Lycoming TEO-540-C1A Maintenance Manual

© 2018 Avco Corporation. All Rights Reserved.

Engine Maintenance Manual

(Principal Manual)

TEO-540-C1A Engine

November 2018

Part No. MM-TEO-540-C1A

TEO-540-C1A Engine

Maintenance Manual

Lycoming Part Number: MM-TEO-540-C1A

Contact Us:

Mailing Address:

Lycoming Engines

652 Oliver Street

Williamsport, PA 17701 USA

Phone:

Factory

U.S. and Canada Toll Free:

Direct:

+1 (800) 258-3279

+1 (570) 323-6181

Technical Support Hotline

• +1 (877) 839-7878 (Toll Free)

• +1 (570) 327-7222

• Email Technicalsupport@lycoming.com

Lycoming’s regular business hours are Monday through Friday from 8:00AM through 5:00PM

Eastern Time (-5 GMT).

Visit us Online: www.lycoming.com

NOTE:

Lycoming recommends that owners of this manual sign up for email notification on the Technical

Publications page of our website https://www.lycoming.com/contact/knowledge-base/publications.

By submitting your email address, you will receive notification whenever Lycoming publishes a new

or revised technical publication, including any revisions to this Engine Maintenance Manual.

TEO-540-C1A Engine Maintenance Manual

© 2018 Avco Corporation. All Rights Reserved Record of Revisions

November 2018 Page i

TEO-540-C1A Engine Maintenance Manual

RECORD OF REVISIONS

Revision

Revision

Date

Revised By

Revision Description

Original

Original Release of Maintenance Manual -

Part No. MM-TEO-540-C1A

TEO-540-C1A Engine Maintenance Manual

Record of Revisions © 2018 Avco Corporation. All Rights Reserved

Page ii November 2018

TEO-540-C1A Engine Maintenance Manual

This page intentionally left blank.

