Lycoming IO-360-N1A Installation And Operation Manual

Engine Installation and Operation Manual

IO-360-N1A Engine

February 2016

Part No. IOM-IO-360-N1A

© 2016 Avco Corporation. All Rights Reserved.

Factory

U.S. and Canada Toll Free:

Direct:

+1 (800) 258-3279

+1 (570) 323-6181

Installation and Operation Manual

Lycoming Part Number: IOM-IO-360-N1A

Contact Us:

Mailing Address:

Lycoming Engines

652 Oliver Street

Williamsport, PA 17701 USA

IO-360-N1A Engine

Phone:

Lycoming’s regular business hours are Monday through Friday from 8:00AM through 5:00PM

Eastern Time (-5 GMT).

Visit us Online: www.Lycoming.com

IO-360-N1A Engine Installation and Operation Manual

Revision

Revision

Date

Revised

By

Revision Description

Original

Original Release of Installation and Operation Manual - Part No.

IOM-IO-360-N1A

RECORD OF REVISIONS

© 2016 Avco Corporation. All Rights Reserved Record of Revisions

February 2016 Page i

IO-360-N1A Engine Installation and Operation Manual

This page intentionally left blank.

Record of Revisions © 2016 Avco Corporation. All Rights Reserved

Page ii February 2016

IO-360-N1A Engine Installation and Operation Manual

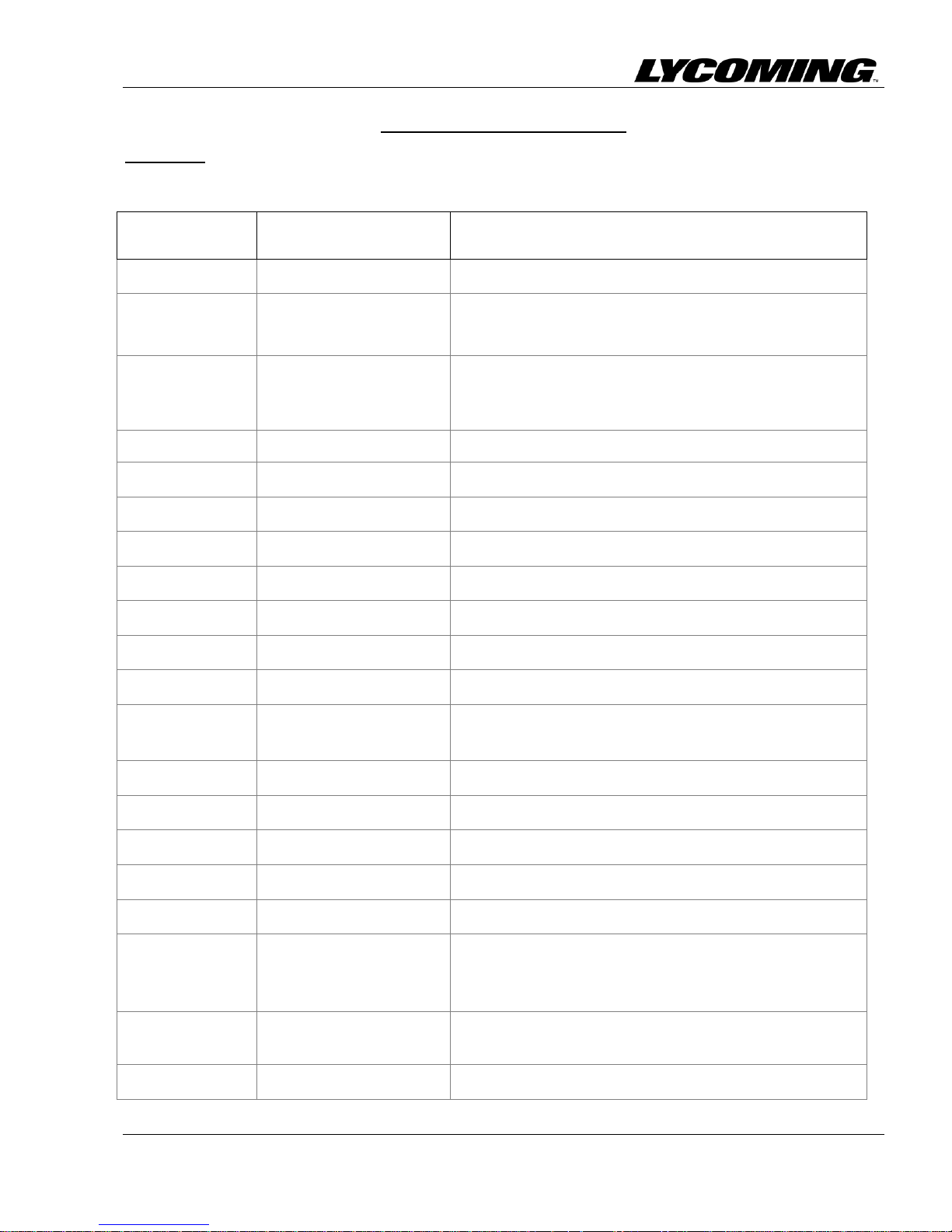

Number

Incorporation

Date

Subject

S.B. 369

02/16

Engine Inspection after Overspeed

S.B. 480

02/16

I. Oil and Filter Change and Screen Cleaning

II. Oil Filter Screen Content Inspection

S.B. 533

02/16

Recommended Action for Sudden Engine Stoppage,

Propeller/Rotor Strike or Loss of Propeller/Rotor

Blade or Tip

S.I. 1009

02/16

Recommended Time Between Overhaul Periods

S.I. 1014

02/16

Lubricating Oil Recommendations

S.I. 1070

02/16

Specified Fuels

S.I. 1098

02/16

Propeller Flange Bushing Location

S.I. 1132

02/16

Magneto Drop-off

S.I. 1154

02/16

FAA Approved Starter and Alternators

S.I. 1241

02/16

Pre-oil the Engine Prior to Initial Start

S.I. 1409

02/16

Lycoming Engines P/N LW-16702, Oil Additive

S.I. 1427

02/16

Lycoming Reciprocating Engine Run-In and Oil

Consumption

S.I. 1443

02/16

Approved Slick Magnetos on Lycoming Engines

S.I. 1472

02/16

Removal of Preservative Oil from Engine

S.I. 1481

02/16

Factory Engine Preservation

S.I. 1505

02/16

Cold Weather Starting

S.I. 1528

02/16

Aircraft Engine Starter Recommendations

S.I. 1530

02/16

Engine Inspection in a Particulate Laden

Environment (Volcanic Ash, Sand, Dust, Airborne

Debris)

L 114

02/16

Reciprocating Engine and Accessory Maintenance

Publications

L180

02/16

Engine Preservation for Active and Stored Aircraft

SERVICE DOCUMENT LIST

NOTICE: The following is a list of service documents referenced in or incorporated into the

information in this manual. Always refer to the latest revision of any service document

for changes or additional information.

© 2016 Avco Corporation. All Rights Reserved Service Document List

February 2016 Page iii

IO-360-N1A Engine Installation and Operation Manual

This page intentionally left blank.

Service Document List © 2016 Avco Corporation. All Rights Reserved

Page iv February 2016

IO-360-N1A Engine Installation and Operation Manual

TABLE OF CONTENTS

Section Page

Frontal __________________________________________________________________________

Record of Revisions .............................................................................................................................. i

Service Document List ....................................................................................................................... iii

Table of Contents ................................................................................................................................ v

List of Figures ..................................................................................................................................... ix

List of Tables ...................................................................................................................................... xi

Abbreviations and Acronyms ......................................................................................................... xiii

Introduction ....................................................................................................................................... xv

System Description ________________________________________________________________

— System Description ................................................................................................................... 1

— Cylinders ................................................................................................................................... 1

— Crankcase .................................................................................................................................. 2

— Ignition System ......................................................................................................................... 2

— Starter ........................................................................................................................................ 3

— Fuel Injection System................................................................................................................ 4

— Lubrication System ................................................................................................................... 4

— Cylinder Number Designations ................................................................................................. 5

