LynRus Aut-O-Loc 3 Installation Instructions Manual

Aut-O-LocTM 3 Installation Instructions

General Warnings

● Read all instructions prior to installation and use.

● This unit is not a person fall protection device.

● This unit must be replaced after catching a falling load.

● Ensure all people are clear of backstop when operating hoisting

equipment. ( Use only supplied hardware, do not substitute)

● This unit is intended for indoor use only

● Use appropriate lock-out and tag-out procedure for backstop hoist

when installing Autoloc.

● During installation, use a tether on the Autoloc that will prevent the

Autoloc from falling.

● Ensure that people are well clear of work area, and that no-one is un-

derneath work platform. When installing unit ensure that work platform

is stable and clear of moving equipment during hoist operation. Work

platform (i.e. man lifts) may tip when extended to great heights. Make

sure the work platform is clear of the backstop when testing the movement of the backstop and Autoloc.

● Belt must move freely through the range of backstop motion. Belt

must not rub against anything as backstop moves; abrasion may cause

Belt failure.

● Keep loose clothing, long hair and jewelry clear of equipment while

installing Autoloc.

2. Locate the Autoloc just above and as close to the pick up point (where the lifting cable attaches) on the backstop mast as possible. The warning tear tab

should be just below the white roller guides at the bottom when the backstop is

in the fully raised position and facing outward so it can be seen easily if deployed.

1. The basketball backstop must be in its deployed (down) position for installation

of the Autoloc.

Unit should be oriented so

the warning tear tab

Is visible from the front of

the basket.

Rev. 6-27-18

Warning Strip

will deploy on

side opposite

the sewn loop

if unit catches

a load.

List of contents in the box:

Description Quantity

Aut-O-Loc

TM

3 1 each

Instruction Set 1 each

Hardware packet containing:

Nut, Hex , 3/8” Flange Lock 1 each

Nut, Hex, 1/2” Flange Lock 2 each

Nut, Hex 5/8” Flange Lock 1 each

Bolt, 3/8” x 3” 1 each

Bolt, 1/2” x 3” 1 each

Bolt, 1/2” x 4” 1 each

Bolt, 5/8” x 4.25” 1 each

Clamp, Belt, Buckle 1 each

Clamp, Pipe (for belt buckle) 1 each

Following is a list of necessary tools:

3/4 inch six or twelve point socket

3/4 inch combination open/box end wrench

9/16 inch socket & wrench (open or adjustable)

15/16 inch socket & wrench (open or adjustable)