TEO-540-C1A Engine Maintenance Manual

© 2018 Avco Corporation. All Rights Reserved Service Document List

November 2018 Page iii

TEO-540-C1A Engine Maintenance Manual

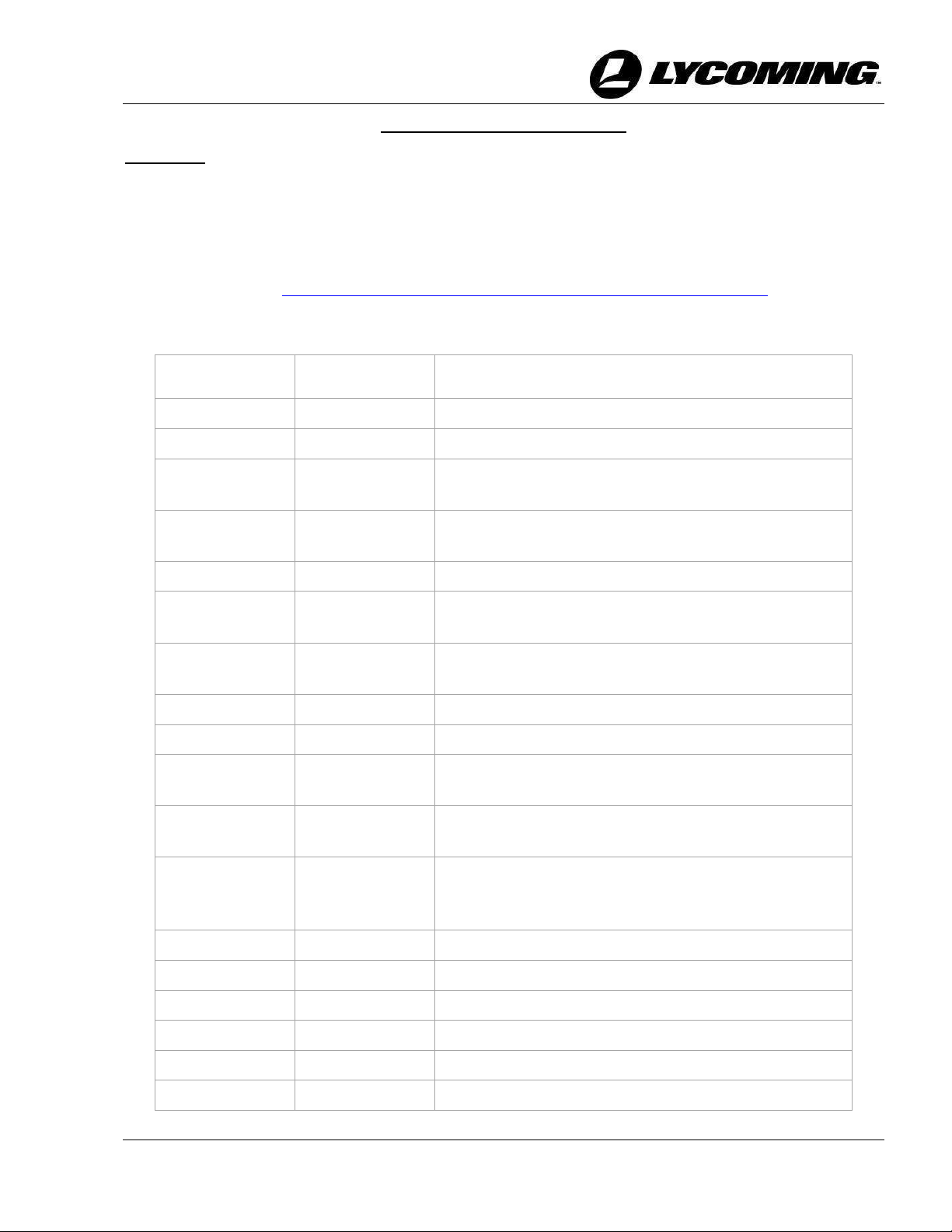

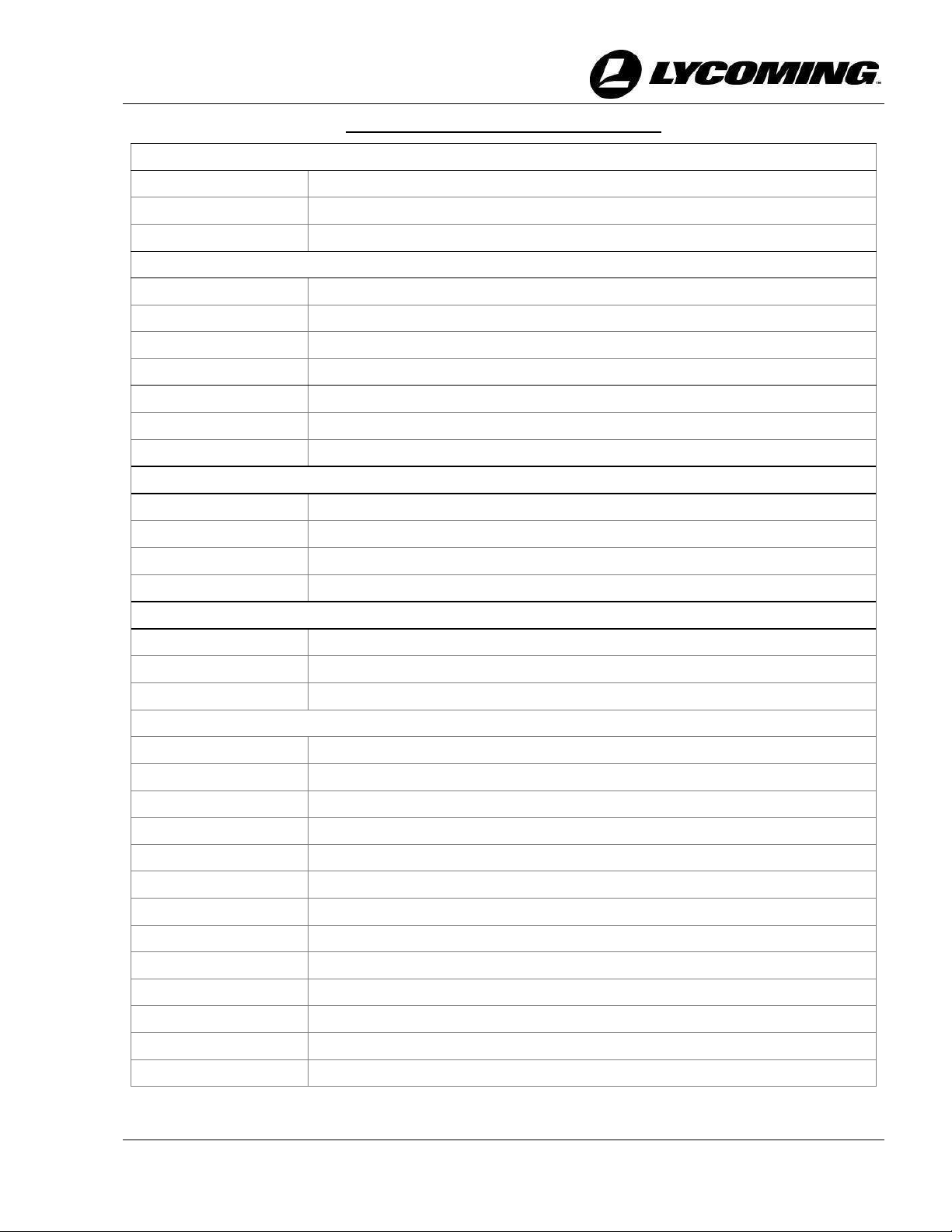

SERVICE DOCUMENT LIST

NOTICE: The following is a list of service documents referenced in or incorporated into the

information in this manual. Always refer to the latest revision of any service document

(including any supplements) for changes or additional information. Supplements to a

service document contain information relevant to the service document but not yet

added to the service document.

The latest revision of all service documents in this list can be downloaded from our

website https://www.lycoming.com/contact/knowledge-base/publications.

To narrow the search parameters and limit the number of returns, enter only the

numerical portion of the service document number in the Search box on the website.

Number

Incorporation

Date

Subject

S.B. 201

11/18

Inspection of Crankshaft Flange

S.B. 225

11/18

Replacement of Valve Rocker Thrust Washers

S.B. 240

11/18

Mandatory Parts Replacement at Overhaul and

During Repair or Maintenance

S.B. 357

11/18

Engine Inspection After an Engine Has Been Soaked

or Immersed

S.B. 369

11/18

Engine Inspection after Overspeed

S. B. 388

11/18

Procedure to Determine Exhaust Valve and Guide

Condition

S.B. 398

11/18

Recommended Corrective Action for Use of

Incorrect Fuel

S.B. 399

11/18

Action to Take If Loss of Oil Pressure

S.B. 401

11/18

Recommendations for Aircraft Struck by Lightning

S.B. 475

11/18

Crankshaft Gear Modification and Assembly

Procedures

S.B. 480

11/18

Oil, Oil Filter, Oil Pressure Screen, and Oil Suction

Screen Servicing

S.B. 533

11/18

Recommended Action for Sudden Engine Stoppage,

Propeller/Rotor Strike or Loss of Propeller/Rotor

Blade or Tip

S.B. 592

11/18

Engine Inspection after Overboost

S.I. 1009

11/18

Time Between Overhaul (TBO) Schedules

S.I. 1011

11/18

Tappets and Lifters

S.I. 1012

11/18

Counterweights and Rollers on Engine Models

S.I. 1014

11/18

Lubricating Oil Recommendations

S.I. 1043

11/18

Spark Plug Heli-Coil® Insert Replacement

TEO-540-C1A Engine Maintenance Manual

Service Document List © 2018 Avco Corporation. All Rights Reserved

Page iv November 2018

TEO-540-C1A Engine Maintenance Manual

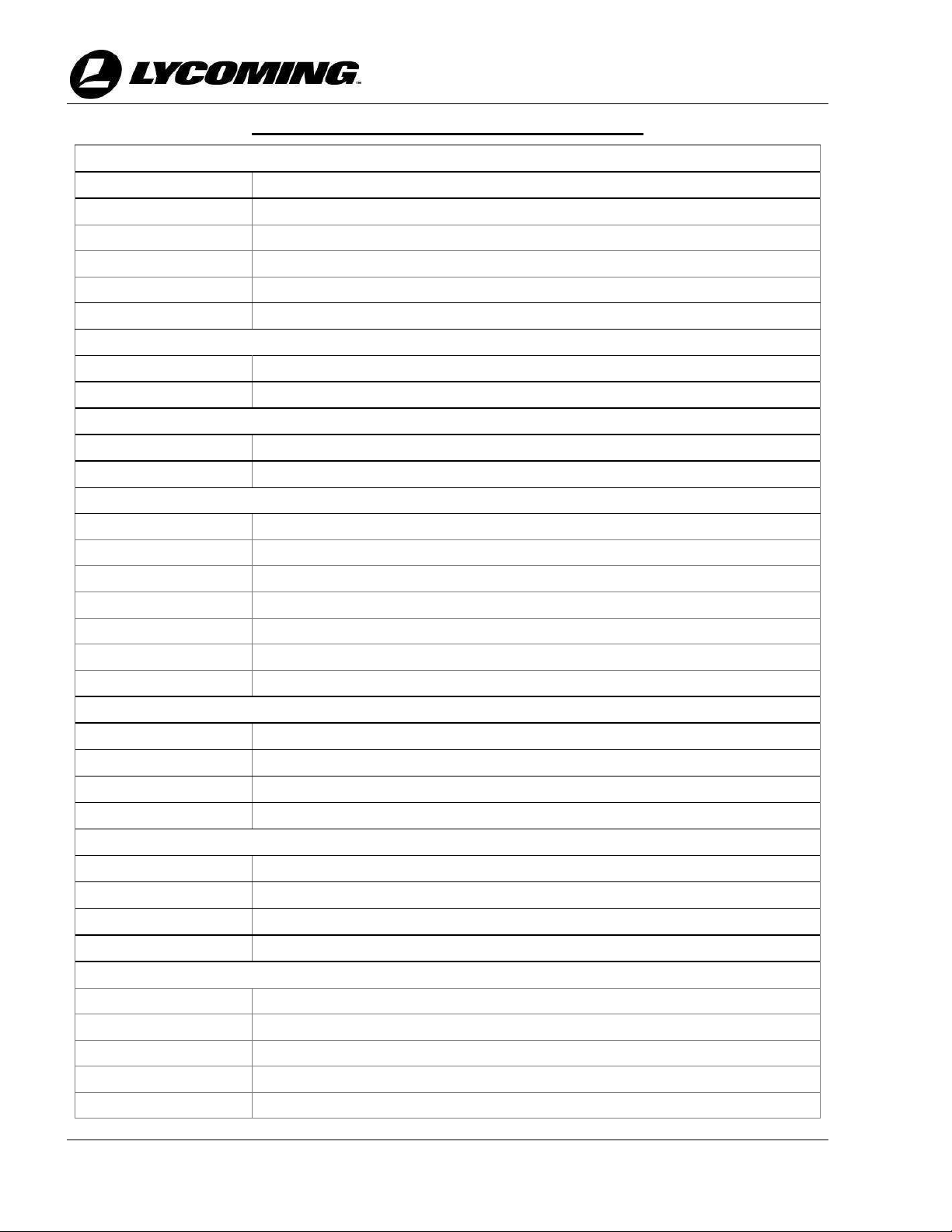

SERVICE DOCUMENT LIST (CONT.)