Engine Reception and Lift __________________________________________________________

— Uncrate Procedure for a New, Rebuilt, or Overhauled Engine ................................................. 7

— Acceptance Check ..................................................................................................................... 7

— Engine Preservative Oil Removal ............................................................................................. 8

— Lift the Engine .......................................................................................................................... 8

Requirements for Engine Installation ________________________________________________

— Overview ................................................................................................................................... 9

— Step 1. Prepare the Engine ........................................................................................................ 9

— Step 2. Supply Interface Items ................................................................................................ 14

— Step 3. Remove Components .................................................................................................. 15

— Step 4. Install Aircraft-Supplied Engine Mounts .................................................................... 15

— Step 5. Prepare the Aircraft Engine Harness ........................................................................... 15

— Step 6. Make Electrical Interface Connections ....................................................................... 15

© 2016 Avco Corporation. All Rights Reserved Table of Contents

February 2016 Page v

IO-360-N1A Engine Installation and Operation Manual

Section Page

Engine Installation ________________________________________________________________

— Engine Installation Overview .................................................................................................. 17

— Step 1. Install the Engine on Mounts ...................................................................................... 18

— Step 2. Connect the Wiring Harness ....................................................................................... 18

— Step 3. Connect the Linkages .................................................................................................. 18

— Step 4. Install External Accessories (as necessary) ................................................................ 18

— Step 5. Install Baffling ............................................................................................................ 18

— Step 6. Install the Compressor Belt (as necessary) ................................................................. 18

— Step 7. Install the Propeller ..................................................................................................... 18

— Step 8. Connect Fuel Lines ..................................................................................................... 19

— Step 9. Connect Oil Lines ....................................................................................................... 19

— Step 10. Install Components That Had Been Removed Before Engine Installation............... 20

— Step 11. Add Oil...................................................................................................................... 20

— Step 12. Add Fuel.................................................................................................................... 21

— Step 13. Engine Pre-Oil Procedure ......................................................................................... 21

Engine Start and Operation ________________________________________________________

— Warranty Requirement ............................................................................................................ 23

— Before Engine Start ................................................................................................................. 23

— Engine Run-In / Engine Break-In ........................................................................................... 23

— Step 1. Prepare an Engine for First Time Operation ............................................................... 24

—Pre-Flight Inspection for First Time Operation Checklist .................................................. 25

— Step 2. Start the Engine ........................................................................................................... 26

—Magnetic Drop-Off Check .................................................................................................. 28

— Step 3. Complete the Engine Run-Up ..................................................................................... 28

— Step 4. Operate the Engine ...................................................................................................... 29

—Operation in Flight .............................................................................................................. 29

—Fuel Mixture Leaning.......................................................................................................... 29

— Step 5. Stop the Engine ........................................................................................................... 30

Table of Contents © 2016 Avco Corporation. All Rights Reserved

Page vi February 2016

IO-360-N1A Engine Installation and Operation Manual

Section Page

Engine Conditions ________________________________________________________________

