

personnel only

Page 31

Page 32

Reference Manual R FR 5010 Version1.4

Installation Instructions

The rack frame chassis R FR 5010 / R FR 5011 is intended for

operation in broadcast environments.

The operation in excessive dust and moisture or extreme

temperature requires special provisions like

• dust filters

• air conditioning

• avoidance of condensed water.

Caution!

The power cords must meet the safety requirements of the

country where the rack frame is used and has to be

approved in this country, e.g.

• CE-Mark in Europe

• UL-listed in USA

• CSA certified in Canada

CAUTION!

The power supply cords are used to disconnect the R FR

5010 / R FR 5011 from the mains supplies, make sure that

the socket-outlets are located/installed near the

equipment and are easily accessible.

CAUTION!

The rack frame chassis is a CLASS I EQUIPMENT, ensure

before initial operation that protective earth is connected

to the building wiring and zero potential is established.

The functional earth connection at the rear termination

panel is connected internally to protective earth. If

necessary, it may be used for potential equalization to

other units.

Page 32

Page 33

Reference Manual R FR 5010 Version1.4

Installations-Anweisung

Das Gerät R FR 5010 / R FR 5011 ist für Anwendungen in

Fernsehstudios vorgesehen. Der Einsatz in erhöhter

staubiger und feuchter Umgebung oder

außergewöhnlichen Temperaturen erfordert besondere

Maßnahmen wie

• Klimatisierung

• Staubfilter

• Vermeiden von Kondenswasser.

Die Netzkabel müssen den Sicherheits-Anforderungen in

dem Land entsprechen in dem das Gerät verwendet

werden soll und in dem Land zugelassen sein, z.B.

• CE-Zeichen in Europa

• UL-gelistet in USA

• CSA-Zulassung in Kanada

ACHTUNG!

Die Netzkabel dienen zur Trennung des Geräts vom Netz. Es

ist sicherzustellen, dass die Steckdosen für den

Netzanschluss in der Nähe des Gerätes angebracht und

zum Trennen leicht zugänglich sind.

ACHTUNG!

Das Gerät ist nach der Schutzklasse I aufgebaut. Vor der

ersten Inbetriebnahme muss sichergestellt werden, dass

der Schutzleiter mit dem zentralen Schutzleiter des

Gebäudes verbunden ist und spannungsfrei ist.

Der Erdanschlussbolzen an der Netzanschlussrückseite ist

intern mit dem Schutzleiter verbunden. Falls erforderlich,

kann er für den Potentialausgleich mit anderen Geräten

verwendet werden.

Page 33

Page 34

Reference Manual R FR 5010 Version1.4

Settings and Control

There are no specific setting and control

parameters for the card rack. This is provided via

controller option (if fitted) and the individual

CardModule assemblies. Please refer to the

reference manuals supplied with these items for

details on specific settings and controls available.

Page 34

Page 35

Reference Manual R FR 5010 Version1.4

Specifications

Mechanical

Size 2 RU high x 32.5 cm deep including connectors

Weight (empty) R FR 5010: 4 kg with single power supply

Connections All connections made on rear of rack

and front cover. 31 cm without front cover.

Standard 19” rack mount.

R FR 5011: 4,25 kg with single power supply

(R FR 5010 / R FR 5011)

Performance

Available Card Slots 10 x CardModules

1 x Controller

2 x Power Supplies (primary and redundant)

Power Indication (alarm) One multifunction LED per supply and GPO output

Fan Alarm through front cover (R FR 5011 only)

Module alarm LEDs visible through front cover

Controller alarm LED bar

Connections (rear connections)

LAN Connector RJ 48

Control 9 Pin female SubD (RS 485)

Extend 9 pin female SubD (RS 232)

Alarm Connector 9 Pin male Sub D (GPO and GPI)

Ref In BNC connection for rack reference, with loop

output

Primary AC IEC power connector, fused (2A)

Redundant AC IEC Power connector, fused (2A)

Electrical Specifications

Power Input 100 – 240VAC, 50Hz – 60Hz. Two separate and

isolated connections for Primary and Redundant

supplies.

Power Consumption 130W max.

Safety IEC 60950/ EN 60950/VDE 0805

Ambient

Temperature 5°C to 40°C Maintaining specifications

0°C to +50°C Operating

Humidity Max 90% non condensing

Supplied Accessories

Documentation R FR 5010 / R FR 5011 Reference Manual

Page 35

Page 36

Reference Manual R FR 5010 Version1.4

Available Options

Below is a list of available options for the R FR 5010

rack frame. Please refer to product brochures or

our web site for more detailed information.

Model Description

R FR 5010 /

R FR 5011

R PS 5010

R FR 5001

R CT 5020

R CT 5030

R CT 5010

Series 5000 Rack Frame (empty) with single

power supply

Redundant power supply for the R FR 5010

Card Frame

Front Cover with integrated fans for

upgrade of R FR 5010

Rack controller for the R FR 5010 Card

Frame

Master controller with TCP/IP Inteface for

the R FR 5010 Card Frame

Rack Bus Extension for the R FR 5010 Card

Frame. In combination with R CT 5020/5030

Page 36

Page 37

Parts List

There are no user serviceable electronic assemblies

within the R FR 5010 module. The parts list below

shows high-level sub assemblies used in this rack,

which can be ordered separately for maintenance

purposes.

R FR 5010 Rack Frame (complete)

Reference Manual R FR 5010 Version1.4

Description Series 5000 Rack Frame

Model Number R FR 5010

Part Number 6.155.001.000

Main sub assemblies

Main term panel Part Number: 6.155.001.030

Front Cover Part Number: 6.155.001.013

R FR 5011 Rack Frame (complete)

Description Series 5000 Rack Frame

Model Number R FR 5011

Part Number 6.155.002.000

Main sub assemblies

Main term panel Part Number: 6.155.001.030

Front Cover (w/ fans) Part Number: 6.155.001.010

Service

If you are experiencing problems, or have questions

concerning your R FR 5010 / R FR 5011 rack

assembly please contact your local distributor for

assistance.

More detailed information and product updates

may be available on our web site:

www.lynx-technik.com

You will also find links to contact us directly for

assistance.

Page 37

Page 38

Reference Manual R FR 5010 Version1.4

Contact Information

Please contact your local distributor; this is your

local and fastest method for obtaining support and

sales information.

Lynx Technik can be contacted directly using the

information below.

Address LYNX Technik AG

Brunnenweg 3

64331 Weiterstadt

Germany

Website www.lynx-technik.com

E-Mail info@lynx-technik.com

LYNX Technik manufactures a complete range of

high quality modular products for broadcast and

Professional markets, please contact your local

representative or visit our web site for more product

information.

Page 38

Page 39

Reference Manual R FR 5010 Version1.4

Notes

Page 39

Loading...

Loading...