Number

Incorporation

Date

Subject

S.I. 1047

11/18

Inspection and Reconditioning Procedures for

Nitride Hardened Steel Cylinders

S.I. 1059

11/18

Pre-Lubrication of Parts Before Assembly

S.I. 1070

11/18

Specified Fuels for Spark-Ignited Gasoline Aircraft

Engine Models

S.I. 1080

11/18

Maintenance Items for Special Attention

S.I. 1098

11/18

Propeller Flange Bushing Location

S.I. 1129

11/18

Methods of Checking DC Alternator and Generator

Belt Tension

S.I. 1142

11/18

Replacement of Crankshaft Counterweight Bushings

S.I. 1172

11/18

Adjustable Oil Pressure Relief Valve Installation and

Valve Seat Repair or Replacement

S.I. 1191

11/18

Cylinder Compression

S.I. 1204

11/18

Exhaust Flange Gaskets

S.I. 1238

11/18

Assembly and Torque Procedures for V-Band

Couplings

S.I. 1241

11/18

Pre-oil the Engine Prior to Initial Start

S.I. 1267

11/18

Piston Pin Plug Usage

S.I. 1285

11/18

Non-Destructive Testing of Lycoming Engine Parts

S.I. 1301

11/18

Identification of Primer and Fuel Injector Lines

S.I. 1304

11/18

Engine Nameplate Replacement

S.I. 1316

11/18

Valve Seat Refacing on Oil Cooler Bypass Valves

S.I. 1324

11/18

Crankshaft Oil Seals

S.I. 1340

11/18

Piston Pin Identification

S.I. 1409

11/18

Lycoming Engines P/N LW-16702 Oil Additives

S.I. 1425

11/18

Suggested Maintenance Procedures to Reduce the

Possibility of Valve Sticking

S.I. 1427

11/18

Field Run-In and Break-In

S.I. 1458

11/18

Connecting Rod Bolts (Identification and

Installation)

S.I. 1462

11/18

Propeller Oil Control Leak Test Procedure

S.I. 1485

11/18

Exhaust Valve and Guide Identification Procedure

S.I. 1492

11/18

Piston Pin Plug Wear Inspection

S.I. 1514

11/18

Roller Tappets Part Information Update

TEO-540-C1A Engine Maintenance Manual

© 2018 Avco Corporation. All Rights Reserved Service Document List

November 2018 Page v

TEO-540-C1A Engine Maintenance Manual

SERVICE DOCUMENT LIST (CONT.)

Number

Incorporation

Date

Subject

S.I. 1530

11/18

Engine Inspection in Particulate-Laden

Environments

S.I. 1535

11/18

Counterweight and Roller Removal, Inspection, and

Installation

S.I. 1562

11/18

Turbocharged Exhaust System Installation

S.I. 1566

11/18

Lycoming Engines Approves the Use of Safety

Cable

S.I. 1573

11/18

Lycoming TEO-540 Engine Series Engine Control

Unit (ECU) Assembly Cross-References

L114

11/18

Reciprocating Engine and Accessory Maintenance

Publications

L171

11/18

General Aspects of Spectrometric Oil Analysis

L180

11/18

Engine Preservation Guidelines for Active and

Stored Aircraft

L192

11/18

Spark Plug Fouling

L193

11/18

Engine Firing Order

L197

11/18

Recommendations to Avoid Valve Sticking

L247

11/18

Shelf Life Requirements

L253

11/18

Warranty Repair of AVStar Fuel Systems, Inc. Fuel

Control Products

L270

11/18

Extended Maintenance Intervals for Spark-Ignited

Engines Operated on Unleaded Fuels

TEO-540-C1A Engine Maintenance Manual

Service Document List © 2018 Avco Corporation. All Rights Reserved

Page vi November 2018

TEO-540-C1A Engine Maintenance Manual

This page intentionally left blank.

TEO-540-C1A Engine Maintenance Manual

© 2018 Avco Corporation. All Rights Reserved Table of Contents

November 2018 Page vii

TEO-540-C1A Engine Maintenance Manual

TABLE OF CONTENTS

Subject Page

Title Page _______________________________________________________________________

Record of Revisions .............................................................................................................................. i

Service Document List ....................................................................................................................... iii

Table of Contents .............................................................................................................................. vii

Abbreviations and Acronyms ........................................................................................................ xvii

Introduction ...................................................................................................................................... xxi

Airworthiness Limitations ............................................................................................................ xxvii

Required Maintenance ................................................................................................. 05-00

— Required Maintenance ............................................................................................................. 1

— General ..................................................................................................................................... 1

— List of Tools for Service and Maintenance .............................................................................. 1

— Table 1 - Tools for Service and Maintenance ..................................................................... 1

— Time Between Overhaul (TBO) ............................................................................................... 3

— Safety Precautions - Before Engine Maintenance .................................................................... 3

— Maintenance Practices .............................................................................................................. 3

— General Engine Inspection Criteria .......................................................................................... 5

— Requirements for Engine Maintenance .................................................................................... 5

— Approved Parts ......................................................................................................................... 5

Time Limits / Inspections ............................................................................................. 05-10

— Engine Inspection Schedule for TEO-540-C1A Engines ........................................................ 7

Required Engine Inspections for TEO-540-C1A Engines ......................................... 05-20

— Engine Inspections .................................................................................................................... 9

— Visual Inspection for TEO-540-C1A Engines .......................................................................... 9

— Operational Leak Check Sheet for TEO-540-C1A Engines ................................................... 16

— 10-Hour Initial Engine Inspection for TEO-540-C1A Engines .............................................. 17

— 25-Hour Engine Inspection for TEO-540-C1A Engines......................................................... 19

— 50-Hour Engine Inspection for TEO-540-C1A Engines......................................................... 21

— 100-Hour or Annual Engine Inspection for TEO-540-C1A Engines ..................................... 24

— 250-Hour Engine Inspection for TEO-540-C1A Engines ....................................................... 29

— 400-Hour Engine Inspection for TEO-540-C1A Engines ....................................................... 30

— 1000-Hour Engine Inspection for TEO-540-C1A Engines..................................................... 32

TEO-540-C1A Engine Maintenance Manual

Table of Contents © 2018 Avco Corporation. All Rights Reserved

Page viii November 2018

TEO-540-C1A Engine Maintenance Manual

Subject Page

Cleaning ......................................................................................................................... 05-30

— Cleaning Guidelines ................................................................................................................ 35

— Table 1 - Cleaning Guidelines for Engine Components .................................................... 36

— Crankshaft Cleaning ................................................................................................................ 38

— Crankshaft Counterbore Cleaning ........................................................................................... 38

— Crankshaft Trigger Gear Assembly Cleaning ......................................................................... 39

— Tappet Cleaning ...................................................................................................................... 40

— Crankcase Cleaning................................................................................................................. 40

— Grit-Blasting............................................................................................................................ 40

— Soft Carbon Removal .............................................................................................................. 41

— Hard Carbon Removal ............................................................................................................ 42

— Cylinder Cleaning ................................................................................................................... 42

— Piston Cleaning ....................................................................................................................... 43

— Steel, Aluminum, or Magnesium Parts Cleaning .................................................................... 43

— Spark Plug Cleaning................................................................................................................ 44

— Lead Deposit Removal ............................................................................................................ 44

— Volcanic Ash Removal ........................................................................................................... 45

— Cleaning Guidelines for a Soaked Engine .............................................................................. 45

— Cleaning Methods for Non-Destructive Testing ..................................................................... 46

Unscheduled Corrective Maintenance ........................................................................ 05-50

— Lightning Strike - After a lightning strike .............................................................................. 47

— Engine Overspeed ................................................................................................................... 47

— Table 1 - Overspeed Values for TEO-540-C1A Engines ................................................. 48

— Engine Overboost .................................................................................................................... 50

— Incorrect Fuel or Fuel Contamination ..................................................................................... 50

— Soaked Engine......................................................................................................................... 51

— Engine on Fire or Near a Fire .................................................................................................. 52

— Hydraulic Lock ....................................................................................................................... 53

— Volcanic Ash/Particulate Contamination ................................................................................ 53

— Table 2 - Action to Take in Volcanic Ash Conditions ...................................................... 54

— Valve Sticking ......................................................................................................................... 55