— Action for Engine Conditions ................................................................................................. 31

—Apply Heat to a Cold Engine .............................................................................................. 32

—Cold Weather Start .............................................................................................................. 33

—Engine Operation in Hot Weather ....................................................................................... 34

—Volcanic Ash ....................................................................................................................... 34

—Overspeed............................................................................................................................ 35

—Low Oil Pressure During Flight .......................................................................................... 35

Flight Test _______________________________________________________________________

— Flight Test ............................................................................................................................... 37

Engine Preservation and Storage ____________________________________________________

— Engine Corrosion and Prevention ........................................................................................... 39

— Engine Preservation - 30 to 60 Days ....................................................................................... 40

— Fuel Injector Preservation ....................................................................................................... 42

— Engine Preservation - 61 to 180 Days ..................................................................................... 42

— Engine Preservation - 181 Days or More ................................................................................ 43

— Cold Weather Storage ............................................................................................................. 43

— Long-Term Storage of Engines that Use Automotive Fuel .................................................... 43

Appendix ________________________________________________________________________

— Appendix A - Engine Specifications and Operating Limits ................................................... 45

— Appendix B - Installation and Wiring Diagrams .................................................................... 49

— Appendix C - Performance Data ............................................................................................. 51

© 2016 Avco Corporation. All Rights Reserved Table of Contents

February 2016 Page vii

IO-360-N1A Engine Installation and Operation Manual

This page intentionally left blank.

Table of Contents © 2016 Avco Corporation. All Rights Reserved

Page viii February 2016

IO-360-N1A Engine Installation and Operation Manual

Fig. No.

Figure Title

Page

System Description Section

1

IO-360-N1A Engine

1 2 Engine Cylinder

1 3 Crankcase

2 4 Crankshaft

2 5 Ignition System

3 6 Starter

3 7 Fuel Injection System

4 8 Lubrication System

4 9 Cylinder Number Designation

5

Engine Reception and Lift Section

1

Engine Data Plate

7 2 Engine Lift

8

Engine Installation

1

Oil Fill Tube and Oil Level Gage (Dipstick)

20

Appendix C - Performance Data

C-1

Sea Level and Altitude Performance

51

C-2

Minimum Fuel Flow vs. Nozzle Pressure

52

C-3

Fuel Consumption vs. Actual Brake Horsepower

53

C-4

Cooling Air Requirements

54

LIST OF FIGURES

© 2016 Avco Corporation. All Rights Reserved List of Figures

February 2016 Page ix

IO-360-N1A Engine Installation and Operation Manual

This page intentionally left blank.

List of Figures © 2016 Avco Corporation. All Rights Reserved

Page x February 2016

IO-360-N1A Engine Installation and Operation Manual

Table

No.

Table Title

Page

Requirements for Engine Installation Section

1

Prerequisites for Engine Installation

9

2

Optional Equipment, Recommendations, and Requirements to Prepare

the Engine for Installation

14

Engine Installation Section

1

Aircraft Where IO-360-N1A Engines Can Be Installed

17 2 Aircraft Where IO-360-N1A Engines Cannot be Installed

17 3 Engine Installation Steps and References

17

Engine Start and Operation Section

1

Prerequisite Requirements for Engine Operation

23

Engine Conditions Section

1

Action for Engine Conditions

31

Appendix A - Engine Specifications and Operating Limits

A-1

IO-360-N1A Engine Specifications

45

A-2

Table of Operating Limits for IO-360-N1A Engine

47

A-3

Accessory Drives for IO-360-N1A Engines

48

LIST OF TABLES

© 2016 Avco Corporation. All Rights Reserved List of Tables

February 2016 Page xi

IO-360-N1A Engine Installation and Operation Manual

This page intentionally left blank.

List of Tables © 2016 Avco Corporation. All Rights Reserved

Page xii February 2016

IO-360-N1A Engine Installation and Operation Manual

A

Amp

Ampere

B

BHP

Brake Horsepower

BSFC

Brake Specific Fuel Consumption

Btu

British Thermal Unit

C

C

Celsius

CHT

Cylinder Head Temperature

cm

Centimeter

E

EGT

Exhaust Gas Temperature

EPA

Environmental Protection Agency

F

F

Fahrenheit

FAA

Federal Aviation Administration

FAR

Federal Aviation (and Space) Regulation

FOD

Foreign Object Debris

Ft.-lb

Foot Pound (torque)

G

G

Force of Gravity

H

HET

Hartzell Engine Technologies

Hg

Mercury

HP

Horsepower

I

ICA

Instructions for Continued Airworthiness

in.-lb

Inch Pound (torque)

in.

Inch, inches

In-Hg

Inches of Mercury

L

lb

Pound

LL

Low Lead (fuel)

ABBREVIATIONS AND ACRONYMS

© 2016 Avco Corporation. All Rights Reserved Abbreviations and Acronyms

February 2016 Page xiii

IO-360-N1A Engine Installation and Operation Manual

M

mm

Millimeter

MSB

Mandatory Service Bulletin

N

Nm

Newton Meter

P

P/N

Part Number

POH

Pilot’s Operating Handbook

ppm

Particles per Million

psi

Pounds per Square Inch

R

rpm

Revolutions per Minute

S

SAE

Society of Automotive Engineers (oil viscosity)

SB

Service Bulletin

SI

Service Instruction

STC

Supplemental Type Certificate

T

TCM

Teledyne Continental Motors

TR

Temporary Revision

V

V

Volt, Voltage

ABBREVIATIONS AND ACRONYMS (CONT.)