5-100 ft lb torque wrench

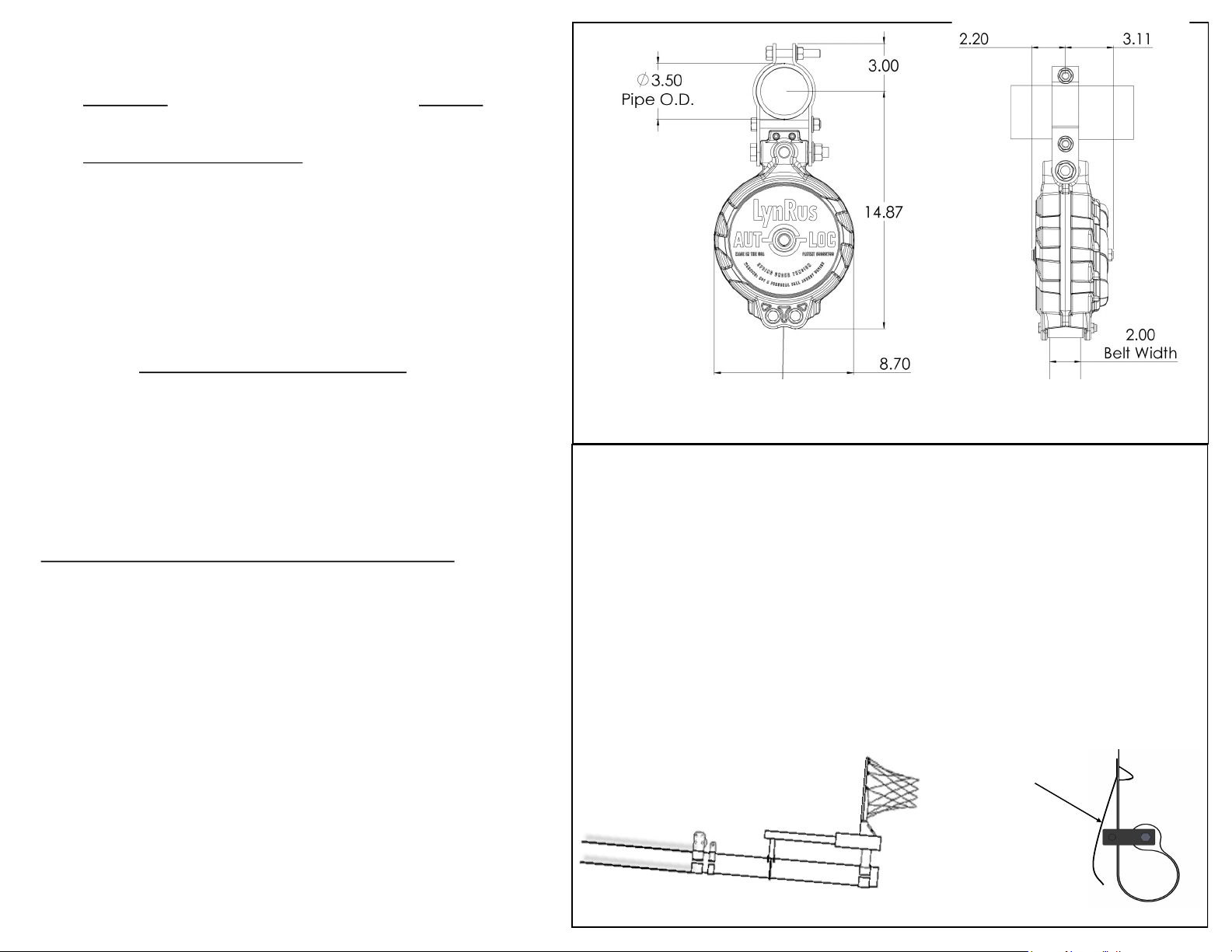

Pictured here as

installed with 3”

pipe. The universal pipe clamp will

also accept 4”

tube.