— Oil Starvation/Sudden Loss of Oil Pressure ........................................................................... 55

— Metal Contamination of the Lubrication System .................................................................... 56

— NTO & TLO Illumination on the Control Panel ..................................................................... 56

— Propeller Strike, Sudden Engine Stoppage or Loss of a Propeller Blade Tip ......................... 57

— Non-Destructive Testing

(Magnetic Particle Inspection and Fluorescent Penetrant Inspection.) ................................... 64

TEO-540-C1A Engine Maintenance Manual

© 2018 Avco Corporation. All Rights Reserved Table of Contents

November 2018 Page ix

TEO-540-C1A Engine Maintenance Manual

Subject Page

Servicing - Replenishing ............................................................................................... 12-10

— Refueling ................................................................................................................................. 65

— Oil Level Check ...................................................................................................................... 65

— Oil Consumption ..................................................................................................................... 66

— Oil Type and Viscosity ........................................................................................................... 66

— Add Oil to the Engine ............................................................................................................. 66

— Oil Leak Check ....................................................................................................................... 67

— Oil Servicing Schedule............................................................................................................ 67

— Table 1 - Oil Servicing Schedule ....................................................................................... 67

— Oil Change Procedure ............................................................................................................. 68

— Engine Pre-Oil Procedure ....................................................................................................... 69

— Oil Suction Screen Removal/Inspection/Cleaning/Installation ............................................... 71

— Oil Filter Replacement ............................................................................................................ 72

— Oil Filter Inspection ................................................................................................................ 73

— Identification of Metallic Solids After Oil Servicing .............................................................. 73

— Visual Inspection of the Oil Filter Element and Oil Suction Screen ...................................... 73

— Table 2 - Guidelines for Identification of Metal Particulates

and Chips & Corrective Action .......................................................................... 75

— Table 3 - Guidelines for Particle Quantity and Size on Oil Filter or Oil Suction Screen .. 77

— Recommended Corrective Action Options ............................................................................. 79

— Table 4 - Recommended Corrective Action Options ......................................................... 79

— Oil Contamination Check........................................................................................................ 80

Fault Isolation ................................................................................................................ 12-30

— Recommended Approach to Fault Isolation ............................................................................ 81

— Table 1 - Fault Isolation Guide .......................................................................................... 81

Engine Removal and Return to Service ...................................................................... 72-00

— Engine Removal Prerequisites .............................................................................................. 101

— Engine Removal Procedure ................................................................................................... 101

— Engine Installation Preparation Requirements ...................................................................... 103

— Table 1 - Materials and Procedures to Prepare a Serviced Engine for Installation ........ 104

— Operational Ground Check ................................................................................................... 104

— Engine Mount Inspection ...................................................................................................... 105

— Return to Service Procedure ................................................................................................. 105

TEO-540-C1A Engine Maintenance Manual

Table of Contents © 2018 Avco Corporation. All Rights Reserved

Page x November 2018

TEO-540-C1A Engine Maintenance Manual

Subject Page

Engine Disassembly....................................................................................................... 72-05

— Engine Disassembly Procedure ............................................................................................. 107

— Table 1 – Sequence of Engine Disassembly Procedure ................................................... 107

Engine Assembly ........................................................................................................... 72-10

— Corrosion Prevention ............................................................................................................. 113

— Painting the Engine and Engine Components ........................................................................ 113

— Table 1 – Paint Stripping and Painting Guidelines for Components ............................... 113

— Limits and Clearances ............................................................................................................ 115

— Inspections ............................................................................................................................. 115

— Engine Assembly Procedure ................................................................................................. 116

— Table 2 – Sequence of Engine Assembly Procedure ....................................................... 116

— Engine Assembly Checklist .................................................................................................. 122

Propeller Flange Bushing Replacement ...................................................................... 72-15

— Propeller Flange Bushing Removal ...................................................................................... 127

— Propeller Flange Bushing Installation ................................................................................... 127

Crankcase Maintenance ............................................................................................... 72-20

— Exterior Crankcase Inspection .............................................................................................. 129

— Connecting Rod Removal ..................................................................................................... 130

— Crankcase Disassembly......................................................................................................... 130

— Crankshaft Disassembly ........................................................................................................ 136

— Interior Crankcase Inspection ............................................................................................... 139

— Crankshaft Inspection ........................................................................................................... 142

— Crankshaft Bearing Surface Inspection ................................................................................. 151

— Table 1 - Crankshaft Undersize Codes ............................................................................ 151

— Bearing Shell Surface Inspection .......................................................................................... 152

— Gear Inspection ..................................................................................................................... 152

— Screwed Fitting Inspection.................................................................................................... 152

— Camshaft Disassembly and Inspection ................................................................................. 153

— Connecting Rod Inspection ................................................................................................... 154

— Connecting Rod Bushing Replacement ................................................................................ 158

— Connecting Rod Parallelism / Squareness Check ................................................................. 159

— Tappet Inspection .................................................................................................................. 160

TEO-540-C1A Engine Maintenance Manual

© 2018 Avco Corporation. All Rights Reserved Table of Contents

November 2018 Page xi

TEO-540-C1A Engine Maintenance Manual

Subject Page

Crankcase Maintenance (Cont.) .................................................................................. 72-20

— Crankshaft Assembly ............................................................................................................ 164

— Piston Cooling Nozzle Installation (if removed) .................................................................. 174

— Oil Plug Installation (if removed) ......................................................................................... 174

— Tappet Assembly Installation................................................................................................ 175

— Crankshaft Bearing and O-Ring Installation ......................................................................... 176

— Propeller Governor Drive Installation ................................................................................... 177

— Table 2 - Thrust Washer Thickness ................................................................................. 177

— Camshaft Assembly and Installation..................................................................................... 179

— Crankshaft Installation .......................................................................................................... 182

— Table 3 - Slinger Clearance at Point A ............................................................................ 183

— Table 4 - End Play Clearance at Point B .......................................................................... 183

— Crankcase Assembly ............................................................................................................. 183

— Table 5 - Crankcase Fastener Torque Values .................................................................. 187

— Crankshaft End Play Clearance Check ................................................................................. 188

— Propeller Oil Control Leak Test ............................................................................................ 189

— Crankshaft Oil Seal Installation ............................................................................................ 191

— Crankshaft Trigger Gear Assembly and Crankshaft Idler Gear Installation ......................... 194

— Crankshaft-to-Camshaft Timing Check ................................................................................ 199

Accessory Housing Maintenance ................................................................................. 72-25

— Accessory Housing Removal ................................................................................................ 201

— Oil Pump Removal ................................................................................................................ 202

— Oil Pump Installation ............................................................................................................ 202

— Accessory Housing Installation ............................................................................................ 203

Cylinder Maintenance .................................................................................................. 72-30

— General .................................................................................................................................. 205

— Table 1 - Regularly Scheduled Cylinder Inspections ...................................................... 205

— Visual Cylinder Inspection.................................................................................................... 205

— Cylinder Compression Check ............................................................................................... 206

— Table 2 - Summary of Cylinder Compression Check Results and Corrective Action .... 210

— Intercylinder Baffle Inspection ............................................................................................. 211

TEO-540-C1A Engine Maintenance Manual

Table of Contents © 2018 Avco Corporation. All Rights Reserved

Page xii November 2018

TEO-540-C1A Engine Maintenance Manual

Subject Page

Cylinder Maintenance (Cont.) ..................................................................................... 72-30

— Cylinder Borescope Inspection ............................................................................................. 212

— Table 3 - Borescope Inspection Steps, Results, and Corrective Action ........................... 213

— Exhaust Valve and Guide Inspection .................................................................................... 213

— Cylinder Removal ................................................................................................................. 218

— Piston Removal ..................................................................................................................... 223

— Cylinder Assembly Inspection .............................................................................................. 224

— Piston Inspection ................................................................................................................... 230

— Piston Ring Replacement ...................................................................................................... 234