Abbreviations and Acronyms © 2016 Avco Corporation. All Rights Reserved

Page xiv February 2016

IO-360-N1A Engine Installation and Operation Manual

Model Number

Meaning

I

Fuel Injected

O

Horizontally Opposed

360

Displacement in cubic inches

INTRODUCTION

Engine Model Nomenclature

The tables below show the definition of each letter and number for IO-360-N1A engines.

Scope of this Manual

This manual supplies instructions (in compliance with FAR 33.5 and 21.50) for engine preparation,

installation, and operation of the IO-360-N1A Lycoming aircraft engines. The installation

instructions in this manual are basic guidelines. When installing the engine in the airframe, follow

the airframe manufacturer’s installation instructions.

Refer to the IO-360-N1A Engine Service Manual for required maintenance (service information)

such as: oil changes, oil addition, oil filter replacement, routine time-interval inspections, routine

service, spark plug replacement/inspection procedures, cylinder inspection, fuel system inspection,

and scheduled servicing procedures.

For airworthiness limitations, guidelines to isolate faults and for procedures to replace components,

disassemble and assemble the engine, refer to the IO-360-N1A Engine Maintenance Manual.

For spare parts information, refer to the IO-360-N1A Illustrated Parts Catalog.

Refer to the latest revision of the Service Table of Limits - SSP-1776, for dimensions, clearances,

measurements, and torque values.

Service Bulletins, Service Instructions, and Service Letters

As advancements in technological applications on this engine continue, Lycoming will make future

revisions to this manual. However, if more timely distribution is necessary, Lycoming supplies

subscribers with up-to-date Service Bulletins (SBs), Service Instructions (SIs) and Service Letters

(which are abbreviated with a capital “L” followed by the number, example L180). Special

Advisories (SAs) are supplied as necessary without a subscription.

For subscription information, look on Lycoming’s website or speak to Lycoming by telephone: U.S.

and Canada toll free: 1-800-258-3279; International Customers: 570-323-6181.

Applicable information from Lycoming Service Bulletins, Service Instructions, and Service Letters

are included in this manual at the time of publication. Any new service information will be included

in the next update of the manual.

For reference and future updates, the Service Document List at the front of this manual shows the

editions of the service documents included in this manual.

Instructions for Continued Airworthiness

The IO-360-N1A Engine Service Manual, IO-360-N1A Engine Maintenance Manual, latest

revision of the Service Table of Limits - SSP-1776, service documents, and related publications

make up the complete set of Instructions for Continued Airworthiness (ICAs). The ICAs are

prepared by Lycoming Engines and are approved by the Federal Aviation Administration (FAA).