SHIPPING WEIGHT:19 LBS

CAPACITY: 1000 LBS MAXIMUM BELT TRAVEL: 35 FEET

Aut-O-LocTM 3 Installation Instructions

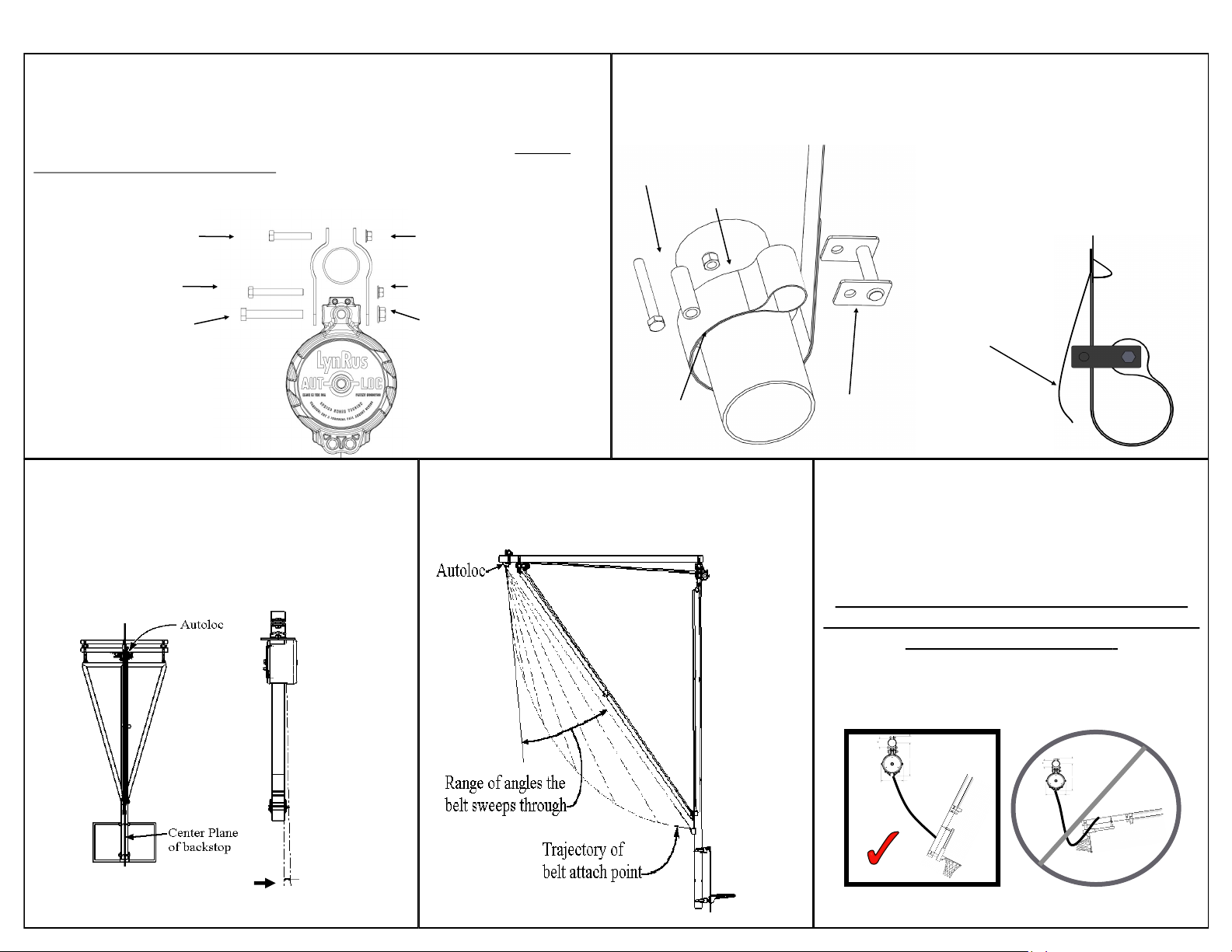

3. Insert 1/2 x 3” bolt in top clamp hole and finger tighten into opposite half

clamp using 1/2” nut. Place clamp over mounting pipe. Lift Autoloc unit up

to clamp, insert 5/8”x 4.25” bolt through bottom hole in both clamp halves

and Autoloc unit and finger tighten using 5/8” nut. If mounting to 3” pipe,

Insert 1/2” x 4” bolt in middle clamp hole and finger tighten nut; 4” tube

will not require this 1/2” x 4” bolt. Position the Autoloc and hand tighten all

bolts so that the Aut-O-Loc will remain in position on the pipe.

* When mounting to 4”

tube, it is not neces-

sary to use the 1/2” x

4” bolt & matching nut

on the pipe clamp.

*

1/2 nut

1/2 nut

5/8” nut

5. The Autoloc must be mounted in the

center plane of backstop motion and the

belt should not angle to the side or rub

against any surface. Maximum belt side

angle should not be greater than 1º at

maximum belt payout.

1° Maximum belt side angle

Rev. 6-27-18

8. The belt should only have a slight bend when

the basket is in the down position.

The Autoloc belt should never form a slack

loop at any point during the movement of the

backboard (see figure B).

If a loop has formed, make sure the Autoloc is directly in line with the pick up point and is not inter-

fering with a retractor reel or other obstruction

9.75

14.61

3.00

3.50

Pipe O.D.

2.00

Belt Width

3.492.19

Figure A

9.75

14.61

3.00

3.50

Pipe O.D.

2.00

Belt Width

3.492.19

Figure B

7. Tighten all bolts on the pipe mount and belt

clamp. When mounting to 4” tube, tighten the

5/8” bolt so the pipe clamp is tight against the

surface of the cast housing.

6. The Autoloc Belt should be clear of obstructions

throughout its sweep. These angles are installa-

tion dependent

4. Wrap end around mast attach point. Place sewn tail of belt loop on the

outside of the loop. Insert bolt through the clamp and clamp tube and tight-

en 3/8” nut on opposite side. You should see a small loop of black material

near the end of the belt that contains the catch warning flag. The flag will

show on the side opposite the loop

when deployed. You should wrap

the strap so the warning strip will be

most visible if deployed in a fall.

Bolt, 3/8” x 2-1/2”

Clamp, Pipe

Nut, Hex 3/8”

Belt, Buckle

Warning Strip

will deploy on

side opposite

the sewn loop

if unit catches

a load.

1/2 x 3” bolt

*

1/2 x 4” bolt

5/8” x 4.25 bolt

Loading...

Loading...