— Piston Installation .................................................................................................................. 235

— Intake Valve Replacement .................................................................................................... 236

— Exhaust Valve Replacement ................................................................................................. 237

— Cylinder Installation .............................................................................................................. 237

— Corrective Action for Valve Sticking ................................................................................... 245

— Intake and Exhaust Valve Guide Replacement ..................................................................... 247

— Intake and Exhaust Valve Seat Replacement ........................................................................ 247

— Barrel Glaze and Varnish Removal from Interior Cylinder Barrel ....................................... 247

— Heli-Coil® Replacement ........................................................................................................ 248

Turbocharger Maintenance ......................................................................................... 72-40

— General .................................................................................................................................. 251

— 50-Hour Turbocharger Inspection ......................................................................................... 251

— 100-Hour Turbocharger Inspection ....................................................................................... 253

— 250-Hour Turbocharger Inspection ....................................................................................... 254

— Turbocharger Removal ......................................................................................................... 254

— Turbocharger Installation ...................................................................................................... 256

— Exhaust Bypass Valve Replacement...................................................................................... 257

Lubrication System Maintenance ................................................................................ 72-50

— Oil Pressure Adjustment ....................................................................................................... 259

— Oil System Inspection ........................................................................................................... 259

— Oil Hose Inspection ............................................................................................................... 259

— Oil Hose Replacement (General Instructions for Any Oil Hose) ......................................... 260

— Oil Filler Extension and Oil Level Gage Assembly Removal .............................................. 260

TEO-540-C1A Engine Maintenance Manual

© 2018 Avco Corporation. All Rights Reserved Table of Contents

November 2018 Page xiii

TEO-540-C1A Engine Maintenance Manual

Subject Page

Lubrication System Maintenance (Cont.) ................................................................... 72-50

— Oil Filler Extension and Oil Level Gage Assembly Installation .......................................... 261

— Oil Pressure Relief Valve Removal ...................................................................................... 261

— Oil Pressure Relief Valve Inspection .................................................................................... 261

— Oil Pressure Relief Vale Installation ..................................................................................... 262

— Oil Cooler Bypass Valve Removal ....................................................................................... 262

— Oil Cooler Bypass Valve Cleaning ....................................................................................... 262

— Oil Cooler Bypass Valve Installation.................................................................................... 262

— Oil Sump Removal ................................................................................................................ 263

— Oil Sump Inspection.............................................................................................................. 264

— Oil Sump Installation ............................................................................................................ 264

Accessory Drives ........................................................................................................... 72-60

— Accessory Drive Inspection .................................................................................................. 267

— Vacuum Pump Replacement ................................................................................................. 267

— Vacuum Pump Drive Gear Replacement .............................................................................. 267

Electrical System Maintenance .................................................................................... 72-70

— Wiring Inspection .................................................................................................................. 269

— Alternator Belt Inspection ..................................................................................................... 270

— Alternator Belt Tension Check/Adjustment .......................................................................... 270

— Alternator and Bracket Removal ........................................................................................... 272

— Alternator and Bracket Installation ....................................................................................... 273

— Alternator Belt Replacement ................................................................................................. 273

— Power Box and PMA ............................................................................................................ 274

— The Electrical System Includes Three Wiring Harnesses ..................................................... 274

— Wiring Harness Connectors .................................................................................................. 275

— Table 2 – Wiring Harness Connector Guidelines ........................................................... 275

— Sensor Replacement Procedures ........................................................................................... 282

— Table 3 - Sensor Replacement Procedures ...................................................................... 282

— Engine-to-Firewall Wiring Harness Removal ....................................................................... 293

— Engine-to-Firewall Wiring Harness Installation ................................................................... 295

— Airframe Interface Wiring Harness Removal ....................................................................... 296

— Airframe Interface Wiring Harness Installation .................................................................... 297

TEO-540-C1A Engine Maintenance Manual

Table of Contents © 2018 Avco Corporation. All Rights Reserved

Page xiv November 2018

TEO-540-C1A Engine Maintenance Manual

Subject Page

Electrical System Maintenance (Cont.) ....................................................................... 72-70

— ECU Removal ....................................................................................................................... 298

— ECU Installation .................................................................................................................... 298

— Power Box Removal ............................................................................................................. 299

— Power Box Installation .......................................................................................................... 299

— Permanent Magnet Alternator (PMA) Replacement ............................................................. 299

— Starter Replacement .............................................................................................................. 300

— Starter Ring Gear Support Replacement ............................................................................... 301

— Starter Ring Gear Replacement ............................................................................................. 302

Induction System Maintenance.................................................................................... 72-80

— Induction System Inspection ................................................................................................. 305

— Intake Pipe Replacement ....................................................................................................... 305

— Fuel Drain Valve Adapter Assembly Inspection .................................................................. 307

— Induction Housing Replacement ........................................................................................... 307

— Air Inlet Housing Replacement ............................................................................................. 308

Engine Fuel and Control - Distribution ...................................................................... 73-10

— Fuel System Inspection ......................................................................................................... 309

— Fuel Hose Inspection ............................................................................................................. 311

— Table 1 - Corrective Action for Fuel Hoses ..................................................................... 313

— Fuel Injector Leak Check ...................................................................................................... 313

— Fuel System Inspection Checklist ......................................................................................... 314

— Fuel Hose Replacement ........................................................................................................ 317

— Fuel Injector Rail Assembly Replacement............................................................................ 319

— Fuel Injector Replacement .................................................................................................... 321

— Fuel Injector Adapter Replacement ...................................................................................... 322

— Fuel Pump Filter Replacement .............................................................................................. 323

— Fuel Pump Replacement ....................................................................................................... 324

— Fuel Pressure Regulator Replacement .................................................................................. 325

TEO-540-C1A Engine Maintenance Manual

© 2018 Avco Corporation. All Rights Reserved Table of Contents

November 2018 Page xv

TEO-540-C1A Engine Maintenance Manual

Subject Page

Engine Fuel and Control - Controlling ....................................................................... 73-20

— (Electronic) Throttle Body Replacement .............................................................................. 329

— Operational Test of Throttle Body ........................................................................................ 330

Ignition System Maintenance ....................................................................................... 74-20

— Ignition Lead Removal.......................................................................................................... 331

— Table 1 - Ignition Leads ................................................................................................... 330

— Spark Plugs ........................................................................................................................... 333

— Spark Plug Removal.............................................................................................................. 333

— Ignition Lead Inspection ....................................................................................................... 333

— Spark Plug Inspection ........................................................................................................... 334

— Table 2 - General Spark Plug Wear/Replacement Guidelines ......................................... 334

— Spark Plug Fouling................................................................................................................ 335

— Spark Plug Port Seal Inspection ............................................................................................ 335

— Spark Plug Cleaning.............................................................................................................. 336

— Spark Plug Gap Setting ......................................................................................................... 336

— Spark Plug Rotation .............................................................................................................. 336

— Table 3 - Spark Plug Rotation Scheme ............................................................................ 334

— Spark Plug Installation .......................................................................................................... 337

— Ignition Lead Installation ...................................................................................................... 337

Coil Assembly and Coil Box Maintenance .................................................................. 74-30

— Coil Box Access..................................................................................................................... 339

— Coil Assembly Replacement .................................................................................................. 340

— Coil Box Removal ................................................................................................................. 341

— Coil Box Installation .............................................................................................................. 342

Exhaust System Maintenance ...................................................................................... 78-00

— Heat Shield Removal ............................................................................................................. 343

— 50-Hour Exhaust System Inspection ..................................................................................... 344

— 100-Hour Exhaust System Inspection.................................................................................... 344

— 250-Hour Exhaust System Inspection.................................................................................... 344

— Heat Shield Installation .......................................................................................................... 347

— Exhaust System Removal ...................................................................................................... 347

— Exhaust System Installation ................................................................................................... 348

TEO-540-C1A Engine Maintenance Manual

Table of Contents © 2018 Avco Corporation. All Rights Reserved

Page xvi November 2018

TEO-540-C1A Engine Maintenance Manual

Subject Page

Appendix A ....................................................................................................................