© 2016 Avco Corporation. All Rights Reserved Introduction

February 2016 Page xv

IO-360-N1A Engine Installation and Operation Manual

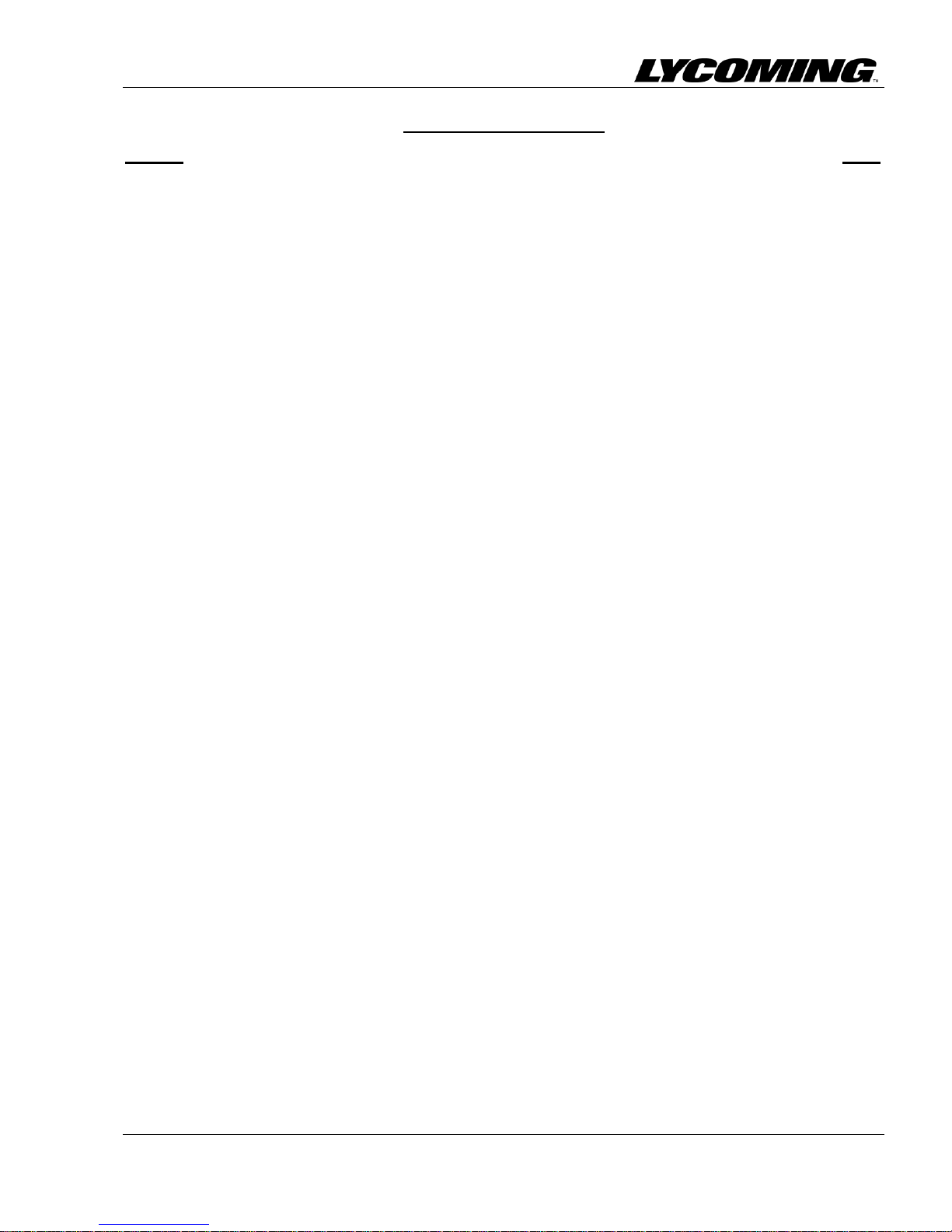

Safety Advisory Conventions

Advisory Word

Definition

DANGER:

Indicates a hazardous situation which, if not avoided, will result

in death or serious injury. This signal word is to be limited to the

most extreme situations.

Indicates a hazardous situation which, if not avoided, could

result in death or serious injury.

Indicates a hazardous situation which, if not avoided, could

result in minor or moderate injury. It can also be used without

the safety alert symbol as an alternative to "NOTICE."

NOTICE:

The preferred signal word to address practices not related to

personal injury.

Compliance Requirements

OPERATE THIS ENGINE IN ACCORDANCE WITH SPECIFICATIONS IN

APPENDIX A OF THIS MANUAL. OPERATING THE ENGINE BEYOND

SPECIFIED OPERATING LIMITS CAN CAUSE PERSONAL INJURY

AND/OR DAMAGE TO THE ENGINE.

YOU ALSO MUST COMPLETE THE NECESSARY SERVICE

PROCEDURES IDENTIFIED IN LYCOMING ENGINES' SERVICE

MANUAL FOR THIS ENGINE AS WELL AS ANY APPLICABLE SERVICE

DOCUMENTS. LYCOMING ENGINES' SERVICE DOCUMENTS

OVERRIDE PROCEDURES IN THIS MANUAL.

PROCEDURES IN THE SERVICE MANUALS MUST BE DONE BY

QUALIFIED PERSONNEL WITH THE REQUISITE CERTIFICATIONS.

Warning, Cautions, and Notices

Be sure to read and obey the Warnings, Cautions and Notices in this manual and in service

documents. Although Lycoming cannot know all possible hazards or damages, it makes a reasonable

effort to supply the best possible guidance and recommended practices for safe operation of its

engines.

The table below defines the four types of safety advisory messages used in this manual per the

American National Standard and ANSI Z535-6-2006.

NOTICE: In this manual, the word "recommended" refers to "best practices."

Simplified Technical English

The text in the manual is written in the form of Simplified Technical English in compliance with

FAA requirements and to make translation into other languages easier.

Figures

Figures in this manual are for conceptual illustrative purposes only.

Introduction © 2016 Avco Corporation. All Rights Reserved

Page xvi February 2016

IO-360-N1A Engine Installation and Operation Manual

Copyright

This publication is a copyrighted work. All rights reserved by Lycoming Engines. Content in this

manual cannot be changed or released as a reprint, electronic media output, or web communiqué

without written permission from Lycoming Engines.

Environmental Compliance

Lycoming Engines recommends that engine owners and engine service personnel be in compliance

with all federal, state, and local environmental regulations when solvents, paint, fuel, oil, chemicals,

or other consumables are used in engine service.

Supplemental Service Information

Refer to the latest revision of Service Letter No. L114 for a list of Lycoming publications available

for purchase.

Feedback

To supply comments, suggestions, or corrections to this manual, either make a call to customer

service or use the Lycoming.com website.

Customer Service

Lycoming has a Customer Service Hot Line to supply information and assistance to owners,

operators, and maintenance personnel servicing Lycoming engines.

Phone:

Factory: U.S. and Canada toll free - +1 (800) 258-3279

International Customers - +1 (570) 323-6181

Sales Department: +1 (570) 327-7278

Fax: +1 (570) 327-7101

Lycoming’s regular business hours are Monday through Friday from 8:00 A.M. through 5:00

P.M. Eastern Time (-5 GMT)

Change of Address Notification

The owner of the manual is responsible to supply of a change of address to Lycoming Engines.

© 2016 Avco Corporation. All Rights Reserved Introduction

February 2016 Page xvii

IO-360-N1A Engine Installation and Operation Manual

This page intentionally left blank.