— Stud Replacement .................................................................................................................. 351

— Air Bleed Nozzle Installation ................................................................................................ 352

— Fin Stabilizer Installation ....................................................................................................... 352

Appendix B ....................................................................................................................

— Wiring Diagrams.................................................................................................................... 353

— Table B-1 - Wiring Harness Leads and Connection Location ......................................... 353

— Schematic T-11327-Y ............................................................................................................ 359

— Communications Bus Data .................................................................................................... 367

Appendix C ......................................................................................................................................

— Field Service Tool User Manual Abbreviations and Acronyms ............................................ 369

— System Requirements ............................................................................................................ 371

— Software Installation .............................................................................................................. 373

— ECU to FST Connection ........................................................................................................ 381

— Access the Field Service Tool ............................................................................................... 383

— Sending Data to Lycoming Technical Support ...................................................................... 391

— Field Service Tool - Software Problems ................................................................................ 393

Appendix D ....................................................................................................................

— Troubleshooting Guide Abbreviations and Acronyms .......................................................... 395

— Troubleshooting Guide .......................................................................................................... 398

TEO-540-C1A Engine Maintenance Manual

© 2018 Avco Corporation. All Rights Reserved Abbreviations and Acronyms

November 2018 Page xvii

TEO-540-C1A Engine Maintenance Manual

ABBREVIATIONS AND ACRONYMS

A

ADL

Data Logger

AMM

Airframe Manufacturer’s Manual

ATA

Air Transportation Association

C

C

Celsius

CAM

Camshaft Speed Sensor

CHT

Cylinder Head Temperature

CIP-P

Primary Compressor Inlet Pressure

CIP-S

Secondary Compressor Inlet Pressure

cm

Centimeter

CRANK

Crankshaft Speed Sensor

D

DECK-P-P

Primary Induction Air Deck Temperature

DECK-P-S

Secondary Induction Air Deck Temperature

DECK-T

Induction Air Deck Temperature

DPS

Delta Pressure Sensor

E

ECU

Engine Control Unit

EECS

Electronic Engine Control System

EGT

Exhaust Gas Temperature

F

F

Fahrenheit

FAA

Federal Aviation Administration

FAR

Federal Aviation Regulation

FFL

Fault Found

FPI

Fluorescent Penetrant Inspection

FPP

Fuel Pump Pressure Sensor

FOD

Foreign Object Debris

FPI

Fluorescent Penetrant Inspection

FPP

Fuel Pump Pressure Sensor

FST

Field Service Tool

ft.-lb.

Foot Pound (torque)

FUEL-P

Fuel (Rail) Pressure Sensor

FUEL-T

Fuel Temperature Sensor

TEO-540-C1A Engine Maintenance Manual

Abbreviations and Acronyms © 2018 Avco Corporation. All Rights Reserved

Page xviii November 2018

TEO-540-C1A Engine Maintenance Manual

ABBREVIATIONS AND ACRONYMS (CONT.)

I

ICA

Instructions for Continued Airworthiness

ID

Identification; Inside/Inner Diameter

in.-lb.

Inch Pound (torque)

in.

Inch, inches

In-Hg

Inches of Mercury

IOM

Engine Installation and Operation Manual

K

KNOCK

Knock Sensor

kPa

Kilopascal

L

l

Liter

Lb.

Pound

M

MAP

Manifold Air Pressure

MAT-P

Primary Induction Air Manifold Temperature Sensor

MAT-S

Secondary Induction Air Manifold Temperature Sensor

MEK

Methyl-Ethyl-Ketone

mm

Millimeter

MPI

Magnetic Particle Inspection

MSB

Mandatory Service Bulletin

N

NDT

Non-Destructive Testing

Nm

Newton Meters

NPT

National Pipe Thread

NTO

No Take-Off

O

OD

Outside/Outer Diameter

OEM

Original Equipment Manufacturer

OIL-P

Oil Pressure Sensor

OIL-T

Oil Temperature Sensor

P

PMA

Permanent Magnet Alternator or Parts Manufacturer Approval

P/N

Part Number

POH

Pilot’s Operating Handbook

ppm

Parts per Million

psi

Pounds per square inch

TEO-540-C1A Engine Maintenance Manual

© 2018 Avco Corporation. All Rights Reserved Abbreviations and Acronyms

November 2018 Page xix

TEO-540-C1A Engine Maintenance Manual

ABBREVIATIONS AND ACRONYMS (CONT.)

R

rpm

Revolutions per Minute

S

SA

Special Advisory

SAE

Society of Automotive Engineers (oil viscosity)

SB

Service Bulletin

SI

Service Instruction

STC

Supplemental Type Certificate

T

TBO

Time Between Overhaul

TDC

Top Dead Center

TIR

Total Indicator Reading

TIT

Turbine Inlet Temperature Sensor

TLO

Time-Limited Operation

TPS

Throttle Position Sensor

TEO-540-C1A Engine Maintenance Manual

Abbreviations and Acronyms © 2018 Avco Corporation. All Rights Reserved

Page xx November 2018

TEO-540-C1A Engine Maintenance Manual

This page intentionally left blank.