Introduction © 2016 Avco Corporation. All Rights Reserved

Page xviii February 2016

IO-360-N1A Engine Installation and Operation Manual

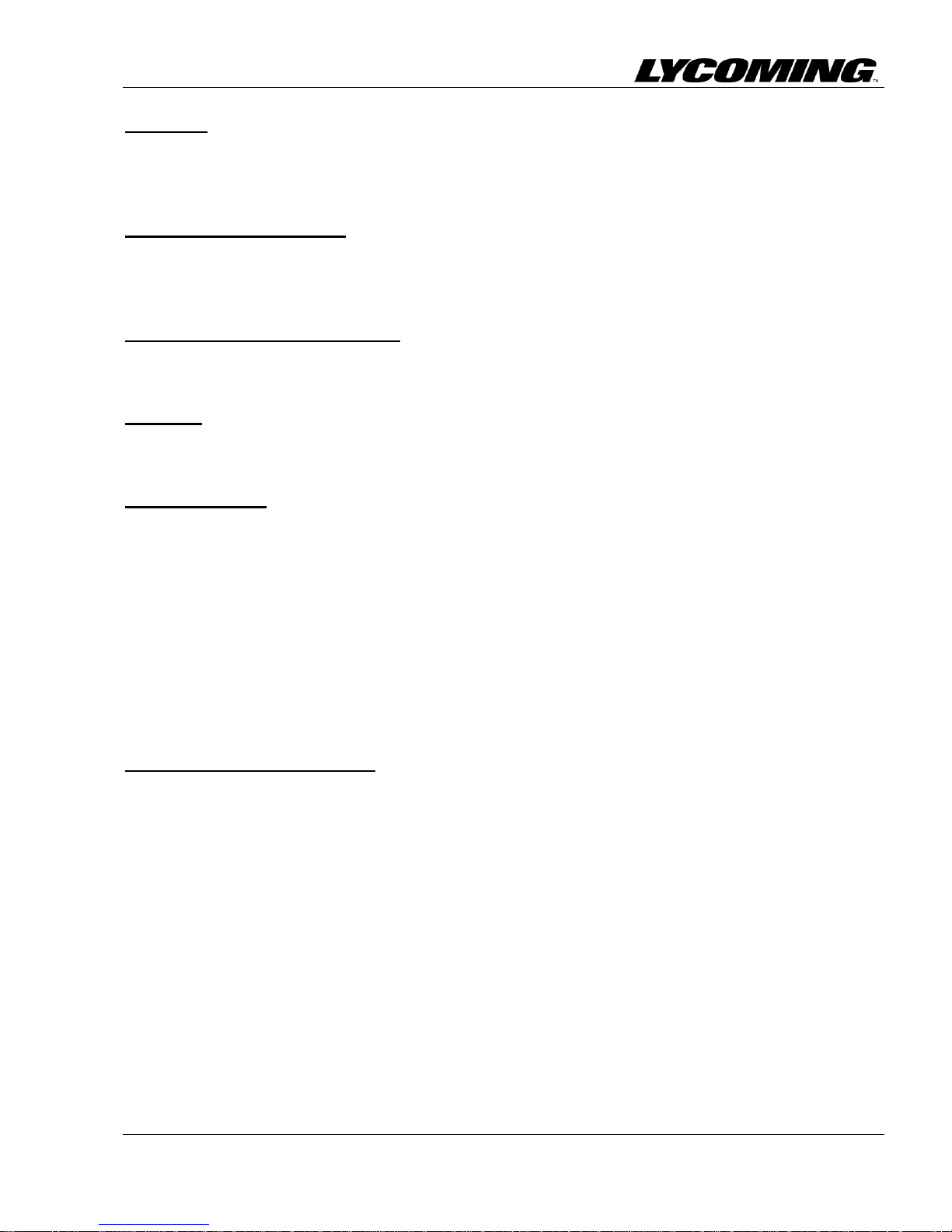

SYSTEM DESCRIPTION

The Lycoming IO-360-N1A engine (Figure 1) is a direct-drive four-cylinder, horizontally opposed,

fuel-injected, air-cooled engine. It has tuned induction, and a down exhaust.

NOTICE: Refer to Appendix C for engine performance data.

Figure 1

IO-360-N1A

Cylinders

There are four cylinders on this engine. Each cylinder (Figure 2) contains a cylinder head, barrel,

piston, parallel intake and exhaust valve guides and valve seats, rocker shafts, rocker covers, and

fins.

Fuel and air enter the cylinder through the cylinder head for mixing and combustion within the

cylinder.

The engine has intercylinder cooling baffles.