TEO-540-C1A Engine Maintenance Manual

© 2018 Avco Corporation. All Rights Reserved Introduction

November 2018 Page xxi

TEO-540-C1A Engine Maintenance Manual

INTRODUCTION

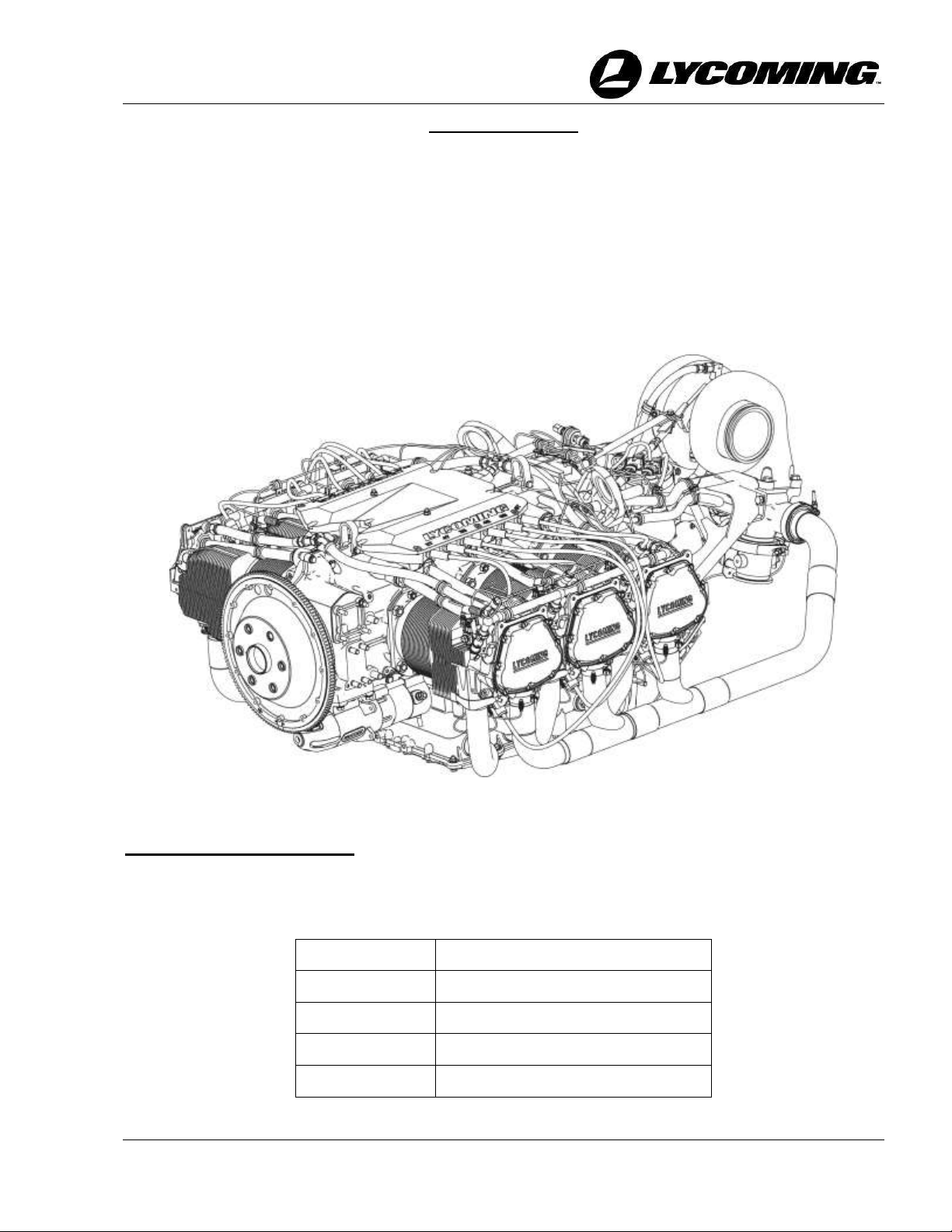

The Lycoming TEO-540-C1A Engine (Figure 1) is a direct-drive six-cylinder, horizontally opposed,

turbocharged, electronically-controlled engine. It has electronic fuel injection, electronic ignition,

and down exhaust. As standard equipment, this engine has an automotive type starter, an alternator,

and two standard AN type accessory drives.

The engine has an Electronic Engine Control System (EECS) which is a microprocessor. The EECS

continuously monitors and automatically adjusts operating conditions such as ignition timing, fuel

injection timing, and fuel mixture. The EECS eliminates the need for magnetos and manual fuel/air

mixture control. Refer to the “System Description” chapter in the TEO-540 C1A Engine Installation

and Operation Manual for more details.

Figure 1

TEO-540-C1A

Engine Model Nomenclature

The table below identifies the basic nomenclature of the TEO-540 engine models. Hyphenated

numbers and letters in the suffix (C1A) of the engine model number are configuration designations

associated with the core engine.

Model Number

Meaning

T

Turbocharged

E

Electronic Engine Control System

O

Horizontally Opposed

540

Displacement in cubic inches

TEO-540-C1A Engine Maintenance Manual

Introduction © 2018 Avco Corporation. All Rights Reserved

Page xxii November 2018

TEO-540-C1A Engine Maintenance Manual

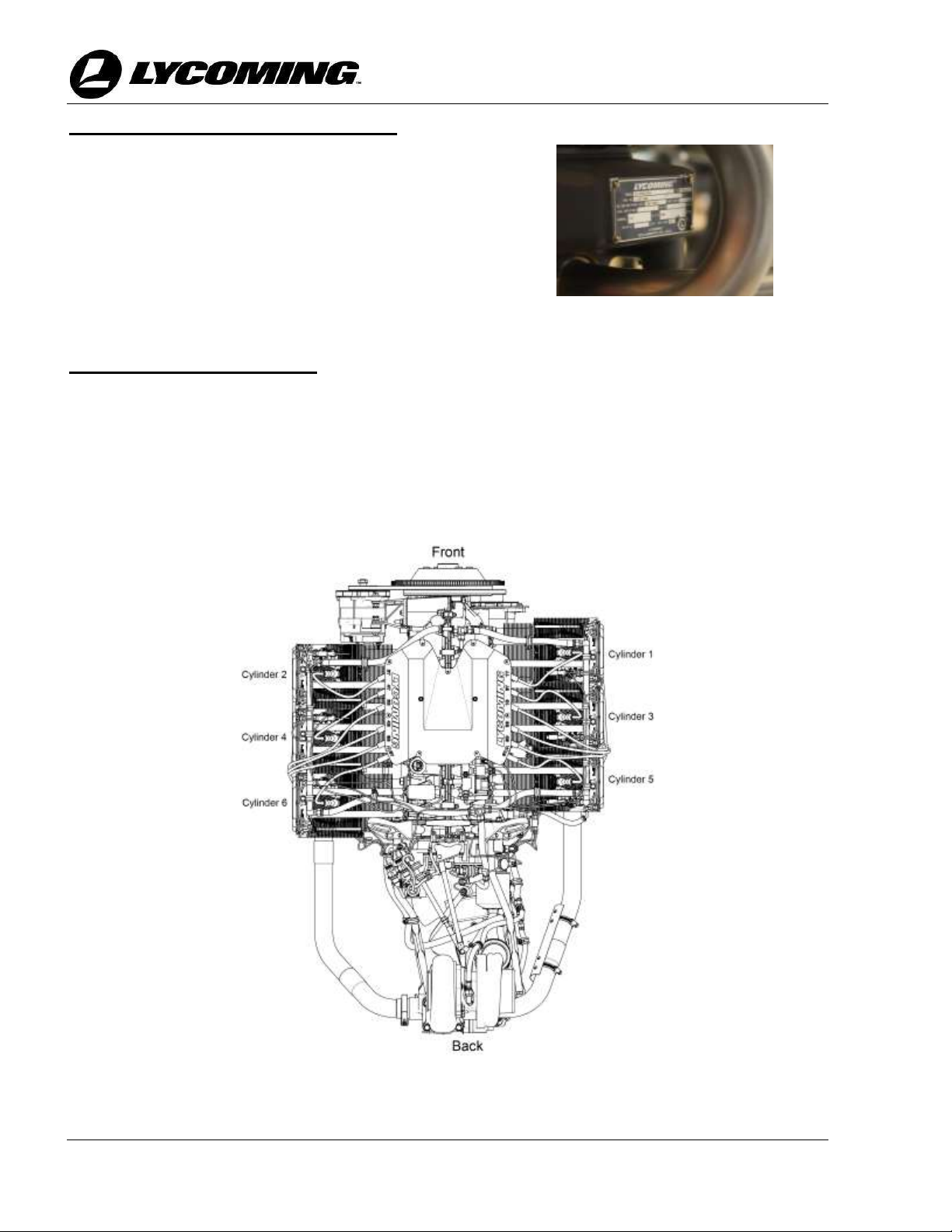

Engine Serial Number/Engine Data Plate

Every engine sent from the factory is identified by a

unique serial number. The engine serial number is

identified on the engine data plate (Figure 2). Do not

remove the engine data plate.

If a data plate is ever lost or damaged, refer to the latest

revision of Service Instruction No. SI-1304 for data

plate replacement information.

Figure 2

Engine Data Plate

Cylinder Number Designations

• The propeller is at the front of the engine and the accessories are at the rear of the engine.

• In a top view of the engine, the left side cylinders are 2-4-6. Cylinder 2 is at the front of the

engine. Refer to Figure 3.

• In a top view of the engine, the cylinders on the right are 1-3-5. Cylinder 1 is at the front of

the engine. Refer to Figure 3.

• The firing order of the cylinders is 1-4-5-2-3-6

Figure 3

Top View of Engine – Cylinder Number Designations

TEO-540-C1A Engine Maintenance Manual

© 2018 Avco Corporation. All Rights Reserved Introduction

November 2018 Page xxiii

TEO-540-C1A Engine Maintenance Manual

Scope of this Manual

This manual supplies instructions (in compliance with Federal Aviation Regulation Part 14 CFR

33.4) for maintenance of the Lycoming TEO-540-C1A engine. These instructions include: required

maintenance (service information) such as: oil changes, oil addition, oil filter replacement, routine

time-interval inspections, routine service, spark plug replacement/inspection procedures, cylinder

inspection, fuel system inspection, scheduled servicing procedures, airworthiness limitations, fault

isolation guidelines and procedures for component replacement, engine disassembly, and engine

assembly. Refer to the TEO-540-C1A Illustrated Parts Catalog to identify spare parts.

Instructions for Continued Airworthiness

This manual, the TEO-540-C1A Engine Overhaul Manual, the latest revision of the Service Table

of Limits - SSP-1776, and service documents applicable to this engine model make up the complete

set of Instructions for Continued Airworthiness (ICAs). The ICAs are prepared by Lycoming

Engines.

Engine Certification

This manual adheres to guidelines set forth by the FAA for certified engines. All inspections,

procedures, and guidelines in this manual must be followed to maintain continued airworthiness.

Compliance Requirements

WARNING FOR CORRECT ENGINE MAINTENANCE, COMPLETE THE NECESSARY

MAINTENANCE PROCEDURES IN THIS MANUAL AND APPLICABLE

SERVICE DOCUMENTS. LYCOMING ENGINES' SERVICE DOCUMENTS

WRITTEN AT A LATER DATE SUPERSEDE PROCEDURES IN THIS

MANUAL UNLESS OTHERWISE SPECIFIED.

PROCEDURES IN THIS MANUAL MUST BE DONE BY QUALIFIED

PERSONNEL WITH THE REQUISITE CERTIFICATIONS.

Before you do maintenance on the TEO-540-C1A engine, read this manual in its entirety. Obey all

procedures and inspections in this manual.

NOTICE: Please read your warranty for a full statement of your rights, limitations and obligations

that exist there under.

Refer to the TEO-540-C1A Engine Installation and Operation Manual for engine description,

uncrating procedures, acceptance check, engine lift procedure, engine preservation and storage,

depreservation, engine installation requirements, engine installation, engine start, operation, and stop

procedures, engine initiation (break-in/flight test), fuels and oil to be used, and operating

specifications.

Refer to the latest revision of the Service Table of Limits - SSP-1776, for dimensions, clearances,

measurements, and torque values.

WARNING OPERATE THIS ENGINE IN ACCORDANCE WITH SPECIFICATIONS IN

APPENDIX A OF THE TEO-540-C1A ENGINE INSTALLATION AND

OPERATION MANUAL. OPERATION OF THE ENGINE OUTSIDE OF THE

SPECIFIED OPERATING LIMITS CAN CAUSE PERSONAL INJURY

AND/OR DAMAGE TO THE ENGINE.

TEO-540-C1A Engine Maintenance Manual

Introduction © 2018 Avco Corporation. All Rights Reserved

Page xxiv November 2018

TEO-540-C1A Engine Maintenance Manual

Environmental Compliance

Lycoming Engines recommends that engine owners and engine service personnel be in compliance

with all federal, state, and local environmental regulations when solvents, paint, fuel, oil, chemicals,

or other consumables are used in engine service.

Warnings, Cautions, and Notices

Be sure to read and obey the Warnings, Cautions, and Notices in this manual and in service

documents. Although Lycoming Engines cannot know all possible hazards or damages, it makes a

reasonable effort to supply the best known guidance and recommended practices for safe operation

and maintenance of its engines.

The table below defines the four types of safety advisory messages used in this manual as per the

American National Standard and ANSI Z535-6-2006.

Safety Advisory Conventions

Advisory Word

Definition

DANGER:

Indicates a hazardous situation which, if not avoided, will result

in death or serious injury. This signal word is to be limited to the

most extreme situations.

WARNING

Indicates a hazardous situation which, if not avoided, could

result in death or serious injury.

CAUTION

Indicates a hazardous situation which, if not avoided, could

result in minor or moderate injury. It also can be used without

the safety alert symbol as an alternative to "NOTICE."

NOTICE:

The preferred signal word to address practices not related to

personal injury.

NOTICE: In this manual, the word "recommend" refers to "best practices."

Service Bulletins, Service Instructions, and Service Letters

As advancements in technological applications on this engine continue, Lycoming will make future

revisions to this manual. However, if more timely distribution is necessary, Lycoming supplies upto-date Service Bulletins (SBs), Service Instructions (SIs) and Service Letters (which are abbreviated

with a capital “L” followed by the number, example L180). Special Advisories (SAs) are supplied as

necessary.

For additional publication information, look on Lycoming’s website (Lycoming.com) or speak to

Lycoming Engines by telephone: U.S. and Canada toll free: +1(800) 258-3279; or Direct: +1 (570)

323-6181.

Applicable information from Lycoming Engines' Service Bulletins, Service Instructions, and Service

Letters are included in this manual at the time of publication. Any new service information will be

included in the next update of the manual.

Reminder: Unless otherwise specified, Lycoming Engines' service documents (which are dated

after this manual’s release date) that pertain to the engine model in this manual

supersede procedures in this manual.

For reference, the Service Document List at the front of this manual shows the service documents

referenced or included in this manual.

TEO-540-C1A Engine Maintenance Manual

© 2018 Avco Corporation. All Rights Reserved Introduction

November 2018 Page xxv

TEO-540-C1A Engine Maintenance Manual

List of Publications

Refer to the latest revision of Service Letter No. L114 for a list of Lycoming Engines' publications.

Simplified Technical English

The text in the manual is written in the form of Simplified Technical English in compliance with

FAA requirements and to make translation into other languages easier.

Format

Chapters in this manual are identified in Air Transport Association (ATA) format.

Figures

Figures in this manual are for illustration purposes only. Figures always start as Figure 1 in each

chapter.

Tables and Checklists

Tables in this manual are used to display detailed information in an organized format. Tables always

start as Table 1 in each chapter. Checklists are used to display a list of tasks to be completed as part

of a specific procedure. Checklists are not numbered because they are used as a reference tool

contained within the procedure.

Copyright

This publication is a copyrighted work. All rights reserved by Lycoming Engines. Content in this

manual cannot be changed or released as a reprint, electronic media output, or web communiqué

without written permission from Lycoming Engines.

Feedback

To supply comments, suggestions, or corrections to this manual, either email or contact Lycoming

Engines Technical Support at the email or phone number in the front of this manual or use the

Lycoming.com website.

Manual Revisions

Lycoming Engines constantly examines our manuals to provide our customers the most complete

and up-to-date information for operating and maintaining our engines. Revisions to this manual will

be published as necessary.

Patents

The following patents apply to the engine and control systems:

• 7,658,184

• 7,875,989

• 7,827,965

• 8,131,406

• 7,828,509

TEO-540-C1A Engine Maintenance Manual

Introduction © 2018 Avco Corporation. All Rights Reserved

Page xxvi November 2018

TEO-540-C1A Engine Maintenance Manual

This page intentionally left blank.

TEO-540-C1A Engine Maintenance Manual

© 2018 Avco Corporation. All Rights Reserved Airworthiness Limitations

November 2018 Page xxvii

TEO-540-C1A Engine Maintenance Manual

AIRWORTHINESS LIMITATIONS

1. General

This Airworthiness Limitations chapter sets forth each mandatory replacement time,

inspection interval, and related procedure required for type certification. The

Airworthiness Limitations section is FAA approved and specifies maintenance required

under 14 CFR §§ 43.16 and 91.403 of the Federal Aviation Regulations (FAR) unless an

alternative program has been FAA-approved.

2. Mandatory Inspection - Exhaust Valve and Guide

At every 1000 hours of operation for TEO-540-C1A engines, examine the exhaust valve

and guide conditions. Refer to the section "Exhaust Valve and Guide Inspection" in

Chapter 72-30.

3. Mandatory Inspection – EECS NTO Faults

Take-off is prohibited with Electronic Engine Control System No Take-Off Faults

annunciated. The NTO annunciator indicates engine control fault(s) exists that exceed 14

CFR Part 33 limitations; the engine is not airworthy with the NTO annunciator

illuminated. The fault(s) must be identified, the condition corrected, and the fault(s)

cleared before take-off.

TEO-540-C1A Engine Maintenance Manual

Airworthiness Limitations © 2018 Avco Corporation. All Rights Reserved

Page xxviii November 2018

TEO-540-C1A Engine Maintenance Manual

This page intentionally left blank.

Loading...

Loading...