Figure 2

Engine Cylinder

© 2016 Avco Corporation. All Rights Reserved System Description

February 2016 Page 1

IO-360-N1A Engine Installation and Operation Manual

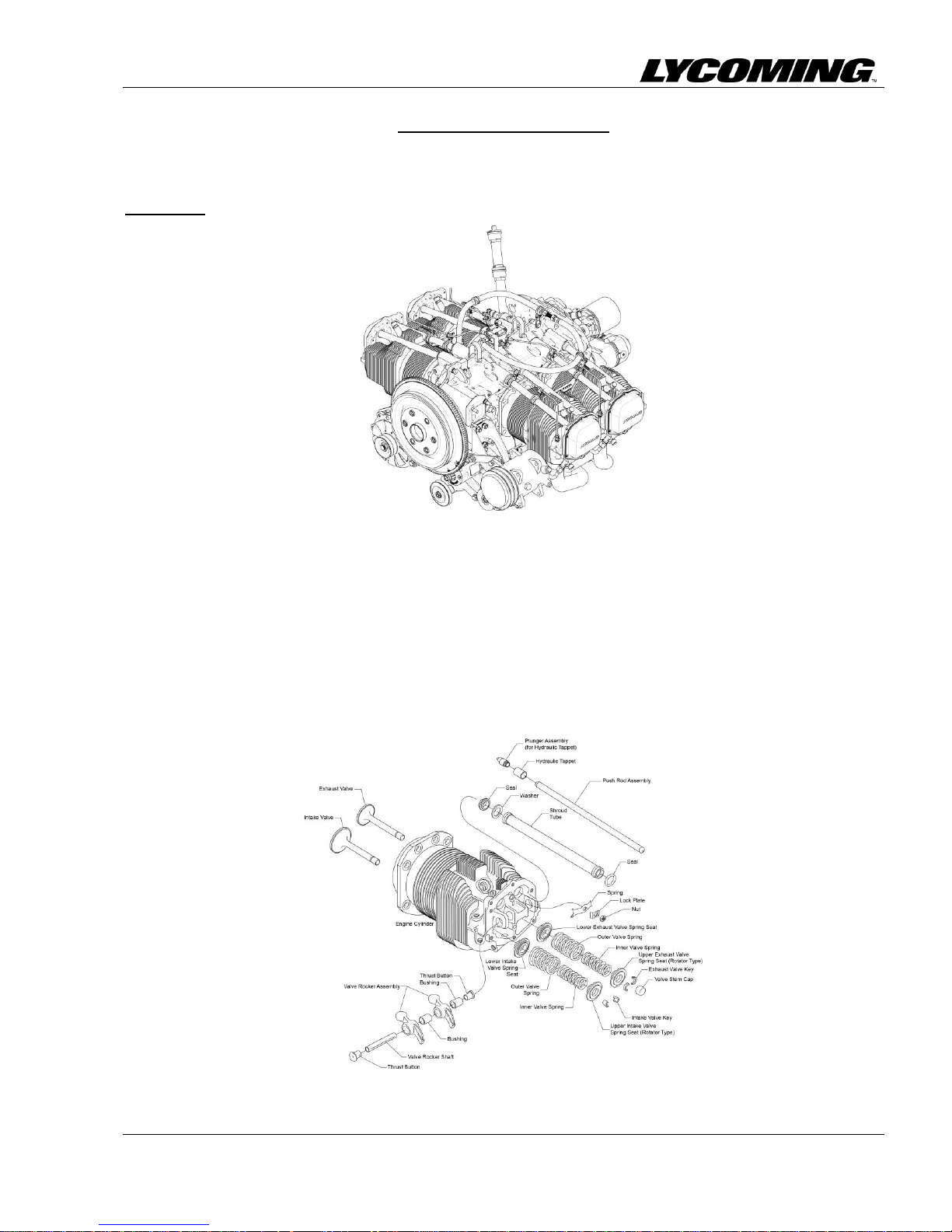

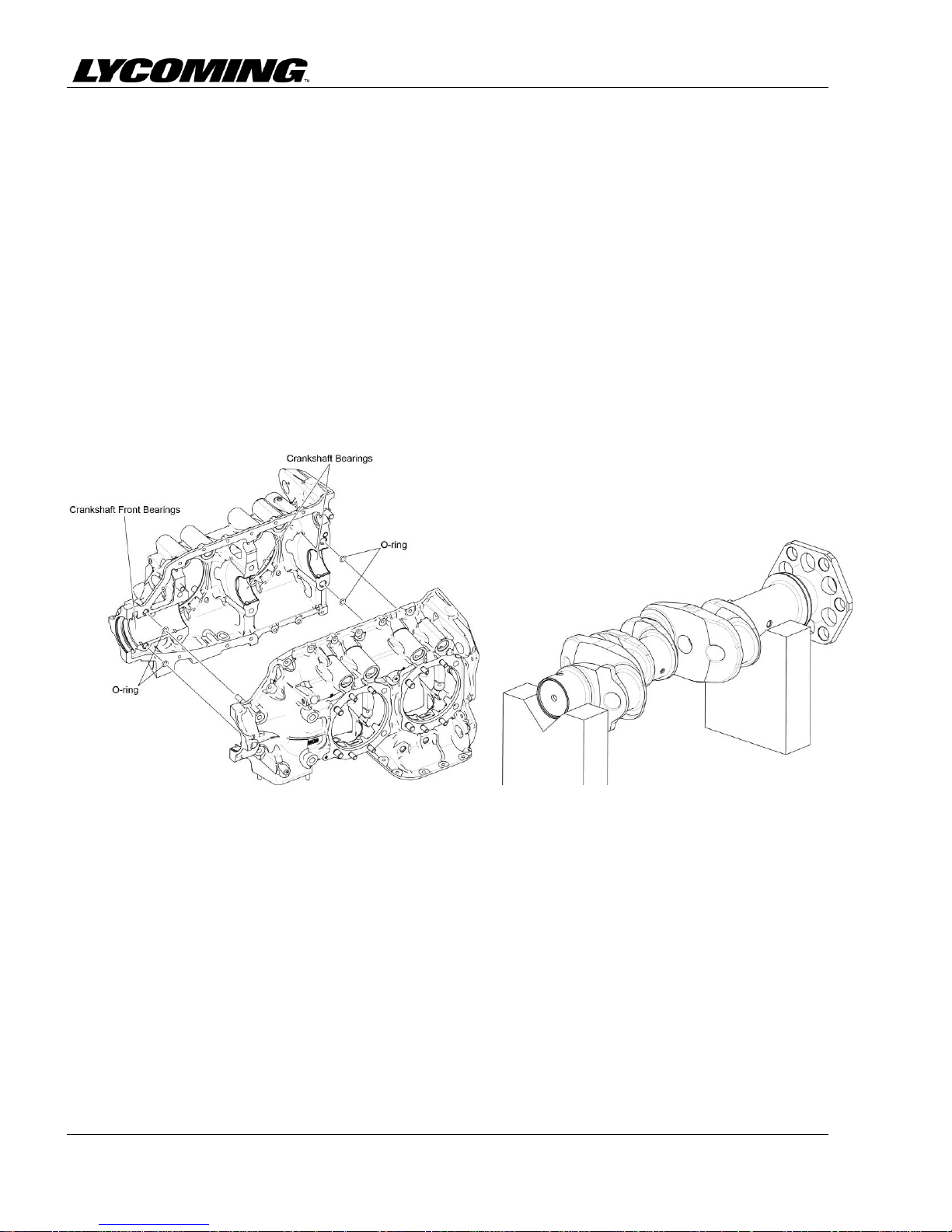

Figure 3

Crankcase

Figure 4

Crankshaft

Crankcase

The crankcase (Figure 3) is made up of two casting halves attached by a series of through-studs,

bolts and nuts.

The crankcase forms the bearings for the camshaft. The camshaft operates the tappets which control

opening and closing of the intake and exhaust valves. The camshaft has an integral spur gear that

drives the propeller governor output shaft.

The main bearing bores are machined for precision-type main bearing inserts. The crankshaft mainbearings are pairs of inserts installed in the crankcase at each journal.

The crankshaft (Figure 4) is within the crankcase. The crankshaft has journals to attach connecting

rods and pistons.

Oil is supplied through the propeller flange for a single-acting controllable pitch propeller.

Four oil nozzles supply oil for internal piston cooling

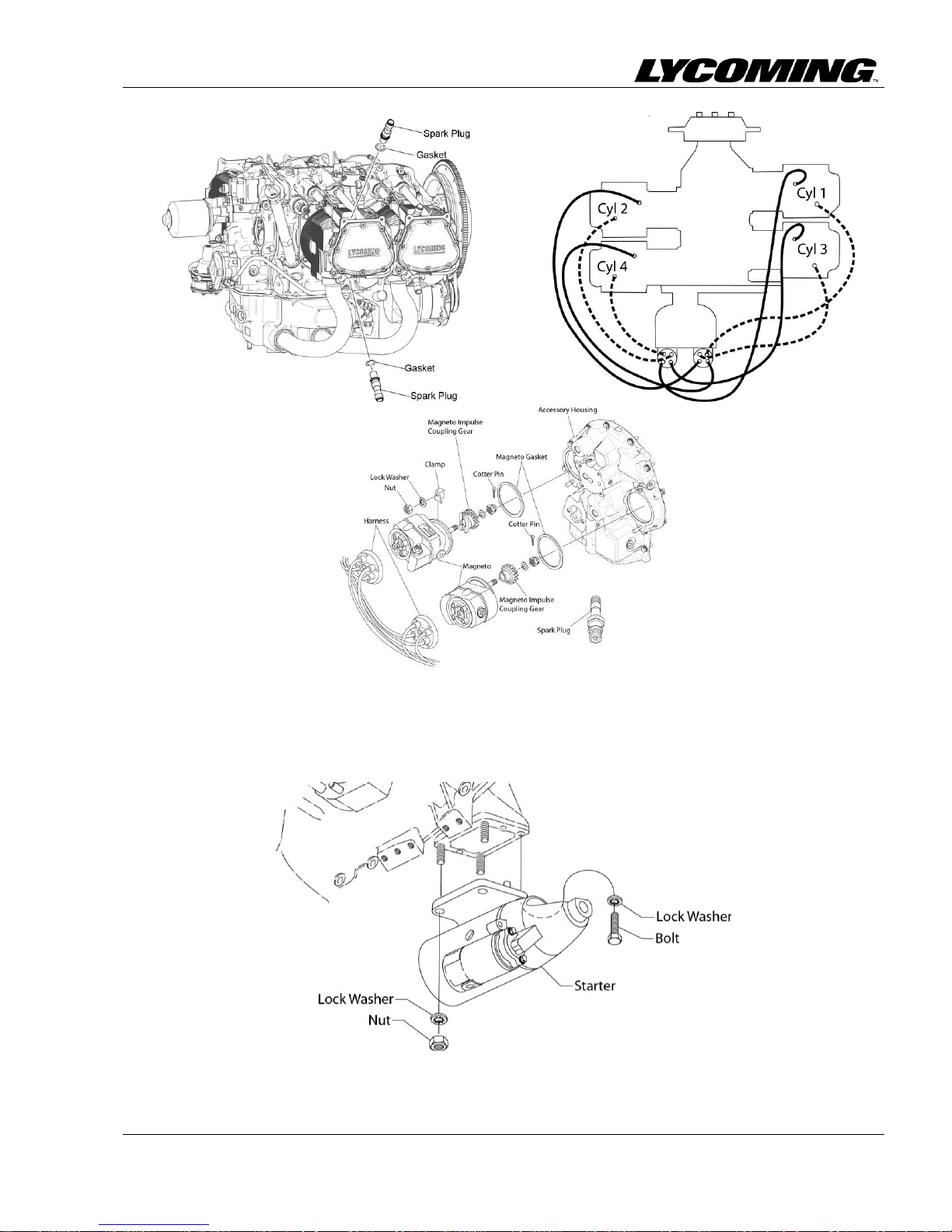

Ignition System

The all weather-shielded ignition system (Figure 5) includes:

Eight spark plugs (two per cylinder)

Ignition harness

Two magnetos (identified in Appendix A).

One magneto can have one retard breaker magneto and one plain magneto. The plain magneto must

be grounded during the start cycle. The shafts in both magnetos rotate clockwise (when facing the

drive pad).

System Description © 2016 Avco Corporation. All Rights Reserved

Page 2 February 2016

IO-360-N1A Engine Installation and Operation Manual

Figure 5

Ignition System

Starter

The engine can have either a 12V or 24V starter (Figure 6). Refer to Appendix A.

© 2016 Avco Corporation. All Rights Reserved System Description

February 2016 Page 3

Figure 6

Starter

Loading...

Loading...